Page 1

Liebherr Mining

Ground Engaging Tools

made for Liebherr Buckets

Page 2

Ground Engaging Tools

2

Ground Engaging Tools Range

• 3 tooth proles in 5 tooth sizes

• Adapter and corner adapter

• Wear cap and corner wear cap

• Wing and lip shroud

Innovative Design

• Self-sharpening teeth

• One single locking system

• Truly hammerless system

• Interchangeable wing shrouds

and corner wear caps

90° tool maneuver

Page 3

Liebherr Mining GET Solution - Outline

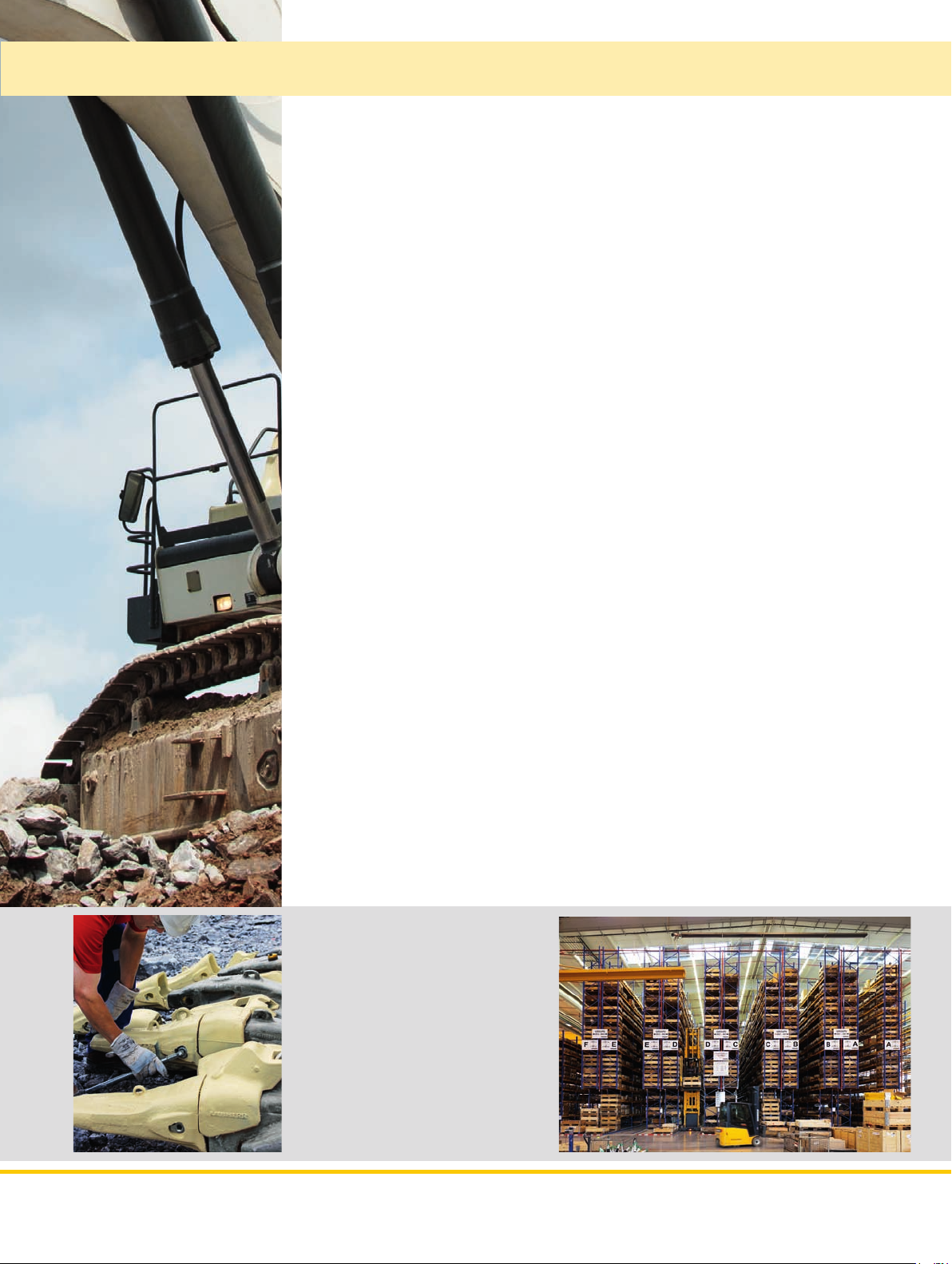

With an ever-increasing productivity focus, Liebherr has developed a complete

mining Ground Engaging Tools solution to complement Liebherr’s mining backhoe

and face shovel bucket design. A synergy that enables easy material penetration

while extending the life of the bucket.

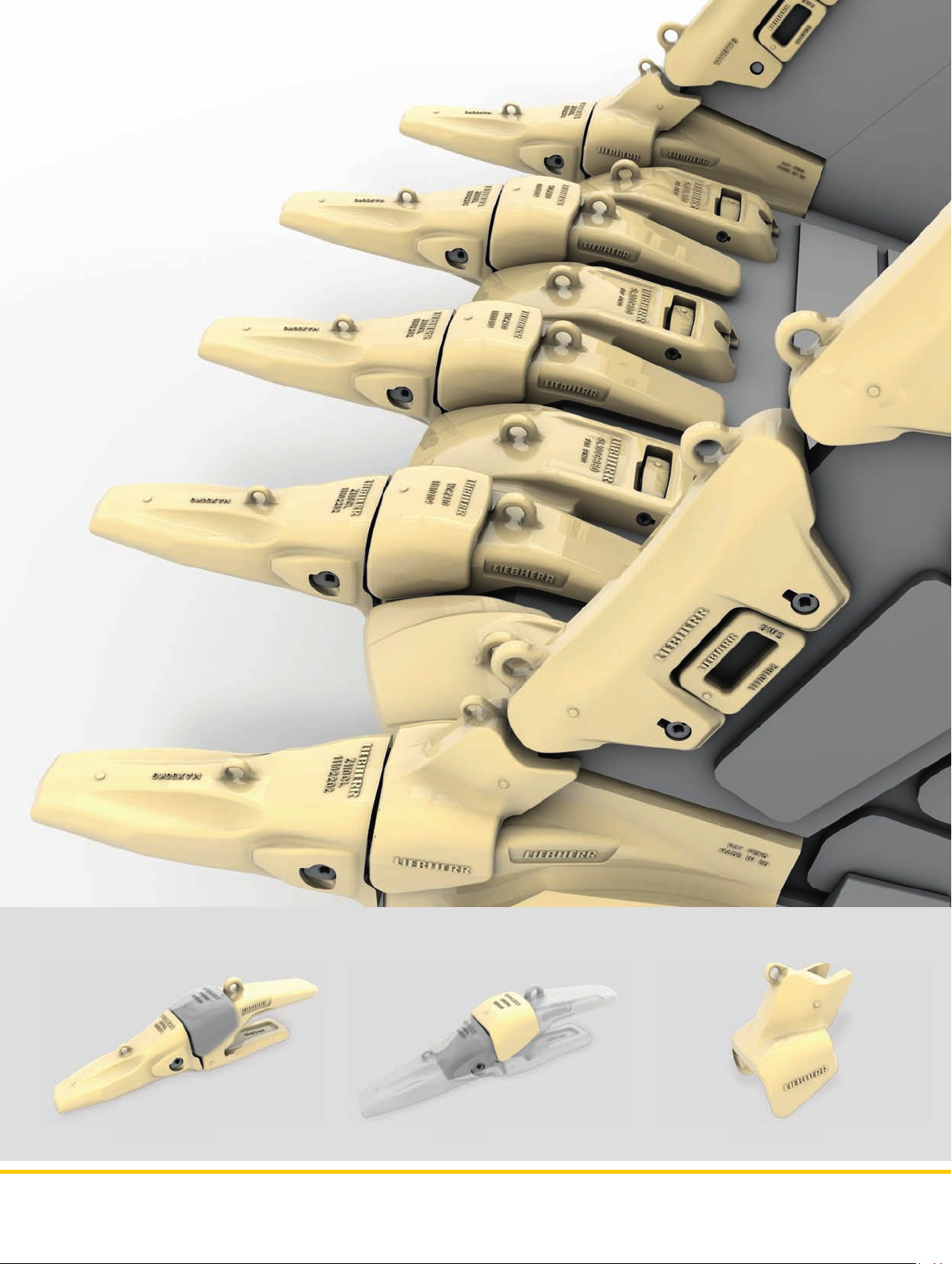

Three Tooth Profiles, in Five Sizes

The Z system is available in three proles to cover an extensive range of applications types, from well-blasted material to very hard ground. Liebherr GET solution

is compatible with mining backhoes and face shovels from R 9100 up to R 9400.

Innovative Design

Thanks to the self-sharpening tooth design, machine operators will experience an

optimal combination of bucket penetration and high ll factor over the teeth lifetime. To reduce parts inventory Liebherr has designed a single wing shrouds and

corner wear caps for each model, interchangeable from left hand side, right hand

side and top to bottom.

One Single Locking System

To increase machine uptime and reduce tooling to one unique extraction tool, the

teeth, shrouds and wing shrouds are equipped with one single locking system. In

addition the wear cap does not require any locking system as it is slipped on the

adaptor and locked by the tooth.

Truly Hammerless System

With its unique hammerless locking system, the replacement of the teeth and the

wing shrouds is simple: the securing pin, the tooth, and the adapter are quickly

locked by a 90° tool maneuver.

Customer Benefits

• Better supply chain coordination

• Higher productivity

• Reduced operating and owning costs

• Reduced parts inventory

• Maximized machine uptime

Easy Serviceability

• One single locking system

• Truly hammerless system

• A simple tooth exchange

• A single person can release it

Proactive Service Supplying

• Global network of Liebherr afliates

and exclusive representatives

• Customer specic requirement study

• Collaborative solution development

Ground Engaging Tools

3

Page 4

Ground Engaging Tools

Tooth and Adapter

Wear Cap

Corner Wear Cap

Page 5

5

Ground Engaging Tools

The Z system is available in three proles to cover an extensive range of application

types, from well-blasted material to very hard ground.

Tooth Profiles

Tooth Profiles

Tooth Sizes

Available in ve different sizes, Liebherr GET are compatible with mining backhoe

Wing Shroud

CL-Prole

The long-drawn pointed shape provides a sharp

CR-Prole

The wide, thick tooth sole delivers long ser vice life in

P-Prole

The pointed shape offers optimal penetration for very

XHD

Page 6

Ground Engaging Tools

6

Page 7

Innovative Design

With its unique design philosophy and innovative approach, the Liebherr Mining

Ground Engaging Tools solution is able to exceed the most stringent customer

expectations. The Liebherr solution reduces owning & operating cost by extending

the equipment life.

Bucket Side Wall Protection

The rounded area of both wing shroud and corner wear cap is fully adaptable

to each bucket side plate shape. To reduce downtime, the corner wear cap is

mechanically attached to the corner adapter and can be removed independently

from the lower wing shroud.

Thanks to the wing shroud “peanut” concept, the material is distributed on both

ends to maximize penetration over the lifetime of the part.

Self-Sharpening Design

Machine operators will experience an optimal combination of bucket penetration

and high ll factor over the teeth lifetime, thanks to the self-sharpening tooth design.

One Single Locking System

To increase machine uptime and reduce tooling to one unique extraction tool, the

teeth, shrouds and wing shrouds are equipped with one single locking system. In

addition the wear cap does not require any locking system as it is slipped on the

adaptor and locked by the tooth.

Truly Hammerless System

A single and easy-to-carry double side extraction tool designed by Liebherr to

match the complete range of tooth sizes.

Tooth Size

Socket Size

Z90 Z100 Z 110 Z120 Z140

1/2’’ 3/4’’

Ground Engaging Tools

7

Page 8

1 2 3

Unlock the securing pin with the locking

spanner.

Ground Engaging Tools

8

Remove the securing pin from the mounting. Draw the worn tooth from the tooth adapter.

Page 9

Easy Serviceability

The Liebherr Z Tooth System is a new, innovative and patented tooth system from

Liebherr. It consists of tooth adapter, tooth, securing bolt with a locking arrangement and a protective plug. All that is required to replace the tooth is one simple

tool – a truly hammerless system.

r

e

v

u

e

n

a

M

l

o

o

T

°

0

9

d

e

l

l

a

t

s

n

i

h

t

o

o

T

Tooth

Exchange

9

0

°

T

o

o

l

M

a

n

e

u

v

e

r

t

u

O

n

i

P

g

n

i

r

u

c

e

S

S

e

c

u

r

i

n

g

P

i

n

I

n

The securing pin, the tooth, and the adapter can be connected in no time, a single

person can effortlessly release and remove the tooth without the need for brute force.

Note

• The wear cap and corner wear cap are slipped on the adaptors and locked by

the teeth; these protectors need to be positioned before tooth assembly.

• The lip and wing shrouds are attached with one unique locking system, the

exchange procedure remains the same and no other tools are required.

h

t

o

o

T

4 5 6

t

n

e

m

e

c

a

l

p

e

R

Slide the new tooth onto the tooth adapter.

Slide the securing pin into the mounting. Lock the securing pin with the locking

spanner.

Ground Engaging Tools

9

Page 10

Application

Application

XHD | Heavy Duty Rock

Application

The Liebherr buckets combined with Liebherr GET are

vertically integrated mining solution.

Page 11

Auckland

Townsville

Tehran

Tashkent

Almaty

Antofagasta

Telfs

Jeddah

Windhoek

Thunis

Tarkwa

Accra

Abidjan

Adelaine

factory and eld testing program to diagnose technical constraints that

The reliability of our eld testing program relies on repeatability and

As a global mining solutions provider, Liebherr is more

than a mining equipment manufacturer. Ensuring a per

With a truly global network composed of Liebherr afli

ters ensure that customers are always well looked after.

Page 12

Wide Product Range

The Liebherr Group is one of the largest construction

To provide consistent, top quality products, Liebherr

techno

Worldwide and Independent

to a group of more than 120 companies with over

www.liebherr.com

+33 369 49 20 00, Fax +33 369 49 23

www.liebherr.com, E-Mail: info.lec@liebherr.com

www.facebook.com

/

Subject to technical modications. Illustrations may incl

Loading...

Loading...