Page 1

Wheel Loaders L 524 – L 542

Tipping load, articulated: 16,535 lb – 22,485 lb

New

Generation

Page 2

L 524

L 528

L 538

Tipping load, articulated:

Bucket capacity: 2.7 yd³

Operating weight: 22,930 lb

Engine output: 121 HP(I)/90 kW

16,535 lb

L 542

Tipping load, articulated:

Bucket capacity: 3.7 yd³

Operating weight: 29,540 lb

Engine output: 161 HP(I)/120 kW

22,485 lb

Tipping load, articulated:

Bucket capacity: 3.0 yd³

Operating weight: 24,030 lb

Engine output: 134 HP(I)/100 kW

18,740 lb

Tipping load, articulated: 20,945 lb

Bucket capacity: 3.4 yd³

Operating weight: 28,220 lb

Engine output: 154 HP(I)/115 kW

2 L 524 – L 542

Page 3

Economy

The Liebherr driveline with Liebherr Power Effi ciency (LPE)

reduces wheel loader fuel consumption by 25 % or more when

compared to conventional travel gears!

Performance

The Liebherr driveline allows for optimal positioning of the diesel

engine. In this wheel loader class the diesel engine is rotated 90°

and mounted transverse to the direction of travel. Compared

to conventionally driven wheel loaders, the operating weight is

much lower, the tipping load is higher, and more material can be

moved each operating hour.

Reliability

All the materials used in the Liebherr wheel loaders have passed

extensive tests to ensure that they meet Liebherr’s exacting

standards even in the toughest conditions. The advanced

concept and proven quality make Liebherr wheel loaders the

benchmark of reliability.

Comfort

The ultra-modern cab design with advanced ergonomics

continuously variable Liebherr driveline for uninterrupted

tractive force, optimum weight distribution and easy service

access lead to extraordinary overall comfort.

L 524 – L 542 3

Page 4

35

30

25

20

15

n=?

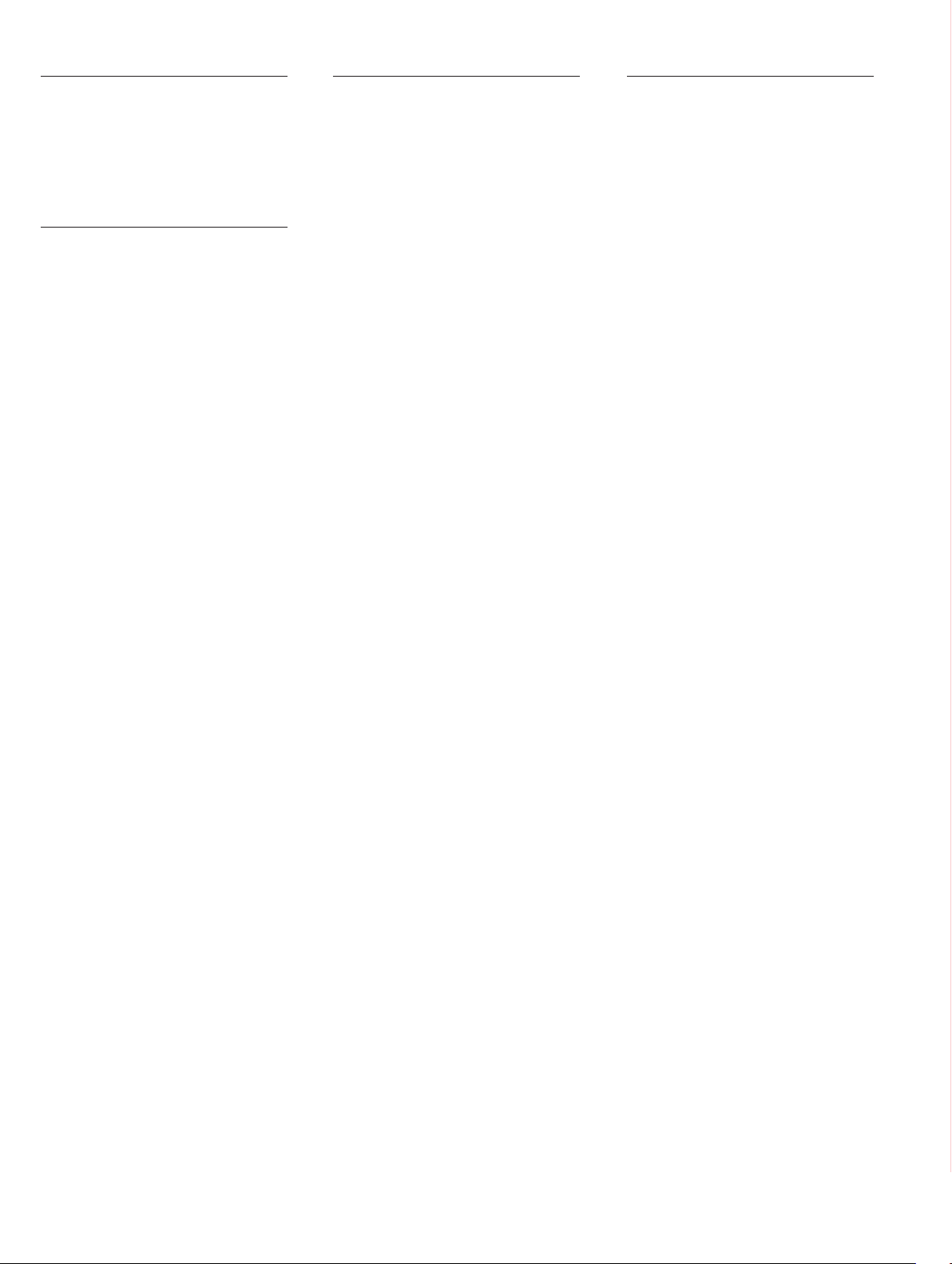

Lower fuel consumption

Effi ciency behaviour without LPE

Favorable

• Up to 25 % less fuel consumption

5

8'2"

B

65'7"

T ~ 35 sec.

A

4

3

2

1

when compared to conventionally

driven machines.

• The Liebherr wheel loaders

demonstrate their fuel effi ciency

in the Liebherr standard Normtest.

Pressure

Effi ciency behaviour with LPE

rpm rpm

4 L 524 – L 542

L0083

Working point

Pressure

Unfavorable

Page 5

Economy

The Liebherr driveline with Liebherr Power Effi ciency (LPE) reduces wheel loader fuel

consumption by 25 % or more when compared to conventional travel gears!

Low operating costs

Minimum costs,

high handling capacity

When it comes to economy, conventional wheel loaders

are no match for Liebherr machines, mainly due to the

following factors:

− Low fuel consumption thanks to higher effi ciency and

low operating weight. Thanks to the newly developed

Liebherr Power Effi ciency system the generation

Tier 4i wheel loaders L 524 – L 542 use up to 8 % less

fuel compared to their predecessors.

− Practically no brake wear thanks to the hydraulic braking

action of the driveline; this ultimately reduces repair

costs.

− Reduced tire wear due to continuous traction control.

Depending on the working conditions, there is up to

25 % less wear.

Liebherr Power Ef fi ciency (LPE)

• The newly developed system known

as Liebherr Power Effi ciency (LPE)

optimizes the interaction between

the drive components. It optimizes

the position of the working point in

the characteristic map with regard

to the degree of effi ciency.

• LPE saves up to an additional 8 %

in fuel compared to wheel loaders

where the system is not used.

Active environmental protection

Economical use

of resources

Low noise emission

The reduction in fuel lowers emissions, thus actively

protecting resources:

0.3 gal of fuel produces up to 7 lb of carbon dioxide (CO

By saving up to 1.3 gal per operating hour, up to 33,070 lb

less CO

2

is produced in 1,000 operating hours. Not only

are operating costs reduced but the environment also

benefi ts from the drastically reduced emissions.

The innovative driveline concept means much lower noise

emission – Liebherr wheel loaders are signifi cantly quieter

in operation.

Reduced tire wear

• The tractive force can be adjusted

continuously. This stops wheel spins

and reduces tire wear by up to 25 %.

Reduced brake wear

• Even under the toughest working

conditions, the Liebherr travel drive

always brakes hydraulically. The

mechanical service brake only acts

as a support and is therefore subject

to hardly any wear.

2

).

L 524 – L 542 5

Page 6

6 L 524 – L 542

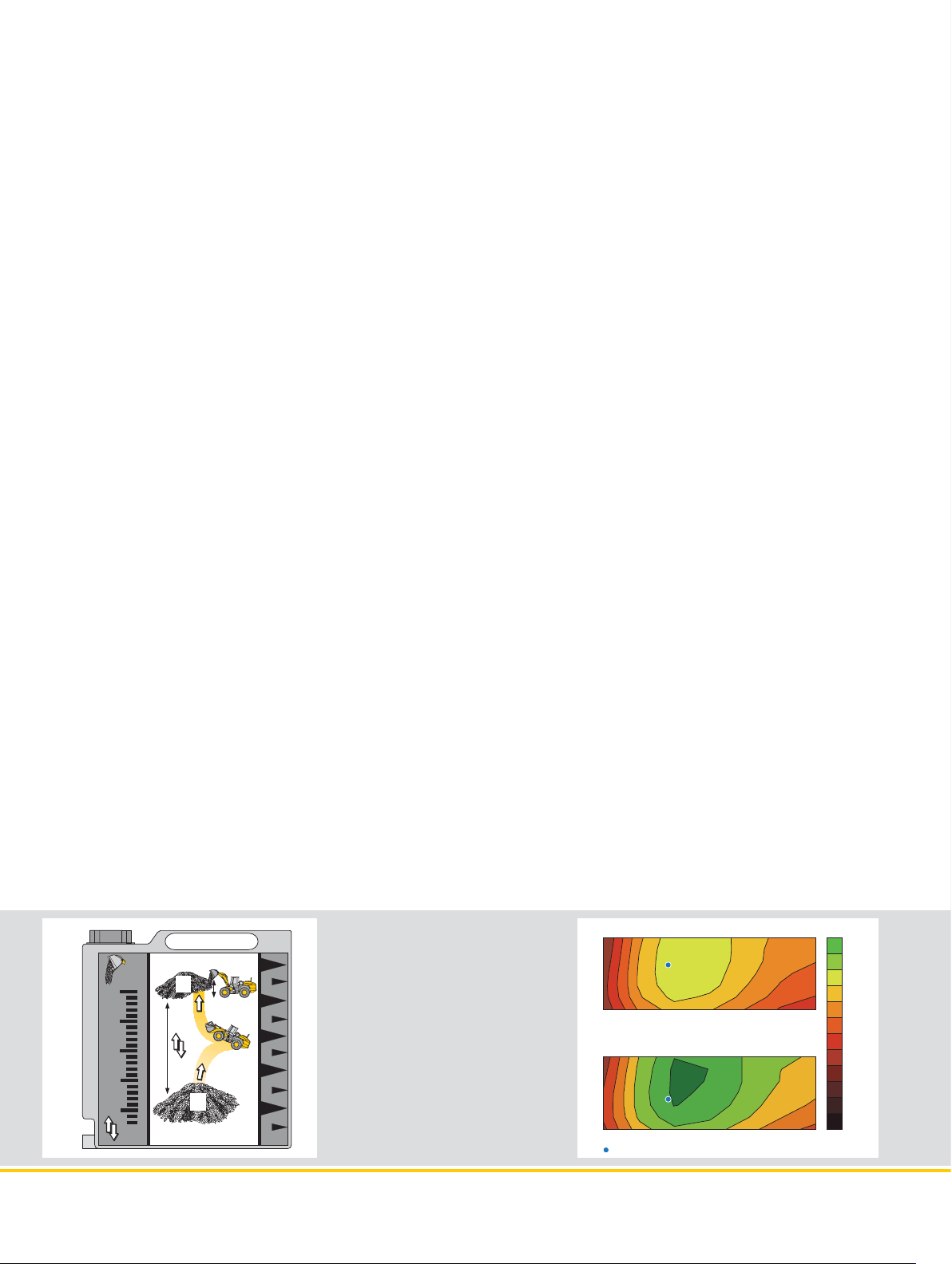

Liebherr driveline

• Optimum weight distribution

thanks to transverse installation

of the diesel engine.

L0073

• The diesel engine as well as the

variable displacement pumps

mounted on the engine act as

counterweight, therefore allowing

higher tipping loads at low

operating weight.

• Compact design improves

visibility in all directions.

L0074

Page 7

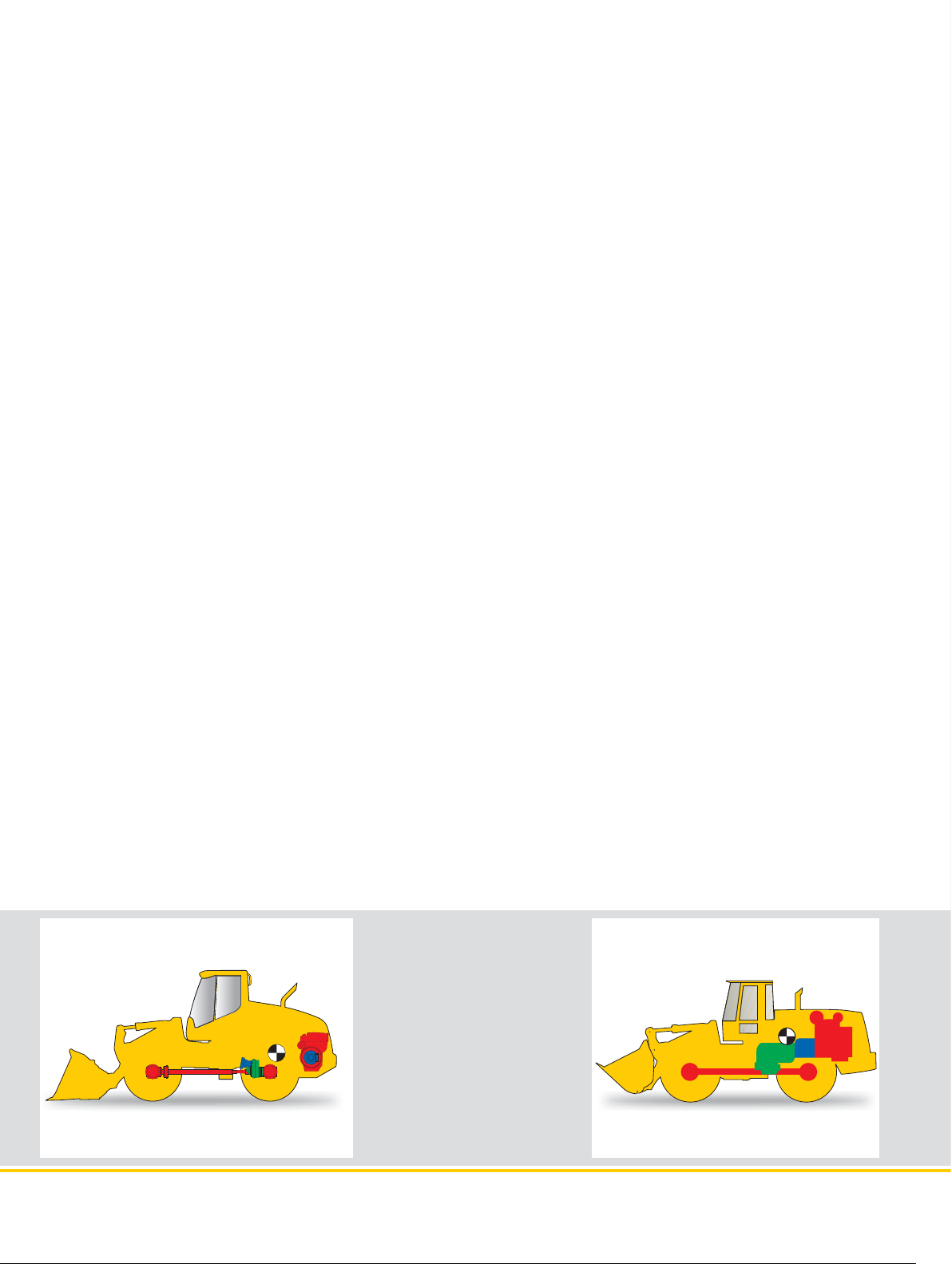

Performance

The Liebherr driveline allows for optimal positioning of the diesel engine. In this wheel

loader class the diesel engine is rotated 90° and mounted transverse to the direction of

travel. Compared to conventionally driven wheel loaders, the operating weight is much

lower, the tipping load is higher, and more material can be moved each operating hour.

Higher performance, lower weight

Higher productivity

Ultra modern Liebherr driveline

Innovative technology

Flexibility puts them ahead

An all-purpose loader

Power All-Rounders

for industry

The combination of the Liebherr driveline and the unique

position of the diesel engine allows for higher tipping loads at low

operating weight. This leads to signifi cantly higher productivity

since there is no need for unnecessary counterweight.

Tractive force and speed are automatically adjusted to the

requirements of the operator without shifting. There is no need

for a mechanical reverse gear because the travel direction is

changed hydraulically.

The parallel linkage is available as an alternative to the standard

Z-bar linkage, at no additional cost. The parallel linkage features

a parallel guide arrangement and high torque in the upper lifting

range - ideal properties for larger and heavier attachments

as well as transporting heavy loads. With its parallel linkage

Liebherr offers a continuous and uniform solution for industrial

operations over the entire range of all-round loaders. With their

compact design, Liebherr wheel loaders can maneuver quickly

and effi ciently - the best choice for high handling capacities.

The new generation Tier 4i all-round wheel loader models have

been specifi cally developed for industrial use in terms of their

performance and stability and ensure even higher productivity

and effi ciency. In addition to increasing the engine performance,

the tipping loads of the whole range have been increased.

Furthermore the steel structure has been reinforced and the

hydraulic system‘s performance enhanced. That, together with

the wide range of equipment available makes these all-round

loaders the perfect solution for all industrial uses.

Conventional travel gear

• Longitudinally mounted diesel

engine moves the center of gravity

further forward.

• Much more additional

counter weight is needed to maintain

stability and to increase the tipping

load.

• This leads to high operating weight

and poor visibility.

L 524 – L 542 7

An all-purpose loader

• The choice between parallel (P) and

Z-bar linkage means that the loader

can always be confi gured to suit

the customer’s specifi c tasks: P for

industrial use, Z for conventional

material handling.

Page 8

8 L 524 – L 542

Liebherr driveline

• The Liebherr driveline consists

of two hydraulic motors, which

accelerate the loader continuously

from a standstill to maximum

speed, either forwards or in

reverse – without a manual gear

shift and a reversing gear unit.

Page 9

Reliability

All the materials used in the Liebherr wheel loaders have passed extensive tests to ensure

that they meet Liebherr’s exacting standards even in the toughest conditions. The advanced

concept and proven quality make Liebherr wheel loaders the benchmark of reliability.

Reliable Liebherr driveline

Fewer components

Controlled cooling

The intelligent

answer

T

he Liebherr driveline includes a self-locking hydraulic

brake, which means the additional wet brake discs are

wear-free since there is no need for a reversing gear unit.

There are fewer components needed, which minimizes the

number of parts susceptible to wear.

The cooling fan is driven independently from the diesel

engine and produces only the cooling air output which is

actually required. Heat sensors ensure reliable control. If

overheating should occur, the wheel loader automatically

shifts down to fi rst travel speed range. The reduced power

consumption protects the engine from overheating. At the

same time, the fan speed is increased to maximum output,

thus preventing the engine from overheating.

Cooling system

• The radiator is installed on the rear

section of the vehicle, between the

diesel engine and the cabin. Cooling

air is drawn in directly behind the

cabin and blown out upwards at

the rear. The fan speed is varied

automatically by heat sensors that

determine the amount of cooling

needed.

• The reversible fan drive is

a standard feature.

Components meet manufacturer’s quality

standards

Everything from

a single source

Optimized engine

technology

Main components such as hydraulic cylinders and

electronics are developed and manufactured by Liebherr

to ensure the highest quality standards. Liebherr Wheel

Loaders are carefully designed down to the smallest detail

to provide customers with the perfect machine solution to

match the application-specifi c demands while achieving

maximum productivity and longevity.

As well as further developments towards greater

environmental compatibility, the new generation of diesel

engines have been optimized in a number of other respects.

In addition to Common Rail technology a diesel particle

fi lter signifi cantly reduces exhaust emissions. With active

regeneration, in most operational circumstances this

fi ltration process ensures effi cient, uninterrupted work.

Diesel engine

• Common Rail technology optimizes the

combustion process and reduces emissions.

• Further reduction of particle emissions due to

the diesel particle fi lter with oxidation catalytic

converter. Active regeneration ensures effi cient,

uninterrupted work.

• Proactive intervention of Liebherr Power

Effi ciency (LPE) in the engine management

system increases effi ciency.

L 524 – L 542 9

Page 10

10 L 524 – L 542

Liebherr control lever

•

The multi-function Liebherr control lever is used

to manage all travel and working movements of

the wheel loader. This ensures the operator’s left

hand always remains on the steering wheel and

therefore increases overall safety. The operator

controls the following functions with his right hand:

– Raise and lower attachment

– Fill and dump the bucket

– Automatic bucket return to dig

– Change of travel direction with

simultaneous travel start

–

Auxiliary control buttons for additional hydraulic functions

Page 11

Comfort

The ultra modern cab design with advanced ergonomics, continuously variable Liebherr

driveline for uninterrupted tractive force, optimum weight distribution and easy service

access lead to extraordinary overall comfort.

First-class cab design

Comfor t cab

Liebherr

control lever

Liebherr driveline

Continuously

variable

transmission

Liebherr Power

Effi ciency

The spacious and ergonomically designed Liebherr

operator’s cab provides a wide view to the working area

to ensure safety. All tool controls and displays have been

carefully arranged for ease of operation and to maintain a

comfortable work environment during working shifts.

All the working and travel functions are operated precisely

from a single control lever. This ensures accurate and safe

handling, and the left hand always remains on the steering

wheel. Jobsite safety is increased.

The Liebherr driveline allows continuous adjustment of

acceleration in all speed ranges, without noticeable gear

shifting or interruption in tractive force.

Liebherr Power Effi ciency (LPE) optimizes the effi ciency and

effectiveness of the travel drive, which places less stress

on the components. The operator actuates the accelerator

pedal in the usual way to obtain the full power performance

desired. An electrical signal is transmitted from the pedal to

the software of the machine which automatically calculates

the most effi cient driving command. This is possible due

to the proactive intervention into the engine management

system. The usual high performance as well as the drive

behavior of the machine as a whole remain unchanged. If

anything, the response is even faster.

LIKUFIX

• Equipment with hydraulic functions

can be changed from the cab in a

matter of seconds.

• No need to climb out and connect

everything mechanically: both

picking up the equipment and

connecting the hydraulic hoses

is fully automatic - safe and with

no oil leaks.

• The convenience and time savings

speak for themselves: LIKUFIX

yield a consistent standard of high

performance, reliability and quality.

LIKUFIX

Time savings

and productivity

LI KUFIX is quick-c hange syste m c omb ined w ith an automat ic

hydraulic coupling system developed in-house by Liebherr.

This option is available for Liebherr wheel loaders and

excavators. LIKUFIX allows the quick exchange between

attachments and all hydraulic connections safely from inside

the cab with a simple press of a button.

Powerful air-conditioning system

• The air-conditioning system comes standard

on all-round wheel loaders providing the

greatest operator comfort for increased

productivity.

• The air fl ow is controlled at 4 different levels –

an automatic air-conditioning system is

available as an option.

– Air fl ow in the feet area

– Defroster

– Air fl ow in the head area

– Air fl ow in the body area

L 524 – L 542 11

Page 12

12 L 524 – L 542

Service accessibility

• The transverse engine facilitates maintenance.

Opening a single cover allows safe and

convenient access to all maintenance points

from ground level.

Page 13

Service/Maintenance

LiDAT

Effi cient management

Diagnostic and remote maintenance

Consistent monitoring

With LiDAT, Liebherr’s own data transmission and positioning

system, you can manage, monitor and control your entire fl eet

effi ciently. LiDAT allows you to access machine data records,

perform data analysis, and review service records within the

fl eet management system. All machine data can be accessed

at anytime simply, via the internet. The system provides you

with comprehensive documentation about operating hours,

increased availability through shorter downtimes, and faster

suppor t from the manufacturer. There is al so faster detection of

stress and overloading, which extends the machine’s service

life to provide more effi cient planning for your company. The

LiDAT system comes standard on the L 524 – L 542 wheel

loaders and it includes a one-year free trial.

The electronic system of the all-round loaders has been

designed just as the large size class. Due to this fact, the allround loaders offer an extended range of options such as the

convenient touchscreen, the integral rear-view monitoring

camera and the newly developed Liebherr weighing device.

The new electronic system permits standard diagnostic and

remote maintenance over the range of machines providing a

clear benefi t in their everyday operations.

Service accessibility

Easy maintenance

With the unique position of the diesel engine, Liebherr wheel

loaders provide outstanding accessibility for maintenance.

The positioning of the cooling system directly behind the

cab results in less contamination, which in turn reduces

maintenance and cleaning; a clear benefi t which saves time

and money.

All service points can be reached from ground level for

routine maintenance. Cleaning of the cooling system is

carried out while positioned on the machine, anti-slip step

surfaces and strong handrails in the access area ensure high

safety standards.

Electronics

• Standard diagnostic and remote maintenance

• Full version of LiDAT including

a one-year free trial.

• Optional touchscreen

• Optional Liebherr rear-view monitoring

camera and weighing device - integrated

in the color touchscreen

L 524 – L 542 13

Page 14

Technical Data

L 524 L 528 L 538 L 542

Diesel engine

Design

Cylinder inline

Fuel injection process ������ electronic Common Rail high-pressure injection

Max. output according to

SAE J1995

at RPM 2,000 2,200 2,000 2,000

Max. torque

at RPM 1,600 1,600 1,600 1,600

Displacement

Bore/Stroke

Air cleaner system

Electrical system

Operating voltage

Battery

Alternator

Starter

Engine

�����������������������

�������������������������

�����������������

���������

HP(I)/kW 121/90 134/100 154/115 161/120

��������������

��������������

�����������������

�����������������

���������������������

������������������

�����������������

lb ft 354 363 454 476

����������

V/A 24/100 24/100 24/100 24/100

V/HP(I) 24/10.5 24/10.5 24/10.5 24/10.5

4045HFL92 4045HFL93 4045HFL93 4045HFL93

water-cooled with exhaust turbo charging, externally

cooled exhaust gas recirculation and diesel particulate

filter

4 4 4 4

in³ 275 275 275 275

in 4.2”/5.0” 4.2”/5.0” 4.2”/5.0” 4.2”/5.0”

Dry air filter with main and safety element,

pre-cleaner, service indicator on the display

V 24 24 24 24

Ah 2 x 135 2 x 135 2 x 135 2 x 135

The exhaust emissions are below the limits in stage IIIB / Tier 4i.

L 524

738

664

590

516

443

369

295

Torque (lb ft)

221

148

74

0

800 1,000 1, 200 1,40 0 1, 60 0 1,8 00 2,000 2,20 0 2,400

rpm

Torque

Output

180/241

150/201

120/161

90/121

60/80

30/40

0

L0010

738

664

590

516

443

369

Output (kW/HP)

295

Torque (lb ft)

221

148

L 528

74

0

800 1,000 1, 200 1,40 0 1, 60 0 1,8 00 2,000 2,20 0 2,400

rpm

Torque

Output

180/241

150/201

120/161

90/121

60/80

30/40

0

L0 011

Output (kW/HP)

738

664

590

516

443

369

295

Torque (lb ft)

221

148

74

0

800 1,000 1, 200 1,40 0 1, 60 0 1,8 00 2,000 2,20 0 2,400

14 L 524 – L 542

L 538

rpm

Torque

Output

180/241

150/201

120/161

90/121

60/80

30/40

0

L0012

738

664

590

516

443

369

Output (kW/HP)

295

Torque (lb ft)

221

148

L 542

74

0

800 1,000 1, 200 1,40 0 1, 60 0 1,8 00 2,000 2,20 0 2,400

rpm

Torque

Output

180/241

150/201

120/161

90/121

60/80

30/40

0

L0013

Output (kW/HP)

Page 15

Technical Data

Travel Drive

Stepless hydrostatic travel drive

Design

Filtering system

Control

Travel speed range

Speed range A1-2

Speed range A1-3

The quoted speeds apply with the tires that are

�������������������������

��������������

������������������������

����������������

Swash plate type variable flow pump and two variable

axial piston motors in closed loop circuit and axle

transfer case. Direction of travel is reversed by changing the flow-direction of the variable-displacement

pump

Suction return line filter for closed circuit

By travel and inching pedal. The inching pedal makes

it possible to control the tractive and thrust forces

steplessly at full engine speed. The Liebherr joystick

is used to control forward and reverse travel

Speed range 1

�����������������������������

�������������������������

�������������������������

0 – 3.7 mph

0 – 9.9 mph

0 – 24.9 mph

standard equipment on the loader.

Axles

Four-wheel drive

���������������������������

Front axle

���������������������������

Rear axle

Differentials

Reduction gear

Track width

�������������������������

������������������������

���������������������

Fixed

Centre pivot, with 10° oscillating angle to each side.

1’7” in height can be driven over (with all four wheels

remain in contact with the ground)

Automatic limited-slip differentials with 45% locking

action in both axles

Planetary final drive in wheel hubs

1,960 mm with all types of tires (L 524, L 528)

1,900 mm with all types of tires (L 538, L 542)

Brakes

Wear-free service brake

Parking brake

The braking system meets the requirements of the EC guidelines 71/320.

�����������

����������������������

Self-locking of the hydrostatic travel drive (acting on

all four wheels) and additional pump-accumulator

brake system with wet multi-disc brakes located in

the differential housing (two seperate brake circuits)

Electro-hydraulically actuated spring-loaded disc

brake system on the front axle

Steering

������������������������������

Design

Articulation angle

Emergency steering

������������������

���������������

”Load-sensing” swash plate type variable flow pump

with pressure cut-off and flow control. Central pivot

with two double-acting steering cylinders

40° (to each side)

Electro-hydraulic emergency steering system

Attachment Hydraulics

������������������������������

Design

�����������������������������

Cooling

����������������������������

Filtration

������������������������������

Control

���������������������������

Lift circuit

���������������������������

Tilt circuit

L 524 L 528 L 538 L 542

Max. flow gpm 27 36 45 45

Max. pressure

������������������

”Load-Sensing” variable axial piston pump with

output and flow control, and pressure cut-off in the

control block

Hydraulic oil cooling using thermostatically controlled

fan and oil cooler

Return line filter in the hydraulic reservoir

”Liebherr joystick” with hydrostatic servo control

Lifting, neutral, lowering

and float position controlled by Liebherr joystick with

detent; automatic hoist kick out as standard

Tilt back, neutral, dump

automatic bucket return to dig

psi 4,569 4,786 5,076 5,076

Attachment

Geometry can be chosen

����������������������������

Bearings

Cycle time at nominal load

ZK PK ZK PK ZK PK ZK PK

Lifting

Dumping

Lowering (empty)

��������������������������

����������������������

���������

���������

��������

�������������

Powerful Z-bar linkage with one tilt cylinder,

hydraulic quick coupler – optional equipment;

Parallel linkage with two tilt cylinders, hydraulic

quick coupler – standard equipment

Sealed

L 524 L 528 L 538 L 542

6.6 s 6.6 s 5.4 s 5.4 s 5.3 s 5.3 s 5.3 s 5.3 s

1.8 s 3.5 s 1.8 s 3.5 s 1.6 s 3.5 s 1.6 s 3.5 s

4.0 s 4.0 s 4.0 s 4.0 s 4.0 s 4.0 s 4.0 s 4.0 s

Operator’s Cab

������������������������������

Design

Liebherr Operator’s seat

Cab heating and ventilation

On elastic bearing on rear section, soundproof

ROPS/FOPS cab. Operator’s door with optional fold-

out window, 105° opening angle, ventilation opening

on the right side, front windscreen made of com-

pound safety glass, green tinted as standard, side

windows made of single-pane safety glass,

grey tinted, continuously adjustable steering column

and joystick control as standard, heated rear window

(ESG)

ROPS roll over protection per EN/ISO 3471/

EN 474-1

FOPS falling objects protection per EN/ISO 3449/

EN 474-1

����������

6 way adjustable seat with lap belt and heating

system; adjustable air suspension from soft to hard;

automatic weight adjustment

�������

Operator’s cab with 4-level air control, cooling water

heating, defroster and air conditioning with electronic

valve control, as well as electronic fresh/recirculated

air control, filter system with pre-filter, fresh air filter

and recirculated air filter, easily replaced, air condition

as standard

/ automatic air conditioning system optional

Noise Emission

L 524 L 528 L 538 L 542

ISO 6396

L

(inside cab)

pA

2000/14/EG

L

(surround noise)

WA

���������������

���������

69 dB(A) 69 dB(A) 69 dB(A) 69 dB(A)

101 dB(A) 101 dB(A) 102 dB(A) 102 dB(A)

Capacities

L 524 L 528 L 538 L 542

Fuel tank

(plastic design)

Fuel tank

(steel version, optional)

Engine oil

(inclusive filter change)

Transmission

Coolant

Front axle/wheel hubs

Rear axle/wheel hubs

Hydraulic tank

Hydraulic system, total

����������������

��������

��������

�������������������

�������������������������

���������

����������

�����������������

��������

gal 54.2 54.2 54.2 54.2

gal 58.1 58.1 58.1 58.1

gal 3.9 5.4 5.4 5.4

gal 1 1 1 1

gal 10 10 10 10

gal 4.3/0.7 4.3/0.7 4.3/0.7 4.3/0.7

gal 4/0.7 4/0.7 4/0.7 4/0.7

gal 29 29 29 29

gal 44.9 44.9 47.6 47.6

L 524 – L 542 15

Page 16

Dimensions

Z-bar linkage

E

D

C

B

45°

F

H

A

L0004.01

G

K

L

I

J

Loading Bucket L 524 L 528 L 538 L 542

Geometry

Bucket type

Cutting tools

Lift arm length ft in

Bucket capacity according to ISO 7546 **

Bucket width ft in

A Dumping height at max. lift height ft in

B Dump-over height ft in

C Max. height of bucket bottom ft in

D Max. height of bucket pivot point ft in

E Max. operating height ft in

F Reach at max. lift height ft in

G Digging depth ft in

H Height above cab ft in

I Height above exhaust ft in

J Ground clearance ft in

K Wheelbase ft in

L Overall length ft in

Turning circle radius

over outside bucket edge ft in

Breakout force (SAE) lbf

Tipping load, straight * lb

Tipping load, articulated at 40° * lb

Operating weight * lb

Tire sizes

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load. (Tipping load, articulated at 40° according to ISO 14397-1)

** Actual bucket capacity may be approx. 10% larger than the calculation according to ISO 7546 standard. The degree to which the bucket can

be filled depends on the material – see page 21.

GPB = General purpose bucket (Rehandling bucket)

STD-QC = General purpose bucket (Rehandling bucket) for hydraulic quick coupler

LMB = Light Material Bucket ZK = Z-bar linkage

T = Welded-on tooth holder with add-on teeth BOCE = Bolt-on cutting edge

ZK ZK ZK ZK ZK ZK ZK ZK ZK ZK ZK ZK

GPB STD-QC LMB GPB STD-QC LMB GPB STD-QC LMB GPB STD-QC LMB

T T BOCE T T BOCE T T BOCE T T BOCE

7’10” 7’10” 7’10” 7’10” 7’10” 7’10” 8’2” 8’2” 8’2” 8’2” 8’2” 8”2”

3

2.7 2.4 3.1 3.0 2.7 3.9 3.4 3.0 4.6 3.7 3.3 5.2

yd

8’2” 8’2” 8’2” 8’2” 8’2” 8’10” 8’2” 8’2” 8’10” 8’2” 8’2” 8’10”

9’4” 8’11” 8’9” 9’1” 8’10” 8’4” 9’4” 9’ 8’7” 9’3” 8’11” 8’3”

10’11” 10’11” 10’11” 10’11” 10’11” 10’11” 11’5” 11’5” 11’5” 11’5” 11’5” 11’5”

11’7” 11’7” 11’7” 11’7” 11’7” 11’7” 12’1” 12’1” 12’1” 12’1” 12’1” 12’1”

12’5” 12’5” 12’5” 12’5” 12’5” 12’5” 12’11” 12’11” 12’11” 12’11” 12’11” 12’11”

16’2” 16’3” 16’11” 16’4” 16’6” 17’2” 17’2” 17’6” 18’2” 17’3” 17’8” 18’4”

2’10” 3’1” 3’6” 3’2” 3’3” 3’8” 3’4” 3’5” 3’10” 3’ 4” 3’7” 4’2”

3” 3” 3” 3” 3” 3” 3” 3” 3” 3” 3” 3”

10’6” 10’6” 10’6” 10’6” 10’6” 10’6” 10’8” 10’8” 10’8” 10’8” 10’8” 10’8”

9’5” 9’5” 9’5” 9’5” 9’5” 9’5” 9’7” 9’7” 9’7” 9’7” 9’7” 9’7”

1’6” 1’6” 1’6” 1’6” 1’6” 1’6” 1’7” 1’7” 1’7” 1’7” 1’7” 1’7”

9’4” 9’4” 9’4” 9’4” 9’4” 9’4” 9’9” 9’9” 9’9” 9’9” 9’9” 9’9”

22’5” 22’9” 24’1” 22’9” 23’1” 23’9” 23’5” 23’11” 24’11” 23’8” 24’1” 25’3”

18’8” 18’9” 18’11” 19’ 19’1” 19’2” 19’11” 20’ 20’1” 19’11” 20’2” 20’4”

20,460 18,435 15,285 20,010 18,210 15,285 26,305 24,505 22,705 25,630 23,155 19,110

18,740 17,415 16,380 21,075 19,070 18,715 23,590 22,485 21,100 25,575 23,600 22,930

16,535 15,430 14,420 18,740 17,020 16,555 20,945 19,840 18,565 22,485 20,945 20,060

22,930 23,810 24,470 24,030 24,910 25,355 28,220 29,100 29,540 29,540 30,425 30,865

17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3

16 L 524 – L 542

Page 17

Dimensions

Parallel Linkage

E

D

C

B

A

G

Loading Bucket

STD HL STD HL STD HL STD HL

Geometry

Cutting tools

Lift arm length ft in

Bucket capacity according to ISO 7546 **

Bucket width ft in

A Dumping height at max. lift height ft in

B Dump-over height ft in

C Max. height of bucket bottom ft in

D Max. height of bucket pivot point ft in

E Max. operating height ft in

F Reach at max. lift height ft in

G Digging depth ft in

H Height above cab ft in

I Height above exhaust ft in

J Ground clearance ft in

K Wheelbase ft in

L Overall length ft in

Turning circle radius over

outside bucket edge ft in

Breakout force (SAE) lbf

Tipping load, straight * lb

Tipping load, articulated at 40° * lb

Operating weight * lb

Tire sizes

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires and

optional equipment will change the operating weight and tipping load. (Tipping load, articulated at 40° according to ISO 14397-1)

** Actual bucket capacity may be approx. 10% larger than the calculation according to ISO 7546 standard. The degree to which the bucket can be filled

depends on the material – see page 21.

=

Rehandling bucket with hydraulic quick coupler

STD = Standard lift arm length HL = High Lift

PK = Parallel linkage including hydraulic quick coupler T = Welded-on tooth holder with add-on teeth

L 524 L 528 L 538 L 542

45°

F

I

J

L0079

K

L

PK PK PK PK PK PK PK PK

T T T T T T T T

8’2” 9’10” 8’2” 9’10” 8’2” 9’10” 8’2” 9’10”

2.4 2.4 2.7 2.7 3.0 3.0 3.3 3.3

yd³

8’2” 8’2” 8’2” 8’2” 8’2” 8’2” 8’2” 8’2”

9’2” 11’2” 9’1” 11’1” 9’ 11’ 8’10” 10’10”

11’1” 13’1” 11’1” 13’1” 11’3” 13’3” 11’3” 13’3”

11’9” 13’9” 11’9” 13’9” 11’11” 14’ 11’11” 14’

12’7” 14’7” 12’7” 14’7” 12’9” 14’10” 12’9” 14’10”

16’6” 18’6” 16’4” 18’9” 17’4” 19’4” 17’6” 19’7”

3’5” 3’4” 3’7” 3’5” 3’7” 3’5” 3’8” 3’7”

2” 3” 2” 3” 2” 1” 2” 1”

10’6” 10’6” 10’6” 10’6” 10’8” 10’8” 10’8” 10’8”

9’5” 9’5” 9’5” 9’5” 9’7” 9’7” 9’7” 9’7”

1’6” 1’6” 1’6” 1’6” 1’7” 1’7” 1’7” 1’7”

9’4” 9’4” 9’4” 9’4” 9’9” 9’9” 9’9” 9’9”

23’5” 25’6” 23’6” 25’7” 24’ 26’3” 24’1” 26’5”

19’ 19’11” 19’3” 19’10” 20’1” 21’ 20’2” 21’1”

18,210 18,435 17,985 17,985 25,180 25,405 24,055 24,280

18,300 14,000 20,505 15,765 22,705 17,815 24,075 19,070

16,205 12,345 18,080 13,890 20,060 15,740 21,495 16,800

25,355 26,235 27,115 27,975 29,500 30,315 30,425 31,215

17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3

H

L 524 – L 542 17

Page 18

Attachment

Light Material Bucket

E

A

F

L0082

L

heavy material density

STD HL STD HL STD HL STD HL

Geometry

Cutting tools

Bucket capacity yd³

Bucket width ft in

A Dumping height at max. lift height ft in

E Max. operating height ft in

F Reach at max. lift height ft in

L Overall length ft in

Tipping load, straight * lb

Tipping load, articulated at 40° * lb

Operating weight * lb

Tire sizes

light material density

STD HL STD HL STD HL STD HL

Geometry

Cutting tools

Bucket capacity yd³

Bucket width ft in

A Dumping height at max. lift height ft in

E Max. operating height ft in

F Reach at max. lift height ft in

L Overall length ft in

Tipping load, straight * lb

Tipping load, articulated at 40° * lb

Operating weight * lb

Tire sizes

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load. (Tipping load, articulated at 40° according to ISO 14397-1)

STD = Standard lift arm length HL = High Lift

PK = Parallel linkage including hydraulic quick coupler BOCE = Bolt-on cutting edge

L 524 L 528 L 538 L 542

PK PK PK PK PK PK PK PK

BOCE BOCE BOCE BOCE BOCE BOCE BOCE BOCE

3.9 3.3 4.6 3.9 5.2 4.6 5.9 5.2

8’10” 8’2” 8’10” 8’10” 8’10” 8’10” 9’ 8’10”

8’8” 10’8” 8’4” 10’7” 8’3” 10’5” 8’ 10’3”

17’4” 19’2” 17’10” 19’4” 17’11” 20’2” 18’3” 20’3”

4’ 3’11” 4’3” 3’11” 4’3” 4’ 4’6” 4’3”

24’2” 26’3” 24’6” 26’4” 25’6” 27’5” 25’10” 27’11”

17,460 13,005 19,775 15,100 21,825 17,040 25,440 18,430

15,390 11,465 17,460 13,340 19,245 15,035 20,480 16,270

26,015 27,050 27,560 28,470 29,985 30,955 31,175 31,660

17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3

L 524 L 528 L 538 L 542

PK PK PK PK PK PK PK PK

BOCE BOCE BOCE BOCE BOCE BOCE BOCE BOCE

7.2 5.2 7.8 5.9 8.5 6.5 9.2 7.2

9’ 9’ 9’ 9’ 9’ 9’ 9’ 9’

7’4” 10’ 7’2” 9’9” 7’2” 9’9” 7’ 9’4”

18’7” 19’6” 17’11” 19’10” 19’5” 20’2” 19’7” 20’6”

5’4” 4’5” 5’6” 4’8” 5’5” 4’7” 5’7” 4’11”

26’ 27’1” 26’3” 27’5” 27’1” 28’4” 27’4” 28’10”

16,160 12,700 18,385 14,570 20,725 16,755 22,180 17,835

14,265 11,220 16,250 12,875 18,300 14,770 19,555 15,720

26,895 27,335 28,440 28,880 30,755 31,195 31,790 32,255

17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3

18 L 524 – L 542

Page 19

Attachment

High-Dump Bucket

40°

E

A

heavy material density

STD HL STD HL STD HL STD HL

Geometry

Cutting tools

Bucket capacity yd³

Bucket width ft in

A Dumping height at max. lift height ft in

E Max. operating height ft in

F Reach at max. lift height ft in

L Overall length ft in

Tipping load, straight * lb

Tipping load, articulated at 40° * lb

Operating weight * lb

Tire sizes

L 524 L 528 L 538 L 542

PK PK PK PK PK PK PK PK

BOCE BOCE BOCE BOCE BOCE BOCE BOCE BOCE

3.9 2.9 4.6 3.3 5.2 3.9 5.9 4.6

8’2” 8’2” 8’2” 8’2” 8’10” 8’2” 8’10” 8’2”

14’9” 16’10” 14’6” 16’8” 14’7” 17’4” 14’4” 17’1”

20’5” 21’9” 20’8” 21’11” 20’11” 22’11” 21’1” 23’2”

4’11” 4’5” 5’2” 4’7” 5’ 4’5” 5’4” 4’8”

25’3” 26’8” 25’7” 26’10” 26’3” 27’8” 26’7” 28’

14,925 11,685 16,955 13,535 19,025 15,280 20,215 16,290

13,160 10,340 14,970 11,970 16,775 13,470 17,835 14,375

27,810 27,865 29,430 29,540 31,910 32,255 32,980 33,355

17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3

F

L0080

L

light material density

STD HL STD HL STD HL STD HL

Geometry

Cutting tools

Bucket capacity yd³

Bucket width ft in

A Dumping height at max. lift height ft in

E Max. operating height ft in

F Reach at max. lift height ft in

L Overall length ft in

Tipping load, straight * lb

Tipping load, articulated at 40° * lb

Operating weight * lb

Tire sizes

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different tires

and optional equipment will change the operating weight and tipping load. (Tipping load, articulated at 40° according to ISO 14397-1)

STD = Standard lift arm length HL = High Lift

PK = Parallel linkage including hydraulic quick coupler BOCE = Bolt-on cutting edge

L 524 – L 542 19

L 524 L 528 L 538 L 542

PK PK PK PK PK PK PK PK

BOCE BOCE BOCE BOCE BOCE BOCE BOCE BOCE

6.5 4.6 7.2 5.2 7.8 5.9 8.8 6.5

8’10” 8’2” 8’10” 8’10” 8’10” 8’10” 9’8” 8’10”

14’8” 17’3” 14’7” 17’3” 14’8” 17’3” 14’6” 17’3”

21’4” 22’8” 21’9” 22’11” 22’2” 23’3” 22’5” 23’6”

5’5” 4’10” 5’6” 4’10” 5’4” 4’9” 5’3” 4’10”

25’9” 27’5” 25’10” 27’5” 26’7” 28’3” 26’11” 28’5”

15,090 11,420 17,705 13,340 20,415 15,540 21,605 16,800

13,315 10,075 15,630 11,775 17,990 13,715 19,050 14,815

27,890 28,220 29,385 29,740 31,570 32,055 32,915 33,180

17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3

Page 20

Attachment

Fork Carrier and Fork

F min

FEM III (500)

FEM IV (600)

E

C

A

F max

L0005.01

FG

L

Fork Carrier and Fork

with hydraulic quick coupler L 524 L 528 L 538 L 542 L 538 L 542

Fork

Geometry

Lift arm length ft in

A Lifting height at max. reach ft in

C Max. lifting height ft in

E Max. operating height ft in

F Reach at loading position ft in

F max. Max. reach ft in

F min. Reach at max. lifting height ft in

G

Fork length

ft in

L Length – basic machine

without forks ft in

Tipping load, straight * lb

Tipping load, articulated at 40° * lb

Recommended payload for

uneven ground = 60% of

tipping load, articulated

1)

lb

Recommended payload for

smooth surfaces = 80% of

tipping load, articulated

1)

lb

Operating weight * lb

Tire sizes

* The figures shown here are valid with tires above and include all lubricants, a full fuel tank, the ROPS/FOPS cab and the operator. Different

tires and optional equipment will change the operating weight and tipping load. (Tipping load, articulated at 40° according to ISO 14397-1)

1)

According to EN 474-3

2)

Payload on forks is limited by tilt cylinder

3)

Load capacity for the fork carrier and forks is limited to 11,025 lb

ZK = Z-bar linkage

PK = Parallel linkage

FEM III FEM IV

ZK PK ZK PK ZK PK ZK PK ZK PK ZK PK

7’10” 8’2” 7’10” 8’2” 8’2” 8’2” 8’2” 8’2” 8’2” 8’2” 8’2” 8’2”

5’7” 5’7” 5’7” 5’7” 5’10” 5’8” 5’10” 5’8” 5’9” 5’8” 5’9” 5’8”

11’9” 12’ 11’9” 12’ 12’3” 12’2” 12’3” 12’2” 12’2” 12’ 12’2” 12’

14’10” 15’ 14’10” 15’ 15’4” 15’2” 15’4” 15’2” 15’5” 15’1” 15’5” 15’1”

3’2” 3’8” 3’2” 3’7” 3’1” 3’2” 3’1” 3’2” 3’2” 3’3” 3’2” 3’3”

5’4” 5’8” 5’4” 5’8” 5’4” 5’4” 5’4” 5’4” 5’4” 5’3” 5’4” 5’3”

2’3” 2’7” 2’3” 2’6” 2’3” 2’3” 2’3” 2’3” 2’3” 3’2” 2’3” 3’2”

3’11” 3’11” 3’11” 3’11” 3’11” 3’11” 3’11” 3’11” 3’11” 3’11” 3’11” 3’11”

20’4” 20’9” 20’4” 20’9” 20’10” 21’ 20’10” 21’ 20’9” 20’11” 20’9” 20’11”

13,230 14,285 14,860 16,225 17,370 17,965 18,630 19,290 17,220 17,815 18,475 19,070

11,685 12,565 13,050 14,350 15,300 15,875 16,425 16,995 15,125 15,695 16,315 16,865

7,010 7,540 7,890 8,600 9,150 9,525 9,835 10,185 8,975 9,415 9,745 10,030

8,840

2) 10,095 9,260

2) 11,025

3)

11,025

3) 11,025

3)

11,025

3) 11,025

3) 11,575 12,565 11,905

2) 13,230

23,370 24,825 24,825 26,235 28,000 28,440 29,055 29,365 28,660 28,990 29,540 29,870

17.5R25 L3 17.5R25 L3 20.5R25 L3 20.5R25 L3 20.5R25 L3 20.5R25 L3

20 L 524 – L 542

Page 21

Bucket selection

L 524 Schaufelauswahltabelle

(19.09.2013) 09.01.2014

enUS

L 538 Schaufelauswahltabelle

(19.09.2013) 09.01.2014

enUS

L 528 Schaufelauswahltabelle

(19.09.2013) 09.01.2014

enUS

L 542 Schaufelauswahltabelle

(19.09.2013) 09.01.2014

enUS

L 524

Lift

arm

ZK

ZK-QC

PK

PK-HL

Bucket

GPB 2.7 yd³

GPB 2.4 yd³

LMB 3.1 yd³

GPB 2.4 yd³

3.9 yd³

LMB

7.2 yd³

3.9 yd³

HDB

6.5 yd³

GPB 2.4 yd³

3.3 yd³

LMB

5.2 yd³

2.9 yd³

HDB

4.6 yd³

Material density (lb/yd³)

674 1,011 1,348 1,686 2,023 2,360 2,697 3,034 3,371

7.2

6.5

5.2

4.6

4.3

3.7

3.1

3.4

4.3

3.9

3.3

2.9

3.1

3.9

2.6

3.0

2.6

2.6

2.4

2.7

2.4

2.4

L 528

Lift

arm

ZK

ZK-QC

PK

PK-HL

Bucket

GPB 3.0 yd³

GPB 2.7 yd³

LMB 3.9 yd³

STD 2.7 yd³

4.6 yd³

LMB

7.8 yd³

4.6 yd³

HDB

7.2 yd³

GPB 2.7 yd³

3.9 yd³

LMB

5.9 yd³

3.3 yd³

HDB

5.2 yd³

Material density (lb/yd³)

674 1,011 1,348 1,686 2,023 2,360 2,697 3,034 3,371

7.8

7.2

5.9

5.2

5.1

4.3

3.7

4.3

5.1

4.6

3.9

3.3

3.9

4.6

3.0

3.3

3.0

3.0

2.7

3.0

2.7

2.7

L 538

Lift

arm

ZK

ZK-QC

PK

PK-HL

Bucket

GPB 3.4 yd³

GPB 3.0 yd³

LMB 4.6 yd³

GPB 3.0 yd³

5.2 yd³

LMB

8.5 yd³

5.2 yd³

HDB

7.8 yd³

GPB 3.0 yd³

4.6 yd³

LMB

6.5 yd³

3.9 yd³

HDB

5.9 yd³

Material density (lb/yd³)

674 1,011 1,348 1,686 2,023 2,360 2,697 3,034 3,371

8.5

7.8

6.5

5.9

5.8

5.1

4.3

5.1

5.8

5.2

4.6

3.9

4.6

5.2

3.3

3.8

3.3

3.3

3.0

3.4

3.0

3.0

L 542

Lift

arm

ZK

ZK-QC

PK

PK-HL

Bucket

GPB 3.7 yd³

GPB 3.3 yd³

LMB 5.2 yd³

GPB 3.3 yd³

5.9 yd³

LMB

9.2 yd³

5.9 yd³

HDB

8.8 yd³

GPB 3.3 yd³

5.2 yd³

LMB

7.2 yd³

4.6 yd³

HDB

6.5 yd³

Material density (lb/yd³)

674 1,011 1,348 1,686 2,023 2,360 2,697 3,034 3,371

9.2

8.8

7.2

6.5

6.5

5.8

5.1

5.8

6.5

5.9

5.2

4.6

5.2

5.9

3.7

4.1

3.7

3.7

3.3

3.7

3.3

3.3

L 524 – L 542 21

Page 22

Bucket selection

Kine-

matik

Schaufel

Materialgewicht (t/m³)

0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0

ZK

STD 2,1 m³

ZK-SW

STD 1,8 m³

LGS 2,4 m³

PK

LGS

3,0 m³

5,5 m³

HKS 5,0 m³

PK-HL

LGS 4,0 m³

HKS 3,5 m³

2,3

2,0

2,6

3,3

5,5

5,0

3,5

4,0

2,1

1,8

2,4

3,0

Schaufelfüllung

L0039 . 01

L0039.02

Bucket Filling Factor

100 % 95 %105 %110 %

Lift arm

ZK Z-bar linkage, standard lift arm length

ZK-QC Z-bar linkage including hydraulic quick coupler, standard lift arm length

PK Parallel linkage including hydraulic quick coupler, standard lift arm length

PK-HL Parallel linkage including hydraulic quick coupler, High Lift

Bucket

GPB General purpose bucket (Rehandling)

LMB Light Material Bucket

HDB High-Dump bucket

Bulk Material Densities and Bucket Filling Factors

lb/yd3 %

Gravel, moist 3,203 105

dry 2,697 105

crushed stone 2,528 100

Sand, dry 2,528 105

wet 3,203 110

Gravel and sand, dry 2,865 105

wet 3,371 100

Sand / clay 2,697 110

Clay, natural 2,697 110

dry 2,360 110

Clay / gravel, dry 2,360 110

wet 2,697 100

Tipping Load

What is tipping load?

Load at centre of gravity of working

equipment, so that the wheel loader just

begins to tip over the front axle.

This is the most unfavourable static-load

posi tion for the wheel loader.

lb/yd

Earth, dry 2,191 115

wet excavated 2,697 110

Topsoil 1,854 110

Basalt 3,287 100

Granite 3,034 95

Sandstone 2,697 100

Slate 2,950 100

Bauxite 2,360 100

Limestone 2,697 100

Gypsum, broken 3,034 100

Coke 843 110

Slag, broken 3,034 100

ISO 14397-1

Pay load.

The pay load must not exceed 50% of the

tipping load when articulated.

This is equivalent to a static stability-margin

factor of 2.0.

Lifting arms horizontal, wheel loader

fully articulated at centre pivot.

3

%

lb/yd

Glass waste, broken 2,360 100

solid 1,686 100

Compost, dry 1,348 105

wet 1,686 110

Wood chips / saw dust 843 110

Paper, shredded / loose 1,011 110

recovered paper / cardboard 1,686 110

Coal, heavy material density 2,023 110

light material density 1,517 110

Waste, domestic waste 843 100

bulky waste 1,686 100

3

%

Bucket capacity.

The bucket volume is determined from the

pay load.

Pay load =

Bucket capacity =

Tipping load, articulated

2

Pay load (lb)

Specific bulk weight of

material (lb/yd

3

)

22 L 524 – L 542

Page 23

The Liebherr Wheel Loaders

Wheel Loader

L 524 L 528 L 538 L 542 L 550

Tipping load lb 16,535 18,740 20,945 22,485 26,785

Bucket capacity yd

Operating weight lb 22,930 24,030 28,220 29,540 38,140

Engine output kW/HP(I) 90/121 100/134 115/154 120/161 129/173

3

2.7 3.0 3.4 3.7 4.2

L0009

L0009

L0009

L0009

Wheel Loader

L 556 L 566 L 580 L 586

Tipping load lb 29,870 34,720 40,785 45,040

Bucket capacity yd

Operating weight lb 39,460 51,035 55,510 69,180

Engine output kW/HP(I) 140/188 190/255 215/288 250/335

3

4.7 5.2 6.5 7.2

Environmental protection can help you earn money!

The Liebherr Standard Consumption Test –

easy to reproduce and practical.

The test consits on determining the number of loading cycles that can

be carried out with 1.3 gal of diesel. The material is taken from pile

A and carried over a distance of 65’7” topoint B. The time needed for

each working cycle should be 35seconds. Discharge at point B should

take place from a height of 8’2”. The working cycles continue until the

1.3 gal of diesel in the external measuring tank have been used up. The

loader’s fuel consumption per operating hour is calculated as follows:

35

n=?

B

5

8'2''

4

04.13

30

25

20

15

3

65'7''

T ~ 35 sec.

2

A

1

L0083

Values for the Liebherr Wheel Loaders

working cycles 100 US tons hour hour**

L 524: 2.7 yd3 n = 47 0.82 2.25 1.88

L 528: 3.0 yd

L 538: 3.4 yd

L 542: 3.7 yd

L 550: 4.2 yd

L 556: 4.7 yd

L 566: 5.2 yd

L 580: 6.5 yd

L 586: 7.2 yd

* Equipped with L5 tires and 7.2 yd

** Wheel loader in practical customer applications (with individual

machine configurations).

Number of loading cycles

3

n = 46 0.76 2.30 1.90

3

n = 39 0.79 2.72 2.25

3

n = 38 0.76 2.77 2.30

3

n = 31 0.82 3.41 2.88

3

n = 27 0.84 3.83 3.20

3

n = 22 0.93 4.81 3.99

3

n = 20 0.82 5.28 4.28

3

n = 14 1.05 7.53* 5.42

400

Numbers of Gallons/ Gallons/ Ø Gallons/

=consumption

3

HD bucket

per hour

L 524 – L 542 23

Page 24

Tires

tread code operating weight over tires dimensions Use

lb ft in ft in

L 524/L 528

Bridgestone 17.5R25 VUT L2 – 104 8’ + 0.16” Gravel, Earthworks, Clay (all ground conditions)

Bridgestone 17.5R25 VJT L3 + 201 8’ + 0.71” Bulk material (firm ground conditions)

Bridgestone 17.5R25 VSDL L5 + 1,407 8’ + 2.24” Stone, Scrap, Recycling (firm ground conditions)

Bridgestone 20.5R25 VJT L3 + 1,182 8’ + 2.76” Bulk material (firm ground conditions)

Bridgestone 20.5R25 VSDL L5 + 2,643 8’ + 4.80” Stone, Scrap, Recycling (firm ground conditions)

Bridgestone 550/65R25 VTS L3 + 853 8’1” + 0.47” Gravel (all ground conditions)

Goodyear 17.5R25 RT-3B L3 + 364 8’1” + 0.83” Gravel (all ground conditions)

Goodyear 17.5R25 TL-3A+ L3 + 514 8’1” + 0.91”

Goodyear 17.5R25 RL-4K L4 + 1,224 8’1” + 1.65” Gravel, Industry, Stone (firm ground conditions)

Goodyear 17.5R25 RL-5K L5 + 1,497 8’1” + 1.65” Stone, Scrap, Recycling (firm ground conditions)

Goodyear 20.5R25 RT-3B L3 + 1,168 8’ + 3.07” Gravel (all ground conditions)

Goodyear 20.5R25 TL-3A+ L3 + 1,488 8’1” + 2.87”

Goodyear 20.5R25 GP-4D L4 + 1,867 8’ + 3.23” Gravel, Industry, Wood (firm ground conditions)

Goodyear 20.5R25 RL-4K L4 + 2,440 8’1” + 3.82” Gravel, Industry, Stone (firm ground conditions)

Goodyear 20.5R25 RL-5K L5 + 2,802 8’1” + 4.37” Stone, Scrap, Recycling (firm ground conditions)

Michelin 17.5R25 XTLA L2 – 154 8’1” + 0.71” Gravel, Earthworks, Clay (all ground conditions)

Michelin 17.5R25 XHA L3 0 8’ 0” Sand, Gravel (all ground conditions)

Michelin 17.5R25 XLD D2A L5 + 802 8’1” + 1.46” Stone, Mining spoil (firm ground conditions)

Michelin 17.5R25 X MINE L5 + 1,208 8’2” + 2.32” Stone, Scrap, Recycling (firm ground conditions)

Michelin 20.5R25 XTLA L2 + 877 8’1” + 2.17” Gravel, Earthworks, Clay (all ground conditions)

Michelin 20.5R25 XHA2 L3 + 1,144 8’ + 2.44” Sand, Gravel (all ground conditions)

Michelin 20.5R25 XLD D2A L5 + 2,094 8’ + 3.62” Stone, Mining spoil (firm ground conditions)

Michelin 20.5R25 X MINE L5 + 2,685 8’ + 4.21” Stone, Scrap, Recycling (firm ground conditions)

Michelin 550/65R25 XLD65 L3 + 963 8’1” + 0.71” Gravel (all ground conditions)

L 538/L 542

Bridgestone 20.5R25 VJT L3 + 37 8’2” + 0.31” Bulk material (firm ground conditions)

Bridgestone 20.5R25 VSDL L5 + 1,477 8’ + 2.36” Stone, Scrap, Recycling (firm ground conditions)

Bridgestone 550/65R25 VTS L3 – 97 8’2” – 1.97” Gravel (all ground conditions)

Bridgestone 650/65R25 VTS L3 + 1,312 8’8” + 0.63” Gravel (all ground conditions)

Goodyear 20.5R25 RT-3B L3 + 24 8’2” + 0.63” Gravel (all ground conditions)

Goodyear 20.5R25 TL-3A+ L3 + 344 8’2” + 0.43”

Goodyear 20.5R25 GP-4D L4 + 723 8’1” + 0.79” Gravel, Industry, Wood (firm ground conditions)

Goodyear 20.5R25 RL-4K L4 + 1,296 8’2” + 1.38” Gravel, Industry, Stone (firm ground conditions)

Goodyear 20.5R25 RL-5K L5 + 1,658 8’2” + 1.93” Stone, Scrap, Recycling (firm ground conditions)

Michelin 20.5R25 XTLA L2 – 267 8’3” – 0.28” Gravel, Earthworks, Clay (all ground conditions)

Michelin 20.5R25 XHA2 L3 0 8’2”

Michelin 20.5R25 XLD D2A L5 + 950 8’2” + 1.18” Stone, Mining spoil (firm ground conditions)

Michelin 20.5R25 X MINE L5 + 1,541 8’1” + 1.77” Stone, Scrap, Recycling (firm ground conditions)

Michelin 550/65R25 XLD65 L3 – 181 8’2” – 1.73” Gravel (all ground conditions)

Michelin 650/65R25 XLD65 L3 + 1,054 8’8” – 0.28” Gravel (all ground conditions)

Size and Change of Width Change in vertical

Sand, Gravel, Earthworks, Clay (all ground conditions)

Sand, Gravel, Earthworks, Clay (all ground conditions)

Sand, Gravel, Earthworks, Clay (all ground conditions)

0” Sand, Gravel (all ground conditions)

Before operating the vehicle with tire foam filling or tire protection chains, please discuss this with the Liebherr-Werk Bischofshofen GmbH.

L 524 – L 542 24

Page 25

Equipment

Crash protection, rear

Access to facilitate windscreen cleaning

Exhaust pipe – stainless steel

Automatic central lubrication system

Battery master switch

Diesel particle filter

Electronical theft protection

Electronic tractive force regulation for difficult ground conditions

Automatic travel mode

Speed range selection

Driver identification (in conjunction with electronic theft lock)

Ride control

Parking brake

Particle protection for radiator

Speed limitation, 12.4 mph

Speed limitation V

Large-mesh radiator

Pre-heat system for cold starting

Combined inching-braking system

Fuel tank steel version

Multi-disc limited slip differentials in both axles

LiDAT (Liebherr Data Transfer System) – one year free of charge

Liebherr biodegredable hydraulic oil

Reversible fan drive

Air cleaner system with pre-filter

Emergency steering system

Reversing obstruction detector

Back-up alarm audible

Back-up alarm visual

Tail lights, single version

Rear-view monitoring camera (integrated in dispay unit)

Headlights front, single version (on front-chassis) – halogen

Lockable doors, service flap and engine hood

Widening for fender and rear mudguard (steel design)

Rubber widening for rear mudguards

Air pre-cleaner Top-Air

Hazard warning lights

Toolbox with toolkit

Weighing device for approved or non-approved weighing (integrated in dispay unit)

Towing hitch

max

Operator’s Cab

Storage box

Armrest, adjustable

Exterior mirror, tiltabel

Exterior mirror, heated

Fold-out window (operator’s door)

Operator’s package

Operator’s seat (mechanically sprung)

Operator’s seat – air sprung with seat heating

Operator’s seat – air sprung without seat heating

Fire extinguisher 4 lb

Cup holder

Rear window heater

Horn

Joystick steering

Floor mat

Clothes hook

Air conditioning system (manual)

Automatic air conditioning system

Storage box with cooling function

Steering column, height-adjustable

Steering column, adjustable

Liebherr joystick control – adjustable

Premium Display, Touchscreen (display unit)

Radio set

Provision for radio including loudspeaker

Interior rear-view mirror

Amber beacon

Soundproof ROPS/FOPS cab

Wash/wipe system for windscreen and rear window

Headlights rear, single or double version – halogen/LED

Headlights front, double version – halogen

Headlights front, double version – LED

Headlights front, single version – XENON

Protective ventilation system

Windscreen guard

Sun visor

Sunblind front/rear

Dust filter system

12 V Outlet

First aid kit

Hot water heater with defroster and recirculated-air system

Wide angle mirror

Basic Machine

524

+ + + +

• • • •

+ + + +

+ + + +

• • • •

• • • •

+ + + +

• • • •

• • • •

• • • •

+ + + +

+ + + +

• • • •

+ + + +

+ + + +

• • • •

• • • •

• • • •

• • • •

+ + + +

• • • •

• • • •

+ + + +

• • • •

• • • •

• • • •

+ + + +

• • • •

+ + + +

• • • •

+ + + +

• • • •

• • • •

+ + + +

+ + + +

+ + + +

• • • •

+ + + +

+ + + +

• • • •

524

• • • •

• • • •

• • • •

+ + + +

+ + + +

• • • •

+ + + +

• • • •

+ + + +

• • • •

• • • •

• • • •

• • • •

+ + + +

• • • •

• • • •

• • • •

+ + + +

+ + + +

+ + + +

• • • •

• • • •

+ + + +

+ + + +

• • • •

• • • •

+ + + +

• • • •

• • • •

+ + + +

• • • •

+ + + +

+ + + +

+ + + +

+ + + +

• • • •

+ + + +

+ + + +

• • • •

+ + + +

• • • •

+ + + +

528

528

538

538

542

Quick coupler, opened

Coolant level

Charge air/fuel temperature too high

Steering system / braking system

Engine oil pressure

Reversing obstruction detector

Back-up alarm

Service codes

Overheating of coolant, fuel, hydraulic oil

Audible Warnings for

Display unit

Working hydraulics lockout

Automatic central lubrication system

Battery charge

Operating voltage

Timer for hours of operation

Indicator light / Hazard warning lights / High beam

Brake accumulator pressure

Date/outside temperature

Diesel particle filter

Rev. Counter

Speed range indicator

Driver identification

Travel speed

Travel direction

Parking brake

Gear level

Heater / Air conditioning

Hydraulic oil temperature

Joystick steering

Fuel level

Fuel consumption

Coolant temperature

Reversible fan drive

Engine oil pressure

Emergency steering system

Service codes

System and function settings

Time

Weighing device

Tractive force regulation

542

Warning symbols for

Battery charge

Brake accumulator pressure

Diesel particle filter

Air cleaner blockage

Engine oil pressure

Emergency steering system

Reversing obstruction detector

Engine overspeed

Equipment

Working hydraulics lockout

Automatic hoist kick out – adjustable

Automatic bucket return to dig – adjustable

Fork carrier and lift forks

High-dump bucket

Log Grapple

Hydraulic quick coupler – Z-bar linkage

Hydraulic servo control of working hydraulics

Tilt cylinder protection

Loading buckets with and without teeth, or bolt-on cutting edge

Country-specific versions

Light material bucket

LIKUFIX

Parallel linkage including quick coupler

Parallel linkage including quick coupler – High Lift version

Load holding valves

Float position

Z-bar linkage

3rd hydraulic control circuit

3rd and 4th hydraulic control circuits

• = Standard, + = Option, - = not available

524

528

524

524

524

528

528

528

538

538

538

538

• • • •

• • • •

• • • •

• • • •

• • • •

+ + + +

• • • •

• • • •

• • • •

• • • •

+ + + +

• • • •

+ + + +

• • • •

• • • •

• • • •

+ + + +

• • • •

• • • •

• • • •

+ + + +

• • • •

• • • •

• • • •

• • • •

+ + + +

• • • •

+ + + +

• • • •

+ + + +

• • • •

• • • •

+ + + +

• • • •

• • • •

+ + + +

• • • •

+ + + +

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

+ + + +

• • • •

• • • •

• • • •

• • • •

+ + + +

+ + + +

+ + + +

+ + + +

• • • •

+ + + +

+ + + +

+ + + +

+ + + +

+ + + +

+ + + +

+ + + +

+ + + +

• • • •

• • • •

+ + + +

+ + + +

542

542

542

542

524-542 IIIB 08.13

L 524 – L 542 25

Page 26

The Liebherr Group of Companies

Wide Product Range

The Liebherr Group is one of the largest construction

equipment manufacturers in the world. Liebherr’s

high-value products and services enjoy a high reputation

in many other fields. The wide range includes domestic

appliances, aerospace and transportation systems,

machine tools and maritime cranes.

Exceptional Customer Benefit

Every product line provides a complete range of models

in many different versions. With both their technical

excel lence and acknowledged quality, Liebherr products

offer a maximum of customer benefits in practical

application.

State-of-the-art Technology

To provide consistent, top quality products, Liebherr

attaches great importance to each product area, its

components and core technologies. Important modules

and components are developed and manufactured

in-house, for instance the entire drive and control

techno logyfor construction equipment and mining trucks.

Worldwide and Independent

Hans Liebherr founded the Liebherr family company in

1949. Since that time, the enterprise has steadily grown

to a group of more than 130 companies with over

38,000employees located on all continents. The corporate

headquarters of the Group is Liebherr-International AG

inBulle, Switzerland. The Liebherr family is the sole owner

of the company.

www.liebherr.us

Liebherr Construction Equipment Co.

4100 Chestnut Avenue, Newport News, VA 23607, USA

+1 (757) 245 5251, Fax +1 (757) 928 8701

www.liebherr.us, E-Mail: info.lce@liebherr.com

www.facebook.com/LiebherrConstruction

Printed in Germany by Schirmer RG-BK-RP LBH/PM 11600850-0.5-01.14�enUS

All illustrations and data may differ from standard equipment. Subject to change without notice.

Loading...

Loading...