Liberty Pumps SXL21=3, SXL24=3, SXH21=3, SXH24=3 Installation Manual

Single Phase Simplex

SXL21=3, SXL24=3, SXH21=3, and SXH24=3

Manufactured by SJE-Rhombus®

Installation Instructions and Operation/Troubleshooting Manual

7000 Apple Tree Avenue

Bergen, New York 14416

Phone: 1-800-543-2550

Email: liberty@libertypumps.com www.libertypumps.com

This control panel must be installed and serviced by a licensed electrician in accordance with the National Electric Code NFPA-70, state and local electrical codes.

All conduit running from the sump or tank to the control panel must be sealed with conduit sealant to prevent moisture or gases from entering the panel. NEMA 1 enclosures are for indoor use only, primarily to provide a degree of protection against contact with enclosed equipment. Cable connectors are not required to be liquid-tight in NEMA 1 enclosures. Do not use NEMA 1 enclosures if subjected to rain, splashing water or hose-directed water. NEMA 4X enclosures are for indoor or outdoor use, primarily to provide a degree of protection against corrosion, windblown dust and rain, splashing water and hose-directed water. Cable connectors must be liquid-tight in NEMA 4X enclosures.

ELECTRICAL SHOCK HAZARD

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing this product. A qualified service person must install and service this product according to applicable electrical and plumbing codes.

EXPLOSION OR FIRE HAZARD

EXPLOSION OR FIRE HAZARD

Do not use this product with flamable liquids Do not install in hazardous locations as defined by National Electrical Code, ANSI/NFPA 70.

Failure to follow these precautions could result in serious injury or death. Replace product immediately if switch cable becomes damaged or severed. Keep these instructions with warranty after installation. This product must be installed in accordance with National Electric Code, ANSI/NFPA 70 so as to prevent moisture from entering or accumulating within boxes, conduit bodies, fittings, float housing, or cable.

Warranty void if panel is modified.

Call factory with servicing questions:

1-800-543-2550

7203000B

Installation Instructions

Installation of Floats

A standard single phase simplex panel is designed to operate with three floats. These

floats operate pump stop, pump start, and high level alarm functions.

Note: Options ordered may affect the number of floats and their functions. Please reference the schematic provided with the control panel for proper installation.

CAUTION: If control switch cables are not wired and mounted in the correct order, the pump system will not function properly.

WARNING: Turn off all power before installing floats in pump chamber. Failure to do so could result in serious or fatal electrical shock.

1.Use float label kit to label floats for specific operation (stop, start, alarm, etc.). See schematic for float options.

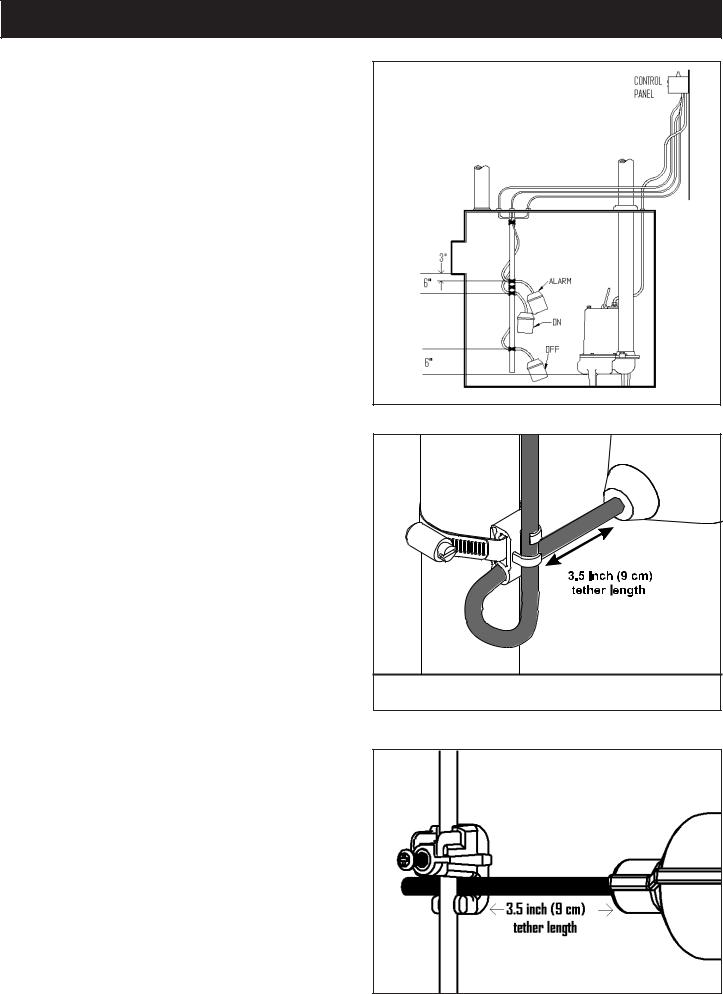

2.Determine your normal operating level, as illustrated in Figure 1.

3.Place the cord into the clamp as shown in

Figure 2 or 3.

4.Locate the clamp at the desired position from step 2, and secure the clamp to the discharge pipe as shown in Figure 2 or 3.

5.Make sure the movement of floats is not restricted.

6.Wire switch per wiring diagram.

7.Check installation. Allow system to cycle to insure proper operation.

NOTE: Do not install cord under hose clamp. Do not install switch in direct line of incoming liquid.

FIGURE 1: Float Locations

Float Locations

Off Float - 6” above pump inlet

On Float - 6” below basin

Alarm Float - 3” below basin

FIGURE 2: Clamp detail, mounting to pipe: |

Note: Approximate activation level of 1.5 inches (4 cm) above or below horizontal.

FIGURE 3

Clamp detail, mounting to Liberty Pumps “Quick Tree”:

7203000B |

- 2 - |

Installation Instructions

Mounting the Control Panel

1.Determine mounting location for panel. If distance exceeds the length of either the float switch cables or the pump power cables, splicing will be required. For outdoor or wet installation, we recommend the use of an SJERhombus® liquid-tight junction box with liquidtight connectors to make required connections.

You must use conduit sealant to prevent moisture or gases from entering the panel.

2.Mount control panel (mounting flanges are furnished with control panel).

3.Determine conduit entrance locations on control panel. Check local codes and schematic for the number of power circuits required.

NOTE: Be sure the proper power supply voltage, and phase are the same as the pump motor being installed. If in doubt, see the pump identification plate for electrical requirements.

4.Drill proper size holes for type of connectors being used.

NOTE: If using conduit, be sure that it is of adequate size to pull the pump and switch cables through. You must use conduit sealant to prevent moisture or gases from entering the panel.

5.Attach cable connectors and/or conduit connectors to control panel.

FOR INSTALLATION WITHOUT A SPLICE, GO TO STEP 11; FOR INSTALLATION REQUIRING

A SPLICE, FOLLOW STEPS 6-10.

6.Determine location for mounting junction box according to local code requirements. Do not mount the junction box inside the sump or basin.

7.Mount junction box to proper support.

8.Run conduit to junction box. Drill proper size holes for the type of conduit used. Attach liquidtight connectors to junction box.

9.Identify and label each wire before pulling through conduit into control panel and junction box. Pull pump power cables and control switch cables through connectors into junction box. Make wire splice connections at junction box.

10.Firmly tighten all fittings on junction box. Insure all cable connectors are liquid-tight and sealed.

11.If a junction box is not required, identify and label cables on both float and stripped ends.

12.Connect pump and float wires to proper position on terminals. See schematic inside control panel for terminal layouts.

13.Connect control, alarm and pump power conductors to proper position on terminals. See schematic inside control panel for terminal connections.

NOTE: It is the recommendation of the factory to use separate pump and control/alarm power sources.

VERIFY CORRECT OPERATION OF

CONTROL PANEL AFTER INSTALLATION IS COMPLETE.

7203000B |

- 3 - |

Operations

Simplex control panels are designed to operate in a three float system as standard. When all floats are in the open or OFF position, the panel is inactive. As the liquid level changes and closes the stop float, the panel remains inactive until the start

float also closes. At this point the pump will start, providing the HOA switch is in the AUTOMATIC mode and the power is ON. The pump will remain

ON until both the stop and start floats open (return to the OFF position). If the liquid level travels beyond both the stop and start floats and reaches the alarm float, the alarm will be activated. The alarm horn can be silenced by moving the test/normal/ silence switch to the silence position.

Alarm System (Horn and Indicator)

When an alarm condition occurs, a red light and horn will be activated. If the test/normal/silence switch is moved to the silence position, the horn will be silenced. When the alarm condition is cleared, the alarm system is reset. The alarm system can be tested by moving the test/normal/silence switch to the test position.

Pump Run Light

The run light will be ON in either the hand or the automatic mode when the pump is called to run.

Circuit Breaker (optional)

The pump circuit has a thermal-magnetic circuit breaker which provides pump disconnect and branch circuit protection.

Dry Auxiliary Contacts (optional)

Normally open - Contacts are open under normal conditions and closed when alarm condition is present.

Normally closed - Contacts are closed under normal conditions and open when alarm condition is present. Both types automatically reset once alarm condition is cleared.

NOTE: Some options ordered may not be included in this manual.

HOA Switch

A hand-off-automatic switch is provided for the pump. In the hand mode, the pump will turn on unless other safety features are employed. In the automatic mode, the pump will turn on from commands by the float switches.

For information regarding the operations of options not listed here or servicing questions, please call a Liberty Pumps customer service technician at

1-800-543-2550

Warranty void if panel is modified.

7203000B |

- 4 - |

Loading...

Loading...