Page 1

Crawler excavator R 976

Operating Weight with Backhoe Attachment: 85,300 – 95,500 kg

Operating Weight with Shovel Attachment: 90,800 – 92,600 kg

Engine Output: 400 kW / 544 HP

Bucket Capacity: 2.00 – 6.60 m³

Shovel Capacity: 4.40 – 5.60 m³

Page 2

Equipment

•Caststeelelements

•Greaterresistancetostresses

•Longerservicelife

•Safetycheckvalvesforstickandboom

cylinderswithintegratedregeneration

forlessfuelconsumption

Tools

•Differentlevelsofprotectiontosuit

thedifferentareasofapplication

•NewLiebherrZ-typetoothsystem

R 976 Litronic

2

Page 3

Operator’s cab

•Newcomfortableandergonomicdesign

•7”highdenitioncolourtouchscreen

•Widerthanthecabinthesmallexcavatorsrange

•Bullet-proofpanelsatthefrontand

intheroofasstandard

•OptionalFOPSandFGPSprotectiveguards

Accessibility

•Maintenanceplatformin

theenginecompartment

•Broad,anti-slipsidecatwalksasstandard

•Newlydesignedundercarriagesteps

foralongerservicelife

Undercarriage

•Robuststructurethankstothemorerigidprole

•Improvedself-cleaningcapacity

•Moldedtwo-toothsprocketforalongerservicelife

•Twotypesofundercarriageavailable:anHDxed-track

gaugeandLC-Vvariable-trackgauge

R 976 Litronic

3

Page 4

Equipment

•Caststeelparts

•Parallelkinematicsforpowerfulandregulardigging

•Bucketcylinderspositionedundertheequipment

forbetterprotectionagainsttheelements

•Safetyvalvesonboomcylinderforpipe

burstprotection

Buckets

•Thefrontshovelistheperfectshapefordiggingdeep

intothematerialandforahighllingrate

•Severallevelsofprotectionforthefrontshovel,

dependingonrequirements

R 976 Litronic

4

Page 5

Operator’s cab

•Newcomfortableandergonomicdesign

•7”high-resolutioncolourtouchscreen

•Widerthanthecabinthesmallexcavatorsrange

•Bullet-proofpanelsatthefrontandintheroofasstandard

•OptionalFOPSandFGPSprotectionguards

•Operator’scabwithaxedriserforafull

viewovertheworkarea

R 976 Litronic

5

Page 6

Technical Data

Engine

Rating per ISO 9249

������������������������������

Model

��������������������������������

Type

Bore/Stroke

Displacement

Engine operation

Exhaust gas treatment

�����������������������������

Cooling

Air cleaner

Fuel tank

Urea tank

Electrical system

Voltage

Batteries

Starter

Alternator

Engine idling

Motor management

�������������������������

���������������������������

��������������������������

�������������

�����������������

���������������

�����������������

����������

�����������������������

���������������������

������������������������

���������������������

�����������������

��������������

400 kW (544 HP) at 1,800 RPM

Liebherr D 9508 A7 SCR

8 cylinder V engine

128/157 mm

16.16 l

4-stroke diesel

Common-Rail

SCR system (Selective Catalytic Reduction)

emission standard stage IIIB / Tier 4i

water-cooled and integrated motor oil cooler,

after-cooled and fuel cooled

dry-type air cleaner with pre-cleaner, primary and

safety elements

1,498 l

140 l

24 V

2 x 180 Ah/12 V

24 V/7.8 kW

three phase current 28 V/100 A

sensor-controlled

connection to the integrated excavator system

controlling via CAN-BUS to the economical

utilisation of the service that is available

Hydraulic System

Hydraulic pump

for attachment and

travel drive

Max. flow

Max. pressure

Pump regulation

Hydraulic pump

for swing drive

Max. flow

Max. pressure

Hydraulic tank

Hydraulic system

Hydraulic oil filter

Hydraulic oil cooler

MODE selection

RPM adjustment

Tool Control

�������������������

���������������������

���������������

������������������

��������������

���������������������

���������������

��������������������

�����������������

�����������������

��������������

������������������

�����������������

�����������������������

two Liebherr variable flow, swash plate pumps

2 x 496 l/min.

350 bar

electro-hydraulic with electronic engine speed

sensing regulation, pressure compensation, flow

compensation, automatic oil flow optimizer

reversible, variable flow, swash plate pump,

closed-loop circuit

315 l/min.

350 bar

536 l

1.134 l

2 full flow filters in return line with integrated fine

filter area (5 µm)

compact cooler for water cooler, after-cooler, fuel

cooler and transmission pump oil, sandwiched

with cooler for oil and condenser of air-condition-

ing with hydrostatically controlled fan drives

adjustment of engine and hydraulic performance

via a mode pre-selector to match application for

especially economical and environmentally

friendly operation or for maximum digging perfor-

mance and heavy-duty jobs

stepless adjustment of engine output via RPM at

each selected mode

10 preadjustable pump flows and pressures for

add-on tools

Hydraulic Controls

Power distribution

Flow summation

Closed-loop circuit

Servo circuit

Attachment and swing

Travel

– speed pre-selection

Additional functions

���������������

������������

�����������������������

�������������������������

���������

����

�������������

via control valves in single block with integrated

safety valves

to boom and stick

for uppercarriage swing drive

electro-hydraulic control

proportional via joystick levers

– proportional via foot pedals or removable

handlevers

via foot pedals or joystick toggle switch

Swing Drive

����������������������������

Drive by

Transmission

Swing ring

Swing speed

Swing torque

Holding brake

Option

����������������������

�������������������������

����������������������

���������������������

��������������������

������������������������������

Operator’s Cab

���������������������������������

Cab

Operator’s seat

Control system

Operation and displays

Air-conditioning

Noise emission

ISO 6396

2000/14/EC

�������������������

�������������������

���������

������������������

���������������������������

������������������������

Undercarriage

Version

�����������������������������

HD

LC-V

Drive

Transmission

Travel speed

Net drawbar pull on crawler

Track components

Track rollers/Carrier rollers

Tracks

Track pads

Digging locks

Brake valves

Lashing eyes

��������������������������

��������������������������������

���������������������

����������������������

���������������

������������������������������

������������������������

���������������������

����������������������

����������������������

Attachment

��������������������������������

Type

Hydraulic cylinders

������������������������������

Pivots

Lubrication

Hydraulic connections

�����������������������������

Bucket

��������������

������������������������

����������

Liebherr swash plate motor with integrated brake

valves

Liebherr compact planetary reduction gear

Liebherr, sealed single race ball bearing swing

ring, internal teeth

0 – 5.9 RPM stepless

295 kNm

wet multi-disc (spring applied, pressure released)

pedal controlled positioning brake

work headlights integrated in the ceiling, a door

with a side window (can be opened on both

sides), large stowing and depositing possibilities,

shock-absorbing suspension, sounddamping

insulating, tinted laminated safety glass, separate

window shades for the sunroof window and wind-

screen, 12 V plug, storage bins, lunchbox, cup

holder

Liebherr-Comfort seat, airsprung with automatic

weight adjustment, vertical and horizontal seat

damping including consoles and joysticks. Seat

and armrests adjustable separately and in combi-

nation, seat heating as standard

arm consoles, swinging with the seat

large high resolution colour display with selfexpla-

natory operation via touch screen, video, versatile

adjusting, control and monitoring facilities, e.g.

climate control, implement and tool parameters

standard automatic air-conditioning, ambient air

function, fast de-icing and demisting at the press

of a button, air vents can be operated via a menu;

ambient air and fresh air filters can be easily

replaced and are accessible from the outside;

heating- cooling unit, designed for extreme out-

side temperatures, sensors for solar radiation,

inside and outside temperatures

LpA (inside cab) = 71 dB(A)

LWA (surround noise) = 109 dB(A)

gauge 3,600 mm

gauge 3,590 mm

Liebherr swash plate motors with integrated

brake valves on both sides

Liebherr planetary reduction gears

low range – 2.7 km/h

high range – 4.3 km/h

����

538 kN

D 9 G, maintenance-free

�����

HD: 8/2

LC-V: 9/3

sealed and greased

double grouser

wet multi-discs (spring applied, pressure

released)

outside the travel motor

integrated

combination of resistant steel plates and cast

steel components

Liebherr cylinders with special seal-system,

shock protection

sealed, low maintenance

automatic central lubrication system (except link

and tilt geometry)

pipes and hoses equipped with SAE split-flange

connections

standard equipped with Liebherr tooth system

6 R 976 Litronic

Page 7

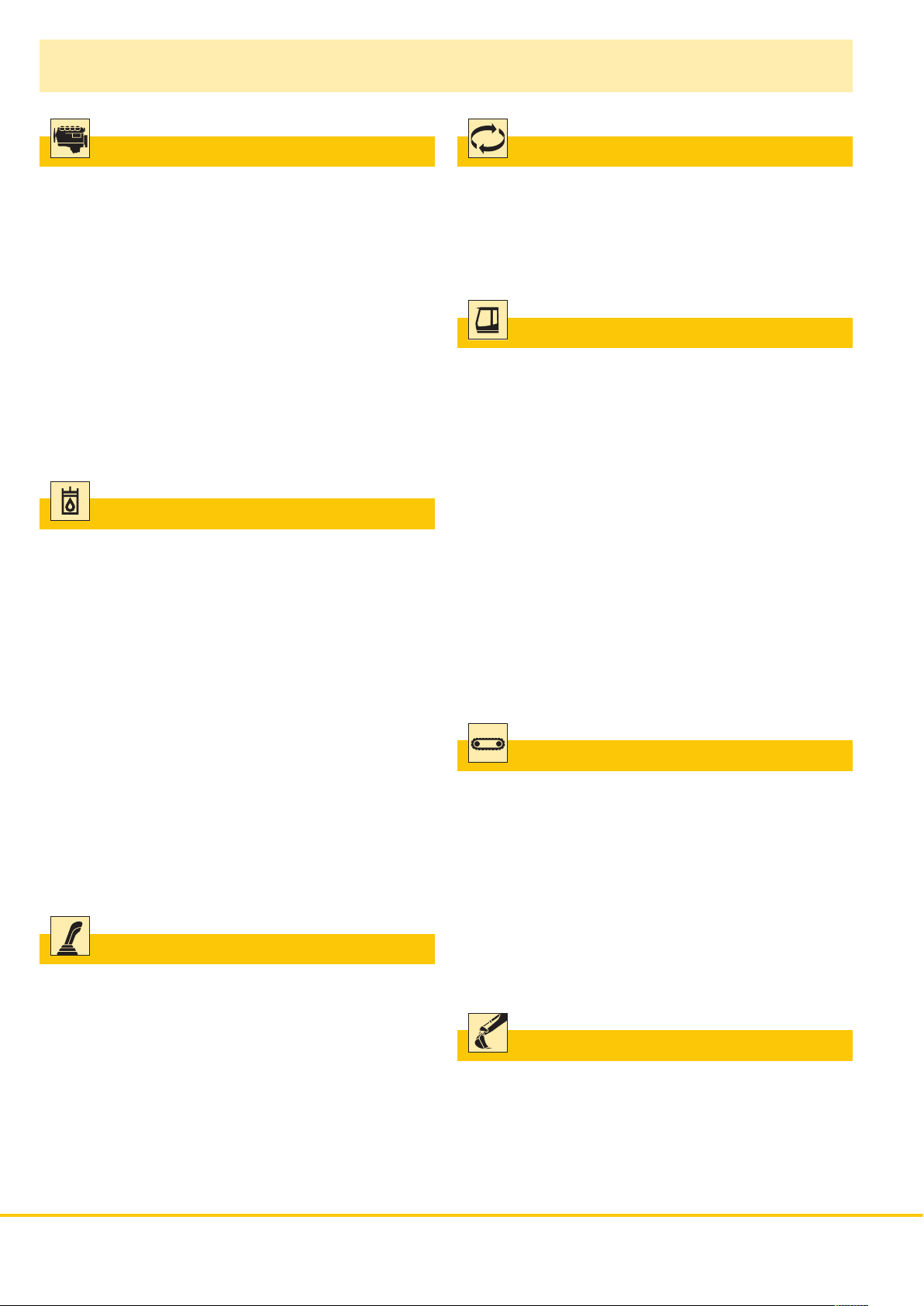

Dimensions

W

A2

E

D

A1

A

L

U

V

X

HD mm LC-V mm

A 3,565 3,565

A1 4,355 4,355

A2 4,730 4,730

C 3,695/3,890* 3,835/4,030*

D 4,515 4,515

E 4,640 4,640

H 3,725 3,865

K 1,620 1,755

L 4,770 5,160

P 1,460 1,495

Q 682 955

S 3,600 2,750**/3,590

U 5,955 6,335

N 500 600 750 500 600 750

B 4,290 4,290 4,350 3,490** 3,490** 3,500**

G 4,540 4,540 4,540 3,870** 3,870** 3,870**

Z 7,490 7,680

* with FOPS top guard

** transport position

H

K

Q

N

S

Z

B

G

HD-Undercarriage

Stick Mono Mono Mono

Length Boom Boom Boom

7.20 m 8.60 m 10.50 m

m mm mm mm

V 2.90 8,450 – –

3.30 8,200 9,950 12,050

3.80 8,100 9,850 11,900

4.70 7,950 9,650 11,700

5.80 – 9,650 11,550

W 2.90 5,100 – –

3.30 5,250 5,450 5,750

3.80 5,550 5,600 5,900

4.70 6,050 6,000 6,100

5.80 – 6,800 6,800

X 2.90 13,800 – –

3.30 13,500 14,900 16,800

3.80 13,400 14,750 16,650

4.70 13,150 14,550 16,450

5.80 – 14,150 16,150

LC-V-Undercarriage

Stick Mono Mono Mono

Length Boom Boom Boom

7.20 m 8.60 m 10.50 m

m mm mm mm

V 2.90 8,600 – –

3.30 8,350 10,100 12,200

3.80 8,200 10,000 12,050

4.70 8,050 9,800 11,850

5.80 – 9,750 11,700

W 2.90 5,150 – –

3.30 5,350 5,500 5,850

3.80 5,600 5,700 6,000

4.70 6,150 6,000 6,200

5.80 – 6,750 6,800

X 2.90 13,800 – –

3.30 13,500 14,900 16,800

3.80 13,450 14,750 16,650

4.70 13,250 14,550 16,500

5.80 – 14,250 16,250

C

P

R0013

R 976 Litronic 7

Page 8

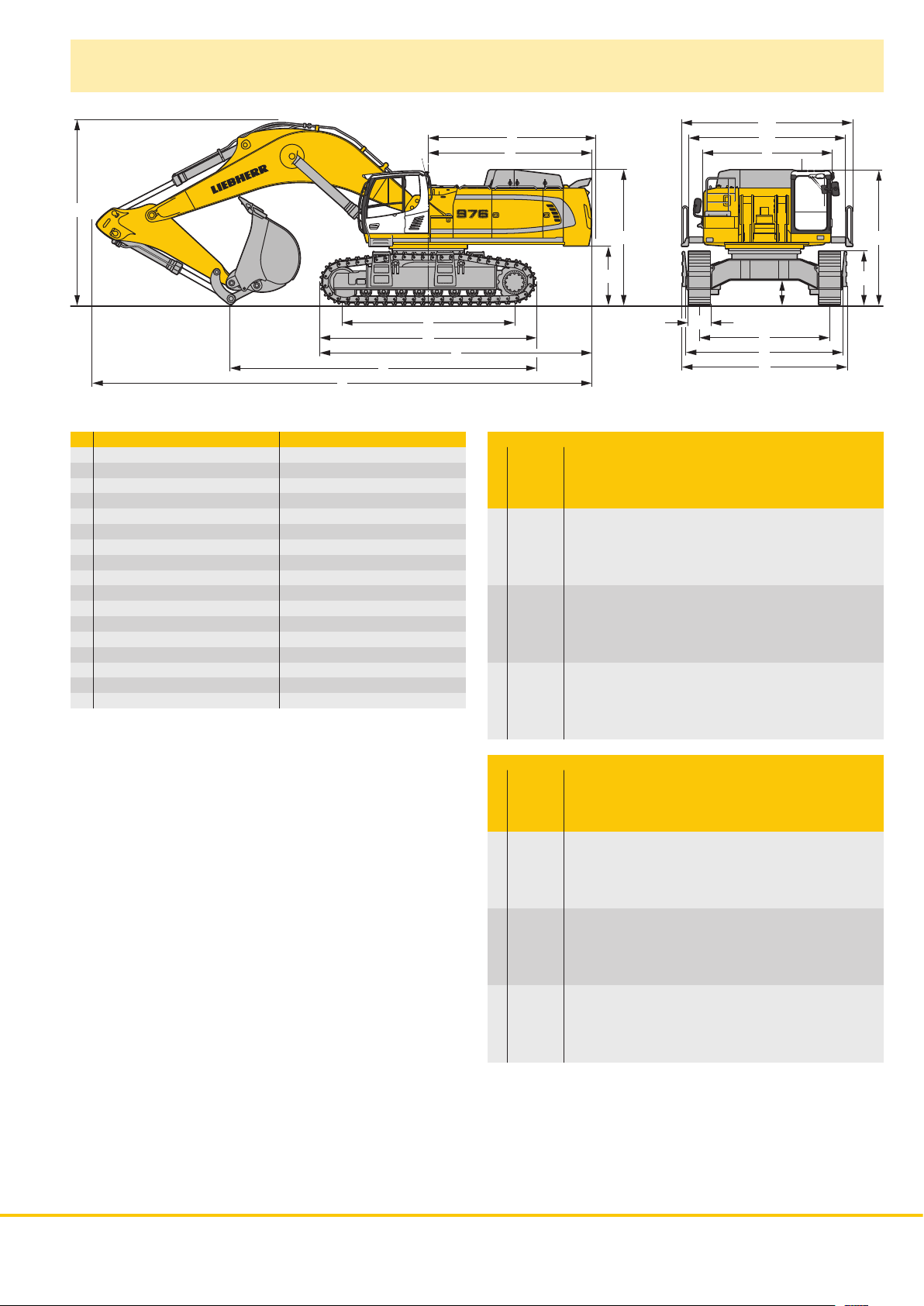

Backhoe Bucket

with Mono Boom 7.20 m

m

-10

-15

-20

-25

-30

ft

14

45

13

40

12

11

35

10

30

9

8

25

7

20

6

5

15

4

10

3

2

5

1

0

0

-1

-5

-2

-3

-4

-5

-6

-7

-8

-9

-10

1

2

3

4

6789101112131415

R0014

0 m1

2345

5101520253035404550

0 ft

Digging Envelope 1 2 3 4

Stick length m 2.90 3.30 3.80 4.70

Max. digging depth m 7.60 8.00 8.50 9.40

Max. reach at ground level m 12.35 12.75 13.20 14.10

Max. dump height m 8.10 8.35 8.60 9.05

Max. teeth height m 12.45 12.70 12.95 13.40

Digging force ISO kN 390 361 329 284

t 39.8 36.8 33.5 28.9

Breakout force ISO kN 485 485 485 485

t 49.4 49.4 49.4 49.4

Operating Weight

and Ground Pressure

Operating weight includes basic machine with mono boom 7.20 m,

stick 2.90 m and bucket 5.20 m

Undercarriage HD LC-V

Pad width mm 500 600 750 500 600 750

Weight kg 85,300 86,000 87,100 90,400 91,200 92,300

Ground pressure kg/cm

Optional: heavy counterweight

(heavy counterweight increases the operating weight by 1,900 kg and

ground pressure by 0.04 kg/cm

3

(4,600 kg).

2

1.65 1.38 1.12 1.62 1.36 1.10

2

)

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

HD-Undercarriage

Cutting

width

Capacity

ISO 7451

mm m

3

1,800 3.80 4,000

1,950 4.30 4,200

1)

2,150 4.80 4,450

2,300 5.20 4,600

STD

2,300 5.80 4,800

2,600 6.60 5,100

1,800 3.60 4,400

1,950 4.10 4,750

2)

2,150 4.60 5,050

2,300 5.20 5,400

HD

2,300 5.60 5,550

2,400 6.20 5,900

1,950 4.20 5,250

3)

2,150 4.70 5,550

2,300 5.20 5,850

HDV

2,300 5.70 6,400

Weight

kg

2.90 3.30 3.80 4.70 2.90 3.30 3.80 4.70

X X X Y X X X Y

X X X Y X X X Y

X X Y V X X Y V

Y Y Y y X X Y y

Y Y V y Y Y V y

V V y v V V y v

X X X Y X X X Y

X X X V X X X Y

X X Y V X X Y V

Y Y V y Y Y Y y

Y V V y Y Y V y

V V y v V V y v

X X X v X X X v

Y Y Y v X X Y v

Y Y V v Y Y V v

V V y v V V y v

* Indicated loads are based on ISO 10567 max. stick length, lifted 360° on firm

1)

Standard bucket with Liebherr teeth Z 90

2)

HD bucket with Liebherr teeth Z 90

3)

HDV bucket with Liebherr teeth Z 90

Other backhoes available on request

Max. material weight

X

= ≤ 2.2 t/m3,

Y

Stick length (m)

= ≤ 1.8 t/m3,

V

= ≤ 1.5 t/m3,

y

= ≤ 1.2 t/m3,

LC-V-Undercarriage

Stick length (m)

v

= not authorized

8 R 976 Litronic

Page 9

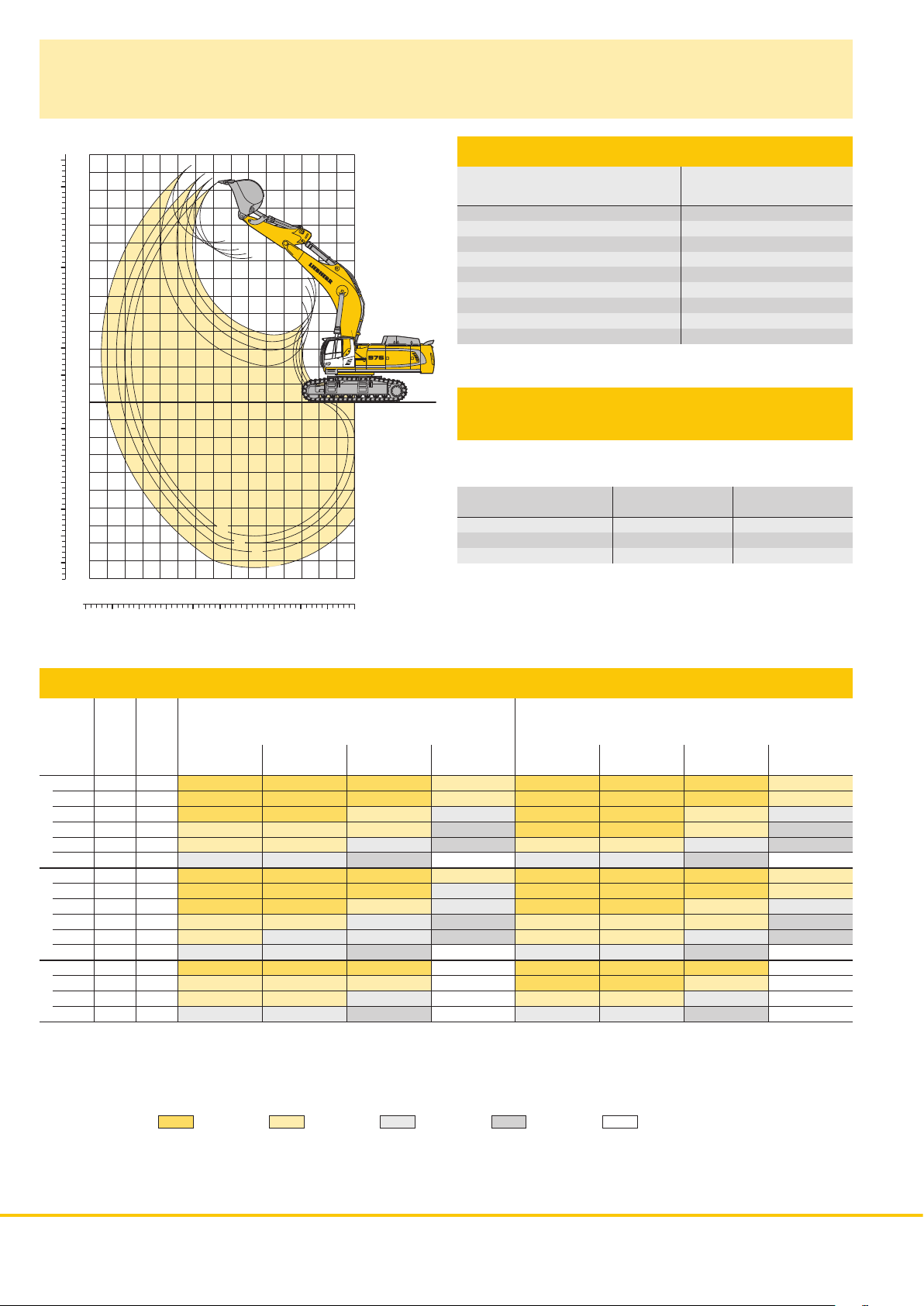

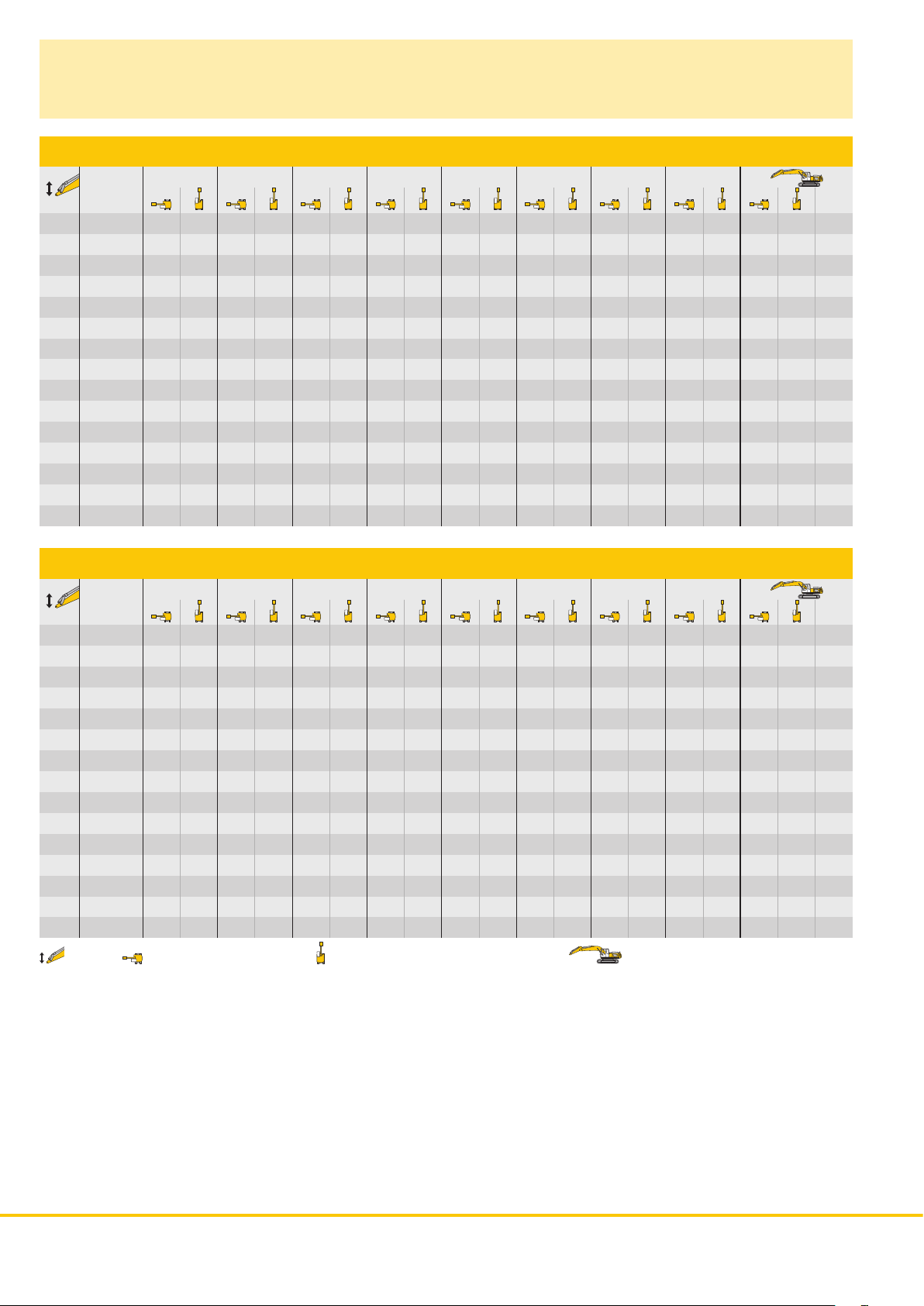

Lift Capacities

with Mono Boom 7.20 m

Stick 2.90 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

23.7* 23.7*

23.5* 23.5*

21.6* 21.6* 21.3* 21.3*

21.6* 21.6* 21.2* 21.2*

21.8* 21.8* 19.1 20.4* 19.1 20.2*

21.9* 21.9* 20.0 20.8* 19.7 20.2*

27.4* 27.4* 23.3* 23.3* 18.9 21.1* 16.6 19.9*

27.7* 27.7* 23.5* 23.5* 19.7 21.1* 17.2 19.9*

31.5* 31.5* 24.1 25.3* 18.3 22.0* 15.2 19.5

31.9* 31.9* 25.1 25.5* 19.1 22.0* 15.8 20.3*

31.6 35.1* 22.9 27.3* 17.6 22.9 14.4 18.7

32.9 35.4* 23.9 27.5* 18.4 23.0* 15.1 20.6*

30.2 36.9* 22.0 28.6* 17.1 22.3 14.3 18.6

31.6 37.0* 23.0 28.7* 17.9 23.7* 15.0 20.8*

29.6 36.7* 21.4 28.6 16.7 21.9 14.7 19.2

31.0 36.6* 22.5 28.8* 17.5 23.5* 15.6 20.9*

38.5* 38.5* 29.5 34.9* 21.3 27.8* 16.6 21.8 15.9 20.8

40.4* 40.4* 30.9 34.7* 22.3 27.6* 17.5 22.1* 16.9 21.0*

40.6* 40.6* 38.8* 38.8* 29.8 31.3* 21.5 24.8* 18.4 20.6*

42.5* 42.5* 38.2* 38.2* 30.8* 30.8* 22.6 24.4* 19.6 20.6*

30.4* 30.4* 24.6* 24.6* 19.1* 19.1*

29.5* 29.5* 23.7* 23.7* 18.9* 18.9*

6.4

8.0

9.0

9.7

10.1

10.3

10.2

9.9

9.3

8.5

7.1

Stick 3.30 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

20.1* 20.1*

19.9* 19.9*

20.3* 20.3* 18.2* 18.2*

20.3* 20.3* 18.1* 18.1*

20.8* 20.8* 19.4 19.8* 17.4* 17.4*

20.9* 20.9* 19.8* 19.8* 17.3* 17.3*

26.0* 26.0* 22.4* 22.4* 19.0 20.3* 15.6 17.1*

26.3* 26.3* 22.5* 22.5* 19.8 20.3* 16.2 17.1*

30.3* 30.3* 24.4 24.5* 18.4 21.3* 14.3 17.3*

30.6* 30.6* 24.7* 24.7* 19.2 21.4* 15.0 17.4* 15.0 17.4*

32.1 34.2* 23.2 26.7* 17.7 22.5* 14.0 18.1 13.7 17.7

33.4 34.5* 24.1 26.9* 18.5 22.6* 14.7 19.8* 14.4 18.1*

30.5 36.5* 22.1 28.3* 17.1 22.3 13.7 17.7 13.5 17.6

31.8 36.7* 23.1 28.4* 17.9 23.4* 14.4 20.0* 14.2 19.3*

29.7 36.9* 21.5 28.6 16.7 21.9 13.9 18.1

31.1 36.9* 22.5 28.8* 17.5 23.6* 14.7 20.0*

36.8* 36.8* 29.4 35.6* 21.2 28.2* 16.5 21.7 14.9 19.5

38.3* 38.3* 30.9 35.4* 22.3 28.0* 17.4 22.6* 15.8 20.2*

36.6* 36.6* 41.2* 41.2* 29.6 32.5* 21.3 25.8* 16.9 20.0*

38.2* 38.2* 40.7* 40.7* 31.1 32.1* 22.4 25.5* 18.1 20.0*

33.5* 33.5* 26.8* 26.8* 20.1* 20.1* 19.1* 19.1*

32.7* 32.7* 26.1* 26.1* 19.2* 19.2* 18.9* 18.9*

7.0

8.4

9.4

10.1

10.5

10.6

10.6

10.3

9.7

8.9

7.7

R 976 Litronic 9

Page 10

Lift Capacities

with Mono Boom 7.20 m

Stick 3.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

18.3* 18.3* 16.8* 16.8*

18.9* 18.9* 16.6* 16.6*

15.8* 15.8* 15.3* 15.3*

16.6* 16.6* 15.3* 15.3*

19.5* 19.5* 18.6* 18.6* 14.7* 14.7*

19.6* 19.6* 18.6* 18.6* 14.7* 14.7*

21.1* 21.1* 19.3 19.3* 14.7 15.6* 14.5 14.5*

21.3* 21.3* 19.4* 19.4* 15.4 16.2* 14.5* 14.5*

28.6* 28.6* 23.4* 23.4* 18.6 20.5* 14.4 18.6 13.4 14.7*

29.0* 29.0* 23.7* 23.7* 19.4 20.6* 15.1 18.7* 14.0 14.7*

32.7 32.9* 23.4 25.8* 17.8 21.8* 14.0 18.1 12.8 15.2*

33.2* 33.2* 24.4 26.0* 18.6 21.9* 14.7 19.3* 13.4 15.2*

30.8 35.8* 22.3 27.7* 17.1 22.4 13.7 17.7 12.6 16.1*

32.2 36.0* 23.3 27.8* 18.0 23.0* 14.3 19.7* 13.3 16.2*

29.8 36.8* 21.5 28.6* 16.6 21.9 13.4 17.5 12.9 16.8

31.2 36.9* 22.6 28.7* 17.5 23.4* 14.1 19.6* 13.7 17.7*

34.9* 34.9* 29.3 36.1* 21.1 28.3 16.4 21.6 13.7 18.0

36.1* 36.1* 30.8 36.0* 22.2 28.3* 17.2 22.9* 14.6 19.2*

32.7* 32.7* 43.7* 43.7* 29.4 33.7* 21.1 26.7* 16.4 21.1* 15.4 19.2*

34.0* 34.0* 43.2* 43.2* 30.8 33.4* 22.2 26.4* 17.3 20.8* 16.4 19.2*

48.1* 48.1* 36.9* 36.9* 29.0* 29.0* 21.5 22.5* 18.7 18.7*

47.0* 47.0* 36.1* 36.1* 28.4* 28.4* 22.0* 22.0* 18.6* 18.6*

19.8* 19.8* 17.2* 17.2*

7.7

9.0

10.0

10.6

11.0

11.1

11.0

10.8

10.3

9.5

8.3

6.5

Stick 4.70 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

12.6* 12.6*

12.6* 12.6* 12.4* 12.4*

15.8* 15.8* 11.7* 11.7*

15.9* 15.9* 11.6* 11.6*

16.5* 16.5* 14.0* 14.0* 11.2* 11.2*

16.5* 16.5* 14.2* 14.2* 11.2* 11.2*

17.4* 17.4* 15.1 16.4* 11.1* 11.1*

18.8* 18.8* 17.5* 17.5* 15.8 16.6* 11.1* 11.1*

25.3* 25.3* 21.3* 21.3* 18.8* 18.8* 14.7 17.3* 11.2* 11.2*

25.7* 25.7* 21.5* 21.5* 19.0* 19.0* 15.3 17.4* 11.2* 11.2*

30.0* 30.0* 23.9* 23.9* 18.1 20.4* 14.2 18.2* 11.4 11.6*

30.4* 30.4* 24.2* 24.2* 18.9 20.5* 14.8 18.2* 11.6* 11.6*

31.6 33.9* 22.7 26.3* 17.3 21.8* 13.7 17.8 11.2 12.2*

32.9 34.1* 23.6 26.5* 18.1 21.9* 14.4 19.0* 11.8 12.3*

30.1 36.0* 21.7 27.8* 16.6 21.9 13.3 17.4 11.4 13.1*

26.1* 26.1* 31.4 36.1* 22.7 27.9* 17.5 22.9* 14.0 19.4* 12.1 13.3*

18.1* 18.1* 32.5* 32.5* 29.3 36.4* 21.0 28.2 16.2 21.4 13.0 17.1 12.0 14.6*

18.9* 18.9* 33.2* 33.2* 30.7 36.4* 22.1 28.3* 17.0 23.0* 13.7 19.1* 12.7 14.8*

27.4* 27.4* 43.5* 43.5* 29.0 35.1* 20.8 27.6* 16.0 21.2 13.1 17.0*

28.3* 28.3* 44.7* 44.7* 30.4 34.9* 21.8 27.4* 16.9 22.1* 14.0 17.3*

39.3* 39.3* 41.8* 41.8* 29.2 31.9* 20.9 25.1* 16.2 19.5* 15.3 17.6*

40.5* 40.5* 41.2* 41.2* 30.7 31.5* 22.0 24.7* 17.1 19.0* 16.4 17.6*

44.9* 44.9* 33.4* 33.4* 25.8* 25.8* 19.3* 19.3* 16.9* 16.9*

43.4* 43.4* 32.4* 32.4* 25.0* 25.0* 18.5* 18.5* 16.8* 16.8*

8.9

10.1

10.9

11.5

11.8

12.0

11.9

11.6

11.2

10.5

9.4

8.0

10 R 976 Litronic

Page 11

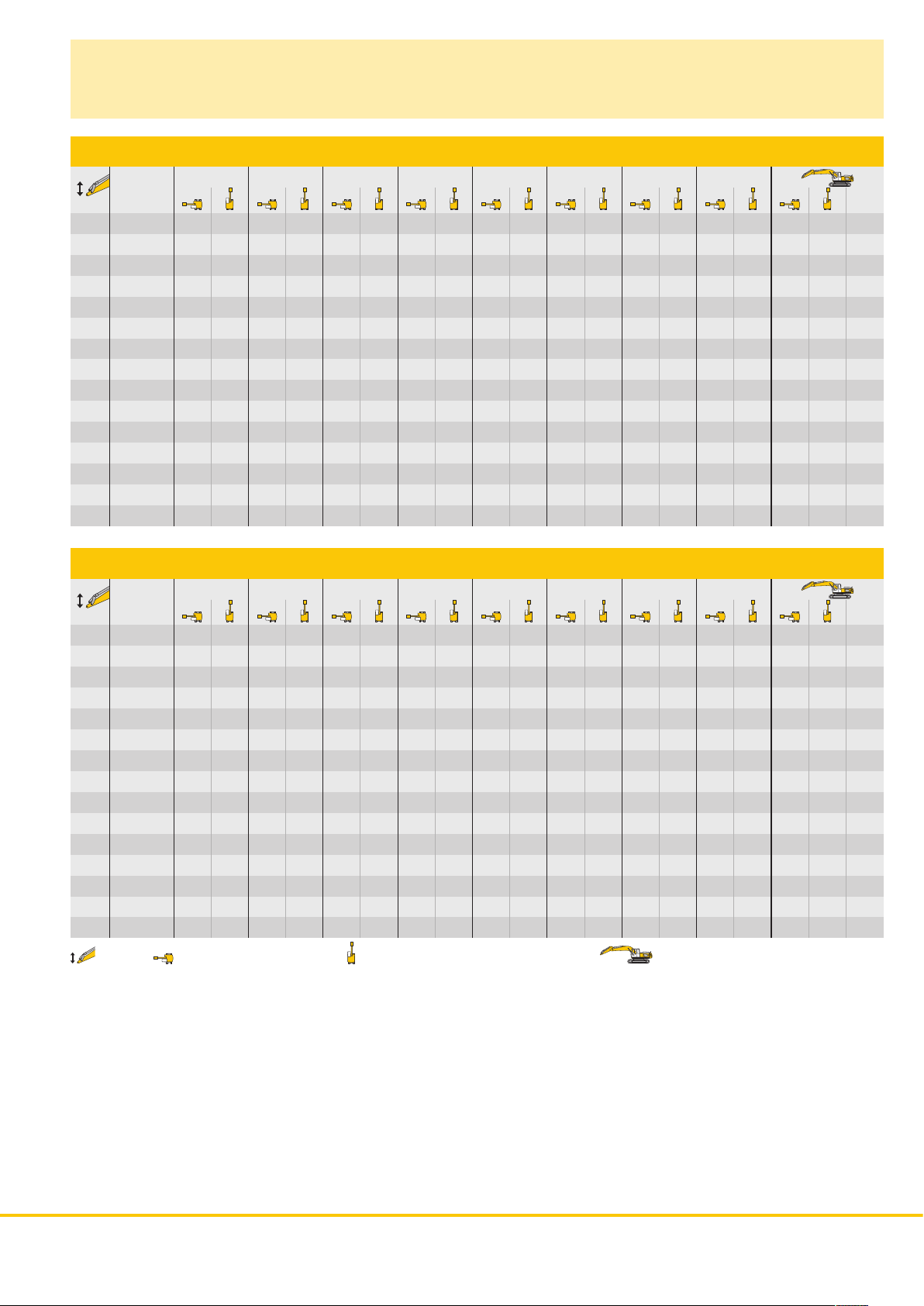

Backhoe Bucket

with Mono Boom 8.60 m

m

50

45

40

35

30

25

20

15

10

-10

-15

-20

-25

-30

-35

-40

ft

16

14

12

10

8

6

4

2

5

0

0

-5

-2

-4

-6

-8

-10

-12

1

2

3

4

681012141618

R0015

0 m

24

Digging Envelope 1 2 3 4

Stick length m 3.30 3.80 4.70 5.80

Max. digging depth m 9.30 9.85 10.75 11.60

Max. reach at ground level m 14.25 14.75 15.60 16.45

Max. dump height m 9.35 9.65 10.15 10.95

Max. teeth height m 13.75 14.10 14.60 15.05

Digging force ISO kN 361 329 284 249

t 36.8 33.5 28.9 25.4

Breakout force ISO kN 485 485 485 356

t 49.4 49.4 49.4 36.3

Operating Weight

and Ground Pressure

Operating weight includes basic machine with mono boom 8.60 m,

stick 3.80 m and bucket 3.80 m

Undercarriage HD LC-V

Pad width mm 500 600 750 500 600 750

Weight kg 85,900 86,600 87,700 91,000 91,800 92,900

Ground pressure kg/cm

Optional: heavy counterweight

(heavy counterweight increases the operating weight by 1,900 kg and

ground pressure by 0.04 kg/cm

3

(4,000 kg).

2

1.66 1.39 1.13 1.63 1.37 1.11

2

)

51015202530354045505 560

0 ft

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

HD-Undercarriage

Cutting

width

Capacity

ISO 7451

mm m

3

1,400 2.70 3,450

1,600 3.20 3,750

1)

1,800 3.80 4,000

1,950 4.30 4,200

STD

2,150 4.80 4,450

2,300 5.20 4,600

1,800 3.60 4,400

2)

1,950 4.10 4,750

HD

2,150 4.60 5,050

1,750 3.00 3,150

3)

1,950 3.50 3,450

STD

1,950 4.00 3,600

1,800 2.50 3,850

4)

2,000 3.00 4,100

HD

2,150 3.50 4,450

Weight

kg

3.30 3.80 4.70 5.80 3.30 3.80 4.70 5.80

X X X v X X X v

X X Y v X X Y v

Y Y V v X X V v

Y V y v Y Y y v

V V y v V V y v

y y v v V y v v

Y Y V v X X V v

V V y v Y Y y v

V y v v V V y v

v v v Y v v v Y

v v v V v v v V

v v v y v v v y

v v v Y v v v Y

v v v V v v v V

v v v y v v v y

* Indicated loads are based on ISO 10567 max. stick length, lifted 360° on firm

1)

Standard bucket with Liebherr teeth Z 90

2)

HD bucket with Liebherr teeth Z 90

3)

Standard bucket from R 966 li tro nic` with Liebherr teeth Z 70

4)

HD bucket from R 966 li tro nic` with Liebherr teeth Z 90

Other backhoes available on request

Max. material weight

X

= ≤ 2.2 t/m3,

Y

Stick length (m)

= ≤ 1.8 t/m3,

V

= ≤ 1.5 t/m3,

y

= ≤ 1.2 t/m3,

LC-V-Undercarriage

Stick length (m)

v

= not authorized

R 976 Litronic 11

Page 12

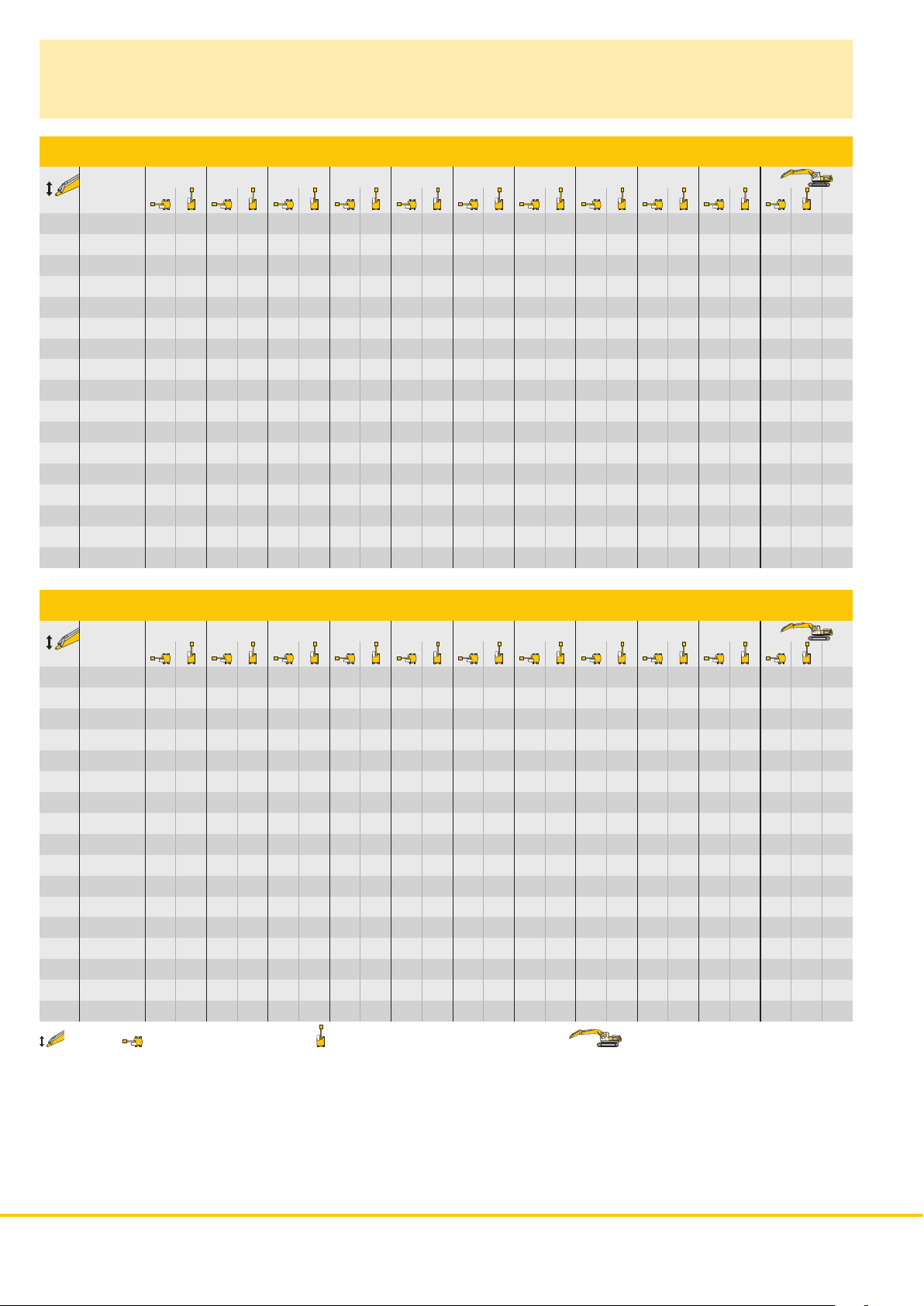

Lift Capacities

with Mono Boom 8.60 m

Stick 3.30 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

16.5* 16.5* 16.6* 16.6*

16.4* 16.4* 16.5* 16.5*

16.1* 16.1* 15.4 16.0*

16.1* 16.1* 15.9 16.0*

18.5* 18.5* 16.7* 16.7* 14.7 15.8* 13.2 15.8*

18.7* 18.7* 16.8* 16.8* 15.4 15.8* 13.7 15.8*

20.6* 20.6* 17.9* 17.9* 14.3 16.3* 11.9 15.4

20.9* 20.9* 18.0* 18.0* 15.0 16.3* 12.4 15.7*

22.8 23.1* 17.5 19.3* 13.8 17.0* 11.1 14.4

23.3* 23.3* 18.2 19.4* 14.5 17.1* 11.6 15.8* 11.6 15.8*

21.3 25.3* 16.6 20.6* 13.3 17.4 10.8 14.1 10.6 13.9

22.3 25.4* 17.4 20.7* 14.0 17.8* 11.4 16.0* 11.2 15.9*

20.3 26.7* 15.9 21.1 12.8 16.9 10.6 13.9 10.5 13.8

21.4 26.7* 16.7 21.7* 13.5 18.4* 11.2 16.2* 11.1 16.1*

19.8 26.9 15.4 20.6 12.5 16.6 10.7 14.1

20.9 27.1* 16.3 22.1* 13.2 18.7* 11.3 16.3*

27.4 31.7* 19.6 26.7 15.2 20.4 12.4 16.4 11.2 14.8

28.9 33.1* 20.7 26.7* 16.1 21.9* 13.1 18.4* 12.0 16.5*

27.5* 27.5* 27.7 31.3* 19.7 25.5* 15.3 20.4 12.5 16.6 12.3 16.3

28.9* 28.9* 29.2 31.1* 20.8 25.4* 16.1 20.9* 13.3 16.9* 13.2 16.6*

33.9* 33.9* 28.1* 28.1* 20.1 23.1* 15.6 18.7* 14.4 16.4*

33.5* 33.5* 27.8* 27.8* 21.2 22.8* 16.5 18.4* 15.4 16.4*

27.6* 27.6* 23.1* 23.1* 18.5* 18.5* 15.6* 15.6*

26.8* 26.8* 22.5* 22.5* 17.9* 17.9* 15.4* 15.4*

9.1

10.3

11.1

11.6

12.0

12.1

12.1

11.8

11.4

10.7

9.7

8.3

Stick 3.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

16.4* 16.4*

16.3* 16.3*

15.2* 15.2* 15.4* 15.4*

15.1* 15.1* 15.4* 15.4*

15.1* 15.1* 14.9* 14.9* 14.1 15.0*

15.2* 15.2* 14.8* 14.8* 14.6 15.0*

15.9* 15.9* 14.9 15.0* 12.3 14.6*

16.0* 16.0* 15.0* 15.0* 12.8 14.6*

19.6* 19.6* 17.1* 17.1* 14.5 15.6* 11.4 14.8 11.1 14.4

19.8* 19.8* 17.2* 17.2* 15.1 15.6* 12.0 14.8* 11.6 14.5*

22.1* 22.1* 17.7 18.5* 13.9 16.4* 11.1 14.5 10.4 13.5

22.3* 22.3* 18.4 18.7* 14.6 16.5* 11.7 15.1* 10.9 14.6*

21.6 24.4* 16.7 20.0* 13.3 17.3* 10.8 14.2 10.0 13.1

22.6 24.6* 17.5 20.1* 14.0 17.3* 11.4 15.6* 10.5 15.0*

20.5 26.1* 16.0 21.2* 12.8 16.9 10.5 13.9 9.8 13.0

21.5 26.2* 16.8 21.2* 13.5 18.1* 11.1 15.9* 10.4 15.2*

19.8 26.9* 15.4 20.6 12.5 16.5 10.3 13.6 10.0 13.2

20.9 26.9* 16.3 21.9* 13.2 18.5* 10.9 15.9* 10.6 15.5*

27.2 31.3* 19.5 26.6 15.1 20.3 12.3 16.3 10.4 13.8

28.7 32.3* 20.6 26.8* 16.0 21.9* 13.0 18.4* 11.1 15.7*

25.8* 25.8* 27.4 32.2* 19.5 25.9* 15.1 20.2 12.3 16.3 11.4 15.0

26.9* 26.9* 28.9 32.0* 20.6 25.8* 15.9 21.2* 13.0 17.5* 12.1 15.8*

29.6* 29.6* 36.5* 36.5* 27.8 29.4* 19.8 24.0* 15.3 19.6* 13.0 15.8*

30.7* 30.7* 36.1* 36.1* 29.1* 29.1* 20.9 23.7* 16.2 19.3* 14.0 15.8*

30.6* 30.6* 25.0* 25.0* 20.3* 20.3* 15.3* 15.3*

30.0* 30.0* 24.5* 24.5* 19.8* 19.8* 15.2* 15.2*

8.3

9.8

10.8

11.6

12.1

12.5

12.6

12.5

12.3

11.9

11.2

10.3

9.0

12 R 976 Litronic

Page 13

Lift Capacities

with Mono Boom 8.60 m

Stick 4.70 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

13.3* 13.3*

13.1* 13.1*

13.4* 13.4* 12.1* 12.1*

13.3* 13.3* 12.1* 12.1*

13.1* 13.1* 11.5* 11.5*

13.1* 13.1* 11.5* 11.5*

13.5* 13.5* 11.8 13.2* 10.8 11.2*

14.3* 14.3* 13.6* 13.6* 12.4 13.2* 11.2* 11.2*

15.5* 15.5* 14.3* 14.3* 11.6 13.5* 9.8 11.1*

17.8* 17.8* 15.7* 15.7* 14.3* 14.3* 12.2 13.5* 10.3 11.1*

20.2* 20.2* 17.1* 17.1* 14.1 15.2* 11.3 14.0* 9.2 11.2*

20.4* 20.4* 17.3* 17.3* 14.8 15.3* 11.8 14.1* 9.7 11.2*

22.2 22.7* 17.0 18.7* 13.5 16.3* 10.9 14.2 8.9 11.4*

23.0* 23.0* 17.8 18.9* 14.1 16.3* 11.4 14.7* 9.4 11.5*

20.9 24.8* 16.1 20.1* 12.9 17.0 10.5 13.8 8.7 11.6

21.8 25.0* 16.9 20.3* 13.5 17.3* 11.1 15.2* 9.3 12.0*

19.9 26.2* 15.4 20.6 12.4 16.5 10.2 13.5 8.8 11.7

20.9 26.2* 16.2 21.2* 13.1 17.9* 10.8 15.6* 9.4 12.7*

26.9 30.4* 19.4 26.5 15.0 20.2 12.1 16.1 10.0 13.3 9.2 12.2

28.4 31.1* 20.4 26.6* 15.8 21.6* 12.8 18.2* 10.6 15.5* 9.8 13.8*

22.9* 22.9* 26.9 33.2* 19.2 26.2 14.8 19.9 11.9 16.0 10.0 13.3 9.8 13.1

23.7* 23.7* 28.3 33.1* 20.3 26.2* 15.6 21.4* 12.6 17.8* 10.6 14.7* 10.5 14.5*

24.3* 24.3* 33.5* 33.5* 27.1 31.2* 19.3 25.0* 14.8 20.0 12.0 16.1 11.0 14.6*

25.1* 25.1* 34.6* 34.6* 28.6 31.0* 20.4 24.8* 15.7 20.3* 12.8 16.6* 11.8 14.6*

35.3* 35.3* 35.3* 35.3* 27.7 27.8* 19.7 22.4* 15.2 18.0* 13.1 14.5*

36.4* 36.4* 34.8* 34.8* 27.5* 27.5* 20.8 22.1* 16.1 17.7* 14.1 14.4*

27.9* 27.9* 22.3* 22.3* 17.6* 17.6* 13.7* 13.7*

27.1* 27.1* 21.7* 21.7* 16.9* 16.9* 13.6* 13.6*

9.5

10.9

11.8

12.5

13.0

13.3

13.5

13.4

13.2

12.8

12.2

11.3

10.1

8.6

Stick 5.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

11.8* 11.8* 9.9* 9.9*

9.8* 9.8*

10.1* 10.1* 9.2* 9.2*

10.5* 10.5* 9.2* 9.2*

11.6* 11.6* 8.8* 8.8*

11.6* 11.6* 8.8* 8.8*

12.1* 12.1* 11.9* 11.9* 9.8* 9.8* 8.6* 8.6*

12.2* 12.2* 11.9* 11.9* 10.0* 10.0* 8.6* 8.6*

13.0* 13.0* 12.2 12.4* 9.7 11.8* 8.5* 8.5*

13.1* 13.1* 12.4* 12.4* 10.2 11.9* 8.5* 8.5*

18.0* 18.0* 15.6* 15.6* 14.1* 14.1* 11.8 13.1* 9.5 12.3 8.3 8.6*

18.3* 18.3* 15.8* 15.8* 14.2* 14.2* 12.3 13.1* 10.0 12.4* 8.6* 8.6*

20.9* 20.9* 17.5* 17.5* 14.0 15.3* 11.3 13.8* 9.2 12.0 8.0 8.8*

21.1* 21.1* 17.6* 17.6* 14.7 15.4* 11.9 13.9* 9.7 12.9* 8.5 8.8*

21.9 23.5* 16.8 19.2* 13.4 16.4* 10.8 14.2 8.9 11.7 7.9 9.1*

22.9 23.7* 17.6 19.3* 14.0 16.5* 11.4 14.6* 9.4 13.3* 8.4 9.1*

20.7 25.4* 16.0 20.5* 12.8 16.9 10.4 13.8 8.7 11.5 7.9 9.6*

21.7 25.5* 16.8 20.6* 13.4 17.4* 11.0 15.2* 9.2 13.6* 8.4 9.6*

27.5 30.2* 19.9 26.5* 15.4 20.6 12.3 16.4 10.1 13.5 8.5 11.3 8.2 10.3*

28.9 30.5* 20.9 26.5* 16.2 21.5* 13.0 18.0* 10.7 15.6* 9.0 13.5 8.7 10.3*

20.4* 20.4* 27.1 34.3* 19.4 26.5 15.0 20.2 12.0 16.1 10.0 13.3 8.6 11.3*

14.1* 14.1* 21.0* 21.0* 28.5 34.3* 20.5 26.7* 15.8 21.7* 12.8 18.2* 10.6 15.5* 9.2 11.4*

19.9* 19.9* 27.8* 27.8* 27.1 33.2* 19.3 26.2* 14.8 20.0 12.0 16.0 10.0 13.3 9.5 12.6

20.5* 20.5* 28.6* 28.6* 28.5 33.0* 20.4 26.1* 15.7 21.3* 12.7 17.7* 10.6 14.6* 10.1 12.9*

27.7* 27.7* 37.9* 37.9* 27.4 30.9* 19.4 24.6* 15.0 20.0* 12.1 16.2 10.8 13.6*

28.5* 28.5* 39.0* 39.0* 28.9 30.6* 20.6 24.4* 15.8 19.9* 12.9 16.1* 11.6 13.6*

38.2* 38.2* 34.8* 34.8* 27.0* 27.0* 19.9 21.5* 15.4 17.1* 13.2 13.5*

39.4* 39.4* 34.1* 34.1* 26.5* 26.5* 21.1 21.2* 16.3 16.8* 13.4* 13.4*

26.0* 26.0* 20.4* 20.4* 15.6* 15.6* 12.5* 12.5*

25.0* 25.0* 19.6* 19.6* 14.7* 14.7* 12.4* 12.4*

11.0

12.2

13.0

13.7

14.1

14.4

14.5

14.5

14.3

13.9

13.3

12.6

11.5

10.2

8.3

R 976 Litronic 13

Page 14

Lift Capacities

with Mono Boom 7.20 m and Heavy Counterweight

Stick 2.90 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

23.7* 23.7*

23.5* 23.5*

21.6* 21.6* 21.3* 21.3*

21.6* 21.6* 21.2* 21.2*

21.8* 21.8* 20.3 20.4* 20.2* 20.2*

21.9* 21.9* 20.8* 20.8* 20.2* 20.2*

27.4* 27.4* 23.3* 23.3* 20.1 21.1* 17.7 19.9*

27.7* 27.7* 23.5* 23.5* 20.9 21.1* 18.3 19.9*

31.5* 31.5* 25.3* 25.3* 19.5 22.0* 16.2 20.2*

31.9* 31.9* 25.5* 25.5* 20.3 22.0* 16.9 20.3*

33.7 35.1* 24.5 27.3* 18.8 23.0* 15.5 19.9

35.0 35.4* 25.5 27.5* 19.6 23.0* 16.2 20.6*

32.3 36.9* 23.5 28.6* 18.3 23.6* 15.3 19.7

33.6 37.0* 24.6 28.7* 19.1 23.7* 16.1 20.8*

31.7 36.7* 23.0 28.9* 17.9 23.3 15.8 20.4

33.1 36.6* 24.0 28.8* 18.7 23.5* 16.6 20.9*

38.5* 38.5* 31.6 34.9* 22.8 27.8* 17.8 22.3* 17.1 21.0*

40.4* 40.4* 33.0 34.7* 23.9 27.6* 18.7 22.1* 18.1 21.0*

40.6* 40.6* 38.8* 38.8* 31.3* 31.3* 23.0 24.8* 19.7 20.6*

42.5* 42.5* 38.2* 38.2* 30.8* 30.8* 24.1 24.4* 20.6* 20.6*

30.4* 30.4* 24.6* 24.6* 19.1* 19.1*

29.5* 29.5* 23.7* 23.7* 18.9* 18.9*

6.4

8.0

9.0

9.7

10.1

10.3

10.2

9.9

9.3

8.5

7.1

Stick 3.30 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

20.1* 20.1*

19.9* 19.9*

20.3* 20.3* 18.2* 18.2*

20.3* 20.3* 18.1* 18.1*

20.8* 20.8* 19.8* 19.8* 17.4* 17.4*

20.9* 20.9* 19.8* 19.8* 17.3* 17.3*

26.0* 26.0* 22.4* 22.4* 20.3 20.3* 16.7 17.1*

26.3* 26.3* 22.5* 22.5* 20.3* 20.3* 17.1* 17.1*

30.3* 30.3* 24.5* 24.5* 19.6 21.3* 15.3 17.3*

30.6* 30.6* 24.7* 24.7* 20.4 21.4* 16.0 17.4* 16.0 17.4*

34.2 34.2* 24.7 26.7* 18.9 22.5* 15.0 19.2 14.7 18.0*

34.5* 34.5* 25.7 26.9* 19.7 22.6* 15.7 19.8* 15.3 18.1*

32.6 36.5* 23.7 28.3* 18.3 23.3* 14.7 18.9 14.5 18.7

33.9 36.7* 24.7 28.4* 19.1 23.4* 15.4 20.0* 15.2 19.3*

31.8 36.9* 23.0 28.9* 17.9 23.3 14.9 19.3

33.2 36.9* 24.1 28.8* 18.7 23.6* 15.7 20.0*

36.8* 36.8* 31.5 35.6* 22.7 28.2* 17.7 22.7* 16.0 20.2*

38.3* 38.3* 33.0 35.4* 23.8 28.0* 18.6 22.6* 16.9 20.2*

36.6* 36.6* 41.2* 41.2* 31.7 32.5* 22.8 25.8* 18.2 20.0*

38.2* 38.2* 40.7* 40.7* 32.1* 32.1* 23.9 25.5* 19.3 20.0*

33.5* 33.5* 26.8* 26.8* 20.1* 20.1* 19.1* 19.1*

32.7* 32.7* 26.1* 26.1* 19.2* 19.2* 18.9* 18.9*

7.0

8.4

9.4

10.1

10.5

10.6

10.6

10.3

9.7

8.9

7.7

14 R 976 Litronic

Page 15

Lift Capacities

with Mono Boom 7.20 m and Heavy Counterweight

Stick 3.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

18.3* 18.3* 16.8* 16.8*

18.9* 18.9* 16.6* 16.6*

15.8* 15.8* 15.3* 15.3*

16.6* 16.6* 15.3* 15.3*

19.5* 19.5* 18.6* 18.6* 14.7* 14.7*

19.6* 19.6* 18.6* 18.6* 14.7* 14.7*

21.1* 21.1* 19.3* 19.3* 15.6* 15.6* 14.5* 14.5*

21.3* 21.3* 19.4* 19.4* 16.2* 16.2* 14.5* 14.5*

28.6* 28.6* 23.4* 23.4* 19.8 20.5* 15.4 18.7* 14.3 14.7*

29.0* 29.0* 23.7* 23.7* 20.6 20.6* 16.1 18.7* 14.7* 14.7*

32.9* 32.9* 25.0 25.8* 19.0 21.8* 15.0 19.3* 13.7 15.2*

33.2* 33.2* 25.9 26.0* 19.8 21.9* 15.7 19.3* 14.4 15.2*

33.0 35.8* 23.9 27.7* 18.4 22.9* 14.7 18.9 13.6 16.1*

34.3 36.0* 24.8 27.8* 19.2 23.0* 15.3 19.7* 14.3 16.2*

31.9 36.8* 23.1 28.6* 17.8 23.2 14.4 18.6 13.9 17.6*

33.3 36.9* 24.1 28.7* 18.7 23.4* 15.1 19.6* 14.6 17.7*

34.9* 34.9* 31.4 36.1* 22.7 28.4* 17.6 23.0 14.8 19.1

36.1* 36.1* 32.9 36.0* 23.7 28.3* 18.4 22.9* 15.6 19.2*

32.7* 32.7* 43.7* 43.7* 31.5 33.7* 22.6 26.7* 17.6 21.1* 16.5 19.2*

34.0* 34.0* 43.2* 43.2* 32.9 33.4* 23.7 26.4* 18.5 20.8* 17.6 19.2*

48.1* 48.1* 36.9* 36.9* 29.0* 29.0* 22.5* 22.5* 18.7* 18.7*

47.0* 47.0* 36.1* 36.1* 28.4* 28.4* 22.0* 22.0* 18.6* 18.6*

19.8* 19.8* 17.2* 17.2*

7.7

9.0

10.0

10.6

11.0

11.1

11.0

10.8

10.3

9.5

8.3

6.5

Stick 4.70 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

12.6* 12.6*

12.6* 12.6* 12.4* 12.4*

15.8* 15.8* 11.7* 11.7*

15.9* 15.9* 11.6* 11.6*

16.5* 16.5* 14.0* 14.0* 11.2* 11.2*

16.5* 16.5* 14.2* 14.2* 11.2* 11.2*

17.4* 17.4* 16.1 16.4* 11.1* 11.1*

18.8* 18.8* 17.5* 17.5* 16.6* 16.6* 11.1* 11.1*

25.3* 25.3* 21.3* 21.3* 18.8* 18.8* 15.7 17.3* 11.2* 11.2*

25.7* 25.7* 21.5* 21.5* 19.0* 19.0* 16.3 17.4* 11.2* 11.2*

30.0* 30.0* 23.9* 23.9* 19.3 20.4* 15.2 18.2* 11.6* 11.6*

30.4* 30.4* 24.2* 24.2* 20.1 20.5* 15.8 18.2* 11.6* 11.6*

33.7 33.9* 24.2 26.3* 18.5 21.8* 14.7 18.9 12.1 12.2*

34.1* 34.1* 25.2 26.5* 19.3 21.9* 15.3 19.0* 12.3* 12.3*

32.2 36.0* 23.2 27.8* 17.9 22.8* 14.3 18.5 12.3 13.1*

26.1* 26.1* 33.5 36.1* 24.2 27.9* 18.7 22.9* 15.0 19.4* 12.9 13.3*

18.1* 18.1* 32.5* 32.5* 31.4 36.4* 22.6 28.3* 17.4 22.8 14.0 18.2 12.9 14.6*

18.9* 18.9* 33.2* 33.2* 32.7 36.4* 23.6 28.3* 18.2 23.0* 14.7 19.1* 13.6 14.8*

27.4* 27.4* 43.5* 43.5* 31.1 35.1* 22.3 27.6* 17.3 22.2* 14.1 17.0*

28.3* 28.3* 44.7* 44.7* 32.5 34.9* 23.4 27.4* 18.1 22.1* 15.0 17.3*

39.3* 39.3* 41.8* 41.8* 31.3 31.9* 22.4 25.1* 17.4 19.5* 16.4 17.6*

40.5* 40.5* 41.2* 41.2* 31.5* 31.5* 23.5 24.7* 18.3 19.0* 17.5 17.6*

44.9* 44.9* 33.4* 33.4* 25.8* 25.8* 19.3* 19.3* 16.9* 16.9*

43.4* 43.4* 32.4* 32.4* 25.0* 25.0* 18.5* 18.5* 16.8* 16.8*

8.9

10.1

10.9

11.5

11.8

12.0

11.9

11.6

11.2

10.5

9.4

8.0

R 976 Litronic 15

Page 16

Lift Capacities

with Mono Boom 8.60 m and Heavy Counterweight

Stick 3.30 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

16.5* 16.5* 16.6* 16.6*

16.4* 16.4* 16.5* 16.5*

16.1* 16.1* 16.0* 16.0*

16.1* 16.1* 16.0* 16.0*

18.5* 18.5* 16.7* 16.7* 15.7 15.8* 14.2 15.8*

18.7* 18.7* 16.8* 16.8* 15.8* 15.8* 14.7 15.8*

20.6* 20.6* 17.9* 17.9* 15.3 16.3* 12.8 15.7*

20.9* 20.9* 18.0* 18.0* 16.0 16.3* 13.3 15.7*

23.1* 23.1* 18.7 19.3* 14.8 17.0* 11.9 15.4

23.3* 23.3* 19.4* 19.4* 15.5 17.1* 12.5 15.8* 12.5 15.8*

22.9 25.3* 17.8 20.6* 14.3 17.8* 11.7 15.1 11.5 14.9

23.8 25.4* 18.6 20.7* 15.0 17.8* 12.2 16.0* 12.0 15.9*

21.9 26.7* 17.1 21.6* 13.8 18.0 11.4 14.9 11.3 14.7

22.9 26.7* 17.9 21.7* 14.5 18.4* 12.0 16.2* 11.9 16.1*

21.3 27.1* 16.6 22.0 13.5 17.7 11.5 15.0

22.4 27.1* 17.5 22.1* 14.2 18.7* 12.2 16.3*

29.5 31.7* 21.2 26.8* 16.4 21.8 13.4 17.6 12.1 15.9

31.0 33.1* 22.2 26.7* 17.3 21.9* 14.1 18.4* 12.9 16.5*

27.5* 27.5* 29.8 31.3* 21.2 25.5* 16.5 21.0* 13.5 17.1* 13.3 16.6*

28.9* 28.9* 31.1* 31.1* 22.3 25.4* 17.3 20.9* 14.3 16.9* 14.2 16.6*

33.9* 33.9* 28.1* 28.1* 21.6 23.1* 16.8 18.7* 15.5 16.4*

33.5* 33.5* 27.8* 27.8* 22.7 22.8* 17.7 18.4* 16.4* 16.4*

27.6* 27.6* 23.1* 23.1* 18.5* 18.5* 15.6* 15.6*

26.8* 26.8* 22.5* 22.5* 17.9* 17.9* 15.4* 15.4*

9.1

10.3

11.1

11.6

12.0

12.1

12.1

11.8

11.4

10.7

9.7

8.3

Stick 3.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

16.4* 16.4*

16.3* 16.3*

15.2* 15.2* 15.4* 15.4*

15.1* 15.1* 15.4* 15.4*

15.1* 15.1* 14.9* 14.9* 15.0* 15.0*

15.2* 15.2* 14.8* 14.8* 15.0* 15.0*

15.9* 15.9* 15.0* 15.0* 13.2 14.6*

16.0* 16.0* 15.0* 15.0* 13.7 14.6*

19.6* 19.6* 17.1* 17.1* 15.5 15.6* 12.2 14.8* 11.9 14.5*

19.8* 19.8* 17.2* 17.2* 15.6* 15.6* 12.8 14.8* 12.5 14.5*

22.1* 22.1* 18.5* 18.5* 14.9 16.4* 12.0 15.1* 11.2 14.5

22.3* 22.3* 18.7* 18.7* 15.6 16.5* 12.6 15.1* 11.7 14.6*

23.2 24.4* 18.0 20.0* 14.3 17.3* 11.7 15.1 10.8 14.0

24.1 24.6* 18.7 20.1* 15.0 17.3* 12.3 15.6* 11.3 15.0*

22.1 26.1* 17.2 21.2* 13.8 18.0* 11.4 14.8 10.6 13.9

23.0 26.2* 18.0 21.2* 14.5 18.1* 12.0 15.9* 11.2 15.2*

21.4 26.9* 16.6 21.9* 13.5 17.7 11.2 14.6 10.8 14.1

22.4 26.9* 17.5 21.9* 14.1 18.5* 11.8 15.9* 11.4 15.5*

29.3 31.3* 21.1 26.9* 16.3 21.7 13.3 17.4 11.3 14.8

30.8 32.3* 22.1 26.8* 17.2 21.9* 14.0 18.4* 12.0 15.7*

25.8* 25.8* 29.5 32.2* 21.0 25.9* 16.3 21.3* 13.3 17.5 12.3 15.8*

26.9* 26.9* 30.9 32.0* 22.1 25.8* 17.2 21.2* 14.0 17.5* 13.1 15.8*

29.6* 29.6* 36.5* 36.5* 29.4* 29.4* 21.3 24.0* 16.5 19.6* 14.1 15.8*

30.7* 30.7* 36.1* 36.1* 29.1* 29.1* 22.4 23.7* 17.4 19.3* 15.0 15.8*

30.6* 30.6* 25.0* 25.0* 20.3* 20.3* 15.3* 15.3*

30.0* 30.0* 24.5* 24.5* 19.8* 19.8* 15.2* 15.2*

8.3

9.8

10.8

11.6

12.1

12.5

12.6

12.5

12.3

11.9

11.2

10.3

9.0

16 R 976 Litronic

Page 17

Lift Capacities

with Mono Boom 8.60 m and Heavy Counterweight

Stick 4.70 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

13.3* 13.3*

13.1* 13.1*

13.4* 13.4* 12.1* 12.1*

13.3* 13.3* 12.1* 12.1*

13.1* 13.1* 11.5* 11.5*

13.1* 13.1* 11.5* 11.5*

13.5* 13.5* 12.7 13.2* 11.2* 11.2*

14.3* 14.3* 13.6* 13.6* 13.2* 13.2* 11.2* 11.2*

15.5* 15.5* 14.3* 14.3* 12.5 13.5* 10.6 11.1*

17.8* 17.8* 15.7* 15.7* 14.3* 14.3* 13.0 13.5* 11.1 11.1*

20.2* 20.2* 17.1* 17.1* 15.1 15.2* 12.1 14.0* 10.0 11.2*

20.4* 20.4* 17.3* 17.3* 15.3* 15.3* 12.7 14.1* 10.5 11.2*

22.7* 22.7* 18.2 18.7* 14.5 16.3* 11.7 14.6* 9.6 11.4*

23.0* 23.0* 18.9* 18.9* 15.1 16.3* 12.3 14.7* 10.1 11.5*

22.4 24.8* 17.3 20.1* 13.9 17.2* 11.3 14.8 9.5 11.9*

23.4 25.0* 18.1 20.3* 14.5 17.3* 11.9 15.2* 10.0 12.0*

21.5 26.2* 16.6 21.2* 13.4 17.6 11.0 14.5 9.6 12.6

22.5 26.2* 17.4 21.2* 14.1 17.9* 11.6 15.6* 10.1 12.7*

29.1 30.4* 20.9 26.6* 16.2 21.5 13.1 17.3 10.8 14.3 9.9 13.1

30.5 31.1* 22.0 26.6* 17.0 21.6* 13.8 18.2* 11.4 15.5* 10.6 13.8*

22.9* 22.9* 29.0 33.2* 20.7 26.3* 16.0 21.3 12.9 17.1 10.8 14.3 10.7 14.0

23.7* 23.7* 30.4 33.1* 21.8 26.2* 16.8 21.4* 13.6 17.8* 11.5 14.7* 11.4 14.5*

24.3* 24.3* 33.5* 33.5* 29.2 31.2* 20.8 25.0* 16.0 20.4* 13.0 16.7* 11.9 14.6*

25.1* 25.1* 34.6* 34.6* 30.7 31.0* 21.9 24.8* 16.9 20.3* 13.8 16.6* 12.7 14.6*

35.3* 35.3* 35.3* 35.3* 27.8* 27.8* 21.2 22.4* 16.4 18.0* 14.1 14.5*

36.4* 36.4* 34.8* 34.8* 27.5* 27.5* 22.1* 22.1* 17.3 17.7* 14.4* 14.4*

27.9* 27.9* 22.3* 22.3* 17.6* 17.6* 13.7* 13.7*

27.1* 27.1* 21.7* 21.7* 16.9* 16.9* 13.6* 13.6*

9.5

10.9

11.8

12.5

13.0

13.3

13.5

13.4

13.2

12.8

12.2

11.3

10.1

8.6

Stick 5.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m

Under m carriage m

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

11.8* 11.8* 9.9* 9.9*

9.8* 9.8*

10.1* 10.1* 9.2* 9.2*

10.5* 10.5* 9.2* 9.2*

11.6* 11.6* 8.8* 8.8*

11.6* 11.6* 8.8* 8.8*

12.1* 12.1* 11.9* 11.9* 9.8* 9.8* 8.6* 8.6*

12.2* 12.2* 11.9* 11.9* 10.0* 10.0* 8.6* 8.6*

13.0* 13.0* 12.4* 12.4* 10.4 11.8* 8.5* 8.5*

13.1* 13.1* 12.4* 12.4* 11.0 11.9* 8.5* 8.5*

18.0* 18.0* 15.6* 15.6* 14.1* 14.1* 12.6 13.1* 10.2 12.4* 8.6* 8.6*

18.3* 18.3* 15.8* 15.8* 14.2* 14.2* 13.1* 13.1* 10.7 12.4* 8.6* 8.6*

20.9* 20.9* 17.5* 17.5* 15.0 15.3* 12.2 13.8* 9.9 12.8* 8.7 8.8*

21.1* 21.1* 17.6* 17.6* 15.4* 15.4* 12.7 13.9* 10.4 12.9* 8.8* 8.8*

23.5 23.5* 18.0 19.2* 14.4 16.4* 11.7 14.6* 9.7 12.6 8.5 9.1*

23.7* 23.7* 18.8 19.3* 15.0 16.5* 12.3 14.6* 10.2 13.3* 9.0 9.1*

22.2 25.4* 17.2 20.5* 13.8 17.4* 11.3 14.8 9.4 12.3 8.6 9.6*

23.2 25.5* 18.0 20.6* 14.4 17.4* 11.9 15.2* 9.9 13.6* 9.1 9.6*

29.6 30.2* 21.4 26.5* 16.6 21.4* 13.3 17.5 11.0 14.4 9.2 12.1 8.9 10.3*

30.5* 30.5* 22.4 26.5* 17.4 21.5* 14.0 18.0* 11.6 15.6* 9.8 13.6* 9.4 10.3*

20.4* 20.4* 29.2 34.3* 21.0 26.7* 16.2 21.5 13.1 17.2 10.8 14.3 9.4 11.3*

14.1* 14.1* 21.0* 21.0* 30.6 34.3* 22.0 26.7* 17.0 21.7* 13.7 18.2* 11.4 15.5* 10.0 11.4*

19.9* 19.9* 27.8* 27.8* 29.2 33.2* 20.8 26.2* 16.1 21.3* 13.0 17.1 10.8 14.3 10.3 12.7*

20.5* 20.5* 28.6* 28.6* 30.6 33.0* 21.9 26.1* 16.9 21.3* 13.7 17.7* 11.5 14.6* 10.9 12.9*

27.7* 27.7* 37.9* 37.9* 29.5 30.9* 21.0 24.6* 16.2 20.0* 13.1 16.3* 11.7 13.6*

28.5* 28.5* 39.0* 39.0* 30.6* 30.6* 22.1 24.4* 17.1 19.9* 13.9 16.1* 12.5 13.6*

38.2* 38.2* 34.8* 34.8* 27.0* 27.0* 21.5 21.5* 16.6 17.1* 13.5* 13.5*

39.4* 39.4* 34.1* 34.1* 26.5* 26.5* 21.2* 21.2* 16.8* 16.8* 13.4* 13.4*

26.0* 26.0* 20.4* 20.4* 15.6* 15.6* 12.5* 12.5*

25.0* 25.0* 19.6* 19.6* 14.7* 14.7* 12.4* 12.4*

11.0

12.2

13.0

13.7

14.1

14.4

14.5

14.5

14.3

13.9

13.3

12.6

11.5

10.2

8.3

R 976 Litronic 17

Page 18

Backhoe Bucket

with Mono Boom 10.50 m and Heavy Counterweight

m

55

50

45

40

35

30

25

20

15

10

-10

-15

-20

-25

-30

-35

-40

-45

ft

16

14

12

10

8

6

4

2

5

0

0

-5

-2

-4

-6

-8

-10

-12

-14

1

2

3

4

R0016

Digging Envelope 1 2 3 4

Stick length m 3.30 3.80 4.70 5.80

Max. digging depth m 11.15 11.65 12.55 13.40

Max. reach at ground level m 16.25 16.70 17.60 18.45

Max. dump height m 10.65 10.90 11.40 12.25

Max. teeth height m 15.05 15.35 15.85 16.30

Digging force ISO kN 361 329 284 249

t 36.8 33.5 28.9 25.4

Breakout force ISO kN 485 485 485 356

t 49.4 49.4 49.4 36.3

Operating Weight

and Ground Pressure

Operating weight includes basic machine with heavy counterweight,

mono boom 10.50 m, stick 4.70 m and bucket 2.20 m

Undercarriage HD LC-V

Pad width mm 500 600 750 500 600 750

Weight kg 88,500 89,200 90,300 93,600 94,400 95,500

Ground pressure kg/cm

3

(3,200 kg).

2

1.71 1.43 1.16 1.68 1.41 1.14

0 m

681012141620 18

24

5101520253035404550556065

0 ft

Buckets Machine stability per ISO 10567* (75 % of tipping capacity)

HD-Undercarriage

Cutting

width

Capacity

ISO 7451

mm m

1,250 2.20 3,200

1)

1,400 2.70 3,450

1,600 3.20 3,750

STD

1,800 3.80 4,000

1,400 2.60 3,800

2)

1,600 3.10 4,250

HD

1,800 3.60 4,400

1,350 2.00 2,750

3)

1,550 2.50 2,950

1,750 3.00 3,150

STD

1,950 3.50 3,450

1,600 2.00 3,550

4)

1,800 2.50 3,850

HD

2,000 3.00 4,100

3

Weight

kg

3.30 3.80 4.70 5.80 3.30 3.80 4.70 5.80

X X Y v X X X v

X Y V v X Y Y v

Y V y v Y V V v

V y v v V y y v

X Y V v X Y Y v

Y y y v Y V V v

V y v v V y y v

v v v Y v v v X

v v v V v v v Y

v v v y v v v V

v v v v v v v y

v v v V v v v Y

v v v y v v v V

v v v v v v v y

* Indicated loads are based on ISO 10567 max. stick length, lifted 360° on firm

1)

Standard bucket with Liebherr teeth Z 90

2)

HD bucket with Liebherr teeth Z 90

3)

Standard bucket from R 966 li tro nic` with Liebherr teeth Z 70

4)

HD bucket from R 966 li tro nic` with Liebherr teeth Z 90

Other backhoes available on request

Max. material weight

X

= ≤ 2.2 t/m3,

Y

Stick length (m)

= ≤ 1.8 t/m3,

V

= ≤ 1.5 t/m3,

y

= ≤ 1.2 t/m3,

LC-V-Undercarriage

Stick length (m)

v

= not authorized

18 R 976 Litronic

Page 19

Lift Capacities

with Mono Boom 10.50 m and Heavy Counterweight

Stick 3.30 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m

Under m carriage m

HD

13.5

LC-V

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

HD

– 10.5

LC-V

12.5* 12.5*

12.5* 12.5* 12.5* 12.5*

12.0* 12.0* 12.1* 12.1*

12.0* 12.0* 12.1* 12.1*

13.4* 13.4* 12.3* 12.3* 11.8* 11.8* 11.2 11.9*

13.4* 13.4* 12.3* 12.3* 11.8* 11.8* 11.6 11.9*

14.6* 14.6* 13.0* 13.0* 12.0 12.0* 9.9 11.8*

14.7* 14.7* 13.0* 13.0* 12.1* 12.1* 10.4 11.8*

16.0* 16.0* 13.8* 13.8* 11.6 12.5* 9.4 11.8* 9.1 11.8*

16.2* 16.2* 13.9* 13.9* 12.1 12.6* 9.9 11.8* 9.6 11.8*

13.5 14.8* 11.1 13.1* 9.1 12.1* 8.6 11.4

14.1 14.9* 11.6 13.1* 9.7 12.1* 9.1 11.9*

12.8 15.7* 10.6 13.7* 8.9 11.8 8.3 11.0

13.5 15.7* 11.2 13.7* 9.4 12.4* 8.8 12.1*

12.3 16.3* 10.2 13.7 8.7 11.5 8.2 10.9

12.9 16.4* 10.8 14.2* 9.2 12.7* 8.7 12.2*

14.6 19.9 11.9 16.1 10.0 13.4 8.5 11.4 8.2 11.0

15.4 20.1* 12.6 16.8* 10.6 14.5* 9.0 12.8* 8.8 12.4*

14.5 19.7 11.8 15.9 9.9 13.3 8.6 11.5

15.3 20.0* 12.5 16.8* 10.5 14.5* 9.1 12.7*

19.1 23.2* 14.5 19.6* 11.8 15.9 9.9 13.3 9.2 12.3

20.2 23.1* 15.4 19.5* 12.5 16.5* 10.5 14.1* 9.8 12.8*

25.6* 25.6* 19.4 22.0* 14.8 18.6* 12.0 15.8* 10.2 13.0* 10.2 12.9*

25.4* 25.4* 20.5 21.8* 15.7 18.5* 12.7 15.7* 10.9 12.9*

26.5* 26.5* 23.4* 23.4* 19.9 20.1* 15.2 17.0* 12.4 14.1* 11.9 12.9*

26.3* 26.3* 23.1* 23.1* 19.9* 19.9* 16.1 16.8* 13.2 13.8* 12.8 12.8*

19.9* 19.9* 17.0* 17.0* 13.9* 13.9* 12.3* 12.3*

19.5* 19.5* 16.7* 16.7* 13.4* 13.4* 12.2* 12.2*

10.4

11.6

12.5

13.2

13.7

14.0

14.1

14.0

13.8

13.4

12.9

12.0

11.0

9.5

Stick 3.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m

Under m carriage m

HD

13.5

LC-V

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

HD

– 10.5

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

12.3* 12.3*

11.5* 11.5* 11.7* 11.7*

11.4* 11.4* 11.6* 11.6*

11.3* 11.3* 11.2* 11.2* 11.3* 11.3*

11.3* 11.3* 11.2* 11.2* 11.3* 11.3*

11.7* 11.7* 11.1* 11.1* 10.4 11.2*

11.7* 11.7* 11.2* 11.2* 10.8 11.2*

13.9* 13.9* 12.4* 12.4* 11.5* 11.5* 9.7 11.1* 9.3 11.1*

14.0* 14.0* 12.5* 12.5* 11.5* 11.5* 10.2 11.1* 9.7 11.1*

15.3* 15.3* 13.3* 13.3* 11.6 12.0* 9.5 11.3* 8.5 11.2*

15.5* 15.5* 13.4* 13.4* 12.1* 12.1* 10.0 11.3* 9.0 11.2*

16.8 16.9* 13.6 14.3* 11.1 12.6* 9.2 11.6* 8.1 10.7

17.0* 17.0* 14.2 14.4* 11.7 12.7* 9.7 11.6* 8.5 11.3*

12.9 15.2* 10.6 13.3* 8.9 11.8 7.8 10.4

13.5 15.3* 11.2 13.3* 9.4 12.0* 8.2 11.4*

12.3 16.0* 10.2 13.6 8.6 11.5 7.7 10.3

13.0 16.0* 10.8 13.9* 9.1 12.3* 8.2 11.6*

14.6 19.8* 11.9 16.0 9.9 13.3 8.4 11.3 7.7 10.4

15.4 19.8* 12.6 16.5* 10.5 14.2* 8.9 12.6* 8.2 11.8*

14.4 19.6 11.7 15.8 9.7 13.1 8.3 11.2 8.0 10.8

15.2 19.9* 12.4 16.7* 10.3 14.4* 8.8 12.5* 8.5 12.0*

18.8 23.5* 14.4 19.6* 11.6 15.7 9.7 13.1 8.5 11.4

19.9 23.5* 15.2 19.6* 12.3 16.5* 10.3 14.2* 9.1 12.2*

26.7* 26.7* 19.0 22.5* 14.5 18.9* 11.7 15.9 9.9 13.3 9.4 12.3*

26.6* 26.6* 20.2 22.3* 15.4 18.8* 12.5 15.9* 10.5 13.4* 10.1 12.3*

28.9* 28.9* 24.6* 24.6* 19.5 20.8* 14.9 17.5* 12.1 14.7* 10.8 12.3*

28.7* 28.7* 24.4* 24.4* 20.6* 20.6* 15.8 17.4* 12.8 14.5* 11.6 12.3*

25.1* 25.1* 21.4* 21.4* 18.1* 18.1* 15.1* 15.1* 12.0* 12.0*

24.7* 24.7* 21.1* 21.1* 17.8* 17.8* 14.8* 14.8* 12.0* 12.0*

16.3* 16.3* 13.4* 13.4* 10.9* 10.9*

12.7* 12.7* 11.4* 11.4*

11.1

12.2

13.1

13.7

14.2

14.5

14.6

14.5

14.3

13.9

13.4

12.6

11.6

10.2

8.4

R 976 Litronic 19

Page 20

Lift Capacities

with Mono Boom 10.50 m and Heavy Counterweight

Stick 4.70 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m

Under m carriage m

HD

13.5

LC-V

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

HD

– 10.5

LC-V

10.8* 10.8*

10.7* 10.7*

10.2* 10.2* 10.3* 10.3*

10.1* 10.1* 10.3* 10.3*

9.9* 9.9* 10.1* 10.1*

9.9* 9.9* 10.1* 10.1*

10.0* 10.0* 9.9* 9.9* 9.1 10.0*

10.1* 10.1* 9.9* 9.9* 9.5 10.0*

11.3* 11.3* 10.5* 10.5* 9.9 10.0* 8.2 10.0*

11.4* 11.4* 10.5* 10.5* 10.0* 10.0* 8.6 10.0*

14.0* 14.0* 12.2* 12.2* 11.1* 11.1* 9.6 10.3* 7.7 10.0* 7.6 10.0*

14.2* 14.2* 12.3* 12.3* 11.1* 11.1* 10.1 10.4* 8.2 10.0* 8.0 10.1*

15.6* 15.6* 13.3* 13.3* 11.2 11.8* 9.2 10.8* 7.5 10.1 7.2 9.6

15.8* 15.8* 13.4* 13.4* 11.8 11.8* 9.7 10.8* 8.0 10.2* 7.6 10.2*

16.1 17.1* 13.0 14.3* 10.7 12.5* 8.8 11.3* 7.3 9.8 6.9 9.3

16.8 17.2* 13.6 14.4* 11.2 12.5* 9.3 11.3* 7.8 10.5* 7.4 10.3*

15.2 18.3* 12.3 15.2* 10.2 13.1* 8.5 11.4 7.1 9.6 6.8 9.2

15.9 18.4* 13.0 15.3* 10.7 13.2* 9.0 11.7* 7.6 10.7* 7.3 10.5*

14.5 19.1* 11.8 15.9* 9.8 13.2 8.2 11.1 7.0 9.5 6.8 9.3

15.3 19.2* 12.5 15.9* 10.4 13.7* 8.7 12.1* 7.5 10.8* 7.3 10.7*

14.2 19.4 11.5 15.6 9.5 12.9 8.1 10.9 7.0 9.6

15.0 19.5* 12.2 16.3* 10.1 14.0* 8.6 12.2* 7.6 10.9*

18.3 23.8* 14.0 19.3 11.3 15.5 9.4 12.8 8.0 10.9 7.4 10.1

19.4 23.7* 14.9 19.5* 12.0 16.3* 10.0 14.0* 8.5 12.1* 8.0 11.1*

23.7* 23.7* 18.5 23.0* 14.1 19.0* 11.3 15.5 9.4 12.8 8.2 11.1 8.1 11.0

24.6* 24.6* 19.6 22.9* 15.0 19.0* 12.1 16.0* 10.1 13.6* 8.7 11.3* 8.7 11.3*

19.6* 19.6* 24.6* 24.6* 26.4* 26.4* 18.8 21.7* 14.3 18.1* 11.5 15.2* 9.7 12.7* 9.2 11.4*

20.4* 20.4* 25.5* 25.5* 26.2* 26.2* 20.0 21.5* 15.2 18.0* 12.3 15.1* 10.3 12.6* 9.9 11.4*

28.9* 28.9* 29.0* 29.0* 23.7* 23.7* 19.4 19.6* 14.8 16.4* 12.0 13.5* 10.9 11.3*

29.8* 29.8* 28.6* 28.6* 23.4* 23.4* 19.4* 19.4* 15.7 16.2* 12.8 13.3* 11.3* 11.3*

23.7* 23.7* 19.7* 19.7* 16.3* 16.3* 13.1* 13.1* 10.8* 10.8*

23.2* 23.2* 19.2* 19.2* 15.9* 15.9* 12.7* 12.7* 10.7* 10.7*

10.8

12.2

13.2

14.1

14.7

15.1

15.3

15.4

15.4

15.2

14.9

14.3

13.6

12.7

11.5

9.8

Stick 5.80 m

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m

Under m carriage m

HD

13.5

LC-V

HD

12.0

LC-V

HD

10.5

LC-V

HD

9.0

LC-V

HD

7.5

LC-V

HD

6.0

LC-V

HD

4.5

LC-V

HD

3.0

LC-V

HD

1.5

LC-V

HD

0

LC-V

HD

– 1.5

LC-V

HD

– 3.0

LC-V

HD

– 4.5

LC-V

HD

– 6.0

LC-V

HD

– 7.5

LC-V

HD

– 9.0

LC-V

HD

– 10.5

LC-V

Height Can be slewed though 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The load values are quoted in tons (t) at stick end (without bucket), and may be swung 360° on firm and even ground. Adjacent values are valid

forthe undercarriage when in the longitudinal position. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on

ISO10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Without bucket cylinder, link and lever the

liftcapacities will increase by 1,300 kg. Lifting capacity of the excavator is limited by machine stability and hydraulic capacity.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

9.3* 9.3* 9.5* 9.5*

9.2* 9.2* 9.5* 9.5*

9.2* 9.2* 9.3* 9.3*

9.2* 9.2* 9.3* 9.3*

8.8* 8.8* 9.0* 9.0*

8.8* 8.8* 9.0* 9.0*

9.1* 9.1* 8.9* 8.9* 8.4 9.0* 8.1 8.7*

9.2* 9.2* 8.9* 8.9* 8.9 9.0* 8.5 8.7*

9.6* 9.6* 9.2* 9.2* 8.4 9.0* 7.4 8.6*

9.7* 9.7* 9.3* 9.3* 8.8 9.0* 7.8 8.6*

11.3* 11.3* 10.3* 10.3* 9.7* 9.7* 8.2 9.2* 6.9 8.5*

12.9* 12.9* 11.4* 11.4* 10.4* 10.4* 9.7* 9.7* 8.6 9.3* 7.3 8.5*

14.5* 14.5* 12.4* 12.4* 11.1* 11.1* 9.6 10.2* 7.9 9.6* 6.5 8.6*

14.6* 14.6* 12.5* 12.5* 11.2* 11.2* 10.1 10.2* 8.4 9.6* 6.9 8.6*

16.1* 16.1* 13.6* 13.6* 11.1 11.9* 9.2 10.7* 7.6 9.9* 6.3 8.5 6.3 8.5

16.3* 16.3* 13.7* 13.7* 11.7 12.0* 9.7 10.8* 8.1 10.0* 6.7 8.9* 6.7 8.7*

15.9 17.6* 12.9 14.6* 10.6 12.7* 8.8 11.3* 7.4 9.9 6.2 8.4

16.7 17.7* 13.5 14.7* 11.1 12.7* 9.3 11.3* 7.8 10.3* 6.6 9.0*

15.1 18.6* 12.2 15.5* 10.1 13.3* 8.5 11.4 7.1 9.7 6.2 8.5

15.9 18.7* 12.9 15.5* 10.7 13.4* 9.0 11.8* 7.6 10.6* 6.7 9.3*

14.5 19.3* 11.8 15.9 9.8 13.2 8.2 11.1 7.0 9.5 6.4 8.7

15.4 19.4* 12.5 16.1* 10.3 13.8* 8.7 12.1* 7.5 10.8* 6.8 9.9*

18.5 24.3* 14.2 19.5 11.5 15.6 9.5 12.9 8.0 10.9 6.9 9.4 6.7 9.1

19.5 24.2* 15.1 19.7* 12.2 16.4* 10.1 14.0* 8.6 12.2* 7.4 10.7* 7.1 10.2*

20.8* 20.8* 18.5 23.9* 14.1 19.4 11.4 15.5 9.4 12.8 8.0 10.9 7.1 9.7

14.5* 14.5* 21.4* 21.4* 19.5 23.8* 15.0 19.5* 12.1 16.4* 10.1 14.0* 8.6 12.1* 7.7 10.4*

16.1* 16.1* 20.3* 20.3* 26.5 28.6* 18.7 23.0* 14.2 19.0* 11.4 15.6 9.5 12.9 8.2 11.1 7.9 10.6*

16.6* 16.6* 20.9* 20.9* 28.0 28.4* 19.8 22.9* 15.1 18.9* 12.2 15.9* 10.1 13.5* 8.7 11.3* 8.5 10.6*

22.7* 22.7* 28.4* 28.4* 26.5* 26.5* 19.1 21.5* 14.5 17.8* 11.7 14.9* 9.8 12.4* 9.1 10.7*

23.4* 23.4* 29.2* 29.2* 26.2* 26.2* 20.2 21.3* 15.4 17.7* 12.4 14.8* 10.5 12.2* 9.8 10.7*

31.3* 31.3* 29.3* 29.3* 23.3* 23.3* 19.1* 19.1* 15.1 15.8* 12.2 12.9* 10.6* 10.6*

32.2* 32.2* 28.9* 28.9* 23.0* 23.0* 18.9* 18.9* 15.6* 15.6* 12.6* 12.6* 10.5* 10.5*

23.0* 23.0* 18.6* 18.6* 15.1* 15.1* 11.8* 11.8* 10.0* 10.0*

18.1* 18.1* 14.7* 14.7* 11.2* 11.2* 9.9* 9.9*

12.3

13.5

14.5

15.2

15.8

16.2

16.4

16.5

16.5

16.3

16.0

15.5

14.8

14.0

12.9

11.5

9.6

20 R 976 Litronic

Page 21

Dimensions Front Shovel

R0017

E

D

A2

A1

A

W

L

U

V

X

HD mm

A 3,565

A1 4,355

A2 4,730

C 4,495/4,690*

D 4,515

E 4,640

H 3,725

K 1,620

L 4,770

P 1,460

* with FOPS top guard

H

K

Q

N

S

Z

B

G

C

P

HD mm

Q 682

S 3,600

U 5,955

N 500 600 750

B 4,290 4,290 4,350

G 4,540 4,540 4,540

Z 7,490

V 11,100

W 4,500

X 13,850

R 976 Litronic 21

Page 22

Front Shovel

ft

m

12

11

35

10

30

9

8

25

20

15

10

-10

7

6

5

4

3

2

5

1

0

0

-1

-5

-2

-3

-4

T

6810 1357911

24

R0018

0 m

Digging Envelope

Max. reach at ground level 9.40 m

Max. dump height 7.80 m

Max. crowd length 3.90 m

Bucket opening width T 1,825 mm

Max. crowd force 690 kN/70.4 t

Max. crowd force at ground level 490 kN/50.0 t

Max. breakout force 500 kN/51.0 t

Operating Weight

and Ground Pressure

Operating weight includes basic machine with cab elevation 800 mm,

shovel attachment and front shovel 5.10 m

Undercarriage HD

Pad width mm 500 600 750

Weight kg 90,800 91,500 92,600

Ground pressure kg/cm

3

(9,100 kg), level II.

2

1.75 1.47 1.19

5101520253035

0 ft

Front Shovels

HD-Undercarriage

Cutting

width

Capacity

ISO 7451

Weight

Wear kit

mm m

3

kg

2,300 4.40 8,300

2,300 4.40 9,150

2,700 5.10 8,450

2,700 5.10 9,100

2,700 5.10 10,150

2,700 5.40 9,900

2,700 5.60 8,750

2,700 5.60 9,450

level

II

III

I

II