Liberty Pumps PDC User Manual [en, es, fr]

Installation Manual |

8338000D |

|

|

|

|

ProVore® Duplex Control

Indoor Models:

PDC-115 – 115 Volt

PDC-230 – 230 Volt

Outdoor Models:

PDCW-115 – 115 Volt

PDCW-230 – 230 Volt

Designed for use with Liberty Pumps

ProVore® 1 hp. residential grinder pumps

Contents

1.) General Information

2.) General operation – On primary Power (115Vac or 230Vac) 3.) Alarm Operation

4.) Front-Panel Indicators

5.) Pumping Alarm Condition – On Primary Power

6.) Operator Controls – On Primary Power

7.) General operation – On Alarm Backup Power

8.) Alarm Operation – On Alarm Backup power

9.) Operator Controls – On Alarm Backup Power

10.) Front-Panel Indicators – On Alarm Backup Power (9 volt battery)

7000 Apple Tree Avenue Bergen, NY 14416 Phone: (800) 543-2550 Fax: (585) 494-1839 www.libertypumps.com

©Copyright 2013 Liberty Pumps Inc. All rights reserved

General Information

Before installation, read the following instructions carefully. Each Liberty pump is individually factory tested to insure proper performance. Closely following these instructions will eliminate potential operating problems, assuring years of trouble-free service.

Risk of electric shock. Always disconnect the controller from the power source before opening the enclosure.

This controller is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle.

DO NOT bypass grounding wires or remove ground prong from attachment plugs.

This controller requires a separate, properly fused and grounded branch circuit. Make sure the power source is properly sized for the voltage and amperage requirements of the pumps, as noted on the nameplate.

The electrical outlet shall be within the length limitations of the power cord, and at least 4 feet above floor level to minimize possible hazards from flood conditions. DO NOT use an extension cord.

The installation must be in accordance with the National Electric Code, Uniform Plumbing Code, International Plumbing Code, as well as all applicable local codes and ordinances.

DO NOT use this product for flammable or corrosive liquid.

DO NOT use this product in applications where human contact with the pumped fluid is common (such as swimming pools, fountains, etc.)

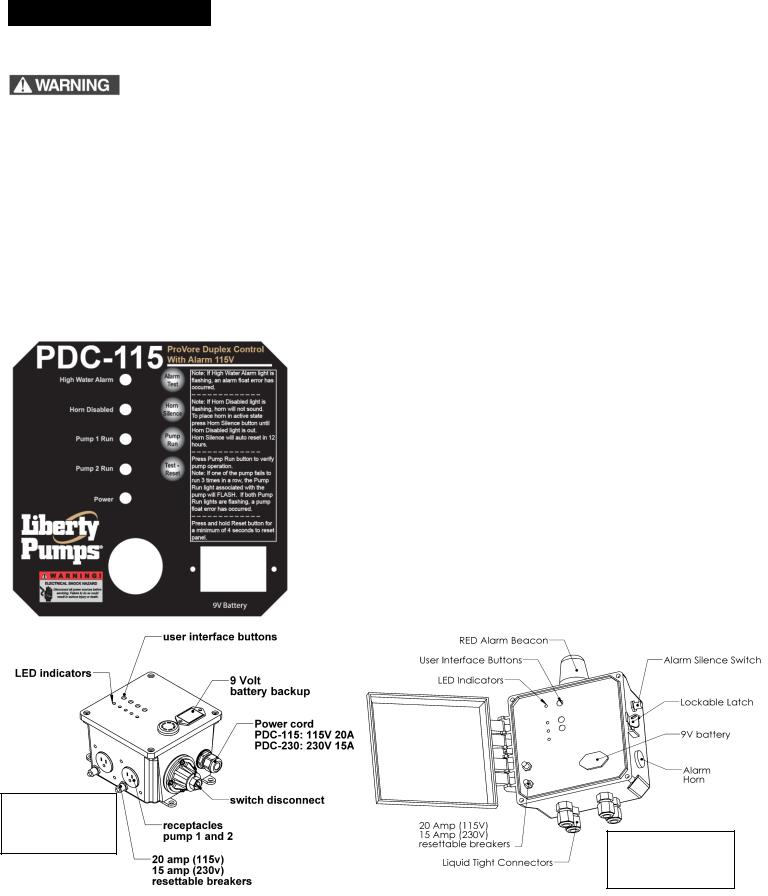

The ProVore® Duplex Control system (PDC-series) monitors the operation of two ProVore® grinder pumps. The control system comes in two parts, the controller with user interface and the float switches mounted inside the basin. The P680 system includes two ProVore® pumps and two float ball switches. The two float ball switches are connected such that only three cords exit the cover. All three cords, two pump power cords and control cord, must be plugged into the controller box for the indoor models, PDC-115 and PDC-230. The outdoor units require hard wiring, the plug ends of the pumps and switch must be cut off and stripped appropriately. The control box monitors the liquid level in the basin and alternates the two grinder pumps each cycle such that both pumps receive equal wear. In the event one pump should fail, the system will automatically switch to the other pump. On the face of the controller are a number of LED lights and push buttons that allow the user to monitor and control the system. Both controllers require a dedicated circuit of the proper ampacity. The PDC(W)-115 requires 115V, 20 amp service while the PDC(W)-230 is 230V, 15 amp service.

Indoor Models: PDC-115 PDC-230

Outdoor Models: PDCW-115 PDCW-230

©Copyright 2013 Liberty Pumps Inc. All rights reserved |

2 |

Models: PDCW-115 and PDCW-230 require hard wiring, the inner panel must be removed to provide access to the terminal block(s) inside the panel. The plug of the pumps and switch must be cut off and wires stripped. Feed the cords, along with the incoming power, through the water tight strain relief bushings and wire into the terminal block mounted in the PDC panel. A wiring schematic is provided beside the terminal block. The panel has a secondary terminal block for auxiliary contacts if required.

The controller normally operates on primary power (115Vac or 230Vac), but if that power fails, an internal 9 volt battery allows the controller to monitor liquid level and to activate the alarm if required.

On alarm backup power ( 9 volt ), the controller cannot run the pumps. Pumps will only operate when primary power is supplied to the control panel.

On alarm backup power, the operator can test the alarm circuits and can change the horn enable/disable status. Since pumps do not operate while the controller is on alarm backup power, the manual run feature will not be functional.

General operation – On primary Power (115Vac or 230Vac)

The PDC panel controls the operation of two ProVore® grinder pumps in a pump-down application. Two floats are mounted to the quick tree: a primary pump control float switch and an alarm float switch. On the front panel of the controller are indicators that show various operating conditions such as pump run status, alarm status, horn enable/disable status, and other conditions. Operator push-button controls are available to manually run the pumps, to manually test the alarm, and to disable or enable the alarm horn, as well as reset the system. Both pumps are individually protected with a manual reset fuse to isolate a failed pump.

When the incoming water activates the primary pump switch, the controller will energize one of the pumps. Normally the water level in the sump will recede as the pump operates; the pump will turn off when the primary pump switch drops to the off position. Upon the next pumping cycle the controller will activate the next pump in sequence from the one that ran previously, providing a pumping redundancy for the system. The controller will continue to alternate pumps on each cycle.

Alarm Operation

In the event water fills the tank faster than it can be pumped out, or if a pump fails to operate, the level can reach an alarm point by flipping the alarm float switch. The following occurs when an alarm condition activates:

1)The pump that is (or should be) running is turned OFF and the next pump in sequence is turned ON.

2)If the Alarm float remains closed (up position) for 4 sec. the alarm indicator on the front panel of the controller will illuminate solid

3)The auxiliary relay will activate, closing its normally open contacts and opening its normally closed contacts.

4)If the horn is enabled (i.e. its indicator is NOT flashing) the horn will sound.

Note, an alarm condition will remain active until the liquid level drops below the Pump Float switch. When that occurs, the following things will take place:

1)The running pump will turn OFF.

2)The front panel alarm indicator will turn OFF.

3)The auxiliary relay will de-activate.

4)The horn (if on) will turn OFF.

If the alarm float remains closed (up position) for 6 hours but the primary float switch is open (down position) the alarm light will flash and the pump is turned off. This feature prevents the pump from running indefinitely.

©Copyright 2013 Liberty Pumps Inc. All rights reserved |

3 |

Front-Panel Indicators

The horn and LED indicators on the front panel are used to show various conditions of the controller. Each indicator is described below.

Indicator |

Indicator state |

Description |

Power led |

OFF |

Power is off to the panel and the battery is dead |

|

On constantly |

Primary power to the panel is ON |

|

Blinking |

Primary power to the panel is OFF; the panel is on alarm backup power. Pumps will |

|

|

NOT run. See Front-Panel indicators – On Alarm backup power. |

*Horn disable |

Blinking |

Horn operation is DISABLED. The horn will NOT sound in an alarm condition. |

LED |

OFF |

Horn operation is ENABLED. The horn WILL sound in an alarm condition |

Alarm LED |

OFF |

There is no alarm condition |

|

On constantly |

An alarm condition is active |

|

Blinking |

The Alarm Float switch is not working properly |

Pump 1 LED |

OFF |

The pump is not being called to run |

|

On constantly |

The pump is being called to run |

|

Blinking |

A pumping alarm condition occurred multiple times; see the section Pumping Alarm |

|

|

Condition below |

Pump 2 LED |

OFF |

The pump is not being called to run |

|

On constantly |

The pump is being called to run |

|

Blinking |

A pumping alarm condition occurred multiple times; see the section Pumping Alarm |

|

|

Condition below |

Both pump 1 & |

Blinking |

The primary float switch is not working properly. |

Pump 2 LED |

|

|

Horn |

OFF |

No alarm condition is present, and the alarm backup battery is in good condition |

|

ON |

An alarm condition is present |

|

Chirping |

The voltage of the alarm backup battery is low and the battery should be replaced |

*Horn disable LED is on PDC-115 and PDC230 units only. Outdoor units, PDCW-115 and PDCW-230, have an alarm silence switch on the exterior of the unit.

Pumping Alarm Condition – On Primary Power

The controller monitors a “pumping alarm condition” where a pump is called to run and the liquid level continues to rise and goes above the Alarm Float switch. If a pumping alarm condition occurs three or more of the last five times a pump is called to run, the pump indicator will blink indicating system components should be checked. Any of the following conditions could cause a pumping alarm condition:

1)A pump fails to operate

2)The Alarm Float switch stays (mechanically stuck) in the closed (on, or up) position.

3)There is a problem (blocked or leak) in the out-flow plumbing

4)The water in-flow rate is greater than the pump-out rate

5)The Primary Float switch stays (mechanically stuck) in the open (off, or down) position.

A blinking light indicates a component failed and service is required. To assist the service technician the controller will indicate which component has failed.

Blinking LED |

Related problem |

Power light |

No AC power, main breaker has tripped or power outage |

Pump 1 |

Pump failed to operate; fuse tripped, jammed impeller, unplugged, short circuit… |

Pump 2 |

Pump failed to operate; fuse tripped, jammed impeller, unplugged, short circuit… |

Pump 1 and pump 2 |

Primary float switch; mechanically stuck open or tangled in an open condition. |

Alarm light |

Alarm float switch; mechanically stuck closed or tangled in a closed condition. |

©Copyright 2013 Liberty Pumps Inc. All rights reserved |

4 |

Operator Controls – On Primary Power

An operator has access to front – panel push-button controls to change the horn enable status, to test the alarm circuits, and to manually run the pumps. Each pump is protected by a manual resettable fuse; the fuses are located on the side panel.

Control Push- |

Existing Conditions(s) |

Action When Pressed |

button |

|

|

*HORN ENABLE |

HORN DISABLED |

Horn Disable indicator will turn OFF and the horn be Enabled |

/ DISABLE |

indicator is blinking |

|

|

HORN DISABLE |

Horn Disable indicator will start blinking and the horn will be |

|

indicator is OFF. |

disabled for 12 hours. After 12 hours, the indicator will turn |

|

|

OFF automatically and the horn will then be Enabled. |

ALARM TEST |

|

Alarm indicator, auxiliary relay, and horn (if enabled) turn On. |

|

|

These actions remain until the button is released. |

MANUAL RUN |

A pump is running |

The pump that is running will be turned OFF; the next pump in |

|

|

sequence will be turned ON. That pump will remain on as long |

|

|

as the button is held. When the button is released, that pump |

|

|

will turn off if the condition calling for a pump to run is no |

|

|

longer present. |

|

Neither pump is running |

The next pump in sequence will be turned ON and will remain |

|

|

on Until the button is released. |

SYSTEM |

Alarm, Pump 1 and / or |

The system will reset and the Alarm, Pump 1 and / or Pump 2 |

RESET |

Pump 2 LED’s are |

LED’s will stop blinking. |

|

blinking |

|

FUSE |

Blown fuse |

Manual resettable fuse |

*Horn disable LED is on PDC-115 and PDC230 units only. Outdoor units, PDCW-115 and PDCW-230, have an alarm silence switch on the exterior of the unit.

General operation – On Alarm Backup Power

On alarm backup power, the controller CANNOT run the pumps. Pumps will ONLY operate when primary (115Vac or 230Vac) is supplied to the control panel.

The Alarm Float switch mounted in the tank is used to monitor liquid level to possibly indicate when an alarm level might be reached. The Pump Float switch is not used when the panel is on alarm backup power, since pumps cannot operate.

Front panel indicator show various operating conditions like alarm status, horn disable status, and other conditions. Operator push-button controls are available to manually test the alarm circuits, and to disable the alarm horn.

When the liquid level drops below the Alarm Float, the switch will be open and there is no alarm condition; when the liquid level rises above the ALARM Float, the switch will be CLOSED and an alarm condition will be indicated.

Alarm Operation – On Alarm Backup power

While on alarm backup power, if water fills the tank and the liquid level rises above the Alarm Float, the float switch will be ON and an alarm condition is activated. The following occurs when an alarm condition activates:

1)The alarm indicator on the front panel of the controller will blink.

2)The auxiliary relay will activate once for one minute, closing its normally open contacts and opening its normally closed contacts, then will de-activate.

3)If the horn is enabled (i.e. its indicator is NOT blinking) the horn will beep.

©Copyright 2013 Liberty Pumps Inc. All rights reserved |

5 |

Operator Controls – On Alarm Backup Power

The operator has access to front – panel push – button controls to change the horn enable status, to test the alarm circuits, and to manually run the pumps.

Control Push- |

Existing Condition(s) |

Action When Pressed |

button |

|

|

*HORN ENABLE |

HORN DISABLE |

Horn Disable indicator will stop blinking and the horn will be enabled. |

/ DISABLE |

indicator is blinking |

|

|

HORN DISABLE |

Horn disabled indicator will start blinking and the horn will be disabled for |

|

indicator is OFF |

12 hours. After 12 hours, the indicator will turn off automatically and the |

|

|

horn will then be enabled |

ALARM TEST |

|

Horn, alarm indicator, and auxiliary relay will turn on. They will remain in |

|

|

that state until the button is released |

MANUAL RUN |

|

The button press is ignored due to lack of primary power. |

*Horn disable LED is on PDC-115 and PDC230 units only. Outdoor units, PDCW-115 and PDCW-230, have an alarm silence switch on the exterior of the unit.

Front-Panel Indicators – On Alarm Backup Power (9 volt battery)

The horn and LED indicators on the front panel, are used to show various conditions in the controller. Each indicator is described below.

Indicator |

Indicator State |

Description |

POWER |

Off |

Power is off to the panel and the backup alarm battery is dead. |

LED |

Blinking |

Primary power to the panel is Off; the panel is on alarm backup power. Pumps will |

|

|

NOT run. See the section on Alarm Backup Power. |

*Horn |

Off |

Horn operation is Enabled. The horn Will beep on and off in an alarm condition. |

Disable LED |

Blinking |

Horn operation is Disabled. |

Alarm LED |

Off |

There is no alarm condition. |

|

Blinking |

An alarm condition is active. |

PUMP 1 |

OFF |

The Pump 1 indicator will always be OFF when on alarm backup power. |

LED |

|

|

PUMP 2 |

OFF |

The Pump 2 indicator will always be OFF when on alarm backup power. |

LED |

|

|

HORN |

OFF |

No alarm condition is present. |

|

BEEPING |

An alarm condition is present. |

*Horn disable LED is on PDC-115 and PDC230 units only. Outdoor units, PDCW-115 and PDCW-230, have an alarm silence switch on the exterior of the unit.

©Copyright 2013 Liberty Pumps Inc. All rights reserved |

6 |

Loading...

Loading...