Page 1

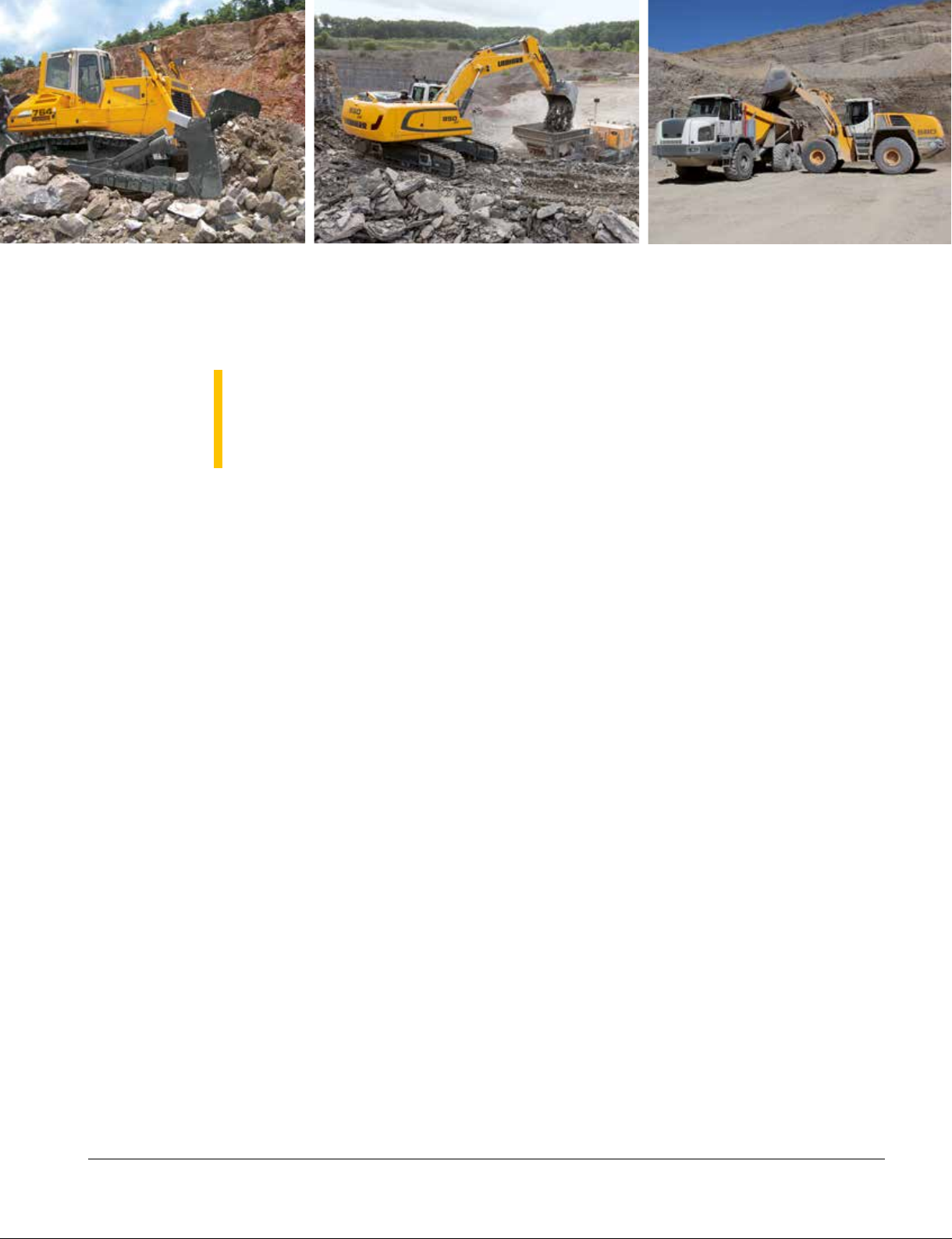

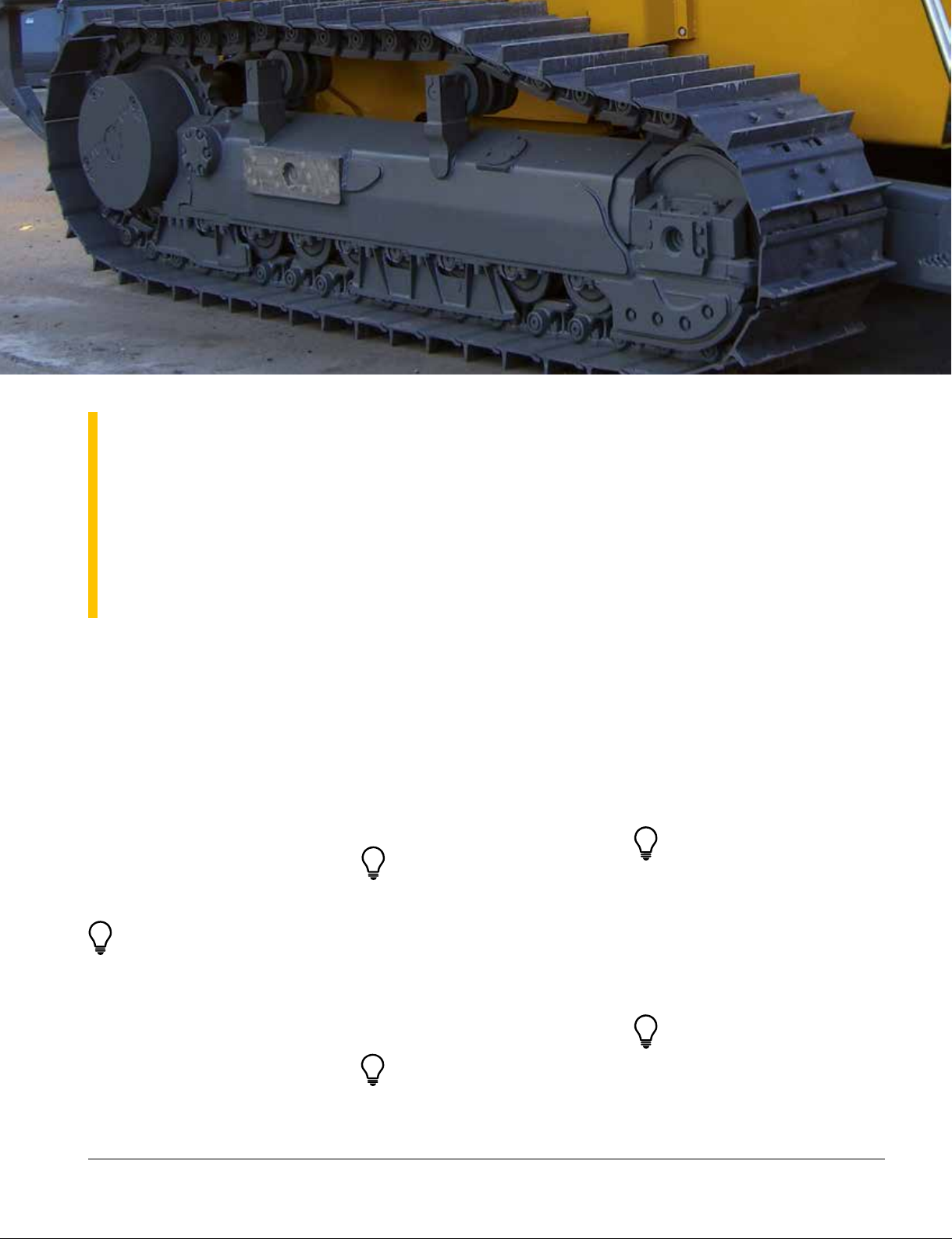

QUARRYING

Innovative Machines in Operation

Features: Experience in quarrying and loading

Advice: Economy in quarrying

Trends: Protective devices for crawler excavators

Page 2

Dear

Readers,

The quarrying industry is experiencing a period of rapid growth. At the same time, it is

also experiencing growing pressures. In view of increased pricing pressure, companies

operating in the industry are being forced to work with maximum efficiency and

economy and to do so in an environment that, by its very nature, demands great input

in terms of time and cost.

In our special, we will show you specific examples from quarrying in practice. How do

companies use Liebherr machines in their quarries and mines? In which operations are

they employed? In what kind of environment do the companies work? And how do

these companies manage to achieve maximum efficiency?

The reports show that the machines used are an important criterion for working

efficiency and operating costs. At the end of the day, the decisions about specific

machines and equipment have an effect on the production costs and ultimately on the

company’s revenue.

In addition to our customers’ experience, we wish to use this publication to tell you

more about our concepts for improving efficiency. The chapter “Economy in quarrying”

will give you tips about operating our machines, enabling you to work efficiently and

prolong the service life of your machines.

Do you have any ideas, suggestions or questions about the use of machines in quarrying?

Please send an email to quarrying@ liebherr.com.

2// Quarrying

The Editorial Team

Page 3

Content

Features

Mineral Baustoff GmbH

Trimming quarries for economy ....................................................... 5

Creaton AG

Hooked on creativity with clay ......................................................... 9

Holemans GmbH

From gravel to sand and on to new lakelands ................................ 12

a & b Ingoldingen

Moraine gravel for asphalt and cement .......................................... 22

Recycling GmbH Lahnau

All quarrying operations under one umbrella .................................. 24

Geocal Mineração

Reliance and partnership for

safe quarrying ............................................................................... 38

J Swap

J Swap Contractors in New Zealand:

Efficiency in heavy operations ........................................................ 40

Lanwehr Naturstein

Third-generation stone quarries ..................................................... 42

Advice

Economy in quarrying

Part 1: Story .................................................................................... 8

Economy in quarrying

Part 2: Wheel loader operating tips ................................................ 27

Quarrying in profile

Carrière des Grands Usages

R 950 SME ................................................................................... 17

Carrière des Grands Caous

R 964 C SME ................................................................................ 28

The Ambazac and

Montebras quarries

Service

............................................................. 32

Undercarriage

10 expert tips for long undercarriage service life ............................ 14

In detail

The Liebherr Z tooth system

The advantages of the Z tooth system ............................................ 31

Trends

Protective devices

for crawler excavators

....................................................... 20

The retarder on the TA 230 Litronic

Braking without compromise ......................................................... 37

Overview

Liebherr machines in quarrying

Hydraulic excavators, wheel loaders, dump trucks and crawlers

for heavy-duty operations ............................................................... 45

Masthead

Publisher

Liebherr-EMtec GmbH

Liebherrstraße 12

88457 Kirchdorf an der Iller (Germany)

info.lhb@ liebherr.com

Responsible for the content

Liebherr-Werk Bischofshofen GmbH

Dr.-Hans- Liebherr-Str. 4

5500 Bischofshofen (Austria)

quarrying@liebherr.com

Editorial team

Conrad Freeling, Maria Graffius, Alexander Katrycz, Bettina Köhler, Catherine Pierrat,

Uwe Richter/Richter B2B, Michel Roche, Barbara Specht, Alban Villaume

Layout/design

For Sale Services GmbH, München

© Liebherr-EMtec GmbH

The content may not be copied or disseminated without permission of the publisher.

Quarrying //3

Page 4

4// Quarrying

Page 5

Feature: Mineral Baustoff GmbH

Trimming quarries

for economy

When talking about reducing costs and boosting efficiency, Wolfgang Beckers is in his element. As chief

representative and regional manager of Mineral Baustoff GmbH for the German state of Thuringia,

he has economically optimized five of the company’s quarries to the last detail. One way of achieving his

ambitious goals is by keeping distances short, but another is the efficient use of Liebherr machines.

With around 200 quarries and gravel pits, Mineral Baustoff, part

of the STRABAG SE Group, is one of the largest raw materials

brands in Central, Southeastern and Eastern Europe.

One of the five limestone quarries operated by Wolfgang Beckers

is at Eigenrieden, near Mühlhausen. Here, two areas of 17.3 and

29.6 acres are mined. From the forecourt of the office building,

we have an unhindered view across both areas. We are able to

watch all productions steps, from quarrying at the face through

to loading onto the customer’s trucks. One thing that is

conspicuous is the fact that there are no dumper trucks or long

conveyor belts in use. The entire organization is based on short

distances, which saves machines, personnel and time.

“Economy is the be-all and end-all.

Our operation is completely mobile.”

Wolfgang Beckers, chief representative and regional manager

MineralBaustoff GmbH for the German state of Thuringia

“Economy is the be-all and end-all. Our operation is completely

mobile. We have no stationary systems. We crush the material

where we find it. Then we process it, put it on a pile and sell it.

In between there are practically no distances to be travelled. We

have to be competitive. In sales, every cent per ton makes a

difference,” Beckers says. “We produce a broad range of end

products here; for example, calcium-magnesium fertilizers, which

we sell to the agricultural industry in the area. Then we have

products for road building, gardening and landscaping. That

includes, for example, frost protection layers, gravel base layers

and hydraulically bonded layers.”

Wolfgang Beckers, chief representative and regional manager

Mineral Baustoff GmbH for the German state of Thuringia.

A new Liebherr R 950 SME crawler excavator recently started

operations at the quarry face loading the crusher. Its reach of

42 ft8 i is exactly configured for the conditions on site. The bucket

size has been optimized for the through put capacity of the crusher.

Beckers is proud of his new acquisition. “The excavator has been

in operation now for three weeks, and we already have superb

experience in terms of productivity and diesel consumption. In

addition to the fact that it offers far better performance and a

larger bucket capacity, its fuel consumption is lower than that of

its predecessor.”

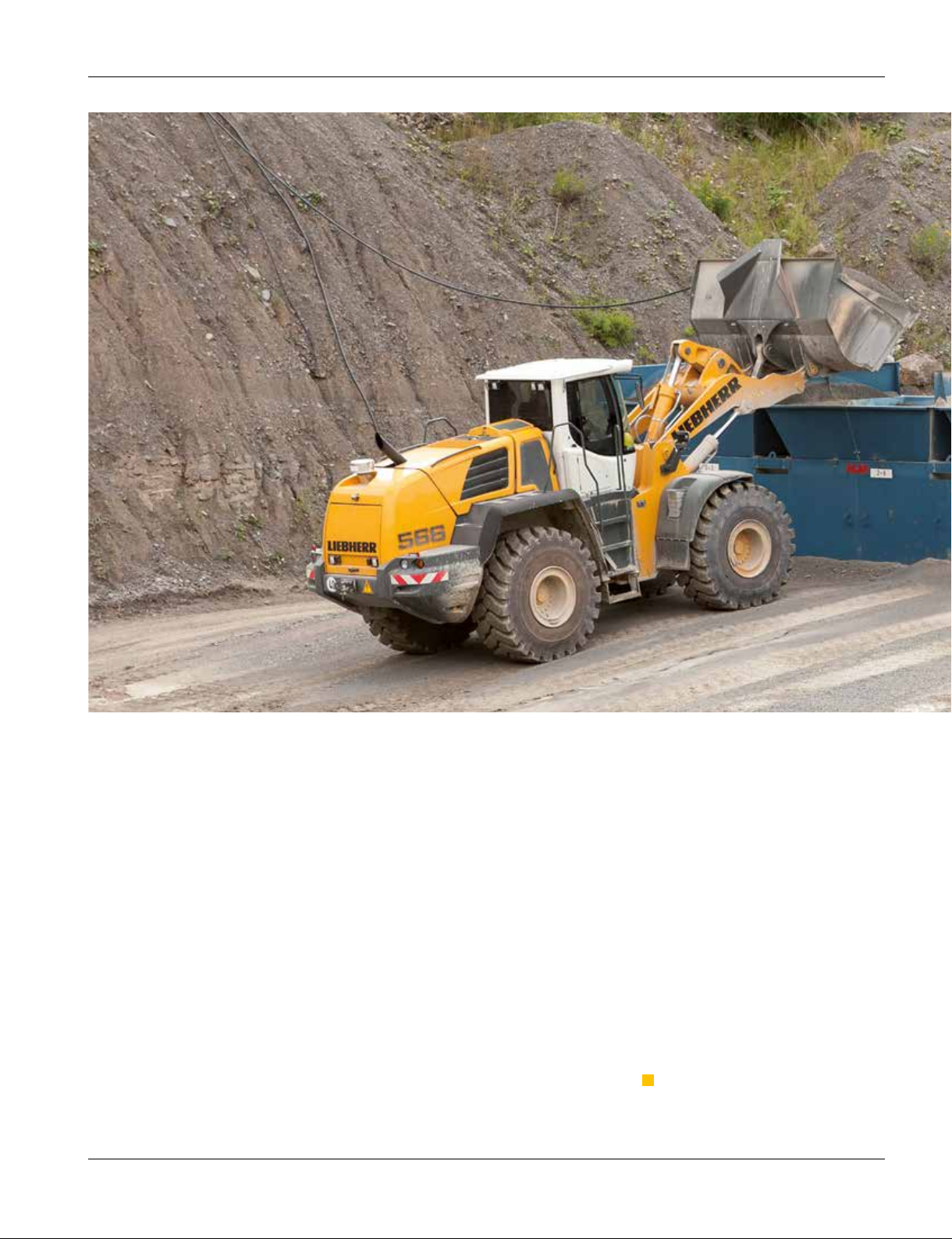

Beckers also puts his faith in Liebherr with his wheel loaders.

Three generations are currently working in parallel. The oldest

one was built in 2005, the youngest, anL566 unit of the latest

generation, has only just been delivered to the Themar quarry.

“What convinces me about Liebherr are the service intervals,

service availability, the advice, the quality and the operation,”

Beckers continues. “The machines are extremely durable and

highly economical in operation. In particular, diesel consumption

is, of course, important for us.”

R 950 SME crawler excavator at the quarry in Eigenrieden:

The material is processed on site and sold where it is found.

Before procuring a new machine, economy and durability are

carefully scrutinized and documented. “We have made direct

comparisons between these machines and competitive models

Quarrying //5

Page 6

Feature: Mineral Baustoff GmbH

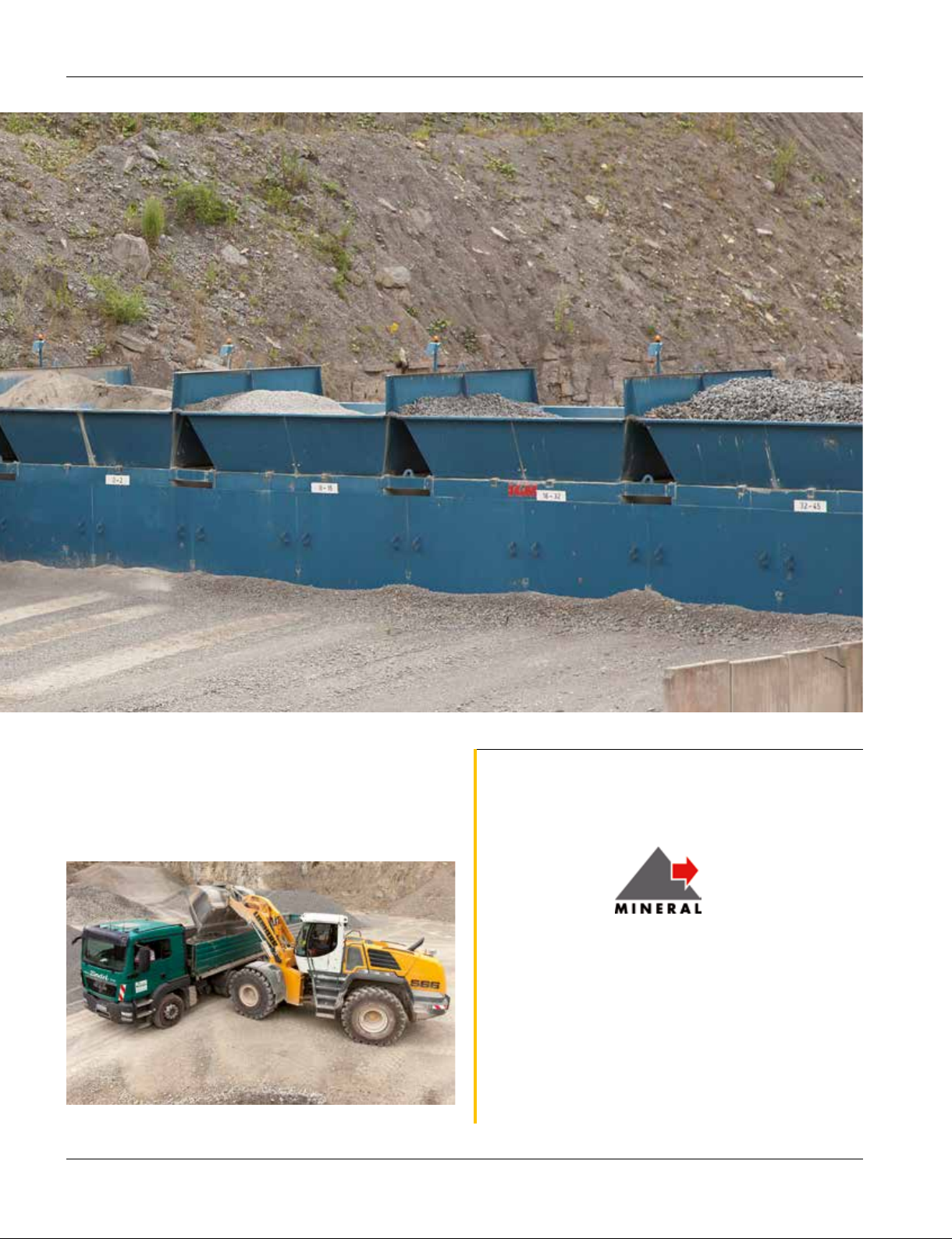

Six-chamber blender: Customers order the grade they need when they arrive at the quarry, are given a recipe card and collect their gravel.

in operations,” explains Beckers. “Fuel consumption and material

movement have been recorded and compared. This has enabled

us to obtain figures for fuel consumption per ton of material

quarried. With Liebherr machines, we can save 1.1 to 1.3 up to

sometimes even 1.6 gallons of diesel per hour. At 15,000

operating hours per year that makes several thousand US $.”

“ Liebherr machines allow us to save

1.1to1.3,sometimes even 1.6 gallons

of diesel per hour.”

Wolfgang Beckers, chief representative and regional manager

Mineral Baustoff GmbH for the German state of Thuringia.

6// Quarrying

Fuel consumption is not the only criterion that is taken into

account for procurements. Service also plays an important role

as it has a decisive influence on machine availability. “Machines

that are not running immediately run up immense losses. That’s

something we can’t afford, and that’s why we use Liebherr

machines,” continues Beckers. “With the Nagel Group, we have

a truly competent and reliable service partner. Whenever we have

a technical question, we always get an answer straight away.”

Despite the fact that operations are heavily trimmed towards

efficiency, expense is not spared on the machines themselves.

“Our drivers work on the machines for up to 10 hours and must

be in top form at all times. That means they get the equipment

they need to make work easier. Comfort seats, climate control

and auxiliary heating, for example, are features on all our machines,”

says Beckers. “This makes work easier and, not least of all, it

is a question of safety.”

Page 7

Feature: Mineral Baustoff GmbH

Loading directly from the pile.

Company profile

Mineral Baustoff GmbH

Sector:

Size of company:

Founded:

Location:

Managing Director:

Website:

Liebherr machines

in operation:

Quarry operator

25 quarries and gravel pits, 122 employees

2008

Germany, Central, Southeastern and

Eastern Europe

Dipl.-Ing. Jörg Henschel, Dipl.-Kfm. Peter Kern

www.mineral.eu.com

L 566,R 950 SME, R 936, etc.

Quarrying //7

Page 8

Advice – Part 1

Economy in quarrying

Companies working in the quarrying sector are under enormous

pressure to save time and reduce costs. Expenditures for operations

and rising fuel costs are forcing companies to work as efficiently and

economically as possible. Every company, therefore, asks the question:

how can we optimize essential production factors such as equipment,

work and energy in order to achieve a good turnover rate while keeping

operating costs low?

Two extremely important considerations

are improving mining and transportation

processes. This starts with the infrastructure

and organisation locally and asking: What

processes are performed at the site, for

example, at the quarry? How fast can the

machines operate? How much energy is

input to operate the conveyor belts and

how much fuel is needed to operate the

machines? How well trained are the

employees operating these machines? The

list of potential savings continues to

sustainable mining, resources and the

environment. We would like to illustrate

these questions by looking at examples of

machines. These have a decisive effect on

the costs per ton of materials extracted.

Wheel loader: up to 25 % less

fuel due to drive concept

Wheel loaders are mainly employed in the

industry for loading and transporting

materials. In mines and quarries, large

wheel loaders with an operating weight of

up to 33.1 tons are primarily used. Despite

this enormous machine weight and the

tough operating conditions, it is important

for fuel consumption to be kept low.

Liebherr wheel loaders achieve this with a

combination of hydrostatic travel drive and

the Liebherr Power Efficiency (LPE) system.

With this drive concept, all Liebherr wheel

loaders of the latest Tier4i / IIIB generation

save up to 25 % of fuel compared to other

machines of the same size class. While

fuel consumption drops, the hydrostatic

travel drive makes it possible to achieve

greater turnover rates per operating hour.

The hydrostatic travel drive allows a

particular installation position of the

Liebherr diesel engine – transverse or

longitudinal at the rear. Compared to

conventionally powered wheel loaders, this

leads to a higher tipping load with much

lower machine weight and an improved

turnover rate per operating hour. The LPE

system proactively influences engine

management by picking up the electronic

signal from the accelerator pedal and

computing the most efficient way of

carrying out the driver’s wishes.

Hydrostatic drive reduces wear

andcosts

At the same time, the hydrostatic drive

ensures that costs caused by brake and

tire wear are reduced. While the freely

variable tractive power control reduces tire

wear by 25 %, the hydraulic braking effect

of the drive system reduces wear on the

brakes. Companies are spared the cost of

repairs caused by wear, which means

lower operating costs and better results.

How much can the impact on the

environment and on our natural resources

be reduced in mining? 0.3 gal of fuel

produces up to 7 lb of carbon dioxide

(CO2). By saving up to 1.3 gal per operating

hour, up to 33,070 lb less CO

in 1,000 operating hours.

Excavator automatically switches

engine off when idling

The excavator can be equipped with a

function that automatically switches the

engine off after a certain period spent

stationary. In conjunction with the sensorcontrolled automatic idling system, fuel

consumption is reduced even further,

lessening the environmental impact. To

optimally adapt the machine to different

conditions, the excavator driver can

choose between four different work

is produced

2

modes. Mode “E” (for economy) is

recommended for normal working

conditions, reducing the impact on both

the budget and the environment. A simple

touch of a button is all the driver has to do

to change modes. A pre-set engine speed

or hydraulic output is then made available

by the machine.

Driver usage, behavior data

improveseconomy

Not every driver uses a machine the same.

If you analyze exactly how a machine is

driven, you can draw conclusions as to how

it can be used more economically. This is

exactly what LiDAT – the electronic data

transmission and positioning system – does.

The data obtained can be used to make

the machine even more economical.

8// Quarrying

Page 9

The fuel consumption of the PR 744 Litronic crawler tractor stays low even at full load.

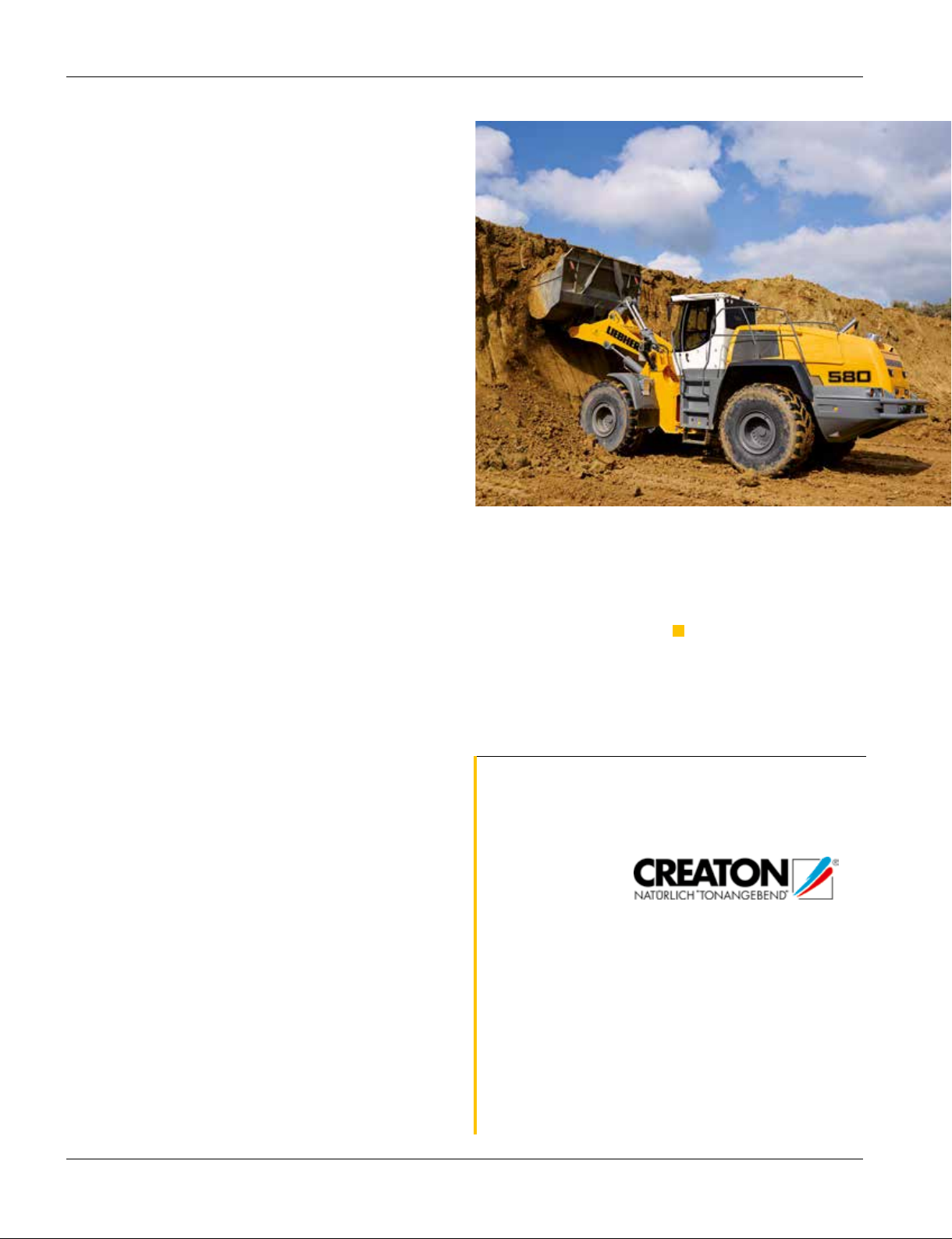

Hooked on creativity with clay

Many forms, many sizes, many colors – from classical to creative. Creaton AG offers a broad range of roof tile

brands. Production runs around the clock, 365 days a year. From the production of the raw materials to sales,

Creaton does everything itself. The entire process is configured for the continuous operation of huge furnaces that

reach a temperature of over 1832°F in their core.

Quarrying //9

Page 10

Feature: Creaton AG

Creaton AG is one of the leading manufacturers of clay tiles in

Europe. The company was formed from the merger of the two

Bavarian tile works Berchthold and Ott. Berchthold was founded

in 1884 in the town of Wertingen near Augsburg, the present-day

location of Creaton’s head office.

In total, Creaton AG has 9 locations with 15 plants and about

1000 employees. Approximately 100 employees work at the

Bavarian locations of Wertingen and Roggden. Small pan tiles

are produced in Wertingen, while beaver tail tiles are made just

1.2 miles away in Roggden. Both products are manufactured in

a range of different styles and colors, with about 50 different

features such as ventilation or apex tiles. They are delivered to

building material wholesalers and larger roofing companies,

primarily in Germany and other European countries. But there are

also customers in other parts of the world who choose Creaton

products. For example, tiles from Wertingen were used to tile the

roof of the Hofbräuhaus brew pub in Las Vegas. “We even have

companies from Singapore and China on our list of customers,”

explains Ferdinand Kanefzky, factory manager at the Wertingen

and Roggden locations.

“80 % of our raw materials is loess, 20 % highly plastic clay. The

clay decides how easy it is to shape the tiles. Of decisive

importance is the exact composition of the different materials

extracted and their mixture,” Ferdinand Kanefzky continues,

explaining the production of roof tiles in Wertingen. Moisture is

Roland and Ferdinand Kanefzky with the final product.

another critical parameter. “We go to great lengths to make sure

that we start with perfect raw materials. That begins with the

analysis and treatment of the material in the pit and continues

through to the meticulous examinations in our own laboratories,”

Ferdinand Kanefzky adds, describing each production step.

“Dosage is the first step in preparing the raw materials. The

material is then put into a machine, which smashes and mixes

the components. It is then sent through two rollers and pressed

to about the thickness of a fingernail. After that, it is put into a

vacuum chamber where the air is drawn out of the material. Now

the tiles can be finished in a press with plaster molds. At this

point, it still consists of about 19.5 % moisture. After the next step

– drying – the residual moisture is reduced

to 2 %. The final step before the furnace is

to apply a glazing, also called engobing, that

produces colors for the top layer out of

minutely ground clay.

Wheel loaders are used for loading.

10// Quarrying

The tiles are placed in furnace cartridges

and conveyed automatically through the

furnace kiln transporters. The furnace in

Wertingen measures some 394 ft long, 16ft

5i wide and 13ft high. It takes 44 hours to

pass through its 15 furnace chambers.The

maximum furnace temperature is more than

1832 F. The tiles are still at about 176 F when

they leave the furnace. The next step is a

final examination, part automatic and part

manual, before the tiles are sorted into

smaller packages that a roofer can easily

handle.

Every year, many tons of loess and clay are

needed for producing tiles in Wertingen and

Roggden. Roland Kanefzky, head of Machine

Engineering and of the vehicle fleet,

describes the process: “We have to be

flexible according to the weather.

Page 11

We cannot extract water from the raw material before molding.

That means that the moisture content must not be higher than

20 %, even in the pit. One Liebherr R 954 C crawler excavator is

in operation at the spoil. We have Liebherr wheel loaders, one

L 586 and oneL538, working on quarrying at the face. We also

have anL580 on order. The main reason was that we could get

a certificate of exemption for single journeys for theL580. That

makes it easier to change sites at short notice due to weather.”

To maintain reserves when operations are stopped, piles up to

623 ft 4 in long and 164 ft wide are laid out directly adjacent to

the pits, and these are protected with a fleece. The wheel loaders

at the face load the dumpers, which carry the material to the piles.

Operations at the face are a great stress on the wheel loaders.

The material is highly compressed and very heavy, causing the

equipment to operate at full throttle about 80 % of the time. The

hydrostatic drive is highly beneficial here. “We have performed

direct comparison tests with other machines and have found truly

enormous differences,” Roland Kanefzky says. “For example, the

Liebherr machines are much more economical in terms of diesel

consumption. The Liebherr drive is also easier to meter. After all,

we have often experienced overheating problems with converterpowered wheel loaders.”

Feature: Creaton AG

The highly compressed material means driving at full throttle 80 %

of the time, which the hydrostatic travel drive handles well.

Ferdinand Kanefzky adds, “We have been working with Liebherr

since 1988. Economy, quality and service are what count for us.

Diesel consumption is, of course, important, especially for the

wheel loaders. Apart from that, we need high-performance

machines that can withstand a lot. To date we have very good

experience with Liebherr as a company. If ever we have had a

problem with a machine, a service representative was always

there very fast. The spare parts supply has always worked totally

smoothly as well. Nagel is a competent service center dealer

close by with very good people who really know what they’re

doing with the machines.”

“We have been working with Liebherr

since 1988. Economy, quality and service

are what count for us.”

Ferdinand Kanefzky, plant manager at the Wertingen and Roggden locations

“We attach great importance to working in harmony with nature,”

Ferdinand Kanefzky says, explaining the company’s slogan:

“Natural clay sets the tone.” “Protection of the environment is

important for us. Creaton is one of the first roof tile manufacturers

to be awarded the Bavarian Environmental Medal. We were one

of the first to change over from disposable pallets to Europool

pallets, and we stopped using plastic foil for our packaging a long

time ago. We elaborately recultivate mined areas, for example,

for agricultural use, or we create a biotope. We have even planted

an orchard with 150 fruit trees.”

Company profile

Creaton AG

Sector:

Size of company:

Founded:

Location:

Managing Director:

Website:

Liebherr machines

in operation:

Clay roof tile manufacturing

9 locations, 15 plants, approx. 1000 employees

1884

Head office at Wertingen, Germany

CEO: Stephan Führling

www.creaton.de

L 538,L542,L566,L580 IIIB, R 954 C,

PR 744 LGP

Quarrying //11

Page 12

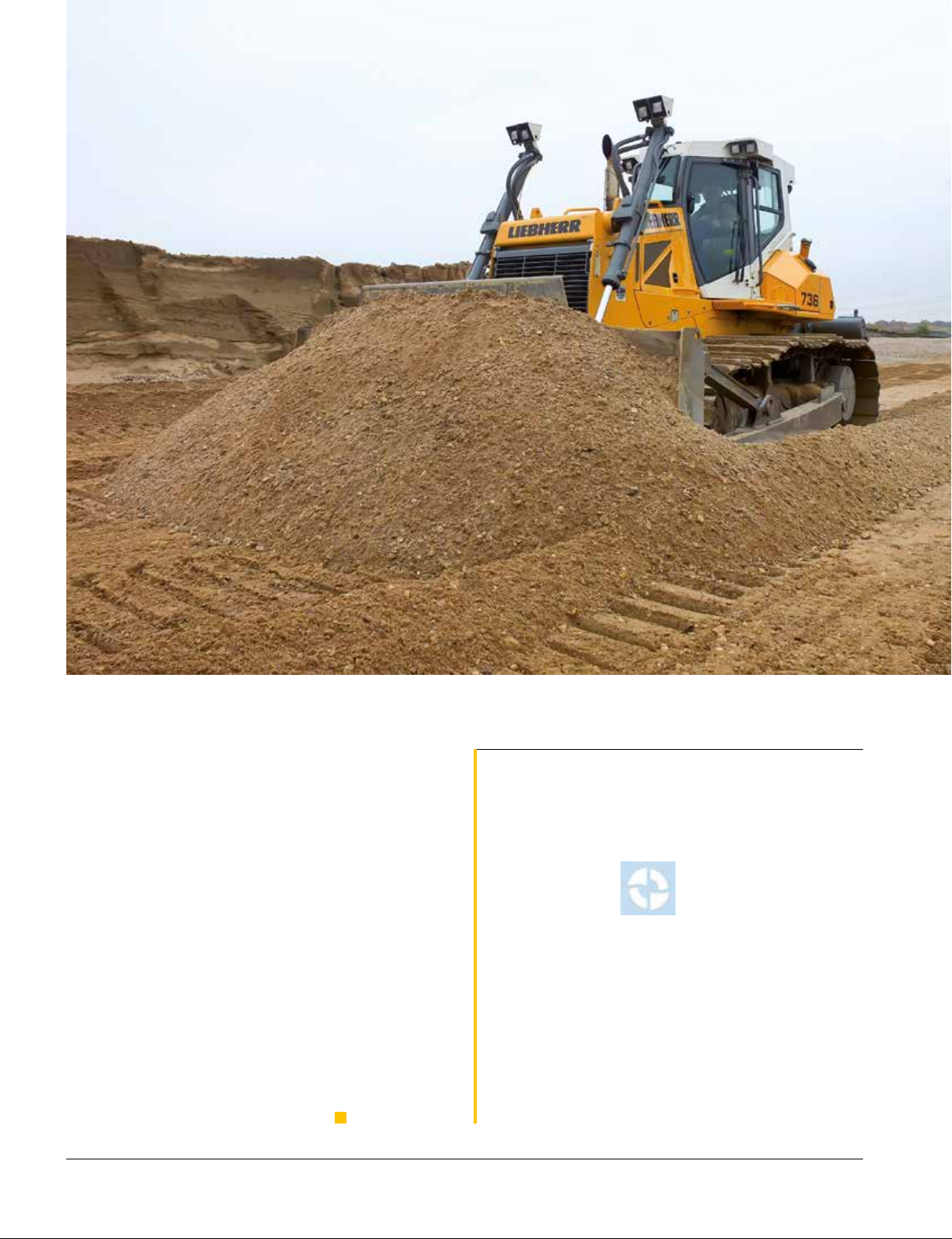

Feature: Holemans GmbH

From gravel to sand

and on to new lakelands

Many gravel pit lakes on the lower Rhine are former quarrying fields of the Holemans Group. Here in the region

between the Ruhr and the Netherlands, companies of the Holemans Group have been extracting gravel and sand

before recultivating the areas affected for many decades. For six months, a PR 736 was in use as a practical test

machine for the new crawler generation 6.

specific requirements of the customers. “Today, concrete

manufacturing is a science in itself. As the industry develops, the

requirements on the raw materials are increasing,” says Thomas

Derksen, commenting on trends in the sector.

The Holemans Group performs mining and recultivation

in stages, many of them in parallel. Embankments and paths

are laid, waterside areas fortified and trees planted. Ten Liebherr

machines are used in these operations: eight wheel loaders, two

wheeled excavators and one crawler.

Thomas Derksen, technical manager.

The roots of the Holemans Group go back to the year 1873 , and

the head office is in the town of Rees directly on the Rhine. Its

core business is the quarrying and marketing of gravel and sand,

and 95 % of this is delivered to the construction industry, where

it is used as raw materials in the production of concrete. The

family business is now in its third generation and employs 130

people. It’s not just the customers who benefit from the

company’s activities. Many protected species of animals and

plants find new homes in the gravel pit lakes that are created.

And the people in the region enjoy the watery recreation areas.

The companies of the Holemans Group deliver some 4.4 million

tons of high-quality gravel and sand every year, mainly to

manufacturers of concrete components, concrete transporters

and construction materials traders. “Sand and gravel can be found

everywhere, for example in buildings, footpaths, roads, bridges

and pipes, to name just a few,” says Thomas Derksen, technical

manager of Holemans GmbH. “Solar cells and microchips also

contain sand.”

Sand is made up of grains of between 0.00025 and 0.08 inches

in diameter. Gravel grains are between 0.08 and 1.26 inches in

diameter. “Sand and gravel are also split up into various size

categories. The individual fractions are separated using different

processes and then mixed in precisely defined ratios for the

Holemans has been placing its trust in Liebherr excavators and

wheel loaders for many years. The crawlers employed to date

include a PR 743. From December 2012 until July 2013, a

preproduction machine of the type PR 736 was tested. The tasks

of the crawler included shifting and depositing gravel fields and

top soil and shaping the topography of the terrain. Some 2100

operating hours were accumulated.

“Service over the entire lifetime of the machine

plays a decisive role for us. With Liebherr, we

know that we can rely on a quick response and

good work.”

Thomas Derksen, technical manager of Holemans GmbH

The PR 736 features an unprecedented electronically regulated

travel control with integrated “eco” function and proactive power

adjustment, which offers the choice between high power out

putand maximum efficiency. “The important thing for us is that

we have power for pushing. That makes up 90 percent of our

operation,” explains Thomas Derksen. “And the power available

is really impressive compared to the predecessor model. Despite

this, fuel consumption is on a similar level.”

Other positive aspects for the drivers were the comfort and clarity

of the cab, which has been developed completely from scratch.

All-round vision provides for additional efficiency and safety –

even in the area around the door – thanks to edges that drop

12// Quarrying

Page 13

Power is needed here. That accounts for 90 % of our operations.

down to all sides and panoramic glazing. The exhaust system is

completely hidden behind the A-pillar, which prevents it from

obstructing the view over the engine cowl.

“Another advantage for ground levelling operations is how quiet

the machine runs,” Thomas Derksen says. Particular attention

was paid to this in the development of the new crawler generation.

The new features also include the undercarriage. A much larger

diameter sprocket wheel and more intermeshing teeth have

noticeably lengthened the service life of the chain and the sprocket

Maintenance has also been optimized. Centralized service points,

wide-opening access hatches and engine compartment doors,

a tilting cab as standard, and an optional radiator that can be

folded out for cleaning all make service work easier.

“Service over the entire lifetime of the machine plays a decisive role

for us. With Liebherr, we know that we can rely on a quick response

and good work,” Thomas Derksen continues. “The reliability of the

preproduction crawler is quite remarkable. Throughout the entire

test phase, there was not one single failure.”

Company profile

Holemans GmbH

Sector:

Size of company:

Founded:

Location:

Managing Director:

Website:

Liebherr machines

in operation:

Quarrying and marketing plus nature and leisure

120 employees

1873

46452 Rees, Germany

Michael Hüging-Holemans

www.holemans.de

8 wheel loaders, 2 wheeled excavators and

acrawler

Quarrying //13

Page 14

10 expert tips for long

undercarriage service life

Regular servicing and the right way of working have a great influence on the service life of the undercarriage.

On construction machines with chains, wear can occur in the chain bushings, sprockets, chain links, guide wheels,

track rollers, carrier rollers and on the track shoes. There are several different ways to prolong the service

life of the undercarriage and to reduce costs related to the undercarriage.

What is undercarriage wear?

Chain bushings

On an oil-lubricated chain, the bushing

moves relative to the sprocket. This causes

wear at the bushing and the teeth.

Rotating bushing chains roll freely from the

sprocket, reducing wear on the bushing

and the sprocket. Because of their form,

rotating bushing chains are only of limited

suita bility for tough operations where

impact stress occurs.

Tip 1: On oillubricated chains, the bushing

can still be used if it is turned around 180°

in good time (with a wear level of 70 to 80 %). The

actual savings depend on the labor costs incurred.

Sprocket

Once the sprocket has become completely

worn, teeth could break and the chain

could jump. An excessively worn sprocket

also increases wear on the bushings many

times over. For this reason, great attention

should be paid to sprocket wear.

Tip 2: As a rule of thumb, the sprocket seg-

ments must not meet tooth tip to tooth tip. At

least a narrow web must be visible. Details of this can

be found in the operating handbook for the machine.

Chain links

The chain links run over the guide

wheel, carrier rollers and track rollers.

Wear occurs on the contact areas. This

often occurs in the form of wave wear.

Tip 3: If vibrations occur when the machine

is in operation, this might be caused by wave

wear on the chain links.

Guide wheel, track rollers

and carrier rollers

Guide wheels and rollers tension and guide

the chain, also transversely. Wear occurs

on the running surfaces and at the side

walls.

Tip 4: It is especially important for the

under carriage to be cleaned in the winter. This

will prevent the carrier rollers in particular from sticking.

At the same time, cleaning will lengthen the service life.

Track shoes

The webs and the track shoes themselves

wear over the course of time, especially

on hard ground such as rocks.

Tip 5: As an alternative to track shoes of

standard quality, Liebherr also offers special

track shoes that have more wearing material for highwear operations. Examples of such special track shoes

are “ES Extreme Service” or “SESS Super Extreme

Service Shoes.”

14// Quarrying

Page 15

What influences undercarriage wear?

Service

Ground material

The type of ground material will have the

greatest influence on undercarriage wear.

Abrasive sand, for example, can cause

wear on a chain within a very short space

of time. In less abrasive materials (top soil,

loam, coal), the undercarriage will last

much longer.

Tip 6: In especially high-wear operations in

soft material, rotating bushing chains can

substantially increase the service life of the

undercarriage. Because of their form, these are

only of limited suitability for tough operations in

which impact stress occurs.

Working with the machine

Travel speed

Excessively high speed – especially when

reversing – can lead to increased wear on

all components.

Cornering or working on a slope

Tight corners or frequent unnecessary

changes of direction when changing tracks

can cause increased wear, especially at the

side walls of the guide wheels, carrier rollers,

track rollers and on the chain.

Tip 8: In general, it is advisable to use a

centrally fitted chain guidance system with

crawler undercarriages. Such a chain guidance

system will absorb some of the lateral forces created

when steering or driving across a slope. Alternatively,

the undercarriage can be fitted with a continuous

chain guard that protects the entire undercarriage

against foreign bodies.

Chain tension

Correctly setting the chain tension is a

basic requirement for optimal service life

of the undercarriage. Practical tests have

shown that the right chain tension can lead

to a service life of the bushing up to 75 %

longer than with the chain overtensioned.

The service life of the sprockets is also

lengthened accordingly. If the chains are

too loose, this could cause the teeth to

wear on one side of the sprocket.

On Liebherr crawler tractors under operating

conditions, the chain should hang down by

between 1.2 and 2.4 inches, depending on

the model, between the guide wheels and

Check your speed

If the chains start to slip this will increase

wear on the track shoes. Drivers should

always adapt their travel speed and blade

load according to the operating conditions

in order to prevent the chains from slipping.

In addition, it should be checked whether

the webs on the track shoes are sufficiently

high to allow optimal traction. This will

greatly improve the pushing performance.

Tip 9: Freely variable or hydrostatic drive

systems allow travel speed to by optimally

adapting to all operating conditions and types of

ground. Because the optimal travel speed can also

be set at full engine speed, there is always sufficient

tractive power available. The efficiency of such

drives is constantly high over the entire speed range

and no manual gear shifts are needed. That makes

fuel consumption especially low compared to

conventional construction machines.

the carrier roller or between the carrier roller

and the gear ring. The correct chain tension

can be easily set with a grease gun. Please

refer to the operating handbook of the

construction machine for details. To prevent

injuries, it is important for the safety

instructions to be observed.

Tip 7: The chain tension can easily be

measured with a board or rod positioned

between the guide wheel and the first carrier roller.

Make sure that the machine is measured under

realistic operating conditions as the chain may be

additionally tensioned by the buildup of material

on the undercarriage.

The right machine configuration

A correctly configured undercarriage will

improve the performance capability of the

machine, especially in critical ground

conditions. At the same time, undercarriage

wear can be drastically influenced.

Fundamentally, crawler undercarriages

differ in the undercarriage length, the track

shoe width and the related track width. As

a general rule: a shorter undercarriage will

provide greater manoeuvr ability and higher

ground pressure on hard ground. For

optimum traction on normal hard ground

and the best possible levelling performance,

a long undercarriage with narrow track

shoes should be chosen. An extra-wide

undercarriage is used on less stable (i.e.,

soft) ground.

Tip 10: For operations on hard or stony

ground, a suitably narrow track shoe width

should be selected as the chain could be damaged

by the lateral forces created when wide track shoes

are used.

Quarrying //15

Page 16

16// Quarrying

Page 17

Quarrying in profile: Carrière des Grands Usages

R 950 SME: The right excavator for

“Carrière des Grands Usages” Quarry.

When the time came for the 50-ton excavator at this limestone quarry to be replaced, the operator

selected the R 950 SME – an excavator of the right size that is specially designed for working at the

faceyet versatile in its operation.

The “Carrière des Grands Usages” quarry covers an area of 173

acres and is owned by the companies Eurovia and Colas. It is

located just a few miles from Bourges, France. At present, 74

acres are being used to produce material for road building and

concrete production. “We offer the full range for the construction

industry, with grain sizes 0/10, 0/20, 0/30 and 0/60 plus 4/10

and 10/20 for the production of concrete,” explains Alexandre

Favin, operations manager of the Carrière des Grands Usages

quarry, or CAGU for short. Other products include filling sands,

drainage materials with 40/70 grain, as well as blocks of rock

from 3.9 to 7.9 in and even 19.7 to 39.4 in. “All of these are

prepared according to the customer’s wish, for example, for

fortifying embankments or as decoration for landscape architects,”

the operations manager adds.

The most important customers of the CAGU quarry are the

members of the syndicate that own the quarry. These include

the locally based companies Eurovia and Colas, but also civil

engineering companies and two ready-mixed concrete plants

in Bourges. The Carrière des Grands Usages quarry includes

the Morthomiers limestone seam, which is very well known in

the region. The excavation permit allows 402, 344 tons per year

to be quarried until 2034.

“Prior to excavation, we have to clear 7.9 to 11.8 in of spoil and

then a 19.7 in to 6.6 ft deep layer of material. Depending on its

quality, the latter layer may either be sold or used for filling on the

quarry grounds,” explains Alexandre Favin. Drilling and blasting

are outsourced to a subcontractor.

A crawler excavator from 2005 was used in the quarry until June

2013. The excavator loads a rigid-frame dumper truck that transports the limestone to the charging hopper of the processing

machine. The material is conveyed by an apron conveyor to a

scalper where the stone is separated and sieved. Material larger

than 4,7 in is carried to the primary impact crusher which produces

material of grain size 0/31.5, 30/70 or 30/150 and 70/150. A

second impact crusher produces material of grain size 0/4, 0/20,

4/10 and 10/20.

The R 950 SME flexibly performs

itstasks on the excavation front.

The materials from the machine are taken to the stocking bays

by a rigid 30-ton dumper truck. Besides the production of construction materials, the quarry is also able to take earth from

construction sites. “Customers tip their earth onto a platform

specially provided for this purpose and we spread it with a crawler

loader to fill the quarry grounds,” explains Alexandre Favin.

“With 11,500 operating hours, the crawler excavator had already

reached a ripe old age,” Alexandre Favin tells us. “Moreover, this

55-ton excavator was somewhat oversized in view of the economic development,” he adds. “More than anything we wanted

a smaller excavator.” The operations manager at the quarry was

really looking for an excavator of about 44 tons.

He compared the offers of the different manufacturers, including

Liebherr. He asked Liebherr if he could test the R 946. Fabien

Denis, technical customer consultant at the SOMTP Centre, the

contractual dealer for Liebherr in the region, recommended the

R 950 SME (Super Mass Excavation), a new machine that was

launched in 2012. “That is the quarry version of the R 946,” Fabien

Denis says. “It has the turntable of the R 946 and the undercarriage of the R 956. Its boom and bucket arm are reinforced and

the ballast weight is higher. The driver’s cab and the tilt cylinder

feature safety devices, and the windows are made out of armored

glass. The underbody is protected by a thick guard plate.” In

contrast to the R 950 SME, neither of the competition models

that were considered was specially designed for work in a quarry.

“In our region, we are heavily involved in the Eurovia companies,”

Fabien Denis adds. “But this is the first R 950 SME within the

Eurovia Group,” Alexandre Favin explains. The Construction

Machines department of the road building company is monitoring

the testing of this model at the CAGU quarry with interest. Another

advantage is the vicinity to the Liebherr contractual dealer SOMTP

Centre. This is just a few miles away from the quarry.

That’s how the R 950 SME came to find its place in the quarry’s

machine fleet. It is equipped with a Liebherr backhoe bucket with

semi-delta cutter and 3 yd

tion as the material is not especially abrasive. “This procurement

was part of a partnership,” Alexandre Favin tells us.

3

capacity without special wear protec-

Quarrying //17

Page 18

Quarrying in profile: Carrière des Grands Usages

“SOMTP Centre can use the opportunity to present the R 950

SME to us as an alternative to its most important competitive

products,” Fabien Denis adds.

“This dealer really has orientated itself toward our requirements.

If necessary, he calls in the evening after production has stopped,”

says Alexandre Favin, who also stresses the responsiveness of

the dealer. When excavator driver Jean-François Méry explained

that it is sometimes difficult to dig into the piles

“The first R950SME

within the Eurovia Group.”

Alexandre Favin, operations manager of

the “Carrière des Grands Usages” Quarry

of material, Fabien Denis proposed trying out more pointed teeth.

“It’s easier with the more pointed teeth,” comments Jean-Francois

Mery. “We have now fitted the backhoe bucket with five teeth of

this form,” explains Alexandre Favin.

The Liebherr engine in the R 950 SME has six cylinders and a

power output of 295 ch, and it complies with European emissions

standard Tier 4i/Tier IIIB. It is equipped with a particulate filter

with active regeneration. “That is something new for us,” Alexandre

Favin says. The degree of contamination is shown on the monitor

on the cab display. When regeneration is due, it starts automatically without interrupting work. “I can defer regeneration, for

example, to the next day if it becomes due near the end of the

day,” Jean-François Méry reports.

The R 950 SME has been in operation since the end of May 2013.

“It is dynamic and has a high rpm speed,” Jean-François Méry

declares. He also appreciates the comfort of the driver’s cab and

the low noise level of the excavator.

The dumper truck is now loaded in nine cycles instead of seven.

“That is just what we need,” says Alexandre Favin. “It is a highly

versatile excavator.” Half the time it is used in production. The

rest of the time it is used for spoil work, loading blocks, and

exploratory work at new parts of the quarry. “The R 950 SME is

equipped for high-volume turnover, which extends its range of

applications. And the excavator driver is able to choose the most

suitable of four working modes for his current work,” Alexandre

Favin adds. “In addition, our excavator driver asked us to choose

the optional boom float function, which prevent unnecessary

18// Quarrying

Page 19

Quarrying in profile: Carrière des Grands Usages

loading of the excavator and improves comfort for our driver.”

The operations manager knows the benefit of the excavator’s

automatic engine shutdown function after a ten-minute idle period,

which saves fuel. Now he is starting to use LiDAT, Liebherr’s data

transmission and positioning system in order to learn more about

the operating and driving times, deceleration and fuel consumption of the excavator.

The Liebherr backhoe bucket with a digging volume of

3 yd³ was equipped with pointed teeth, which are superbly

wellsuited to the material.

Transport of excavated and prepared material via conveyor belts.

Company profile

Carrière des

Grands Usages

(CAGU)

Sector:

Size of company:

Founded:

Location:

Managing Director:

Website:

Liebherr machines

in operation:

Excavation of building materials

7 employees

1980

Bourges (18)

Alexandre Favin, operations manager

www.eurovia.fr

R 950 SME

Quarrying //19

Page 20

Trends

Protective devices

for crawler excavators

Several excavator components at risk of damage caused by flying stones when working in the quarry,

especiallywhen they are performing wrecking ball operations. Liebherr has developed special protective

measuresforsuch operations to prolong the service life of the most important components.

Operators can choose between a piston rod guard for the

cylinders, bottom boom protection for the stick or monoblock,

wear plates on the undercarriage and many other individual

measures for protecting both man and machine.

1. Piston rod guard

•

Simultaneously moving metal covers protect the chrome-plated

piston rods against damage.

•

Available for bucket cylinders (all machine types), hoist cylinderson

R 956 to R 980 SME, crowd cylinders for front shovel machines

from R 956 to R 9 80 SME.

2. Hoist cylinder hose protection

•

Protection for hydraulic lines and line-break protection

forhoist cylinders.

•

Optional for R 936 to R 950 SME.

3. Bottom boom protection for stick and monoblock

•

Prevents damage to the stick and the monoblock.

•

Protects the underside of the stick (bottom boom) and/or the

monoblock with a solid metal cover.

•

Especially suitable for working under hard conditions.

•

Stick: available for R 936 to R 980 SME.

•

Monoblock: available for excavators R 918 to R 980, R 936

to R 960 SME.

5. Protective grille for driver’s cab

•

Protective grille in front (FGPS) and top (FOPS) area of the

driver’s cab protects against flying stones.

•

Available for all types of machines.

6. Armoured glass

•

Front and roof glass in the driver’s cab can be equipped

with impact-resistant armoured glass, offering additional

protection for the driver.

•

Available for all types of machines, standard for R 966.

7. Guard plate

•

Protects the undercarriage against damage and wear, especially

when working on loose piles of material and/or during wrecking

ball operations.

•

Available for R 950 SME to R 980 SME.

8. Travel drive guard and reinforcement kit for

transmission bearings

•

Reinforcement panels protect the outsides of the travel drive

and the transmission bearings on the inside of the longitudinal

members against damage (e. g., when working on piles of loose

material).

•

Available for excavators R 950 SME to R 980 SME.

4. Protection for slewing mechanism and

lubricationlines

•

Protects the slewing mechanism and the lubrication lines in this

area against damage, especially during wrecking ball operations.

•

Covers the slewing mechanism and the lubrication lines.

•

Available for excavators R 950 to R 980.

20// Quarrying

Page 21

Piston rod guard

Bottom boom protection

forstick

Bottom boom protection

for monoblock

Hoist cylinder hose protection

Guard plate

Protection for slewing

mechanism and lubrication

lines

Travel drive guard

Travel drive guard

Quarrying //21

Page 22

Feature: a + b

Moraine gravel for asphalt and cement

a + b Asphalt- und Betonmischwerke is a medium-sized company that produces and sells ready-mixed concrete,

asphalt, gravel, and grit. The company was founded 43 years ago and now has 65 employees. In the Oberschwaben

region of Germany, a + b operates four ready-mixed concrete works, plus an asphalt, gravel and grit plant. Its range of

services is rounded off with concrete pumps, asphalt milling and materials recycling. Its customers include companies

working in the field of gardening and landscaping and major road building and structural engineering companies.

“Even in ancient Rome, asphalt was used for road building,”

explains David Gütler, managing director of a+b Asphalt- und

Betonmischwerke. “Asphalt is versatile in its use and can be

adapted to meet different requirements. Depending on the

purpose, load profile and climatic conditions, we can configure

the right asphalt for any customer requirement, prepare the initial

tests, select the most suitable raw materials and manufacture

our product entirely according to generally accepted technical

standards. Asphalt production is monitored in our laboratory. In

addition, an independent institution also conducts checks.

We bunker the asphalt in different silos, each holding about

blocks. Besides the possibilities provided by classic asphalt

recycling, tarred asphalt milled material is also used. a+b prepares

this in a mixing plant to form hydraulically bonded base layers

for use in approved construction activities.

And concrete production? “Sand, gravel, water, cement from

limestone, clay and sand: mother nature supplies all the

ingredients needed for concrete. What we make of these depends

on the exact mix,” explains Gütler. “We produce ready-mixed

concrete with different physical characteristics, but always the

right recipe for the appropriate application and environmental

conditions. Our range includes: standard and heavy-duty

concrete, concrete for bored piles, fiber concrete with steel and

plastic fibers, colored concrete, drainage concrete, single-grain

and road construction concrete, easy-use concrete, and

hydraulically bonded base layers.

We rely entirely on Liebherr machines in this field. Our four

concrete mixing machines are all supplied by Liebherr, as are our

32 truck mixers – articulated mixers, demountable mixer systems

and interchangeable mixer systems. This is partly because we

are absolutely convinced of the quality. But the closeness to the

manufacturer is also, of course, highly beneficial. LiebherrMischtechnik GmbH is based here in Bad Schussenried, just

3miles away.”

L 576 wheel loader loading a stationary mixing plant.

132 tons. We can store up to six different types there. The readyto-use asphalt is loaded onto the customers’ lorries at

temperatures of about 356 F. When we have real power days,

we start work at about 3.00 a.m. so that we have about 661

tons ready by the time operations start in the morning. The types

depend directly on what the customers have ordered. If needed,

we can fill all the silos with a single type. That sometimes happens

when a customer is working on a major construction site.”

Asphalt has another benefit; the construction material is 100 %

reusable, which reduces environmental impact and offers good

economic benefits. In the asphalt machine operated by a+b,

reclaimed asphalt is input in the form of milled material or fault

22// Quarrying

“The drivers are all highly satisfied with the

Liebherr machines. One of them said the new

580 machine is the best machine he’s ever

driven. And he’s been driving wheel loaders for

more than 20 years.”

David Gütler, managing director

Quarrying operations take place over 173 acres. “The premises

here are larger than the center of the village of Ingoldingen,” Gütler

tells us. At the bottom of a steep slope, directly in the gravel pit,

Liebherr equipment is hard at work – a Liebherr L 580 wheel

loader and a TA 230 Litronic dumper. Gütler explains, “The newest

wheel loader is always sent to the face. That is where we need

Page 23

TheL580 wheel loader extracts more than 1,308 yd³ of material every day.

the most powerful machine. Every day, the wheel loader has to

extract and load more than 1,093yd

3

of material. The machine

it replaces goes to the top for piling, loading lorries and feeding

the asphalt machine with grit. The drivers are all highly satisfied

with the Liebherr machines. One of them said the new 580

machine is the best machine he’s ever driven. And he’s been

driving wheel loaders for more than 20years.”

The driver fills the shovel with several tons of gravel at the face,

apparently effortlessly. “Yes, theL580 certainly does have power,”

says Gütler, adding with a twinkle in his eye, “but we’re lucky.

The good thing about Oberschwaben is the wonderfully loose

moraine gravel, which is easy for the wheel loader to pick up off

the face. We extract the gravel over several layers. On the lower

levels we have finer grain, while the coarser grains are higher up.

The finer layers are taken to the concrete plant, the coarser ones

to the grit plant. We produce grit for our asphalt with three crushers

and different sieves with grain sizes 0/2, 2/5, 5/8, 8/11, 11/16.

The charging hopper for grit production is located directly below

in the pit. Ultimately, the grit comes out next to the asphalt plant,

so we only have to cover short distances with the wheel loader.

The dumpers take the finer gravel for the concrete plant up to a

second charging hopper.”

After operations have finished, the area is reclaimed and the pit

recultivated. Gutler explains, “We don’t refill, but rather take the

spoil that we have taken away back to the pit bed and then add

a layer of topsoil. Effectively, everything is then as it used to be,

just 19 or 20 yards deeper. Some of the areas are used for

agriculture. But biotopes are also created, where nature can

evolve freely. For example, storks are often seen on this meadow

before they migrate to Africa.”

Company profile

a + b

Sector:

Size of company:

Founded:

Location:

Managing Director:

Website:

Liebherr machines

in operation:

Asphalt, ready-mixed concrete, gravel, sand

65 employees

1970

Biberach, Ingoldingen, Ochsenhausen, Aulendorf,

Otterwisch

David Gütler

www.asphalt-und-beton.de

30 Liebherr truck mixers, 3 with conveyor

belt,L580 andL576 wheel loaders,

TA 230 Litronic dumper truck, R 932 excavator

Quarrying //23

Page 24

Feature: Recycling GmbH Lahnau

All quarrying operations

under one umbrella

The company name Recycling GmbH Lahnau is misleading. For many years, the focus of the company’s activities

has been on quarrying operations, and its range of services covers all tasks relating to the quarrying and

preparation of natural stone, gravel, sand and clay. The professionals from the German state of Hesse do this with

75 large machines – 48of them from Liebherr.

Recycling GmbH Lahnau was founded in 1998 and has a direct

interest in two basalt quarries and a clay and quartz sand

quarry. The company also operates its own earth deposit and

construction waste dump plus three construction waste

recycling plants in the region of central Hesse. The most

important part of the company’s activities, however, is quarrying

work to customer specifications.

“When I joined the company 13 years ago, there were 11 of us.

Today, the company has more than 70 employees actively working

in commercial operations. This development certainly has a lot

to do with our broad range of services,” explains Ralph Lang,

technical manager and director. “We offer all services related to

the quarrying process under a single umbrella.” The company

looks after moving spoils and earth and has its own authorized

blasting expert. Quarrying raw materials is also possible without

explosives using hydraulic hammers. From releasing to loading

to transporting, Recycling GmbH Lahnau is able to perform all

surface quarrying operations. Manufacturing of end products

with mobile crushers and sieves, plus decontamination and

renaturalization of surface quarrying sites, are also part of the

services available.

R 946 loading a TA230.

Recycling Lahnau orientates its services to the individual needs

of the customer. Ralph Lang puts it like this: “We offer both

partial services and the complete execution of all quarrying and

preparation work. For the customer, that means that he doesn’t

have to invest heavily in new machines or take on new staff. Many

of our customers also appreciate the fact, for example, that they

have full flexibility in how they plan their delivery volume. This

enables them to respond to fluctuations in the market and, at the

same time, to plan reliably. You know how much a ton of mined

materials costs at the start of the year, for example.”

24// Quarrying

Page 25

On average, the quarrying specialists at Recycling Lahnau are

in action at around 20 different locations. One of the largest

construction sites at the moment is the quarrying of limestone

for Rheinkalk GmbH in Dornap near Wuppertal. Between the

spoil and the actual limestone, there is a so-called cleaning cut

containing some relatively good limestone, which has to be sieved

before it can be prepared in order to clean out the impurities.

The resulting stone material is then used to produce mineral

mixtures. In Dornap, the company provides all machines and

staff. Twelve earth-moving machines, including four excavators

and three wheel loaders from Liebherr, are in operation here. In

addition, there is also a mobile hammer crusher, a mobile impact

mill with integrated sieve unit, and a coarse sieving machine.

In total, there are 75 large, modern machines. These include

crawler excavators with an operating weight of 28 to 99 tons,

rigid-frame dumper trucks with between 44- and 72-ton payloads,

articulated trucks in the 33-, 39-, 44- and 55-ton classes, crawlers

for various operations, in-hole and outer-hammer drilling rigs for

various borehole diameters, wheel loaders of all sizes, mobile

crushers, sieve systems and hydraulic hammers. Forty-eight

machines bear the Liebherr name, including all 15 wheel loaders,

15 crawler excavators, all eight crawlers and nine articulated

trucks. “The quality and resilience of the Liebherr machines are

right, and that is especially important for us,” says Ralph Lang.

“We also only hear positive feedback from the drivers: good handling, good performance, plenty of space and comfort in the cab.

We even have excavator drivers who state categorically that they

don’t want any other brand.”

“We even have excavator drivers who

L 586 wheel loader in front of a coarse sieving machine.

Another decisive criterion for the use of so many Liebherr

machines is flexibility. “As a service provider, we have to be able

to respond extremely flexibly to customer wishes, and to make

enough of the right machines available for a certain period of

time,” explains Ralph Lang. “Where the next job is and exactly

what is to be done there is always decided a new, sometimes on

very short notice. Liebherr and, in particular, the rental service of

Liebherr Mietpartner GmbH give us exactly the flexibility we need.

We have been collaborating successfully since 2003. We have

competent consultants and use their experience when it comes

to, say, the right choice of attachments. The machines are ordered

and built exactly to our wishes and expectations. And even if a

job is arranged on very short notice, we are able to bridge the

time up to the delivery of a new machine with rental machines

that are available immediately.”

With 48 machines in operation nationwide, service is a key factor.

In most cases, a mechanic can be on site the same say or, at the

latest, the following day. “The availability and response time of

the Liebherr service teams are superb. The collaboration with

Liebherr is perfect for our needs,” Ralph Lang tells us.

state categorically that they don’t want

any other brand.”

Ralph Lang, technical manager and director

The four reverse gears on the articulated trucks are praised

especially highly. They make it easy to cover short distances in

reverse, alleviating the need for maneuvering and saving lots of

time. The handling of the retarder is something else the drivers rate

highly. A lever on the dashboard freely adjusts the effectiveness

between 0 and 100 %, adjusting it perfectly to the profile of the

terrain. That relieves the service brake and creates greater safety.

R 964 C with hydraulic hammer and

R 960 SME for loading a dumper body.

Company profile

Recycling GmbH

Lahnau

Sector:

Size of company:

Founded:

Location:

Managing Director:

Website:

Liebherr machines

in operation:

stones and earth

72 employees

1998

Lahnau, Hessen

Martin Bender, Peter Bill

www.recycling-lahnau.de

1 wheeled excavator, 9 dumper trucks, 8 crawler

tractors, 15 wheel loaders, 15 crawler excavators

Quarrying //25

Page 26

26// Quarrying

Page 27

Advice – Part 2

Wheel loader operating tips

Engine speed range, drive stage and shovel control are the essential parameters that drivers can use to

influence the economy of their wheel loader. The following tips will help you to get the most out of your

machine, achieve good turnover rates and, at the same time, save fuel.

Engine revolutions

at a glance

Engine speed / drive level:

full power at low revs

On a Tier 4i/stage IIIB generation loader,

the engine speed should be between

1300 and 1500 rpm and for machines of

the Tier 3/stage IIIA wheel loader between

1400 and 1600 rpm. The hydrostatic drive

achieves its full pump performance at 60

to 70 percent of the engine speed,

depending on the type of use. Full power

and low revs enable drivers to work

efficiently and save fuel.

Shovel position: fill the shovel

in a cutting, flowing process

The driver can achieve maximum results

by taking the material onto the shovel in

a cutting process. Note the control angle

and the alignment of the shovel

attachment. These show you the shovel

position in the material from the parallelity

of the blade. If you practice the right shovel

guidance, the cutting process takes care

of itself during forward movement and lift.

Fill the shovel in a flowing movement

without interruption. Filling a shovel

without touching the material with the front

tires will also reduce tire wear. Fast and

precise work are also supported by the

automatic shovel return, which makes it

easier to return the shovel to the parallel

rest position.

Only use manual tractive

power control when needed

When working on very loose ground such

as sand, you should set the machine’s

tractive power to manual. Manually

reduced tractive power will enable you to

move and work with the highest traction

possible. When you are working in sand,

for example, this will prevent the tires from

spinning. Manual tractive power control is

available on all medium and larger series

Liebherr wheel loaders. For standard

operations you do not need manual

tractive power control. Conventional

wheel loader operations require pressure

peaks on the drivetrain in certain situations.

If in this case you reduce traction manually,

there will not be enough power on the

travel drive.Trying to increase this with the

throttle will unnecessarily use more fuel.

Use the inch pedal as necessary

to freely control traction

If necessary, you can freely control traction

with the inch pedal. This may be necessary

for deliberately slow forward traction with

simultaneously high working hydraulic

performance, for example, when loading

a truck. As a rule, it is not necessary to

brake manually as the hydrostatic travel

drive already features a self-actuating

braking effect.

The inch pedal should be used for

deliberately slow forward traction

with simultaneously high working

hydraulic performance.

With full power at low engine speed,

drivers work efficiently and save fuel.

Quarrying //27

Page 28

Quarrying in profile: Carrière des Grands Caous

R 964 C SME crawler excavator in the

“Carrière des Grands Caous” Quarry.

On account of its extensive experience, construction contractor Eiffage Travaux Publics has procured a new

R 964 C SME for its porphyry quarry at Saint-Raphaël. The crawler excavator is the heart of the machine fleet at the

“Grands Caous” quarry.

“It is the only hard-stone quarry in the Provence-Alpes-Côte

d’Azur region,” explains Dominique Seux, director of the Grands

Caous quarry, which is part of the Eiffage Group. The materials

produced here, thanks to the presence of porphyry, achieve a

value of 57 in the PSV test (Polished Stone Value). A value of 56

is the minimum required for the surface course of roadways. Half

of the production is used for road construction. Of the other half,

35 % is used for producing ready-mixed concrete and 15 % is

used as coarse gravel in civil engineering or as reinforcement

blocks in marine and river engineering.

Porphyry has been extracted from the quarries close to the sea

in the Massif de l’Estérel, where the Grands Caous quarry is

located, for many years. This is where the Romans extracted the

stones used to build the Via Aurelia from Rome to Narbonne.

Within the immediate vicinity, the Massif de l’Estérel has supplied

some of the gravel for the PLM (Paris-Lyon-Marseille) railway and

paving stones for the famous Paris to Roubaix road.

In the course of the twentieth century, the quarries in these hills

were gradually abandoned. However, in 1959, a civil engineering

contractor opened the Grands Caous quarry. This was a deposit

for the blue porphyry known as “Estérellite” with feldspar points

and pyrite inclusions. At the time it made a significant contribution

to the construction of the A8 autoroute, which links Aix-enProvence to the Côte d’Azur. In 1989, the quarry was sold to

GSM. In 1998 it was taken over by Appia, part of the Eiffage

Group. In 2012, a license was granted to extract up to

881,849 tons per year until 2042.

28// Quarrying

Page 29

“Because the quarry is located in a specially protected area, it is

subject to two different kinds of regulations,” explains Dominique

Seux. “Firstly, we need the approval of the administration

department, just like any other quarry operator, but secondly, we

also need state approval.” This approval stipulates that the quarry

must remain within its current boundaries, which gives it an area

of 111 acres. To continue production, therefore, the quarry digs

deeper. The quarry stretches from a height of 361 feet AMSL

(above mean sea level) to 59 feet AMSL, i.e., just above the level

of the nearby Mediterranean Sea. Only about 5 acres of the area

are actually directly on the coast. Currently, about half of the

mining area of the quarry is covered by a lake of about 2.5 acres

in area and 49 feet in depth, filled with surface water. When

quarrying is completed, the entire area of the quarry will form a

lake, which will be naturally fed from this surface water.

Quarrying in profile: Carrière des Grands Caous

Jeoffrey Sausse, commercial manager of the contractual dealer

Pic, with Dominique Seux, general manager of the Grands Caous

quarry (left) and Alexandre Pfeiffer, technical manager of the quarry.

In meantime, quarrying will gradually spread across the remaining

area of the quarry and onto the surrounding grounds at an elevation

of 230 to 295 feet above mean sea level, where the production

equipment for building materials is currently located. “In 2016, we

want to set up a new industrial installation at an elevation

of 59 feet above mean sea level while we continue to use

the old equipment during the construction work,” explains

Dominique Seux. “We will also take this opportunity to

modernize the machines, crushers and the sieving

machines, which all herald from the 1970s.”

The deposits are extracted in a closely interlinked process chain.

“We perform all surveying operations ourselves, including drilling

and blasting. The explosives for the weekly blasting are sourced

from a supplier,” Dominique Seux says. A Liebherr R 964 C SME

crawler excavator with an operating weight of 86 tons loads the

four rigid dumper trucks at the quarry. Three to four times an

hour, these transport the material for a distance of slightly more

than half a mile to a charging hopper, which in turn feeds the

primary crusher. After it has been treated in the secondary and

tertiary crushers, the stone is washed as necessary. “We feed

the washingplant with water pumped from our lake,” Dominique

Seux tells us. The residual sand is transported to a cyclone

separator, while the waste water is treated by way of flocculation

in a purification plant. The sludge is then treated in a sludge press.

“We recycle 85 % of our water, which is then fed back into the

washing plant,” explains the quarry manager. “And we also have

customers for the sludge, which is highly impermeable.” This is

used principally for sealing class 1 deposits. “In other words, we

sell our entire production.”

The prepared materials are moved by a LiebherrL 586 wheel

loader. The fleet is supplemented by a Liebherr R 944 crawler

excavator, which is used in the stocking area. This is used to pile

up the material so that vehicles do not have to drive over it. But

it is also used for smaller jobs in the quarry, for example, clearing

away surface layers.

Blocks that are too large are made smaller with a wrecking ball.

The backhoe bucket has special “guide slats” for this purpose.

Quarrying //29

Page 30

Quarrying in profile: Carrière des Grands Caous

In the Grands Caous quarry, a LiebherrL586 is

used to load the end products.

The Liebherr R 964 C SME, which was procured in June 2008,

had clocked up 11,200 operating hours, so it was time to have

it replaced. Inquiries were made to four manufacturers. “With

one of the dealers it was difficult to even get an answer,”

Dominique Seux says. Another dealer was located an hour away

from the quarry. “In an operation like ours, everything revolves

around the excavator that works directly at the face. If that is

out of action for just one hour, the consequences are farreaching.” So there remained a third manufacturer and Liebherr,

which both have dealers close to the quarry. “The decision was

made on the final straight,” Dominique Seux confesses. “We

used to have an excavator from another manufacturer, but we

had lots of problems with that. It wasn’t built for use in a quarry,”

the manager adds.

been specially developed for use in quarries. It features the

undercarriage of the next larger model in a X-shaped construction

to realize a better distribution of forces and prevent material

from accumulating.”

Several times a year, an inspector from Liebherr customer

services conducts an on-site visit together with his colleague

from Pic. The technical manager of the quarry appreciates such

visits. On one of these visits, a crack was discovered in the

boom. “ Liebherr replaced the defective equipment; that’s what

I call proactive service,” he explains. “Whenever Pic performs

arepair, then everything really is in proper working order.”

It was partly the experience with the excavator and partly the

experience with the Liebherr contractual dealer that led to the

procurement of the R 964 C SME. The decision to purchase was

made by the director of the Grands Caous quarry, in agreement

with the local technical manager, the regional director of the

quarries and the regional manager of Eiffage Travaux Publics for

building materials. The new R 964 C SME has an operating

weight of 86 tons and is powered by a V8 engine generating

320 kW. It has now taken over the work of previous Liebherr

excavator and has been loading the four dumper trucks at the

quarry since May 2013.

Company profile

“We have positive experience with the

R 964 C SME. It was specially developed

for use in quarries, has a robust construction

and is extremely versatile.”

Alexandre Pfeiffer, technical manager of the quarry

“By contrast, we only have positive experience with the Liebherr

R 964 C SME,” explains Alexandre Pfeiffer, technical manager

of the quarry. He sees one advantage in the steel construction

of the excavator. “The Liebherr crawler excavator is more flexible

than the excavators made by the competition, and also the

heaviest,” he adds. Jeoffrey Sausse, commercial director of

Pic, Liebherr’s contractual dealer, explains, “This excavator has

30// Quarrying

Carrière des Grands Caous

Sector:

Size of company:

Founded:

Location:

Managing Director:

Website:

Liebherr machines

in operation:

Excavation of building materials

30 employees

1959

Saint-Raphaël (83)

Dominique Seux

www.eiffagetravauxpublics.com

R 964 C SME, R 944,L586

Page 31

Genau betrachtet

The Liebherr Z tooth system

The right tooth for every application: a comprehensive tooth range and many

different tooth shapes form the basis for a wide variety of tasks.

To operate a hydraulic excavator economically, the teeth must have the right shape for the intended application. Liebherr’s new,

patented tooth system provides the right solution for every application. It consists of a tooth adapter, tooth, securing bolt with lock

and protective plug. To change a tooth, all that is needed is a simple removal tool. No hammer is needed. The securing bolt, which

connects the tooth and the adapter, can be quickly and easily removed by one person without the need for great force.

The advantages of the Z tooth system:

•

Optimized tooth design for a clear increase in productivity.

•

High-strength steel for increased wear resistance.

•

Lip and side shrouds for increased

bucket service life.

•

Long-lasting tooth performance due to

self-sharpening shape.

•

Innovative tooth forms designed for every type of ground,

offering better penetration and higher efficiency.

Unlocking the securing bolt with

the locking wrench.

Quarrying //31

Page 32