Page 1

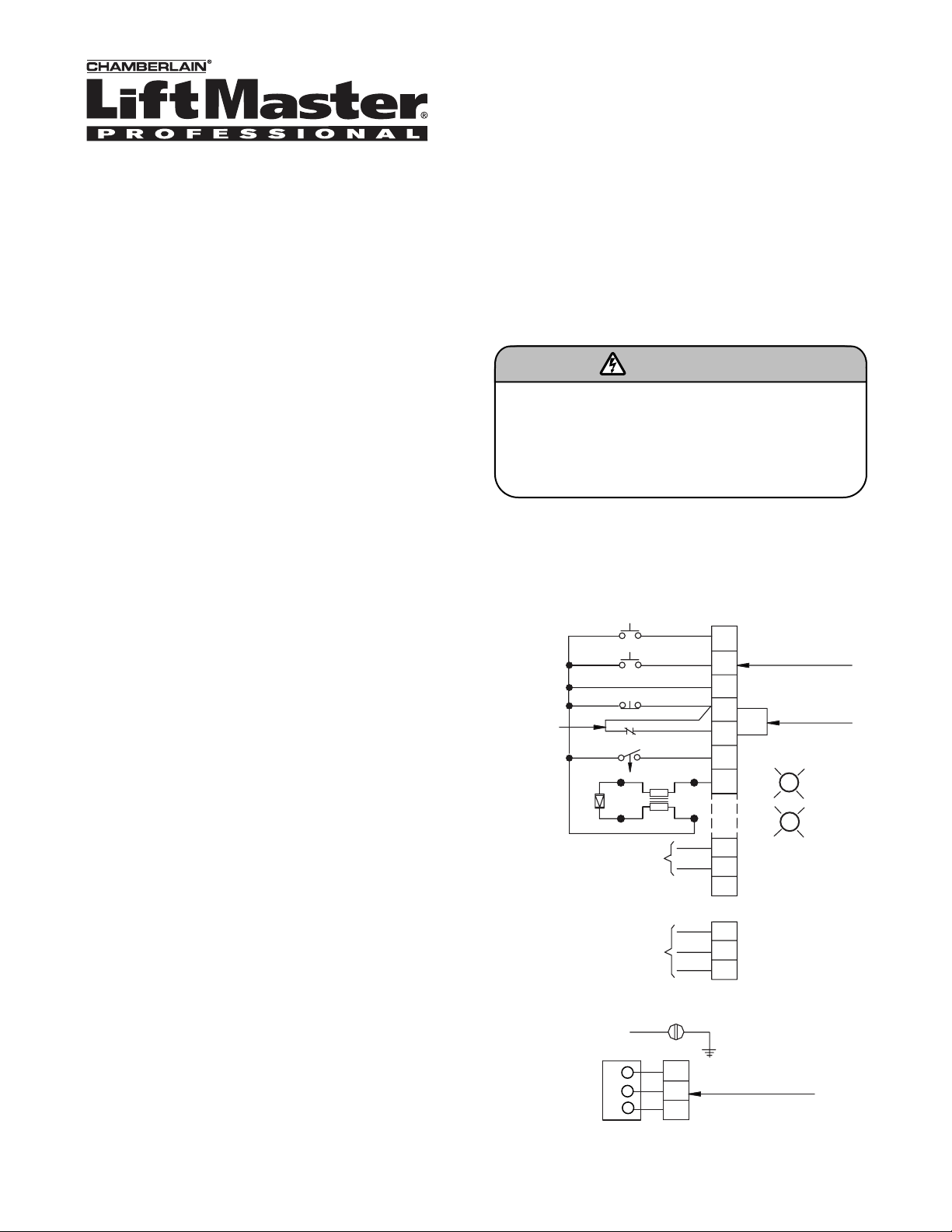

APPLICATION

This modification is available to Model T, GT, J, H, GH, GSD and SD standard door operators with 24V control circuits (M).

Required for use with 4-wire “fail-safe” type electrical edges.

NOTE: For operators with logic control board (L), use the CPSII commercial protector system II.

F2 WIRING TYPE (K-LINE

OPERATORS) CONVERSION

90F2 FOR MODELS: T, GT, J, H, GH, SD, GSD

WIRING

1. Disconnect power to operator.

2. Position door in mid-position, set limit nuts so that both

open and close limits switches are depressed (listen for

click).

3. Connect the diode (provided in operator box) to the two

wires of the four wire safety edge as shown. The polarity

must be correct for the fail safe circuit to function.

4. Connect the remaining two leads of the safety edge to

terminals 3 and 10 as shown.

5. Restore power to operator.

6. Refer to the two test lights built into the fail safe circuit

board in the control box.

• If red light flashes, reverse connections terminal 3 and

10.

• If both red and green flash, the diode is connected

improperly. Check connections.

• If green light only is on, connections are correct.

Proceed with limit switch adjustment per owner's

manual.

FIELD WIRING

To prevent possible SERIOUS INJURY or DEATH from

electrocution, disconnect electric power to operator

BEFORE installing.

ALL electrical connections MUST be made by a qualified

individual.

WARNING

NOTE: The door will not close if safety edge or wiring is

damaged. Do not apply power until after reading fail safe

safety instructions.

OPEN

1

TERMINAL BLOCK

2

3

4

5

7

10

L1

L2

L3

REMOVE JUMPER

WHEN EXTERNAL

SWITCH IS USED.

O.K.

G

R

N.G.

TEST

LIGHTS

EXTERNAL

INTERLOCK

FAIL - SAFE

SAFETY EDGE

CLOSE

STOP

TO OPEN AND CLOSE

R

DIODE

BL

1 PHASE

POWER IN

GROUND

RADIO

RECEIVER

3 PHASE

POWER IN

3

2

1

L1

L2

L3

R3

R2

R1

(OPTIONAL)

AUX. TERMINAL BLOCK

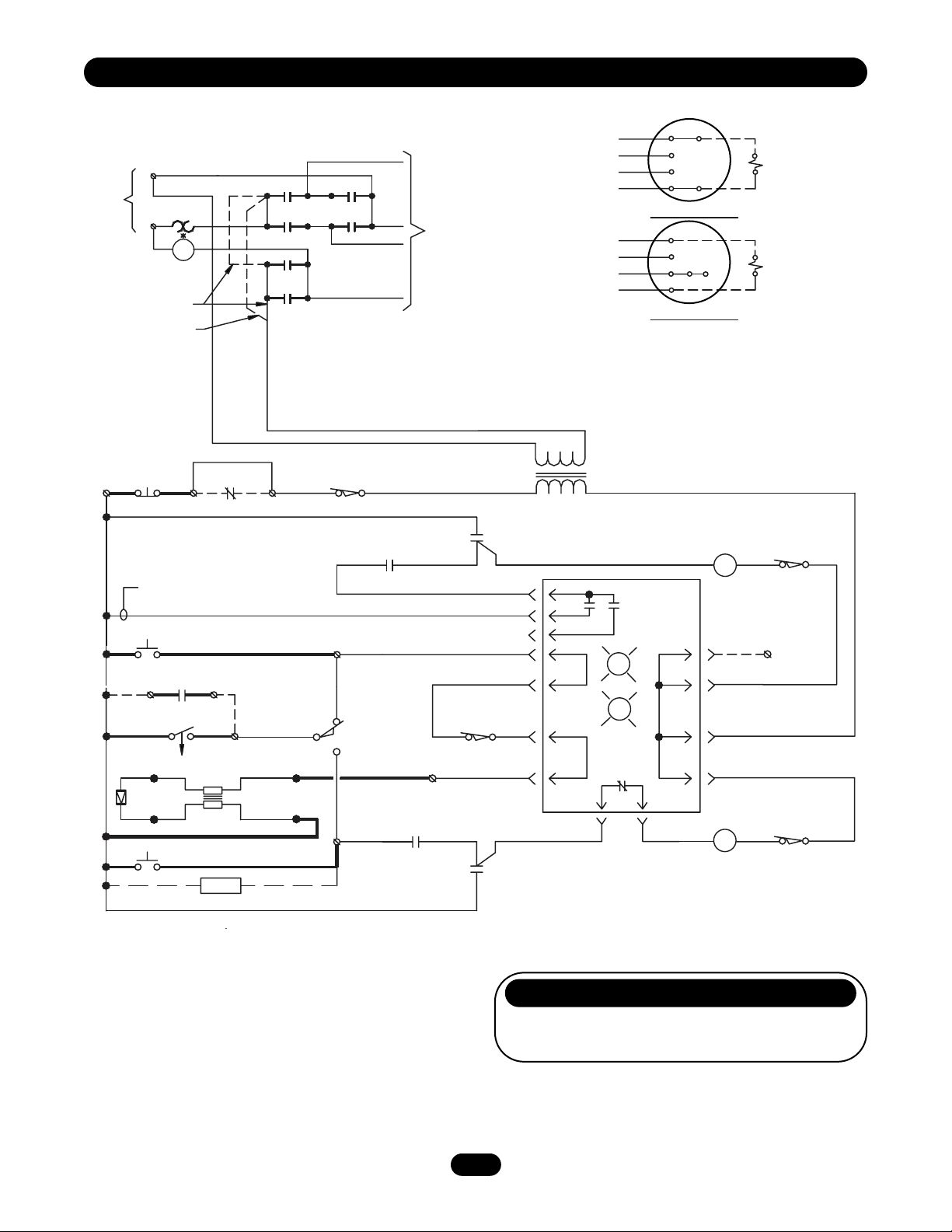

Page 2

*I.R. COIL VOLTAGE IS THE

2

NOTES:

1. I.R. (Instant Reverse) relay is wired normally open and

is held closed when motor is not running.

2. Terminals R1, R2, and R3 are on optional external

terminal block.

3. Optional timer to close will, after preset time, close the

door whenever it is not fully closed and all open and

safety devices are cleared.

4. We recommend the use of 16 gauge or heavier wire for

all control circuit wiring.

REPLACEMENT PARTS

Fail Safe Board P/N 7129505

Diode P/N 2940051

1 PHASE F2 WIRING- 0192

SAME AS THE LINE VOLTAGE.

W

L2

O/L

BK

POWER IN

L1

115V. ONLY

230V. ONLY

BK

BK BK

I.R.

3PDT.

GY

CL

4

4OP31

OP

2

CL

6

OP

3

1

5

6

5

CL

2

BL

P

Y

TO

MOTOR

INTERCHANGE PURPLE & GRAY WIRES.

3

P

BL

Y

GY

P

BL

Y

GY

TO REVERSE MOTOR DIRECTION,

1

8

5

4

115V. CONNECTION

1

8

523

4

230V. CONNECTION

BK-BK

2

BK-BK

BK-BK

BK-BK

SOLENOID

115V. BRAKE

(WHEN REQUIRED)

SOLENOID

230V. BRAKE

(WHEN REQUIRED)

STOP

3

Y

FOR DELAY ON REVERSE MOVE TO 3d

OPEN

OPEN AND CLOSE

R1

OR

AND CLOSE

R

DIODE

BL

CLOSE

INTERLOCK

4

RADIO TO

R2

TO OPEN

4 WIRE

FAILSAFE EDGE

Y

TIMER

(OPTIONAL)

Y

7

EXTERNAL

BR

W

5

Y

(WHEN PROVIDED)

Y

Y

HAND CHAIN

SWITCH

OR

OR

1

OR

OR

N.C.

AUX OPEN L/S

N.O.

C

P

2

R

BR

PRI.

F1

TEST

LIGHTS

6

Y

G

O.K.

N.G.

R

F2

OR

OP

A1

P.C. BOARD

8

7

PP

CL

A2

R

OR

Y

P

A1

OR

A2

OPEN

N.C.

R3

CLOSE L/S

N.C.

LS

P

C

P

C

Y

24 VAC.

14

OP

IR

IR

P

13

Y

OR

AUX. CLOSE L/S

GY

N.C.

10

GY

RP

GY

C

14

CL

13

SEC.

1

3i

3d

9

9

10

10

Page 3

3

3 PHASE F2 WIRING - 193

NOTE: Terminals R1, R2 and R3 are on optional external terminal block.

O/L (WHEN PROVIDED)

BK

L2

BK

L1

POWER IN

BK

L1

BR

STOP

3

Y

FOR DELAY ON REVERSE MOVE TO 3d

OPEN

RADIO TO

OPEN AND CLOSE

R1

OR

TO OPEN

AND CLOSE

FAILSAFE EDGE

R

DIODE

BL

CLOSE

CL

4

OP

4

OP

2

CL

6

EXTERNAL

INTERLOCK

4

R2

7

4 WIRE

3

3

1

5

Y

GY

OP

6

5

CL

2

1

P

Y

BR

BR

HAND CHAIN

Y OR BR

5

SWITCH

(WHEN PROVIDED)

1

OR

Y

C

P

2

TO

MOTOR

BR

Y

OR

OR

OR

N.C.

AUX. OPEN L/S

N.O.

24

P

R

MOTOR O/L

OR

O/L PILOT

14

13

AUX. CLOSE L/S

GY

N.C.

10

GY

BL

14

13

Y OR BR

OP

OR

CL

GY

1

7

BR

P

BR

BR

BR

PRI.

24 VAC.

SEC.

3d

9

GY

C

10

P

2

Y

3

208V./230V. CONNECTION

GY

1

P

2

Y

3

460V. CONNECTION

TO REVERSE MOTOR DIRECTION,

INTERCHANGE ANY TWO INCOMING

POWER LEADS AT TERMINAL STRIP.

Y

1

F1

3i

TEST

LIGHTS

6

G

R

F2

9

10

4

8

5

9

6JJ

4

7

8

9

P.C. BOARD

O.K.

N.G.

J

5

6

J

OR

A1

8R

7

P

A2

BL-BK

O/L (WHEN REQ’D)

(UP TO 3/4 HP)

BL-BK

BL-BK

(WHEN REQ’D)

O/L

(UP TO 3/4 HP)

BL-BK

OPEN L/S

OR

OP

A2

N.C.

R3

OR

Y

P

CLOSE L/S

P

CL

A1

N.C.

C

C

SOLENOID

230V. BRAKE

(WHEN REQUIRED)

SOLENOID

230V. BRAKE

(WHEN REQUIRED)

OR

P

Page 4

© 2006, The Chamberlain Group, Inc.

01-13410B All Rights Reserved

Loading...

Loading...