Page 1

T WIRING TYPE

MODIFICATION

Models: T, GT, J, H, GH, SD, and GSD

APPLICATION REQUIREMENTS:

This wiring modification is available to models T, GT, J, H, GH, SD and GSD standard door operator

with 24VAC line voltage. Not for use with Logic Control Board.

FUNCTIONS:

Momentary contact to open, close and stop, with open override and Timer-to-Close. OPEN button may

be connected to activate timer if desired. Auxiliary controls may be connected to open and activate

Timer-to-Close, or to open and close without activating timer. If a timer has been activated, all opening

devices will recycle timer. Includes wiring for sensing devices to reverse but not reactivate timer.

PREP

ARATION:

Unpack kit to verify the parts listed below are included. Refer to installation instructions on reverse

side.

PACKING LIST

PART NUMBER

01-12414

14-10198

24-24-1

26-438

27-10199

27-8002-K

31-11119

40-10222

42-103

74-12415

82-PX06-06T

82-PX06-16

82-WX10-08T

84-LH-06

84-ST-06

DESCRIPTION

T WIRING INSTRUCTIONS

PLASTIC BAG, 16” X 12” X 4 MILL.

RELAY 24VAC COIL DPDT

ARTISAN TIMER

5-1/2” CABLE TIE

AUXILIARY CONTACT BLOCK

SPACER

LABEL, 4 POSITION TERMINAL BLOCK

3 POSITION TERMINAL BLOCK

“T” WIRING, R2 AND R3 WIRING ASSEMBLY

SCREW, #6-32 X 3/8” PAN HD PHILLIPS SELF TAP

SCREW, #6-32 X 1” PAN HD PHILLIPS

SCREW, #10-32 X 1/2” HEX WASHER SELF TAP

#6-32 LOCK HEX NUT

#6-32 TINNERMAN NUT (SINGLE)

QUANTITY

1

1

2

1

4

1

2

1

1

1

4

2

2

2

4

95-PU07-69

95-BR03-66

95-BL10-16

*1262-1

**1262-3

* = 1 Phase Operators Only

** = 3 Phase Operators Only

WIRE 18GA. PURPLE 7”, .250 FORK X .250 INSUL. FASTON

WIRE 18GA. BROWN 3”, .250 FORK X .250 FORK

WIRE 18GA. BLUE 10”, .250 FORK X STRIP

“T” WIRING DIAGRAM 1 PHASE

“T” WIRING DIAGRAM 3 PHASE

2

1

1

1

1

Page 2

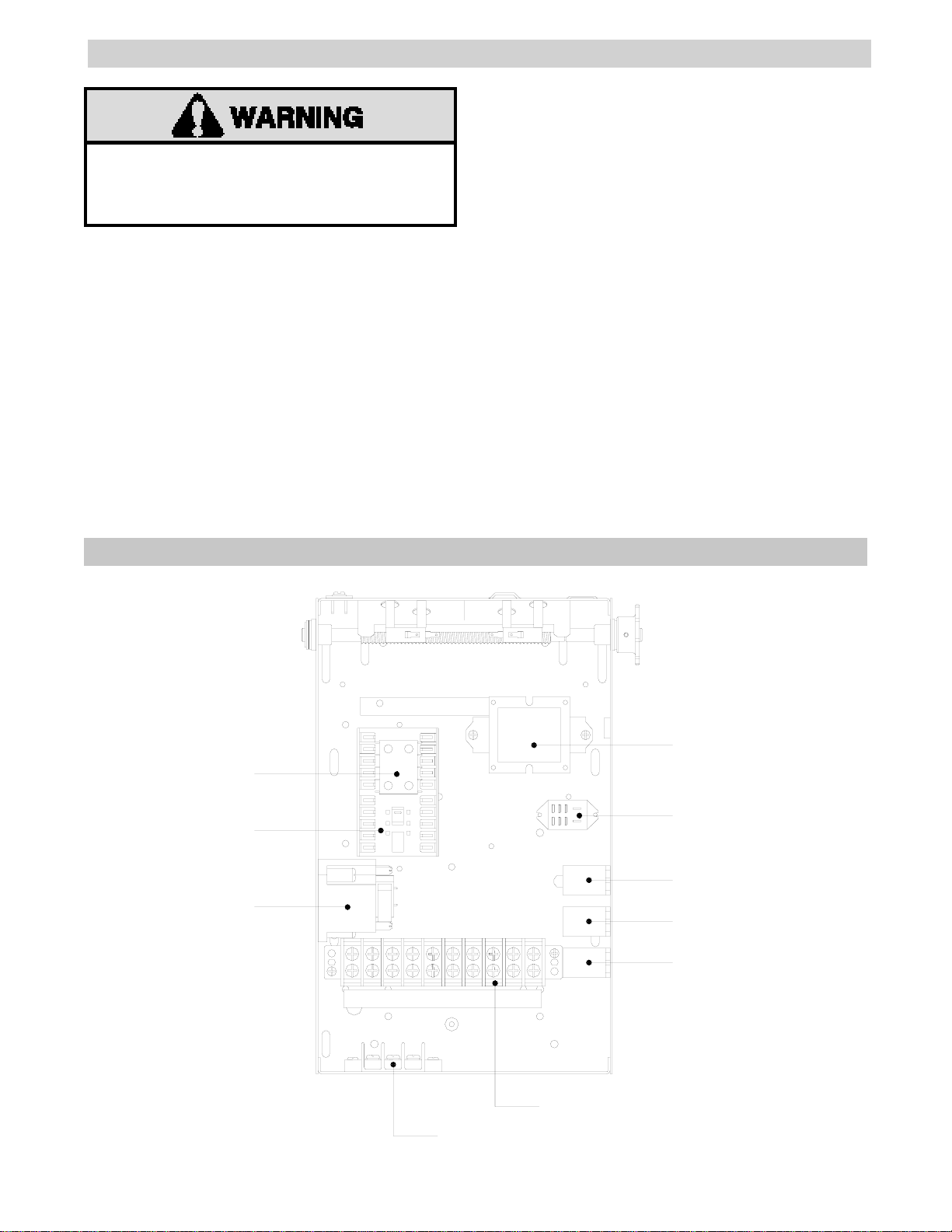

COMPONENT MOUNTING

TO AVOID SERIOUS PERSONAL INJURY OR DEATH

FROM ELECTROCUTION, DISCONNECT ELECTRIC

POWER TO OPERATOR BEFORE INSTALLING “T”

WIRING MODIFICATION.

1. For additional help during any of the following

steps refer to the electrical box layout on the bottom

of the page.

2. Remove the (IR) Relay from the wall of the

electrical box (this is the relay closest to the terminal

block) and reattach on the floor of the electrical box

next to the (R1) Relay. Use old hardware to secure in

place.

3. Install the two new relays in the electrical box.

Mount one of the relays in the holes where the relay

from step two was just removed and the other relay in

the existing holes right next to it.

Use (4) #6-32 x 3/8” long self tapping pan head

screws and (4) #6-32 tinnerman nuts supplied to

secure in place. Be sure when mounting relays to

mount them coil side out.

4. Install the new four position terminal block on the

the back wall of the electrical box above the 10

position terminal block, use the holes that are 1” from

the lid of the box. Use (2) #8-32 x 1/2” self tapping

hex head screws supplied to secure in place. Label it

11, 12, 13 with the new label supplied.

5. Install the new timer to the side wall of the

electrical box, this is the side opposite the relays.

Use (2) #6-32 x 1” long pan head screws, (2)

standoffs and (2) #6-32 locknuts to secure in place.

6. Install the new auxiliary contact block on the

closed side of the contactor, this is the half nearest

the limit switches and has purple wires on the coils.

NEW AUXILIARY

CONTACT BLOCK

CONTACTOR

NEW TIMER

TYPICAL ELECTRICAL BOX LAYOUT

TRANSFORMER

(IR) RELAY

R1 RELAY

NEW R2 RELAY

NEW R3 RELAY

10 POLE TERMINAL BLOCK

NEW 3 POLE TERMINAL BLOCK

1

Page 3

WIRING INSTRUCTIONS

1. For additional help during any of the following

steps refer to the wiring diagram on the bottom of the

page.

2. Connect the blue wire running from the (NO) on

the R2 relay to terminal #3 on the ten position

terminal block.

3. Connect the orange wire running from the (C) on

the R2 relay to terminal #1 on the ten position

terminal block.

4. Connect the yellow wire running from the (COIL)

on the R2 relay to terminal #11 on the new terminal

block.

5. Connect the yellow wire running from the (COIL)

on the R2 relay to #62 on the auxiliary contact block.

WIRING DIAGRAM

6. Connect the yellow wire running from the (COIL)

on the R3 relay to #61 on the auxiliary contact block.

7. Connect the purple wire running from the (C) on

the R3 relay to terminal #12 on the new terminal

block.

8. Connect a new purple wire from the timer to

terminal #13 on the new terminal block.

9. Connect a new purple wire from the timer to

terminal #2 on the ten position terminal block.

10. Connect a new brown wire from terminal #12 on

the new terminal block to terminal #13 on the new

terminal block.

11. Connect a new blue wire from #62 on the

auxiliary contact block to the existing wire nut.

R2 RELAY

R3 RELAY

NC

NC

BL

NO

BL

NO

TERMINAL 3

TERMINAL 1

OR

COIL

C

BL

COIL

C

PU

YE

YE

YE

TERMINAL 11 (NEW)

AUXILIARY

CONTACT

BLOCK

62

61

54

53

EXISTING

WIRE NUT

EXISTING

WIRES

BL

TERMINAL

12 (NEW)

TERMINAL

13 (NEW)

2

PUBR

TIMER TO

CLOSE

PU

TERMINAL 2

Page 4

WILL SET TIMER

WILL NOT SET TIMER

CONTROL DEVICE CONNECTIONS

11 3

1 3 7 3

TIMER DEFEAT

12 13

01-12414A All Rights Reserved

© 1998, The Chamberlain Group, Inc.

Loading...

Loading...