Page 1

OUTBO ARD BRAKE KIT

INSTRUCTIONS MANUAL

For Models: T, J and H

APPLICA

TION REQUIREMENTS:

This wiring modification is available to models T, J and H. Brake kit for all 115, 230/460

and 575V operators.

BRAKE FUNCTIONS:

Ensure your Brake Kit matches your operator and provides up to 5ft.-lb. of braking

torque @ 1725 RPM motor shaft. May be factory or field installed.

VOLTAGE REQUIREMENTS:

Models T and J

71-EB120 For operators with 115V incoming power source.

71-EB240 For operators with 230V and 460V incoming power source.

71-EB575 For operators with 575V incoming power source.

Model H

71-EB120H For operators with cable and 115V incoming power source.

71-EB240H For operators with cable and 230V and 460V incoming power source.

71-EB575H For operators with cable and 575V incoming power source.

INSTALLATION INSTRUCTIONS FOR OUTBOARD BRAKE KITS

NOTE: Refer to Brake illustration on page 3 and

Figure 1 on page 4 for additional help with

installation.

1. Locate the new Brake Mounting Bracket (item #4).

Mount the bracket to the motor studs in the same

position as the solenoid is to reside. Secure in place

with the (2) new flange nuts (item #20), select proper

thread to mate with motor studs.

2. Locate the (2) new Motor Standoffs (item #12).

Standoffs are threaded #10-32 on one end and #8-32

on the other, select the proper thread to mate with

motor studs. Mount the standoffs to the two

remaining motor studs, apply loctite to the motor

studs before installing.

3. Locate the new Brake Hub (item #14) and Push

Nut (item #23). Slide the new hub onto the shaft until

it lay against the motor pulley, secure in place with

the set screw and push nut supplied.

4. Locate the new Brake Mounting Plate (item #16)

and (2) new Collars (item #7). Install the collars into

the keyhole slots on the brake mounting plate (set

screws in collars to be located away from motor).

TO AVOID SERIOUS PERSONAL INJURY OR DEATH

FROM ELECTROCUTION, DISCONNECT ELECTRIC

POWER TO OPERATOR BEFORE INSTALLING.

5. Place Brake Assembly over motor shaft, align the

(2) Collars from step 4 with the (2) Standoffs from

step 2 and slide entire assembly into position on

Brake Hub (depress brake actuator lever to allow

rotation of brake disc for alignment).

6. Position Brake Assembly so that the edge of the

1.25 square extrusion in the Brake Disc (item #3) is

flush with the front of the Brake Hub. Secure in place

by installing (2) #10-32 screws and flat washers

through the (2) slots in Brake Mounting Plate, into the

(2) tapped holes in Brake Mounting Bracket and

tighten. Assure Assembly is square to motor and

tighten the (2) set screws (item #18), (1) in each

Collar.

Page 2

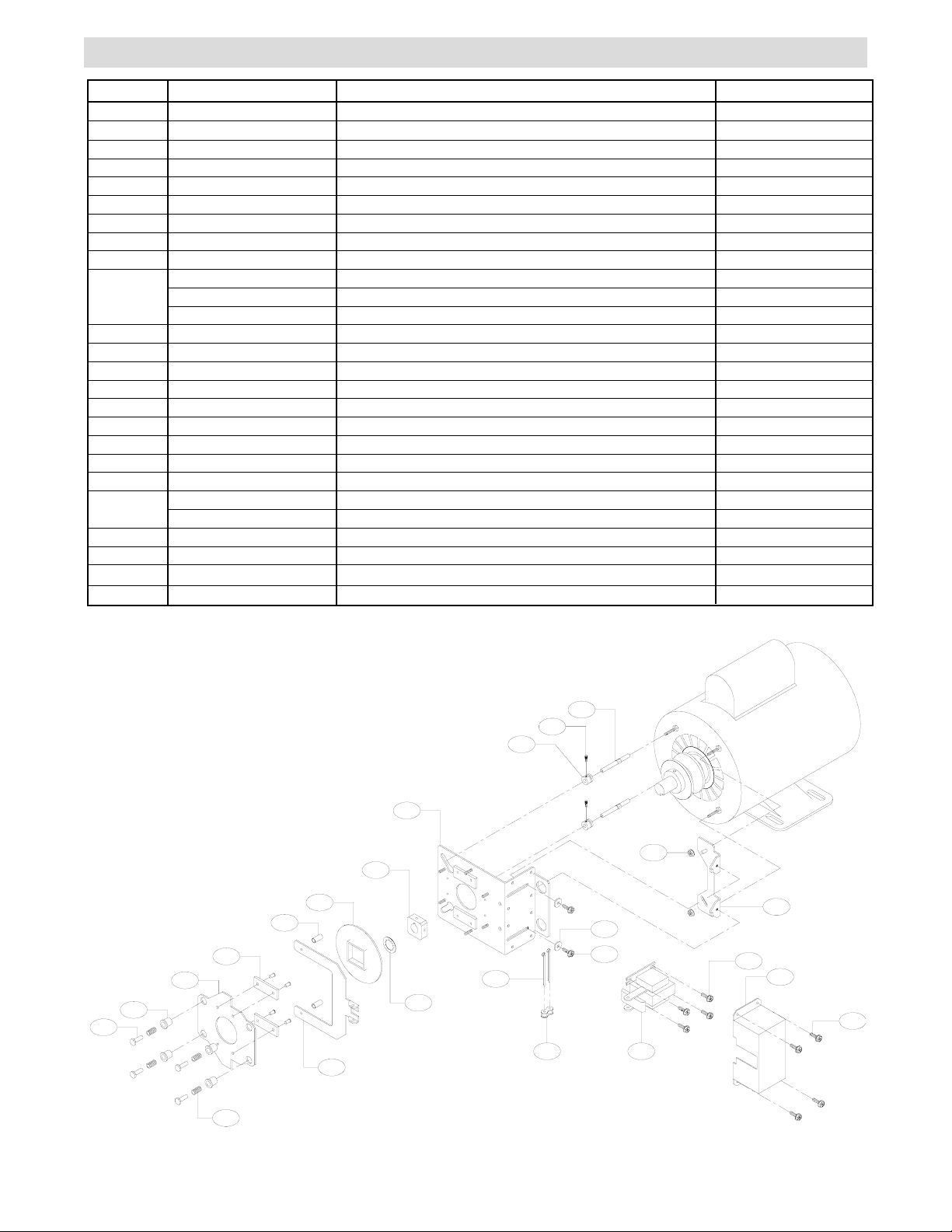

BRAKE KIT ILLUSTRATION

ITEM

1

2

3

4

5

6

7

8

9

*10

11

12

13

14

15

16

17

18

19

20

21

22

23

#24

PART NUMBER

10-10187

10-10190

10-10191

10-15039

11-10192

11-10193

12-14737

18-10194

19-48001

22-120

22-240

22-575

31-10186

31-15018

39-10182

75-10177

75-10184

75-15522

80-14414

82-SH06-03

82-WX10-08T

84-FN-08

84-FN-10

85-FW-10

86-CP04-112

87-P-062

75-11634

DESCRIPTION

BRAKE SOLENOID COVER

BRAKE RELEASE LEVER

BRAKE DISC

MOUNTING BRACKET, SUPPORT

SPRING CUP FOR BRAKE

BRAKE STUD

COLLAR, BRAKE ADJUSTMENT

SPRING, COMPRESSION

CHAIN,#48 X 1 PITCH

BRAKE SOLENOID 115V

BRAKE SOLENOID 230/460V

BRAKE SOLENOID 575V

SPACER,.20 I.D. X .31 O.D.

STANDOFF, BRAKE ASSEMBLY

BRAKE PAD

BRAKE HUB ASSY

BRAKE PRESSURE PLATE ASSEMBLY

BRAKE MOUNTING PLATE ASSEMBLY

KEY,3/16 X 3/16 X 2.0

SCREW, #6-32 X 3/16" SOCKET HEAD

SCREW, #10-32 X 5/8" FLANGE HEAD

NUT,#8-32 SERRATED FLANGE

NUT 10-32 SERRATED FLANGE

FLATWASHER #10

COTTERPIN 1/8" X 1-3/4" LONG

PUSH RING, 5/8"

BRAKE RELEASE CABLE ASSEMBLY

QUANTITY

1

1

1

1

4

4

2

4

1

1

1

1

2

2

2

1

1

1

1

2

10

2

2

2

2

1

1

* = Solenoid Shipped Depends on Operator Voltage

** = Flange Nuts used Depends on Motor Mounting Studs.

# = Shipped with Model “H” Operators (Refer to Page 4 for Instructions)

18

7

16

14

3

11

13

15

5

6

2

23

22

9

12

21

19

20

4

19

1

19

10

8

2

Page 3

WIRING INSTRUCTIONS FOR OUTBOARD BRAKE KITS

1. Disconnect the ends of wires running to the motor

and remove the conduit connector from the end of the

conduit, set off to the side for reinstallation.

2. Install the new double connector supplied to the

conduit where the connector was just removed in step

1. Reconnect the motor wires in the same manner as

they were removed in step 1.

3. Reinstall the conduit connector removed in step 1

to the new piece of conduit supplied.

MOTOR WIRING DIAGRAMS

ELECTRO MECHANICALSINGLE PHASE

3

1

P

8

BL

5

Y

2

4

GY

115V. CONNECTION

BL-BK

BL-BK

115V. BRAKE SOLENOID

4. Connect the (2) new blue/black wires supplied to

the brake solenoid. Feed the wires through the brake

mounting plate and then the conduit from step 4

(conduit connector side first). Secure the conduit

connector to the brake mounting plate.

5. Feed the brake wire through the new double

connector and secure the connector the conduit.

6. Wire the brake wires to the motor (refer to motor

wiring diagrams below). Secure the double connector

to the motor.

1

P

8

BL

5

Y

GY

2

4

230V. CONNECTION

BL-BK

3

BL-BK

230V. BRAKE SOLENOID

GY

BR

P

BR

Y

230V. CONNECTION

ELECTRO MECHANICALTHREE PHASE

J

J

BL-BK

OVERLOAD

BL-BK

(UP TO 3/4 HP)

575V. BRAKE SOLENOID

BL-BK

1

1

7

4

2

3

J

5

8

6

9

J

OVERLOAD

(UP TO 3/4 HP)

BL-BK

230V. BRAKE SOLENOID

GY

BR

P

BR

Y

2

7

8

936

460V. CONNECTION

BL-BK

4

J

5

J

OVERLOAD

(UP TO 3/4 HP)

BL-BK

460V. BRAKE SOLENOID

GY

BR

P

BR

Y

1

2

3

575V. CONNECTION

LOGIC CONTROL SINGLE PHASE

P

Y

BL

GY

1

8

5

4

115V. CONNECTION

BL-BK

BL-BK

115V. BRAKE SOLENOID

P

Y

GY

BL (Not Used)

1

5

4

230V. CONNECTION

BL-BK

BL-BK

230V. BRAKE SOLENOID

LOGIC CONTROL THREE PHASE

BL-BK

4

J

5

J

OVERLOAD

(UP TO 3/4 HP)

BL-BK

460V. BRAKE SOLENOID

GY

BR

P

BR

Y

230V. CONNECTION

BL-BK

1

1

7

4

2

3

J

5

8

6

9

J

OVERLOAD

(UP TO 3/4 HP)

BL-BK

230V. BRAKE SOLENOID

GY

BR

P

BR

Y

2

7

8

936

460V. CONNECTION

3

Page 4

RELEASE CABLE INSTALLATION INSTRUCTIONS

1. Locate the screw threads protruding through the

brake mounting plate opposite the brake solenoid.

Mount the new cable clamp supplied to the thread that is

second from the top and closest the motor and secure in

place with the #10 flange nut supplied.

2. Locate the release cable, cable sleeving and (2)

spring clamps. Install the two spring clamps onto one

end of the sleeving. Feed the release cable from the

side without the spring into the sleeving from the side

with the spring clamps.

3. Take the release cable assembly from above and

feed the release cable and sleeving through the cable

clamp installed in step 1, through the top hole of the

brake mounting bracket and brake mounting plate.

Once you get to the brake release lever feed only the

release cable through the top hole. Secure in place by

installing a #8 flatwasher and a 1/16” cable stop sleeve.

Secure cable stop sleeve in place by crimping down on it

with pliers (refer to detail 1).

DETAIL 1

#8 FLATWASHER

4. Locate the frame spacer that has the release chain

going through it. Take the end of the cable sleeving with

the two collars and slide it down into the notch in the

center of the bracket (be sure that one collar is on each

side of bracket). By releasing the collars, slide the

sleeving until there is at least 3” of sleeving protruding

out past the bracket. Secure in place by sliding the

collars as tight to the bracket as possible and snugging

up on the set screw (do not over tighten) refer to detail 2.

7. Pull release chain and release cable so that both are

taunt, being careful not to engage either of the two.

Connect the two together using the keyring on the end of

the spring.

TEST BRAKE RELEASE:

After the installation is complete pull the release chain to

insure the brake disengages. If the brake does not fully

disengage it can be adjusted by hooking the key ring

further away from the operator. Move the key ring one

chain link at a time, testing each time. Refer to drawing

below for additional help.

DETAIL 2

COLLAR W/SET SCREW

FIGURE 1

CABLE STOP SLEEVE

CABLE CLAMP

DETAIL 1

RELEASE CABLE

CABLE SLEEVING

CABLE SLEEVING

TO ADJUST TENSION ON BRAKE RELEASE, MOVE

KEYRING AWAY FROM OPERATOR ONE LINK AT A

TIME. BE SURE TO TEST AFTER EACH

ADJUSTMENT.

© 1999, The Chamberlain Group, Inc.

01-15519B All Rights Reserved

RELEASE CABLE

Loading...

Loading...