Page 1

Diesel truck

Original instructions

H40D, H45D, H50D

394 807 10 01 EN – 07/2011

Page 2

Page 3

Linde − Your Partner

Preface

g

With over 100

house machin

the world’s l

handling equ

for this succ

not only for t

nology, but a

ating costs,

than those of

The high quality of Linde products is also

matched by the quality of our service. With ten

production plants worldwide and an extensive

network of sales partners, we are at your

service round the clock and around the world.

Operating Instructions – 394 807 10 01 EN – 07/2011 I

,000 fork lift trucks and warees sold annually, Linde is one of

eading manufacturers of material

ipment. There are many reasons

ess: Linde products are renowned

heir innovative, cutting-edge tech-

lso for their low energy and operwhich are up to 40 per cent lower

their competitors.

Your local Li

complete pac

ranging from

of sales and s

appropriate

or lease-pur

with the flexi

your individ

Linde Material Handling GmbH

Carl-von-Linde-Platz

63743 Aschaffenburg

Telephone +49 (0) 6021 99-0

Fax +49 (0) 6021 99-1570

Mail: info@linde-mh.com

Web: http://www.linde-mh.com

nde partner can offer you a

kage from a single source;

expert advice on all aspects

ervice through, of course, to

finance options. Our leasing, hire

chase agreements provide you

bility to tailor decision-making to

ual business requirements.

Page 4

Page 5

Table of contents

1 Introduction

Your forklift truck ..................................................... 2

Proper use .......................................................... 3

Impermissible use .................................................... 3

Description of use and climatic conditions ................................... 3

Symbols used ....................................................... 4

Technical description .................................................. 4

Truck operation when using a shovel ...................................... 6

Receiving the industrial t

Legal requirements for marketing ......................................... 7

ruck ............................................ 6

2Safety

Safety guidelines .................................................... 10

Residual risks ...................................................... 11

Stability ........................................................... 12

In the case of tip-over ................................................. 12

Handling consumable

Competent person ................................................... 13

Regulations ........................................................ 13

Instructions for fit

Fork carriage emergency lowering ....................................... 15

Emergency exit with attached rear window ................................. 16

s ................................................ 12

ting attachments ....................................... 14

g

3Overview

Identification pl

General view ....................................................... 20

Operating devices ................................................... 21

Display unit ........................................................ 22

Switch panel ....................................................... 28

ates .................................................. 18

4 Operation

Service plan before initial commissioning .................................. 30

Running-in i

Operating Instructions – 394 807 10 01 EN – 07/2011 III

nstructions ............................................... 30

Page 6

Table of contents

g

Pre-shift-checks ..................................................... 31

Standard equipment ................................................. 32

Entering and exiting the truck

Adjusting the standard driver’s seat and comfort driver’s seat .................... 32

Adjustingtheheight-adjustablecomfortdriver’sseat .......................... 34

Adjusting the luxury driver

Adjustingthearmrest ................................................. 39

Adjustingthesteeringcolumn ........................................... 40

Settingtheclock ..................................................... 40

Seatbelt .......................................................... 41

Drive engine (dual-pedal operation) ...................................... 43

Driving (dual-pedal opera

Drive engine (single-pedal operation) ..................................... 49

Driving (single-pedal operation) ......................................... 53

Steeringsystem ..................................................... 56

Brakesystem ....................................................... 56

Signal horn ........................................................ 58

Joystick with central le

Joystickwithsingleleveroperation ....................................... 65

Special equipment ................................................... 71

Depressurisation .................................................... 71

Driver’scab ........................................................ 72

Lighting ........................................................... 72

Windscreenwiper ................................................... 74

Window heater ...................................................... 77

Heating system, air conditioning ......................................... 78

Linde Forklift Data M

Adjustingthedriver’sseatwithrotatingdevice ............................... 88

Liftmastpositioning .................................................. 89

Working under load .................................................. 91

Beforetakingupaload ................................................ 91

Adjustingtheforkspread .............................................. 93

Takingupload ...................................................... 94

Travellingwithload .................................................. 95

Setting down loads ................................................... 96

Towcoupling ....................................................... 96

Before leaving the lift truck unattended .................................... 97

Beforeleavingthetruck ............................................... 97

Loading / Transpo

Securing the hose pulley against rolling up ................................. 98

Removingtheliftmast ................................................ 99

ver operation ...................................... 59

anagement (LFM) .................................... 81

rting ................................................ 98

........................................... 32

’sseat ......................................... 36

tion) .......................................... 46

IV Operating Instructions – 394 807 10 01 EN – 07/2011

Page 7

Table of contents

Driving without the lift mast .............................................100

Loading ...........................................................100

Transportation by lorry or low

loading trucks ................................102

5 Maintenance

General information ..................................................104

Inspection and maintenance data ........................................105

Recommendations for cons

Inspection and maintenance overview ....................................108

Serviceplanasrequired ...............................................108

1000hserviceplan ................................................ . . 109

3000hserviceplan ................................................ . . 111

6000hserviceplan ................................................ . . 114

9000hServiceplan ................................................ . . 117

Engine ............................................................120

Checking the engine oil level ...........................................120

Change engine oil ...................................................121

Changing the engine oil filter ............................................123

Fuel ............................................................ . . 124

Draining water from th

Changing the fuel filter . ...............................................126

Cleanthefueltankventilationhose .......................................127

Checking the coolant

Changing the coolant . . ...............................................129

Checkingthecoolantconcentration ......................................131

Cleaning the water c

Checking the condition and secure positioning of the engine support and engine

mounting ........................................................134

Check condition of the ribbed vee belt .....................................135

Replacing ribbed V-

Checking the condition and tension of toothed belt ............................137

Renew the toothed belt and idler pulley ....................................139

Change the water pu

Changing the air filter cartridge, checking the vacuum-operated switch . . ..........139

Changing the air filter safety cartridge .....................................141

Check the dust disc

Changing the breather filter for the charge air pressure regulator .................142

Cleaningtheprefilter(specialequipment) ..................................143

Cleaning the oil b

Change the oil in the oil bath air cleaner (Optional) ............................144

ath air filter (special equipment) ............................143

umables ......................................105

efuelfilter. ........................................126

level .............................................128

oolerandhydraulicoilcooler,andcheckingthemforleaks ......133

belt ...............................................136

mp ...............................................139

hargevalve .........................................141

g

Operating Instructions – 394 807 10 01 EN – 07/2011 V

Page 8

Table of contents

g

Check suction and exhaust pipes for leaks .................................145

Regenerating the particle filter ..........................................146

Regenerating the changing par

Checkingtheparticlefiltersystem(specialequipment) ........................151

Draining water from the water trap at the changing particle filter (special equip-

ment) ........................................................... 152

Cleaning the water trap at th

Cleaning the pressure control device at the changing particle filter (special equip-

ment) ........................................................... 153

Gearbox ..........................................................154

Axle clamps and wheel motors

Checkingandadjustingthesidestopsonthedriveaxle ........................154

Checkingthedriveaxlebearingsforwear ..................................155

Checking the hydraulic pu

Chassis, bodywork and fittings ..........................................156

Cleaning the truck ...................................................156

Bonnet . . .........................................................156

Floorplate .........................................................158

Maintaining the heating system and air conditioning (special equipment) ...........159

Checking the condition

Check fastening for frame, tilt cylinders and steering axle .......................162

Checking and oiling other bearing points and joints ...........................162

Topping up the washer sy

Chassis frame ......................................................164

Changing a wheel ...................................................164

Tighten the wheel nut

Checkthetyresfordamageandforeignobjects ..............................165

Checkingthetyrepressure .............................................166

Checking the conditi

Cleaning and greasing the steering axle ...................................167

Checking the mountings of the steering cylinder and steering pivot pin . . . ..........168

Controls ..........................................................169

Checking the parking brake for correct operation . . ...........................169

Checking the pedals ..................................................169

Checking the bellow

Electrics ..........................................................171

Check the condition and secure positioning of electric cables, cable connectors and

connections ..................................................... . 171

Battery: Check con

Hydraulics .........................................................174

Change hydraulic oil ..................................................174

s ................................................165

onoftheantistaticbelt .................................167

sattheactuatinglever .................................170

dition,levelanddensityofacid ............................171

ticlefilter ...................................149

e changing particle filter (special equipment) ...........152

: checking the mountings .......................154

mp’s mounting on the engine ........................155

andcorrectfunctionoftheseatbelt .....................160

stemwatertank(specialequipment) ..................163

VI Operating Instructions – 394 807 10 01 EN – 07/2011

Page 9

Table of contents

Hydraulicsystem:Checktheoillevel. .....................................175

Hydraulic system: changing the filter ......................................176

Check the bleeder valve on the h

Checkthehydraulicsystemforleaks .....................................180

Check tilt cylinder bearings for wear ......................................180

Check the tension of double hos

Load lift system .....................................................182

Workingontheliftmastandatthefrontofthetruck ...........................182

Cleaning and spraying the li

Lift mast, lift mast chains, lift cylinder and end stops: Check mounting, condition and

function ........................................................ . 186

Adjustingtheliftmastchain ............................................186

Check the forks and fork qu

Cleansideshift(specialequipment)andgrease,checkfastening .................189

Checking the slide guides on the sideshift (special equipment) for wear . . ..........190

Self-help ..........................................................191

Openingthecovertotheelectricalsystem ..................................191

Fuses for basic and special equipment ....................................192

Main fuses in engine comp

Diagnosticconnector .................................................193

Malfunctions during operation ...........................................194

Malfunctions, Causes a

Malfunctions,causesandremedies(hydraulicsystem) ........................199

Jumpstart ....................................................... . . 201

Towing .......................................................... . 202

Shutting down ......................................................205

Shuttingdownthetruck ...............................................205

Disposal of old truck

ndRemedies(dieselengine) ..........................196

s .................................................206

ydraulicoiltankforcorrectoperation .............179

es .......................................181

ftmastchain ...................................185

ick-releases ...................................188

artment .......................................192

g

Operating Instructions – 394 807 10 01 EN – 07/2011 VII

Page 10

Table of contents

g

6 Technical data

Type sheet H 40, as at 07/2011 ..........................................208

Type sheet H 45, as at 07/2011 ..........................................21

Type sheet H 50/500, as at 07/2011 ......................................214

Type sheet H 50/600, as at 07/2011 ......................................217

Type sheet H 40 elevated dri

Type sheet H 45 elevated driver’s compartment, as at 07/2011 ..................223

Type sheet H 50/500 elevated driver’s compartment, as at 07/2011 ...............226

Type sheet H 40 container, a

Type sheet H 45 container, as at 07/2011 ..................................232

Type sheet H 50/500 container, as at 07/2011 ...............................235

Type sheet H 50/600 conta

Truck configuration ..................................................241

Tyre variants and rim sizes .............................................242

Load capacity diagrams

Additional capacity rating plate for attachments ..............................247

Noise emission values ................................................248

Vibration character

istic values for bodily vibrations ...........................249

ver’s compartment, as at 07/2011 ..................220

s at 07/2011 ..................................229

iner, as at 07/2011 ...............................238

and lift mast data as at 07/2011 .......................244

1

Annex

7 Circuit diagram

Wiring diagram .....................................................264

Basic equipment for diesel with pump injection engine — Sheet 01 ................264

Basic equipment

Basic equipment for diesel with pump injection engine — sheet 03 ................268

Special equipment sheet 01 — working spotlight . . ...........................270

Special equipm

sion ............................................................ 272

Special equipment sheet 03 — Heating system, air conditioning, flashing/rotating

beacon, reversing signal, interior lighting/clipboard lighting ...................274

Special equipment sheet 04 — hazard warning system for reverse travel, truck deacti-

vation,mastpositioning .............................................276

Special equip

Special equipment sheet 06 — Higher lighting, 12 V socket, diesel filter water trap

warning ......................................................... 280

VIII Operating Instructions – 394 807 10 01 EN – 07/2011

s

for diesel with pump injection engine — sheet 02 ................266

ent sheet 02 — Windscreen wipers, seat heater, seat with air suspen-

ment sheet 05 — particle filter, radio . ...........................278

Page 11

Table of contents

Special equipment sheet 07 – Truck data management, LPG volume display . . . .....282

Special equipment sheet 08 – LPG volume display for volumetric filling with shut-off

valve, changing particle filter, camera system .............................284

Special equipment sheet 09 — ba

centrebrake/taillight ...............................................286

Special equipment sheet 10 — third auxiliary hydraulics with third joystick ..........288

Special equipment sheet 11 — Lighting, direction indicator and hazard warning sys-

tem,brakelight .................................................. . . 290

Special equipment sheet 12 —

hydraulics and double auxil

Hydraulic circuit diagram ..............................................294

Traction,workingandsteeringhydraulics ..................................294

Accumulator ..................................................... . . 296

ttery main switch with display unit power supply, rear

single lever for lifting/lowering, tilting, single auxiliary

iaryhydraulics ................................292

g

Operating Instructions – 394 807 10 01 EN – 07/2011 IX

Page 12

Page 13

1

Introduction

Page 14

1 Introduction

Your forklift truck

Your forklift truck

offers optimum economic efficiency, safety

and driving comfort. It is primarily down to

you to maintain these characteristics for a

long time and take advantage of the resulting

benefits.

During manufacture:

• all safety requirements of t

directives were observed

• all conformity assessment procedures

stipulated in the applicable directives were

carried out

This is attested by the CE mark shown on the

nameplate.

These operating instruct

thing you need to know abou

driving and maintenance.

The attachment operating instructions are enclosed for trucks that are delivered from the

factory with an attachment. Before commissioning a truck with an attachment, you must

check that loads are handled securely. Depending on the type of attachment, it may be

necessary to make adjustments, e.g. pressure settings or adjusting stops and operating

speeds. See the attachment operating instructions for the corresponding instructions.

The instructions for operation of the attachment must also be observed.

Carry out the specified work regularly, at the

due times and using the consumables envisaged for this purpose in accordance with the

inspection and maintenance overview. Please

make sure you record the work performed in

the registration document for the industrial

truck; this is essential for any warranty claims.

The designations use

left, right) always r

position of the parts

as the drive directio

forwards).

Servicing work not described here will require

specialist knowledge, measuring devices and

frequently also special tools. Please ask your

authorised dealer to carry out this work.

efer to the installation

described, with forwards

n for the truck (fork arms

he relevant EC

ions contain every-

t commissioning,

d in the text (front, back,

Servicing should only be carried out by qualified personnel approved by Linde (specialists).

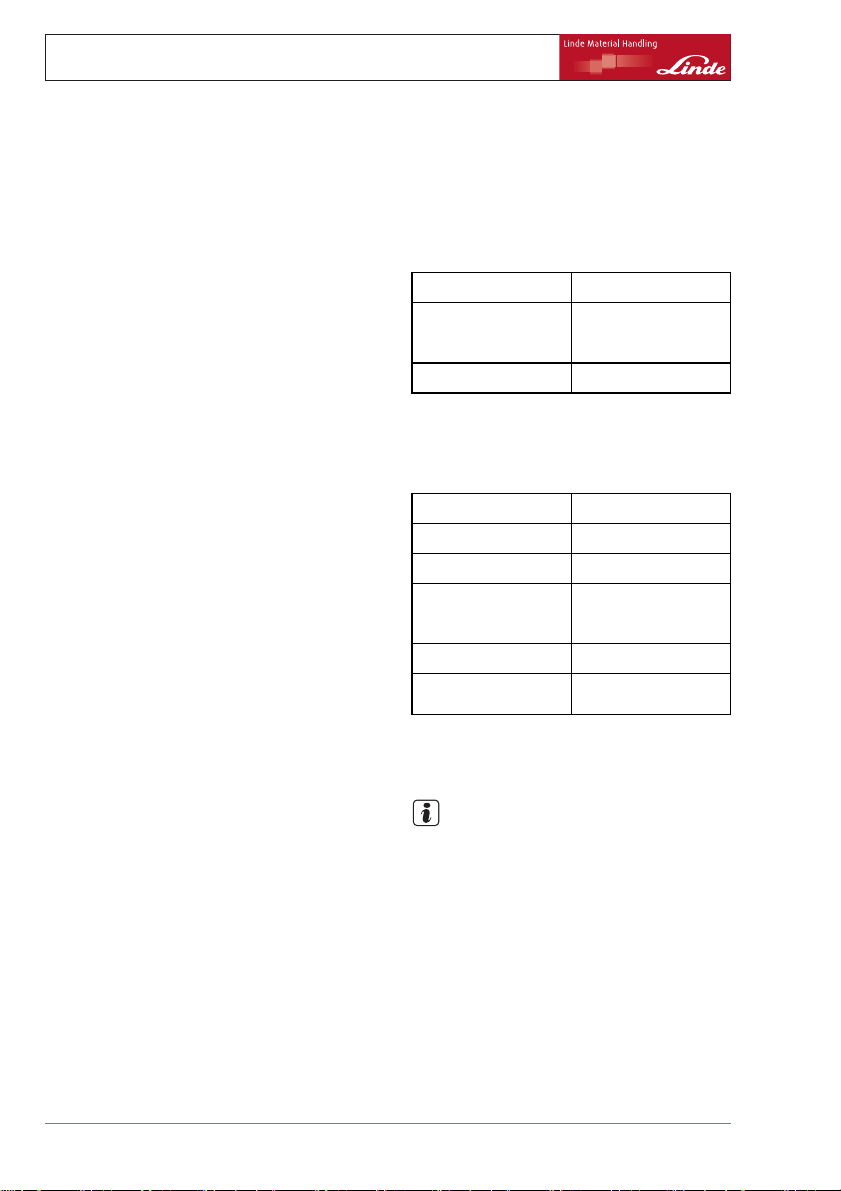

With orders for parts, please specify the

following along with the parts numbers:

Truck model:

Chassis number/year of manufacture:

Handover date:

The production number must also be specified

for parts from the following units: engine, lift

mast, hydraulic variable displacement pump,

drive axle and steering axle.

Engine number:

Lift mast number:

Lift mast lift:

Hydraulic variable

displacement pump

number:

Drive axle number

Steering axle

number:

When taking over the truck, this data should

be copied from the identification plates of the

units into these operating instructions.

NOTE

:

In the event of repairs, only use genuine Linde

spare parts. This is the only way to guarantee

that your truck remains in the same technical

condition as at the time of reception.

Please address all queries and orders for

spare parts relating to your truck only to

your authorised dealer, stating your mailing

address.

Linde is cons

development

understandi

are subject t

tantly engaged in the further

of its products. We ask for your

ng that figures and technical data

o technical modification in terms of

2 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 15

Introduction 1

Description of use and climatic conditions

form, equipment and expertise in the interest

of progress.

For this reason, no claims can be asserted

on the basis of the following data, figures and

descriptions in these operating instructions.

Proper use

The truck is used for moving and lifting the

loads indicated on the capacity rating plate.

Please pay particular attention to:

• The VDMA brochure on "Rule

use of industrial truck

operating instruction

• Regulations for driving on public roads, as

well as any country-specific restrictions on

winter road conditions

• Specific measures for using the industrial

truck in operating areas with magnetic fields

s

s for proper

s", supplied with these

Impermissible use

The operating compa

manufacturer, is li

manner that is not pe

It is not permitted to use the truck:

• for taking passengers

• in areas where ther

explosion

ny or driver, and not the

ableifthetruckisusedina

rmitted.

e is a risk of fire of

These operating instructions must not be

reproduced, translated or made accessible to

third parties—including as excerpts—except

with the express written approval of the

manufacturer.

that have magnetic flux densities greater

than 5 mT

• Other specific national re

It is essential that operating personnel and

repair personnel observe the rules for the

proper use of industrial trucks.

Modifications, in particular attachments or

conversions, are not permitted to be made to

the industrial truck without the manufacturer’s

approval.

The user, and not the man

for any hazards caused

• for stacking/unsta

slopes

• For stepping onto the fork arms when the lift

mast is raised

• If the maximum load capacity is exceeded

gulations.

ufacturer, is liable

by improper use.

cking operations on

Description of u

Normal use

• Indoor and outdoor use

• Ambient temperature in tropical and Nordic

regions ranging from -15 °C to 50 °C

• Start capabili

• Maximum start time of 20 seconds

• Use at up to 2000 metres above sea level.

Operating Instructions – 394 807 10 01 EN – 07/2011 3

se and climatic conditions

tyat-15°Cto50°C

Special use (pa

rtly with special mea-

sures)

• Use, e.g. in the event of abrasive dust (such

as AL203), lint, acid, leach, salt, corundum,

incombustible substances

• Ambient temperature in tropical regions up

to 55 °C

• Start capabil

• Use at up to 3500 metres above sea level.

ity to -25 °C

Page 16

1 Introduction

Technical description

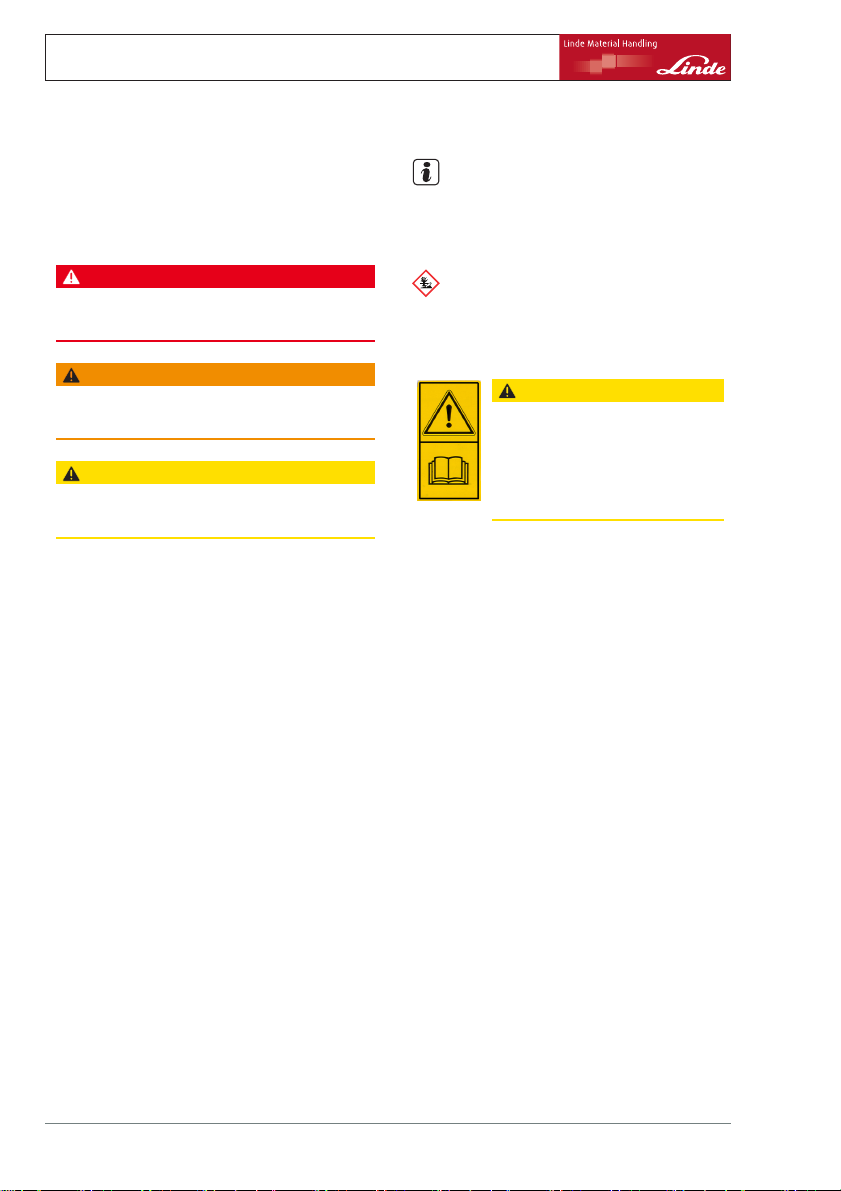

Symbols used

The terms DANGER, WARNING, CAUTION,

NOTE and ENVIRONMENT NOTE are used

in these operating instructions for notes on

particular hazards or for unusual information

that needs to be highlighted:

DANGER

Means that failure to comply can cause risk to life

and/or major damage to property.

WARNING

Means that failure to comply can cause risk of

serious injury and/or major damage to property.

CAUTION

Means that failure to comply can cause risk of

material damage or destruction.

Technical description

The forklift trucks in the 394 series allow

loading and palletising to be performed for

loadsupto4twithH40,upto4.5twithH45

and up to 5 t with H 50-500, at a load distance

of 500 mm.

Details on the exact lift-height-specific maximum loads are available in the load capacity

diagram.

The trucks are eco-friendly and their quiet

operational noise and low emission levels

benefit both the driver and the environment.

Their distinguishing features are the compact

design and small turning radius. For this

reason, the trucks are particularly well-suited

to narrow entrances and operational areas

where space is at a premium.

Engine

The drive engine is a 4-cylinder, four-stroke

diesel engine with turbocharging and state-of-

NOTE

Means that particular attention is drawn to

combinations of technical factors which may

not be evident even to a specialist.

ENVIRONMENT NOTE

The instructions listed

with as otherwise enviro

here must be complied

nmental damage may

result.

CAUTION

This label is found on the truck in

the areas where particular care and

attention are required.

You should refer to the appropriate

sectionintheseoperatinginstructions.

For your safety, additional symbols are also

used. Please heed the various symbols.

the-art pump injection technology. It powers

the truck’s hydraulic pumps and varies its

speed depending on the load. The engine is

cooled by means of a closed coolant circuit

with expansion tank.

Forced circulation lubrication with an oil pump

in the oil sump is used for engine lubrication.

The combustion air is cleaned by means of a

dry air filter with a paper insert. Diesel engines

with state-of-the-art engine technology are

used for:

• High torque

• Low fuel consumption

• Low exhaust emissions

• Low particulate emissions

• Low noise levels

Hydraulic system

The drive unit consists of a hydraulic variable

displacement pump, two hydraulic fixed

4 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 17

Introduction 1

Technical description

displacement wheel motors (assembled as

a drive axle unit), as well as a hydraulic pump

(fixed displacement pump) for the working

and steering hydraulics. Drive direction and

driving speed are regulated by means of two

accelerator pedals via the hydraulic variable

displacement pump.

The hydraulic fixed displacement wheel

motors in the drive axle are supplied by the

hydraulic variable displacement pump and are

used to power the drive wheels via two side

gearboxes.

Operation

One accelerator pedal eac

and reverse travel (dual p

used to simultaneously re

variable displacement pu

speed. The hydrostatic dr

driving speed to be contin

both directions, ranging

maximum speed. The dualmeans that operation of t

safe, non-fatiguing and

The driver always has both hands free for

steering and controlling operational movements. This results in fast reversing and efficient stacking.

An optional version is also available whereby

the driving speed is regulated by an accelerator pedal (single pedal operation) and the

drive direction controlled by means of a drive

direction switch.

To control the operati

ing, lowering and tilt

ating lever (joystick

for actuation of addi

erational movements

using two or four joys

tion version).

h for forward travel

edal operation) is

gulate the hydraulic

mp and the engine

ive enables the

uously varied in

from standstill to the

pedal control

he truck is simple,

efficient.

onal movements of lift-

ing, there is only one actu-

). Another joystick is fitted

tional attachments. Op-

canalsobecontrolled

ticks (single lever opera-

Linde Load Control

The truck’s Linde Load Control (LLC) control

electronics system enables:

• Millimetre-precise and secure load handling

• Effortless finger-tip control of all lift mast

functions

• Drive and lifting functions ar

separate.

e entirely

Linde Truck Control

The truck’s Linde Truck Control control

electronics system (LTC) offers:

• Reliable control unit

• A high level of safety thank

monitoring systems

• Automatic, load-dependent control of

engine speed

• Protection from dust and dirt though use of

a fully enclosed housing.

s to multiple

Brakes

The hydrostatic drive i

brake. This means that

maintenance-free. Tw

incorporated in the wh

as the parking brake. W

switched off, the mult

meaning that the truck

function. Always appl

when parking the truck

s used as the service

the service brake is

o multi-disc brakes

eel motors are used

hen the engine is

i-disc brakes engage,

has an automatic brake

y the parking brake

.

Steering

The steering is a hydrostatic steering system,

under which the steering wheel acts on the

steering cylinder to actuate the rear wheels.

If the power applied to the steering wheel is

increased, the steering can also be operated

when the engine has been switched off.

Lift mast

The free-view lift mast enables:

• Ideal visibility

• Full load capacity up to maximum lift heights

• Enormous residual load capacity

due to slim lift mast profiles

Operating Instructions – 394 807 10 01 EN – 07/2011 5

Page 18

1 Introduction

Receiving the industrial truck

• Maintenance-free storage of the lift mast

and tilt cylinder via rubber-cushioned

linkage points

• Electric tilt angle limitation.

Electrical system

The electrical system is powered by the

three-phase alternator with 12 V DC voltage. A

12 V battery with 88 Ah is installed for starting

the engine. It is located under the driver’s seat

in the engine compartment.

Truck operation when using a shovel

When operating the truck with a shovel, stall

protection can be activated by your authorised

dealer.

In this case, extreme load

engine due to the associa

decrease leads to a sligh

the working hydraulics.

Receiving the industr

Before the industrial

it undergoes a thoro

order to guarantee t

and that it contains

specified in the orde

In order to prevent complaints from occurring

further down the line, the exact condition

of the industrial truck and the integrity of

the equipment are checked and the proper

handover/acceptance of the truck is confirmed

by the dealer.

NOTE

In trucks that lea

mast, an addition

mitation is locat

tor pedal (dual-

ve our factory without a lift

al stop screw for speed li-

ed under the reverse accelera-

pedal operation) or under the

ing of the drive

ted engine speed

t delay in executing

ial truck

truck leaves our factory,

ugh inspection process in

hat it is in perfect condition

all of the equipment

r.

For a period of extended l

engine, the joystick mus

zero position in order t

hydraulics again.

accelerator pedal (si

This must be removed

mast; see the sectio

aliftmast.

The following techn

each industrial tru

• Operating instructions for the truck

• Operating instructions for the attachment

• EC declaration of c

• Safety rules for the use of industrial trucks

• Registration document for the industrial

NOTE

oading of the

t be switched to the

o release the working

ngle-pedal operation).

after installing the lift

n entitled Driving without

ical documents belong to

ck:

(only applies to trucks delivered from the

factory with an attachment)

ompliance

(VDMA)

truck, which is issued by authorised dealers

as part of the handover.

6 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 19

Legal requirements for marketing

Declaration

Linde Material Handling GmbH

Carl-von-Linde-Platz

D-63743 Aschaffenburg, Germany

We declare that the machine

Introduction 1

Legal requirements for marketing

Industrial tru

Model

complies with the most recent version of machinery directive 2006/42/EC.

Personnel a

see EC declaration of conformity

Linde Mat

ck

uthorised to compile the technical documents:

erial Handling GmbH

EC declaration of conformity

The manufacturer declares that the truck complies with the requirements of the EC machinery directive and any other EC directives, if

applicable, that are valid at the time of marketing. This is confirmed by the EC declaration

of conformity and by the CE labelling on the

nameplate.

The EC declaration of conformity document

is delivered with the truck. The declaration

according to these operating instructions

according to these operating instructions

shown explains the conformity with the requirements of the EC machinery directive.

An independent structural change or addition

to the truck can compromise safety, thus

invalidating the EC declaration of conformity.

The EC declaration of conformity must be

carefully stored and made available to the

responsible authorities if applicable. It must

also be handed over to the new owner if the

truck is sold on.

Operating Instructions – 394 807 10 01 EN – 07/2011 7

Page 20

1 Introduction

Legal requirements for marketing

8 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 21

2

Safety

Page 22

2 Safety

Safety guidelines

Safety guidelines

It is essential that operating personnel and

repair personnel observe the" rules for the

proper use of industrial trucks" enclosed with

these operating instructions.

Examples of those listed are:

• Operating industrial trucks

• Driving licence

• Driveways and working areas

• Rights, duties and rules of behaviour for the

driver

• Special operating areas

• Information regarding setting off, driving

and braking

• Information for maintenance and repair

• Regular tests

• Disposal of greases, oils and batteries

The operating company or the person it has

commissioned must ensure that the driver

understands all safety information and that

all guidelines and safety regulations are

observed.

During training, the driver must familiarise

themselves with the following:

• The operating conditio

areas

• The specific technical characteristics of the

industrial truck

• The operation of attachments

Practise driving, con

ations with an unloade

completely mastered.

industrial truck be us

Safety information

DANGER

The industrial truck must not be used by unauthorised persons.

Only trained persons and those authorised for

operation may have access to the industrial truck.

ns of the working

trol and steering oper-

d truck until they are

Only then can a loaded

ed for practice.

DANGER

In operating areas with magnetic fields that have a

magnetic flux density greater than 5 mT, unintentional truck and lift mast movementscannot be entirely

excluded under unfavourable circumstances.

For magnetic fields with magnetic flux densities

greater than 5 mT, components developed especially for this purpose must be used.

Contact your authorised dealer.

DANGER

Safety systems (e.g. the seat switch) are there for

safety.

Safety systems must never be disabled, regardless

of the kind.

DANGER

Any additional bores or welding to the overhead

guard will compromise its rigidity.

It is therefore strictly prohibited to drill holes in the

overhead guard or to weld to it.

CAUTION

Welding operations on other parts of the vehicle

can cause damage to the electronics.

Therefore, before performing any welding, always

disconnect the battery and all connections to the

electronic control units.

CAUTION

Different functions are supported by gas springs.

Gas springs are under a high internal pressure of

up to 300 bar.

They must only be removed when not under compression and must not be opened without instructions. Any kind of damage, lateral forces, buckling,

temperatures in excess of 80° C and heavy contamination must be avoided under all circumstances.

Damaged or defective gas springs must be replaced immediately.

Contact your authorised dealer.

10 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 23

Safety 2

Residual risks

WARNING

In trucks with an accumulator, serious injuries can

occur if the accumulator is not properly handled.

Before starting work on the accumulator it must be

depressurised.

Contact your authorised dealer.

WARNING

Depending on the duration of use and

operating time, components carrying

exhaust gases and exhaust air may

become hot.

Protective equipment must therefore

be worn.

WARNING

Thetruckworkingareamustbesufficientlylit.

If it is insufficiently lit, working spotlights must be

installed to ensure that the driver can see properly.

Residual risks

Despite careful work and compliance with

all applicable standards and regulations, the

possibility of other dangers when using the

industrial truck cannot be entirely excluded.

The industrial truck and its possible attachments comply with current safety regulations.

Nevertheless, even when the truck is used for

its proper purpose and all instructions are followed, some residual risk cannot be excluded.

Even beyond the narrow danger areas of the

industrial truck itself, a residual risk cannot

be excluded. Persons in the area around the

industrial truck must exercise a heightened

degree of awareness, so that they can react

immediately in the event of any malfunction,

incident or breakdown.

CAUTION

Various pieces of special equipment are connected

to the special "speed reduction" function. This is

simply an assistance function, on which the driver

must not solely rely during operation.

The driver is always responsible for safe operation.

CAUTION

If drivers have active medical equipment, e. g. pace

makers or hearing aids, these may be impaired.

Check with a doctor or the medical equipment

manufacturer whether the equipment is sufficiently

protected against electromagnetic interference.

NOTE

If your truck is equipped with a fire extinguisher, make sure that you familiarise yourself

with it in case of an emergency. Handling information is provided on the fire extinguisher.

DANGER

Persons in the vicinity of the industrial truck must

be instructed with regard to the dangers that arise

through use of the truck.

These operating instructions also contain additional

safety regulations.

Residual dangers can include:

• Escape of consumables due to leakages or

the rupture of lines, hoses or containers,

• Risk of accident when driving over difficult

ground such as gradients, smooth or

irregular surfaces, or with poor visibility,

• Risk of falling, tripping, slipping etc. during

movement of the industrial truck, especially

in the wet, with leaking consumables or on

icy surfaces,

• Risk of fire and explosion due to the battery

and electrical voltages,

• Human error,

• Disregarding the safety regulations,

• Risk caused by unrepaired damage,

Operating Instructions – 394 807 10 01 EN – 07/2011 11

Page 24

2 Safety

Handling consumables

• Risk caused by insufficient maintenance or

testing,

• Risk caused by using the wrong consumables.

Stability

Stability is guaranteed if your industrial truck is

used according to its intended purpose.

Stability will not be guaranteed in the event of:

• cornering at excessive sp

• moving with the load raised,

• moving with a load that is protruding to the

side (e.g. sideshift),

eeds,

In the case of tip-over

• turning and driving diagonally across

descents or ascents,

• driving on descents or asc

on the downhill side,

• loads that are too wide,

• driving with a swinging load,

• ramp edges or steps.

ents with the load

• Stay buckled up

•Don’tjump

• Hold on tight

•Bracefeet

• Lean away

Handling con

ENVIRONMENT NOTE

Consumables must be handled properly

and in accordance with the manufacturer’s

instructions.

• Consumables should only be stored in

containers complying with applicable

regulations and at the locations stipulated.

• Do not brin

contact wi

• When topping up consumables, use only

clean containers.

12 Operating Instructions – 394 807 10 01 EN – 07/2011

sumables

g flammable consumables into

th hot objects or a naked flame.

The stability of your industrial truck is ensured

if used properly and as intended. Should the

industrial truck tip over during an unapproved

application or due to incorrect operation,

always follow the instructions depicted above.

• Observe the manufacturer’s instructions

relating to safety and disposal.

• Avoid spill

• Remove any spilled fluid immediately with a

suitable binder and dispose of it according

to applicable regulations.

• Old and contaminated operating materials

should be disposed of according to the

regulations.

• Comply wit

• Before performing greasing, filter changes

or any work on the hydraulic system,

ing.

h the statutory provisions.

Page 25

Safety 2

Regulations

carefully clean the area around the part

involved.

• Dispose of used spare parts in an environmentally friendly manner.

WARNING

The penetration of pressurised hydraulic fluid into

the skin, e.g. due to leakage, is hazardous. If an

injury of this type occurs, always consult a doctor.

Protective equipment must be worn.

Competent person

A competent person is a specialist in the field

of industrial trucks who has:

• Successfully completed training, as at least

a service engineer for industrial trucks

• Many years of professional experience with

industrial trucks

• Knowledge of the accident prevention

regulations

• Knowledge of the relevant national technical regulations

Regulations

Periodic safety inspection

Periodic safety inspections are required in

order to maintain the function and security of

the industrial truck.

Comply with the national regulations for your

country.

In Europe, the national laws are based

on the directives 95/63/EC, 99/92/EC and

2001/45/EC. These stipulate that periodic

safety inspections of the industrial truck must

be carried out by competent personnel, in order to ensure proper condition.

WARNING

The improper handling of coolant and coolant additives presents a risk to health and the environment.

Observe the manufacturer’s instructions without

fail.

The competent person is able to assess the

condition of industrial trucks in terms of health

and safety.

Operating Instructions – 394 807 10 01 EN – 07/2011 13

Page 26

2 Safety

Instructions for fitting attachments

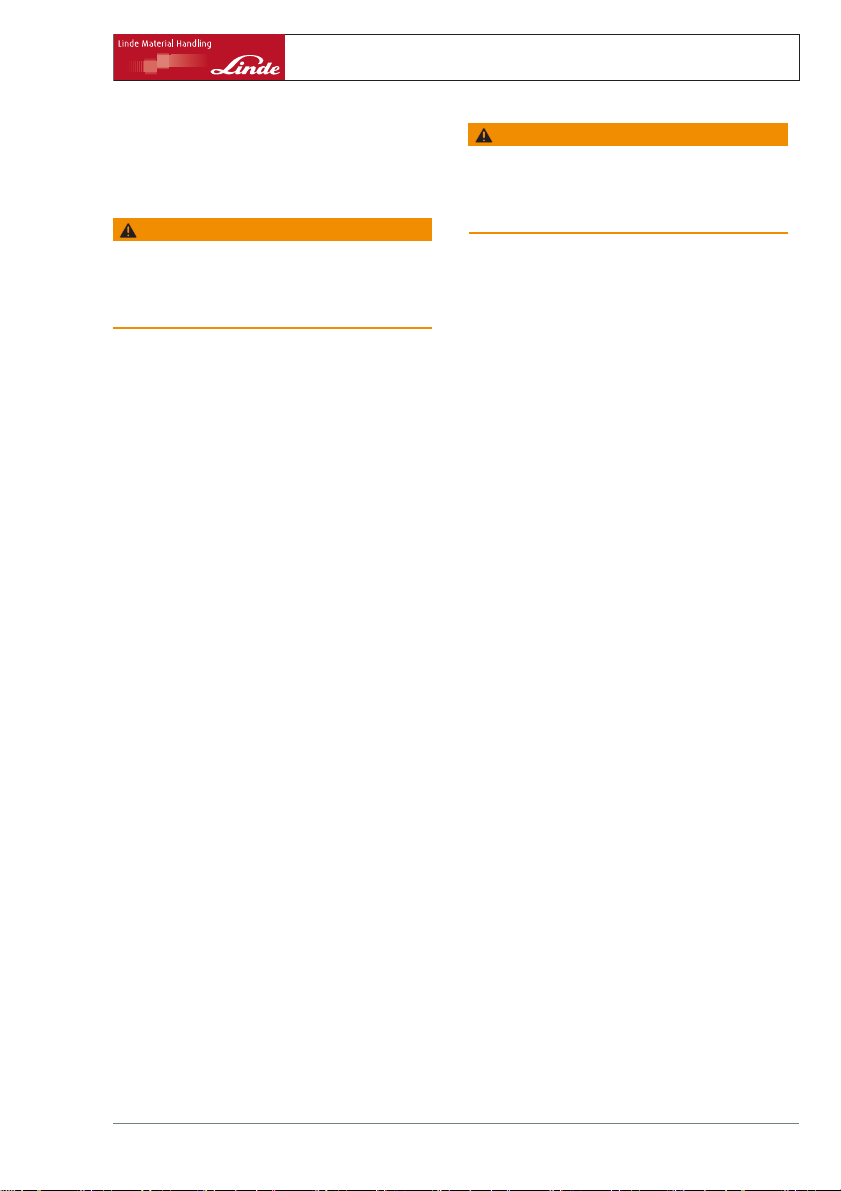

There is a recommendation setting out the

scope of the periodic safety inspection —FEM

4.004 of the European Industrial Truck Association— which defines a test log to document

the current safety inspection and an inspection

sticker for the next safety inspection. The next

safety inspection date is shown by the year

number (3) on an adhesive label (2), which

changes colour every year and is found on a

label (1).

The scope of the safety inspection is added

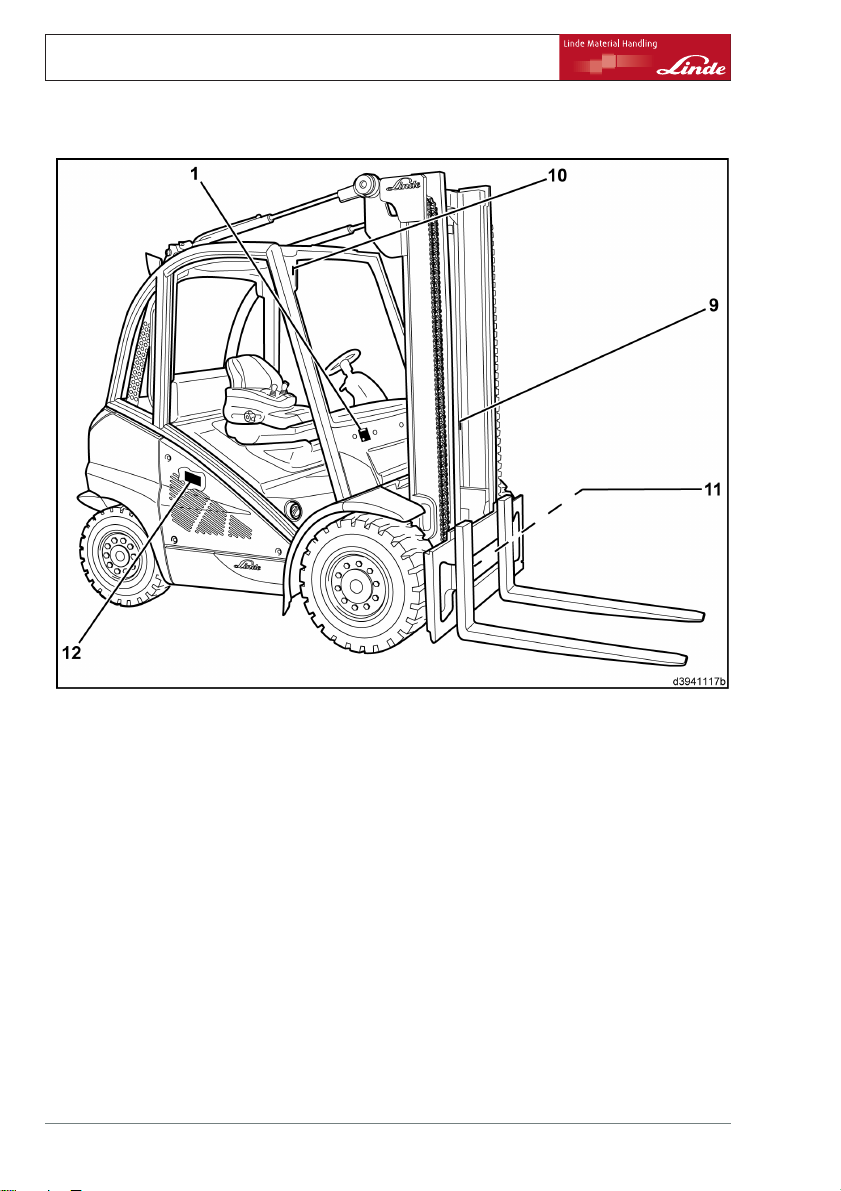

by the manufacturer in accordance with

the specific truck type. Please ask your

authorised dealer to carry out this work.

Diesel engine emissions

Diesel engine emissions i

hazardous materials. The

allowed to infiltrate the a

If trucks with diesel engines are used in fully

or partially enclosed spaces, this must first be

reported to the relevant occupational health

and safety authorities. Operating instructions

must be displayed in the working areas.

The national regulations must be observed

without fail.

nclude carcinogenic

se should not be

ir in workplaces.

Checking the particle filter system

Particle filter syste

and tested every 6 mon

person. The test resu

enclosed with the rep

national regulation

Instructions for fi

To depressurise th

fitting an attachme

for the auxiliary h

using an accumulat

depressurised

See the section entitled "Depressurisation".

14 Operating Instructions – 394 807 10 01 EN – 07/2011

ms must be maintained

thsbyacompetent

lts must be recorded and

ort book. Observe the

s for your country.

tting attachments

e oil in the lines before

nt, the hydraulic system

ydraulics can be connected

or (Special equipment)

WARNING

Improper handling of the accumulator may lead to

serious injuries.

Before starting work on the accumulator, it must be

depressurised. Contact your authorised dealer.

Page 27

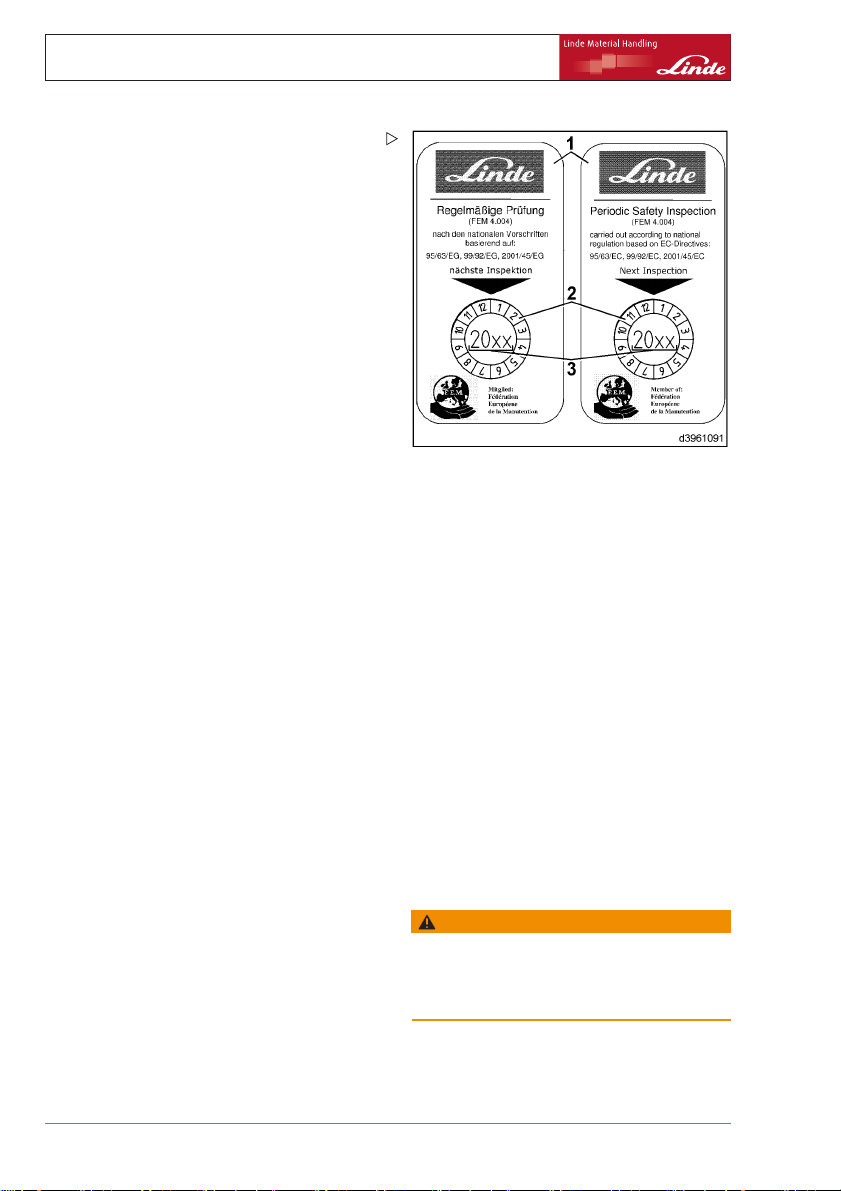

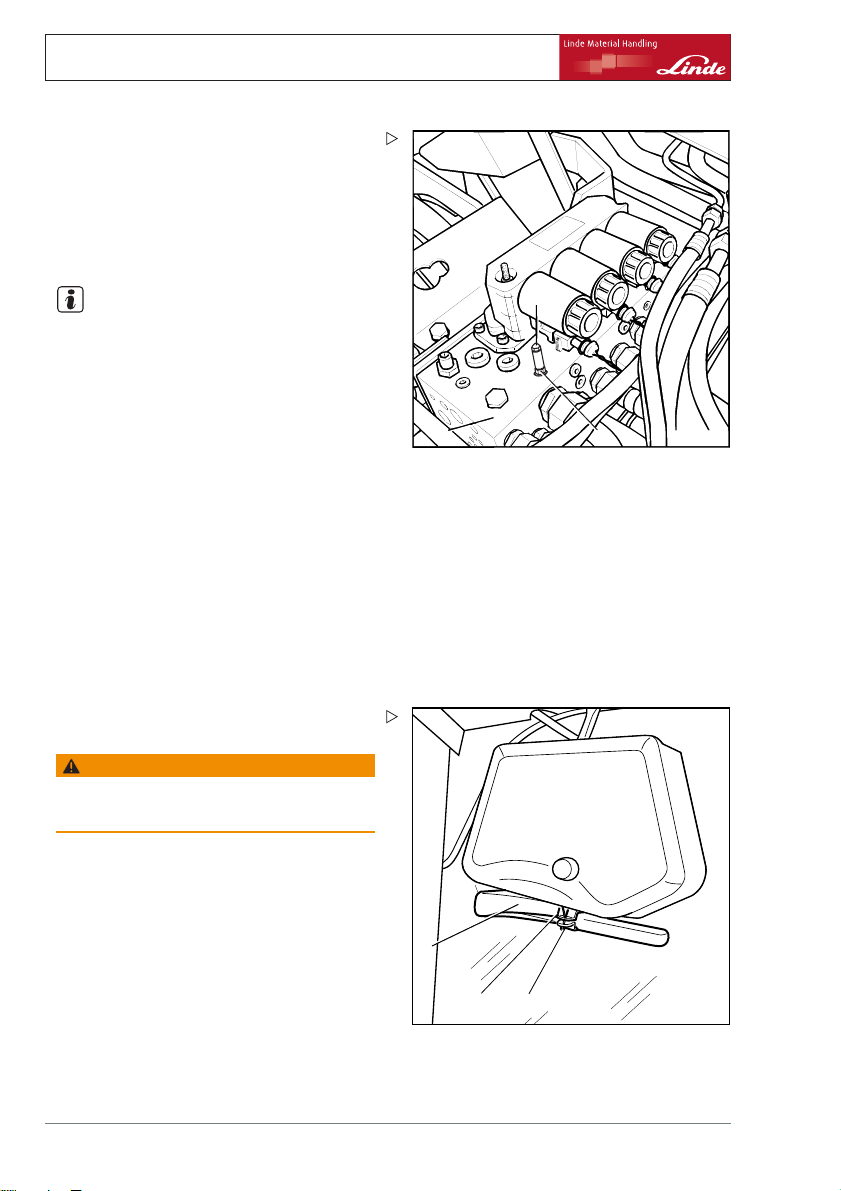

Fork carriage emergency lowering

If there is a malfunction, the fork carriage can

be lowered manually.

¾ Remove floormat.

DANGER

Risk of accident or danger to life

when lowering the fork carriage with

fork arms.

People are not allowed to stand in the

vicinity of the fork arms when they are

being lowered.

During lowering, leave the socket

wrench on the threaded stud (1) on

the valve block (3) to enable lowering

to be interrupted at any time.

¾ Insert the 8 mm WAF socket wrench

through the opening in the bottom plate.

¾ Using the socket wrench slowly rotate

the threaded stud (1) approx. 3 turns

anti-clockwise until the fork carriage has

been completely lowered.

¾ Open the bonnet.

¾ Open the bottom plate and secure it in

place.

¾ Undo the self-locking nut (2) about 2 turns.

Safety 2

Fork carriage emergency lowering

Operating Instructions – 394 807 10 01 EN – 07/2011 15

Page 28

2 Safety

Emergency exit with attached rear window

¾ Screw the threaded stud (1) back in clock-

wise. Otherwise it will not be possible to lift

the fork carriage using the joystick.

Tightening torque 10 Nm.

¾ Retighten the self locking nut

Tightening torque 9.5 Nm

NOTE

After emergency lowering

med three times, a new thre

locking nut must be used.

¾ Close the bottom plate and bonnet.

¾ Insert the floormat.

(2).

has been perfor-

aded stud with self

1

3

2

d3941386

Emergency exit wi

th attached

rear window

If a truck with a

window breaks d

driver may poss

at the side. In t

driver can exit

For this purpos

broken with an e

¾ Bend open split pin (1) from the support

mounting (2) under the rear wiper motor.

WARNING

Glass splinters may cause injuries.

Remove glass splinters carefully.

¾ Take the emergency hammer (3) out of the

support mounting and carefully break the

rear window.

¾ Climb out carefully.

n attached front and rear

own in a narrow aisle, the

ibly be unable to exit the truck

he event of acute danger, the

the truck via the rear window.

e, the rear window must be

mergency hammer.

3

2

1

t3921371

16 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 29

3

Overview

Page 30

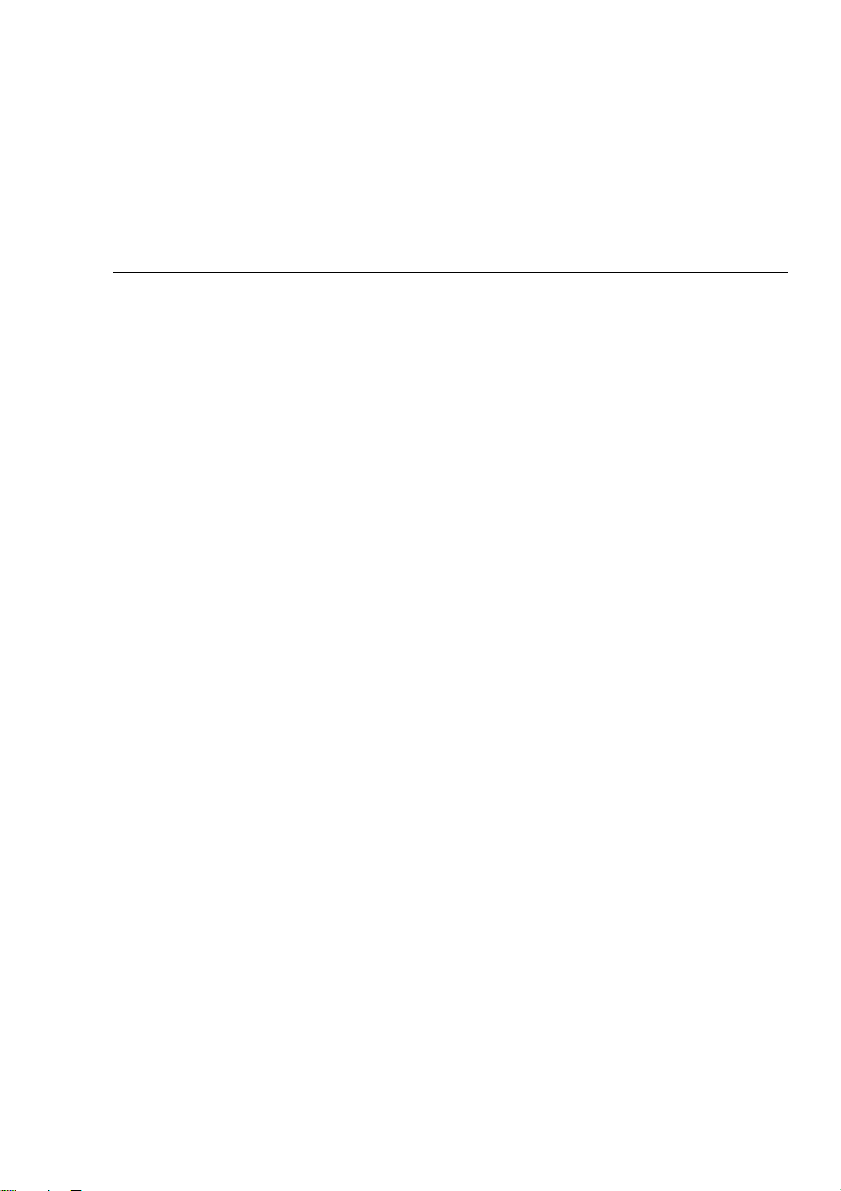

3 Overview

Identification plates

Identification plates

1 Nameplate

9

Lift mast n

10

Serial number (stamped into the

front right of the junction plate on

the overhead guard)

11

Drive axle identification plate

12

Engine

18 Operating Instructions – 394 807 10 01 EN – 07/2011

umber (adhesive label)

identification plate

Page 31

Nameplate

1 Nameplate

2

Manufacturer

3

Type/chassis number/year of

manufacture

4 Tare weight

5

Placeholder for "data-matrix code"

6

CE mark

7

Rated driving power

8 Rated load capacity

NOTE

The CE mark confirms compliance with the EC

machinery directive and with all regulations

applicable to the truck.

Steering axle identification plate

13

Steering axle identification plate

Overview 3

Identification plates

Operating Instructions – 394 807 10 01 EN – 07/2011 19

Page 32

3 Overview

General view

General view

1Liftmast

2 Lift cylinder

3 Composite instrument

4 Tilt cylinders

5 Switch panel for toggle switch (special

equipment)

6 Joystick

7 Steering wheel/hydrostatic power steering

8 Operator’s seat

9 Electrical system cover

10 Fuses (behind the electrical system cover)

11 Counterweight

12 Steering axle

20 Operating Instructions – 394 807 10 01 EN – 07/2011

13 Access cover

14 Chassis and overhead guard

15 Bonnet

16 Step for mounting and dismounting

17 Fuses (in the engine compartment)

18 Left drive unit

19 Fork carriage

20 Fork quick-releases

21 Forks

22 Fork stops

23 Handhold for entering and exiting the truck

(special equipment)

24 Lift mast chain

Page 33

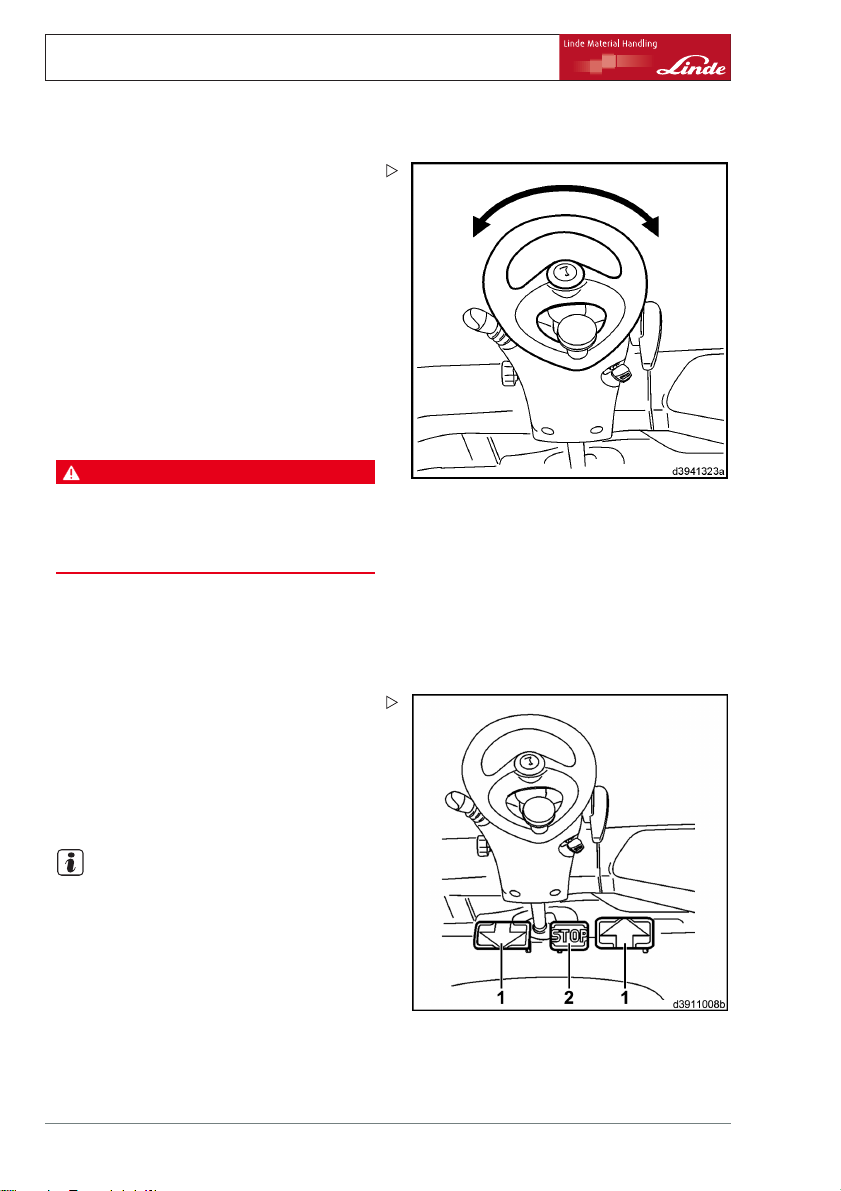

Operating devices

Overview 3

Operating devices

1 Indicator light for turn indicator and hazard

warning system (green) (special equipment)

2 Clamping screw for adjusting the steering

column

3 Multifunction lever for wiper/washer system

and turn indicator (special equipment)

4 Steering wheel / hydrostatic steering

5 Parking brake lever

6 Startingswitchwithswitchkey

7 Compartment

8 Joystick for working hydraulics

9 Joystick for auxiliary hydraulics (attach-

ments) (special equipment)

Operating Instructions – 394 807 10 01 EN – 07/2011 21

10 Symbol label for auxiliary hydraulics (attach-

ments) (special equipment)

11 Symbol label for working hydraulics

12 Signal button

13 Armrest on driver’s seat

14 Driver’s seat

15 Forward travel accelerator pedal

16 Stop pedal

17 Reverse travel accelerator pedal

18 "Guaranteed sound power level" label

19 "Truck configuration" sign (for description,

see "truck configuration sign")

Page 34

3 Overview

Display unit

Display unit

22 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 35

Overview 3

Display unit

1 Display unit

2 Hydraulic oil temperature indicator

3 Charging indicator

4 Engine oil pressure indicator / engine oil

level indicator (special equipment)

5 Electrical controller fault

6 Engine coolant temperature indicator

7 Joystick display electronically unlocked

8 Particle filter warning

9 Symbol without function

10 Water in the fuel filter (special equipment)

11 Hydraulic oil microfilter indicator (special

equipment)

12 Level display for diesel tank, LPG tank /

replacement cylinders or CNG tank

13 Symbol for "Particle filter"

14 Symbol without function

15 Symbol for "Service interval exceeded"

16 Operating hours symbol

17 Operating hours display

18 Symbol without function

19 Symbol for "Clock display (am/pm)"

20 Symbol without function

21 Function key

22 Reset button

23 Time display

24 "Do not start the engine" symbol

25 Symbol for "Parking brake applied"

26 Symbol for "Operating hours until the next

service" (shown for only 5 sec in the display

(17))

27 Symbol for "Seat belt not fastened" (special

equipment)

28 Text field

29 "Lift mast positioning" symbol active (special

equipment)

30 Display

31 Air filter vacuum indicator

32 Coolant level indicator

33 Preheating indicator (function only available

on diesel trucks)

34 Gas system error light (function only avail-

able on LPG trucks)

35 Engine malfunction warning light

The display unit (1) is mounted to the top right on the overhead guard. It is positioned within the

driver’s field of vision and provides centralised information about all functions of the truck. After

the key switch has been switched on, a self-test of the display unit is then performed. During the

self-test, all indicator lights and the displays are activated.

Display element

(2) Hydraulic oil temperature

indicator

(red)

Function

- Lights up if the maximum

permissible temperature is

reached. A buzzer also sounds

if the temperature limit is

exceeded.

When the "Engine protection"*

function is activated):

Possible malfunctions

Remedy

Insufficient oil in the hydraulic

circuit

Incorrect oil used

Oil filter clogged

il cooler contaminated

O

- Truck moves at creep speed

(approx. 2 km/h)

Display in the text field (28):

- Error code

X205

Switch off the buzzer with the

reset button (22)

Operating Instructions – 394 807 10 01 EN – 07/2011 23

Page 36

3 Overview

Display unit

Display element

(3) Charging indicator

(red)

(4) Engine oil pressure

indicator/engine oil level

indicator

(red)

(5) Electrical controller fault

(red)

(6) Engine coolant temperature indicator

(red)

(7)Joystick display electronically unlocked

(green)

Function

- Lights up if there are

generator malfunctions.

- Lights up and buzzer sounds

when the oil pressure is too

low.

- If the text field (28) also

shows

Oil with a double

arrow pointing downwards,

the engine oil level is too low.

(special equipment)

When the "Engine protection"*

function is activated):

- Truck moves at creep speed

(approx. 2 km/h)

Display in the text field (28):

- Error code

pressure is too low

- Error code

with double arrow pointing

down, if the oil level is too low.

- Lights up when an electrical

fault is present.

Error code is displayed in the

text field (28).

- Lights up if the maximum

permissible temperature is

reached. A buzzer also sounds

if the temperature limit is

exceeded.

When the "Engine protection"*

function is activated):

- Truck moves at creep speed

(approx. 2 km/h)

Display in the text field (28):

- Error code

- Lights up when the "Joystick

unlocked" function is activated.

X202 if the oil

X201 and Oil

X204

Possible malfunctions

Remedy

V-ribbed belt split or v-ribbed

belt tension too slack

V-ribbed belt tensioner faulty

Cable faulty

Alternator faulty

Charging controller or cut-out

relay faulty

Short circuit at output D+ of the

display unit

Insufficient oil i

Engine too hot

Incorrect oil used

Internal leakage in the

lubricating oil circuit

Top up with engine oil

Switch off the buzzer with the

reset button (22)

Fan motor fa

Thermal sw

Water co

Leakage in the cooling circuit

Coolant level too low

Switch off the buzzer with the

reset button (22)

n the crankcase

ulty

itch faulty

oler contaminated

24 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 37

Overview 3

Display unit

Display element

(8) Particle filter error

(red)

(9) Symbol without func

(10) Water in the fuel filter

(yellow)

(special equipment)

(11) Hydraulic oil microfilter

indicator

(yellow)

(special equipment)

(12) Level display for diesel

tank, LPG tank/replacement

cylinders or CNG tank

(green or red depending on

the fuel level)

(13) Symbol for "Particle

filter"

(14) Symbol without function

(15)"Service interval

exceeded" symbol

(16) Operating hours symbol

tion

Function

- Lights up when the particle

filtercontrolsystemis

activated, if the load period

of the particle filter exceeds

8.5 h

- Additionally, a buzzer sounds

and an error code appears in

the text field (28) in the event of

an error in the particle filter

control system. The truck

moves only at creep speed

(approx. 2 km/h).

- Lights up if water has

collected in the fuel filter

- Additionally, a buzzer sounds

if the warning light is activated

for more than 5 seconds

- Lights up if the pressure filters

require maintenance work.

Shows the current fuel

level in the diesel tank, the

current level in the LPG

tank/replacement cylinders

or the current level in the CNG

tank.

- Lights up if the particle filter

control system is active.

If the number of operating

hours until the next service

is less than or equal to

zero, the symbol flashes for

10 seconds every time the

truck is started, and then lights

up continuously.

Flashes when operating hours

are being counted (only when

the ignition is on and the engine

speed exceeds 300 rpm).

Possible malfunctions

Remedy

Regenerate the particle filter

immediately

Error in the particle filter control

system

Drain water from the fuel filter

Switch off the buzzer with the

reset button (22)

Microfilter clogged, change it

The display can only be reset

using the diagnostic program.

Operating Instructions – 394 807 10 01 EN – 07/2011 25

Page 38

3 Overview

Display unit

Display element

(17) Operating hours display

(18) Symbol without funct

(19) Clock display (am/pm)

(20) Symbol without function

(21) Function key

(22) Reset button

(23) Time display

(24)"Do not start the engine"

symbol

(25)"Parking brake" symbol

(26)"Operating hours until the

next service" symbol

(27) Symbol for "Seat belt not

fastened"

(special equipment)

ion

Function

Indicates the operating hours

of the truck. This display

is evidence of the truck’s

operating time and of the

inspection and maintenance

work to be performed.

For 12-hour format:

am = morning

pm = afternoon

- Adjusting the time

- Scrolling through error

messages

- Adjusting the time

- Scrolling through erro

messages

- Turning off the warnin

24-hour clock displa

Adjustable using the

(22) push buttons.

- Lights up when the

has stalled. (A blo

repeat starting is

engine cannot be st

- Lights up if the parking brake

is activated

After the ignition has been

switched on, display field (17)

shows the operating hours

until the next service (counting

backwards).

Symbol (26) lights up. After

5 seconds, symbol (26) goes

out and display (17) switches

automatically to the truck’s

operating hours; the operating

hours symbol (16) flashes.

- Lights up if seat belt was not

fastened

r

g sound

y.

(21) and

engine

ck against

active and the

arted).

Possible malfunctions

Remedy

If a faulty display unit is

replaced, the operating hours

up to that point must be

recorded. Affix the data on an

embossed strip near the display

unit. There is also the option of

updating the new display unit at

a later time.

The diagnostic program can be

used to reset the display to a

12-hour clock.

The diagnostic program can be

used to reset the display to a

12-hour clock.

Always leave the ignition

switched on until the symbol

goes out.

Then repeat the start attempt.

Fasten the seat belt

26 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 39

Overview 3

Display unit

Display element

Text field (28)

(29)"Lift mast positioning"

symbol

(special equipment)

Display (30)

(31) Air filter vacuum

indicator

(yellow)

(32) Coolant level indicator

(yellow)

(33) Glow plug indicator

(yellow)

(34) Gas system error light

(red)

(35) Engine malfunction

warning light

(yellow)

Function

Serves as display field for error

code display and charge status

display for the particle filter (in

line 1).

- Lights up when the "Lift

mast positioning" function is

activated

Serves as a text display and

symbol display

- Lights up when the air filter is

excessively clogged.

- Lights up when the coolant

level is below the minimum

When the "Engine protection"*

function is activated):

- Truck moves at creep speed

(approx. 2 km/h)

Display in the text field (28):

- Error code

Function only available on

diesel trucks:

- Lights up whilst the glow plugs

are preheating, then goes out

- Flashes when a malfunction

exists in the engine or in the

engine control unit.

Function only available on LPG

trucks:

- Lights up if an error is detected

in the gas system.

- Lights up if an error is detected

by the engine control unit.

X203

Possible malfunctions

Remedy

Charge status display:

- 0 symbols blacked out =>

particle filter empty

- 11 symbols blacked out =>

particle filter full

Air filter clogged, change it.

Top up the coolant.

Identify the error using the

diagnostic program.

Identify the error using the

diagnostic program.

Identify the error using the

diagnostic program.

*) The "Engine protection" function (special equipment) can be disabled using the diagnostic

program. Contact your authorised dealer.

Operating Instructions – 394 807 10 01 EN – 07/2011 27

Page 40

3 Overview

Switch panel

Switch panel

The switch panel is mounted at the top right of the

overhead guard.

1 Interior lighting

2 Standard or higher lighting

3 Working spotlight position 1/2

4 Working spotlight position 3/4 or working

spotlight position 5/6

5 Working spotlight position 7/8

6 Front windscreen wiper and rear window

wiper — continuous operation on/off (inter-

val depends on the drive direction and the

washer system is always activated)

7 Roof panel wiper - intermittent mode or

continuous operation on/off (washer system

is activated)

8 Rear window heating

9 Hazard warning light

10 Rotating beacon or flashing beacon

11 Particle filter starting switch

12 Particle filter stop/reset switch

13 Changing particle filter system error light

NOTE

The configuration of the switch panel and

arrangement of individual switches may vary,

depending on the version. Observe the switch

symbols.

28 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 41

4

Operation

Page 42

4 Operation

Running-in instructions

Service plan before initial commissioning

Engine

Fill up with fuel

Check the engine oil level

Checking the coolant level

Regenerate the particle filter

Chassis frame

Tighten wheel fastenings

Check the tyre pressure

Checking the brake system

Check steering system.

Electrics / Electronics

Battery: check condition, acid level and acid density

Hydraulics

Hydraulic system: Check the oil level.

Check lifting system and attachments.

Carried

out

9

8

Running-in instructions

The truck can be operated quickly immediately. Avoid high sustained loads on the working hydraulics and on the travel drive in the

first 50 hours. The wheel fasteners must be

tightened before the commissioning and after

each wheel change. Then after 100 service

30 Operating Instructions – 394 807 10 01 EN – 07/2011

hours minimum. Tighten opposite wheel fasteners to a torque of

Front: 425 Nm

Rear: 640 Nm

Page 43

Pre-shift-checks

Pre-shift-checks

Engine

Check the fuel level

Check the engine oil level

Checking the coolant level

Chassis frame

Check the tyre pressure

Check the condition of the antistatic belt (only when using tyres that are not antistatic)

Hydraulics

Hydraulic system: Check the oil level.

Operation 4

Carried

out

8

9

Operating Instructions – 394 807 10 01 EN – 07/2011 31

Page 44

4 Operation

Standard equipment

Standard equipment

Entering and exiting the truck

WARNING

Entering and exiting the truck can result in injuries

to the feet or back.

Always face the truck when you enter or exit the

truck.

NOTE

Do not use the steering wheel or the actuating

levers as an aid to get in or out.

¾ Use handle (1) (special equipment) or

longitudinal member (2) and step (3).

Adjusting the standard driver’s seat

and comfort driver’s seat

WARNING

If the seat is not adjusted correctly, this may cause

injury to the driver’s back. The adjustment controls

for the driver’s seat should not be used during

operation.

Before starting the truck and whenever changing

drivers, adjust the seat to correspond to the driver’s

weight and make sure that the settings have all

engaged properly. Do not place any objects in the

driver’s rotation range.

32 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 45

NOTE

Sitting for long periods of tim

pressure on the spine. Try to co

this by performing regular sim

e puts a lot of

mpensate for

ple gymnastic

movements.

Longitudinal adjustment

¾ Pull lever (1) upwards.

¾ Move the driver’s seat backwards or for-

wards on the runners to find the most comfortable position for the driver in relation to

the steering wheel and the accelerator pedals.

¾ Allow lever (1) to snap in

to place.

Operation 4

Standard equipment

Adjusting the seat back

¾ Push lever (2) upwards and hold in place.

¾ Move the seat backrest forwards or back-

wards until a comfortable seating position

for the driver is found.

¾ Release lever (2).

Setting the driver’s

NOTE

rest

weight

The individual driver’s weight must be set

when the driver’s seat is under load.

¾ Check the weight setting in the inspection

window (4).

The correct driver’s weight has been set

when the arrow is in the centre position in

the inspection window (4).

Adjust the driver’s weight as necessary.

¾ Pull out the lever (3).

Move the lever to set the driver’s weight for the

suspension.

¾ Move the lever (3) upwards for a heavier

weight.

¾ Move the lever (3) downwards for a lighter

weight.

Operating Instructions – 394 807 10 01 EN – 07/2011 33

Page 46

4 Operation

Standard equipment

Adjusting the lumbar support (only with a

comfort driver’s seat)

NOTE

The lumbar support enables optimum configuration of the seat back contour to the driver’s

body.

¾ Turn knob (5) to the left or right.

The extent to which the lower and upper

areas of the backrest are curved is adjusted

individually.

Adjusting the height-adjustable

comfort driver’s seat

WARNING

If the seat is not adjusted correctly, this may cause

injury to the driver’s back. The adjustment controls

for the driver’s seat should not be used during

operation.

Before starting the truck and whenever changing

drivers, adjust the seat to correspond to the driver’s

weight and make sure that the settings have all

engaged properly. Do not place any objects in the

driver’s rotation range.

NOTE

Sitting for long periods of time puts a lot of

pressure on the spine. Try to compensate for

this by performing regular simple gymnastic

movements.

34 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 47

Longitudinal adjustment

¾ Pull lever (1) upwards.

¾ Move the driver’s seat backwar

wards on the runners to find the m

fortable position for the driv

the steering wheel and the acce

als.

¾ Allow lever (1) to snap into place.

ds or for-

ost com-

er in relation to

lerator ped-

Adjusting the seat backrest

¾ Push lever (2) upwards and hold in place.

¾ Move the seat backrest forw

wards until a comfortabl

for the driver is found.

¾ Release lever (2).

ards or back-

e seating position

Setting the driver’s weight

NOTE

The individual driver’s weight must be set

when the driver’s seat is under load.

¾ Check the weight setting in the inspection

window (4).

The correct driver’s weight has been set

when the arrow is in the centre position in

the inspection window (4).

Adjust the driver’s weight as necessary.

¾ Pulling the lever (3) upwards signifies a

higher weight.

¾ Pushing the lever (3) downwards signifies a

lower weight.

Operation 4

Standard equipment

Operating Instructions – 394 807 10 01 EN – 07/2011 35

Page 48

4 Operation

Standard equipment

Adjusting the lumbar support

NOTE

The lumbar support enables optimum configuration of the seat back contour to the driver’s

body.

¾ Turn knob (5) to the left or right.

The extent to which the lower and upper

areas of the backrest are curved is adjusted

individually.

Adjusting the seat height

Adjust the seat height as required.

¾ Pulling the lever (

seat moves upward

¾ Pushing the lever (3) downwards means

that the seat moves downwards.

3) upwards means that the

s.

NOTE

After making the adjustment, the arrow in the

inspection window (4) may deviate somewhat

from the centre position.

Adjusting the luxury driver’s seat

WARNING

If the seat is not adjusted correctly, this may cause

injury to the driver’s back. The adjustment controls

for the driver’s seat should not be used during

operation.

Before starting the truck and whenever changing

drivers, adjust the seat to correspond to the driver’s

weight and make sure that the settings have all

engaged properly. Do not place any objects in the

driver’s rotation range.

36 Operating Instructions – 394 807 10 01 EN – 07/2011

Page 49

NOTE

Sitting for long periods of tim

pressure on the spine. Try to co

this by performing regular sim

e puts a lot of

mpensate for

ple gymnastic

movements.

Longitudinal adjustment

¾ Pull lever (1) upwards.

¾ Move the driver’s seat backwards or for-

wards on the runners to find the most comfortable position for the driver in relation to

the steering wheel and the accelerator pedals.

¾ Allow lever (1) to snap in

to place.

Operation 4

Standard equipment

Adjusting the seat back

¾ Push lever (2) upwards and hold in place.

¾ Move the seat backrest forwards or back-

wards until a comfortable seating position

for the driver is found.