Page 1

Malfunctions

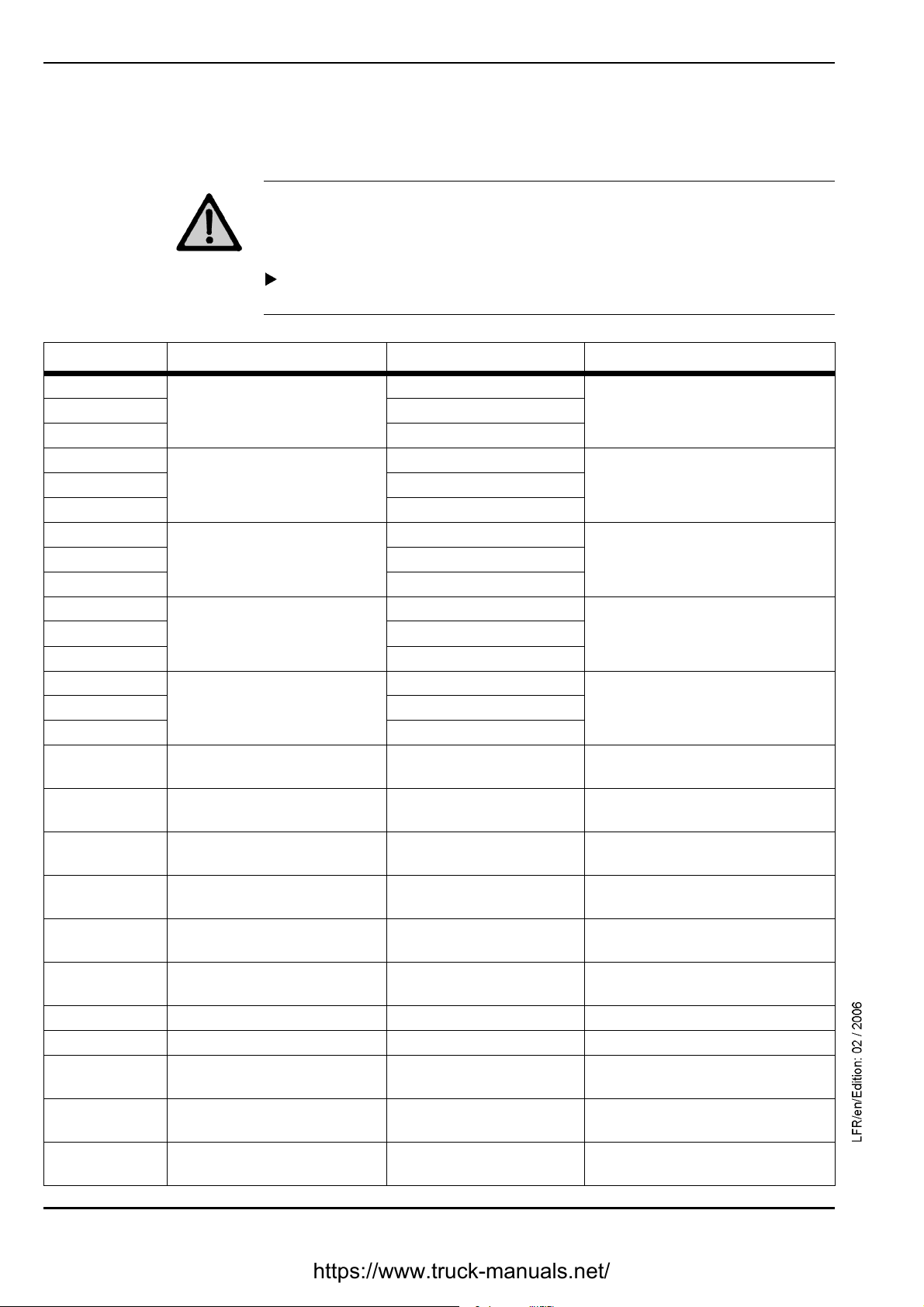

Error code charts

Operating instructions

4.1 Error code charts

Danger!

When switching over to emergency operation, the speed can no longer be changed

using the arrow keys on the monitoring screen. The servo control, parking brake

and swing gear brake can no longer be activated.

Please also note the subheading Emergency operations in the chapter Operating the machine in this regard.

Error code Effect Cause Measure / remedy

E 004 Engine coolant level Short circuit to earth Check engine coolant level.

E 005 Short circuit + 24 V

E 006 Cable break

E 010 Hydraulic oil level not being

E 011 Short circuit + 24 V

E 012 Cable break

E 013 Hydraulic oil temperature not

E 014 Short circuit + 24 V

E 015 Cable break

E 016 Gear oil temperature Short circuit to earth Check gear oil temperature.

E 017 Short circuit + 24 V

E 018 Cable break

E 022 Diesel engine RPM Short circuit to earth

E 023 Short circuit + 24 V

E 024 Cable break

E 027 Solenoid valve for power con-

E 033 Solenoid valve for cooler fan

E 036 Solenoid valve for flow con-

E 039 Solenoid valve for flow con-

E 042 Solenoid valve - Reserve

E 045 Solenoid valve - Pressure op-

E 068 Fan RPM Fan RPM defective

E 302 Keyboard No coding plug

E 303 Keyboard No CAN bus connection to

E 305 Keyboard No CAN bus connection to

E 308 Display No connection between

monitored.

being monitored.

trol (LR)

regulation (EV5)

trol (hydraulic pump 1) EV1

trol (hydraulic pump 1) EV2

(EV3)

erate (EV6)

Short circuit to earth Check hydraulic oil level.

Short circuit to earth Check that the radiator is not dirty.

Cable break

Cable break

Cable break

Cable break

Cable break

Cable break

BST

ESP01 board

keyboard and display

4 -

2

MJFCIFSS

R 984 C - Litronic / 10069859

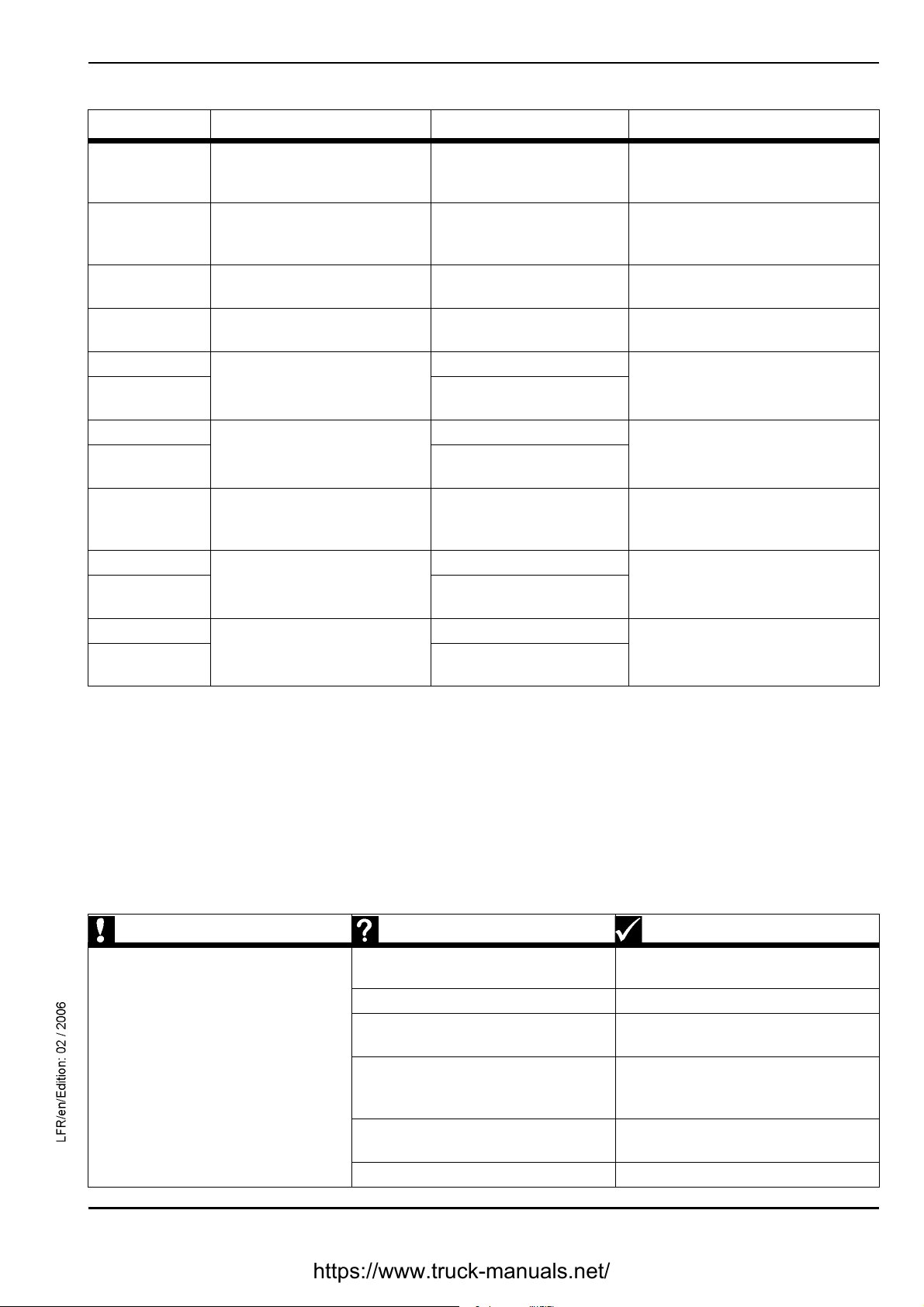

Page 2

Operating instructions

Error code Effect Cause Measure / remedy

E 309 Display No Software compatibility

between keyboard and

display

E 319 BST No compatibility between

hardware coding and software coding

E 321 BST No reception of recog-

nised machine typ by BBT

E 322 BST Unknown Hardware cod-

ing

E 442 Joystick left Short circuit + 24 V

E 443 Short circuit to earth or

Cable break

E 445 Joystick right Short circuit + 24 V

E 446 Short circuit to earth or

Cable break

E 450 The pressure for pressure-

less boom down movement

not being monitored.

E 454 Rotation gear speed Short circuit + 24 V

E 455 Short circuit to earth or

E 456 Fuel tank sensor Short circuit + 24 V

E 458 Short circuit to earth or

Cable break

Cable break

Cable break

Malfunctions

Faults and remedies

4.2 Faults and remedies

4.2.1 Diesel engine and fuel system

Fault / error Cause Solution

Diesel engine does not start Fuel tank almost or completely emp-tyFill tank and vent fuel system

Low pressure in tank Remove fuel filler cap

Fuel filter dirty Clean or change filter and vent fuel

system, drain fuel / clean tank

Outside temperature below 0°C For operation under specific climatic

conditions, see operating instructions

Starter motor not drawing through Check line connections, overhaul

starter motor

Batteries have no power Charge / replace

R 984 C - Litronic / 10069859

MJFCIFSS

4 - 3

Page 3

Malfunctions

Faults and remedies

Fault / error Cause Solution

Operating instructions

Engine starts but stops immediately

after or runs irregularly

Diesel engine emitting grey or black

smoke

Diesel engine continually emitting

while smoke (steam)

Diesel engine does not reach full

speed

Diesel engine becomes too hot Too little coolant Fill coolant, check for leaks

Diesel engine has insufficient oil

pressure

Note!

Switch off diesel engine immediately

Diesel engine consumes too much

oil

Oil in coolant or coolant in oil Consult customer service

Unusual noise / sounddevelopment

on exhaust side

Fuel tank empty (low pressure in

tank)

Fuel filter dirty Clean or change filter and vent fuel

Particularly in winter: too viscous

engine oil used

Dry-air filter dirty Clean or change main filter element

Air in fuel system Vent fuel system

Ventilation in fuel tank obstructed Clean

Fuel line bent Check line and repair if required

Dry-air filter dirty Clean or change filter

Water in combustion chamber Consult customer service

Speed adjustment not set to maximum value

Injection system is set incorrectly Consult customer service

Dry-air filter dirty Clean or replace filter

Bad fuel supply Clean or change fuel filter, check

Water pump defective Repair

Thermostats do not work Change thermostats

Coolant contaminated Clean coolant

Oil level too low Correct oil level

Oil pressure display faulty Change oil pressure switch

External leak on diesel engine Retighten screws, replace seals if

Exhaust system leaking Check exhaust system / repair

Fill tank and vent fuel system

system (tank)

Use engine oil suitable for the outside temperature

Set speed adjustment to maximum

value

lines, drain water from tank

required

4.2.2 Hydraulic system

Fault / error Cause Solution

Unusual noise / sounddevelopment

at hydraulic pumps

Note!

Switch off diesel engine immediately

Modes E and P showing lack of

power

4

4 -

Shutoff valve on hydraulic tank

closed

Hydraulic pumps taking in air Check oil level in hydraulic tank,

No power adjustment via proportional solenoid valve Y50

MJFCIFSS

Open stop cock

check intake lines for leaks

Unplug cable of Y50 connection, remove safety cotter pin, move lever

to emergency setting

R 984 C - Litronic / 10069859

Page 4

Operating instructions

Fault / error Cause Solution

Hydraulic oil temperature too high Coolant contaminated Clean coolant

Fan or fan control defective Rectify error / consult customer

service

Hydraulic oil level too low Oil loss Repair leaks, exchange hoses, refill

oil via return-line filter

Cannot drive Push the safety lever up Push the safety lever down

No direction of travel preselected Use drive selection switch in right

joystick to determine direction of

travel

Parking brake pressure switch defective

Parking brake not released Release parking brake using switch

Parking brake will not release despite switch being operated

Service brake engaged Release service brake

Slewing gear not functioning No servo control Push the safety lever down

Slewing gear brake activated Push the safety lever down

No working movement No servo control Push the safety lever down

No servo pressure present Consult customer service

No pump high pressure present Consult customer service

Consult customer service

Servo pressure present:

Operate emergency function Y6

Servo pressure not present:

Consult customer service

Switch on servo control

Release slewing gear brake

Switch on servo control

Malfunctions

Faults and remedies

4.2.3 Transmission

Fault / error Cause Solution

Oil flowing out on track rollers, support rollers or leading wheel

Insufficient crawler tracking on leading wheel

Crawler jumps off or over Crawler tension too low / crawler

Correctly tensioned crawler losing

tension quickly during use

Track roller or support roller sticking Running gear extremely dirty Clean running gear

Seal defective Replace seal

Leading wheel tracking on track roller mounting has too much play

wheel worn

Crawler tensioning cylinder defective

Adjust the leading wheel tracking

play

Adjust crawler tension

Check crawler tensioning cylinder,

change if required or seal (only authorized specialist personnel)

R 984 C - Litronic / 10069859

MJFCIFSS

4 - 5

Page 5

Malfunctions

Faults and remedies

4.2.4 Electrical system

Fault / error Cause Solution

Operating instructions

Battery charge telltale light does not

goes out

Batteries do not charge or charge

poorly

Telltale light or display instrument

not functioning or functioning incorrectly

Some or all functions on instrument

panel drop out

Diesel speed adjustment via operating keypad (mode and arrow keys)

not functioning

Automatic idling not functioning,

speed does not reduce

Servo control cannot be activated

using switch

Parking brake cannot be released

using switch

Slewing gear brake cannot be released using switch

Drive belt for alternator loose or torn Tension or replace drive belt

Alternator defective Replace alternator

Batteries defective Replace batteries

Battery connections dirty / oxidised Clean battery connections

Cable loose or damaged Connect or replace cable

Bulb burnt out, display instrument

defective

Plug connector separated or damaged, earth lead interrupted, short

circuit fuse defective

Automatic idling switch S20 is activated

Excavator speed adjustment electronics do not function

No signal emits from speed sensor

B12

Permanent sensor signal Consult customer service

Switch S20 is deactivated Activate switch S20

Excavator electrics faulty Switch on emergency function using

Replace defective part

Mount plug connector correctly or

change, rectify short circuit, replace

fuse or activate overload cut-outs

Touch the joystick or deactivate automatic idling switch S20.

Switch the emergency function over

from AUTO to MANU using

switch S71 in the right control panel.

Set speed using switch S72. Emergency function display appears on

monitoring screen. Consult customer service.

switch S73 in the right control panel

Caution: Servo circuit and brake circuit can only be switched off using

the safety lever. Keypad not functioning. Consult customer service.

4.2.5 Heating/air-conditioning system

Fault / error Cause Solution

Heating not giving out warm air Shutoff valves for coolant line on

diesel engine closed

Engine not at operating temperature Bring engine to operating tempera-

Heating fan does not operate No power supply Check fuse and wiring / repair

Fan motor defective Change fan motor

Only low air flow in cab Outside air filter / recirculated air fil-

ter dirty

Air vent closed Open air vent

6

4 -

MJFCIFSS

Open shutoff valve

ture

Clean air intake opening, replace

outside air filter

R 984 C - Litronic / 10069859

Page 6

Operating instructions

4.2.6 Work equipment

Fault / error Cause Solution

Cylinder stretches when loaded Piston seal in cylinder defective Overhaul cylinder

Bearing clearance too high on

equipment

Grab / bucket does not move Valve block on tilting cylinder incor-

Add-on unit cannot be turned / rotated / operated

Bearing points worn out Replace bearing parts

Switch over valve block

rectly switched

Auxiliary function has not been released

Lines are not connected Connect lines

Release auxiliary function using

switch S19

Malfunctions

Faults and remedies

R 984 C - Litronic / 10069859

MJFCIFSS

4 - 7

Loading...

Loading...