Page 1

MULTI

F

MAX

MULTI

F

Low Wall Console

INDOOR UNIT

ENGINEERING MANUAL

Vertical-Horizontal

Air Handling Units

Art CoolTM Mirror

Wall-Mounted

Four-Way Ceiling Cassette

Indoor Units for Multi-Zone Heat Pump Systems

7,000 to 36,000 Btu/h

Ceiling-Concealed Duct

Art CoolTM Gallery

Wall-Mounted

Page 2

PROPRIETARY DATA NOTICE

DANGER

WARNING

CAUTION

This document, as well as all reports, illustrations, data, information, and

other materials are the property of LG Electronics U.S.A., Inc., and are

disclosed by LG Electronics U.S.A., Inc., only in confidence.

This document is for design purposes only.

For continual product development, LG reserves the right to change specifications without notice.

©LG Electronics Inc.

TABLE OF SYMBOLS

This document, as well as all reports, illustrations, data, information, and other materials are the property of LG Electronics U.S.A., Inc.

Note:

This symbol indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

This symbol indicates situations that may result in equipment or property damage accidents only.

This symbol indicates an action that should not be performed.

Page 3

MULTI

MAX

MULTI

F

TABLE OF CONTENTS

Convergence of Technology,

Innovation, Flexibility, & Style ....................................................4

Unit Nomenclature .......................................................................5

Functions, Controls and

Options Overview ........................................................................6

Art Cool Mirror Indoor Units .....................................................10

Art Cool Gallery Indoor Units ...................................................29

Standard Wall-Mounted Indoor Units ......................................49

Low Wall Console Indoor Units ................................................73

Duct (Low Static) Indoor Units .................................................94

Mechanical Specications and Features ........................................... 10

General Data / Specications .............................................................11

Dimensions ........................................................................................ 12

Cooling Capacity Table ...................................................................... 14

Heating Capacity Table ...................................................................... 16

Acoustic Data .................................................................................... 17

Air Velocity and Temperature Distribution .......................................... 18

Refrigerant Flow Diagram .................................................................. 19

Wiring Diagram .................................................................................. 20

Factory Supplied Parts and Materials ................................................ 21

Installation and Best Layout Practices ............................................... 22

Mechanical Specications and Features ........................................... 29

General Data / Specications ............................................................ 30

Dimensions ........................................................................................ 31

Cooling Capacity Table ...................................................................... 32

Heating Capacity Table ...................................................................... 33

Acoustic Data .................................................................................... 34

Air Velocity and Temperature Distribution .......................................... 35

Refrigerant Flow Diagram .................................................................. 36

Wiring Diagram .................................................................................. 37

Factory Supplied Parts and Materials ................................................ 38

Installation and Best Layout Practices ............................................... 39

Mechanical Specications and Features ........................................... 49

General Data / Specications ............................................................ 50

Dimensions ........................................................................................ 51

Cooling Capacity Table ...................................................................... 53

Heating Capacity Table ...................................................................... 56

Acoustic Data .................................................................................... 58

Air Velocity and Temperature Distribution .......................................... 60

Refrigerant Flow Diagram .................................................................. 62

Wiring Diagram .................................................................................. 63

Factory Supplied Parts and Materials ................................................ 65

Installation and Best Layout Practices ............................................... 66

Mechanical Specications and Features ........................................... 73

General Data / Specications ............................................................ 74

Dimensions ........................................................................................ 75

Cooling Capacity Table ...................................................................... 76

Heating Capacity Table ...................................................................... 78

Acoustic Data .................................................................................... 79

Air Velocity and Temperature Distribution .......................................... 81

Refrigerant Flow Diagram .................................................................. 82

Wiring Diagram .................................................................................. 83

Factory Supplied Parts and Materials ................................................ 84

Installation and Best Layout Practices ............................................... 85

Mechanical Specications and Features ........................................... 94

General Data / Specications ............................................................ 95

Dimensions ........................................................................................ 96

Cooling Capacity Table ...................................................................... 97

Heating Capacity Table ...................................................................... 99

External Static Pressure .................................................................. 100

Acoustic Data .................................................................................. 101

Refrigerant Flow Diagram ................................................................ 102

Wiring Diagram ................................................................................ 104

Factory Supplied Parts and Materials .............................................. 106

Installation and Best Layout Practices ............................................. 107

Duct (High Static) Indoor Units ..............................................117

Mechanical Specications and Features ..........................................117

General Data / Specications ...........................................................118

Dimensions .......................................................................................119

Cooling Capacity Table .................................................................... 121

Heating Capacity Table .................................................................... 122

External Static Pressure / Acoustic Data ......................................... 123

Refrigerant Flow Diagrams .............................................................. 124

Wiring Diagrams .............................................................................. 125

Factory Supplied Parts and Materials .............................................. 126

Installation and Best Layout Practices ............................................. 127

Four-Way Ceiling Cassette Indoor Units ...............................136

Mechanical Specications and Features ......................................... 136

General Data / Specications .......................................................... 137

Dimensions ...................................................................................... 138

Cooling Capacity Table .................................................................... 140

Heating Capacity Table .................................................................... 142

Acoustic Data .................................................................................. 144

Air Velocity and Temperature Distribution ........................................ 146

Refrigerant Flow Diagram ................................................................ 148

Wiring Diagram ................................................................................ 149

Factory Supplied Parts and Materials .............................................. 150

Installation and Best Layout Practices ............................................. 151

Two-Way VAHU Indoor Units .................................................. 160

Mechanical Specications and Features ......................................... 160

General Data / Specications .......................................................... 161

Dimensions ...................................................................................... 162

Cooling Capacity Table .................................................................... 163

Heating Capacity Table .................................................................... 164

External Static Pressure .................................................................. 165

Acoustic Data .................................................................................. 166

Refrigerant Flow Diagram ................................................................ 167

Wiring Diagram ................................................................................ 168

Factory Supplied Parts and Materials .............................................. 170

Installation and Best Layout Practices ............................................. 171

Four-Way VAHU Indoor Units ................................................. 180

Mechanical Specications and Features ......................................... 180

General Data / Specications .......................................................... 181

Dimensions ...................................................................................... 182

Cooling Capacity Table .................................................................... 183

Heating Capacity Table .................................................................... 185

External Static Pressure .................................................................. 187

Heater Capacities ............................................................................ 189

Acoustic Data .................................................................................. 190

Refrigerant Flow Diagram ................................................................ 192

Wiring Diagram ................................................................................ 193

Factory Supplied Parts and Materials .............................................. 195

Installation and Best Layout Practices ............................................. 196

Equipment Selection Procedure ............................................206

Placement Considerations ............................................................... 213

Refrigerant Piping Design ......................................................220

Design Guideline Summary ............................................................. 220

Creating a Balanced System / Manual Layout Procedure 224

Condensate Drain Piping ................................................................. 225

Electrical Connections ............................................................227

General Information ......................................................................... 227

Power Wiring (208-230V) and Comm Cable Details ....................... 230

Remote Controller Connections ...................................................... 240

Indoor Unit Group Control ............................................................... 241

Acronyms .................................................................................242

INTRODUCTION | 3

Introduction

Page 4

CONVERGENCE OF TECHNOLOGY,

MULTI

F

INNOVATION, FLEXIBILITY, & STYLE

About LG Electronics, Inc.

LG Electronics is a global leader and technology innovator in consumer electronics, mobile communications, and home appliances.

LG Electronics comprises five business units—Home Entertainment,

Mobile Communications, Air Conditioning, Business Solutions, and

Home Appliance. LG is one of the world’s leading producers of flat

panel televisions, audio and video products, mobile handsets, air

conditioners, and washing machines. LG’s commercial air conditioning business unit was established in 1968 and has built its lineup of

residential and commercial products to include VRF, Multi F, ductfree split systems, packaged terminal air conditioners (PTACs), and

room air conditioners. In 2011, the air conditioning and energy solutions business unit grew to include LED lighting and solar products.

For more information, visit www.lg.com.

Multi-Zone Systems

LG HVAC systems offer a range of solutions that are cost efficient,

quiet and attractive. Multi-zone systems are “split” into indoor and

outdoor units, and provide a smart alternative to both central HVAC

and window-mounted air conditioners. These inverter heat pump systems are available in a variety of configurations to suit different cooling and heating situations. Installation by a trained HVAC contractor

is safe and easy – little to no duct work or sheet metal is required.

be used with different controllers, allowing the customer to set the

temperature individually. Indoor units are available in several different

congurations: Art Cool™ Mirror-mounted, Art Cool Gallery wall-

mounted, standard wall-mounted, low wall console, four-way ceiling

cassettes, ceiling-concealed duct (high and low static), and verticalhorizontal air handling models. Multi F MAX systems can operate up

to eight indoor units through two-, three-, or four-port branch distribution units.

Adaptable and Flexible

Multi F outdoor units can be adapted to a wide range of building ap-

plications and sizes such as schools, hotels, hospitals, ofces, and

residences. The system components are lightweight and compact so

they can be placed in buildings without expensive cranes, they easily

fit into most service elevators, and they can be set in place with

minimal structural reinforcements requirements.

Multi F technology allows you to pipe farther by reaching areas of the

building that would require the installation of a second system when

using traditional direct-expansion cooling and heating equipment. Multi

F provides the designer with uncompromised pipe system engineering

exibility—long pipe runs and large elevation differences. Whether your

building is a condominium, a hotel, a school, or an ofce complex, Multi

F is best suited to reach the farthest corners and elevations.

Multi F Systems

LG’s inverter heat pumps can support two, three, or four indoor

units that are typically installed in separate rooms. Indoor units can

Benefits of Multi F Systems

• Individual zone control

• Long refrigerant piping lengths

• High refrigerant piping elevation differences

• Maximum flexibility

• Operating ranges of 14°F to 118°F (DB) in cooling and -4°F to

75°F (DB) in heating if connected to standard Multi F Outdoor Units

or -13°F to 75°F (DB) in heating if connected to Multi F with LG

REDº Outdoor Units.

• Quiet and comfortable environment

Multi F and Multi F MAX Indoor Unit Engineering Manual

• Reduced ductwork

Smaller Chases and Plenums

LG Multi F systems use refrigerant piping to move heat, resulting in

smaller space requirements for piping as compared to chilled water

or roof top systems. This helps reduce the overall construction and

material cost of the building, and gives back leasable space. Flexible

and logical placement of system components, reduced back-andforth pipe lengths, and fewer joints lowers installation costs and

minimizes potential leaking.

Quality Commitment

LG is committed to the success of duct-free projects. We provide

technical support during installation and commissioning. LG offers

a variety of classes designed for

installers and servicers on Multi

F installation. Classes are conducted at LG’s training centers

and in field locations at various

times throughout the year and on

special request.

4 | INTRODUCTION

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 5

MULTI

F

MAX

MULTI

F

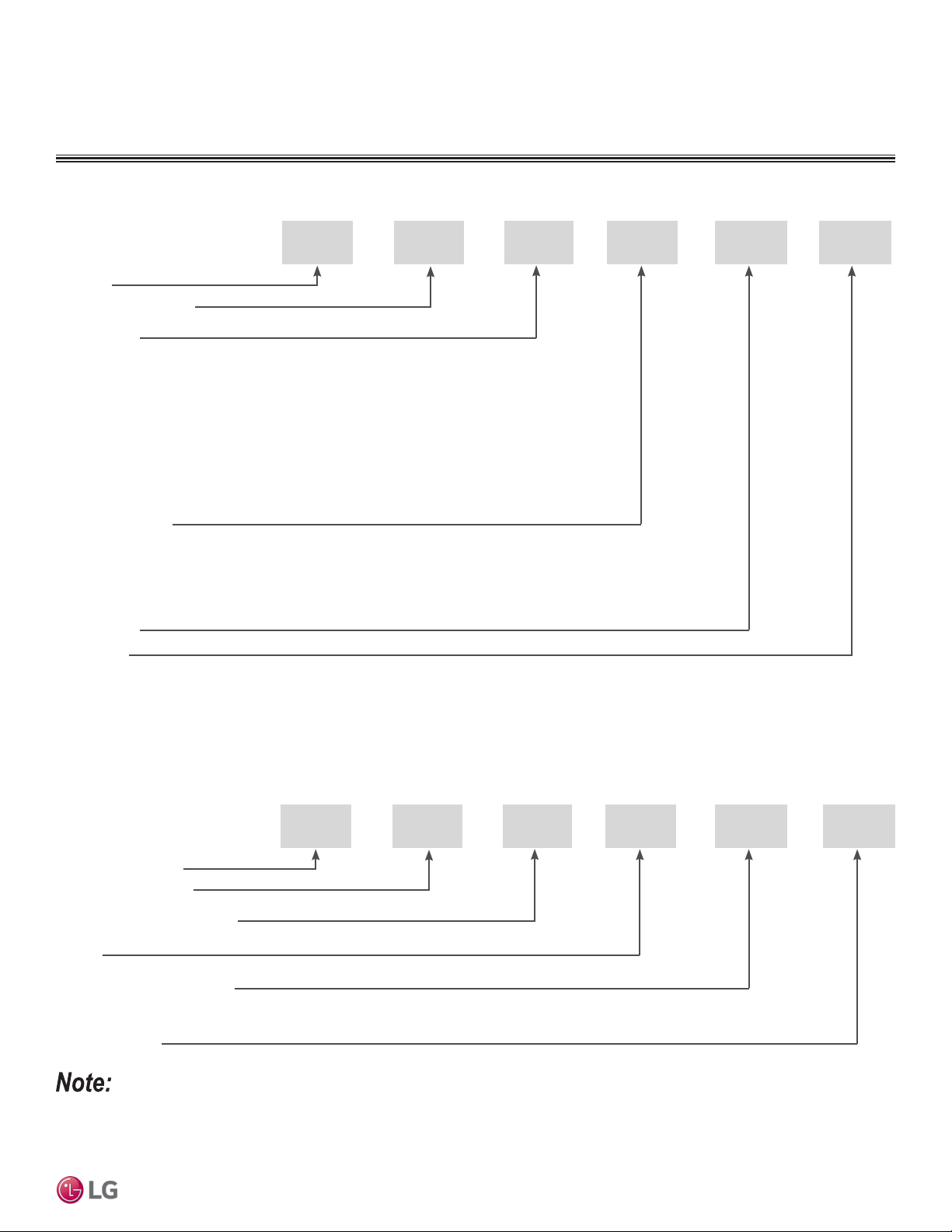

UNIT NOMENCLATURE

Multi-Zone Systems — Indoor Units and Outdoor Units

L

L = LG

Type: M = Multi-Zone

Component:

AN: Art Cool™ Wall-Mounted Indoor Unit

N: Standard Wall-Mounted Indoor Unit

QN: Low Wall Console Indoor Unit

CN: Four-Way Ceiling-Cassette Indoor Unit

DN: Ceiling-Concealed Duct (Low Static) Indoor Unit

HN: Ceiling-Concealed Duct (High Static) Indoor Unit

VN: Vertical-Horizontal Air Handling Indoor Unit

U: Outdoor Unit

Nominal Capacity

(Nominal cooling capacity in Btu/h):

07 = 7,000

09 = 9,000

12 = 12,000

Generation

Features:

H = Heat Pump

V = Inverter

T = High Wall-Mounted Indoor Unit

P = Art Cool Gallery Indoor Unit

15 = 15,000

18 = 18,000

24 = 24,000

30 = 30,000

36 = 36,000

42 = 42,000

M

48 = 48,000

54 = 54,000

60 = 60,000

CN 07 8 HV

Introduction

Branch Distribution Units

P = Part (Accessory)

Type: M = Multi-Zone

BD: Branch Distribution Unit

Family

Number of Port Connections

(Maximum Number of Connectable Indoor Units): 2, 3, 4

• Voltage for all equipment is 208-230V, 60 Hz, 1-phase.

• All indoor units are compatible with wired controllers.

• All outdoor units are LGAP control network compatible with PI-485 V-net Control Integration Board (PMNFP14A1, sold separately).

• Compatible single zone IDU nomenclature is listed in the Single Zone Wall-Mounted IDU Engineering Manual.

Generation: 0, 1

P

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

M

BD 36

02

INTRODUCTION | 5

Page 6

MULTI

F

MAX

MULTI

F

FUNCTIONS, CONTROLS AND

OPTIONS OVERVIEW

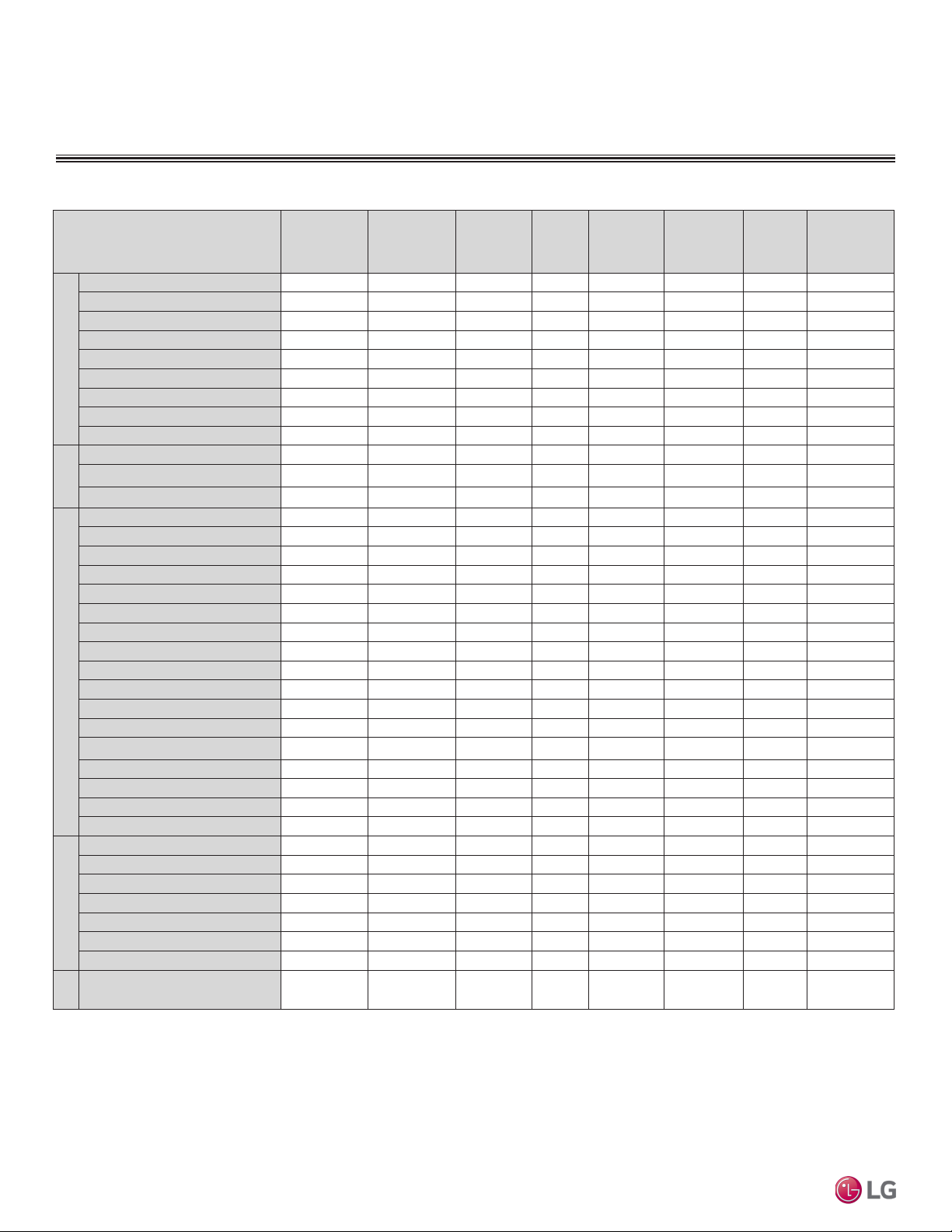

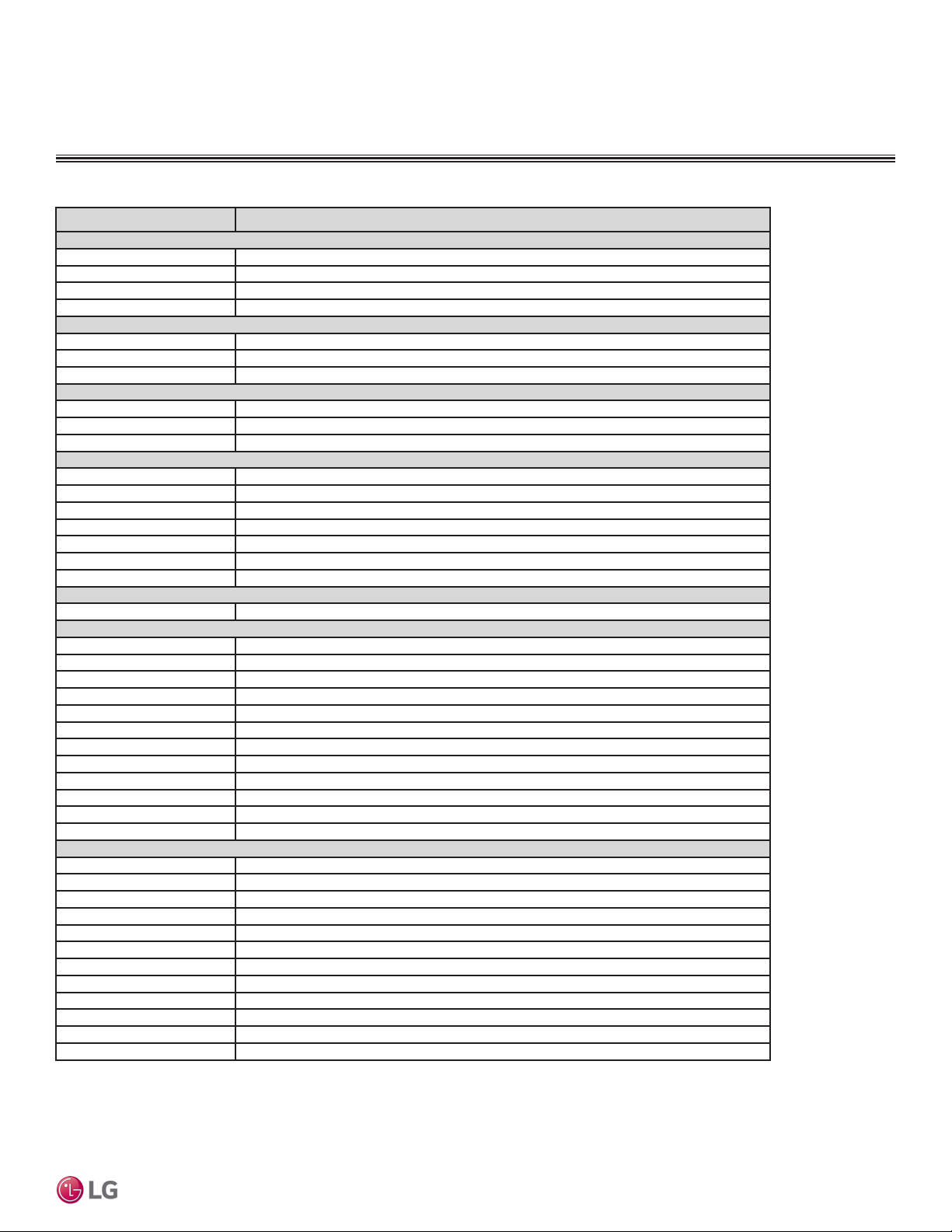

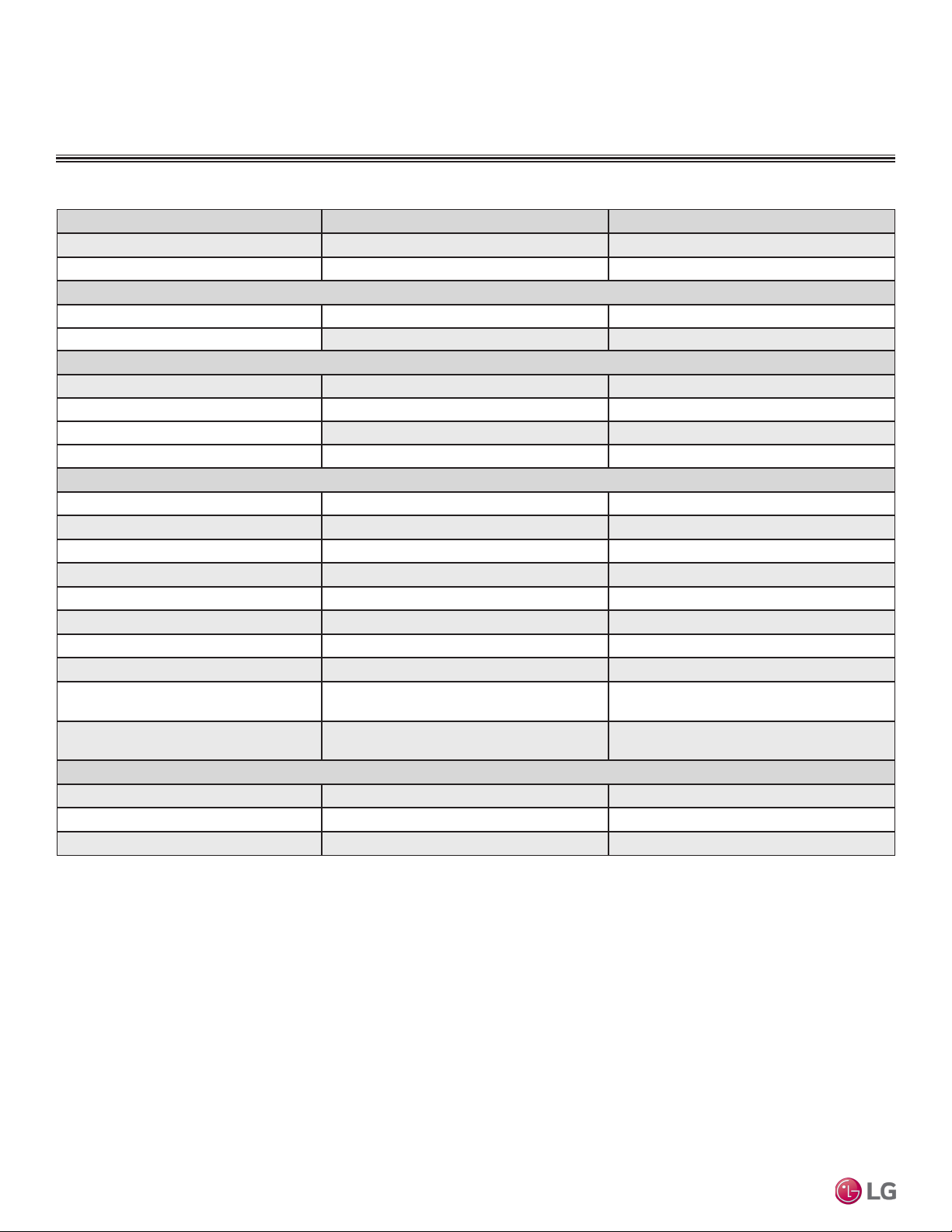

Table 1: Indoor Units—Functions, Controls and Options.

Indoor Unit Type

Air supply outlets

Airflow direction (left/right)

Airflow direction (up/down)

Auto swing (left/right)

Auto swing (up/down)

Airow

Airflow steps (fan/cool/heat)

Comfort Air (random fan speed)

Jet-cool/Jet Heat (power wind)

ART COOL™

Mirror Wall

Mounted

1 3 1 2 1 1 4 1

Auto Auto Auto Manual

Auto Auto Auto Auto Auto

√ √ √

√ √ √ √ √

6 / 6 / 6 5 / 5 / 4 6 / 6 / 6 5 / 5 / 5 3 / 3 / 3 3 / 3 / 3 4 / 5 / 4 3 / 3 / 3

√ √ √ √ √

√ √ √ √ √

ART COOL™

Gallery

Swirl wind

Washable anti-fungal

3M Micro Dust Filter

Filter

Ventilation

1

2

√ √ √ √ √ √ √

√ √

Drain pump

E.S.P. control

Electric heater

High ceiling

Hot Start

Self diagnostics

Soft Dry (dehumidification)

Auto operation

Auto clean (coil dry)

Auto restart

Operation

Child lock

Forced operation

Group control

Sleep mode

Timer (on/off)

Weekly schedule

Two thermistor control

7-Day programmable controller

Simple wired remote controller

Multi F and Multi F MAX Indoor Unit Engineering Manual

Wireless LCD remote control

Dry contact

Dry contact (temperature setting)

Controllers

Central control (LGAP)

Connector for Water Sensor

Wi-Fi

Special

Function

5

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √

√ √ √ √ √ √ √

o o o √

√ √ √ √ √

o o o √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

o o o √ √ √ o √

o o o √ o o o o

o o o o o o o o

o o o o o o o o

√ √ √ √ o

o o o o o o o √

o o o o o o o o

√ √ √ √ √ √ √ √

√ √ √ √

8

√ o √ o o o o o

Standard

Wall

Mounted

Low Wall

Console

6

6

Ceiling

Concealed

(Low Static)

Ducted

Ceiling

Concealed

(High Static)

Ducted

Four-Way

Ceiling

Cassette

√

4

√

√ √ √

√ √

√

o o o o

o o o o

6

6

o

√ o

VerticalHorizontal Air

Handling Unit

o

5

6

7

1

2

3

Plasma kit.

4

limitations apply).

5

6 | INTRODUCTION

Primary washable filters.

Secondary filter

Branch location and static pressure requirements. Requires PTPKQ0

Requires ventilation kit PTVK430 (Temperature, humidity, and volume

Group control will affect available features

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

6

Requires wired zone controller

7

For use with 3rd party thermostat

8

Embedded. Optional for HSD, LVNxxxHV4 4-way VAHU; LDN 9/12 MBH

LSD are compatible as of June 2018 production. Not available for 2-way

LMVNxxxHV VAHU. LMANxxxHVP Art Cool Gallery compatible as of

January 2019 production.

√ = Standard feature

o = Unit option

Page 7

MULTI

F

MAX

MULTI

F

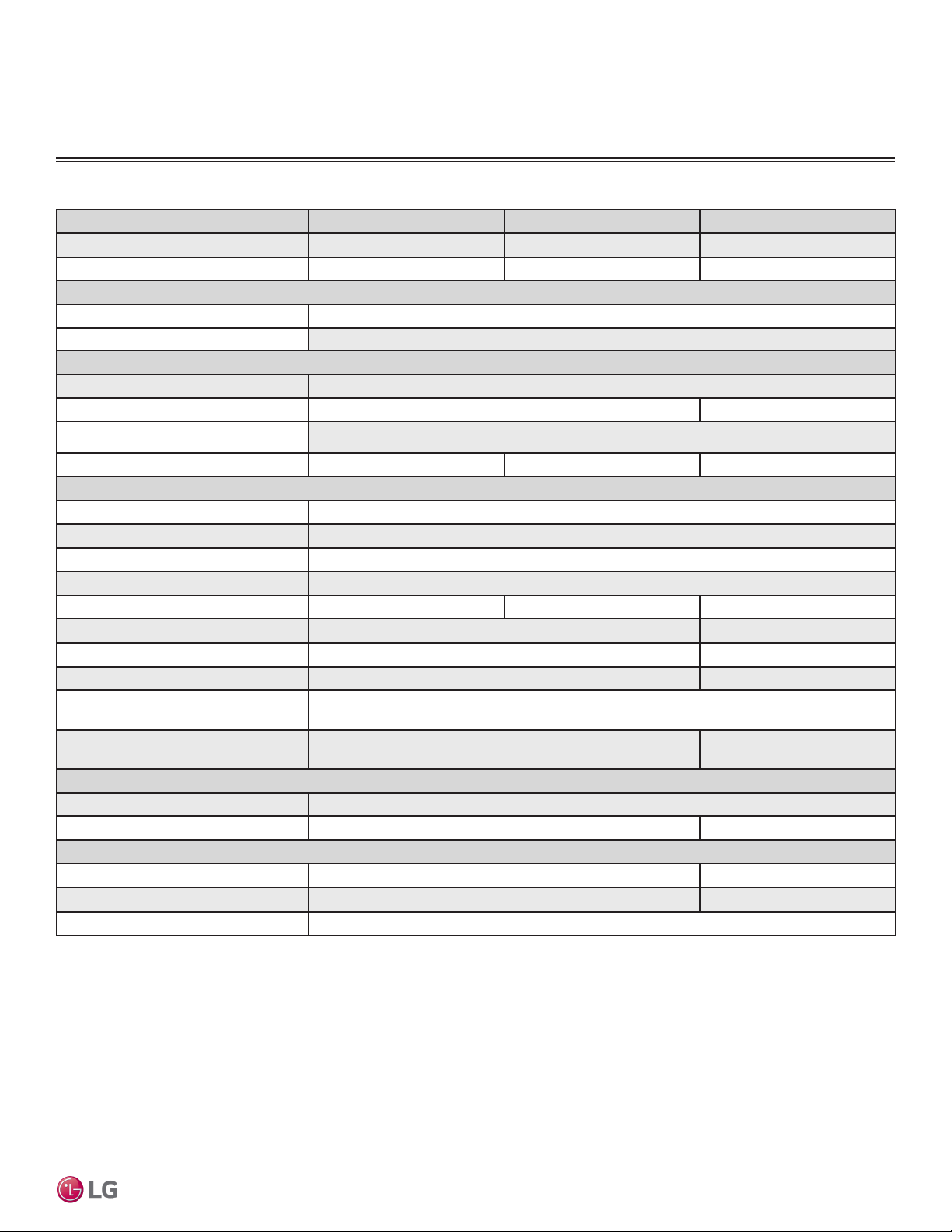

Table 2: Indoor Unit Accessories Overview.

Model No. Description

For Four-Way Ceiling-Cassette Indoor Units

PT-QCHW0 Ceiling Grille

PTDCQ Decorative Cover

PRARH0 Aux Heat Relay Kit

PWFMDD200 Wi-Fi Module

For Wall-Mounted Indoor Units

PWFMDD200 Wi-Fi Module

AG-9300-LG Condensate Sensor

PRARS1 Aux Heat Relay Kit

For Low Wall Console Units

PWFMDD200 Wi-Fi Module

AG-9300-LG Condensate Sensor

PRARH0 Aux Heat Relay Kit

For Vertical-Horizontal Air Handing Units

PNDFJ0 Downflow Conversion Kit (18/24/36MBH)

ANEH033B1 3 kW Electric Heater (18-36MBH)

ANEH053B1 5 kW Electric Heater (18-36MBH)

ANEH083B2 8 kW Electric Heater (18-36MBH)

ANEH103B2 10 kW Electric Heater (18-36MBH)

PRARH0 Aux Heat Relay Kit

PWFMDD200 Wi-Fi Module

For Ceiling-Concealed Duct (Low Static) Indoor Units

PWFMDD200 Wi-Fi Module

For Ceiling-Concealed Duct (High Static) Indoor Units

ZFBXM101A High Efficiency Filter Box for LHN248HV

ZFBXM201A High Efficiency Filter Box for LHN368HV

ZFBXD201A Dynamic V8 2VL Low Profile Air Cleaner

ZPLMV201A Dynamic 2VL Air Cleaner Low Profile Return Air Plenum

ZFBXD402A Dynamic V8 4VL Low Profile Air Cleaner

ZPLMV402A Dynamic 4VL Air Cleaner Low Profile Return Air Plenum

ZFLT1301A 4-Pack Dynamic V8 VL Air Cleaner Replacement Filter Pads

ZFLT1302A 24-Pack Dynamic V8 VL Air Cleaner Replacement Filter Pads

ZGRLRA01A Dynamic V8 Air Cleaner Louvered Return Air Grille (one per plenum )

ZGRLRA02A Dynamic V8 Air Cleaner Egg Crate Return Air Grille (one per plenum)

PRARH0 Aux Heat Relay Kit

PWFMDD200 Wi-Fi Module

Controls Accessories

PQWRHQ0FDB Wireless Handheld Remote (Duct/VAHU)

PREMTA000A Premium Controller

PREMTC00U Simple Controller

PREMTBVC0 MultiSITE CRC1 Base Controller

PREMTBVC1 MultiSITE CRC1 Plus Controller

ZVRCZ**** MultiSITE CRC1 Wireless Accessories

PDRYCB100 Dry Contact (Simple)

PDRYCB300 Dry Contact (3rd party controller)

PDRYCB400 Dry Contact (Setback)

ZRTBS01 Remote Temp Sensor (Cassette/Console/Duct/VAHU)

PZCWRCG3 Group Control Cable Kit

PZCWRC1 Controller Extension Cable

FUNCTIONS, CONTROLS AND

OPTIONS OVERVIEW

Introduction

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

INTRODUCTION | 7

Page 8

Multi F and Multi F MAX Indoor Unit Engineering Manual

MULTI

F

MAX

MULTI

F

8 | INTRODUCTION

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 9

™

ART COO

L

MIRROR

INDOOR UNIT DATA

“Mechanical Specifications” on page 10

“General Data / Specifications” on page 11

“Dimensions” on page 12

“Cooling Capacity Table” on page 14

“Heating Capacity Table” on page 16

“Acoustic Data” on page 17

“Air Velocity and Temperature Distribution” on page 18

“Refrigerant Flow Diagram” on page 19

“Wiring Diagram” on page 20

“Factory Supplied Parts and Materials” on page 21

“Installation and Best Layout Practices” on page 22

Page 10

ART COOL MIRROR INDOOR UNITS

MULTI

F

MAX

MULTI

F

Mechanical Specications and Features

ART COOL Mirror Wall-Mounted

Indoor Units

General

All LG indoor units are factory assembled, wired, piped, and provided with a control circuit board, fan, and motor. ART COOL Mirror

Wall-Mounted indoor units have a sound rating no higher than 44

dB(A) as tested per KSA0701 ISO Standard 3745.

Coil

Indoor unit coils are comprised of a minimum of two rows of

aluminum fins mechanically bonded to copper tubing. The coils are

pressure tested at the factory. Each unit is provided with a factory

installed condensate drain pan below the coil.

Refrigerant System

System is designed for use with R410A refrigerant. The refrigeration

circuit is pressure-tested at the factory and shipped with a holding

charge of helium gas. Refrigerant pipe connections are 45° flare.

All refrigerant lines from the outdoor unit to the indoor units must be

field insulated.

Electrical

Each indoor unit is designed to operate using 208–230/60/1 power

with voltage variances of ±10%.

Casing

Units are designed to mount on a vertical surface, and are shipped

with a separate back plate that secures the unit to the wall, protruding no more than nine (9) inches. Unit is designed so that refrigerant

piping can be installed in one (1) of four (4) different directions.

Finish

The Art Cool Mirror unit has a flat, architectural panel with a smoked

charcoal mirror finish. Unit casing has a dark grey finish and is

manufactured of heavy-duty acrylonitrile butadiene styrene (ABS)

and high impact polystyrene (HIPS) plastic.

Fan Assembly and Control

The unit has a single, direct-drive, crossow fan made of high strength

ABS plastic. The fan motor is brushless digitally controlled (BLDC)

with permanently lubricated and sealed ball bearings. The fan and

Multi F and Multi F MAX Indoor Unit Engineering Manual

motor assembly is mounted on vibration attenuating rubber grommets.

Fan speed is controlled using a microprocessor-based direct digitally

controlled algorithm that provides pre-programmed, eld-selectable

xed or auto fan speeds in the Heating and Cooling modes. For Art

Cool Mirror Wall-Mounted units, the indoor fan has Low, Med, High,

Jet Cool and Auto settings for Cooling mode; and has Low, Med, High,

Jet Heat and Auto settings for Heating mode. The Auto setting adjusts

the fan speed based on the difference between the controller setpoint

and space temperature. Also, the separate Chaos setting provides a

simultaneous and random change in fan speed and ow direction at

the discharge, simulating a natural outdoor breeze.

Air Filter

Return air inlet has a factory-supplied primary removable, washable

filter. The unit is also equipped with a secondary 3M Micro Dust

filter. Filters are accessed from the front of the unit without the use

of tools.

Airflow Guide Vanes

A motorized guide vane is factory installed, and allows the ability to

control the direction of airflow from side to side. A motorized louver

provides an automatic change in airflow by directing the air up and

down to provide uniform air distribution.

Microprocessor Control

The indoor unit is provided with an integrated control panel to communicate with the outdoor unit. All unit operation parameters are

stored in non-volatile memory resident on the unit microprocessor.

The microprocessor controls space temperature through using the

value provided by the temperature sensor within the indoor unit.

The microprocessor control will activate indoor unit operation when

the indoor room temperature falls below or rises above a setpoint

temperature, at which point, a signal is sent to the outdoor unit to

begin the appropriate mode. The microprocessor will also provide

self-diagnostics and auto restart functions. A field-supplied four-wire

power/communications cable must be installed to connect the indoor

unit(s) to the outdoor unit.

Controls

The indoor unit casing has a factory-standard, integral infrared

sensor designed to communicate with the supplied LG wireless

handheld remote controller. An optional LG supplied wired controller

is available as an additional accessory. Communication between the

indoor units and the outdoor unit is accomplished through 14 AWG,

four-core, stranded and shielded power/communication cable. The

indoor unit has built-in wi-fi and can be controlled with LG’s SmartThinQ app on a smart device. A field-supplied wi-fi network and

smart device are required. The SmartThinQ app is free and is available for Android and iOS smart devices.

Condensate

The unit is designed for gravity draining of condensate and includes

a flexible drain hose capable of installation in one of two directions.

Unit includes a connection that is compatible with the AquaGuard®

AG-9300-LG condensate sensor.

Features

• Inverter (Variable speed fan)

• Comfort Air

• 3M filter

• Jet cool/Jet heat

10 | ART COOL MIR ROR

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

• Group Control

• Self-cleaning indoor coil

• Auto operation

• Auto restart operation

Due to our policy of continuous product innovation, some specications may change without notication.

Figure 1: Multi F Art Cool Mirror Wall-Mounted Indoor Unit.

• Built-in wi-fi

• Dehumidifying function

• Self diagnosis function

• Wireless LCD remote control included

Page 11

ART COOL MIRROR INDOOR UNITS

MULTI

F

MAX

MULTI

F

Table 3: Multi F Art Cool Mirror Indoor Unit General Data.

Model Name LAN090HSV5 LAN120HSV5 LAN180HSV5

Nominal Cooling Capacity (Btu/h)

Nominal Heating Capacity (Btu/h)

Operating Range

Cooling (°F WB)

Heating (°F DB)

Fan

Type

Motor Output (W) x Qty.

1

1

General Data / Specications

9,000 12,000 18,000

10,900 13,600 21,600

57-77

59-81

Cross Flow

30 x 1 60.0 x 1

Motor/Drive

Airflow Rate CFM (H/M/L)

Unit Data

Refrigerant Type

2

Refrigerant Control

Power Supply V, Ø, Hz3

Rated Amps (A)

Sound Pressure Level dB(A) (H/M/L)4

Dimensions (W x H x D, in.)

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Power Wiring / Communications Cable

(No. x AWG)5

Heat Exchanger

(Row x Column x Fin / inch) x Number

Pipe Size

Liquid (in.)

Vapor (in.)

Connection Size

Liquid (in.)

Vapor (in.)

Drain O.D. / I.D. (in.)

Brushless Digitally Controlled / Direct

268 / 218 / 169 282 / 233 / 177 558 / 438 / 353

R410A

EEV

208-230, 1, 60

0.4

36 / 32 / 27 38 / 34 / 29 44 / 38 / 34

32-15/16 x 12-1/8 x 7-9/16 39-9/32 x 13-19/32 x 8-11/32

20.5 29.8

25.6 36.4

4 x 14

(2 x 23 x 22) x 1 (2 x 16 x 20) x 1

1/4

3/8 1/2

1/4 3/8

3/8 5/8

27/32, 5/8

Art Cool Mirror™

1

accordance with standard length of each outdoor unit and a 0 ft. level difference between outdoor and

indoor units. All capacities are net with a combination ratio between 95 – 105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and 67ºF

wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and 60ºF

wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

2

Nominal capacity is rated 0 ft. above sea level with corresponding refrigerant piping length in

This unit comes with a dry helium charge.

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

3

Acceptable operating voltage: 187V-253V.

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the

same in both cooling and heating mode. These values can increase due to ambient conditions during

operation.

5

All power wiring / communications cable to the IDUs be minimum 14 AWG, 4-conductor, stranded,

shielded or unshielded (if shielded, must be grounded to chassis at ODU only) and must comply with

applicable local and national codes.

ART COOL M IRROR | 11

Page 12

ART COOL MIRROR INDOOR UNITS

MULTI

F

MAX

MULTI

F

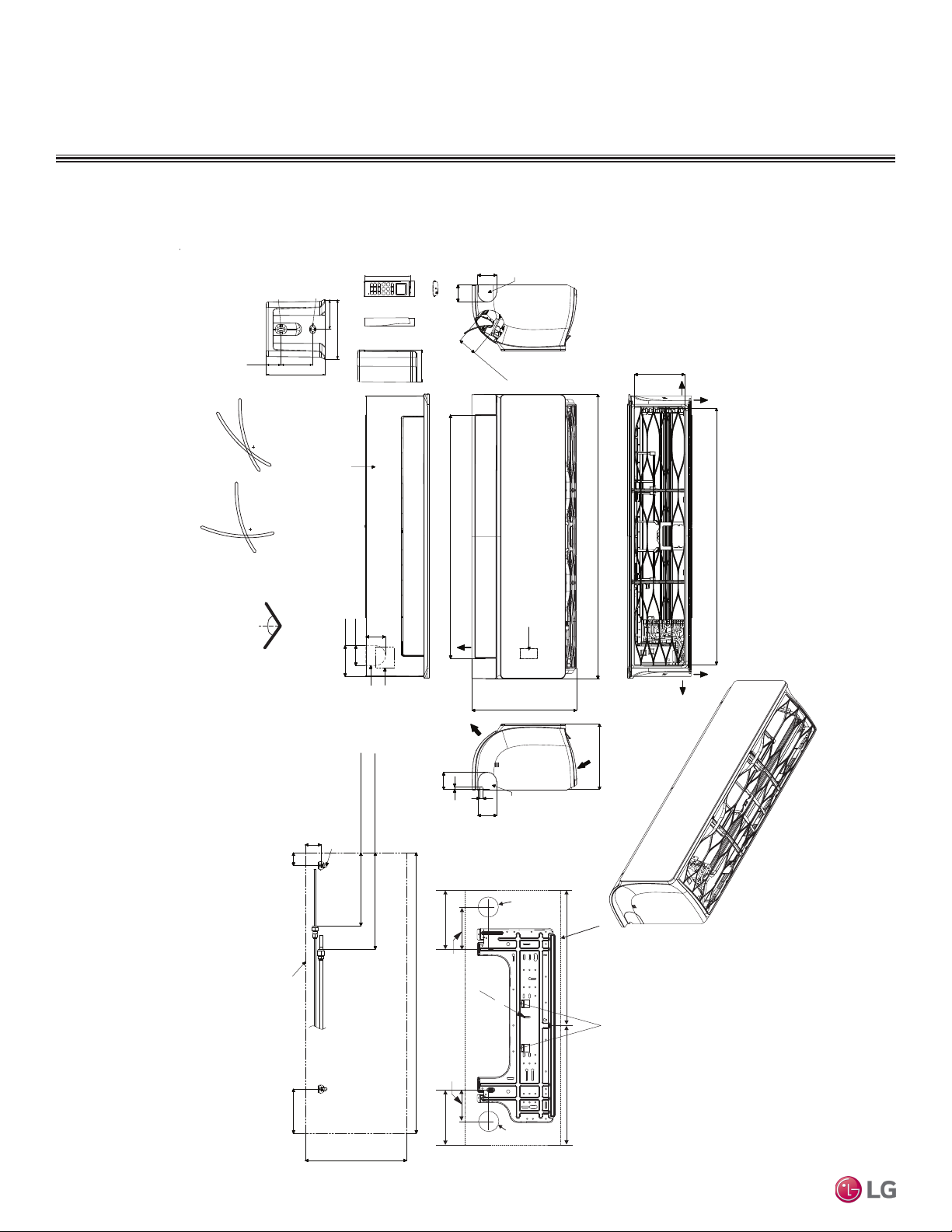

Dimensions

Figure 2: LAN090HSV5 and LAN120HSV5 Dimensions.

Refrigerant, Drain

Pipe, and Cable

Knock Out Hole

1/8 (3) x 1/4 (6)

1/4 (6) x 1/8 (3)

1-1/4 (31)

2-7/16 (61.5)

5-31/32 (152)

1-3/32 (50.2)

1-1/16 (26.2)

2-7/32 (56)

2 (51)

Unit : inch (mm)

1-7/16 (33.5)

Terminal Block for

Power Supply and

Communication

Approx. 11-11/32 (288) to gas pipe

85°

45°

15°

15°

5/8 (15.3)

55°

55°

1-9/32 (32.7)

(61)

2-13/32

* If airflow direction control is available,

Cooling Heating

1-27/32(47)

1-1/2 (38)

Up & Down Left & Right

Connection

Decoration Cover

3-5/8 (92)

2-3/8 (60)

2-5/16

(59)

Refrigerant, Drain

Pipe and Cable

Knock Out Hole

Approx. 8-19/32 (218) to liquid pipe

Drain Hose

Multi F and Multi F MAX Indoor Unit Engineering Manual

Connecting Gas/Liquid Pipe

Unit Outline

32-15/16 (837)

Air Outlet Hole

Air Outlet Hole

[28-5/32 (715)]

Bottom

Air Outlet

2 (51)

5/16 (8)

11/32 (9)

2-7/32(56)

Left Rear piping

C Type

2-7/32 (56)

12-1/8 (308)

Installation Plate

Display & Remote

Controller Signal

Receiver Signal

Refrigerant,

Drain Pipe

and Cable

Knock

Out Hole

Ø2-9/16"

[5-29/32 (150)]

Air Intake Hole

Left

Rear

32-15/16 (837)

Air Intake

7-9/16 (192)

Unit Outline

C Type : 16.5 C Type : 16.5

Attaching the Installation Plate, Drilling Hole

Place a Level on Raised Tab

Right

Air Intake Hole

[30-3/16 (767)]

Rear

12 | ART COO L MIRROR

C Type : 5.3C Type : 3.9

In Case of Left Side Piping

5-3/16 (132)

12-1/8 (308)

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

7.66

Right Rear piping

Ø2-9/16”

Ø2-9/16"

Page 13

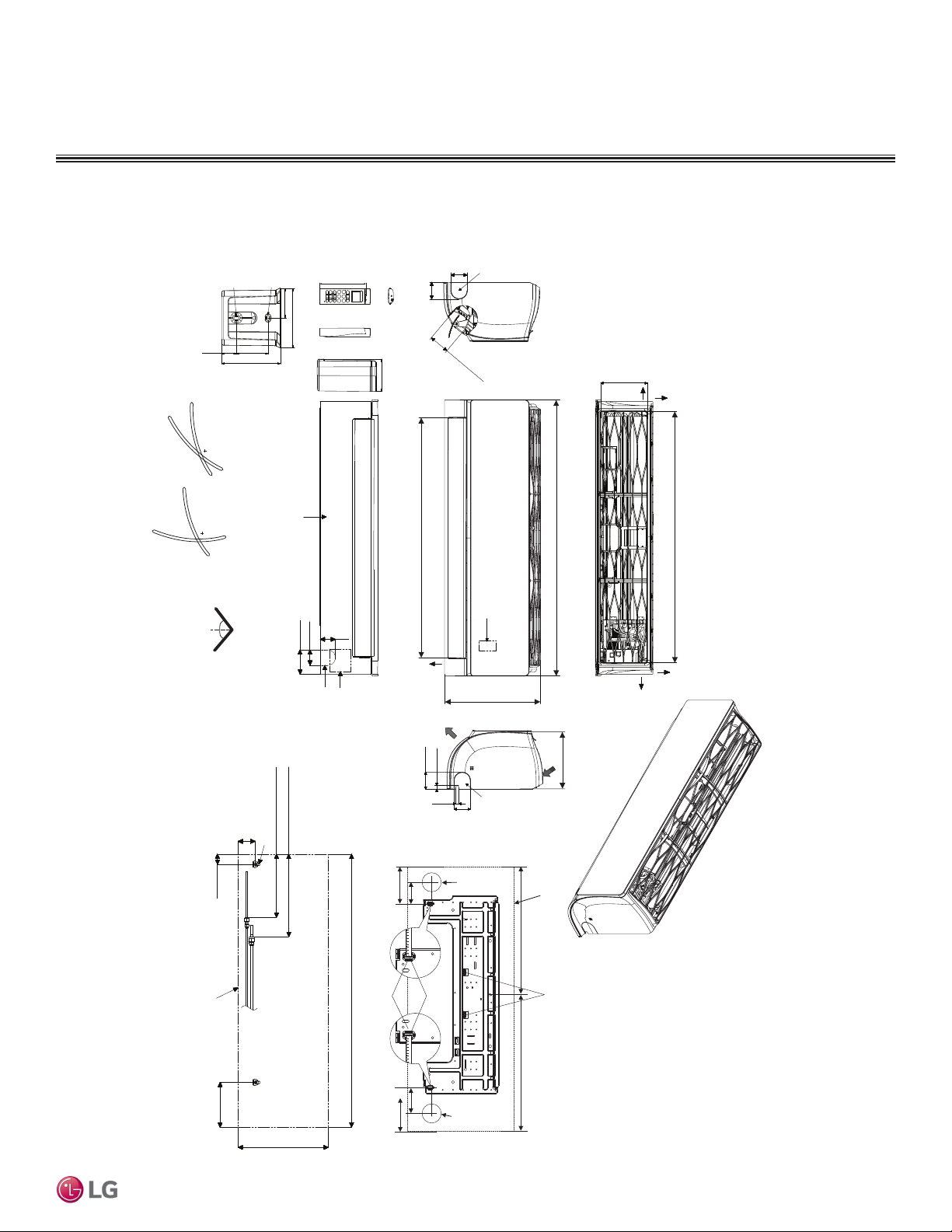

Figure 3: LAN180HSV5 Dimensions.

MULTI

F

MAX

MULTI

F

1/8 (3) x 1/4 (6)

5/8 (15.3)

1-9/32 (32.7)

2-13/32

15°

45°

Cooling Heating

1/4 (6) x 1/8 (3)

(61)

If airflow direction control is available,*

1-1/4 (31)

2-7/16 (61.5)

ART COOL MIRROR INDOOR UNITS

Dimensions

Refrigerant, Drain

Pipe, and Cable

Knock Out Hole

5-31/32 (152)

1-3/32 (50.2)

1-1/16 (26.2)

1-7/16 (33.5)

2-3/8 (60)

2-3/8 (60)

A le

ir Outlet Ho

[2-29/32 (74)]

[6-11/16 (170)]

Air Intake Hole

Left

Rear

Unit : inch (mm)

85°

20°

50°

50°

2-15/32 (63)

1-15/32 (37)

Up & Down Left & Right

Decoration Cover

3-17/32 (90)

2-1/4 (57)

2-7/32 (56)

Refrigerant, Drain

Pipe and Cable

Knock Out Hole

Communication

Drain Hose Connection

Approx. 6-5/16 (160) to liquid pipe

Approx. 9-7/16 (240) to gas pipe

Terminal Block for

Power Supply and

C Type: 5.3

[34-11/32 (872)]

Air Outlet Hole

Bottom

Air

Outlet

2-3/8 (60)

7/16 (11)

7/16(11)

2-3/8 (60)

Left Rear piping

3.3

Controller Signal

Receiver Signal

13-19/32 (345)

Knock

Out Hole

Ø2-9/16

"

39-9/32 (998)

Display & Remote

Air Intake

Refrigerant,

Drain Pipe

and Cable

Unit Outline

C Type: 19.4 C Type: 19.8

Attaching the Installation Plate, Drilling Hole

8-11/32 (212)

Right

[36-5/32 (918)]

Air Intake Hole

Rear

Art Cool Mirror™

Connecting Gas/Liquid Pipe

Unit Outline

6-15/32 (164)

13-19/32 (345)

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Measuring Tape

Hanger

39-9/32 (998)

In case of Left Side Piping

C Type: 5.9

Due to our policy of continuous product innovation, some specications may change without notication.

Measuring Tape

3.3

Ø2-9/16"

Right Rear piping

Place a Level on Raised Tab

ART COOL M IRROR | 13

Page 14

ART COOL MIRROR INDOOR UNITS

MULTI

F

MAX

MULTI

F

Cooling Capacity Table

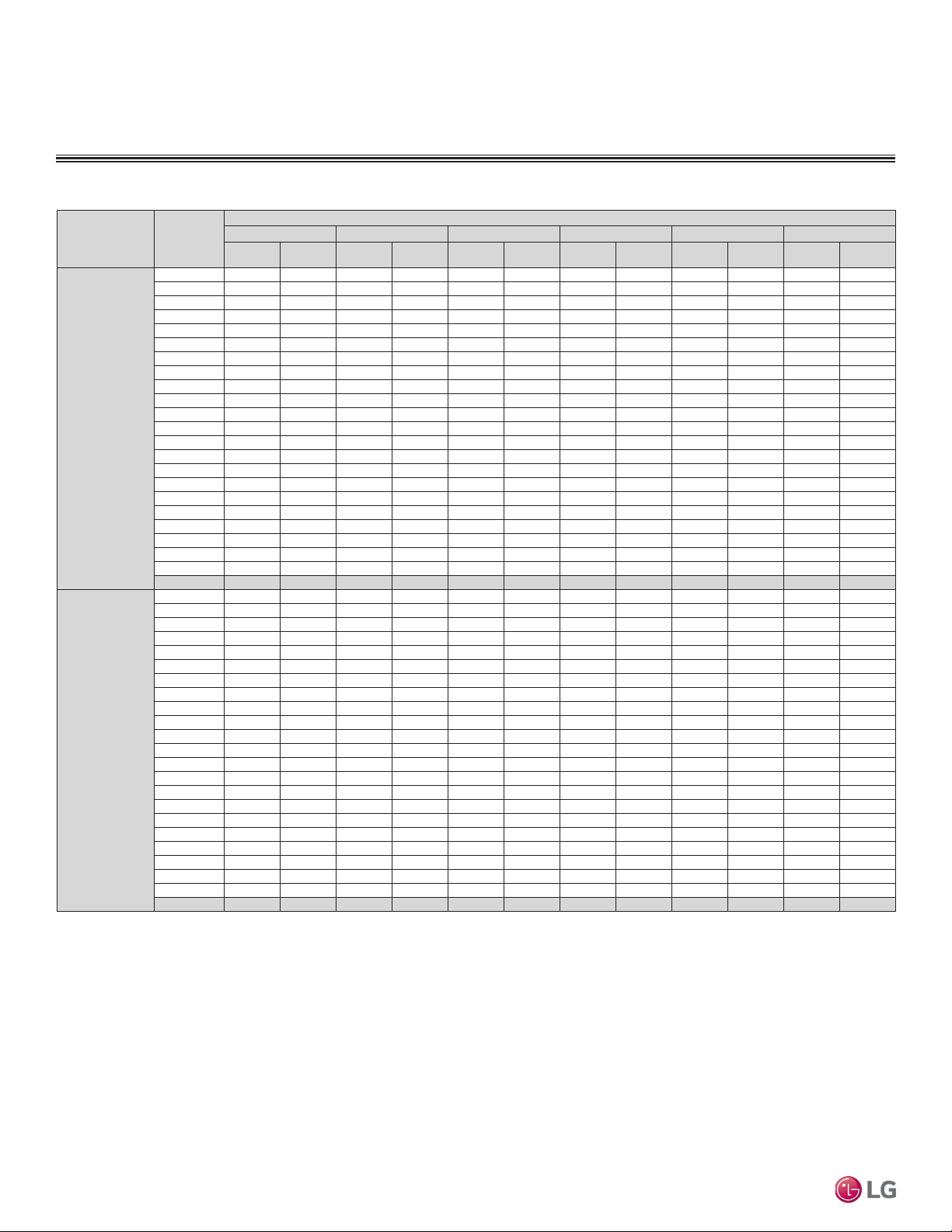

Table 4: Multi F Art Cool Mirror Indoor Units Cooling Capacity Table.

Model No. /

Nominal Capacity

of Indoor Unit

(Btu/h)

LAN090HSV5

9,000

LAN120HSV5

12,000

Multi F and Multi F MAX Indoor Unit Engineering Manual

TC = Total Capacity (kBtu/h).

SHC: Sensible Heat Capacity (kBtu/h).

Nominal capacity as rated 0 ft. above sea level and a 0 ft. level difference between outdoor and indoor units. Corresponding refrigerant piping length is accordance with standard length of each outdoor unit.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and 67ºF wet bulb (WB), and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

The shaded table columns and rows indicate reference data. When operating at this temperature, these values can be different if the system is not running consistently.

Outdoor Air

Temp.

(°F DB)

14 8.82 6.04 9.37 6.38 9.92 6.18 10.31 6.31 11.01 6.36 11.56 6.48

20 8.82 6.09 9.36 6.43 9.91 6.23 10.31 6.36 11.01 6.41 11.55 6.53

25 8.81 6.13 9.36 6.48 9.90 6.27 10.30 6.41 11.00 6.46 11.54 6.58

30 8.80 6.18 9.35 6.53 9.90 6.32 10.29 6.46 10.99 6.51 11.54 6.63

35 8.80 6.23 9.34 6.58 9.89 6.37 10.28 6.50 10.98 6.56 11.53 6.68

40 8.79 6.28 9.33 6.63 9.88 6.42 10.27 6.55 10.97 6.61 11.52 6.73

45 8.78 6.32 9.33 6.68 9.87 6.47 10.27 6.60 10.96 6.66 11.51 6.78

50 8.78 6.37 9.32 6.73 9.87 6.51 10.26 6.65 10.96 6.71 11.50 6.83

55 8.77 6.42 9.31 6.78 9.86 6.56 10.25 6.70 10.95 6.76 11.49 6.88

60 8.76 6.46 9.31 6.83 9.85 6.61 10.24 6.75 10.94 6.81 11.48 6.93

65 8.76 6.51 9.30 6.88 9.84 6.66 10.24 6.80 10.93 6.85 11.47 6.98

70 8.75 6.56 9.29 6.92 9.84 6.70 10.23 6.85 10.92 6.90 11.47 7.03

75 8.54 6.45 9.08 6.82 9.62 6.61 10.01 6.75 10.71 6.82 11.25 6.96

80 8.33 6.34 8.87 6.71 9.41 6.51 9.80 6.66 10.49 6.73 11.03 6.87

85 8.12 6.22 8.66 6.60 9.20 6.41 9.59 6.56 10.28 6.64 10.82 6.79

90 7.91 6.10 8.45 6.48 8.99 6.31 9.37 6.46 10.06 6.55 10.60 6.70

95 7.68 6.04 8.22 6.43 8.75 6.26 9.00 6.32 9.83 6.52 10.36 6.67

100 7.50 5.88 8.03 6.26 8.57 6.11 8.88 6.22 9.64 6.37 10.17 6.53

105 7.31 5.72 7.84 6.10 8.38 5.96 8.77 6.12 9.45 6.23 9.99 6.39

110 7.12 5.52 7.66 5.90 8.19 5.78 8.58 5.94 9.26 6.06 9.80 6.22

115 6.94 5.36 7.47 5.74 8.01 5.63 8.39 5.79 9.08 5.91 9.61 6.08

118 6.82 5.32 7.36 5.70 7.89 5.60 8.28 5.76 8.96 5.89 9.50 6.06

122 6.79 5.30 7.32 5.69 7.86 5.59 8.24 5.76 8.93 5.89 9.46 6.06

14 11.76 8.51 12.49 8.99 13.22 8.70 13.75 8.88 14.69 8.96 15.42 9.13

20 11.75 8.57 12.48 9.06 13.21 8.77 13.74 8.95 14.67 9.03 15.40 9.20

25 11.75 8.64 12.48 9.13 13.20 8.84 13.73 9.02 14.66 9.10 15.39 9.27

30 11.74 8.71 12.47 9.20 13.19 8.90 13.72 9.09 14.65 9.17 15.38 9.34

35 11.73 8.77 12.46 9.27 13.18 8.97 13.71 9.16 14.64 9.24 15.37 9.41

40 11.72 8.84 12.45 9.34 13.17 9.04 13.70 9.23 14.63 9.31 15.36 9.48

45 11.71 8.90 12.44 9.41 13.16 9.11 13.69 9.30 14.62 9.38 15.35 9.55

50 11.70 8.97 12.43 9.47 13.15 9.17 13.68 9.37 14.61 9.45 15.33 9.62

55 11.69 9.03 12.42 9.54 13.14 9.24 13.67 9.44 14.60 9.52 15.32 9.70

60 11.68 9.10 12.41 9.61 13.13 9.31 13.66 9.50 14.59 9.58 15.31 9.77

65 11.67 9.17 12.40 9.68 13.12 9.38 13.65 9.57 14.57 9.65 15.30 9.84

70 11.66 9.23 12.39 9.75 13.11 9.44 13.64 9.64 14.56 9.72 15.29 9.91

75 11.38 9.08 12.11 9.60 12.83 9.31 13.35 9.51 14.27 9.60 15.00 9.79

80 11.10 8.92 11.82 9.45 12.55 9.17 13.07 9.38 13.99 9.48 14.71 9.68

85 10.83 8.76 11.54 9.29 12.26 9.03 12.78 9.24 13.70 9.36 14.42 9.56

90 10.55 8.60 11.26 9.13 11.98 8.88 12.50 9.10 13.42 9.22 14.13 9.43

95 10.25 8.51 10.96 9.05 11.67 8.82 12.00 8.90 13.10 9.18 13.81 9.39

100 10.00 8.28 10.71 8.82 11.42 8.61 11.84 8.76 12.85 8.98 13.56 9.20

105 9.75 8.05 10.46 8.59 11.17 8.40 11.69 8.62 12.60 8.78 13.31 9.01

110 9.50 7.77 10.21 8.31 10.92 8.14 11.44 8.37 12.35 8.53 13.07 8.76

115 9.25 7.54 9.96 8.08 10.67 7.92 11.19 8.15 12.10 8.33 12.82 8.56

118 9.10 7.49 9.81 8.03 10.52 7.88 11.04 8.12 11.95 8.30 12.67 8.54

122 9.05 7.47 9.76 8.01 10.48 7.87 10.99 8.11 11.90 8.29 12.62 8.53

68 / 57 73 / 61 77 / 64 80 / 67 86 / 72 90 / 75

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

Indoor Air Temp. °F DB / °F WB

14 | ART COO L MIRROR

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 15

ART COOL MIRROR INDOOR UNITS

MULTI

F

MAX

MULTI

F

Cooling Capacity Table

Table 5: Multi F Art Cool Mirror Indoor Units Cooling Capacity Table (continued).

Model No. /

Nominal Capacity

of Indoor Unit

(Btu/h)

LAN180HSV5

18,000

TC = Total Capacity (kBtu/h).

SHC: Sensible Heat Capacity (kBtu/h).

Nominal capacity as rated 0 ft. above sea level and a 0 ft. level difference between outdoor and indoor units. Corresponding refrigerant piping length is accordance with standard length of each outdoor unit.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and 67ºF wet bulb (WB), and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

The shaded table columns and rows indicate reference data. When operating at this temperature, these values can be different if the system is not running consistently.

Outdoor Air

Temp.

(°F DB)

14 17.65 12.33 18.74 13.02 19.84 12.61 20.63 12.88 22.03 12.98 23.12 13.23

20 17.63 12.43 18.73 13.13 19.82 12.71 20.61 12.98 22.01 13.09 23.11 13.33

25 17.62 12.52 18.71 13.23 19.81 12.81 20.60 13.08 22.00 13.19 23.09 13.44

30 17.60 12.62 18.70 13.33 19.79 12.91 20.58 13.18 21.98 13.29 23.07 13.54

35 17.59 12.71 18.68 13.43 19.78 13.00 20.57 13.28 21.96 13.39 23.05 13.64

40 17.58 12.81 18.67 13.53 19.76 13.10 20.55 13.38 21.94 13.49 23.04 13.75

45 17.56 12.90 18.66 13.63 19.75 13.20 20.53 13.48 21.93 13.59 23.02 13.85

50 17.55 13.00 18.64 13.73 19.73 13.30 20.52 13.58 21.91 13.69 23.00 13.95

55 17.54 13.10 18.63 13.83 19.72 13.39 20.50 13.68 21.89 13.79 22.98 14.05

60 17.52 13.19 18.61 13.93 19.70 13.49 20.49 13.78 21.88 13.89 22.97 14.16

65 17.51 13.29 18.60 14.03 19.69 13.59 20.47 13.87 21.86 13.99 22.95 14.26

70 17.50 13.38 18.58 14.13 19.67 13.69 20.46 13.97 21.84 14.09 22.93 14.36

75 17.08 13.16 18.16 13.92 19.24 13.49 20.03 13.79 21.41 13.92 22.50 14.20

80 16.66 12.93 17.74 13.70 18.82 13.30 19.60 13.60 20.98 13.75 22.06 14.03

85 16.24 12.70 17.32 13.47 18.40 13.09 19.17 13.40 20.55 13.56 21.63 13.85

90 15.82 12.46 16.90 13.23 17.97 12.88 18.75 13.19 20.12 13.37 21.20 13.67

95 15.37 12.33 16.44 13.12 17.51 12.78 18.00 12.90 19.65 13.30 20.72 13.61

100 14.99 12.00 16.06 12.78 17.13 12.47 17.77 12.70 19.28 13.01 20.35 13.33

105 14.62 11.67 15.69 12.45 16.76 12.17 17.53 12.50 18.90 12.73 19.97 13.05

110 14.24 11.27 15.32 12.05 16.39 11.79 17.16 12.13 18.53 12.36 19.60 12.70

115 13.87 10.93 14.94 11.71 16.01 11.48 16.79 11.82 18.15 12.07 19.22 12.41

118 13.65 10.85 14.72 11.64 15.79 11.42 16.56 11.77 17.93 12.03 19.00 12.37

122 13.57 10.83 14.64 11.62 15.71 11.40 16.49 11.75 17.85 12.01 18.92 12.36

68 / 57 73 / 61 77 / 64 80 / 67 86 / 72 90 / 75

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

Indoor Air Temp. °F DB / °F WB

Art Cool Mirror™

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

ART COOL M IRROR | 15

Page 16

ART COOL MIRROR INDOOR UNITS

MULTI

F

MAX

MULTI

F

Heating Capacity Table

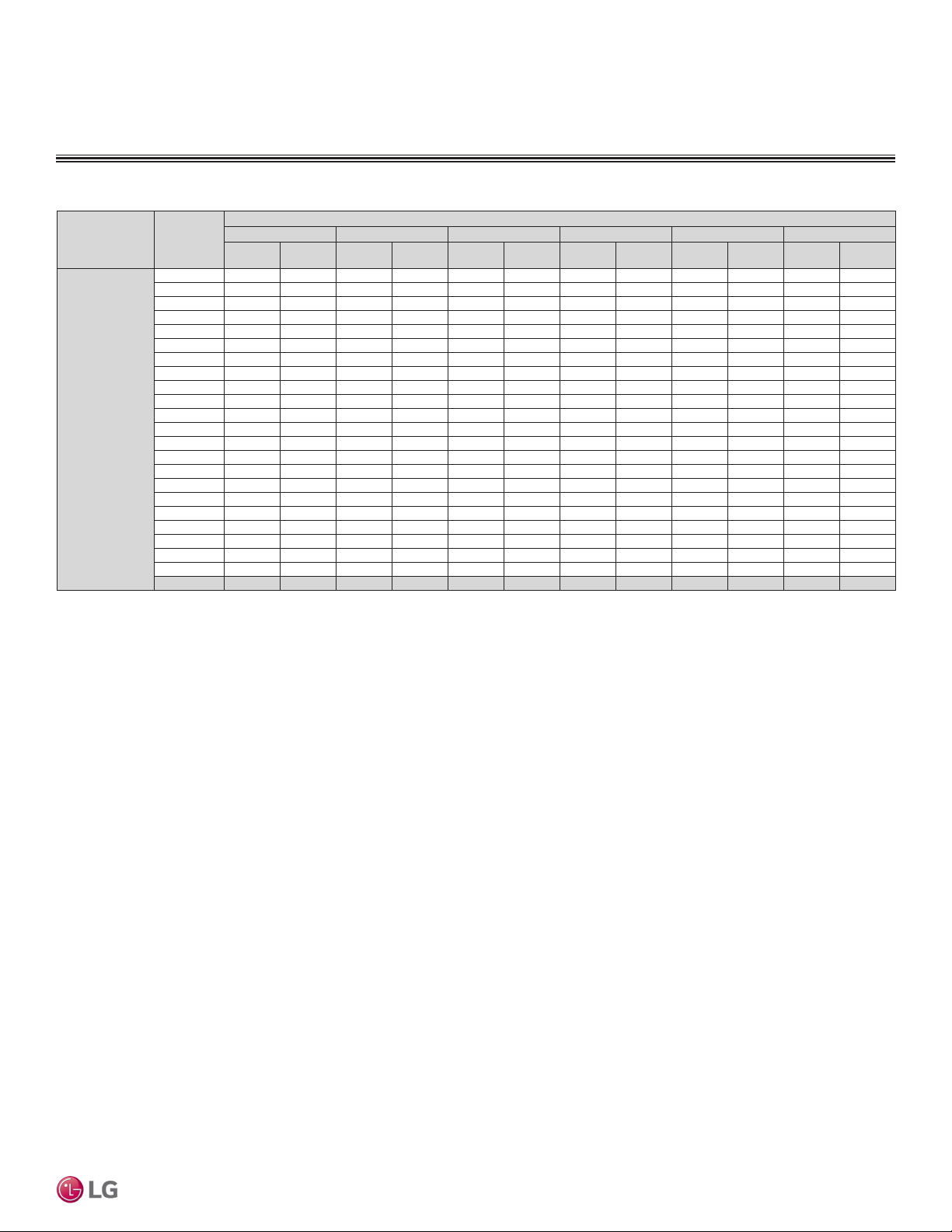

Table 6: Multi F Art Cool Mirror Indoor Units Heating Capacity Table.

Model No. /

Nominal Capacity of

Indoor Unit

(Btu/h)

LAN090HSV5

10,900

LAN120HSV5

13,600

LAN180HSV5

21,600

Multi F and Multi F MAX Indoor Unit Engineering Manual

TC = Total Capacity (kBtu/h).

Nominal capacity as rated 0 ft. above sea level and a 0 ft. level difference between outdoor and indoor units. Corresponding refrigerant piping length is accordance with standard length of each outdoor unit.

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and 60ºF wet bulb (WB), and outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

Outdoor Air Temp. Indoor Air Temp. °F DB

61 64 68 70 72 75

°F DB °F WB

0 -0.4 5.61 5.53 5.48 5.45 5.37 5.14

5 4.5 6.32 6.24 6.18 6.16 6.08 5.85

10 9 7.03 6.95 6.90 6.88 6.79 6.56

17 15 7.98 7.90 7.85 7.82 7.75 7.48

20 19 8.33 8.26 8.21 8.18 8.09 7.82

25 23 8.93 8.85 8.79 8.77 8.69 8.37

30 28 9.44 9.36 9.31 9.29 9.20 8.93

35 32 9.96 9.87 9.82 9.79 9.72 9.47

40 36 10.42 10.33 10.28 10.25 10.18 9.94

45 41 10.87 10.80 10.74 10.71 10.64 10.40

47 43 11.06 10.98 10.93 10.90 10.82 10.59

50 46 11.24 11.15 11.10 11.08 10.99 10.73

55 51 11.53 11.46 11.40 11.37 11.30 10.98

60 56 11.53 11.46 11.40 11.37 11.30 11.03

63 59 11.53 11.46 11.40 11.37 11.30 11.06

68 64 11.53 11.46 11.40 11.37 11.30 11.11

0 -0.4 7.00 6.90 6.83 6.80 6.70 6.50

5 4.5 7.89 7.78 7.71 7.69 7.59 7.40

10 9 8.78 8.67 8.60 8.58 8.48 8.31

17 15 9.95 9.86 9.79 9.76 9.67 9.47

20 19 10.40 10.30 10.23 10.20 10.10 9.90

25 23 11.14 11.03 10.96 10.95 10.85 10.60

30 28 11.78 11.67 11.60 11.59 11.49 11.30

35 32 12.42 12.31 12.24 12.21 12.13 11.99

40 36 13.00 12.89 12.82 12.79 12.70 12.58

45 41 13.56 13.46 13.39 13.36 13.28 13.16

47 43 13.80 13.70 13.63 13.60 13.50 13.40

50 46 14.02 13.91 13.84 13.82 13.72 13.59

55 51 14.39 14.29 14.22 14.19 14.10 13.90

60 56 14.39 14.29 14.22 14.19 14.10 13.96

63 59 14.39 14.29 14.22 14.19 14.10 14.00

68 64 14.39 14.29 14.22 14.19 14.10 14.06

0 -0.4 11.11 10.96 10.85 10.80 10.64 10.18

5 4.5 12.52 12.37 12.26 12.21 12.06 11.58

10 9 13.93 13.77 13.67 13.61 13.46 12.99

17 15 15.81 15.65 15.55 15.49 15.34 14.84

20 19 16.51 16.36 16.25 16.20 16.04 15.49

25 23 17.69 17.53 17.43 17.37 17.22 16.59

30 28 18.70 18.55 18.44 18.39 18.24 17.69

35 32 19.72 19.56 19.46 19.41 19.25 18.79

40 36 20.63 20.48 20.37 20.32 20.17 19.70

45 41 21.55 21.39 21.29 21.24 21.08 20.61

47 43 21.91 21.76 21.65 21.60 21.44 20.98

50 46 22.26 22.11 22.01 21.95 21.80 21.27

55 51 22.86 22.70 22.59 22.53 22.38 21.76

60 56 22.86 22.70 22.59 22.53 22.38 21.85

63 59 22.86 22.70 22.59 22.53 22.38 21.91

68 64 22.86 22.70 22.59 22.53 22.38 22.02

TC TC TC TC TC TC

16 | ART C OOL MIR ROR

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 17

ART COOL MIRROR INDOOR UNITS

MULTI

F

MAX

MULTI

F

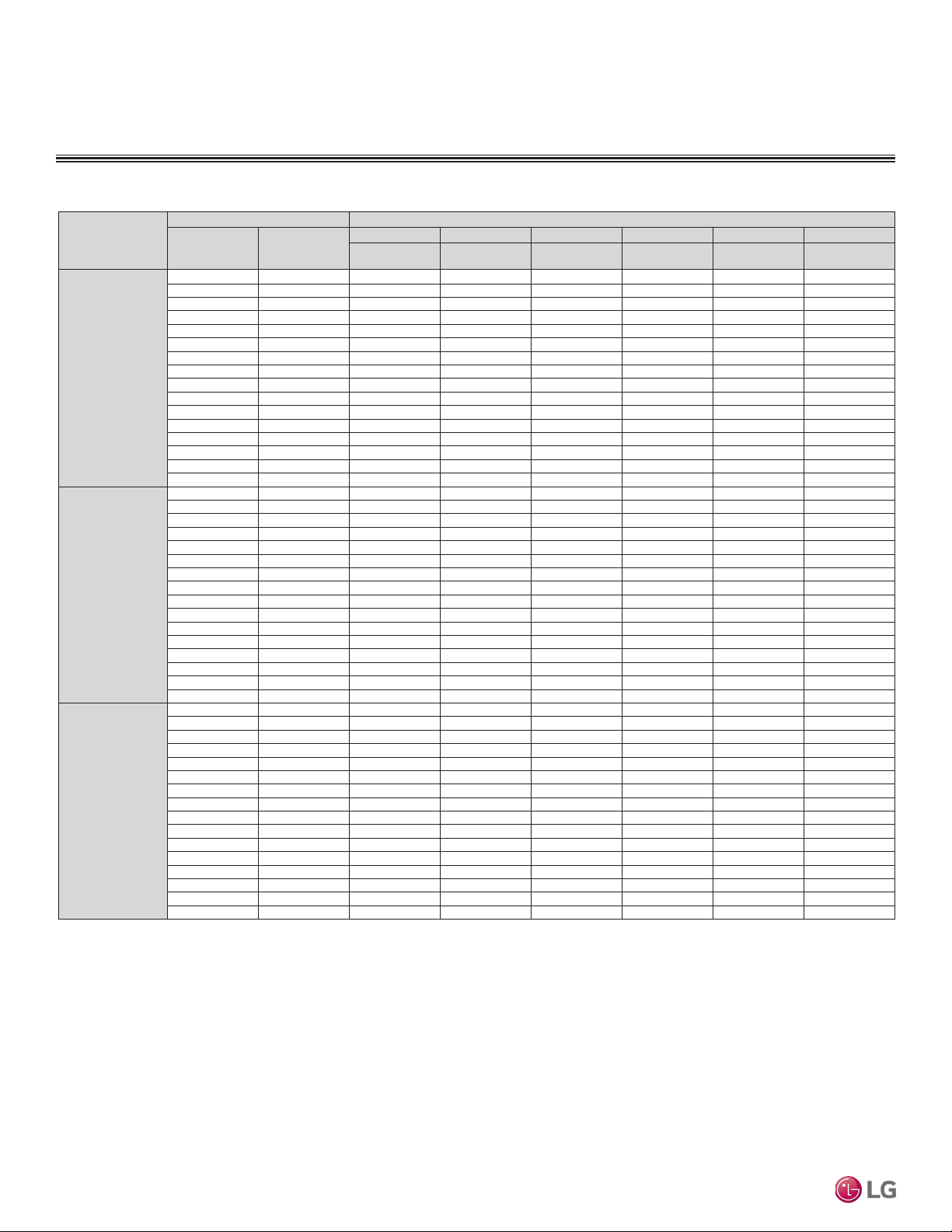

Acoustic Data

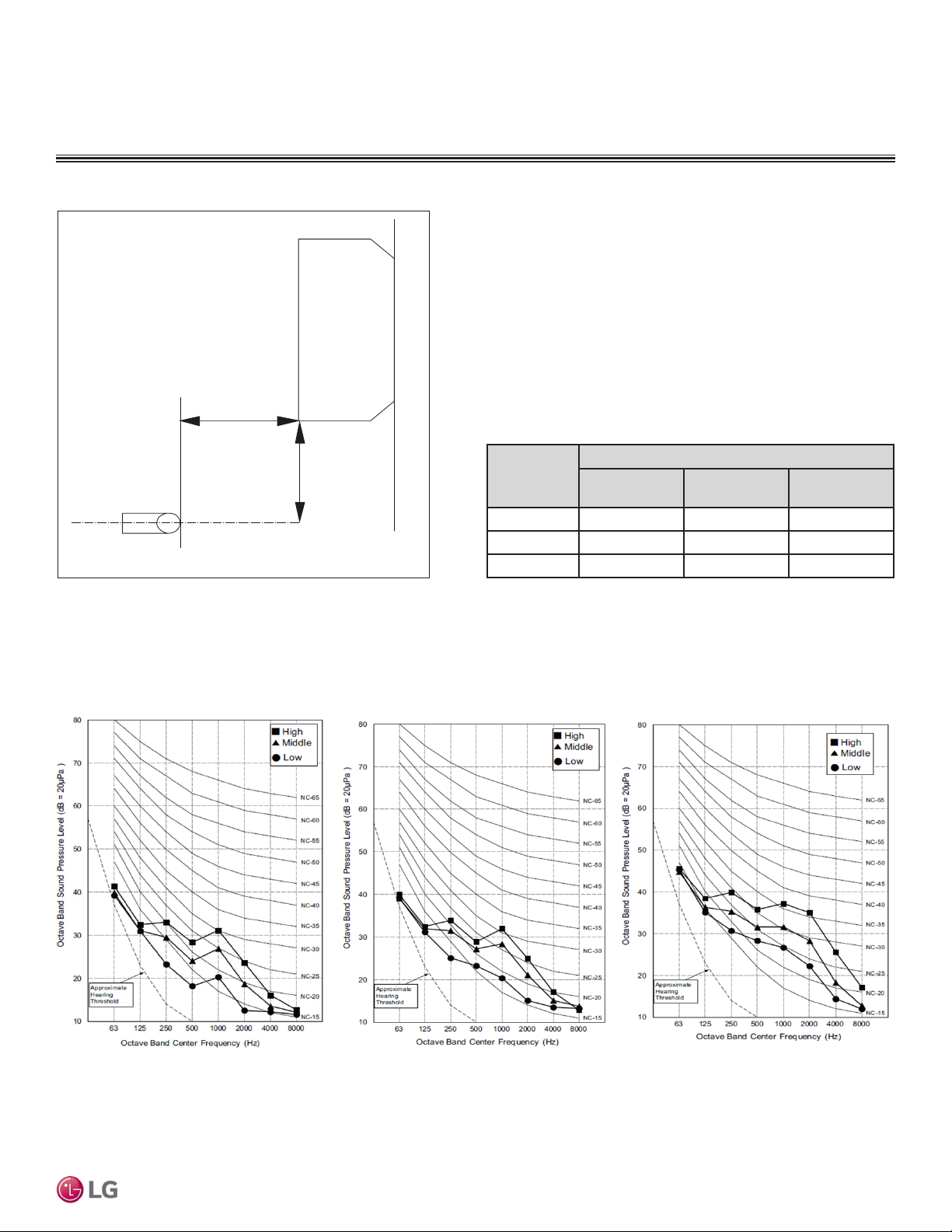

Figure 4: Sound Pressure Level Measurement Location.

3.3 ft.

2.6 ft.

Microphone

• Measurement taken 2.6′ below the bottom of the unit and at a

distance of 3.3′ from face of unit.

• Measurements taken with no attenuation and units operating at full

load normal operating condition.

• Sound level will vary depending on a range of factors such as

construction (acoustic absorption coefficient) of particular area in

which the equipment is installed.

• Sound power levels are measured in dB(A).

• Tested in anechoic chamber per ISO Standard 3745.

Table 7:Sound Pressure Levels (dB[A]).

Sound Pressure Levels (dB[A]) (Cooling and Heating)

Model No.

LAN090HSV5 36 32 27

LAN120HSV5 38 34 29

LAN180HSV5 44 38 34

High Fan Speed

Medium Fan

Speed

Low Fan Speed

Art Cool Mirror™

Figure 5: Sound Pressure Level Diagrams.

LAN090HSV5 LAN120HSV5

LAN180HSV5

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

ART COOL M IRROR | 17

Page 18

ART COOL MIRROR INDOOR UNITS

MULTI

F

MAX

MULTI

F

Air Velocity and Temperature Distribution

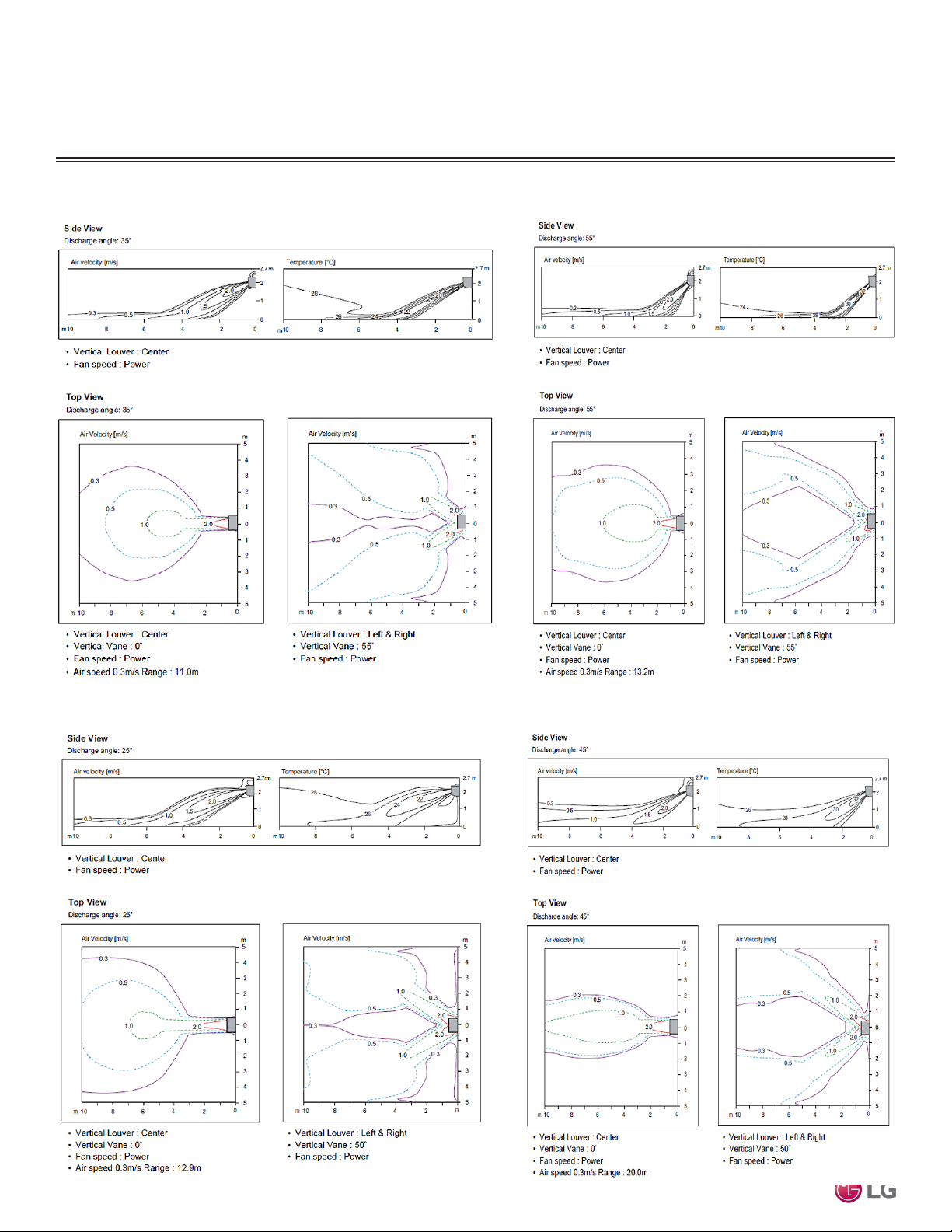

Figure 6: LAN090HSV5 and LAN120HSV5 Air Velocity and Temperature Distribution Charts.

Cooling

Heating

Figure 7: LAN180HSV5 Air Velocity and Temperature Distribution Charts.

Cooling

Multi F and Multi F MAX Indoor Unit Engineering Manual

Heating

18 | ART COOL MIR ROR

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 19

ART COOL MIRROR INDOOR UNITS

Vapor pipe connection port

Liquid pipe connection port

MULTI

F

MAX

MULTI

F

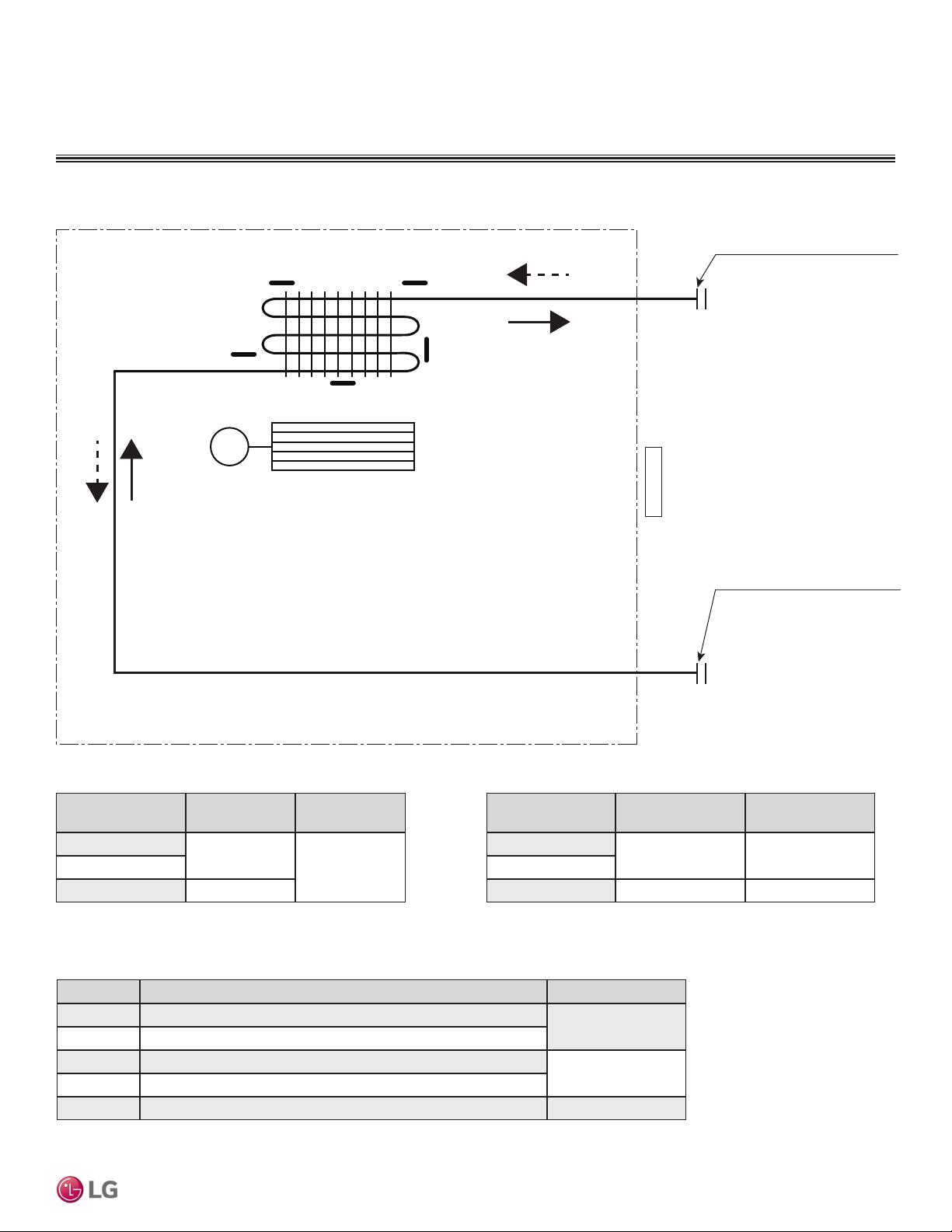

Figure 8: Art Cool Mirror Indoor Unit Refrigerant Flow Diagram.

Refrigerant Flow Diagram

M

Th2

Th1

Heat

Exchanger

Th3

Cross Flow Fan

Th4

Th5

Heating

(flare connection)

Cooling

Indoor Air Temperature

Thermistor for

Art Cool Mirror™

(flare connection)

Table 8: Art Cool Mirror Indoor Unit Refrigerant Pipe Sizes.

Table 10: Art Cool Mirror Indoor Unit Thermistor Details.

Table 9: Art Cool Mirror Indoor Unit Refrigerant Pipe Connections

Indoor Unit Capacity

9,000 Btu/h

18,000 Btu/h Ø1/2

Location Description (Based on Cooling Mode) IDU PCB Connector

Th1 Indoor Air Temperature Thermistor

Th2 Evaporator Inlet Temperature Thermistor

Th3 Evaporator Middle Temperature Thermistor

Th4 Evaporator Outlet Temperature Thermistor

Th5 Water Level Sensor (Optional) CN-TH3

Vapor Line Size

(in., OD)

Ø3/8

Liquid Line Size

(in., OD)

Ø1/412,000 Btu/h

Indoor Unit Capacity

9,000 Btu/h

12,000 Btu/h

18,000 Btu/h Ø5/8 Ø3/8

Connection (in., OD)

CN-TH1

CN-TH2

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Vapor Line

Ø3/8 Ø1/4

Liquid Line

Connection (in., OD)

ART COOL M IRROR | 19

Page 20

ART COOL MIRROR INDOOR UNITS

MULTI

F

MAX

MULTI

F

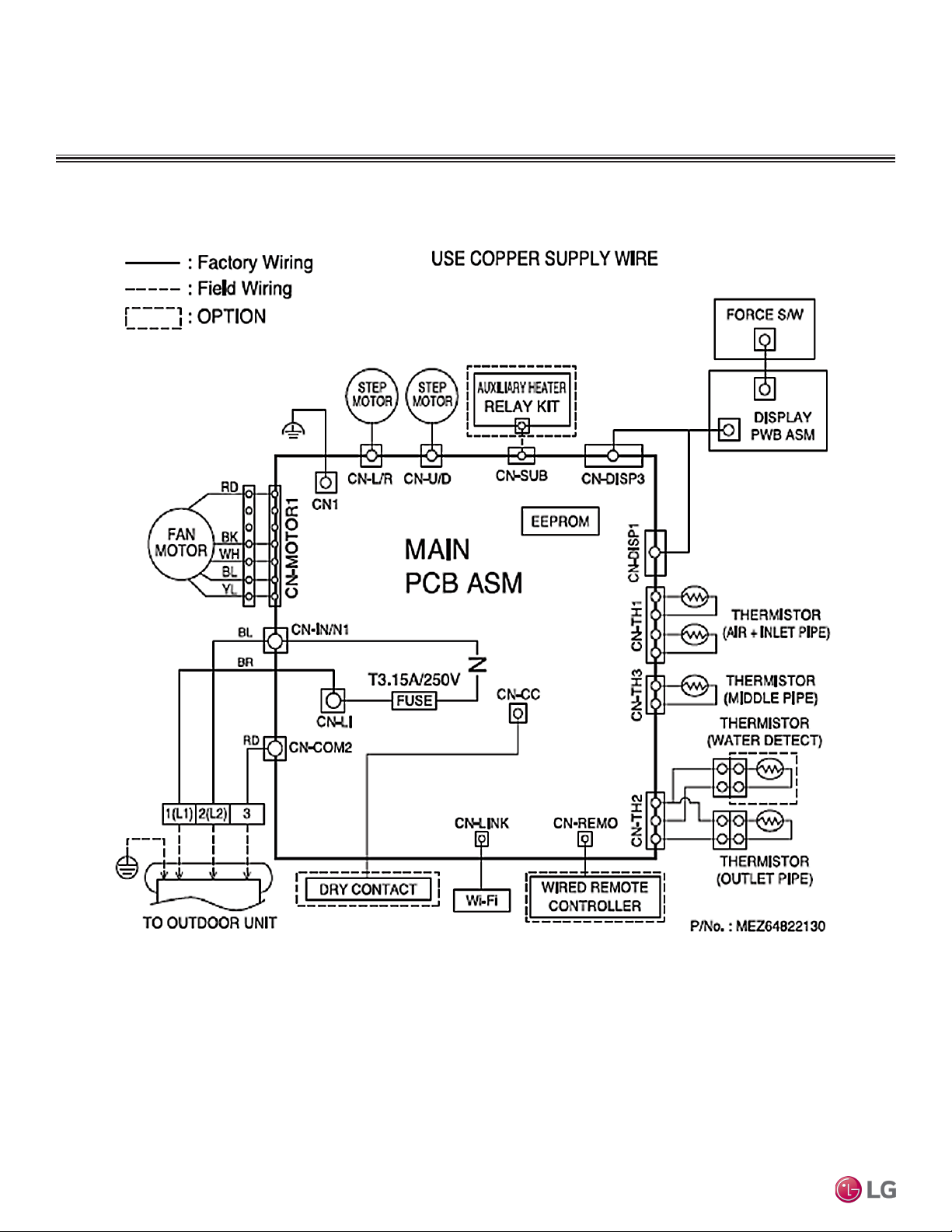

Wiring Diagram

Figure 9: Multi F Art Cool Mirror LAN090HSV5, LAN120HSV5, and LAN180HSV5 Indoor Units Wiring Diagram.

Multi F and Multi F MAX Indoor Unit Engineering Manual

20 | ART COOL M IRR OR

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 21

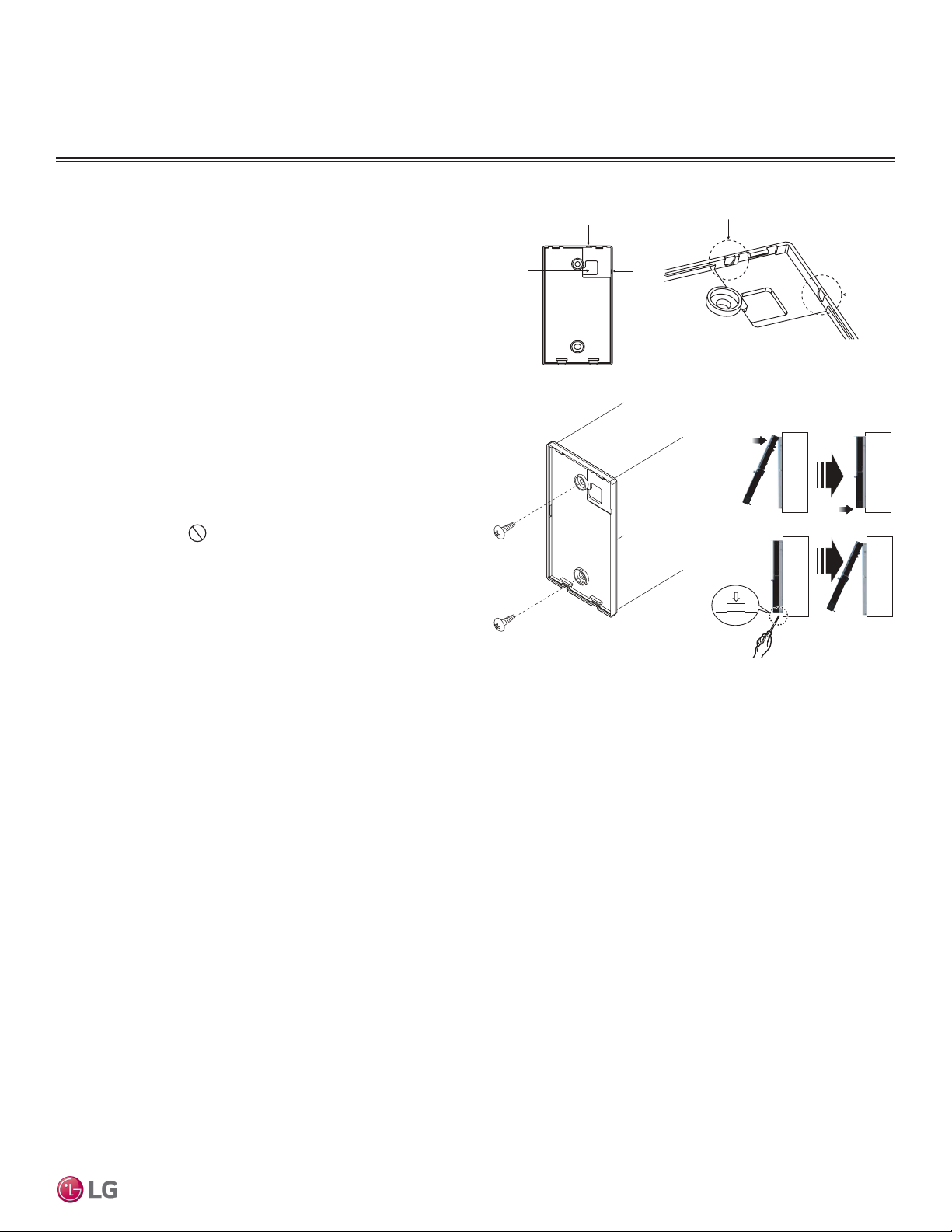

Factory Supplied Parts

WARNING

MULTI

F

MAX

MULTI

F

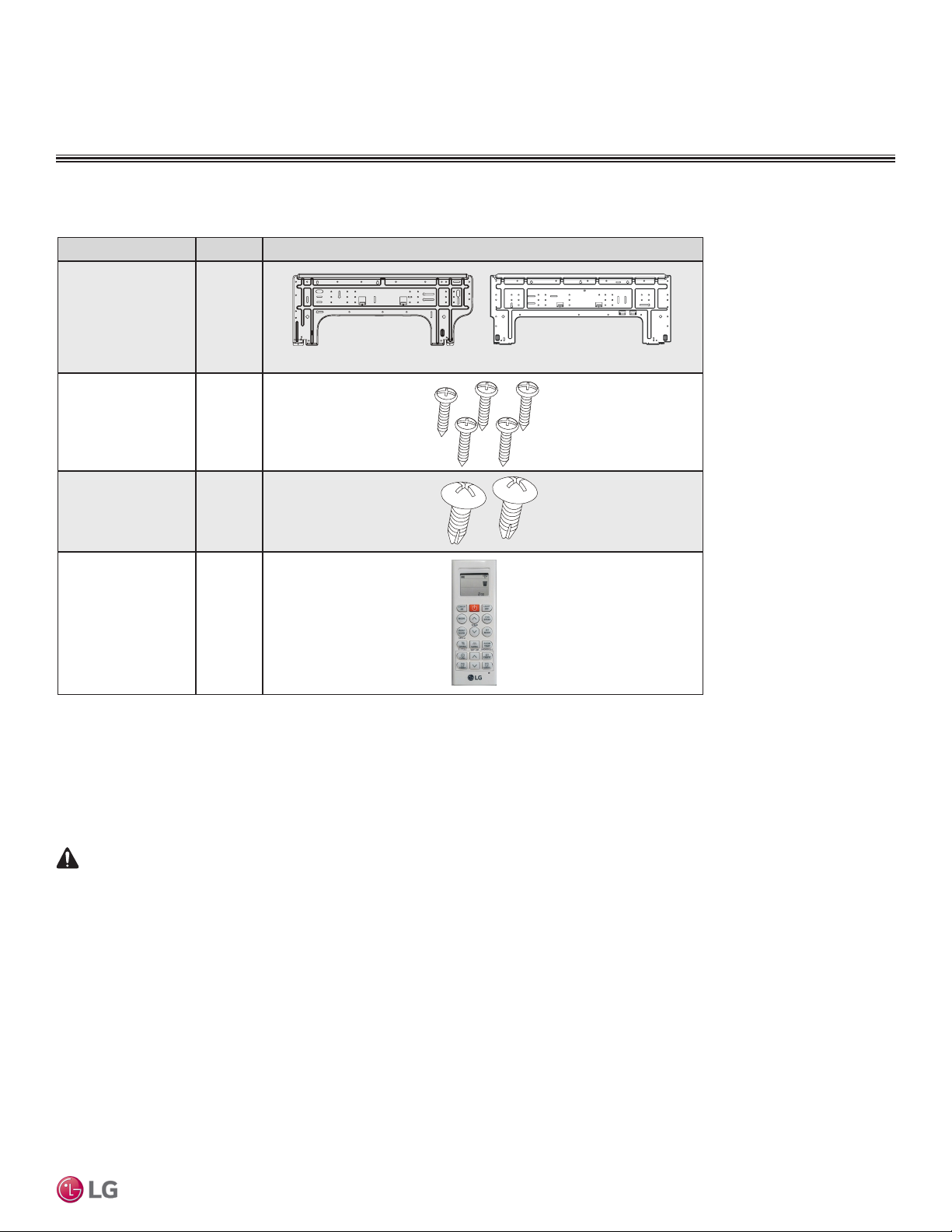

Table 11: Parts Table.

Part Quantity Image

Installation Plate One (1)

Type “A” Screws Five (5)

ART COOL MIRROR INDOOR UNITS

Factory Supplied Parts and Materials

LAN090HSV5 and LAN120HSV5 LAN180HSV5

Type “B” Screws

(M4 x 12L)

Wireless Handheld

Controller with Holder

AKB74955602

Factory Supplied Materials

• Owner’s Manual

• Installation Manual

Installation work must be performed by trained personnel and in accordance with national wiring standards and all local or other applicable codes.

Improper installation can result in re, electric shock, physical injury, or death.

Note:

Read all instructions before installing this product. Become familiar with the unit’s components and connections, and the order of installation. Incorrect

installation can degrade or prevent proper operation.

Two (2)

One (1)

Required Tools

• Level

• Screwdriver

• Electric drill

• Hole core drill

• Flaring tool set

• Spanner (Half union)

• Thermometer

Art Cool Mirror™

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

ART COOL M IRROR | 21

Page 22

ART COOL MIRROR INDOOR UNITS

DANGER

>4 inches

>4 inches

MULTI

F

MAX

MULTI

F

Installation and Best Layout Practices

To avoid the possibility of re, do not install the unit in an area where combustible gas will generate, ow, stagnate, or leak. Failure to do so will

cause serious bodily injury or death. Before beginning installation, read the safety summary at the beginning of this manual.

Select a location for installing the wall-mounted indoor unit (IDU) that meets the following conditions:

• Where there is enough structural strength to bear the weight of the unit

• Where air circulation will not be blocked

• Where noise prevention is taken into consideration

• Ensure there is sufficient space from the ceiling and floor

• Locate the indoor unit in a location where it can be easily connected to the outdoor unit/branch distribution unit

• Include space for drainage to ensure condensate flows properly out of the unit when it is in cooling mode

• Use a level indicator to ensure the unit is installed on a level plane

Note:

The unit will be damaged, will malfunction, and/or will not operate as designed if installed in any of the following conditions:

Do not install the unit where it will be subjected to direct thermal radiation from other heat sources.

Do not install the unit in an area where combustible gas will generate, flow, stagnate, or leak.

Do not install the unit in a location where acidic solution and spray (sulfur) are often used.

Do not use the unit in environments where oil, steam, or sulfuric gas are present.

Do not install additional ventilation products on the chassis of the unit.

Do not install the unit near high-frequency generator sources.

Do not install the unit near a doorway.

• Indoor units (IDUs) must not be placed in an environment where the IDUs will be exposed to harmful volatile organic compounds (VOCs)

or in environments where there is improper air make up or supply or inadequate ventilation. If there are concerns about VOCs in the environment where the IDUs are installed, proper air make up or supply and/or adequate ventilation must be provided. Additionally, in buildings

where IDUs will be exposed to VOCs, consider a third party factory-applied epoxy coating to the fan coils for each IDU where the entire coil

is dipped, not sprayed.

• If the unit is installed near a body of water, the installation parts are at risk of corroding. Appropriate anti-corrosion methods must be taken

for the unit and all installation parts.

Installing in an Area Exposed to Unconditioned Air

In some installation applications, areas (floors, walls) in some rooms

will be exposed to unconditioned air (room will be above or next to

an unheated garage or storeroom). To countermeasure:

Multi F and Multi F MAX Indoor Unit Engineering Manual

• Verify that carpet is or will be installed (carpet will increase the

temperature by three degrees).

• Add insulation between the floor joists.

• Install radiant heat or another type of heating system to the floor.

Required Clearances

Figure 10 shows required clearance distances around a typical

installed wall-mounted unit.

Mounting the Installation Plate

The mounting wall must be strong and solid enough to protect the unit from vibration.

• Mount the installation plate on the wall using the Type “A” screws. If mounting the unit on concrete, consider using anchor bolts.

• Always mount the installation plate horizontally. Measure the wall and mark the centerline using thread and a level.

22 | ART CO OL MIRROR

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Figure 10:Minimum Clearance Requirements.

≥5 inches

Recommended height

>6-1/2 feet from floor

Page 23

Unit Outline

Ø2-3/4 inches

Place a level on raised tab

ART COOL MIRROR INDOOR UNITS

Installation plate

Right

Tubing Clamp

Down

Left

Back

Frame Cover

(3/16"~5/16")

Indoor

WALL

Outdoor

Bushing

Core Drill

Sleeve

MULTI

F

MAX

MULTI

F

Installation and Best Layout Practices

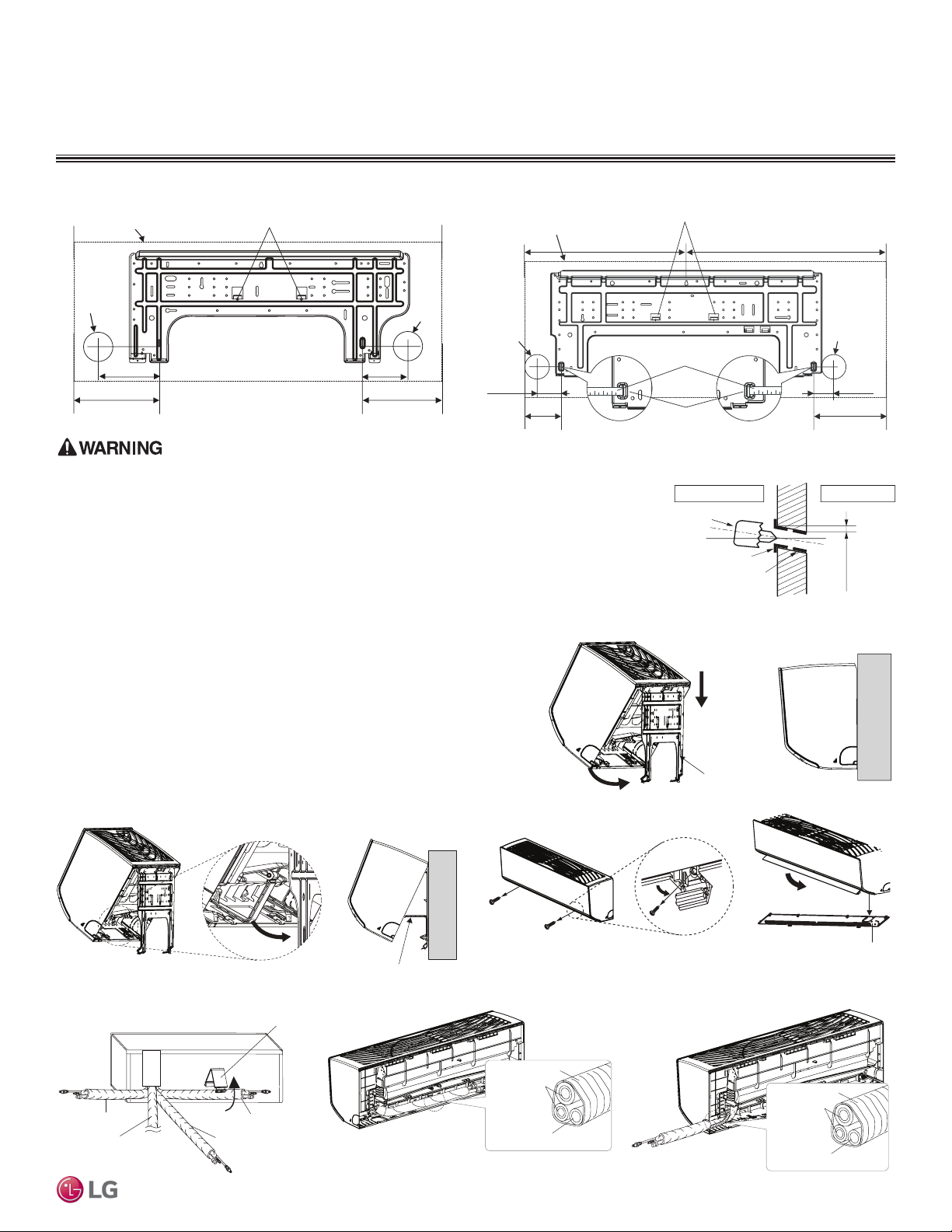

Figure 11:Installation Plate for LAN090HSV5 and LAN120HSV5 Units. Figure 12:Installation Plate for LAN180HSV5 Units.

Place a level on raised tab

Unit Outline

18-1/8 inches 22-7/16 inches

Ø2-3/4 inches

Left rear piping

5-1/4 inches

6-7/8 inches

Installation Plate

3-3/4 inches

Ø2-3/4

inches

8-17/32 inches

Right rear piping

Left rear

piping

2-23/32 inches

4-1/8 inches

Drilling Piping Hole in the Wall

Use caution when drilling holes through walls. Drilling into power wiring in the wall can cause serious

bodily injury or death.

Follow the left or right piping clearance recommendations.

1. Using a 2-5/8 (ø 65mm) inch hole core drill bit, drill a hole at either the right or left side of the

wall mounting. The hole must slant 3/16” to 5/16” from level (upward on the indoor unit side and

downward on the outdoor unit side).

2. Finish off the newly drilled hole as shown with bushing and sleeve covering. Sleeve and bushing prevents damage to the tubing/bundling of the piping.

Hanging the Indoor Unit Chassis

1. Attach the three (3) hooks on the top of the indoor unit to the top edge of

the installation plate. Verify the hooks are properly attached to the installation plate by gently shaking the indoor unit from side to side.

2. Unlock the tubing clamp from the indoor unit frame. For easier access between the bottom of the indoor unit and the wall, prop the clamp between

the indoor unit frame and installation plate.

3. Remove the screw covers at the bottom of the indoor unit, unscrew the

two (2) screws, remove the frame cover, remove the piping connection

cover, and position the piping for installation (down, back, left, or right).

Figure 14:Accessing the Back of the Indoor Unit.

Figure 15:Removing the Frame Cover.

Figure 13:Locking the Indoor Unit onto the Installation Plate.

Installation Plate

Measuring Tape

Measuring Tape Hanger

Figure 19:Drilling Piping Hole

Ø2-3/4 inches

Right rear

piping

2-7/32 inches

8-5/32 inches

Art Cool Mirror™

Tubing Clamp

Figure 16:Exterior Back View of Indoor Unit. Figure 17:Piping Installed to the Left.

Tape

Connecting

pipe

Drain hose

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Figure 18:Piping Installed to the Right.

Tape

Connecting

pipe

Drain hose

ART COOL M IRROR | 23

Page 24

ART COOL MIRROR INDOOR UNITS

Terminal block

Power wiring /

communications cable

Wired Remote Controlle

r

Terminal (Optional)

Cable restraint

MULTI

F

MAX

MULTI

F

Installation and Best Layout Practices

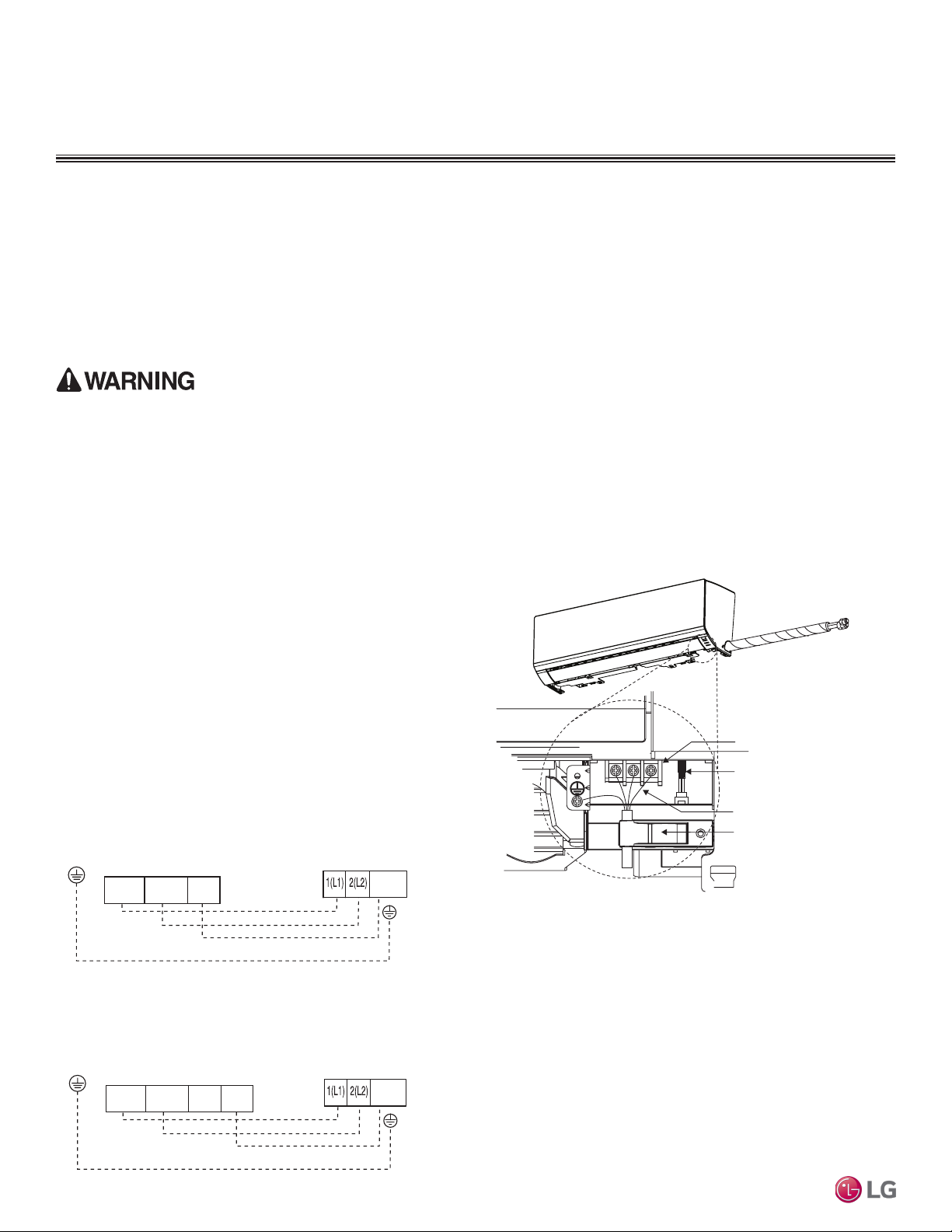

Power Wiring / Communications Cable Guidelines

• Follow manufacturer’s circuit diagrams in the technical manuals.

• Confirm power source specifications.

• Confirm that the electrical capacity is sufficient.

• Starting current must be maintained ±10 percent of the rated current marked on the outdoor unit name plate.

• Confirm cable thickness specifications.

• It is required that a circuit breaker is installed, especially if conditions could become wet or moist.

• Include a disconnect in the power wiring system, add an air gap contact separation of at least 1/8 inch in each active (phase) conductor.

• Loose wiring will cause unit to malfunction, overheat, and catch fire, resulting in severe injury or death.

Note:

• Terminal screws will become loose during transport. Properly tighten the terminal connections during installation.

A voltage drop will cause the following problems:

• Magnetic switch vibration, fuse breaks, or disturbance to the normal function of an overload protection device.

• Compressor will not receive the proper starting current.

Connecting the Power Wiring and Communications Cable

1. Insert the power wiring/communications cable from the outdoor

unit or branch distribution unit (Multi F MAX systems only)

through the bottom of the indoor unit.

2. Connect each wire to its appropriate terminal on the indoor unit

control board. Verify that the color and terminal numbers from

the outdoor unit or branch distribution unit (Multi F MAX systems

only) wiring match the color and terminal numbers on the indoor

unit.

3. Secure the power wiring/communications cable with the cable

restraint.

Figure 21:Simplied View of Indoor Unit to Outdoor Unit / Branch

Distribution Unit Terminal Connections—LAN090HSV5 and

LAN120HSV5 models.

GND

Indoor Unit Terminal Block

Multi F and Multi F MAX Indoor Unit Engineering Manual

BR

GRN / YLW

32(L2)1(L1)

BL

RD

Outdoor Unit Terminal Block or

Branch Distribution Unit Terminal Block

(Multi F MAX Systems Only)

3 or S

GND

Figure 20:Connecting the Power Wiring / Communications Cable.

Figure 22:Simplied View of Indoor Unit to Outdoor Unit / Branch

Distribution Unit Terminal Connections—LAN180HSV5 models.

24 | ART COOL MIRROR

GND

GRN / YLW

Indoor Unit Terminal Block

1(L1 )2(L2)

BR

BL

Outdoor Unit Terminal Block or

Branch Distribution Unit Terminal Block

(Multi F MAX Systems Only)

3

RD

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

3 or S

GND

Page 25

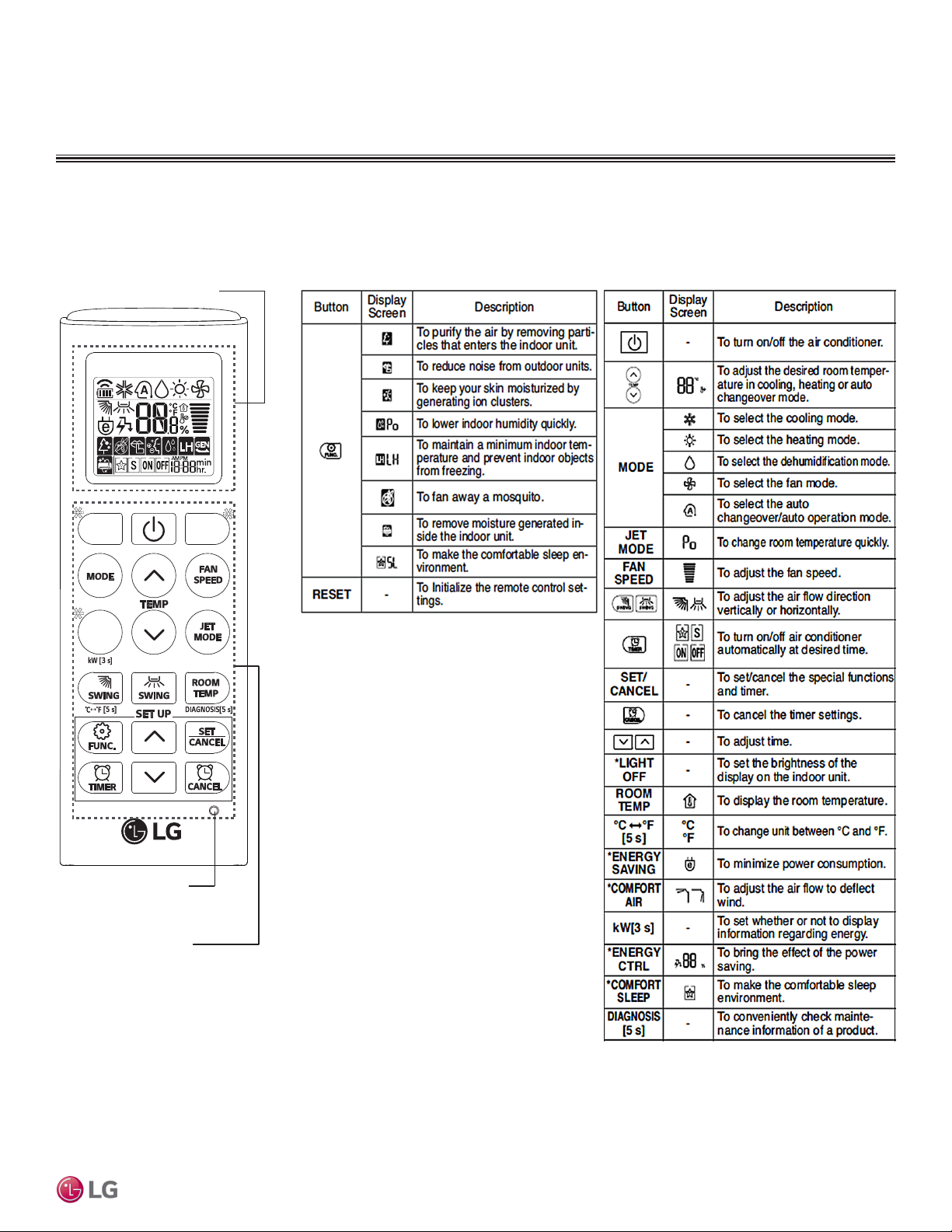

Wireless Handheld Controller

MULTI

F

MAX

MULTI

F

Screen Display

ART COOL MIRROR INDOOR UNITS

Installation and Best Layout Practices

Table 12: AKB74955602 Wireless Controller Functions.Figure 23:AKB74955602 Wireless Controller.

*

*

RESET

Buttons

*

Art Cool Mirror™

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

ART COOL M IRROR | 25

Page 26

ART COOL MIRROR INDOOR UNITS

Indoor Unit Terminal Block

1(L1 )2(L2)

GND

GRN / YLW

BR

BL

RD

CN-REMO

To Outdoor Unit or Branch Distribution Unit

(Multi F MAX Systems Only)

To Wired Controller

3

Indoor Unit Terminal Block

1(L1 )2(L2)

GND

GRN / YLW

BR

BL

RD

CN-REMO

To Outdoor Unit or Branch Distribution Unit

(Multi F MAX Systems Only)

To Wired Controller

3

4 to 5 feet

above the floor

NO

NO

NO

YES

Remote Controller

TEMP

Remote Controller

TEMP

Re

m

ot

e

C

o

n

t

r

ol

l

er

TEMP

MULTI

F

MAX

MULTI

F

Installation and Best Layout Practices

Wired Controller Connections

Figure 24:Wired Controller Connection on the Indoor Unit Terminal

Block—LAN090HSV5 and LAN120HSV5 models.

Figure 25:Wired Controller Connection on the Indoor Unit Terminal

Block—LAN180HSV5 models.

Wired Controller Placement

Wired controllers include a sensor to detect room temperature. To maintain comfort

levels in the conditioned space, the wired controller must be installed in a location

away from direct sunlight, high humidity, and where it could be directly exposed to

cold air. Controller must be installed four (4) to five (5) feet above the floor where its

LED display can be read easily, in an area with good air circulation, and where it can

detect an average room temperature.

Do not install the wired controller near or in:

• Drafts or dead spots behind doors and in corners

• Hot or cold air from ducts

• Radiant heat from the sun or appliances

• Concealed pipes and chimneys

• An area where temperatures are uncontrolled, such as an outside wall

Figure 26:Proper Location for the Wired Controller.

Multi F and Multi F MAX Indoor Unit Engineering Manual

Operation Mode Sequence

Cooling Mode

↓

Auto Operation

↓

Dehumidification Mode

26 | ART COOL MIRR OR

↓

Heating Mode

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 27

ART COOL MIRROR INDOOR UNITS

Top

Wall Wall

Wall Wall

Installing the Controller

Removing the Controller

MULTI

F

MAX

MULTI

F

Installation and Best Layout Practices

Hanging the Wired Controller

1. The controller wiring/cable can be installed in one of three direc-

tions: top, back, or on the right side. If top or right side installation

is desired, remove cable guide grooves on the controller, and

then position wiring/cable on applicable side.

2. Choose and mark the area of installation, and then screw the wall

plate into place (using the provided parts). Install the controller

wall plate to fit the electrical box if one is present. Ensure that no

gaps exist between the wall plate and the wall itself.

3. Arrange wiring/cables so as not to interfere with the controller

circuitry. Position the wired controller on the wall plate. Snap into

place by pressing the bottom part of the wired controller onto

the wall plate. Make sure that no gaps exist between the wired

controller and the wall plate on all sides.

4. To remove wired controller from the wall plate, insert a screwdriver into the two holes at the bottom. Twist screwdriver to

release controller. Do not damage the controller components

when removing.

Figure 27:Removing the Cable Guide Grooves.

Top

Back

Figure 28:Attaching the Wall Plate. Figure 29:Installing/Removing the

Right

Side

Controller.

Right

Side

Art Cool Mirror™

Assigning the Thermistor for Temperature Detection

Each indoor unit includes a return air thermistor assigned to sense the temperature. If a wired controller is installed, there is a choice of

sensing temperature with either the indoor unit return air thermistor or the thermistor in the wired controller. It is also an option to set both

thermistors to sense temperature so that indoor unit bases its operation on the first thermistor to reach the designated temperature differential. For applicable indoor units, an optional Remote Temperature Sensor can be used in lieu of the return air thermistor—either alone or in

conjunction with a wired controller thermistor as previously described.

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

ART COOL M IRROR | 27

Page 28

™

ART COO

L

GALLERY

INDOOR UNIT DATA

“Mechanical Specifications” on page 29

“General Data / Specifications” on page 30

“Dimensions” on page 31

“Cooling Capacity Table” on page 32

“Heating Capacity Table” on page 33

“Acoustic Data” on page 34

“Air Velocity and Temperature Distribution” on page 35

“Refrigerant Flow Diagram” on page 36

“Wiring Diagram” on page 37

“Factory Supplied Parts and Materials” on page 38

“Installation and Best Layout Practices” on page 39

Page 29

ART COOL GALLERY INDOOR UNITS

MULTI

F

MAX

MULTI

F

Mechanical Specications and Features

ART COOL Gallery Indoor Units

General

All LG indoor units are factory assembled, wired, piped, and provided with a control circuit board, fan, and motor. Art Cool Gallery

indoor units have a sound rating no higher than 42 dB(A) as tested

per KSA0701 ISO Standard 3745.

Coil

Indoor unit coils are comprised of a minimum of two rows of

aluminum fins mechanically bonded to copper tubing. The coils are

pressure tested at the factory. Each unit is provided with a factory

installed condensate drain pan below the coil.

Refrigerant System

System is designed for use with R410A refrigerant. The refrigeration

circuit is pressure-tested at the factory and shipped with a holding

charge of helium gas. Refrigerant pipe connections are 45° flare.

All refrigerant lines from the outdoor unit to the indoor units must be

field insulated.

Electrical

Each indoor unit is designed to operate using 208–230/60/1 power

with voltage variances of ±10%.

Casing

Units are designed to mount on a vertical surface, and are shipped

with a separate back plate that secures the unit to the wall, protruding no more than six (6) inches. Unit is designed so that refrigerant

piping can be installed in one of four different directions.

Cases / Finishes

The Art Cool Gallery unit has a frame that can accommodate a 20" x

20" photograph, picture or artwork. Unit casing has a gray finish and

is manufactured of heavy-duty acrylonitrile butadiene styrene (ABS)

and high impact polystyrene (HIPS) plastic.

Fan Assembly and Control

The unit has a single, direct-drive, crossflow fan made of high

strength ABS plastic. The fan motor is brushless digitally controlled

(BLDC) with permanently lubricated and sealed ball bearings. The

fan/motor assembly is mounted on vibration attenuating rubber

grommets. Fan speed is controlled using a microprocessor-based

direct digitally controlled algorithm that provides pre-programmed,

field-selectable fixed or auto fan speeds in the Heating and Cooling

modes. For Art Cool Gallery units, the indoor fan has Low, Med,

High, Power Cool and Auto settings for Cooling mode; and has Low,

Med, High, and Auto settings for Heating mode. The Auto setting

adjusts the fan speed based on the difference between the controller

setpoint and space temperature. Also, the separate Chaos setting

provides a simultaneous and random change in fan speed and flow

direction at the discharge,

simulating a natural outdoor

breeze.

Figure 30: Multi F Art Cool Gallery

Indoor Unit.

Air Filter

Return air is filtered with a

factory-supplied, removable,

washable pre-filter. Filter