LiftMaster 8557 Owner's Manual

ELITE Series

Garage Door Opener

Models

• 8550 - DC Belt Drive

with Battery Backup

• 8557 - 3/4 hp

Belt Drive

FOR RESIDENTIAL USE ONLY

■ Please read this manual and the enclosed safety materials carefully!

■ Fasten the manual near the garage door after installation.

■ The door WILL NOT CLOSE unless the Protector System

aligned.

■ Periodic checks of the garage door opener are required to ensure safe operation.

■ The model number label is located on the left side panel of your garage door opener.

■ This garage door opener is ONLY compatible with MyQ

accessories.

■ DO NOT enable the Timer-to-Close feature if you are installing the garage door

opener on a one-piece door. The Timer-to-Close is to be used ONLY with

sectional doors.

NOTE: If you are installing the garage door opener on a one-piece door, visit

www.liftmaster.com for installation instructions.

Write down the following information for

future reference:

.

Serial Number:

Date of Purchase:

®

is connected and properly

®

and Security✚ 2.0™

CONTENTS

Preparation. . . . . . . . . . . . . . . .2-3

Assembly . . . . . . . . . . . . . . . . .4-5

Installation . . . . . . . . . . . . . . .6-13

Install the Door Control. . . . . . 14-16

Install the Protector System

Power. . . . . . . . . . . . . . . . . . 21-22

Adjustments . . . . . . . . . . . . . 23-25

Battery Backup*. . . . . . . . . . . 26-27

Operation . . . . . . . . . . . . . . . . . 28

Features . . . . . . . . . . . . . . . . . . 29

Door Control . . . . . . . . . . . . . 30-31

Remote Control . . . . . . . . . . . 32-33

To Erase the Memory . . . . . . . . . 33

To Open the Door Manually . . . . . 34

Maintenance . . . . . . . . . . . . . . . 34

Troubleshooting. . . . . . . . . . . 35-36

Accessories. . . . . . . . . . . . . . . . 37

Warranty. . . . . . . . . . . . . . . . . . 38

Repair Parts . . . . . . . . . . . . . 39-41

* If applicable

The Chamberlain Group, Inc.

Elmhurst, Illinois 60126-1196

®

. . 17-20

www.liftmaster.com

845 Larch Avenue

Torsion Spring

Extension Spring

OR

2

1

3/16

7/16

1/2

5/32

5/16

5/8

9/16

1/4

7/16

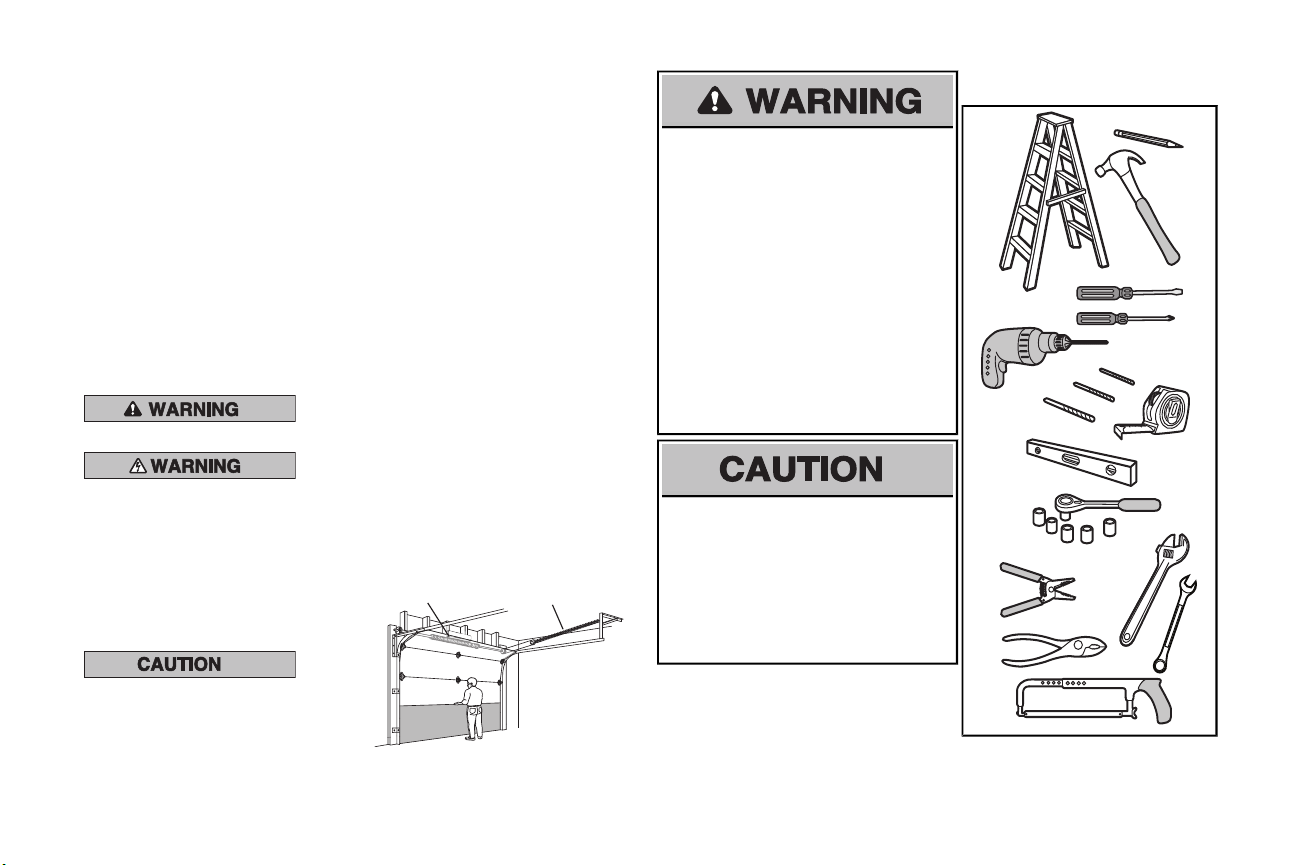

Preparation

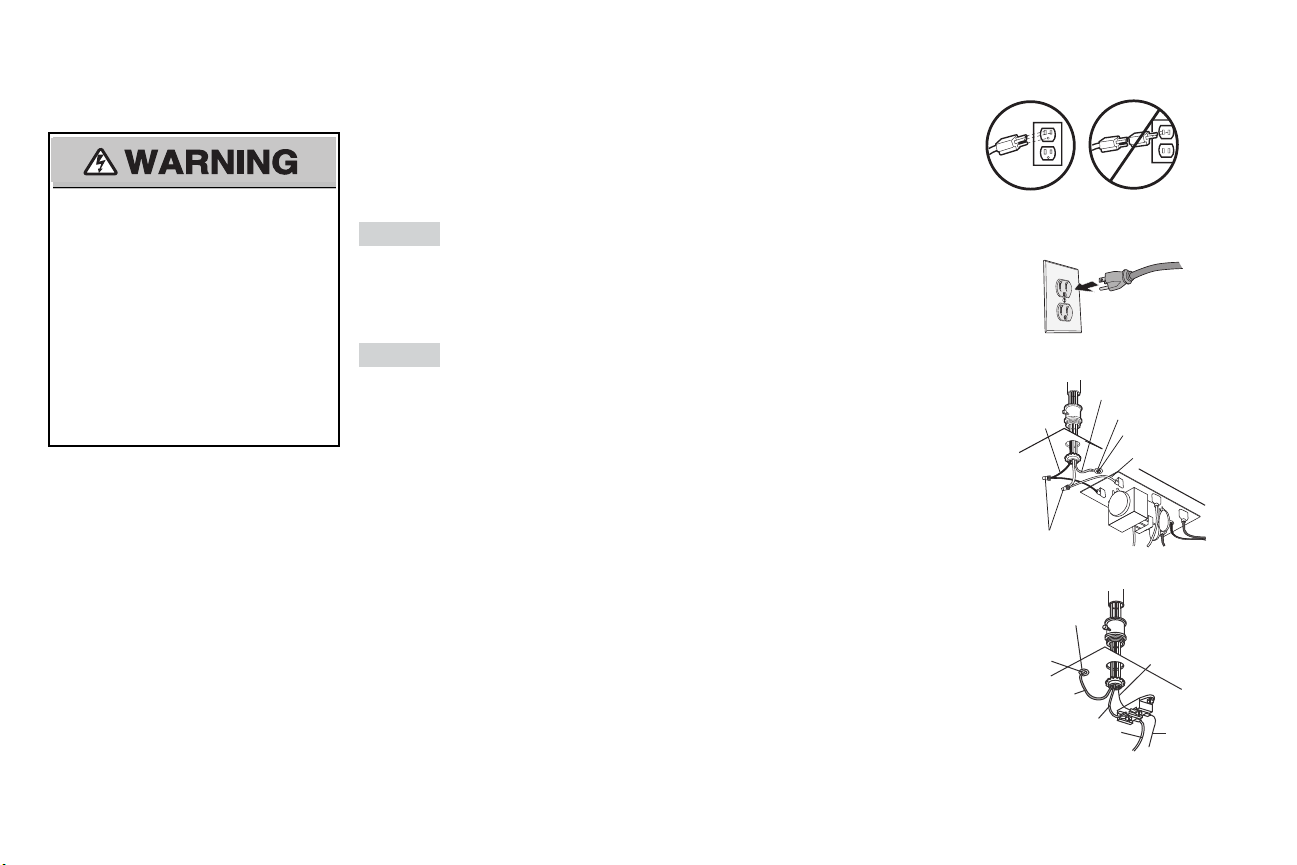

Safety Symbol and Signal Word Review

Thisgarage door opener has been designed and

tested tooffersafeservice provided it is installed,

operated, maintained and tested in strict

accordance with the instructionsand warnings

contained in thismanual.

When you see these Safety Symbols and Signal

Words on the following pages,they will alert you

to the possibilityof serious injury or death if you

do notcomplywith the warnings that accompany

them.The hazard maycome fromsomething

mechanical or fromelectricshock. Read the

warnings carefully.

Mechanical

Electrical

When you see this Signal Word on the following

pages, it will alertyou to the possibilityofdamage

to your garage door and/or thegarage door

opener if you do not comply with the cautionary

statementsthataccompanyit.Read them

carefully.

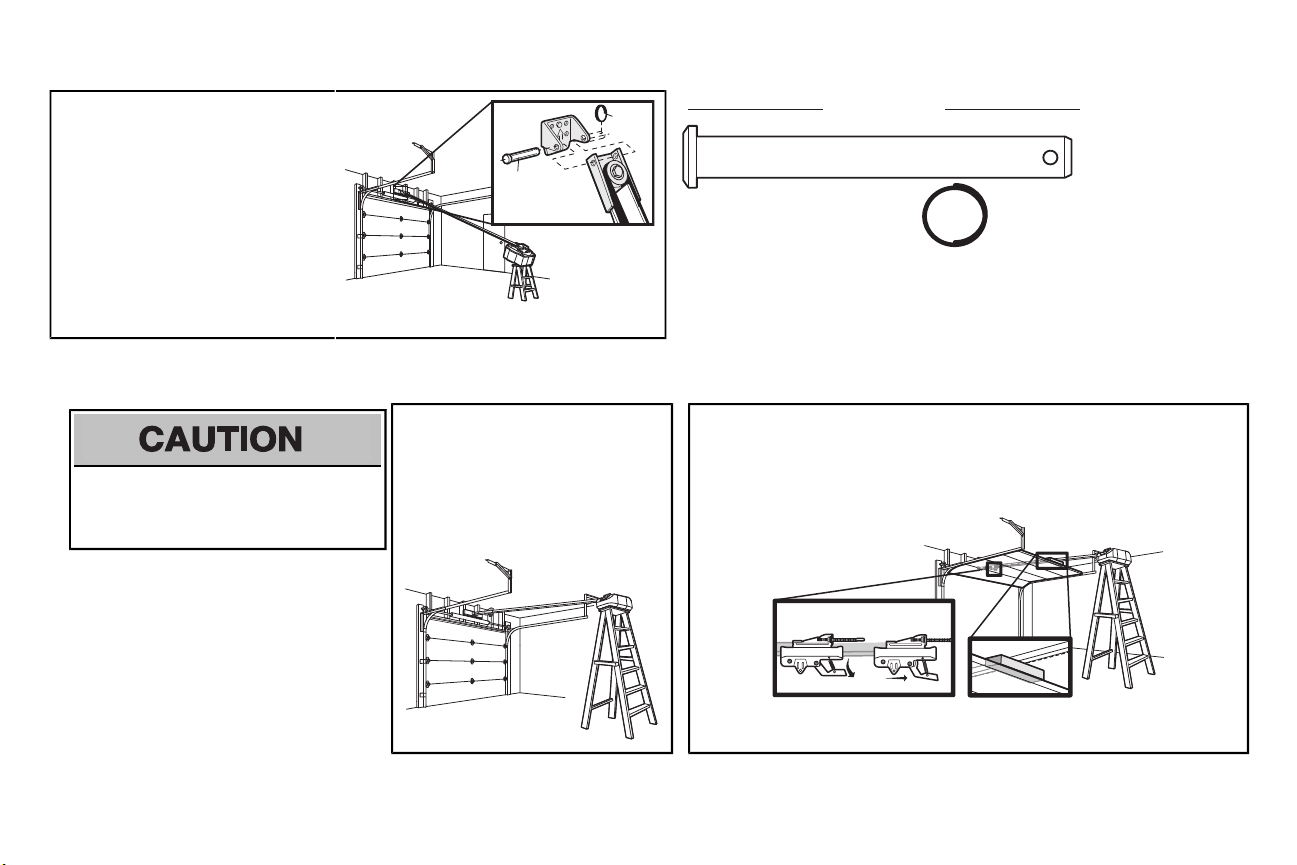

Check the Door

1. Disable locksand removeany ropes

connected to the garage door.

2. Liftthe door halfwayup. Release the

door. If balanced, it should stayin

place, supported entirelyby itssprings.

3. Raise and lower the door to check for

binding or sticking.Ifyour door binds,

sticks,or is out ofbalance, call a trained

door systemstechnician.

4. Checkthe seal on the bottom of the

door. Anygap between the floor and

the bottom of the door mustnot exceed

1/4 inch (6 mm).Otherwise,thesafety

reversal system may not workproperly.

5. The opener should be installed above

the center of thedoor. If there isa

torsion spring or center bearing plate

in the wayofthe header bracket,itmay

be installed within 4 feet(1.2 m) to the

leftor rightofthe door center.See

page 7.

Tools Needed

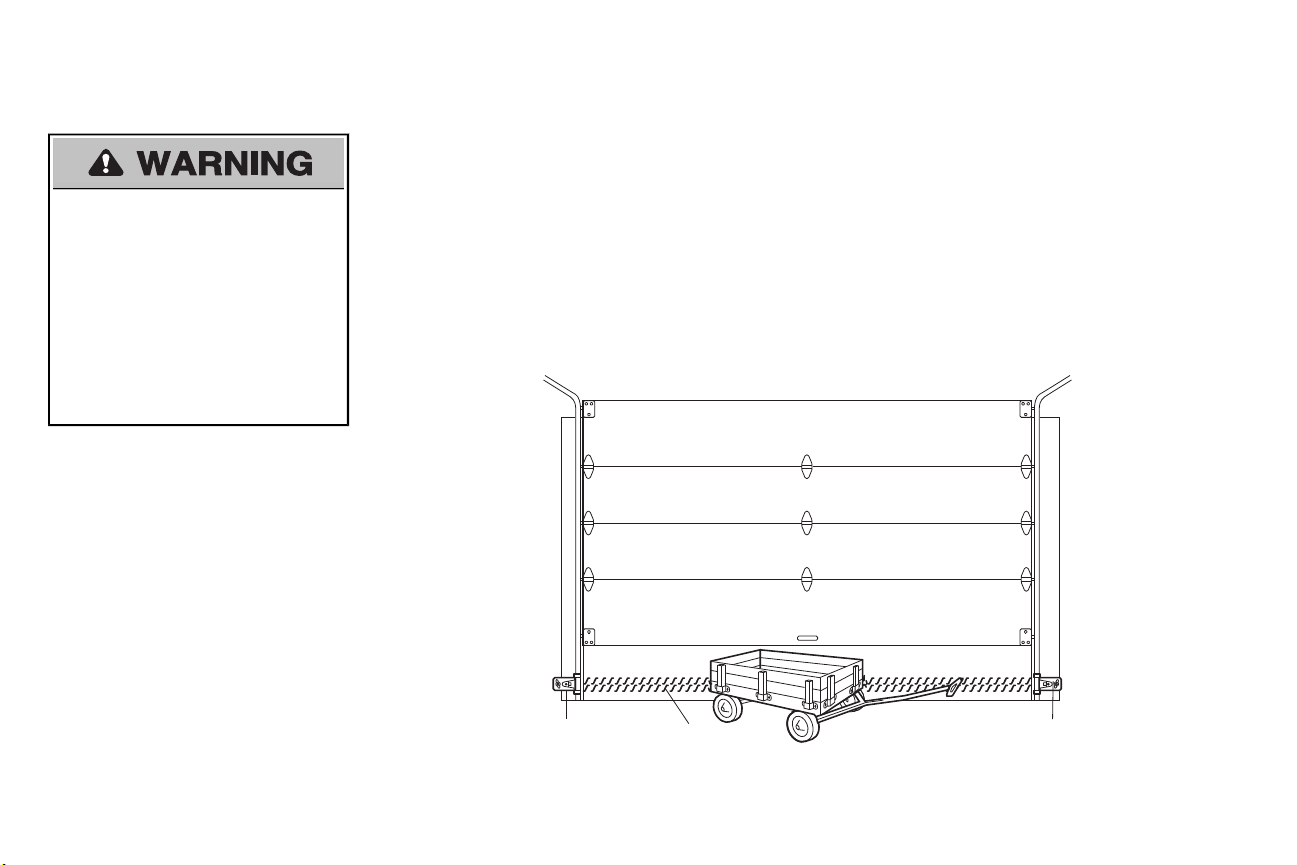

To prevent possible SERIOUSINJURYor

DEATH:

• ALWAYS call a trained door systems

technician if garage door binds, sticks,or is

out of balance.An unbalanced garage

door mayNOTreverse when required.

• NEVER try to loosen,moveor adjust

garage door, door springs, cables,pulleys,

bracketsor their hardware,ALLof which

are under EXTREMEtension.

• Disable ALLlocksand removeALLropes

connected to garage door BEFORE

installation and operating garage door

opener to avoid entanglement.

To prevent damage to garage door and

opener:

• ALWAYS disable locks BEFORE installing

and operating the opener.

• ONLY operate garage door opener at

120 V,60 Hz to avoidmalfunction and

damage.

2

A

B

C

J

N

I

O

P

D

E

F

H

G

K

L

M

Carton Inventory

A. tekcarb redaeH

B. Pulley and bracket

C. tekcarb rooD

D. mra rood devruC

E. mra rood thgiartS

F. yellorT

G. Emergency release rope and handle

H. Rail

I. renepo rood egaraG

NOTE: Accessories will vary depending on the garage door opener model purchased. Depending on your specific model, other accessories

may be included with your garage door opener. The instructions for these accessories will be attached to the accessory and are not included

in this manual. The images throughout this manual are for reference and your product may look different.

J. swercs dna revoc tekcorpS

K. tleB

L. lortnoc rooD

M. eriw etihw/der dna etihW

N.

srosnes gnisrever ytefaS

with white and white/black wire attached:

Sending Sensor (1) Receiving Sensor (1)

and Safety Sensor Brackets (2)

O. erutaretil dna slebal ytefaS

P. Rail grease

Not Provided

Not Provided

Hardware

895MAX

Remote Control

880LM

Smart Control

Panel

®

829LM

Garage Door

Monitor

SECURITY✚ 2.0

TM

ACCESSORIES

The Protector System

®

Installation

Hex Bolt 5/16"-18 x 7/8" (4)

Lag Screw 5/16"-9 x 1-5/8" (2)

Clevis Pin 5/16" x 2-3/4" (1)

Clevis Pin 5/16" x 1-1/4" (1)

Clevis Pin 5/16" x 1" (1)

Nut 5/16"-18 (4)

Lock Washer 5/16" (4)

Self-Threading Screw 1/4"-14 x 5/8" (2)

Ring Fastener (3)

Carriage Bolt 1/4"-20 x 1/2" (2)

Wing Nut 1/4"-20 (2)

Door Control Hardware

Screw 6AB x 1" (2)

Screw 6-32 x 1" (2)

Drywall Anchors (2)

Insulated Staples

3

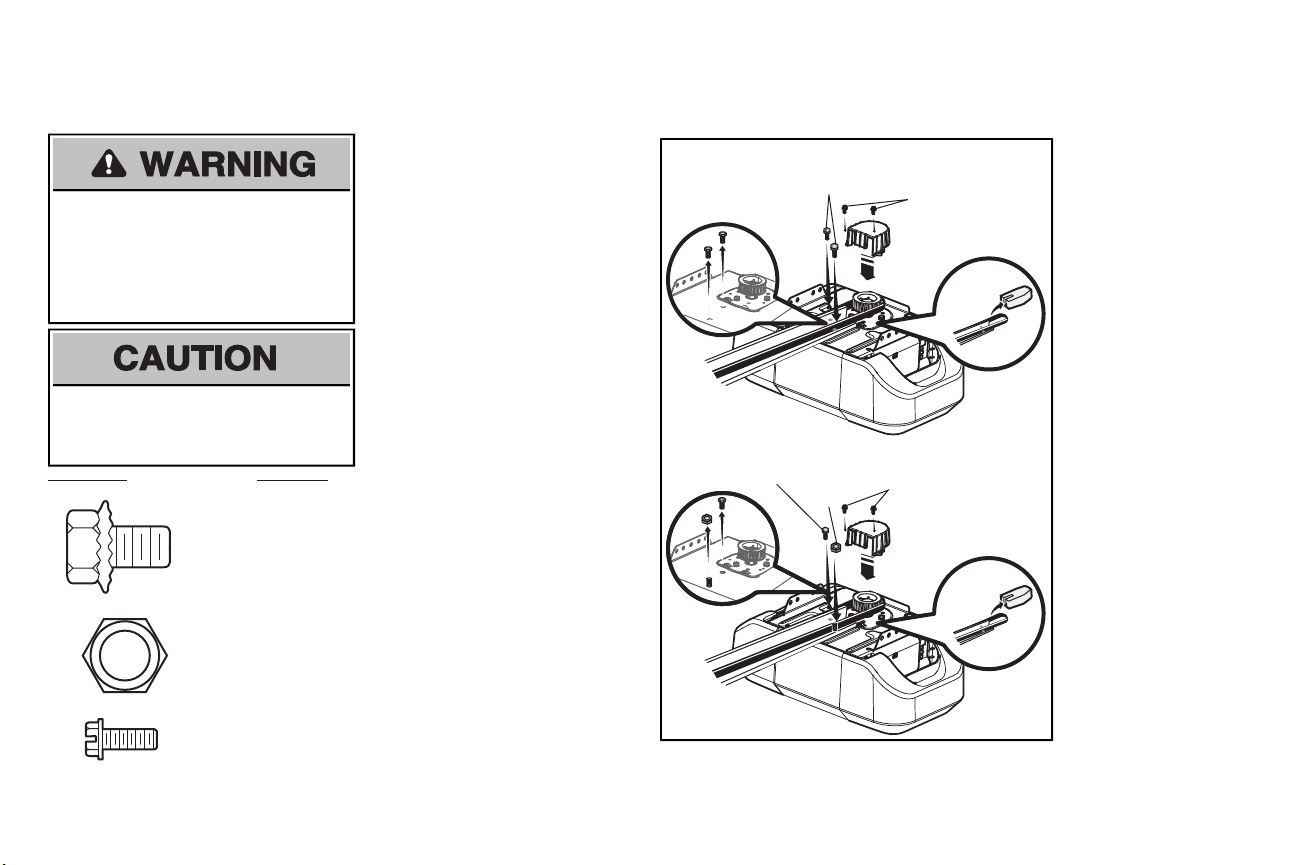

Washered Bolt

5/16"-18x1/2"

(Mounted in the

garage door opener)

Model 8550 (2)

Model 8557 (1)

HARDWARE

Hex Screw

#8x3/8"

(Packed with the

sprocket cover)

Lock Nut

(Mounted in the

garage door opener)

Model 8557 (1)

Model 8550

Model 8557

Washered Bolt

5/16"-18x1/2"

Hex Screw

#8x3/8"

Washered Bolt

5/16"-18x1/2"

Hex Screw

#8x3/8"

Lock Nut

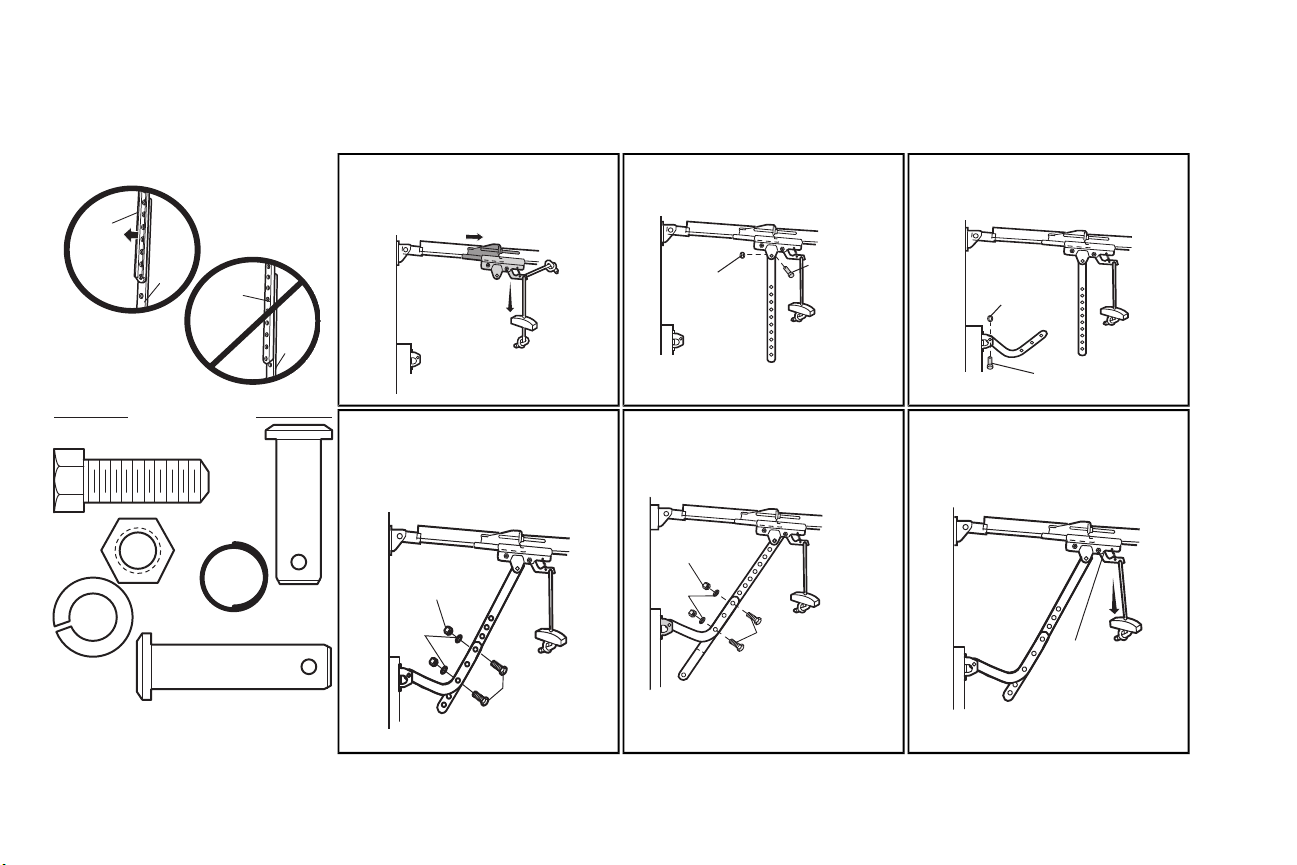

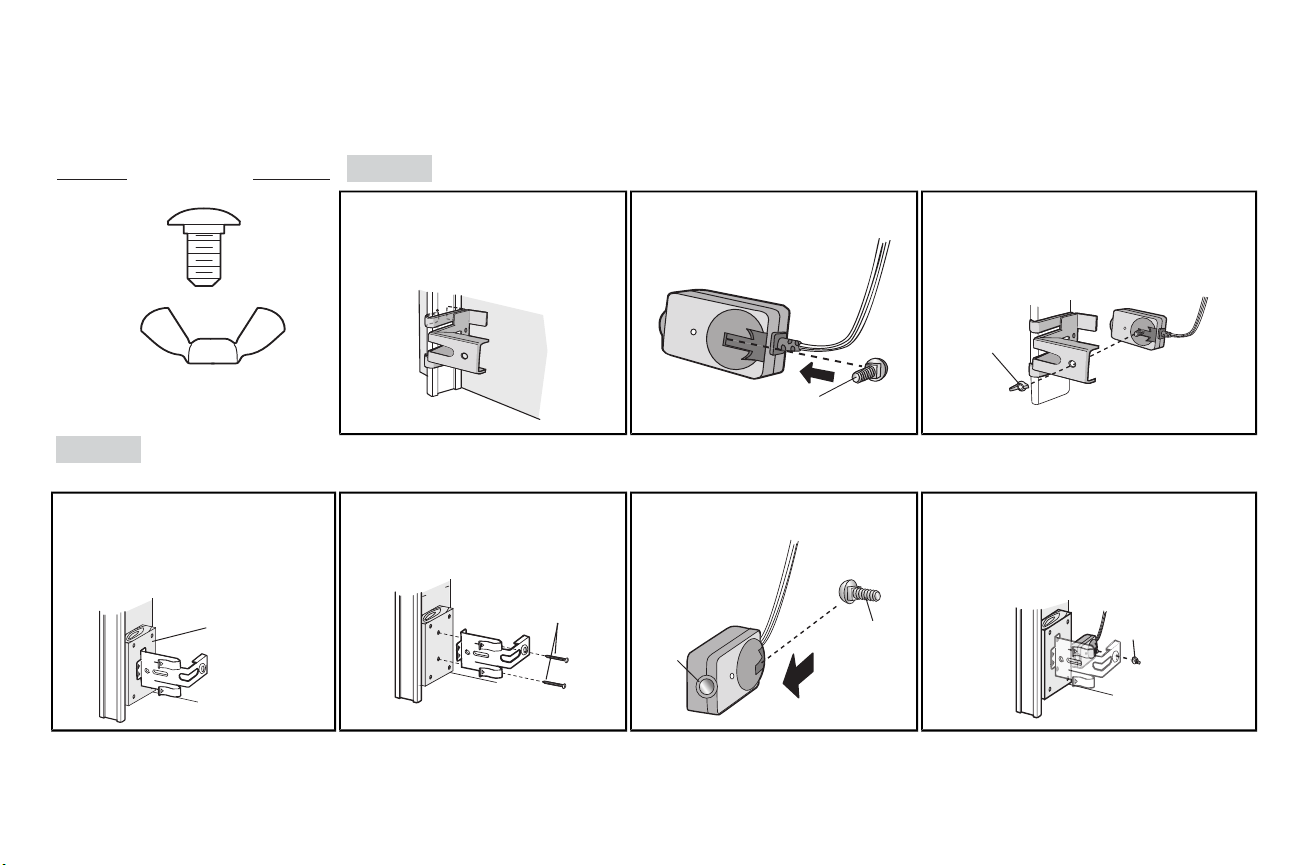

Assembly

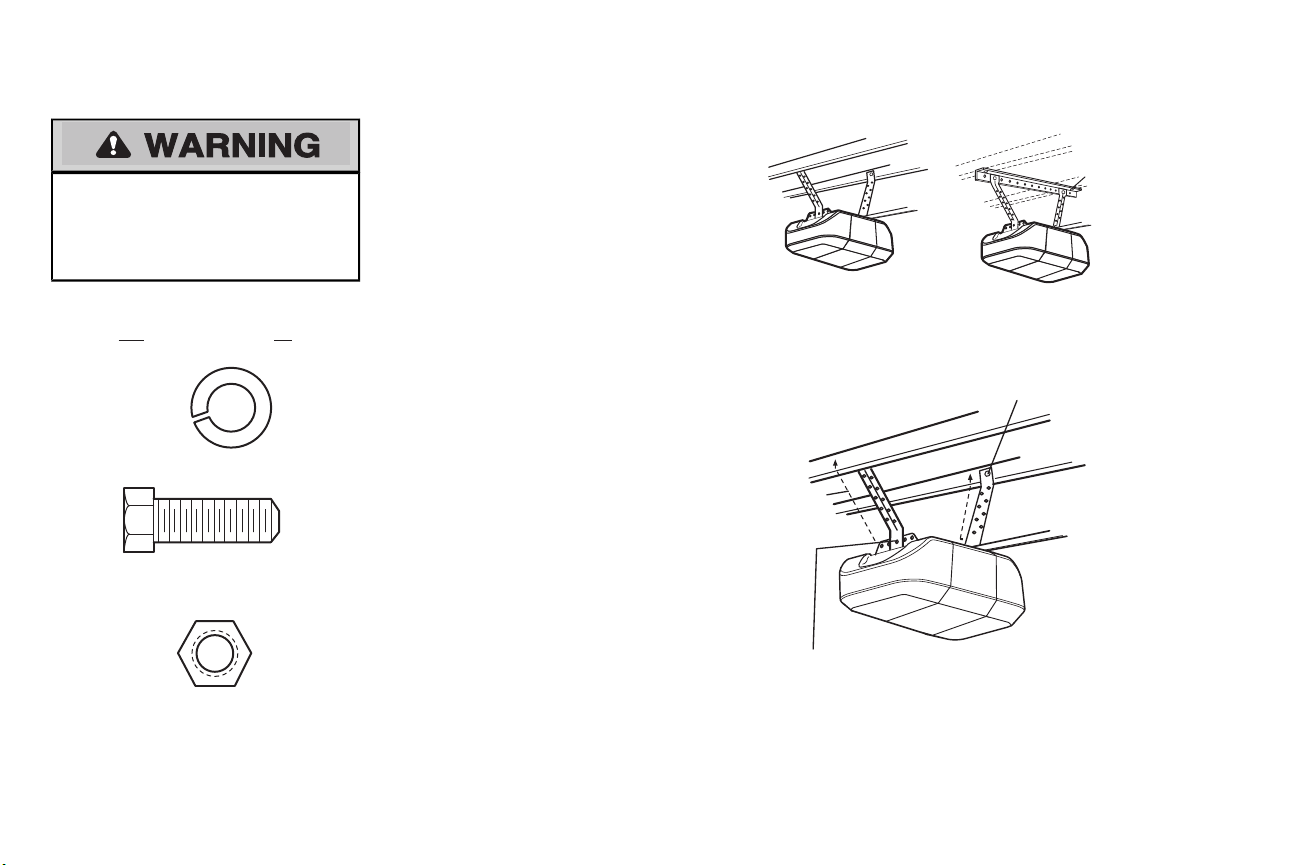

1 Attach the rail to the garage door opener

To avoid possible SERIOUS INJURY to finger from

moving garage door opener:

• ALWAYS keep hand clear ofsprocket while

operating opener.

• Securely attach sprocketcoverBEFORE

operating.

To avoid SERIOUSdamage to garage door

opener, useONLY those bolts/fasteners

mounted in the top of theopener.

NOTE: ONLY use the bolts removed from the

garage door opener. Place the garage door

opener on the packing material to prevent

scratching.

1.1 Remove the two boltsfrom the top of the

garage door opener.

1.2 Align the rail and the styrofoam over the

sprocket. Cut the tape fromthe rail, belt,

and styrofoam.

1.3 Model8550:

Fasten therail with the previously

removed bolts.

Model 8557:

Fasten therail with the previously

removed washer boltand locknut.

1.4 Position the belt around the garage

door opener sprocket.

1.5 Attach the sprocketcover over the

garage door opener sprocket and

attach with hexscrews.

4

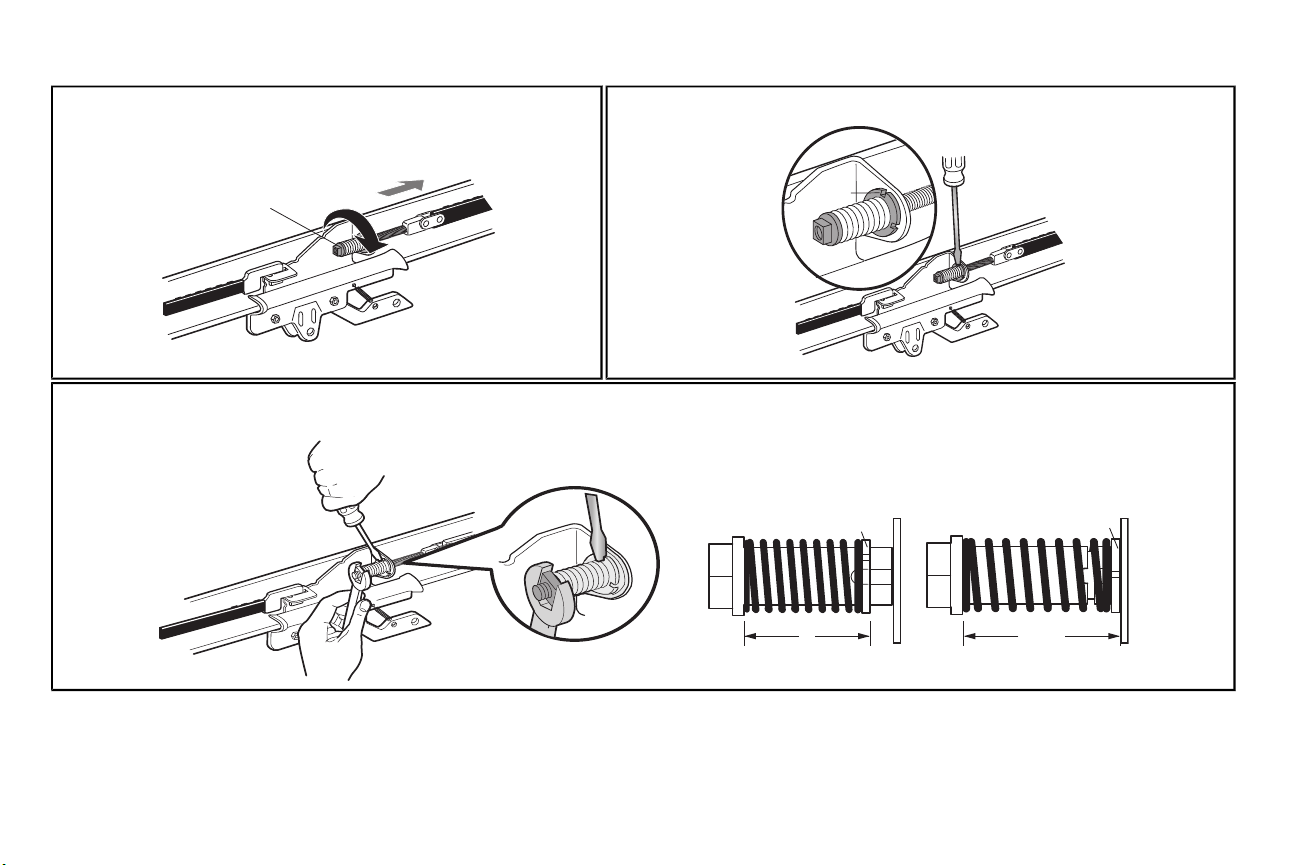

2 Tighten the Belt

Spring Trolley Nut

(To motor unit)

Nut ring

slot

Nut Ring

Nut Ring

AFTER RELEASE

1-1/4"

(3.18 cm)

BEFORE

1"

(2.5 cm)

2.1 By hand,thread the spring trolley nut on the threaded shaftuntil it is finger tightagainst

2.2 Inserta flathead screwdriver tip into one ofthe nut ring slotsand brace it firmlyagainst the trolley.

the trolley. Do not useany tools.

2.3 Tighten the spring trolley nutwith an adjustable wrenchor a 7/16" open end wrench about a quarter turn until the spring releasesand snaps the nutring againstthe trolley. This setsthe spring to

optimumbelt tension.

5

WARNING

Installation

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTALLATIONWARNINGS AND INSTRUCTIONS.

2. Install garage door opener ONLY on properlybalanced and lubricated garage door. An

improperly balanced door mayNOT reverse when required and could result in SEVERE

INJURY or DEATH.

3. ALL repairs to cables, spring assembliesand other hardware MUST be made bya trained

door systemstechnician BEFORE installing opener.

4. Disable ALL locksand remove ALL ropesconnectedto garage door BEFORE installing

opener to avoid entanglement.

5. Install garage door opener 7 feet(2.13 m) or more abovefloor.

6. Mount the emergencyrelease within reach, butatleast6 feet (1.83 m)above the floor and

avoiding contact with vehicles to avoid accidental release.

7. NEVER connect garage door opener to power source until instructedto do so.

8. NEVERwearwatches, rings or loose clothing while installing or servicing opener.Theycould

be caughtin garage door or opener mechanisms.

NOTE:If you are installing the garage door opener on a one-piece door,visit www.liftmaster.com for installation instructions.

9. Install wall-mounted garage door control:

• within sight ofthegarage door.

• out ofreach of children at minimum heightof 5 feet (1.5 m).

• away from ALL moving parts of the door.

10. Placeentrapment warning label on wall nextto garage door control.

11. Placemanual release/safetyreversetestlabel in plain viewon inside of garage door.

12. Upon completion ofinstallation,testsafetyreversal system.Door MUST reverse on contactwith

a 1-1/2"(3.8 cm) high object(or a 2x4 laid flat) on thefloor.

13. To avoid SERIOUS PERSONAL INJURYor DEATH from electrocution, disconnectALL

electricand battery power BEFORE performing ANY service or maintenance.

14. DO NOT enable the Timer-to-Close functionalityif operating either one-piece or swinging

garage doors. To be enabled ONLY when operating a sectional door.

6

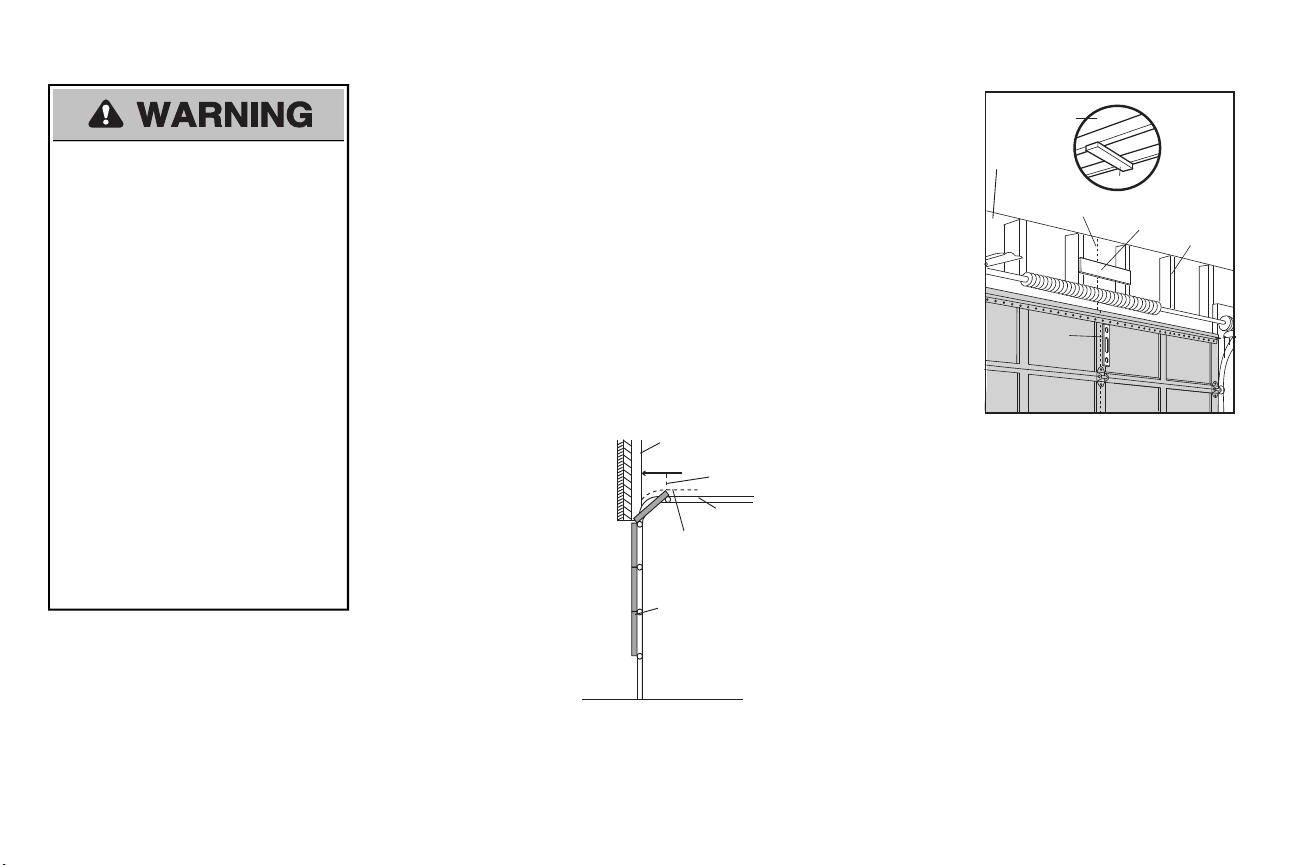

1 Determine the header bracket location

Sectional door with curved track

Header Wall

Track

2" (5 cm)

Highest Point

of Travel

Door

Header Wall

Unfinished

Ceiling

Vertical Centerline

of Garage Door

2x4

2x4

Structural

Supports

Level

(Optional)

OPTIONAL

CEILING

MOUNT FOR

HEADER

BRACKET

To prevent possible SERIOUS INJURY or

DEATH:

• Header bracketMUST be RIGIDLY

fastened to structural support on header

wall or ceiling, otherwise garage door might

NOTreverse when required. DO NOT

install header bracketover drywall.

• Concrete anchors MUST be used if

mounting header bracket or 2x4 into

masonry.

• NEVER try to loosen,moveor adjust

garage door, springs, cables, pulleys,

brackets, or their hardware, ALL of which

are under EXTREME tension.

• ALWAYS call a trained door systems

technician if garage door binds, sticks,or is

out of balance.An unbalanced garage

door mightNOTreverse when required.

• DO NOT enable the Timer-to-Close

functionality if operating either one-piece or

swinging garage doors. To be enabled

ONLY when operating a sectional door.

NOTE: Ifyou are installing the garage door opener on a one-piece door, visit www.liftmaster.com for

installation instructions.

1.1 Close the door and markthe inside vertical centerline of the garage door.

1.2 Extend the line onto the header wall above the door.

Youcan fastenthe header bracket within4 feet(1.22 m)of the left orrightof the door

center onlyifa torsionspringorcenterbearingplateis inthe way; oryoucan attachitto

the ceiling when clearance is minimal.(Itmay be mounted on the wallupside downif

necessary, to gain approximately 1/2" (1 cm).

Ifyou need to install the header bracketon a 2x4 (on wall or ceiling), use lag screws(not

provided) tosecurelyfasten the2x4 to structural supports.

1.3 Open your door to the highestpoint of travel as shown.Drawan intersecting horizontal line on

the header wall 2"(5 cm) abovethe high point. This height will provide travel clearance for the

top edge of the door.

NOTE: Ifthe total number of inches exceeds the heightavailable in your garage, use the maximum

height possible, or refer to page 8 for ceiling installation.

7

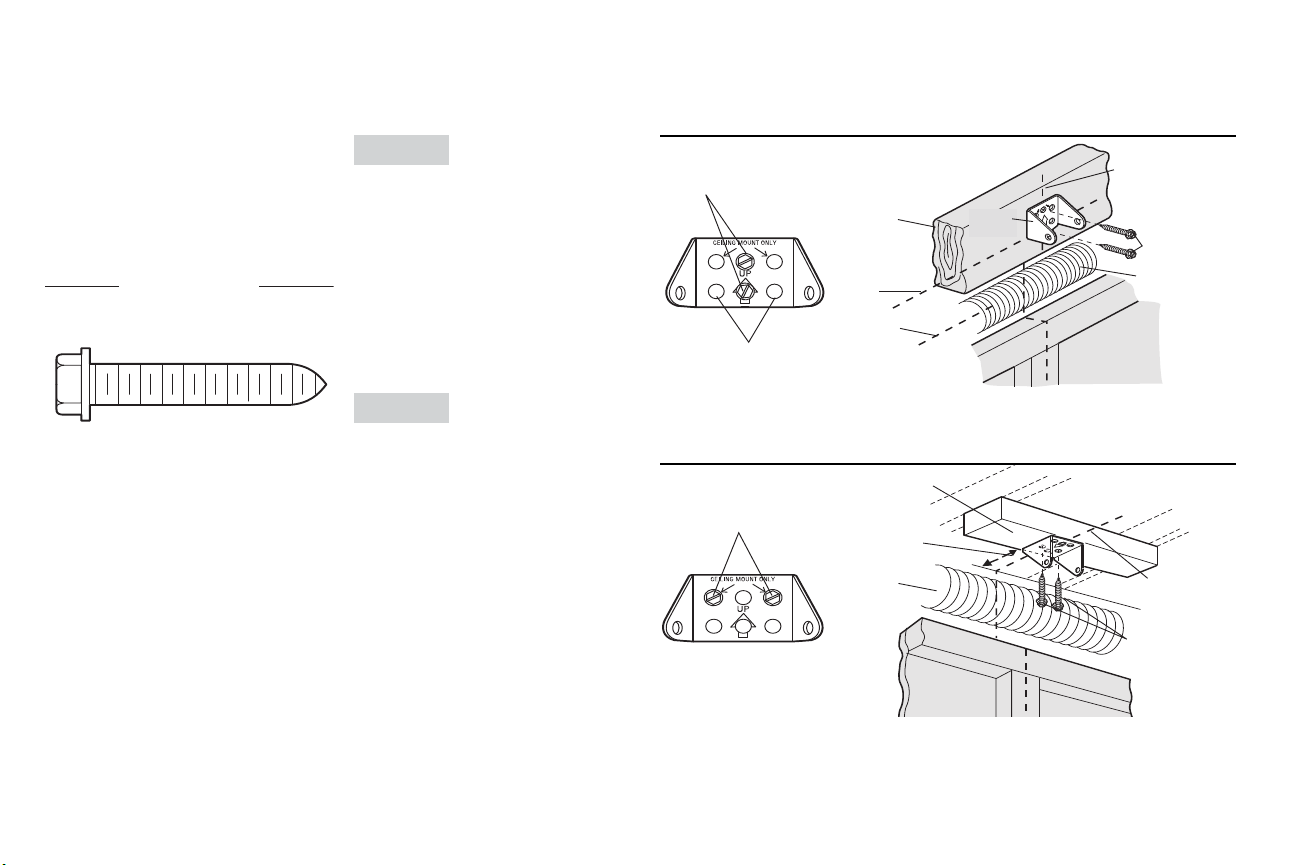

HARDWARE

Lag Screw

5/16" - 9 x 1-5/8"

Wall Mount

Optional

Mounting

Holes

Vertical

Centerline of

Garage Door

(Header Wall)

Header

Bra

cket

2x4 Structural

Support

Door Spring

(Garage Door)

Highest Point of

Garage Door

Travel

Horizontal

Line

Lag Screw

5/16

" - 9 x 1-5/8"

(Header Wall)

Ce

iling Mounting Holes

(Finished Ceiling)

Vertical

Centerline of

Garage Door

Header

Bracket

6" (15 cm)

Maximum

Door Spring

(Garage Door)

Lag Screw

5/16" - 9 x 1-5/8"

Installation

2 Install the Header Bracket

You can attachthe headerbracketeither to the

wall above thegarage door, or to the ceiling.

Follow the instructionswhich will work bestfor

your particular requirements.Donot installthe

headerbracket over drywall.If installing into

masonry,use concrete anchors (not provided).

OPTION A WALL INSTALLATION

2.1A Center the bracketon the vertical

centerline with the bottom edge of the

bracketon the horizontal line as shown

(withthe arrowpointing toward the

ceiling).

2.2A Mark the vertical set of bracket holes(do

not use the holes designated forceiling

mount).Drill 3/16" pilotholes and fasten

the bracket securely to a structural

support with lag screws.

OPTION B CEILING INSTALLATION

2.1B Extend the vertical centerline onto the

ceiling asshown.

2.2B Center the bracketon the vertical mark,

no more than 6" (15 cm) from the wall.

Make sure the arrow is pointing toward

the wall. The bracketcan be mounted

flushagainst the ceiling when clearance

is minimal.

2.3B Mark the side holes. Drill 3/16"pilot holes

and fasten bracket securely to a structural

support with lag screws.

8

Ring

Fastener

Clevis Pin

5/16" X 2-3/4"

HARDWARE

Clevis Pin

5/16" x 2-3/4"

Ring Fastener

Connected Disconnected

3 Attach the rail to the header bracket

3.1 Align the rail withthe headerbracket.

Inserttheclevispin through the holesin

the header bracket and rail. Secure

withthe ring fastener.

NOTE: Use the packing material as a

protective base for the garage door opener.

4 Position the garage door opener

To prevent damage to garage door, restgarage

door opener rail on 2x4 placed on top section of

door.

4.1 Removethe packing material and liftthe

garage door opener onto a ladder.

NOTE: A 2x4 is ideal for setting the distance

between the rail and the door. Ifthe ladder is

not tall enough you will need help at this point.

9

4.2 Fully open the door and place a 2x4 (laid flat)under therail.

NOTE: Ifthe door hitsthe trolley when itis raised, pull the trolley release arm down to

disconnectthe inner and outer trolley. Slide the outer trolley toward the garage door opener.

The trolley can remain disconnected until instructed.

HARDWARE

Hex Bolt 5/16"- 18x7/8"

Nut 5/16"-18

Lock Washer

5/16"

Installation

FIGURE 1

FIGURE 2

(Not Provided)

Lag Screws

5/16"- 18x1-7/8"

Measure

Distance

Hex Bolt 5/16"- 18x7/8", Lock Washer 5/16", Nut 5/16"-18

FIGURE 3

Not Provided

Finished Ceiling

Unfinished Ceiling

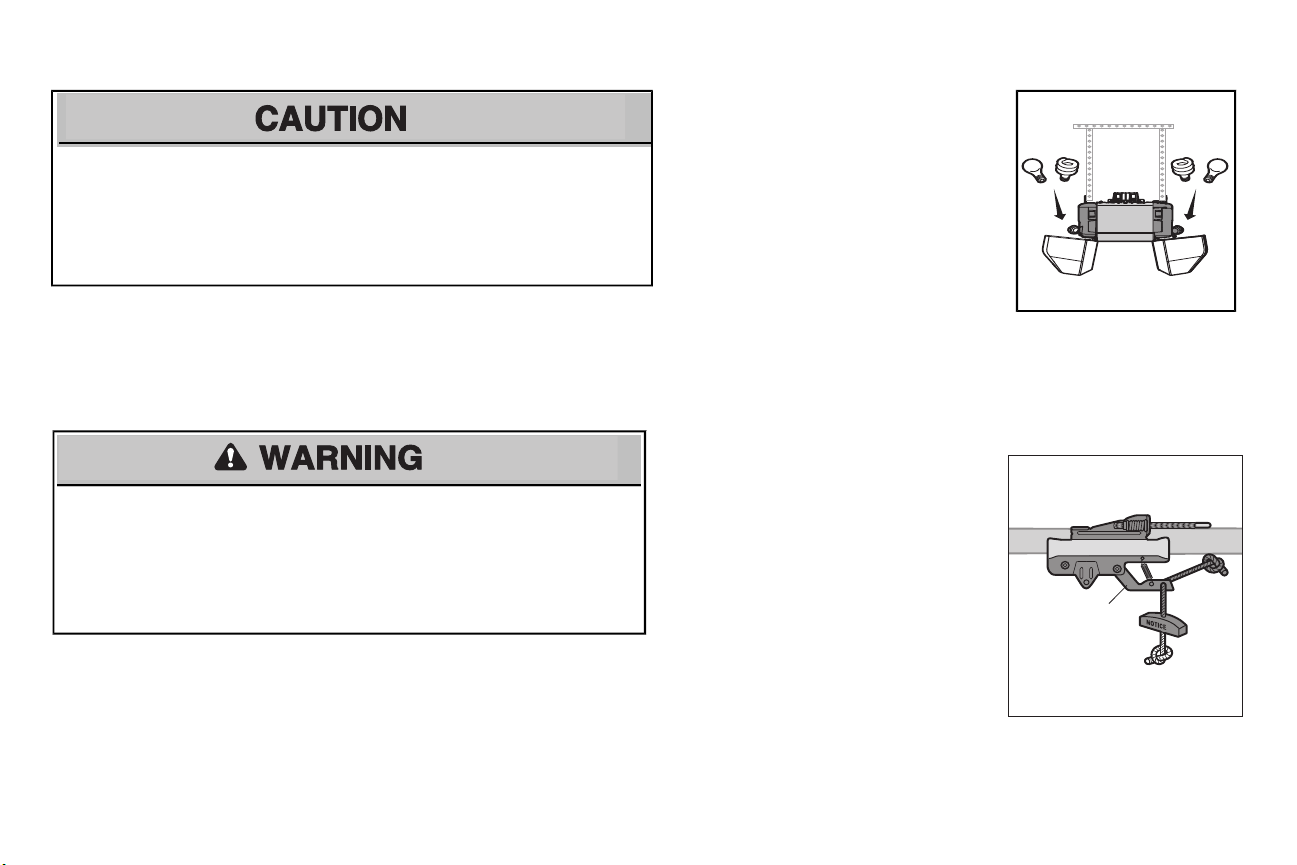

5 Hang the garage door opener

To avoid possible SERIOUS INJURY from a falling

garage door opener, fasten it SECURELY to

structural supportsofthegarage. Concrete anchors

MUSTbe used ifinstalling ANY brackets into

masonry.

Hanging your garage door opener will vary depending on your

garage. Two representative installations are shown.Yours may

be different.Hanging bracketsshould be angled (Figure 1) to

provide rigid support. On finished ceilings (Figure 2), attach a

sturdymetalbrackettostructural supportsbeforeinstalling the

opener. This bracketand fastening hardware are notprovided.

Instructionsbelow are for attaching the garage door opener

directlyto structural supports.

5.1 Measure the distance from each side of themotor unit to

the structural support.

5.2 Cutboth pieces of the hanging bracketto required lengths.

5.3 Drill 3/16" pilot holes in the structural supports.

5.4 Attachone end of each brackettoa support with 5/16"-

18x1-7/8" lag screws (not provided).

5.5 Fasten the opener to the hanging bracketswith5/16"-

18x7/8" hex bolts,lockwashersand nuts.

5.6 Checkto make sure the rail is centered over the door (or in

line with the header bracketifthe bracket is not centered

above the door).

5.7 Removethe 2x4. Operatethe door manually. Ifthe door

hitsthe rail, raisethe header bracket.

NOTE: DO NOT connect power to opener at this time.

10

or or

Trolley

Re

lease Arm

6 Install the light bulbs

To prevent possible OVERHEATING of theend panel or light socket:

• UseONLY A19 incandescent (100Wmaximum)or compactfluorescent(26Wmaximum) light

bulbs.

• DO NOT use incandescentbulbs larger than 100W.

• DO NOT use compact fluorescentlight bulbslarger than 26W (100Wequivalent).

• DO NOT use halogen bulbs.

• DO NOT use shortneckor specialtylight bulbs.

7 Attach the emergency release rope and handle

To prevent possible SERIOUS INJURY or DEATH from a falling garage door:

• Ifpossible,use emergency releasehandle todisengage trolley ONLY when garage door is

CLOSED. Weak or broken springs or unbalanced door could result in an open door falling

rapidly and/or unexpectedly.

• NEVER use emergencyrelease handle unless garage doorwayisclear of personsand

obstructions.

• NEVER use handle to pull door open or closed. If rope knotbecomesuntied, you could fall.

6.1 Pull on the topcenter of the lightlens and rotate the

light lens down.

6.2 Insertan A19 incandescent (100W maximum) or

compactfluorescent (26W, 100Wequivalent)light

bulb into the lightsocket.

NOTE: Do not use halogen, short neck,or specialtylight

bulbs as these mayoverheat the end panel or lightsocket.

Do not use LED bulbs astheymayreduce the range or

performance of your remote control(s).

6.3 Rotatethe lens up to close.

7.1 Insertone end of the emergencyrelease rope

through the handle. Make sure that “NOTICE” is

right side up. Tie a knotat least 1 inch(2.5 cm) from

the end of the emergencyrelease rope.

7.2 Insertthe other end of the emergencyrelease rope

through the hole in the trolley release arm. Mount

the emergency releasewithin reach, but atleast6

feet(1.83 m) above the floor, avoiding contactwith

vehiclesto prevent accidental release and secure

witha knot.

NOTE: Ifit is necessaryto cut the emergency release rope,

seal the cutend with a match or lighter to prevent

unraveling. Ensure the emergencyrelease rope and

handle are above the top ofall vehicles to avoid

entanglement.

11

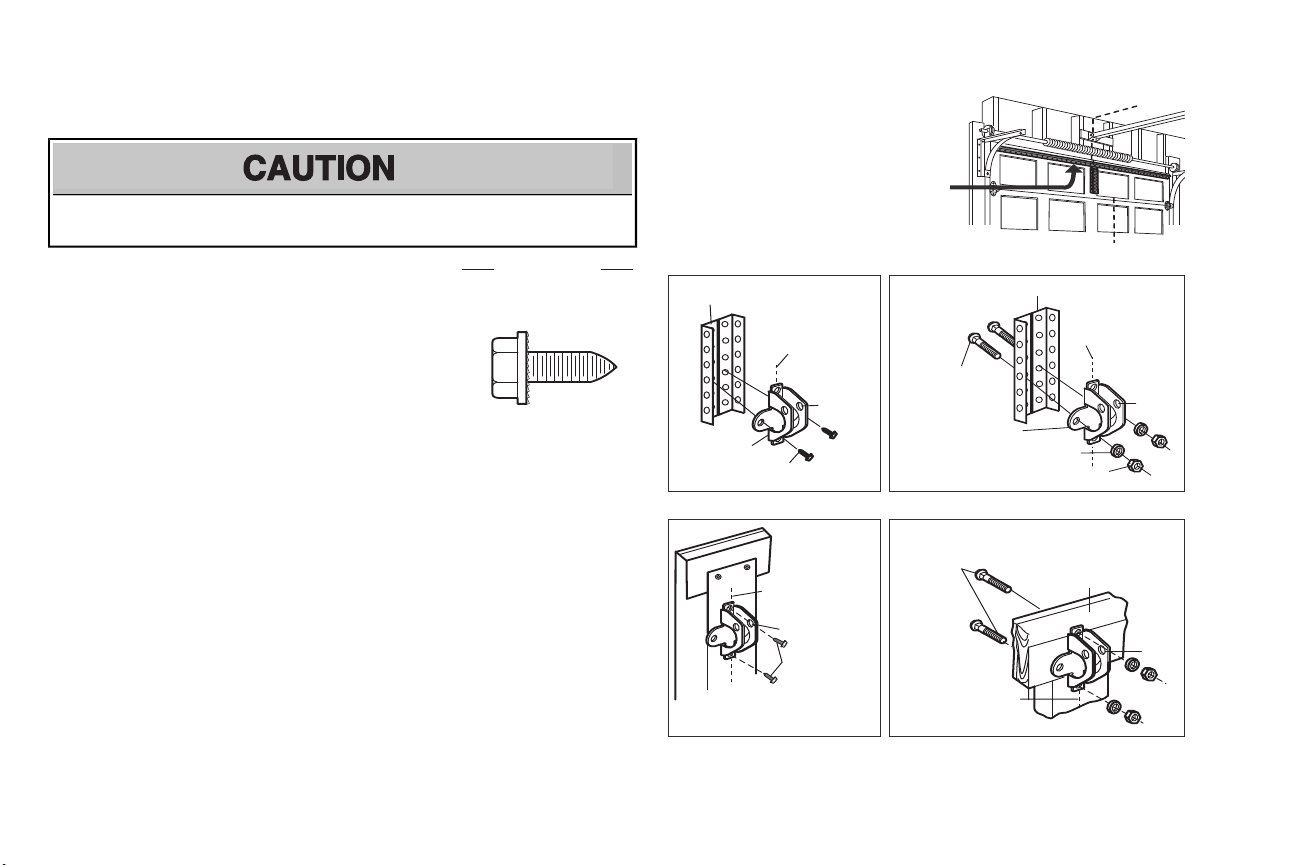

Self-Threading Screw

1/4"-14x5/8"

HARDWARE

A horizontal and vertical reinforcement

is needed for lightweight garage doors

(fi berglass, aluminum, steel, doors

with glass panel, etc.) (not provided).

A horizontal reinforcement brace

should be long enough to be secured

to two or three vertical supports.

A vertical reinforcement brace should

cover the height of the top panel.

FIGURE 1

FIGURE 2

FIGURE 4

FIGURE 5

FIGURE 3

Vertical Reinforcement

Vertical Centerline

of Garage Door

UP

Door Bracket

Self-Threading Screw

1/4" - 14x 5/8"

Self-Threading

Screw

1/4" - 14x 5/8"

Vertical Reinforcement

Bolt 5/16"-18x2"

(Not provided)

Lock Washer 5/16"

Nut 5/16"-18

Door Bracket

UP

Vertical Centerline

of Garage Door

UP

Vertical

Centerline of

Garage Door

Bolt 5/16"-18x2"

(Not provided)

UP

Inside Edge of Door or

Reinforcement Board

Vertical Centerline

of Garage Door

Installation

8 Install the door bracket

Fiberglass,aluminum or lightweight steel garage doors WILLREQUIREreinforcementBEFORE

installation of door bracket.Contact your door manufacturer for reinforcement kit.

Figure 1 showsone pieceof angle iron asthe horizontal brace.

For the vertical brace,2 pieces of angle iron are used to create a

U-shaped support. The bestsolution is to check with your garage

door manufacturer for an opener installation door reinforcement

kit.

NOTE: Many door reinforcement kitsprovide for directattachment

of the clevis pin and door arm. In this case you will not need the

door bracket; proceed to the next step.

SECTIONALDOORS

8.1 Center the door bracket on the previously marked vertical centerline used for the header bracket

installation.NotecorrectUP placement,as stamped inside thebracket.

8.2 Position the topedge ofthe bracket 2"-4" (5-10 cm) belowthe top edge of the door, OR directly below

any structural support acrossthe top ofthedoor.

8.3 Mark,drill holesand install asfollows, depending on your door’sconstruction:

Metal orlight weight doors usinga verticalangle ironbracebetween the doorpanelsupport

andthe doorbracket:

• Drill 3/16" fastening holes. Secure the door bracketusing the two self threading screws.

(Figure 2)

• Alternately, use two 5/16" bolts,lockwashers and nuts (not provided).(Figure 3)

Metal,insulated orlight weightfactory reinforceddoors:

• Drill 3/16" fastening holes. Secure the door bracketusing the self-threading screws.(Figure 4)

Wood Doors:

• Use top and bottom or side to side door bracket holes. Drill 5/16” holes through the door and

secure bracket with 5/16"-18x2" carriage bolts,lockwashersand nuts(notprovided). (Figure 5)

NOTE: The 1/4"-14x5/8" self-threading screws are not intended for use on wood doors.

12

Straight

Door Arm

Curved

Door

Arm

(Groove

facing out)

CORRECT

INCORRECT

Straight

Door

Arm

Curved

Door

Arm

Ring

Fastener

Clevis Pin

5/16" x 1"

Ring

Fastener

Clevis Pin

5/16" x 1-1/4"

HARDWARE

Hex Bolt 5/16"-18x7/8"

Nut

5/16"-18

Lock

Washer

5/16"

Clevis Pin

5/16"x1"

Clevis Pin 5/16"x1-1/4"

Ring Fastener

Nut 5/16"

- 18

Lock

Washer

5/16"

Hex Bolt

5/16" - 18 x 7/8"

If the straight door arm is hanging

down too far, you may cut

6 inches

(15 cm) from the solid end.

Nut 5/16" - 18

Lock

Washer

5/16"

Hex Bolt

5/16" - 18 x 7/8"

Trolley

re

lease

arm

9 Connect the door arm to the trolley

IMPORTANT: The groove on the straight door arm MUST face away from the curved door arm.

9.1 Close the door.Disconnect the trolley by

pulling the emergency releasehandle.

Slide the outer trolley back(awayfrom

the door)about 2" (5 cm).

9.4 Align the straight door arm with the

curved door arm.Select two aligned

holes (as farapart as possible) and

attach using the bolts,nutsand lock

washers.

9.2 Attachthe straight door arm to the outer

trolley using the clevispin.Attachwith

the ring fastener.

NOTE: Ifthe holes do not line up, reverse the

straight door arm.Select two aligned holes (as

far apart as possible) and attachusing the

bolts,nutsand lock washers.

13

9.3 Attachthe curved door arm to the door

bracketusing the clevis pin. Attach with

the ring fastener.

9.5 Pull the emergency releasehandle

toward the garage door opener until the

trolley release arm is horizontal. The

trolley will re-engage automatically when

the garage door opener is activated.

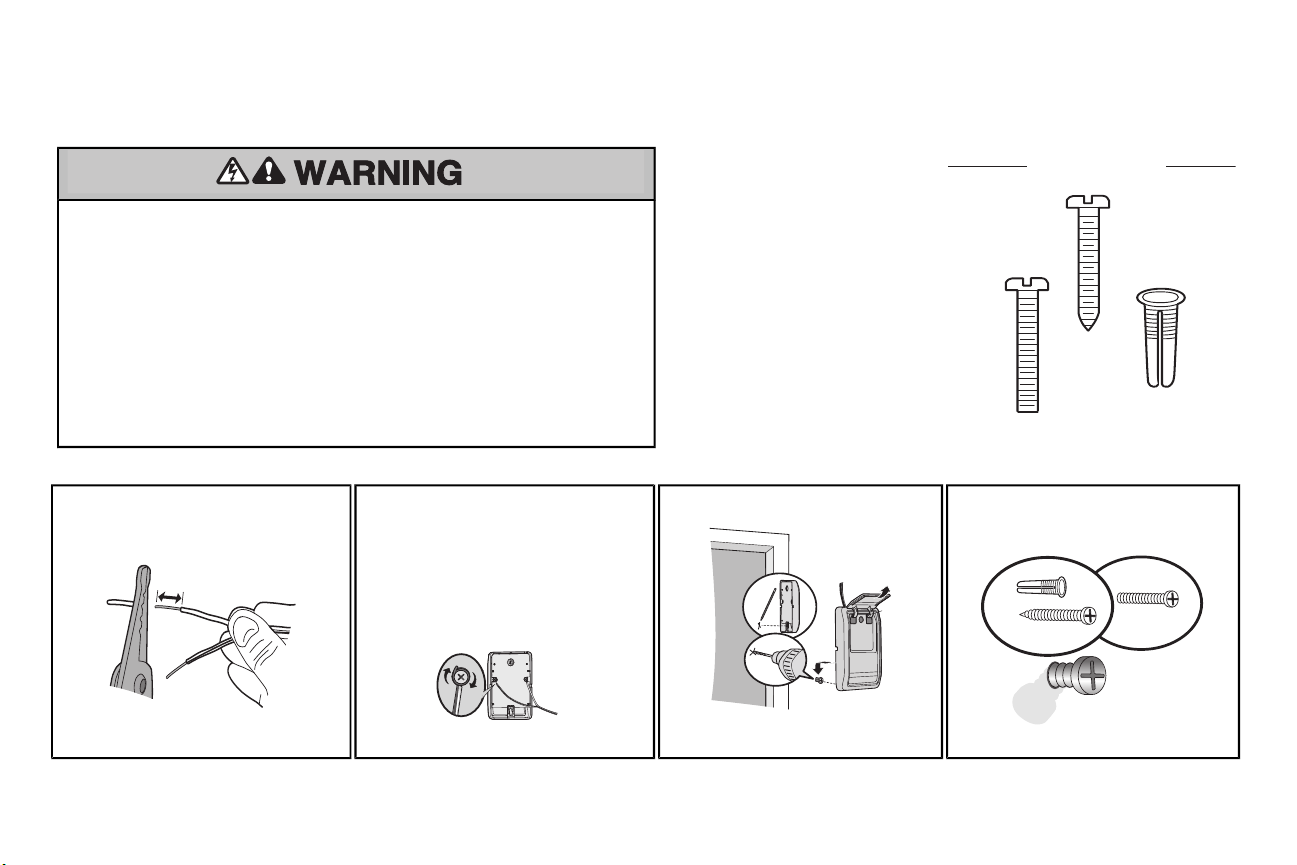

Install the Door Control

Screw

6ABx1"

HARDWARE

Drywall

Anchors

Screw

6-32x

1"

7/16"

(11

mm)

Wall

Screw

6-32 x

1"

DRYWALL

GANG BOX

Screw

6AB x 1"

Drywall Anchor

1 Install the door control

INTRODUCTION

Compatible with MyQ®and Security+ 2.0™

To prevent possible SERIOUS INJURY or DEATH from electrocution:

• Be sure power isNOTconnected BEFORE installing door control.

• Connect ONLY to12 VOLTlow voltage wires.

To prevent possible SERIOUS INJURY or DEATH from a closinggarage door:

• Installdoor controlwithin sight of garage door,outof reach ofchildren at a minimum heightof5 feet

(1.5 m), and away from ALL moving parts of door.

• NEVER permitchildren to operate or playwithdoor control push buttons or remotecontrol

transmitters.

• Activate door ONLY when it can be seen clearly,is properly adjusted,and there are no

obstructions to door travel.

• ALWAYS keep garage doorin sight untilcompletelyclosed.NEVERpermit anyone to crosspath of

closing garage door.

NOTE: For gang box installations it is not necessaryto drill holesor install the drywall anchors. Use the existing holes in the gang box.

1.1 Strip 7/16 inch (11 mm)of insulation from

one end of the wire and separate the wires.

1.2 Connectone wire to each ofthe two screws

on the backof the door control.The wires

can be connected to either screw.

PRE-WIREDINSTALLATIONS:Choose

any two wires to connect, note which wires

are used so the correct wires are connected

at the garage door opener in a later step.

accessories, see page 37. Your garage door

opener is compatible with up to 2 SmartControl

Panels or 4 ofanyother Security+ 2.0™ door

controls.NOTE:Older LiftMaster door controls

and third party products are not compatible.

Install thedoor controlwithin sight of the door at

a minimum heightof 5 feet(1.5m) where small

children cannotreach, and awayfromthe

moving parts of the door.

NOTE: Your product may look different than

moving parts of the door the illustrations.

1.3 Mark the location ofthe bottom mounting

hole and drill a 5/32 inch (4 mm)hole.

1.4 Install the bottomscrew, allowing 1/8 inch

(3 mm) to protrude from the wall.

14

Install the Door Control

DRYWALL

Drywall Anchor

Screw

6-32 x 1"

Screw

6AB x 1"

GANG

BOX

HARDWARE

Insulated Staple

(N

ot shown)

Staple

7/16"

(11

mm)

RED

WHITE

WHITE

GREY

k

1.5 Position the bottom hole of the door

1.6 Lift the pushbar up and markthe top hole. 1.7 Removethe door control from the wall

control over the screwand slide

down into place.

2 Wire the door control to the garage door opener

2.1

Run the white and red/white wire fromthe door control to

the garage door opener. Attachthe wire to thewall and

ceiling with the staples (notapplicable forgang box or

pre-wired installations).Do not pierce the wire with the

staple as this may cause a short or an open circuit.

PRE-WIRED INSTALLATIONS: When wiring

the door control to the garage door opener

make sure you use the same wires thatare

connected to the door control.

and drill a 5/32 inch (4 mm) hole for

the top screw.

2.2

Strip 7/16 inch (11 mm)of insulation

fromthe end of the wire near the

garage door opener.

15

door controlover the screw and

slide down into place. Attach the

top screw.

2.3

Connectthe wire to the red and

white terminals on thegarage

door opener. To insertor

release wires fromtheterminal,

push in the tab with screwdriver

tip.

1.8 Position the bottom hole of the

Install the Door Control

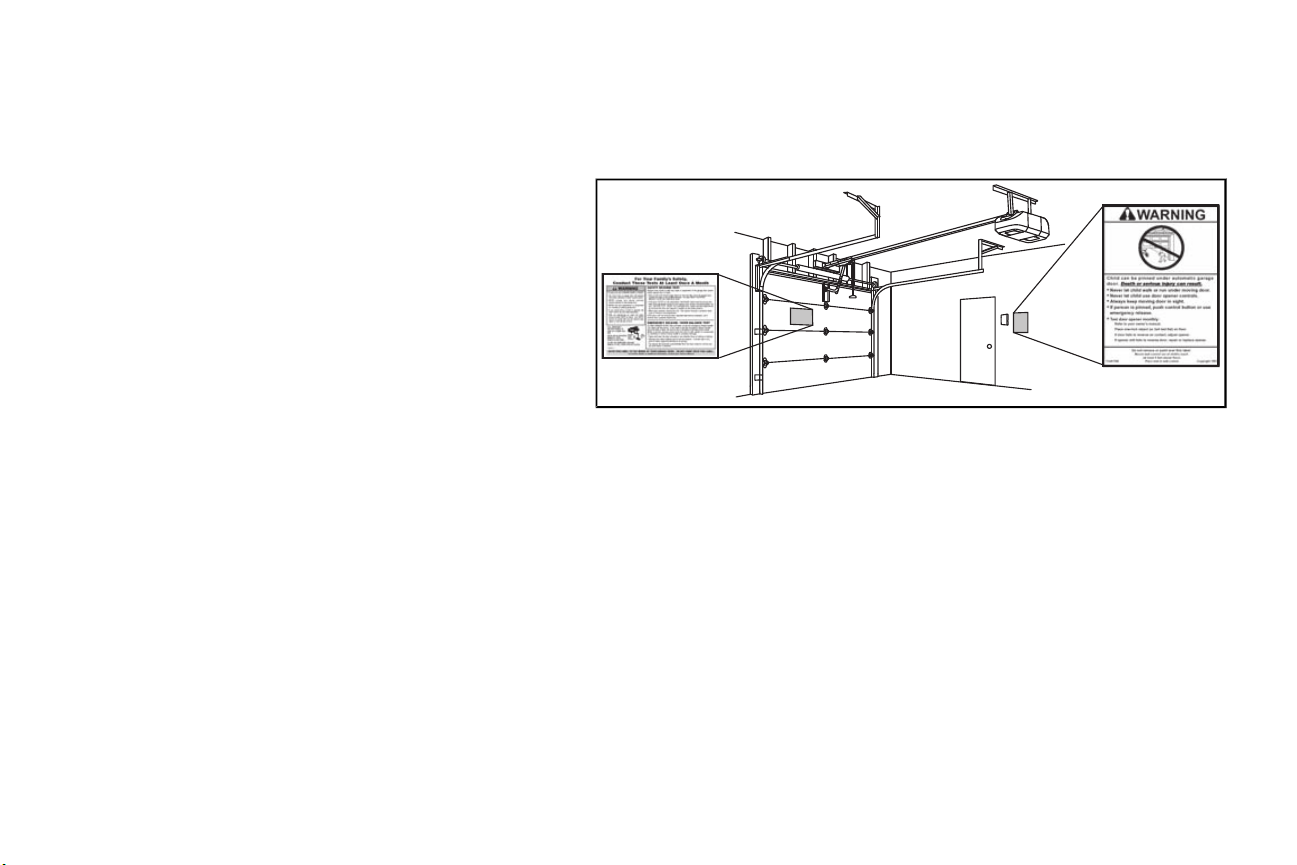

3 Attach the warning labels

3.1 Attach the entrapment warning label on the wall near the door control with tacksor

staples.

3.2 Attach the manual release/safety reverse test label in a visible location on the inside of

the garage door.

16

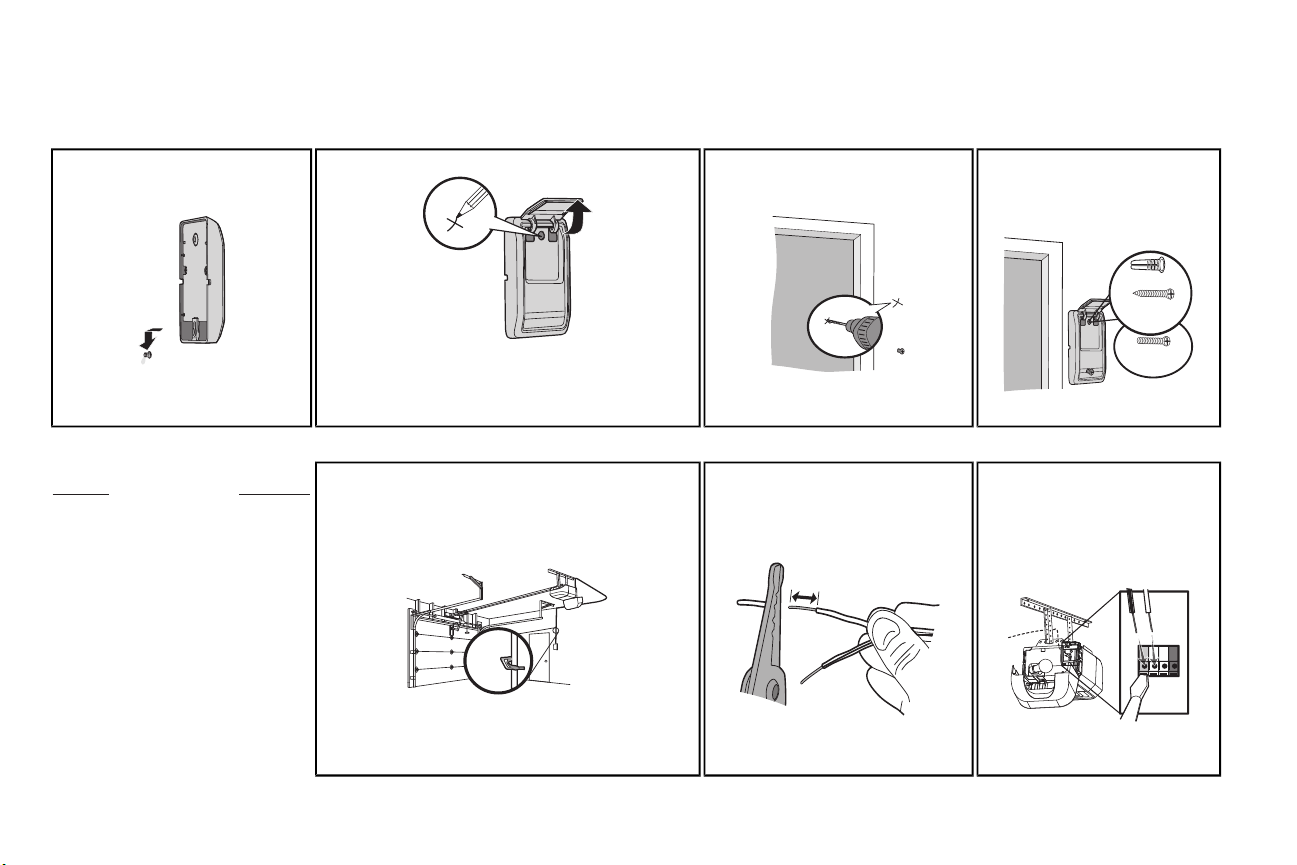

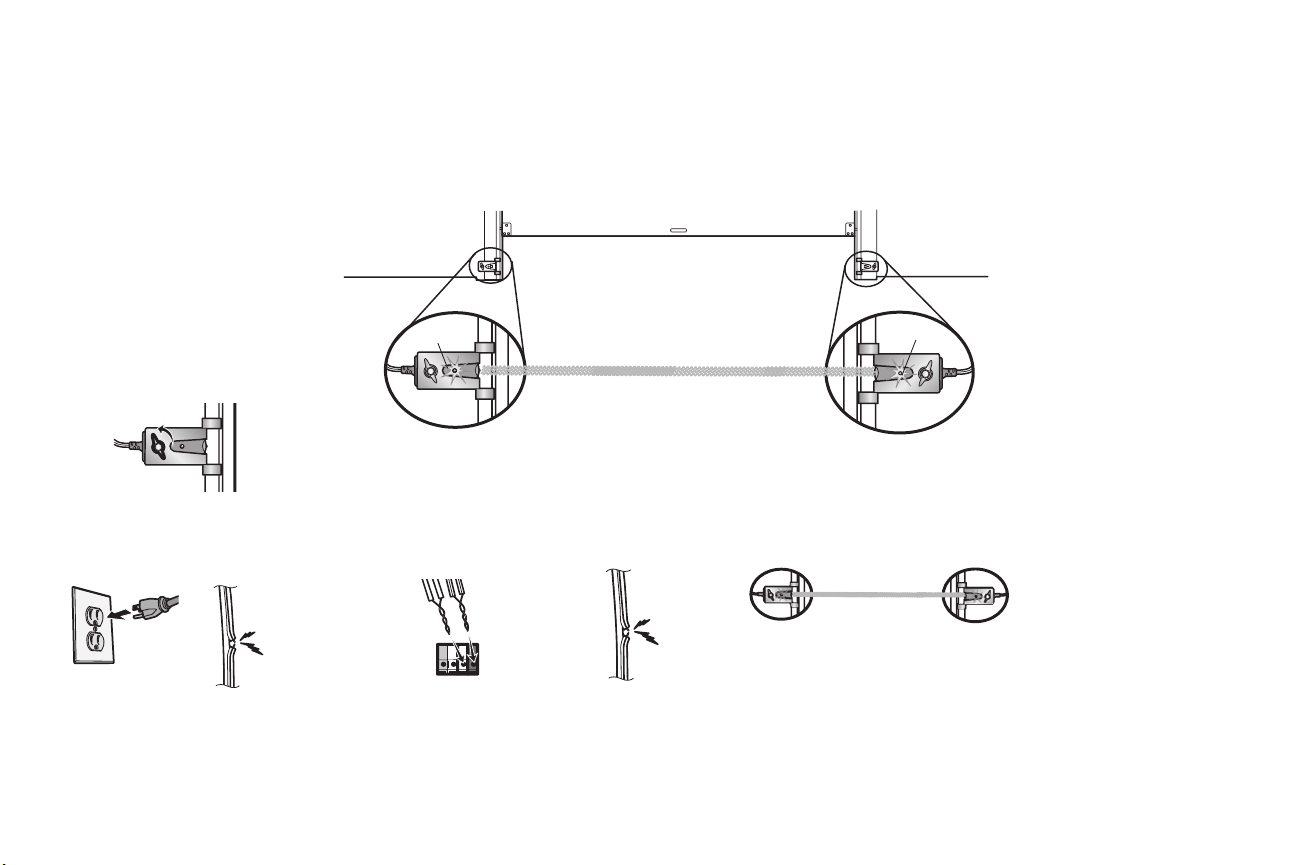

Install the Protector System

Invisible Light Beam

Protection Area

Safety Reversing Sensor

6" (15 cm) max. above floor

Safety Reversing Sensor

6" (15 cm) max. above floor

®

Introduction

Be sure power is NOTconnectedto the garage

door opener BEFORE installing the safety

reversing sensor.

To prevent SERIOUS INJURY or DEATHfrom

closing garage door:

• Correctlyconnectand align the safety

reversing sensor. This required safety

device MUSTNOT be disabled.

• Installthe safetyreversing sensor so beam

is NO HIGHER than 6" (15 cm) above

garage floor.

IMPORTANTINFORMATIONABOUTTHESAFETYREVERSINGSENSORS

Thesafety reversing sensors must beconnected andalignedcorrectlybeforethe garagedoor openerwillmoveinthe downdirection.

The sending sensor (with an amber LED)transmits an invisible light beam to thereceiving sensor (with a green LED). Ifan obstruction breaks the light

beam while the door is closing, the door will stop and reverse to the full open position,and thegarage door opener lightswill flash 10 times.

NOTE: For energyefficiency the garage door opener will enter sleep mode when the door is fully closed. The sleep mode shuts the garage door

opener down until activated. The sleep mode issequenced with the garage door opener light bulb;as the light bulb turns off the sensor LEDs will turn

off and whenever the garage door opener lights turn on the sensor LEDswill light. The garage door opener will not go into the sleep mode until the

garage door opener has completed 5 cycles upon power up.

Wheninstalling the safety reversingsensors check the following:

• Sensorsare installed inside the garage, one on either side of the door.

• Sensorsare facing eachother with the lensesaligned and thereceiving sensor lensdoes not receive directsunlight.

• Sensorsare no more than 6 inches (15 cm) above thefloor and the lightbeam is unobstructed.

17

Install the Protector System

HARDWARE

Carriage Bolt

1/4"-20x1/2"

Wing Nut

1/4"-20

Carriage Bolt

1/4" - 20 x 1/2"

Wing Nut

1/4" - 20

(not provided)

In

side

G

a

rage

Wal

l

(not provided)

Lens

Carriage Bolt

1/4" - 20 x 1/2"

Wing Nut

1/4" - 20

®

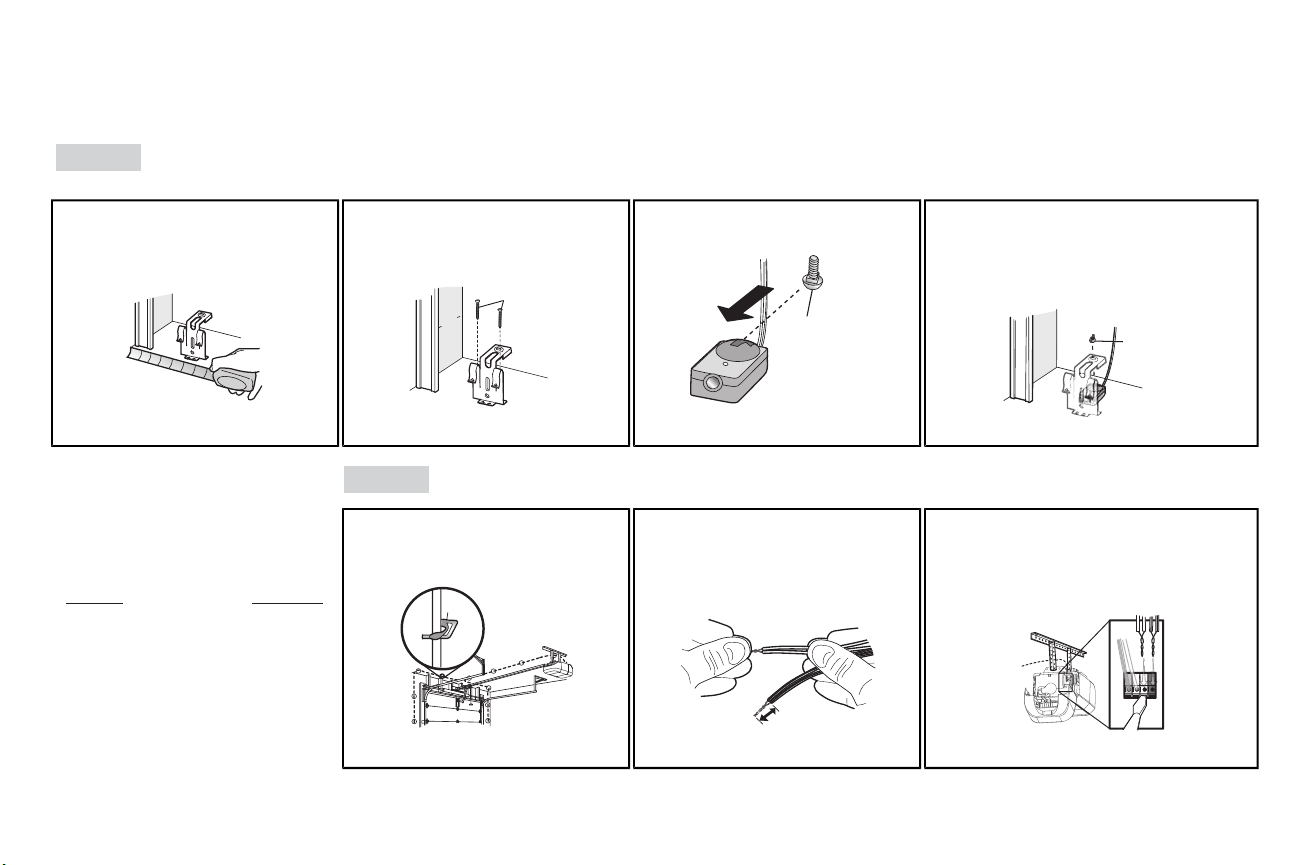

1 Install the Safety Reversing Sensors

The safetyreversing sensors can be attached to the door track,the wall,or the floor.Ifthe door track will notsupport the sensor bracket a wall installation is recommended. Choose one of thefollowing installations.

OPTION A

1.1A Slide the curved armsofthe sensor

OPTION B WALLINSTALLATION

Ifadditional clearanceis needed an extension bracket(notprovided) or wood blockscanbe used. Make sure each bracket has the sameamount of clearance so they will align correctly.

1.1B Position thesensor bracket against the

wall with the curved armsfacing the

door. Make sure there is enough

clearance for thebeam to be

unobstructed.Markholes.

1.2B Drill 3/16 inch pilotholes for eachsensor

DOOR TRACK INSTALLATION

bracketaround the edge of the door

track. Snap into placeso thatthe

sensor bracket is flush againstthe

track.

bracketand attach the sensor brackets

to the wall using lag screws(not

provided).

1.2A Slide the carriage bolt into thesloton

each sensor.

1.3B Slide the carriage bolt into the sloton

each sensor.

1.3A Insert the boltthrough the hole in the sensor

bracketand attach with the wing nut.The lenses

on bothsensorsshould pointtowardeach other.

Make sure the lens is not obstructed by the

sensor bracket.

1.4B

Insertthebolt through the hole in the sensor

bracketand attach with the wing nut.The lenses

on bothsensorsshould pointtowardeach

other. Make sure the lens is notobstructed by

the sensor bracket.

18

Install the Protector System

Insi

d

e

Garage

Wa

l

l

(not provided)

Carriage Bolt

1/4" - 20 x 1/2"

Wing Nut

1/4" - 20

HARDWARE

Insulated Staple

(N

ot shown)

Staple

7/16"

(11 mm)

RED

WHITE

WHITE

GREY

®

1 Install the Safety Reversing Sensors

OPTION C

Usean extension bracket(not provided) or wood block to raise the sensor bracket if needed.

1.1C Carefully measure theposition of both

FLOOR INSTALLATION

sensor bracketsso they will be the same

distancefromthe wall and unobstructed.

1.2C

Attach thesensor bracketstothe floor

using concrete anchors (not

provided).

1.3C

Slide the carriage bolt into the sloton

each sensor.

1.4C

Insertthebolt through the hole in the sensor

bracketand attach with the wing nut.The lens

on bothsensorsshould pointtowardeach

other. Make sure the lens is notobstructed by

the sensor bracket.

2 Wire the Safety Reversing

Sensors

PRE-WIRED INSTALLATIONS: If your garage

already haswiresinstalled for the safety reversing

sensors,seepage 20.

OPTION A

INSTALLATION WITHOUT PRE-WIRING

2.1A Run thewire from both sensors to the

garage door opener. Attach the wire to

the wall and ceiling withthe staples.

2.2A Strip 7/16 inch (11 mm) of insulation

fromeach set of wires. Separate the

wires.Twistthe white wires together.

Twist the white/blackwires together.

19

2.3A Insert the white wires intothe white terminal on

the garage door opener. Insert the white/black

wires into the grey terminal on the garage door

opener. To insertor remove thewires from the

terminal,push in the tab with a screwdrivertip.

Install the Protector System

7/16"

(11 mm)

7/16"

(11 mm)

Safety reversing sensor wires

Pre-installed

wires

White

White/Black

Yellow

(for example)

Purple

(for example)

Not Provided

Pre-installed

wires

Safety reversing sensor wires

7/16"

(11 mm)

Yellow

Purple

RED

WHITE

WHITE

GREY

Purple

(for example)

Yellow

(for example)

To insert or remove the wires

from

the terminal, push in the

tab with a screwdriver tip.

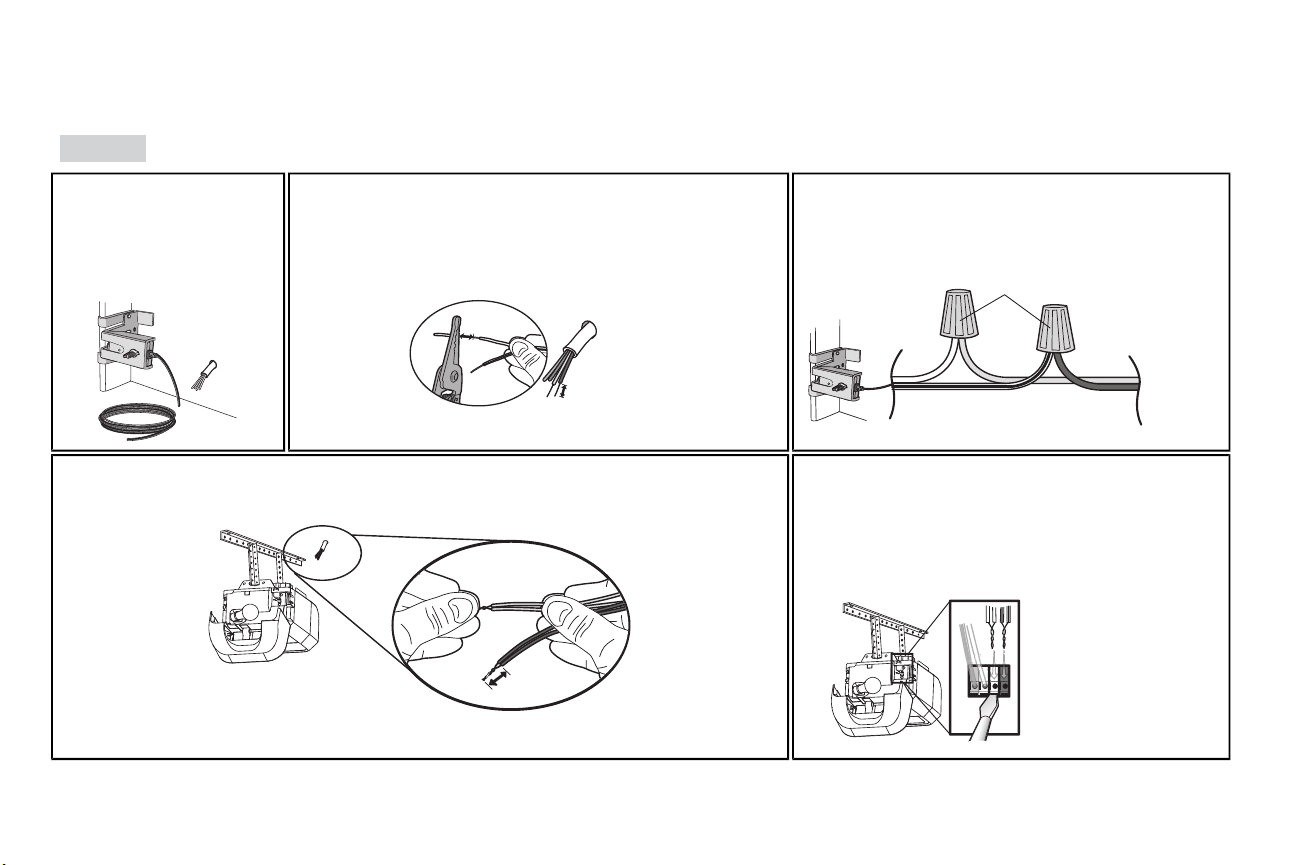

OPTION B PRE-WIRED INSTALLATION

®

2.1B Cut the end of the safety

reversing sensor wire, making

sure there isenough wire to

reach the pre-installed wires

2.2B Separate the safetyreversing sensor wires and strip 7/16 inch(11 mm) of

insulation from eachend. Choose two of thepre-installed wires and strip 7/16

inch (11 mm) of insulation fromeach end. Make sure that you choose the

same color pre-installed wires for eachsensor.

fromthe wall.

2.4B At the garage door opener, strip 7/16 inch(11 mm) ofinsulation from each end of the wirespreviouslychosen for the

safety reversing sensors. Twistthe like-colored wires together.

20

2.3B Connectthe pre-installed wires to thesensor wires with wire nuts

making sure the colors correspond foreach sensor. For example,

the white wire would connect to the yellowwire and the white/black

wire would connecttothe purple wire.

2.5B Insert the wires connected to thewhitesafetysensor wirestothe

white terminal on the garage door opener. Insert the wiresthatare

connected to the white/black safetysensor wiresto the grey

terminal on the garage door opener.

Power

Ground Tab

Ground Tab

Green Ground

Screw

Green

Ground

Screw

Ground Wire

Ground

Wire

Black

Wire

White Wire

White Wire

PERMANENT WIRING (Filter Board)

PERMANENT WIRING (Terminal Block)

Wire Nuts

TYPICAL WIRING

Black

Wire

Black

Wire

1 Connect Power

To avoid installation difficulties, do not activate thegarage door opener at this time.

To reduce the risk of electric shock, your garage door opener has a grounding type plug witha third grounding pin. This

plug will only fit into a grounding type outlet. If the plug doesn’t fit intoyour outlet,contacta qualified electricianto install

the proper outlet.

To prevent possible SERIOUS INJURY or DEATH

from electrocution or fire:

• Be sure power is NOT connectedtotheopener,

anddisconnectpower to circuit BEFORE

removing cover toestablish permanent wiring

connection.

• Garage door installationandwiringMUST be in

compliancewith ALL local electrical andbuilding

codes.

• NEVER use an extension cord, 2-wire adapter, or

changeplugin any way to make it fit outlet.Be

sure the opener is grounded.

THEREARETWO OPTIONS FOR CONNECTINGPOWER:

OPTION A

TYPICAL WIRING

1.1A Plugin the garagedoor opener intoa grounded outlet.

1.2A DO NOT run garage door opener at this time.

OPTION B

If permanent wiring is required by your local code, refer to the following procedure.

To makea permanent connection through the7/8inch hole in the top of the motor unit (according to local code):

Wiringthrough a filter board(8550 models manufactured beforeApril12, 2013):

PERMANENT WIRING

1.1B Besure power is NOT connected to the opener, and disconnect power to circuit.

1.2B Remove the garage door opener cover andset aside.

1.3B Remove the attachedgreengroundterminal.

1.4B Cut black and whitewires. Strip away 1/2 inch (1 cm) of insulation, 3 inches (7.5 cm) before spade terminals.

1.5B Remove the power cord fromopener.

1.6B Install a conduit or flex cable adapter tothe7/8inch hole.

1.7B Run wires throughconduit, cuttoproper length andstrip insulation.

1.8B Attach with wire nuts provided. Attach the groundwireto the green groundscrew. The opener must be

grounded.

1.9B Properly secure wire under plastic ties sothatwire does notcomein contact with moving parts.

1.10B Reinstall the cover. DO NOT run garage door opener at this time.

Wiringthrough a terminal block (8550 modelsmanufacturedafter April 12, 2013 and all8557 models):

1.1B Remove the motor unit cover screws and set the cover aside.

1.2B Remove the attached3-prong cord.

1.3B Connect the black (line) wire to the screw on the brass terminal; the white (neutral) wire to the screw on the silver

terminal; and the groundwire to the green groundscrew. The opener must be grounded.

1.4B Reinstall the cover.

21

Green LED

ROSNES GNIVIECERROSNES GNIDNES

Amber LED

If the receiving sensor is in

direct sunlight, switch

it with

sending sensor so it is on the

opposite side of the door.

(invisible light beam)

Make sure there is

power to the garage

door opener.

Make sure the

sensor wire is

not

shorted/broken.

RED

WHITE

WHITE

GREY

Make sure the sensor has been wired

correctly: white wires to white terminal

and white/black wires to grey terminal.

Make sure the sensors are aligned.Make sure the sensor wire is

not shorted/broken.

Power

2 Ensure the Safety Reversing Sensors are aligned

Thedoor willnot close ifthe sensors

have not been installedandaligned

correctly.

When the light beam isobstructed or

misaligned while the door is closing, the

door will reverse and the garage door

opener lights will flash ten times.Ifthe door

is alreadyopen, it will notclose.The

sensorscan be aligned by loosening the

wing nuts, aligning the sensors,and

tightening the wing nuts.

IFTHEAMBER LED ON THE SENDING SENSORIS NOT GLOWING: IF THE GREENLEDON THE RECEIVING SENSOR IS NOT GLOWING:

2.1 Checkto make sure the LEDsin bothsensorsare glowing steadily.TheLEDs in both sensorswill glow steadily if they

are aligned and wired correctly.

3 Ensure the Door Control is wired correctly

Ifthedoor controlhas been installed and wired correctlya message will display on the screen.

22

UP (Open)

DOWN (Close)

UP Button

Adjustment

Button

DOWN Button

PROGRAMMING BUTTONS

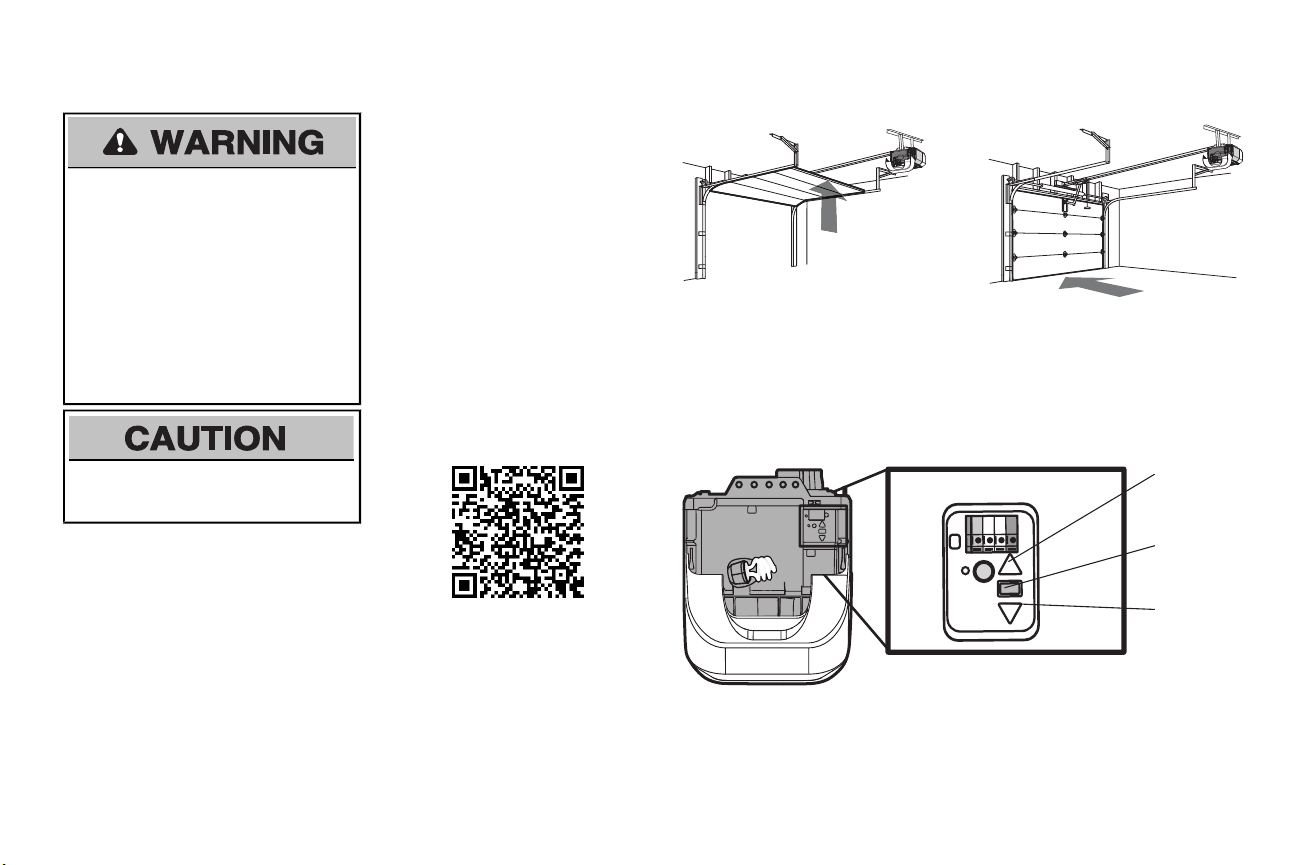

Adjustments

Withouta properly installed safetyreversal

system,persons(particularly small children)

could be SERIOUSLY INJURED or KILLED by a

closing garage door.

• Incorrectadjustmentofgarage door travel

limitswillinterfere with proper operation of

safety reversal system.

• After ANY adjustments are made,the safety

reversal system MUST be tested. Door

MUSTreverse on contact with 1-1/2" (3.8

cm)high object(or 2x4 laid flat) on floor.

To prevent damage to vehicles,be sure fully

open door providesadequate clearance.

INTRODUCTION

Your garage door opener is designed with

electronic controlsto make setup and

adjustmentseasy. The adjustmentsallow you

to programwhere the door will stop in the

open (UP) and close(DOWN) position. The

electronic controlssense the amountofforce

required to open and closethe door. The

force is adjusted automatically when you

program thetravel.

NOTE: Ifanything interferes with the door’s

upward travel it will stop. Ifanything interferes

with the door’sdownward travel, it will reverse.

To watcha short instructional video on

programming your new garage door opener

use your smartphone to read the QR Code

below:

PROGRAMMING BUTTONS

The programmingbuttonsare located on the

leftside panel of the garage door opener and

are used to programthe travel.

23

Adjustments

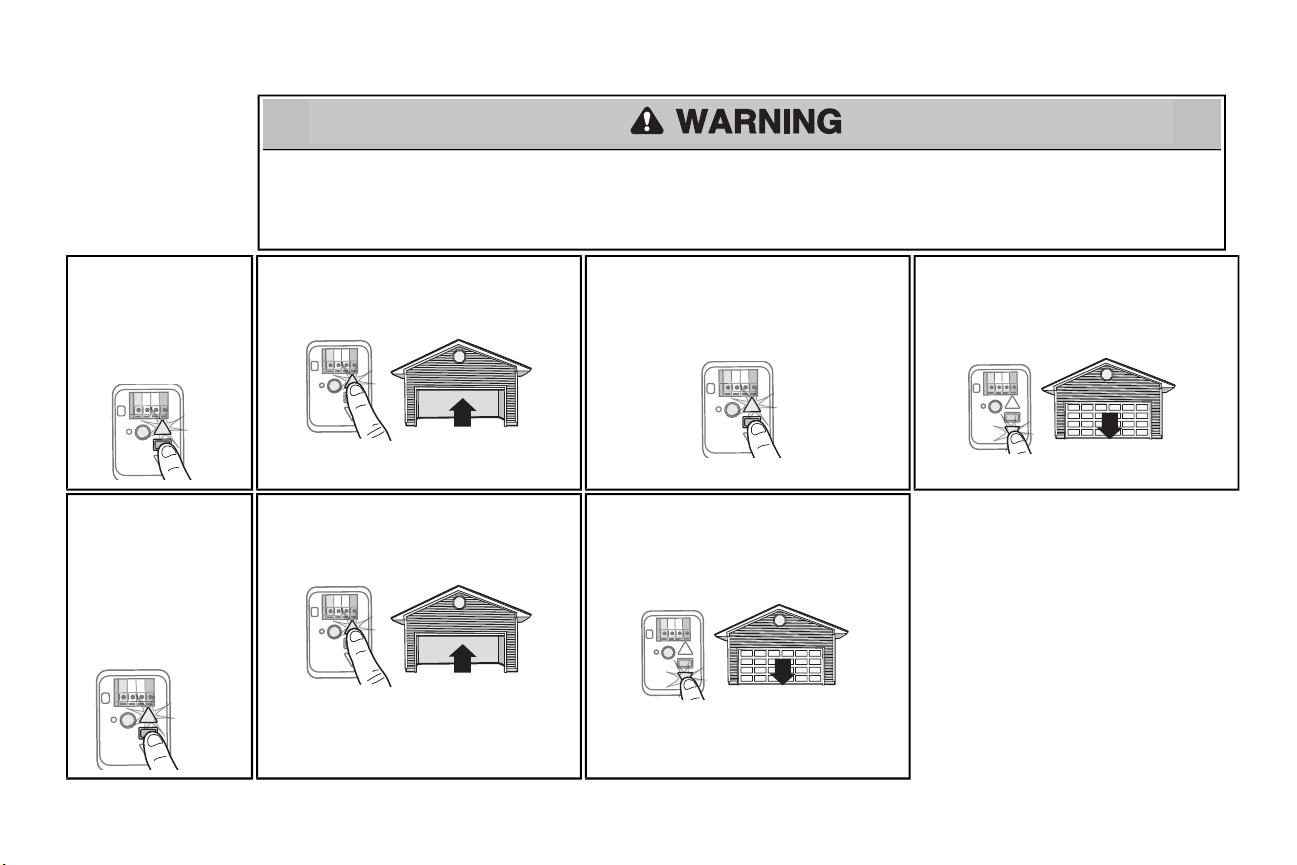

1 Program the

Travel

Withouta properly installed safetyreversal system,persons (particularly small children) could be SERIOUSLY INJURED or KILLED by a closing garage door.

• Incorrectadjustmentofgarage door travel limitswill interfere with proper operation of safetyreversal system.

• After ANY adjustments are made, the safetyreversal system MUSTbe tested. Door MUST reverse on contactwith 1-1/2"(3.8 cm) high object (or 2x4 laid flat) on

floor.

1.1 Press and hold the

AdjustmentButtonuntil

the UP Button begins to

flashand/or a beep is

heard.

1.5 Once the door isin the

desired DOWN position

press and release the

AdjustmentButton.The

garage door opener

lights will flash twice

and theUP Button will

begin toflash.

1.2 Press and hold theUP Button until thedoor isin

the desired UP position.

NOTE: The UPand DOWNButtons can be

used to move the door up and down asneeded.

1.6 Press and release the UP Button.When the

door travelsto theprogrammed UPposition,the

DOWNButton will begin to flash.

1.3 Once the door isin the desired UP position

press and release the Adjustment Button. The

garage door opener lightswill flash twiceand

the DOWN Button will begin to flash.

1.7 Press and release the DOWNButton.Thedoor

will travel to the programmed DOWN position.

Programming iscomplete.

24

1.4 Press and hold theDOWNButton until the door

is in thedesired DOWNposition.

NOTE: The UPand DOWNButtons can be

used to move the door up and down asneeded.

Ifthegarage door opener lightsare flashing 5 times

during the stepsfor Programthe Travel,the

programming has timed out. Ifthe garage door opener

lights are flashing 10 times during the steps for

Program theTravel,the safetyreversingsensorsare

misaligned or obstructed (refer to page 22). When the

sensorsare aligned and unobstructed,cycle the door

through a complete up and downcycle using the

remote control or the UP and DOWN buttons.

Programming iscomplete.Ifyou are unable to operate

the door up and down, repeatthe stepsfor

Programming the Travel.

Adjustments

2 Test the Safety Reversal System

Withouta properly installed safetyreversal system,

persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing

garage door.

• Safetyreversal system MUST be tested every

month.

• After ANY adjustments are made,the safety

reversal system MUST be tested. Door MUST

reverse on contact with 1-1/2" (3.8cm)high

object (or 2x4 laid flat)on the floor.

3 Test the Protector System

Withouta properly installed safetyreversing

sensor,persons (particularly small children) could

be SERIOUSLY INJUREDor KILLED by a closing

garage door.

®

2.1 With the door fully open, placea 1-1/2

inch (3.8 cm) board (or a 2x4 laid flat) on

the floor, centered under the garage

door.

3.1 Open the door. Place the garage door

opener carton in thepath of the door.

2.2 Press the remote control push button to

close the door.The door MUSTreverse

when it makes contactwiththe board.

3.2 Press the remote control push button to

close the door.The door will not move

more than an inch (2.5 cm),and the

garage door opener lightswill flash 10

times.

Ifthedoor stops and does notreverseon

the obstruction,increase the downtravel

(refer to Adjustment Step 1).

Repeat the test.When the door reverses

upon contact with the 1-1/2inch board,

remove the board and open/close the

door 3 or 4 times to testthe adjustment.

Ifthegarage door opener continuesto fail

the safetyreversaltest, call a trained door

systemstechnician.

The garage door opener will not close

froma remote control ifthe LED in either

safety reversing sensoris off(alerting you

to the fact thatthe sensor is misaligned or

obstructed).

Ifthegarage door opener closesthe door

when the safety reversing sensor is

obstructed (and the sensorsare no more

than 6 inches [15 cm]above the floor),call

for a trained doorsystemstechnician.

25

Loading...

Loading...