Page 1

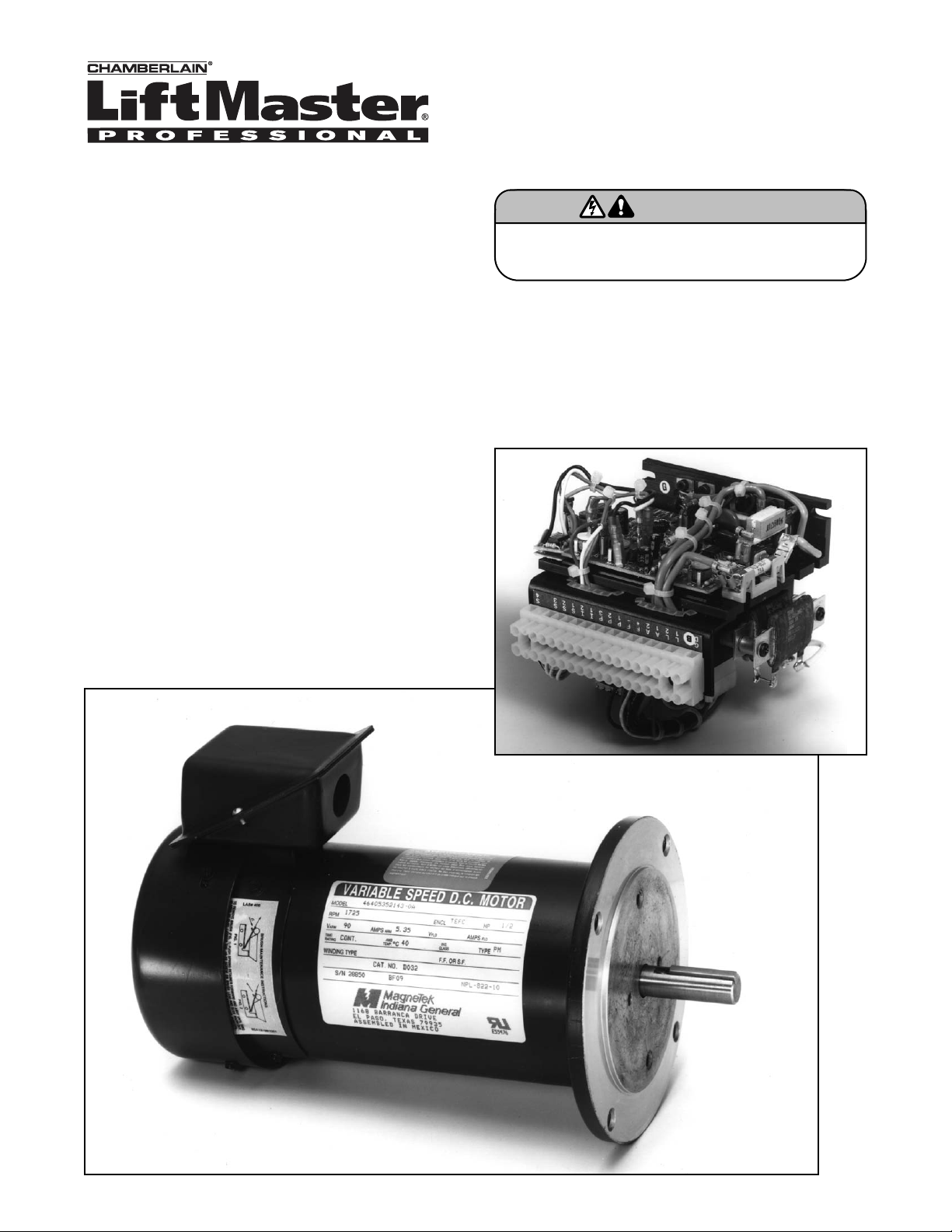

VARIABLE SPEED

MODIFICATION ADDENDUM

MODELS: GH & GT (1/2 - 1HP, 1PH. ONLY)

Variable Speed DC Motor

DC Controller

Safety equipment MUST be used with operators

employing this modification.

WARNING

WARNING

APPLICATION

This operator is equipped with a variable speed

modification. The AC motor and control circuit in a door

operator has been replaced with a DC variable speed drive

control and permanent magnet DC motor. May be provided

for either 115 or 230VAC single phase power. Allows

adjustment of the door speed over a wide range, up to 4

ft/sec on some applications. Acceleration adjustment gives

“ramp up”, or soft starts to allow operation of very heavy

doors. Dynamic brake and current limit circuits replace

mechanical brake and clutch respectively, minimizing the

number of moving parts that may wear out. Suitable for

continuous duty and high cycling applications.

Refer to the wiring diagram included with this addendum in

lieu of diagrams included with owner's manual.

VARIABLE SPEED WITH DECELERATION (OPTIONAL)

PART NUMBER: 90-827

When present, provides a adjustable “ramp down” or soft

stop at the full open and full close position.

NOTE: This modification will usually affect the horsepower

selection for a given model. Higher speeds require higher

horsepower for the same door. If you have concerns,

consult your representative for specific horsepower rating

information on your application.

Page 2

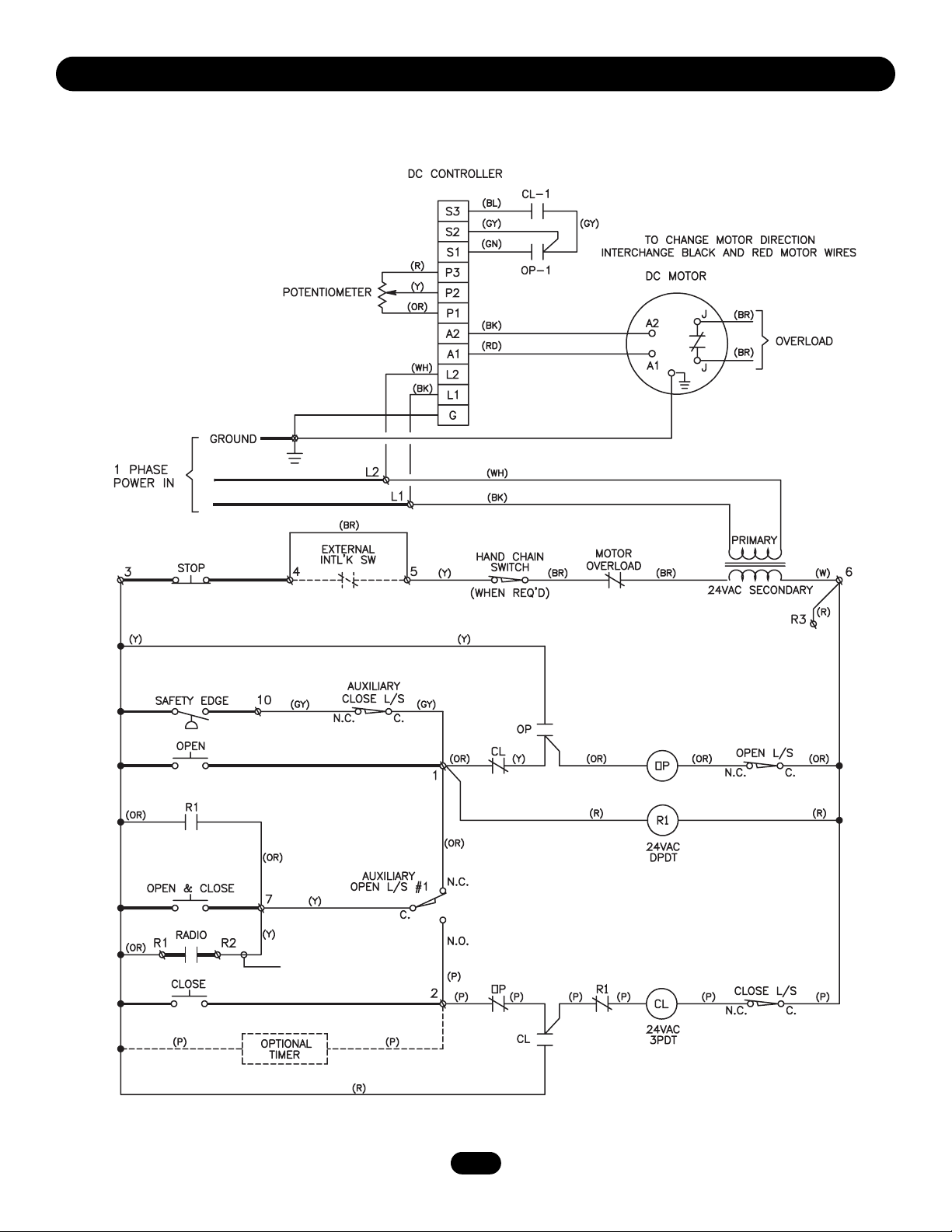

VARIABLE SPEED MODIFICATION

SCHEMATIC DIAGRAM

1211

2

SEE NOTE

NOTE: When equipped with a Timer to Close the yellow wire will connect from terminal R2 to terminal 1

and the radio will only open and set the timer.

Page 3

1639

VARIABLE SPEED MODIFICATION WITH

OPTIONAL DECELERATION (P/N 90-827)

SCHEMATIC DIAGRAM

3

SEE NOTE

NOTE: When equipped with a Timer to Close the yellow wire will connect from terminal R2 to terminal 1

and the radio will only open and set the timer.

Page 4

© 2006, The Chamberlain Group, Inc.

01-12437B All Rights Reserved

CONTROL CONNECTION DIAGRAM

IMPORTANT NOTES:

1. The 3-button control station provided must be

connected for operation.

2. If a STOP button is not used, a jumper must be placed

between terminals 3 and 4.

3. Auxiliary control equipment may be any normally open

two wire device such as pull switch, single button, loop

detector, card key or such device.

4. Use 16 gauge or heavier wire for all control circuit wiring.

3-BUTTON STATION or 3 POSITION KEYSWITCH w/ SPRING RETURN TO CENTER AND STOP BUTTON

STANDARD

1234

Open

Close

Stop

ALL WIRING TYPES

2 BUTTON STATION or 3 POSITION KEY SWITCH w/ SPRING RETURN TO CENTER

STANDARD

124

Open

Close

ALL WIRING TYPES

124

Open

Close

ALL WIRING TYPES

2 OR MORE

1234

Open

Close

Stop

2 OR MORE

Open

Close

Open

Close

Stop

SEE NOTE #2SEE NOTE #2 SEE NOTES

KEY LOCKOUT

1

234

Open

Close

Stop

KEY SWITCH

ALL WIRING TYPESALL WIRING TYPES

1 BUTTON STATION or

ANY AUXILIARY DEVICE

3

7

#2 AND #3

OPEN / CLOSE

B2 or T1

WIRING TYPES ONLY

SENSING DEVICE TO REVERSE OR STOP

3

10

SENSING DEVICE

ALL WIRING TYPES

EXTERNAL INTERLOCK

REMOVE JUMPER

WHEN INTERLOCK IS USED

4

5

ONE

ALL WIRING TYPES

4

2 OR MORE

5

RESIDENTIAL RADIO CONTROLS

OPEN TIMER TO CLOSE

**

R2

R1

RADIO CONTROL

ALL WIRING TYPES

T1 WIRING - RADIO TO OPEN ONLY

**

R3

EXTERNAL

TERMINAL BLOCK

Loading...

Loading...