Page 1

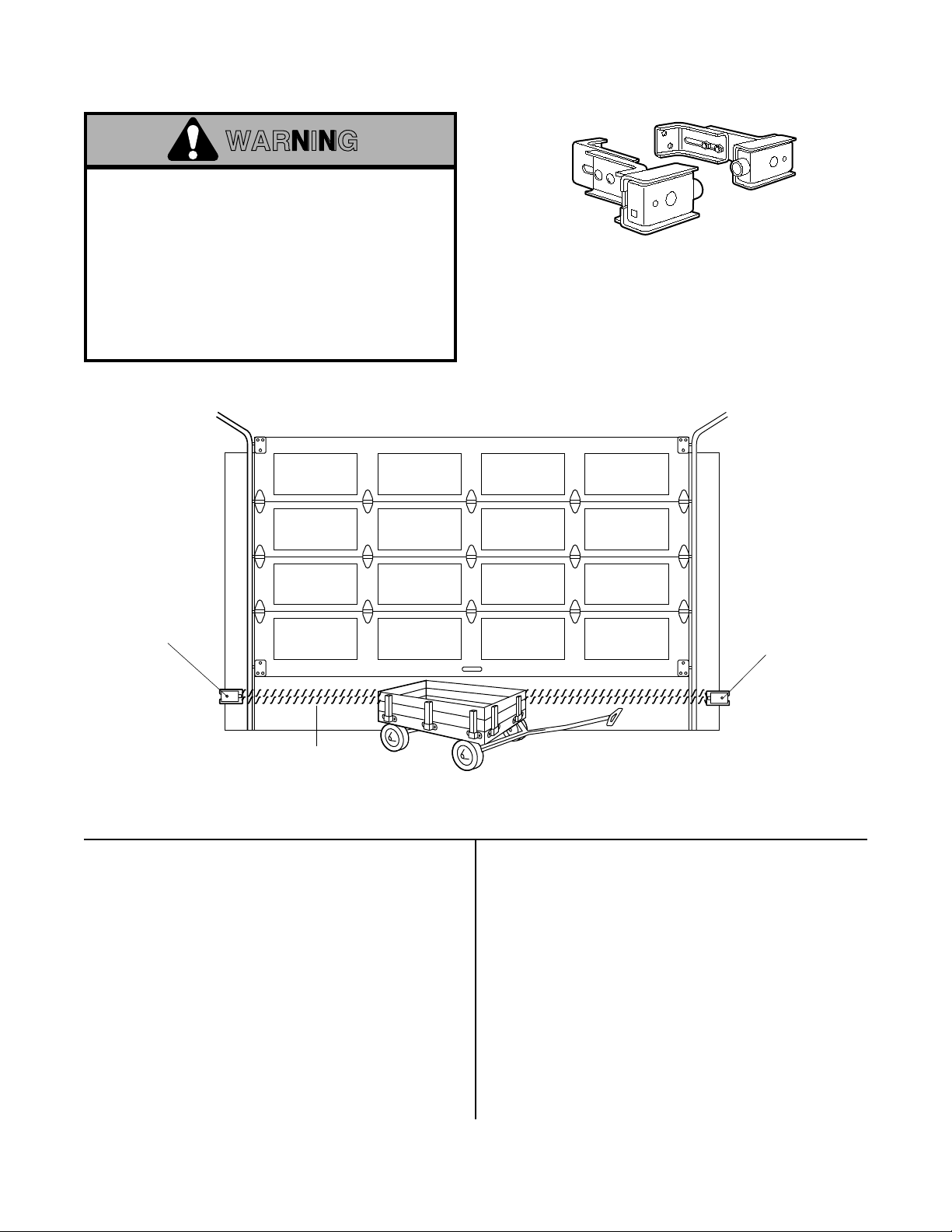

The Protector System™

Safety Reversing Sensor Model 87LM

WARNING

Without a properly working safety reversing

sensor, persons (particularly children) could be

killed by a closing garage door.

all instructions.

To protect small children, install the safety

reversing sensor so the beam is no higher than

4"-6" above the garage floor.

Disconnect power to the garage door opener

before installing the Protector System.

Read and follow

Installation procedures are

the same for sectional and

one-piece doors.

—Left Side of Garage—

Sensor

Unit

Invisible Light Beam

Protection Area

FIGURE 1 Facing the door from inside the garage

Look at the label on the connector end of each case

to identify the sensors.

The sending eye transmits an invisible light beam to

the receiving eye.

If an obstruction breaks the light beam while the

garage door is closing, the door will stop and reverse

to full open position; and the opener lights will flash

for 5 seconds to alert you to the obstruction.

The units can be installed on either side of the garage

door (Figure 1) as long as the sun never shines

directly into the receiving eye lens,

must be connected and fastened so that the sending

and receiving eyes face each other as shown in

Figure 1.

but

the brackets

— Right Side of Garage —

Sensor

Unit

The brackets

surface such as the studs on either side of the door,

or add a piece of wood at each location if installing in

masonry construction.

The invisible light beam path must be unobstructed.

No part of the garage door (or door tracks, springs,

hinges, rollers or other hardware) can interrupt the

beam while the door is closing. If it does, use a piece

of wood to build out each sensor mounting location to

the minimum depth required for light beam clearance.

must

be securely fastened to a solid

1

Page 2

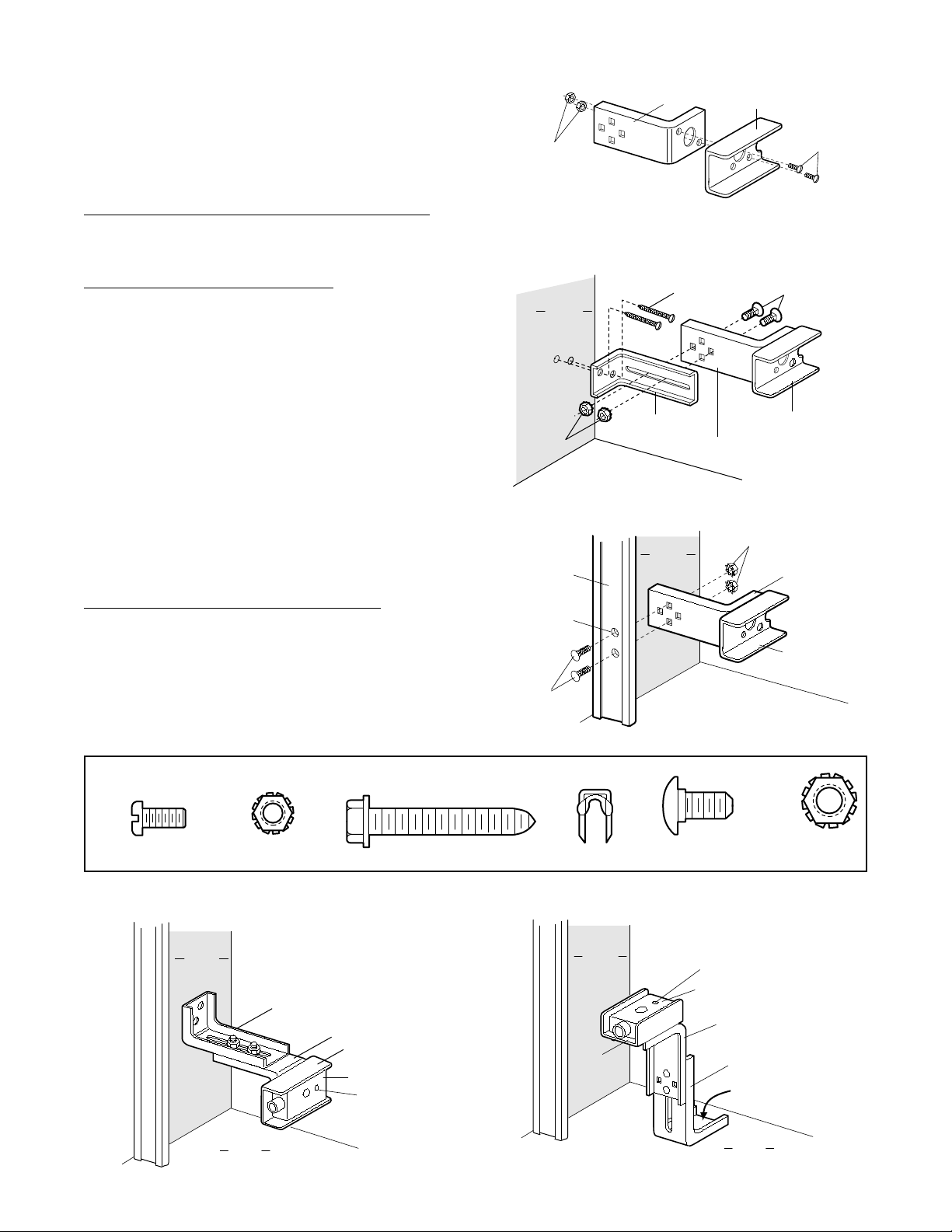

Figures 2 , 3 and 4 show recommended assembly of

bracket(s) and "C" wrap based on the

wall

installation of

the sensors on each side of the garage door as shown

on page 1, or on the

garage door tracks

themselves.

Figures 5 and 6 are variations which may fit your

installation requirements better. Make sure the wraps

and brackets are aligned so the sensors will face

each other across the garage door.

Garage Wall or Door Track

Installation Procedure

• Fasten the "C" wraps to the mounting brackets with

square holes, using the hardware shown in Fig. 2.

Garage Wall

Installation Procedure

• Connect each assembly to a slotted bracket, using the

hardware shown in Fig. 3. Note alignment of

brackets for left and right sides of the door.

• Finger tighten the lock nuts.

• Use bracket mounting holes as a template to locate

and drill (2) 3/16" diameter pilot holes on both sides of

the garage door, 4"-6" above the floor (but not

exceeding 6"). See Warning on page 1.

• Attach bracket assemblies with 1/4"x1-1/2" lag screws

as shown in Fig. 3.

• Adjust right and left side bracket assemblies to the

same distance out from mounting surface. Make sure

all door hardware obstructions are cleared. Tighten the

nuts securely .

Garage WALL or DOOR TRACK Installation

Mounting Bracket

With Square Holes

#10 - 32

Lock Nuts

FIGURE 2

Garage WALL Installation

Inside

Garage

Wall

Lock Nuts

Garage

Door Track

1/4 x 1-1/2"

Lag Screws

Mounting Bracket

with Slot1/4" - 20

Garage DOOR Track Installation

Inside

Garage

Wall

1/4-20 x 1/2" Carriage Bolts

Mounting Bracket

with Square Holes

1/4 " Lock Nuts

"C" Wrap

#10-32x3/8"

Screws

(with square shoulder)

"C" Wrap

FIGURE 3

Mounting Bracket

with Square Holes

Garage Door Track

Installation Procedure

Discard slotted bracket. Drill 3/8" holes in each track and

fasten securely with hardware as shown in Fig. 4.

Hardware Shown Actual Size

#10 - 32 x 3/8"

Screw

Garage

#10 x 32

Lock Nut

Alternate Wall Mount

Inside

Wall

Mounting Bracket

with Slot

Mounting Bracket

with Square Holes

"C" Wrap

Sensor

Indicator Light

1/4 x 1-1/2"

Lag Screw

Drill 3/8"

Holes

1/4-20 x 1/2"

Carriage Bolts

Staples

Alternate Floor Mount

Inside

Garage

Wall

"C" Wrap

Indicator Light

FIGURE 4

1/4" - 20 x 1/2"

Carriage Bolts

Sensor

Mounting Bracket

with Square Holes

Mounting Bracket

"C" Shaped

Wrap

1/4" - 20

Lock Nut

with Slot

Attach with

concrete anchors

(not provided)

Garage

Floor

Garage

Floor

FIGURE 5 FIGURE 6

2

Page 3

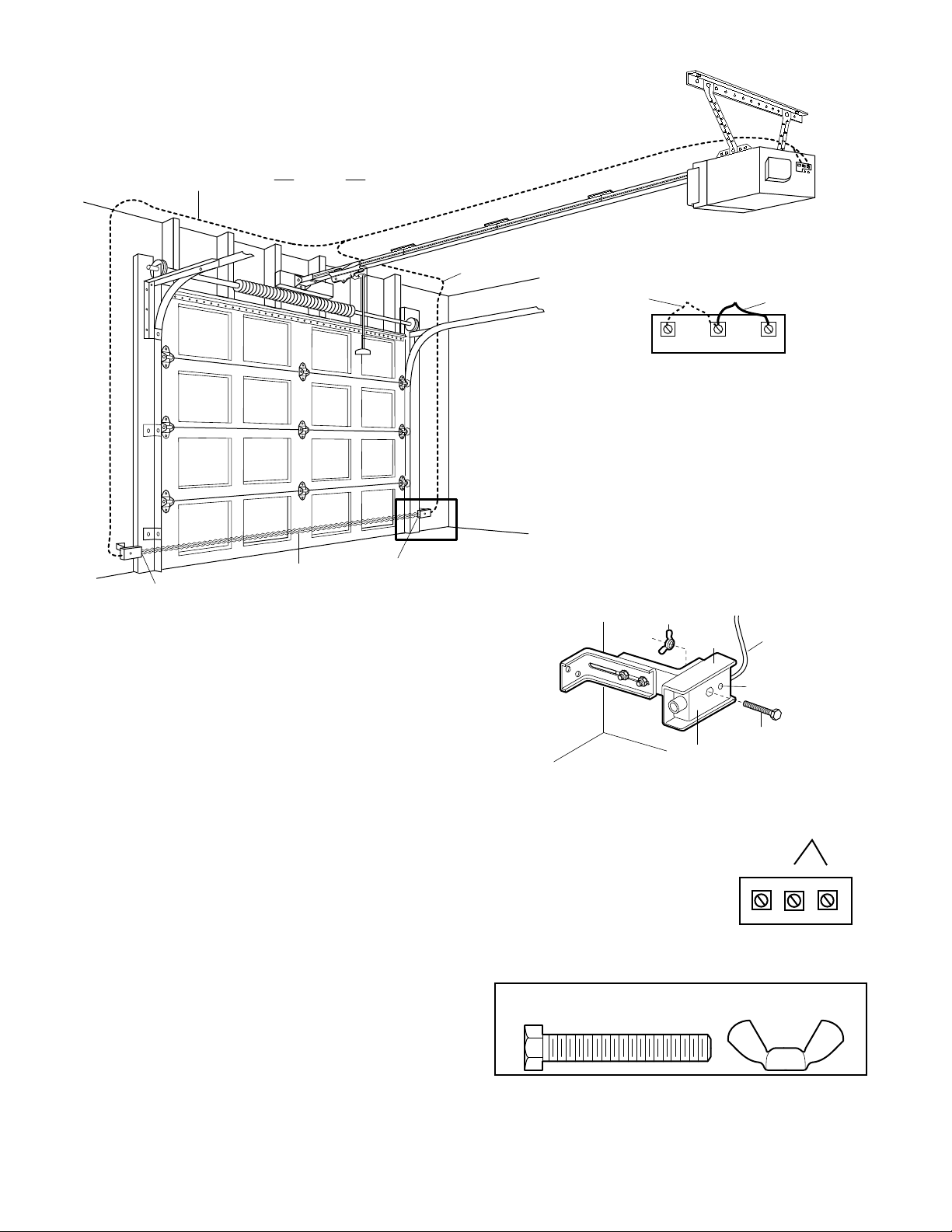

FIGURE 7

Connect Wire to

Opener Terminals

Bell Wire

Sensor

Finished

Ceiling

Invisible Light Beam

Protection Area

Sensor

• Center each sensor unit in a "C" wrap with lenses

pointing toward each other across the door.

• Secure sensors with the hardware shown in Figure

7. Finger tighten the wing nut on the

receiving eye

allow for final adjustment. Securely tighten the

sending eye

wing nut.

• Run wires from both sensors to the opener as

shown in Figure 7. Use insulated staples to secure

the wire to the wall and ceiling.

• Connect both sets of wires to the opener terminals

as shown (depending upon your model).

• Plug in the opener. If your opener has the Multi-

Function Door Control, make sure the Lock Feature

is

off

. Red indicator lights in both the sending and

receiving eyes will

glow

if wiring connections and

alignment are correct.

If the indicator lights are

blinking

(and the invisible

light beam path is not obstructed), alignment is

required.

• Loosen the receiving eye wing nut to allow slight

rotation of unit. Adjust sensor vertically and/or

horizontally until the red indicator light

glows

.

• When indicator lights are glowing in both units,

tighten the wing nut in the receiving eye unit.

Bell Wire

to

Door Control

Connections

(dotted line)

RED-1

OPENER TERMINAL SCREWS

Wing Nut

WHT-2

"C" Wrap

Sensor

Connect Sensor Wires

to Opener Terminals

Hardware Shown Actual Size

1/4-20 x 1-1/2"

Hex Bolt

Sensor

Connections

BLK-3

Wire

Indicator Light

1/4-20 x 1-1/2"

Hex Bolt

Sensor Connections

BLK

WHT

RED

Wing Nut

3

Page 4

TEST THE PROTECTOR™ SYSTEM

• Press the remote control push button to open the door .

• Place the opener carton in the path of the door.

• Press the remote control push button to close the door.

The door will not move more than an inch, and the

opener light(s) will flash.

The garage door opener will not close from a remote

control if the indicator light in either sensor is

blinking

a. not connected, b. misaligned or c. obstructed).

The garage door can be closed by pressing and

holding the Door Control push button until down travel

is completed.

(alerting you to the fact that the sensor is:

TEST THE SAFETY REVERSE SYSTEM

TEST:

• Place a one-inch board (or a 2x4 laid flat) on the

floor, centered under the garage door.

• Operate the door in the down direction. The door

must

reverse on striking the obstruction.

ADJUSTMENT:

If the door

far enough in the down direction.

• Increase the DOWN limit by turning the DOWN limit

adjustment screw counterclockwise 1/4 turn.

• Repeat the test.

On a sectional door, make sure limit adjustments

do not force the door arm beyond a straight up

and down position.

• When the door reverses on the one-inch object,

remove the obstruction and run the opener through

3 or 4 complete travel cycles to test adjustment.

If the door will not reverse after repeated

adjustment attempts, call for professional door

service.

stops

on the obstruction, it is not traveling

WARNING

Without a properly working Protector™

System, persons (particularly children) could

be seriously injured or killed by a closing

garage door.

Repeat this test once a month.

Professional service is required if the opener

closes the door when the Protector System is

obstructed.

WARNING

Failure to test and adjust the safety reverse

system may result in serious injury or death

from a closing garage door.

once a month and adjust as needed.

GARAGE DOOR

Repeat this test

One-Inch board (or a 2x4 laid flat)

1 Inch Obstruction

Trouble Shooting

1. If the

sending eye

does not glow after installation, check for:

• Electric power to the opener.

• A short in the black/white wires. These can occur

under staples or at screw terminal connections.

• Incorrect wiring between sensors and opener.

• An open wire (wire break).

or

receiving eye

indicator light

2. If only the

the invisible light beam path is

check for an open wire to the receiving eye.

3. If both sensors are blinking, realign or remove

obstruction.

receiving eye

indicator light is

not

obstructed),

off

(and

Replacement Parts

TOLL FREE NUMBER - 1-800-528-9131

2-strand black & white wire with connector 41B41 15

Safety Sensor Kit (receiving and sending eyes only) 41A4373

Safety sensor hardware bag 41A41 16

©1993, The Chamberlain Group, Inc.

114A1564G All Rights Reserved Printed in Mexico

C-Wrap Bracket 12B483

Square Hole Bracket 12B484

Slotted Bracket 12B485

Loading...

Loading...