Page 1

Wheel Loaders

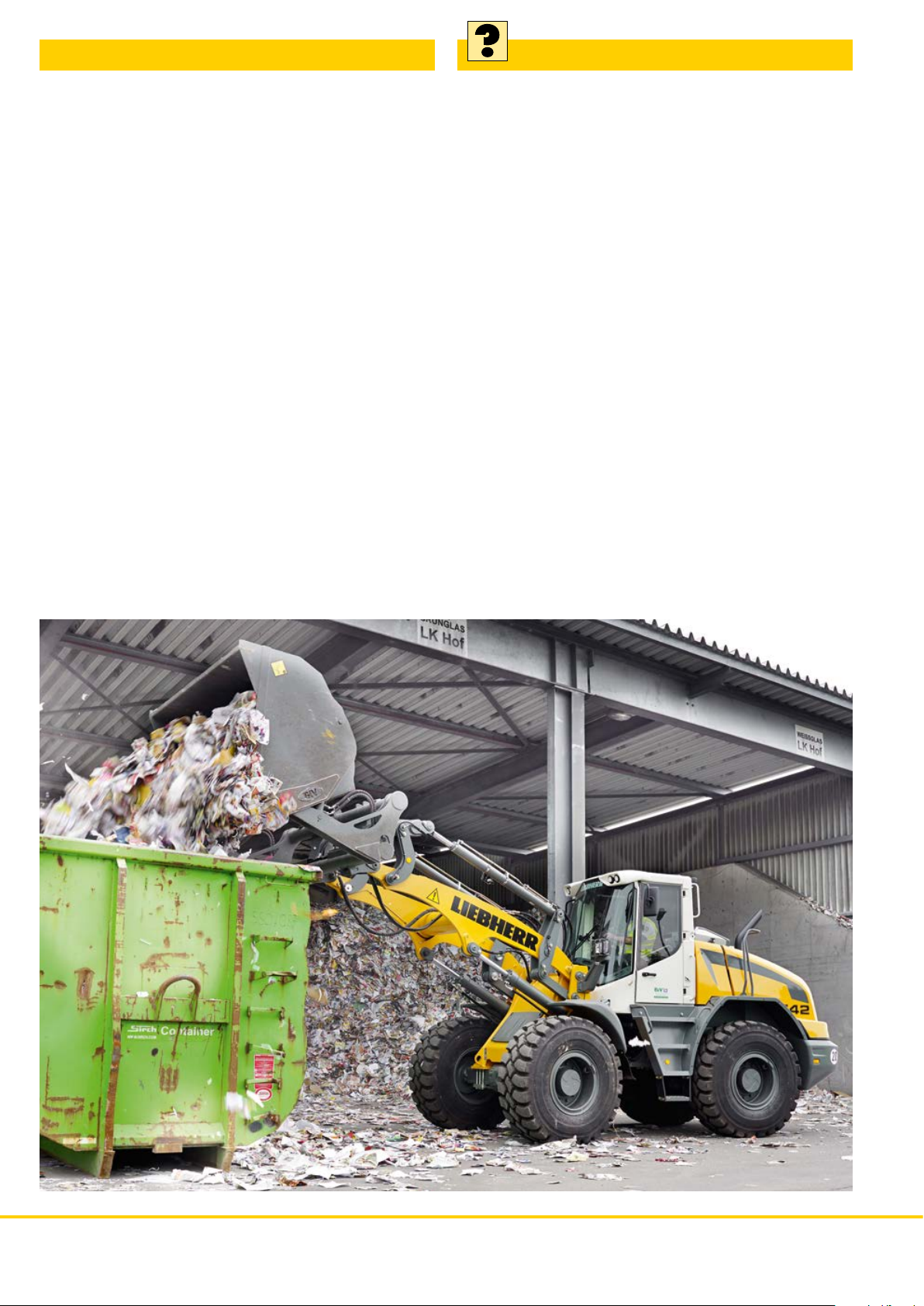

L 524 and L 542

Job Report

The Liebherr L 524 and L 542 wheel loaders

in use for collecting recyclable material

at Böhme GmbH in Rehau

Page 2

Situation

Task

Böhme was founded as a haulage company in 1938 by Willy

Böhme in Rehau. In 1951 the company added trench and sewer

cleaning divisions. In 1954 the company extended its activities

to include waste disposal. Böhme GmbH Wertstofferfassung

was founded in 1985 by Rudolf Böhme and is primarily focused

on the collection and sorting of recyclable materials such as

green, brown, clear and mixed glass, aluminum and tin cans,

paper and plastic packaging waste and waste paper. The

company has a storage capacity of approx. 1,500 tonnes for

deliveries of paper. The company also has a storage capacity of

approx. 200 tonnes for plastics. At full capacity the workforce

works a 4-shift model on every day of the week. Today the

company is managed by Stefan Böhme, Rudolf Böhme’s son.

Once all the recyclables have been collected on the large storage sites, they are transported to a material preparation system

for sorting. They are transported on conveyor belts. To ensure

that the materials are evenly distributed on the belts they are

first fed into metering bunkers. After the initial automatic sorting process in the system, the recyclables are sorted manually.

The next step is to press the fractions into homogeneous bales

for transporting in a bale press, after which they are pushed

into the bale storage facility where they are stored separately

by material type. After this they can be delivered to recycling

contractors.

The company has been using three Liebherr L 524 wheel loaders

for several years. These operate for around 2,500 hours per

year and are used to form the waste into heaps and then feed

it on to the conveyor belts. The Liebherr wheel loaders have

proved to be an invaluable tool both for forming the heaps near

the sorting system and in the actual material handling process.

Since the wheel loaders can be used for a wide range of jobs

in the company and the management team are delighted with

them, the company placed an order for another wheel loader in

spring 2013, but this time an L 542.

2

L 524 - L 542

Page 3

Solution

The L 542 also features the hydrostatic travel drive which has

proved so successful in Liebherr wheel loaders. It enables

the Liebherr diesel engine to be installed in the best possible

position. By comparison to rival machines, this unit also arrives

with a lower net weight and a high tipping load since the diesel

engine is used as a natural counterweight. Compared to

machines form other manufacturers, this represents a reduction

in fuel consumption of more than 30%.

Stefan Böhme, manager of the recycling company, also

highlights another positive effect. ”The hydrostatic travel drive

also makes for minimum braking and tire wear due to its infinite

traction force control. Despite the very demanding work, the

tires have suffered very little wear at all.”

Technical Data

Operating weight

Tipping load, articulated

Engine output

______________________________________________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________________________________

16,440 kg

7,010 k g

120 kW / 163 HP

The wheel loaders are fitted with a P-kinematic ”High Lift” arm

which, when combined with the high-tip bucket, enables the

material load to be loaded into the ”walking floor” trailer at a

height of over four meters. The high-tip function also allows

the loaded materials to be compacted on the ”walking floor”.

The L 524 and L 542 models achieve a greater emptying height

compared to rival wheel loaders with a similar tipping load. The

rapid change system allows the operator to select a bucket

suitable for the material.

Liebherr wheel loaders also score heavily in terms of service

and maintenance. The installation position of the cooling

system is particularly advantageous for jobs in dusty and dirty

environments. The cooling system is immediately behind the

driver’s cab and ensures that it only draws in air with a low dust

content. This ensures that the cooling system becomes less

contaminated, thus reduce the maintenance and cleaning work.

The dust filter also prevents drawing in fluff and dust particles

in advance. Since the fan also has to be cleaned after a certain

length of time, the machine was also fitted with a reversible fan

drive unit.

____________________________________________________________________________________________________________________________________________________________________________________

Bucket capacity

Fuel consumption

_______________________________________________________________________________________________________________________________

Tires

____________________________________________________________________________________________________________________________________

Goodyear GP-4D 6S 20.5R25

9.7 litres / hour

4.5 m

3

L 524 - L 542

3

Page 4

The Liebherr Wheel Loaders

Tipping load kg 7,500 8,500 9,500 10,200 12,150

Operating weight kg 10,400 10,900 12,800 13,400 17,300

Operating weight kg 17,900 23,150 24,450 25,180 31,380

Operating weight kg 5,180 5,470 5,600 6,390 8,350

Engine output kW/HP 46/63 50/68 50/68 54/73 77/105

Wheel Loader

L 506Compact L 507Stereo L 508Compact L 509Stereo L 514Stereo

Tipping load kg 3,450 3,712 3,850 4,430 5,680

Bucket capacity m

3

0.8 0.9 1.0 1.2 1.5

Wheel Loader

L 524 L 528 L 538 L 542 L 550

Bucket capacity m3 2.1 2.3 2.6 2.8 3.2

Engine output kW/HP 90/122 100/136 115/156 120/163 129/175

L0009

L0009

L0009

L0009

Wheel Loader

L 556 L 566 L 576 L 580 L 586

Tipping load kg 13,550 15,750 17,500 18,500 20,430

Bucket capacity m

Engine output kW/HP 140/191 190/259 205/279 215/292 250/340

3

3.6 4.0 4.5 5.0 5.5

Environmental protection can help you earn money!

The Liebherr Standard Consumption Test –

easy to reproduce and practical.

The Liebherr Standard Consumption Test determines the number of

loading cycles that can be carried out with 5 litres of diesel.

The material is taken from pile A and carried over a distance of 20

metres to point B. The time needed for each working cycle should

be 35 seconds. Discharge at point B should take place from a height

of 2.5 m. The working cycles continue until the 5 litres of diesel in

the external measuring tank have been used up. The loader’s fuel

consumption per operating hour is calculated as follows:

35

n=?

B

5

2,5m

4

07.13

30

25

20 m

T ~ 35 sec.

20

15

Liebherr-Werk Bischofshofen GmbH

Postfach 49, A-5500 Bischofshofen

+43 50809 1-0, Fax +43 50809 11385

www.liebherr.com, E-Mail: info.lbh@liebherr.com

www.facebook.com/LiebherrConstruction

A

3

2

1

Number of loading cycles

Values for the Liebherr Wheel Loaders

Numbers of Litres/ Litres/ Ø Litres/

working cycles 100 tons hour hour**

L 524: 2.1 m

L 528: 2.3 m

L 538: 2.6 m

L 542: 2.8 m

L 550: 3.2 m

L 556: 3.6 m

L 566: 4.0 m

L 576: 4.5 m

L 580: 5.0 m

L 586: 5.5 m

* Equipped with L5 tyres and 5.5 m

** Wheel loader in practical customer applications (with individual

machine configurations).

3

n = 47 2.8 8.5 7.1

3

n = 46 2.6 8.7 7.2

3

n = 39 2.7 10.3 8.5

3

n = 38 2.6 10.5 8.7

3

n = 31 2.8 12.9 10.9

3

n = 27 2.9 14.5 12.1

3

n = 22 3.2 18.2 15.1

3

n = 21 2.9 19.1 15.8

3

n = 20 2.8 20.0 16.2

3

n = 14 3.6 28.5* 20.5

400

consumption

=

3

HD bucket

per hour

BK LBH 11657822_DD -09.13_enG B Subje ct to technical modifi cations.

Loading...

Loading...