Page 1

IP LDK-20 Installation Manual

P

IIP

INSTALLATION MANUAL

L

L

D

D

K

K

2

2

0

0

Page 2

IP LDK-20 Installation Manual

RREEVVIISSIIOONN HHIISSTTOORRYY

ISSUE DATE CONTENTS OF CHANGES REMARK

ISSUE 1.0

ISSUE 1.1

2005.3

2005.5

Initial Release

Add Expansion Modules and VMIBE/AAFBE

Page 3

IP LDK-20 Installation Manual

TTAABBLLEE OOFF CCOONNTTEENNTTSS

■ IMPORTANT SAFETY INSTRUCTIONS ....................................................... 1

Safety requirements .................................................................................................................... 1

■ PRECAUTION................................................................................................. 2

■ THE STRUCTURE OF MANUAL ................................................................... 3

SECTION 1. INTRODUCTION................................................................................ 4

1.1 The IP LDK-20 System highlights......................................................................................... 4

1.2 System Connection Diagram ............................................................................................... 4

1.3 System Components ............................................................................................................ 5

1.4 Specifications ....................................................................................................................... 6

1.4.1 General specifications.............................................................................................................. 6

1.4.2 System Capacity ...................................................................................................................... 7

SECTION 2. KSU INSTALLATION ......................................................................... 8

2.1 Pre-Installation...................................................................................................................... 8

2.1.1 Safety installation instructions ................................................................................................. 8

2.1.2 Installation precautions ............................................................................................................ 8

2.1.3 Wiring precautions ................................................................................................................... 8

2.2 KSU Installation .................................................................................................................... 9

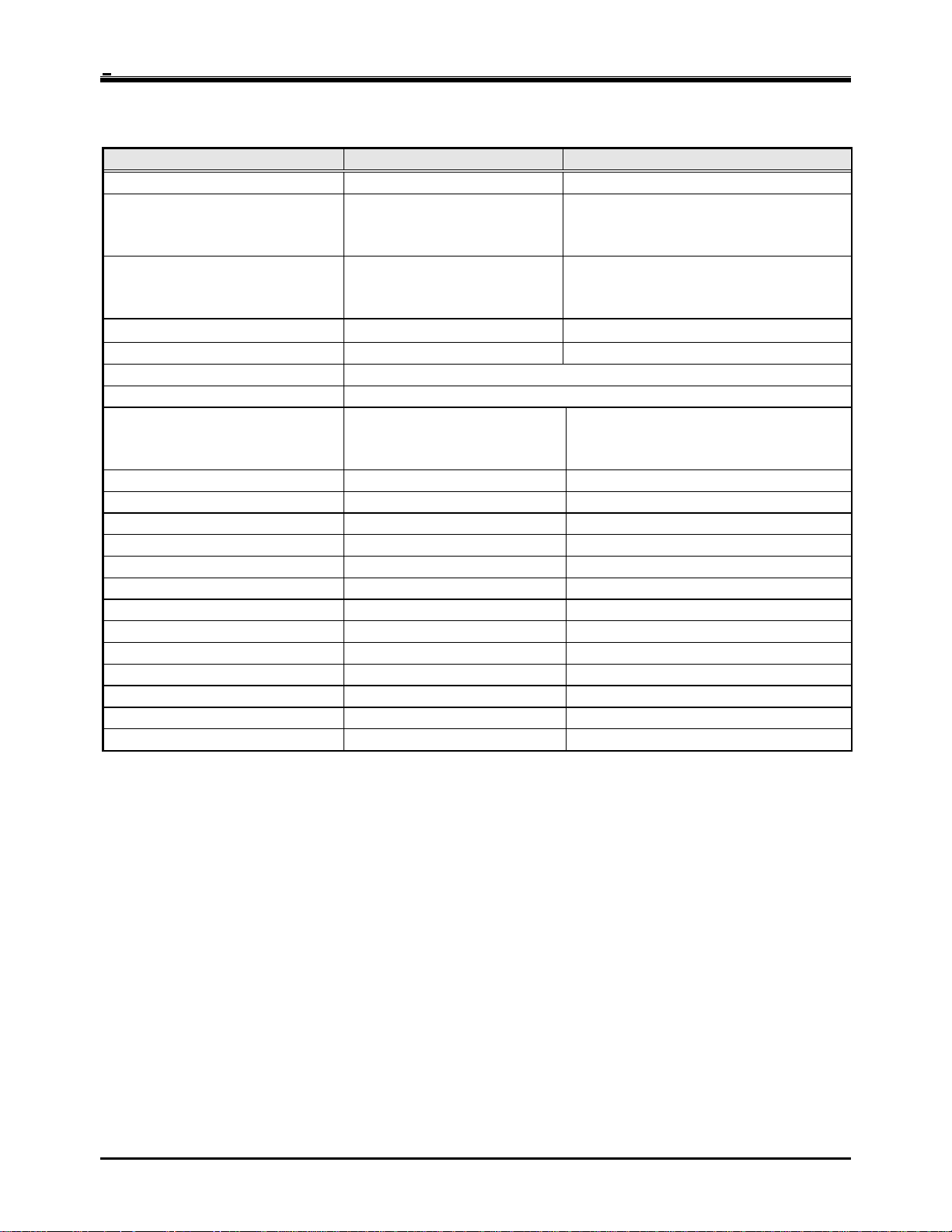

2.2.1 Unpacking ................................................................................................................................ 9

2.2.2 KSU exterior and dimension ................................................................................................... 10

2.2.3 KSU with expansion module exterior and dimension............................................................. 11

2.2.4 Opening and closing the front cover......................................................................................12

2.2.5 Frame ground connection ...................................................................................................... 14

2.2.6 Power Supply Unit (PSU) installation .................................................................................... 15

2.2.7 External backup batteries installation .................................................................................... 16

2.2.8 KSU mounting ........................................................................................................................ 17

SECTION 3. BOARD INSTALLATION.................................................................. 20

3.1 Installation of the Boards.................................................................................................... 20

3.2 MBUB (Main Board Unit) ................................................................................................... 21

3.2.1 Modular Jack(MJ1~MJ3) Pin Assignment............................................................................. 23

3.3 Installation of the CO Line Board ....................................................................................... 29

3.3.1 LCOB (CID Loop Start CO line Interface Board)................................................................... 29

3.3.2 STIB (Basic Rate Interface Board: Selectable S/T interface) ............................................... 32

3.3.3 CBIB (CID Loop Start CO line + Basic Rate Interface Board) .............................................. 36

3.4 Installation of the Extension Board .................................................................................... 39

3.4.1 DTIB4 (Digital Terminal Interface Board) .............................................................................. 39

3.4.2 DTIB8 (Digital Terminal Interface Board) .............................................................................. 40

3.4.3 SLIB4 (Single Line Interface Board) ......................................................................................41

3.4.4 SLIB8 (Single Line Interface Board) ......................................................................................42

3.5 Other Board Installations.................................................................................................... 43

3.5.1 VMIBE (Voice Mail Interface Board Enhanced) .................................................................... 43

3.5.2 AAFBE(Auto Attendant Function Board Enhanced) ............................................................. 44

3.5.3 LANU (LAN interface Unit)..................................................................................................... 45

3.5.4 MODU (MODEM function Unit) ............................................................................................. 46

SECTION 4. EXPANSION MODULE INSTALLATION .......................................... 47

i

Page 4

IP LDK-20 Installation Manual

4.1 Unpacking............................................................................................................................ 47

4.2 Opening and closing the front cover ................................................................................... 48

4.2.1 Opening the front cover .......................................................................................................... 48

4.2.2 Closing the front cover ............................................................................................................ 49

4.3 Opening and closing the front cover ................................................................................... 50

4.3.1 Connecting Expansion Module to KSU .................................................................................. 50

4.3.2 Wall mounting ......................................................................................................................... 51

4.3.3 Rack Mounting ........................................................................................................................ 52

4.4 External backup batteries connection................................................................................. 54

4.5 VOIM (Voice over Internet Protocol Interface Module) installation.................................... 55

Various switches and connectors functions .................................................................................... 56

4.5.1 Pin assignment........................................................................................................................ 57

4.5.2 VOIU(Voice over Internet Protocol Interface Unit) ................................................................. 58

4.6 SLIM(SLT Interface Module) Installation ............................................................................ 59

4.6.1 Pin assignment........................................................................................................................ 59

4.7 DTIM(DKT Interface Module).............................................................................................. 60

4.7.1 Pin assignment........................................................................................................................ 60

SECTION 5. TERMINAL CONNECTION.............................................................. 61

5.1 Terminal Models ................................................................................................................. 61

5.2 Terminal Cabling Distance................................................................................................. 62

5.3 Keyset Connection ............................................................................................................. 63

5.3.1 Digital Keyset ......................................................................................................................... 63

5.3.2 SLT......................................................................................................................................... 63

5.4 Connecting Additional Terminals ....................................................................................... 64

5.4.1 External Music Source wiring ................................................................................................ 64

5.4.2 Relay Contacts....................................................................................................................... 64

5.4.3 External Paging wiring ........................................................................................................... 64

5.4.4 Alarm Detection wiring ........................................................................................................... 64

SECTION 6. STARTING THE IPLDK-20 SYSTEM .............................................. 65

6.1 Before Starting the IP LDK-20 System .............................................................................. 65

6.2 Basic Preprogramming.......................................................................................................65

6.2.1 DKTU (Station 10) programming ........................................................................................... 65

6.2.2 Entering programming mode ................................................................................................. 67

6.2.3 Pre-programming ................................................................................................................... 68

SECTION 7. TROUBLESHOOTING ...................................................................... 76

ii

Page 5

IP LDK-20 Installation Manual Introduction

■ Important Safety Instructions

Safety requirements

When using your telephone equipment, basic safety precautions should always be followed to reduce the risk of fire,

electric shock and other personal injury, including the following:

• Please read and understand all instructions.

• Follow all warnings and instructions marked on the product.

• Unplug this product from the wall outlet before cleaning. Just a damp cloth should be used for cleaning; do not

use liquid or aerosol cleaners.

• Do not use this product near water, such as in a bathtub, wash bowl, kitchen sink, or laundry tub, in a wet

basement, or near a swimming pool.

• Do not place this product on an unstable cart, stand, or table. The product may fall, causing serious damage to

the product or personal injury.

• Slots and openings in the KSU and the back or bottom are provided for ventilation, to protect it from overheating,

these openings must not be blocked or covered. The openings should never be blocked by placing the product on

a bed, sofa, rug, or other similar surface. This product should never be placed near or over a radiator or other

heat source. This product should not be placed in a built-in installation without proper ventilation.

• This product should be operated only from the type of power source indicated on the product label. If you are not

sure of the type of power supply to your home, consult your dealer or local power company.

• Do not allow anything to rest on the power cord. Do not locate this product where the cord could be abused by

people walking on it.

• Do not overload wall outlets and extension cords as this can result in the risk of fire or electric shock.

• Never push objects of any kind into this product through KSU slots or connectors as they may touch dangerous

voltage points or short out parts that could result in a risk of fire or electric shock. Never spill liquid of any kind on

the product.

• To reduce the risk of electric shock, do not disassemble this product. Instead, take it to a qualified person when

service or repair work is required. Opening or removing covers may expose you to dangerous voltages or other

risk. Incorrect reassemble can cause electric shock when the appliance is subsequently used.

• Unplug this product from the wall outlet and refer servicing to qualified service personnel under the following

conditions:

- When the power supply cord or plug is damaged or frayed.

- If liquid has been spilled into the product.

- If the product has been exposed to rain or water.

- If the product does not operate normally by following the operating instructions. Adjust only those controls that

are covered by the operating instructions because improper adjustment of other controls may result in

damage and will often require extensive work by a qualified technician to restore the product to normal

operation.

- If the product has been dropped or the KSU has been damaged.

- If the product exhibits a distinct change in performance.

• Avoid using a telephone during an electrical storm. There may be a remote risk of electric shock from lightning.

• In the event of a gas leak, do not use the telephone near the leak.

1

Page 6

IP LDK-20 Installation Manual Introduction

■ Precaution

• Keep the system away from heating appliances and electrical noise generating devices such as fluorescent

lamps, motors and televisions. These noise sources can interfere with the performance of the IP LDK-20

System.

• This system should be kept free of dust, moisture, high temperature (more than 40 degrees) and vibration,

and should not be exposed to direct sunlight.

• Never attempt to insert wires, pins, etc. into the system. If the system does not operate properly, the trouble

has been repaired by an authorized LG service center.

• Do not use benzene, paint thinner, or any abrasive powder to clean the KSU. Wipe it with a soft cloth.

CAUTION

• This system should only be installed and serviced by qualified service personnel.

• When a failure occurs which exposes any internal parts, disconnect the power supply cord immediately and

return this system to your dealer.

• To prevent the risk of fire, electric shock or energy hazard, do not expose this product to rain or any type of

moisture.

• To protect PCB from static electricity, discharge body static before touching connectors and/or components

by touching ground or wearing a ground strap.

WARNING

Danger of explosion if battery is incor r ectly replaced. Replace only with the same or equ iv ale nt ty pe rec omme nd ed by

the manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

2

Page 7

IP LDK-20 Installation Manual Introduction

■ The Structure of Manual

This installation manual is designed to provide as general information for the IP LDK-20 System. It provides

instructions for installing the hardware, and programming the IP LDK-20 System using keyset. This manual contains

the following sections:

Section 1. Introduction

Provides general information on the IP LDK-20 System, including the system specifications and capacity.

Section 2. KSU Installation

Describes detailed instructions for planning the installation site and procedures to install the IP LDK-20 System.

Section 3. Board Instal lat ion

Describes general information and detailed instructions for installing boards and add-on boards.

Section 4. Expansion Module Installation

Describes the kinds of terminals, maximum distance, and the other device connections for the terminal.

Section 5. Terminal Connection

Describes the kinds of terminals, maximum distance, and the other device connections for the terminal.

Section 6. Starting the IP LDK -20 Sy st em

Provides general information for starting the system and basic preprogramming.

Section 7. Troubleshooting

Provides information on the IP LDK-20 System and troubleshooting.

3

Page 8

IP LDK-20 Installation Manual Introduction

SECTION 1. INTRODUCTION

1.1 The IP LDK-20 System highlights

Features of the IP LDK-20 System include:

• Flexible architecture

• Optional LAN Interface

• Stable & enhanced voice features

• Simple installation & efficient system management

- Remote admin through BRI connection

- Remote admin through PSTN modem

- Remote admin through LAN connection

• Value-added features

- Distinctive voice mail

- CID (CO & SLT)

- VOIP Service

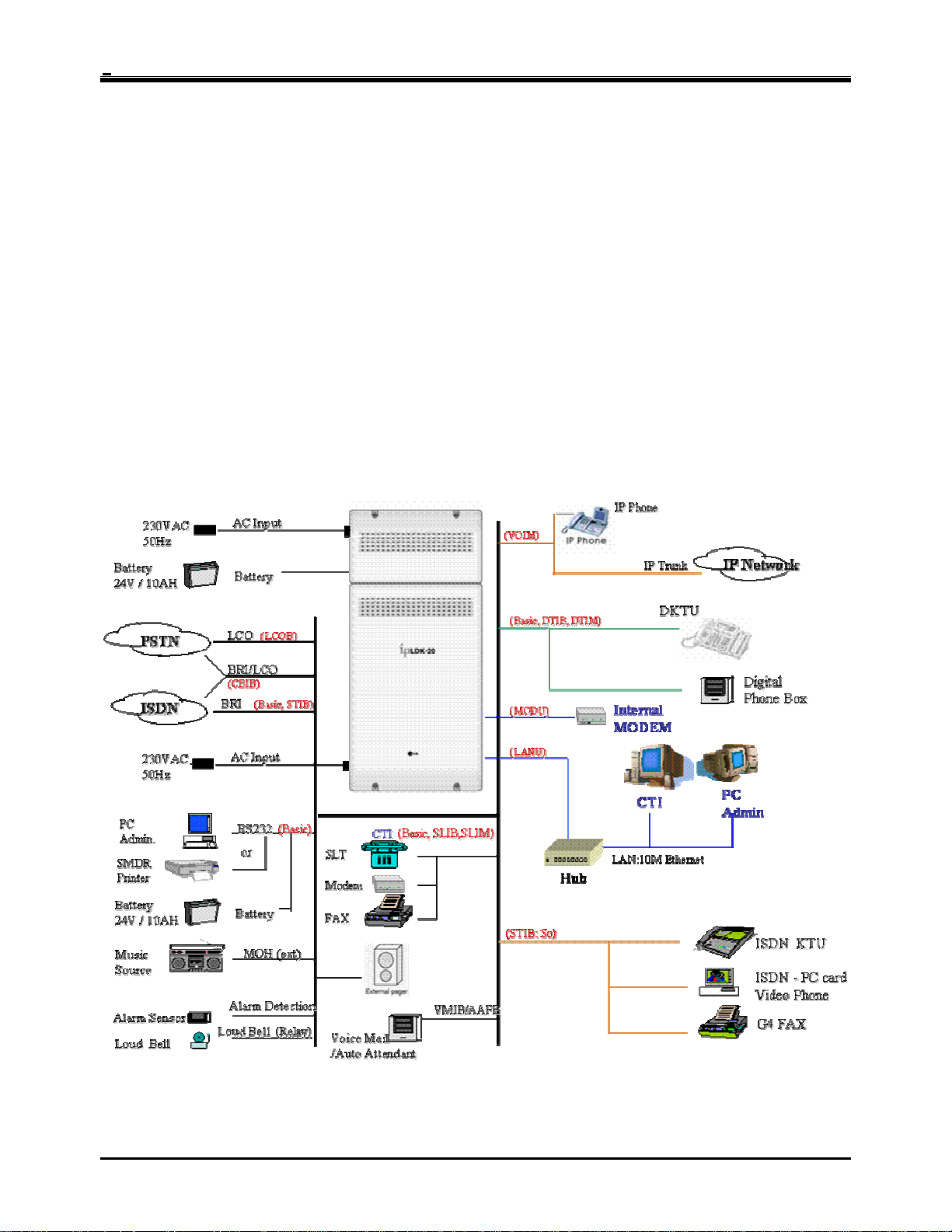

1.2 System Connection Diagram

Figure 1.2 IP LDK System Connection Diagram

4

Page 9

IP LDK-20 Installation Manual Introduction

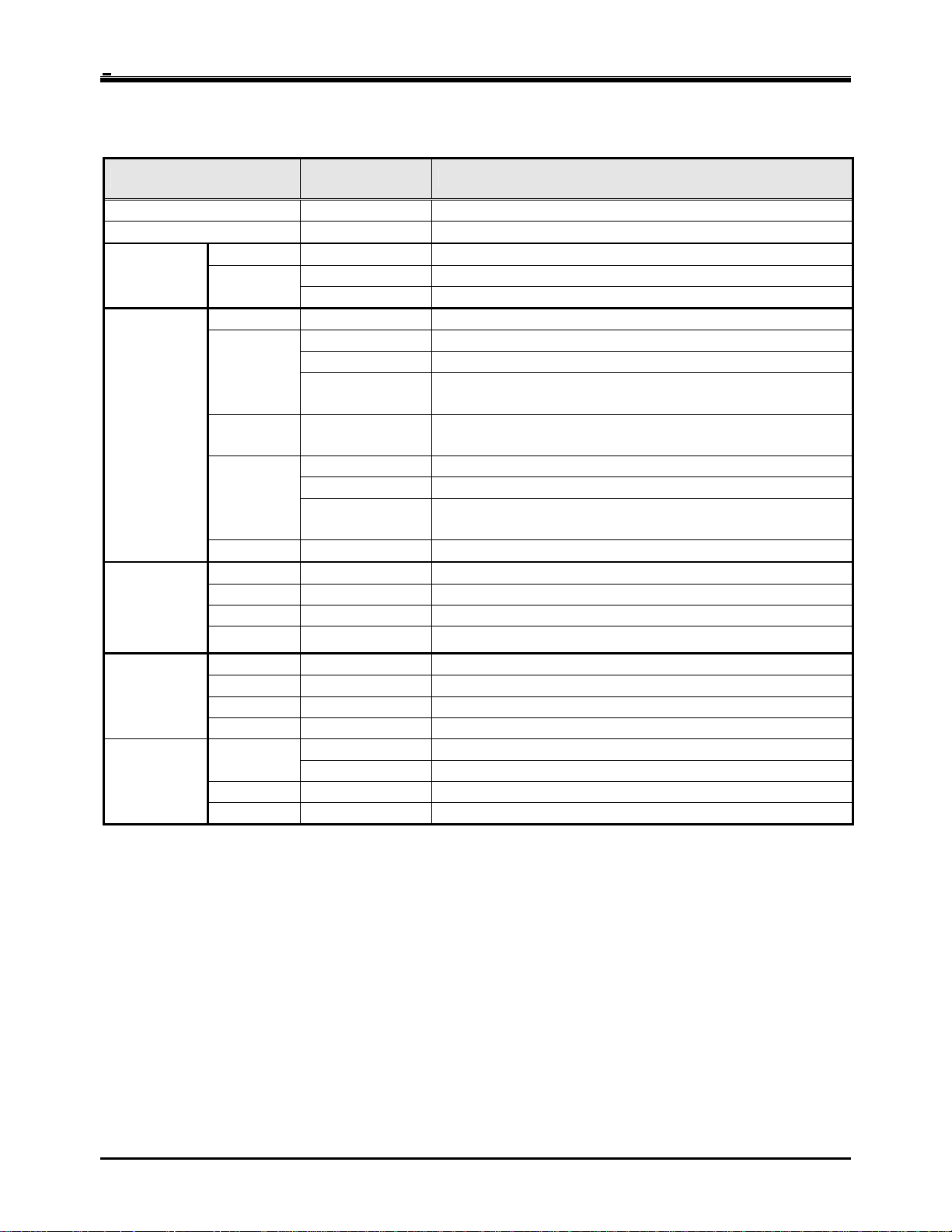

1.3 System Components

ITEM OPTION BOARD DESCRIPTION

Main

Board

CO Line

Boards

Extension

Boards

Other

Boards

Expansion

Modules

KSU

PSU

Key Service Unit

Power Supply Unit, 90W

MBUB

LCOB

PRU4 Polarity Reversal detection Unit

CBIB

STIB

DTIB4

DTIB8

SLIB4

SLIB8

VMIBE

AAFBE

LANU

MODU

VOIM

SLIM

DTIM

Voice over Internet protocol interface module (4 channels)

Main Board Unit (2BRI, 4DKT, 2DKT/SLT, and 2SLT)

CO boards Central Office Line interface boards (LCOB, STIB,CBIB)

EXT boards Extension boards (DTIB, SLIB)

Loop Start CO Interface, 4 lines

PRCPTU4 Polarity Reversal & Call Progress Tone detection Unit

CPCU4

PRU2 Polarity Reversal detection Unit

PRCPTU2 Polarity Reversal & Call Progress Tone detection Unit

CPCU2

ISDN Basic Rate (S/T) Interface Board, 2 lines (4channels)

Digital Terminal Interface Board, 4 ports

Digital Terminal Interface Board, 8 ports

SLT Interface (+36V Feed) Board, 4ports

Enhanced Voice Mail Interface Board, 4 channels

Enhanced Auto Attendant Function Board, 3 channels

LAN interface Unit (10Mbase-T only)

MODEM unit (33Kbps)

VOIU Voice over Internet protocol interface unit.(4 channels)

SLT Interface (+36V Feed) module, 8ports

Digital Terminal Interface module, 8 ports

Caller-ID(FSK), Polarity Reversal & Call Progress Tone

detection Unit

Loop Start CO Interface, 2 lines

Basic Rate(Only T) Interface Board, 1 line (2 channels)

Caller-ID(FSK), Polarity Reversal & Call Progress Tone

detection Unit

SLT Interface (+36V Feed) Board, 8ports

5

Page 10

IP LDK-20 Installation Manual Introduction

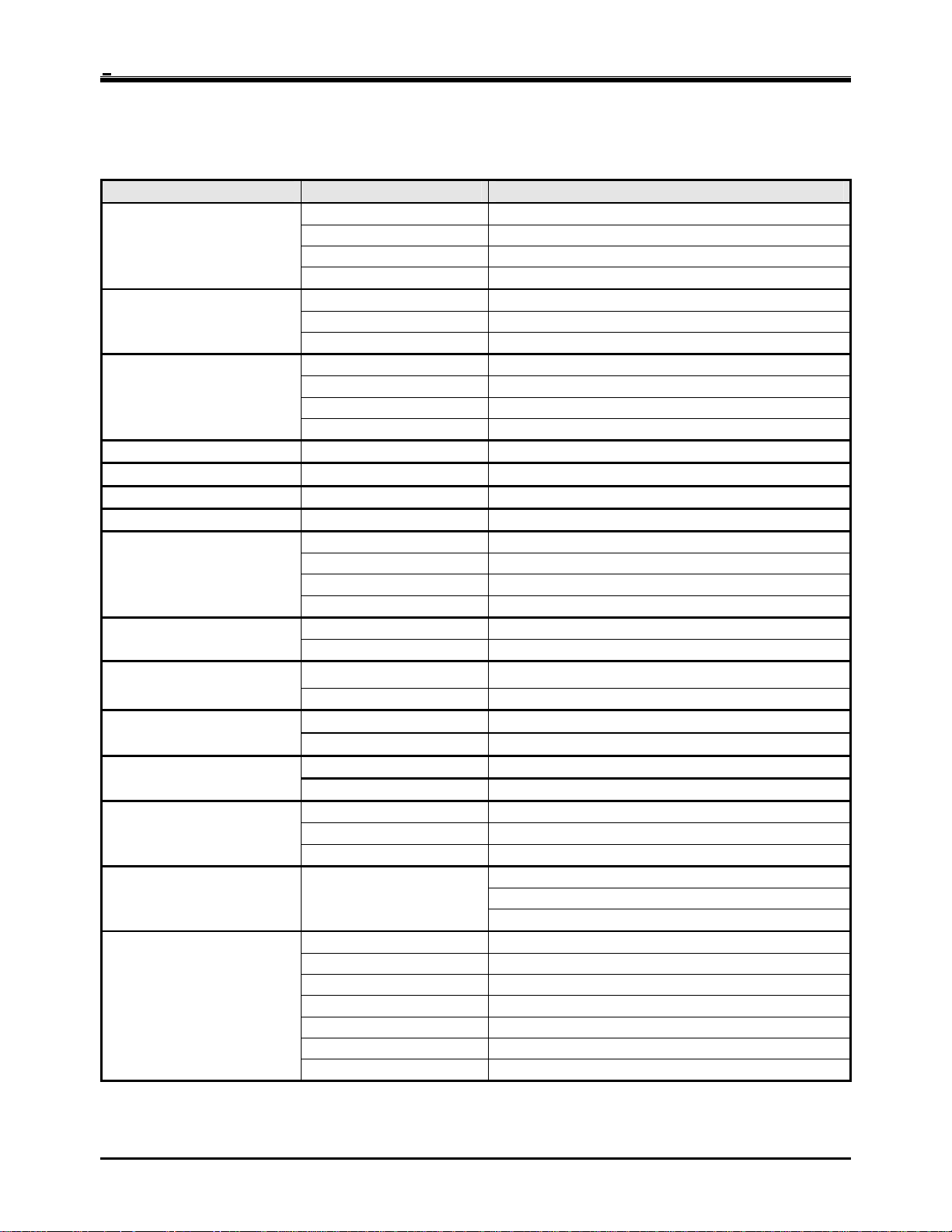

1.4 Specifications

1.4.1 General specifications

ITEM DESCRIPTION SPECIFICATION

PSU

AC Adaptor

Battery Backup

External Relay Contact 1A @ 30 Volt DC

Music Source Input 0 dBm @ 600ohm

External Paging Port 0 dBm @ 600ohm

Ring Detect Sensitivity 30Vrms @ 16-55Hz

DTMF Dialing

Operating Temperature

Environment Humidity 0-80%(non condensing)

LANU

MODU Analog modem

VOIM

AC Voltage Input 230 +/-10% Volt AC @47-63Hz

AC Power 90W

AC Input Fuse 1.25A @ 250Volt AC

DC Output Voltage +5, -5, +30Volt DC

AC Voltage Input 230 +/-10% Volt AC @47-63Hz

AC Input Fuse 1A @ 250Volt AC

DC Output Voltage 48Volt DC

Input Voltage 24 Volt DC

Battery Fuse 5.0A @ 250Volt AC

Charging Current Max. 100mA

Battery Load Current Max. 3A (with Analog CO or ISDN CO)

Frequency Deviation Less than +/-1.8%

Signal Rise Time Max.5ms

Tone Duration, on time Min.50ms

Inter-digit Time Min.30ms

Pulse Rate 10 PPS Pulse Dialing

Break/Make Ratio 60/40% or 66/33%

0(℃)-40(℃)

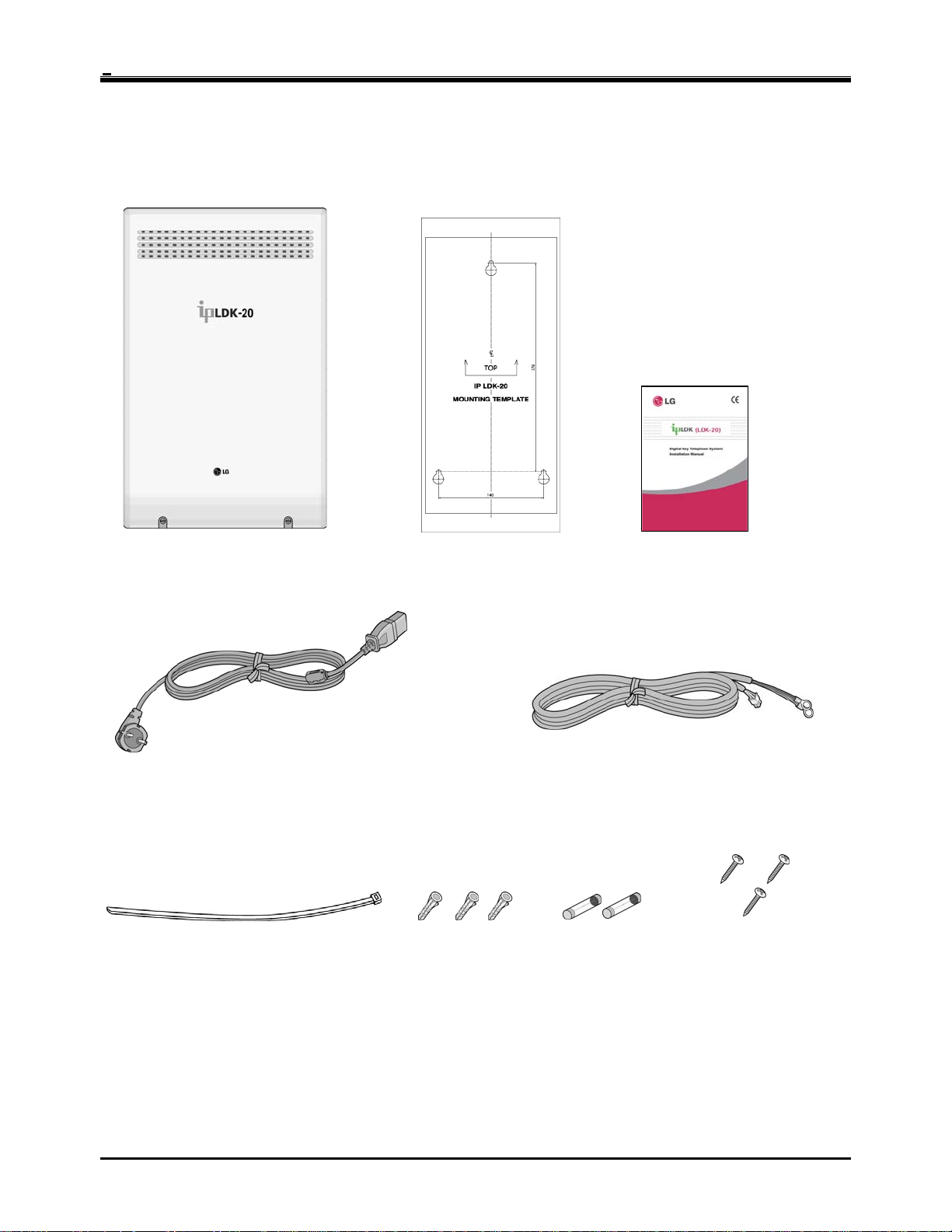

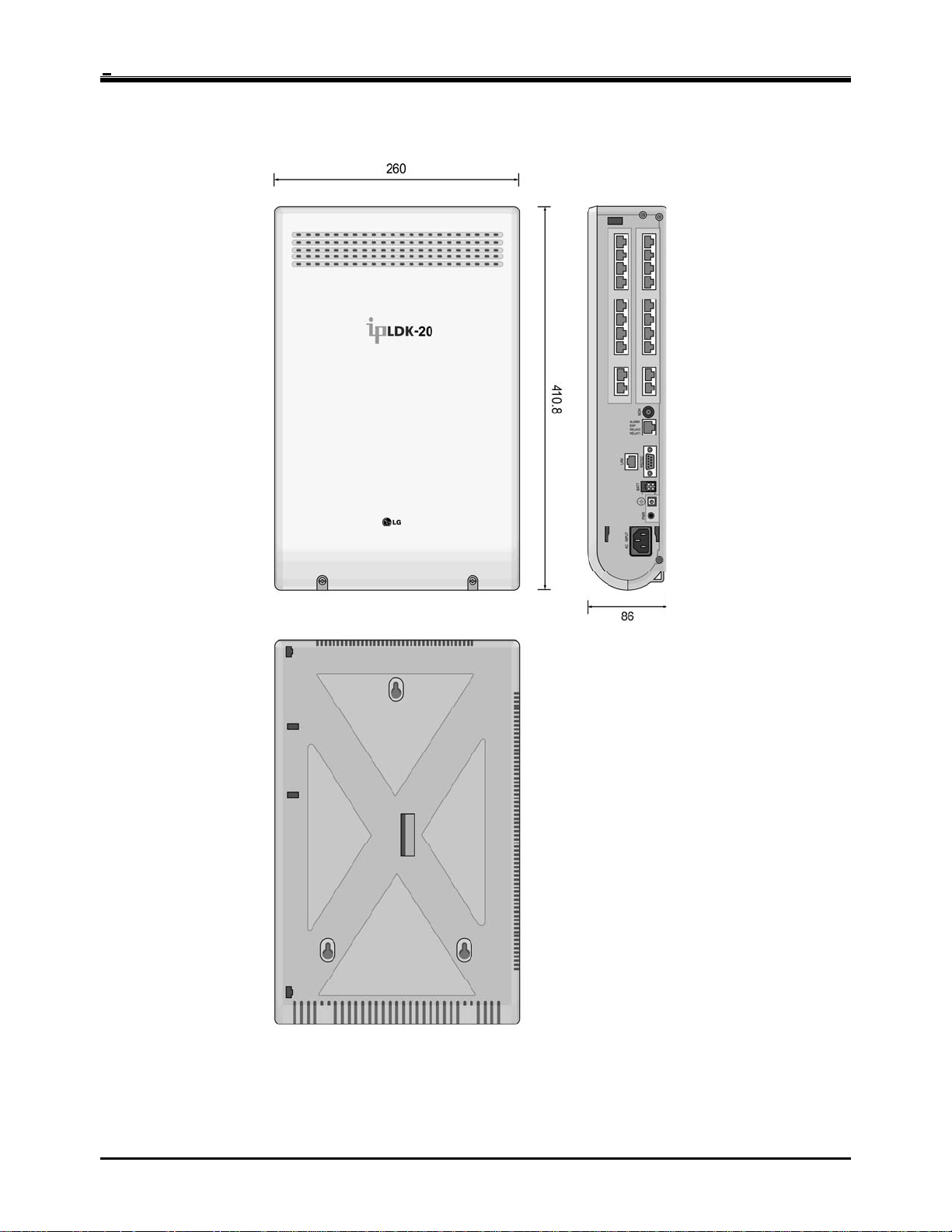

KSU 260mm(W)*410mm(H)*86mm(D) Dimension

Expansion Module 260mm(W)*145mm(H)*86mm(D)

KSU 2.5Kg Weight

Expansion Module DTIM/SLIM: 1.16Kg, VOIM: 0.58Kg

LAN Interface 10 Base -T Ethernet (IEEE 802.3)

Speed 10 Mbps

Duplex Half duplex or Full duplex (Auto-Negotiation)

Bell, ITU-T, V.34, V.32BIS, V.90

300bps up to 33Kbps speed rate

Automatic rate negotiation

LAN Interface 10 / 100 Base-T Ethernet (IEEE 802.3)

Speed 10 Mbps or 100 Mbps (Auto-Negotiation)

Duplex Half Duplex or Full Duplex (Auto-Negotiation)

VOIP Protocol H.323 Revision 2

Voice Compression G.711/G.726/G729/G.723.1

Voice/Fax Switching T.38

Echo cancellation G.165

6

Page 11

IP LDK-20 Installation Manual Introduction

1.4.2 System Capacity

DESCRIPTION CAPACITY/BOARD TOTAL

Time Slots 96

4/MBUB(BRI)

CO Line Ports

Max direct Station connections

Max LAN port 1/LANU 1

Max MODEM Channel 1/MODU 1

Attendant Positions 5/System

Intercom Links Non-blocking

Paging

- All Call

- Internal

Station Speed Dial 100/station, 24 digits each 500

System Speed Dial 24 digits each 500

Last Number Redial 10 32 digits

CO Line Group 8 8

Station Group 10 10

Conference 3-Party no limit

Music Source Input 1/MBUB 1

External Paging 1/MBUB 1

External Control Contact 2/MBUB 2

Alarm Input 1/MBUB 1

RS-232C Port 1/MBUB 1

DTMF Receiver 3/MBUB, 2/SLIB, 2/SLIM 7

Auto Fax detection 1/MBUB 1

4/LCOB or 4/STIB

8/VOIM

8/MBUB

8/DTIB or 8/SLIB

8/DTIM, 8 SLIM, or 8/VOIM

(Analog CO, ISDN BRI and/or IP trunk)

Max. 16

Max. 24

1 zone

5 zones

7

Page 12

IP LDK-20 Installation Manual KSU Installation

SECTION 2. KSU INSTALLATION

2.1 Pre-Installation

Please read the following guidelines concerning installation and connection before installing the IP LDK-20 System.

Be sure also to comply with applicable local regulations.

2.1.1 Safety installation instructions

When installing the telephone wiring, basic safety precautions should always be followed to reduce the risk of fire,

electric shock and personal injury, including the following:

• Never install the telephone wiring during a lightning storm.

• Never install the telephone jack in wet locations unless the jack is specifically designed for wet locations.

• Never touch uninsulated telephone wires or terminals unless the telephone line has been disconnected at the

network interface.

• Use caution when installing or modifying telephone lines.

• Anti-static precautions should be taken during installation.

2.1.2 Installation precautions

The IP LDK-20 System is designed for wall mounting or a free-standing rack. Avoid installing in the following places.

• In direct sunlight and hot, cold, or humid places. Temperature range : 0 to 40℃

• Places where shocks or vibrations are frequent or strong.

• Dusty places, or places where water or oil may come into contact with the system.

• Near high-frequency generating devices such as sewing machines or electric welders.

• On or near computers, fax machines, or other office equipment, as well as microwave ovens or air conditioners.

• Do not obstruct the area around the IP LDK-20 System (for reasons of maintenance and inspection)

• Do not block the openings on the top of the IP LDK-20 System.

• Do not stack up the optional service boards.

2.1.3 Wiring precautions

Be sure to follow these precautions when wiring.

• Do not wire the telephone cable in parallel with an AC power source, such as a computer, fax machine, etc. If the

cables are run near those wires, shield the cables with metal tubing or use shielded cables and ground the shields.

• If the cables are run on the floor, use protectors to prevent the wires from being stepped on. Avoid wiring under

carpets.

• Avoid using the same power supply outlet for computers, fax machines, and other office equipment to avoid

induction noise interruption when using the IP LDK-20 near other machines.

• The power and battery switches of the IP LDK-20 System must be OFF during wiring. After the wiring is

completed, the power switch may be turned ON.

• Incorrect wiring may cause the IP LDK-20 System to operate improperly.

• If an extension does not operate properly, disconnect the telephone from the extension line and then re-connect,

or turn the power of the IP LDK-20 System OFF and ON again.

• Use twisted pair cable for CO line connection.

8

Page 13

IP LDK-20 Installation Manual KSU Installation

2.2 KSU Installation

2.2.1 Unpacking

Open the box and verify the items shown in Figure 2.2.1 are included:

Key service unit

Power cord

Tie cable Anchor plug

Mounting template

Figure 2.2.1 Unpacking

Battery cable

Fuse

Manual

Screw

9

Page 14

IP LDK-20 Installation Manual KSU Installation

2.2.2 KSU exterior and dimension

Figure 2.2.2 shows the exterior and dimensions of the KSU:

Figure 2.2.2 KSU exterior and dimension

10

Page 15

IP LDK-20 Installation Manual KSU Installation

2.2.3 KSU with e xpansion modu le exterior and dimension

Figure 2.2.3 shows the exterior and dimensions of the KSU:

Figure 2.2.3 KSU with expansion module exterior and dimension

11

Page 16

IP LDK-20 Installation Manual KSU Installation

2.2.4 Opening and closing the front cover

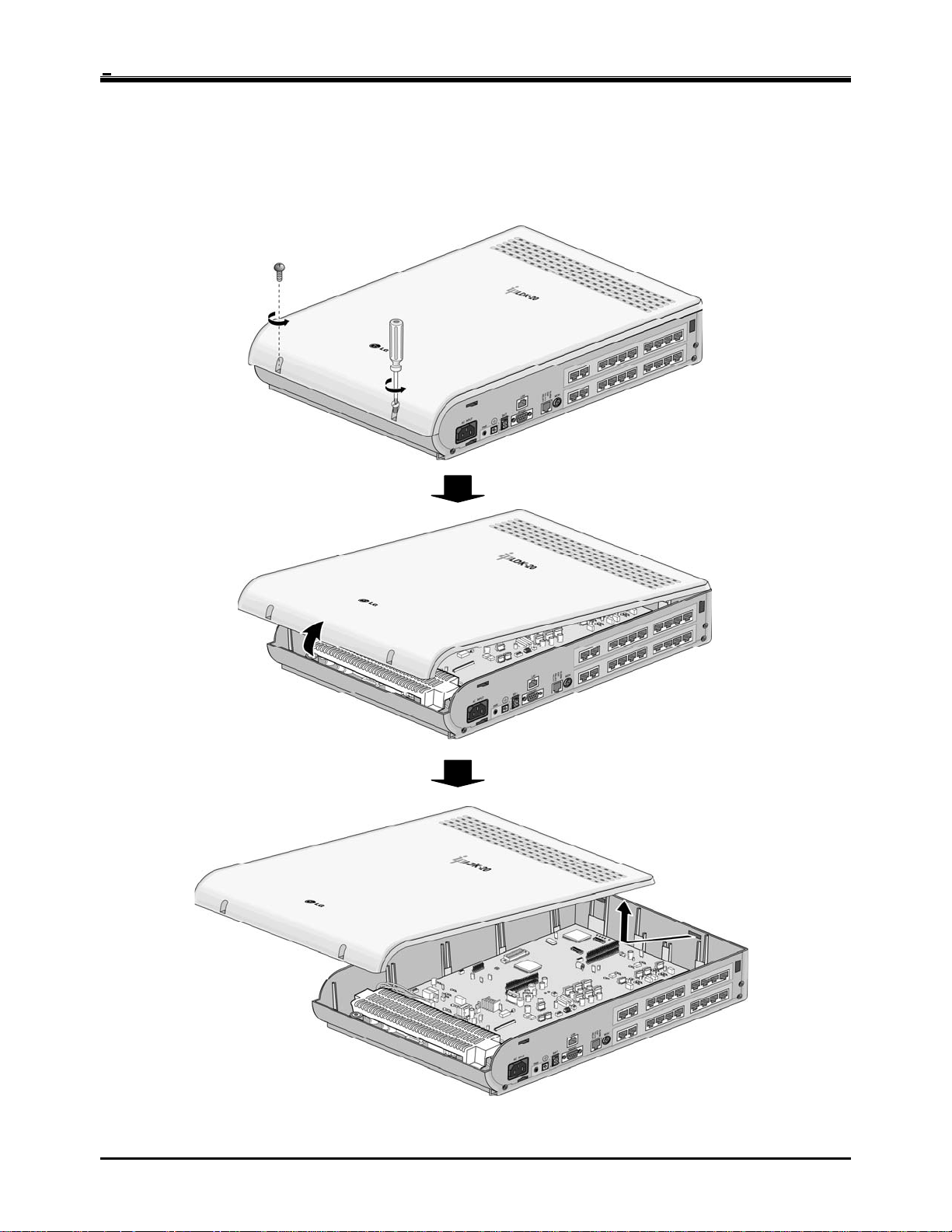

2.2.4.1 Opening the front cover

1. Turn the screw counter-clockwise to loosen as shown in Figure 2.2.4.1.

2. Lift the front cover in the direction of the arrow as shown:

Figure 2.2.4.1 Opening the front cover

12

Page 17

IP LDK-20 Installation Manual KSU Installation

2.2.4.2 Closing the front cover

Insert the front cover into the slot on the KSU as show in Figure 2.2.4.2.

Then put the front cover down on the KSU in the direction of the arrow, as shown.

Turn the screws clockwise to tighten, as in the Figure.

Figure 2.2.4.2 Closing the front cover

※

NOTE

For safety reasons, close the front cover and tighten the screws prior to operating the IP LDK-20 System.

13

Page 18

IP LDK-20 Installation Manual KSU Installation

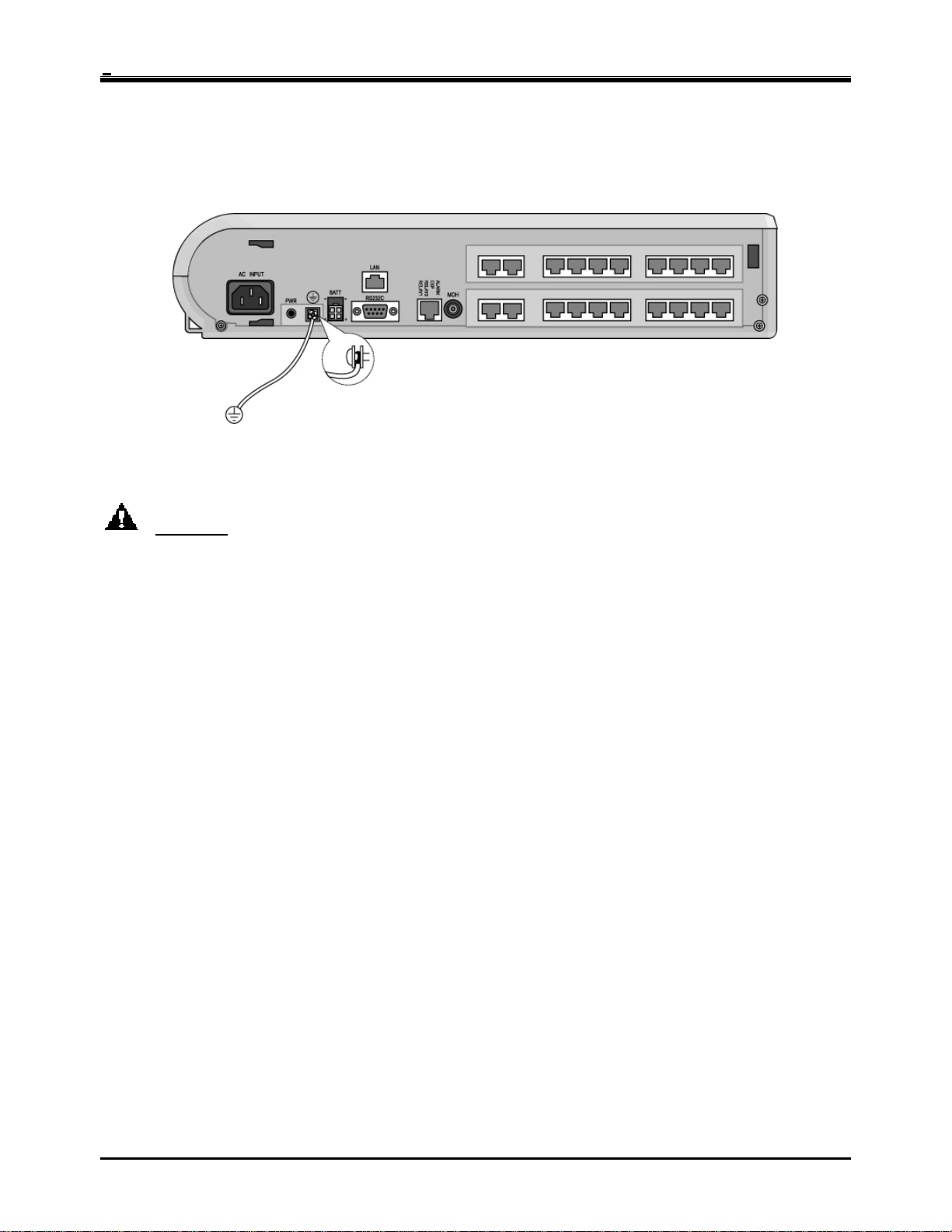

2.2.5 Frame ground connection

It is very important the frame of the IP LDK-20 system is grounded:

1. Turn the screw counter-clockwise to loosen. Then insert the grounding wire.

2. Tighten the screw. Then connect the grounding wire to ground source as shown in Figure 2.2.5.

Figure 2.2.5 Grounding the KSU

CAUTION

• The equipment should be connected to a socket-outlet with a protective ground connection.

• For ground wire, green-and-yellow insulation is required, and the cross-sectional area of the conductor must

be more than UL 1015 AWG# 18 (1.0mm). It is recommended that the ground wire be shorter than 1 meter

(3.28 feet).

• Proper grounding is very important to protect the IP LDK-20 system from external noise or to reduce the risk

of electrocution in the event of lightning strike.

• Be sure to comply with applicable local regulations.

14

Page 19

IP LDK-20 Installation Manual KSU Installation

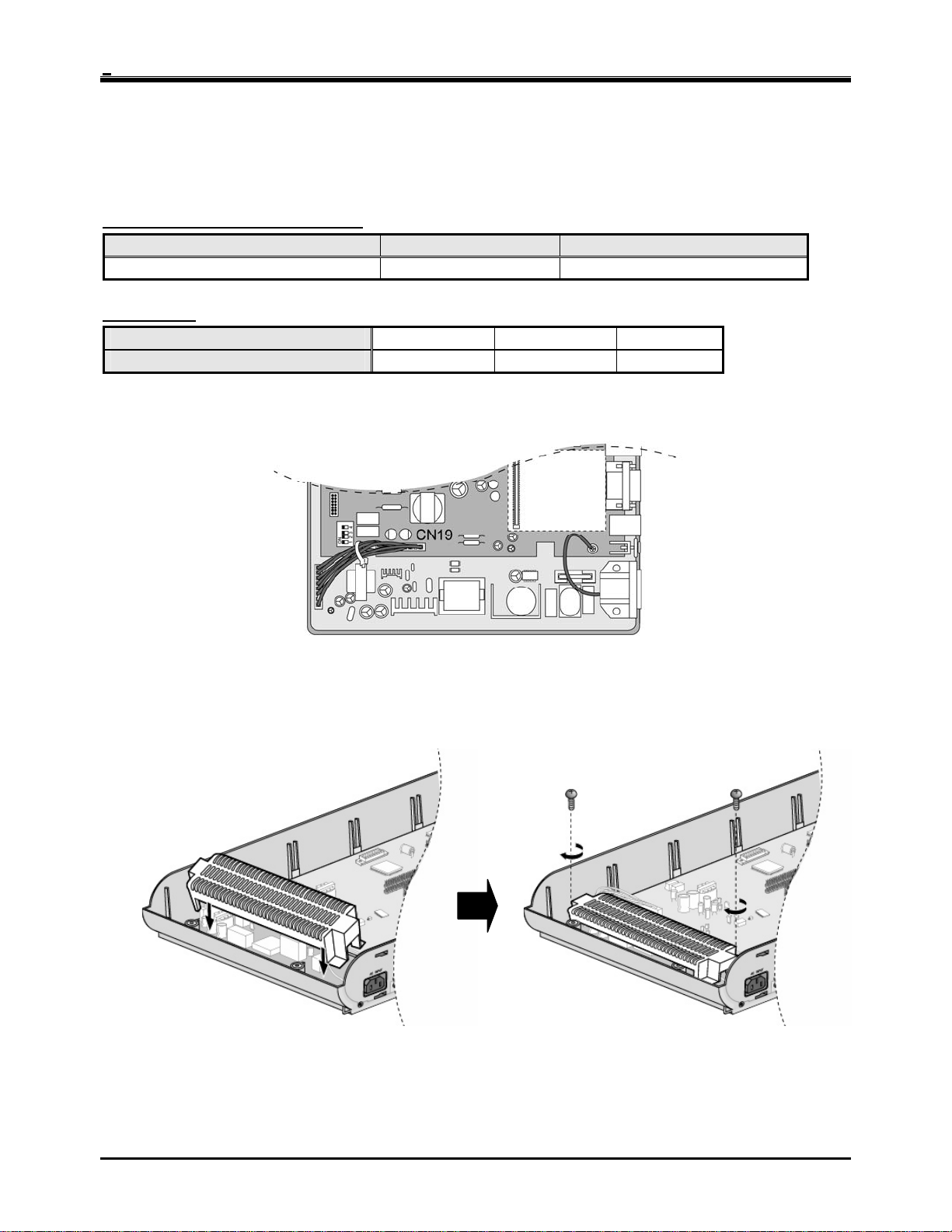

2.2.6 Power Sup ply Unit (PSU) installation

Before installation, make sure that the KSU not plugged into an outlet. The PSU is located at the left-most area of the

KSU, and is capable of providing three kinds of power sources to MBUB through the 7PIN connector, CN19 (refer to

the following table).

The AC Input Voltage and Fuse Rating

RANGE OF INPUT VOLTAGE CONNECT TO FUSE RATINGS

207V AC - 253V AC CN19 on the MBUB 1.25A @250V

PSU Capacity

1. To secure the wire of PSU as shown in Figure 2.2.6a, tie the wire with the cable tie provided.

2. Place the PSU cover on the PSU as shown in Figure 2.2.6b. Then turn the screws clockwise to tighten, and secure.

PSU TYPE +5V DC -5V DC +30V DC

PSU (SMPS)

3.0A 100mA 1.9A

Figure 2.2.6a PSU Installation

Figure 2.2.6b PSU Installation

15

Page 20

IP LDK-20 Installation Manual KSU Installation

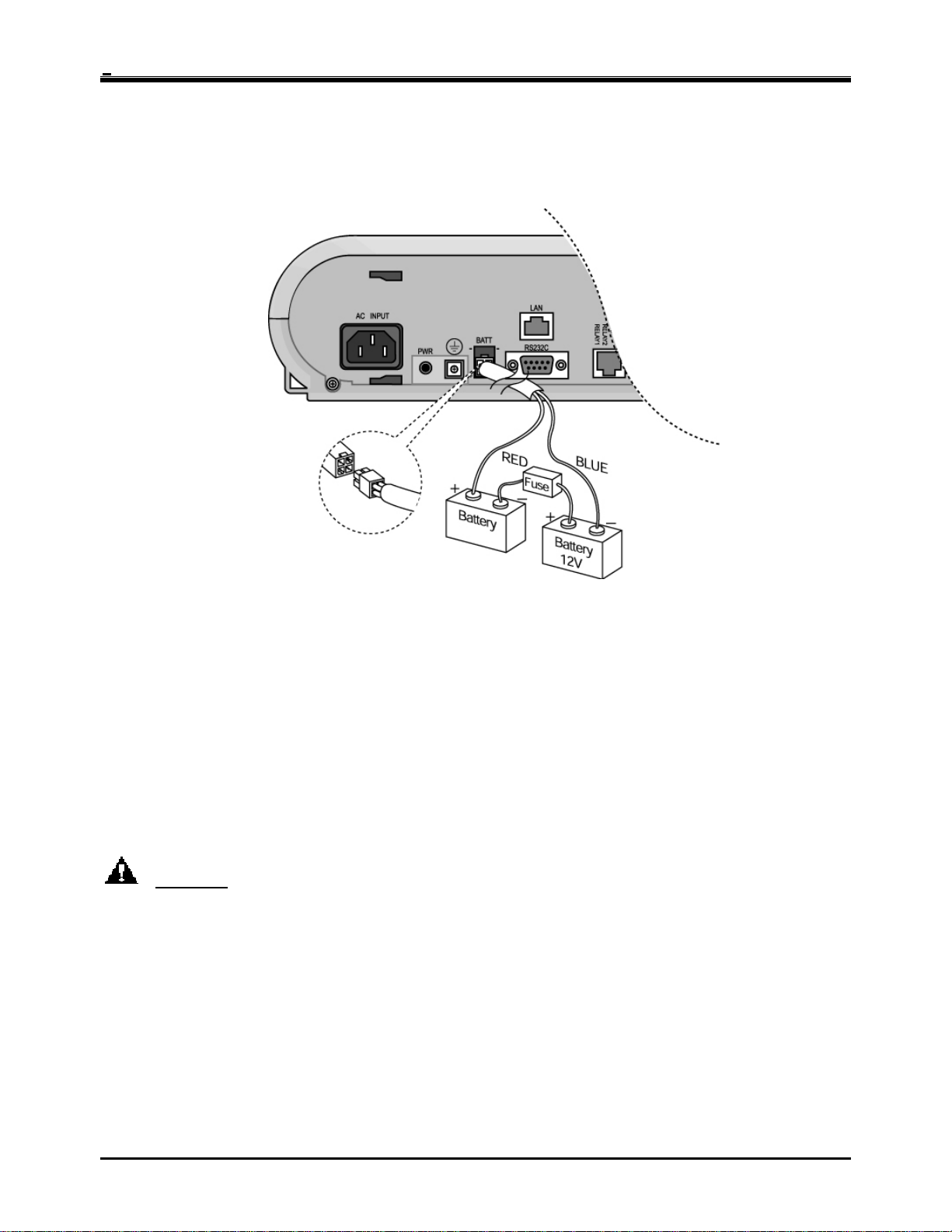

2.2.7 External backup batteries installation

In case of power failure, the external backup batteries automatically maintain uninterrupted power for the IP LDK-20

system. The external batteries must provide 24 Volts DC. This is generally accomplished by connecting two 12 Volt

batteries in a series arrangement.

Figure 2.2.7 External Back Up Battery Installation

※

Note : The cable for connecting the batter y is supp lied with the KSU .

Operation of the batteries is controlled by the MBUB. This IP LDK-20 MBUB will provide charging current to the

batteries during normal AC power operation at a maximum of about 100mA. During battery operation, the battery

operation of MBUB will be stopped if the AC power re-applied or the battery voltage is too low to maintain full-system

operation.

The external batteries can maintain system operation as needed depending on several elements such as, battery

charge status, condition and capacity of the batteries, and system configuration (number of station ports).

CAUTION

• It is recommended to use a fuse (5A @250V) between battery and system.

• Recommended battery capacity is 24V/10AH MF battery; the IP LDK-20 system should operate more than 3

hours with batteries that are in good condition.

• Carefully check the battery polarity with cable colors (RED and BLUE) when connecting the battery to the

system.

• Make sure that you do not short-out the external backup batteries or cables.

• There is a danger of explosion if external backup batteries are incorrectly replaced. Replace only with the

same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

16

Page 21

IP LDK-20 Installation Manual KSU Installation

2.2.8 KSU mounting

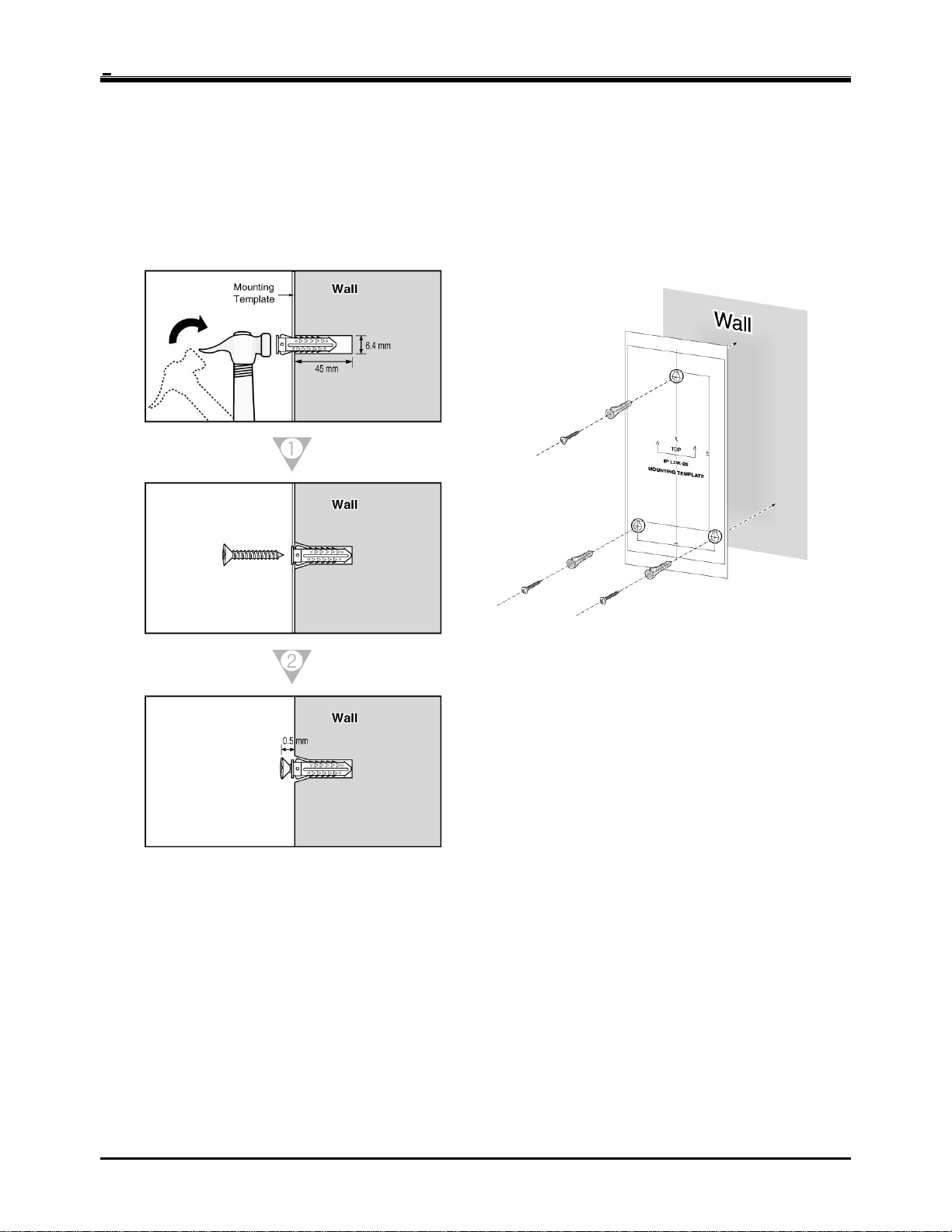

2.2.8.1 Wall mounting

1. Install 3 anchor plugs in the wall using the mounting template included for accurate placement (Figure 2.2.8.1a).

2. Attach the mounting template with the included 3 screws.

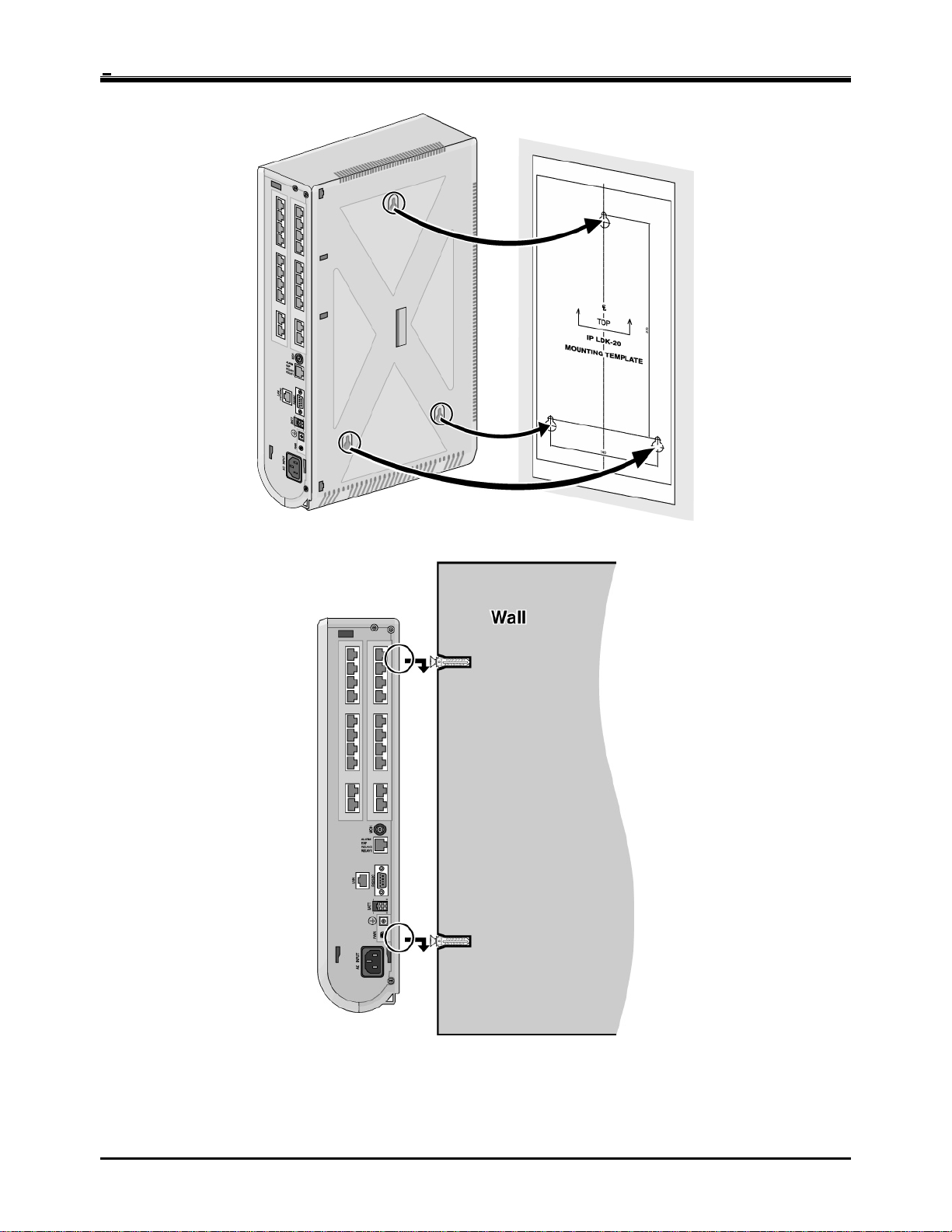

3. Hook the KSU onto the screws, making sure that the system slides down securely (Figure 2.2.8.1b).

Figure 2.2.8.1a Mounting Template

17

Page 22

IP LDK-20 Installation Manual KSU Installation

Figure 2.2.8.1b KSU Wall Mounting

※ Note : Be careful not to drop the KSU.

18

Page 23

IP LDK-20 Installation Manual KSU Installation

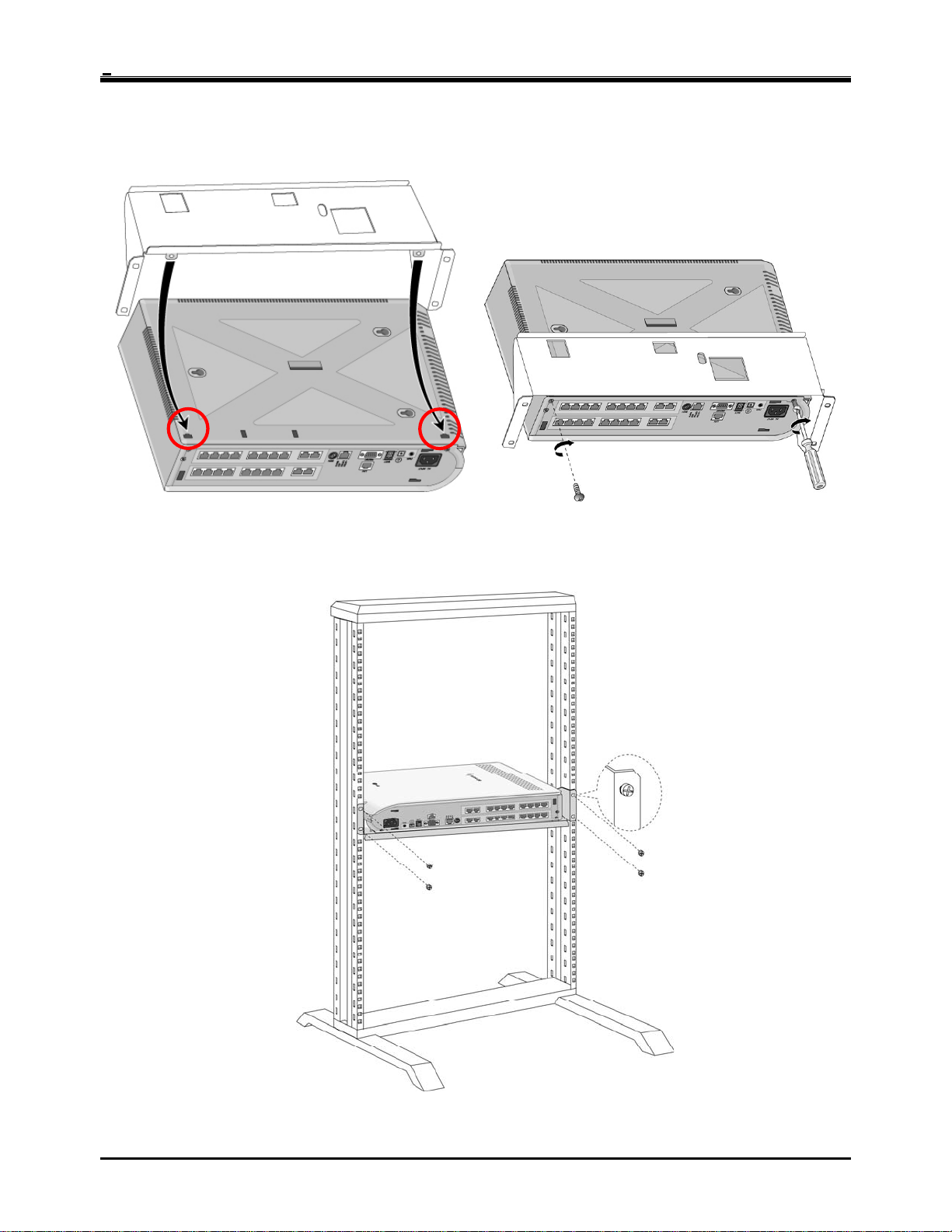

2.2.8.2 Rack mounting

1. Attach the rack bracket to the bottom of the IP LDK-20 system as shown in Figure 2.2.8.2a, and attach it to the

system securely by tightening the screws clockwise.

Figure 2.2.8.2a Rack Bracket

2. To attach the IP LDK-20 system to the rack, affix the bracket with the 4 screws provided (Figure 2.2.8.2b).

Figure 2.2.8.2b KSU Rack Mounting

19

Page 24

IP LDK-20 Installation Manual Board Installation

SECTION 3. BOARD INSTALLATION

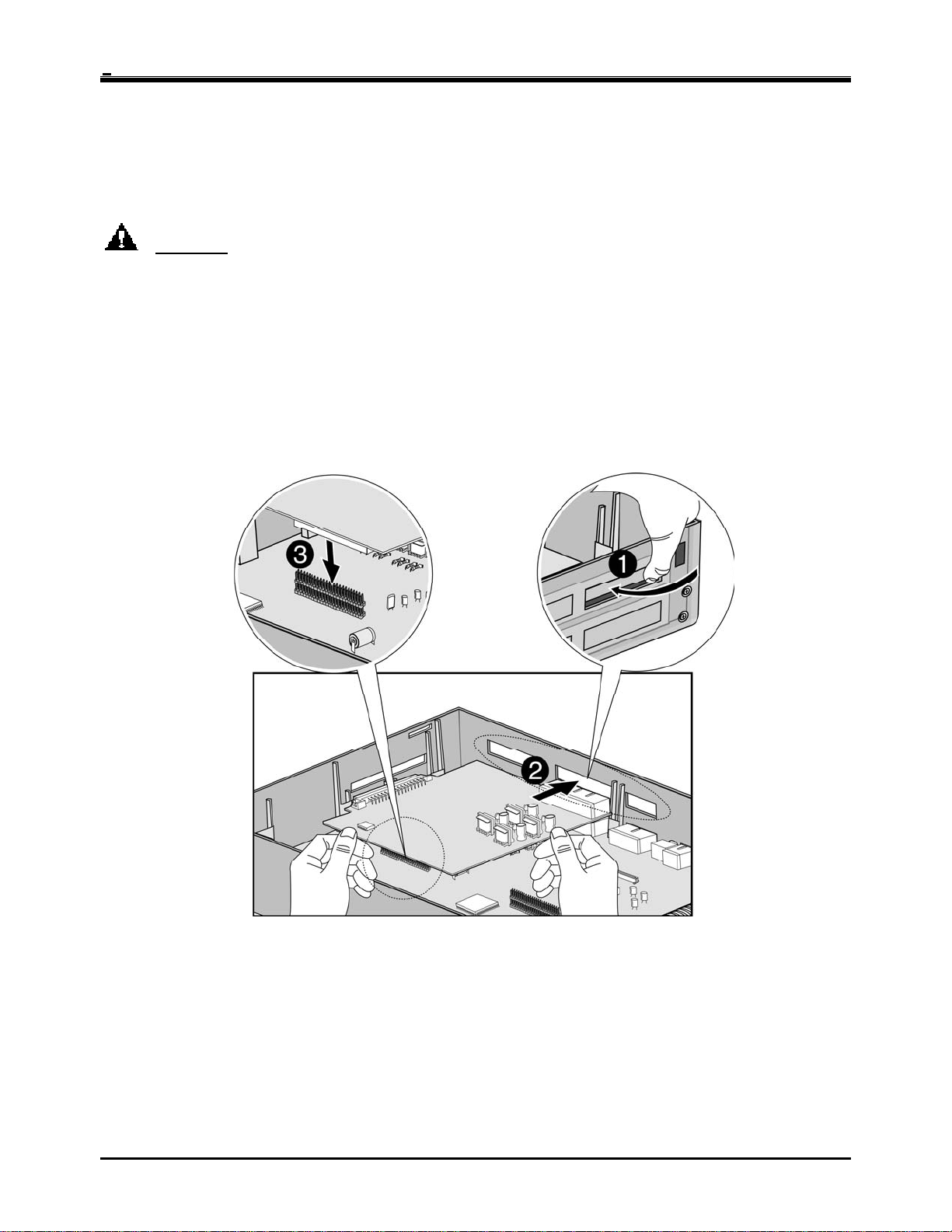

3.1 Installation of the Boards

Prior to Board Installation, the following should be considered:

CAUTION

• Power must be turned OFF.

• To protect the system from static electricity, do not touch the boards. To discharge static, touch a grounded

object, or wear a grounding strap.

• Insert boards carefully to avoid bending connector pins (male pins on MBUB).

To install the board, perform the following Steps:

1. Before inserting the board, remove the dummy, shown #1 in Figure 3.1.

2. Holding the board as shown in #2 of the diagram, insert the board in the direction of the arrow carefully so that the

board securely engages with the connector on the main board (#3).

Figure 3.1 Board Installation

20

Page 25

IP LDK-20 Installation Manual Board Installation

3.2 MBUB (Main Board Unit)

Description

The MBUB controls communication between the peripheral interfaces, supervises all resources in the system,

controls the gain adjustment of the PCM signal, generates the system tones, and manages system call processing.

The MBUB (Figure 3.2a) incorporates the main control of the system, and is composed of the main microprocessor

(RAM and ROM), the PCM management (the CO/Extension interface circuits), and miscellaneous functional circuits.

Figure 3.2a MBUB

Figure 3.2a shows the MBUB, which provides Basic Rate Interface (BRI) circuits, Digital keyset and SLT interface

circuits, DTMF receivers, phase locked loop circuit (for 32Mhz clock synchronization), Ring Generation Unit, two

external relay contacts, one alarm detection circuit, one external PAGE port, internal/external MOH circuit, the

peripheral device decoding circuit, the master clock generation circuit, the RS-232C interface circuit, the system

battery backup circuit, as well as the system’s PCM voice processing circuit that has a flash memory for PCM tone

generation and PCM Gain control.

21

Page 26

IP LDK-20 Installation Manual Board Installation

Figure 3.2b Connection

The MBUB is installed in the KSU and provides various kinds of connectors and RJ45 modular jacks for the

connection of peripheral boards and miscellaneous functions (refer to the following Table).

Connector/Modular Jack/Switch Functions

SWITCH/CONNECTOR FUNCTIONS REMARK

CN5 CO board (LCOB, STIB, CBIB) installation

CN6 Extension board (DTIB, SLIB) installation

CN7 & CN8 MODU installation

CN9 VMIBE/AAFBE installation

CN11 LANU installation

CN16 JTAG Port for emulator

CN18 System Backup Battery connection

CN19 PSU connection (+5V, -5V, +30V)

CN20 External GND Terminal

CN22 RS-232C interface

MJ1 2 ISDN BRIs connection (Selectable S/T)

MJ2 4DKTs

MJ3 2DKT/SLTs connection and 2SLTs connection

MJ4 External Relays, External Paging, and Alarm Sensor

PJ1 (Red) External MOH connection

SW1 Lithium Battery ON/OFF switch for Memory and RTC Database back-up

SW2 System reset button

SW3 4 poles DIP switch for software usage

SW4 1 pole DIP switch for JTAG reset Reserved

22

Page 27

IP LDK-20 Installation Manual Board Installation

)

R

R

3.2.1 Modular Jack(MJ1~MJ3) Pin Assignment

3.2.1.1 MBUB MJ1(CO)

T Mode

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RJ45

R

R

1 2

1

2

3

TX+

6

TX

-

4

+

5

RX

-

Max. 1000 meters

3

+

6

-

4

RX+

5

RX

-

Interface

T

ON

OFF

1 2

RJ45 type jack

S

BRI Port2

Only T

RJ45 type jack

Figure 3.2.1.1a T Mode(Basic BRI Line Connector and Terminating Resistors)

4

3

SW5

ON

OFF

SW7

OFF : T mode

interface

ON

OFF

ON : Termination

1,2,7,8 Reserved

3 TX+ Transmit Data

4 RX+ Receive Data

5 RX- Receive Data

6 TX- Transmit Data

NT1(NT

RX+

RX

TX+

TX

RX+

RX

TX+

TX

3

6

4

5

NT1(NT

3

6

4

5

BOX

-

BOX)

-

From/to PX

From/to PX

23

Page 28

IP LDK-20 Installation Manual Board Installation

)

y

R

R

S Mode

SW5 and SW6 : 1,2 Pin Setting(The Default = All On Position)

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RJ45

BRI Port1 Onl

interface

S

ON

1 2

RJ45 type jack

T

S

CN21

Figure 3.2.1.1b S Mode(Basic BRI Line Connector and Terminating Resistors)

3 4

SW5

ON

ON : S mode

1 2

SW7

RX+

3

RX

6

TX+

4

TX

5

Max. 1000 meters

1,2,7,8 Reserved

3 RX+ Receive Data

4 TX+ Transmit Data

5 TX- Transmit Data

6 RX- Receive Data

TE1(or TA

TX+

-

-

TX

RX+

RX

3

-

6

4

5

-

LINE NO RJ45 TYPE JACK

Line 1 MJ1 SW5 Termination Open

Line 2 MJ1 SW6 Termination Open

T or S Switch Setting of Basic BRI

LINE

NO

Line 1

Line 2 T Only

※ NOTE

- SW5(PIN3, 4) : -40V POWER FEEDING. P

- SW7: THE MODE CHANGE OF THE BRI TRANSCEIVER.

MODE

S ON ON

T OFF OFF

SW5

PIN 3, 4

SWITCH AND CONNECTOR

SW7 CN21

TERMINATING RESI ST OR S

SWITCH PIN1, 2 ON PIN1, 2 OFF

REMARK

T

S

T

S

Default

REMARK

24

Page 29

IP LDK-20 Installation Manual Board Installation

- CN21: SET FOUR 2PIN JUMPERS AS SHOWN IN THE ABOVE TABLE ACCORDING TO EACH MODE.

3.2.1.2 MBUB MJ2 & MJ3(Extension)

MBUB MJ2 (EXTENSION)

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ45

1,2,3 Reserved

4,5 DKT-R, DKT-T

6,7,8 Reserved

MBUB MJ3-1, 2 (EXTENSION)

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ45

1,2 DKT-R, DKT-T

3 Reserved

4,5 SLT-R, SLT-T

6,7,8 Reserved

CAUTION

When installing DKT or SLT on Hybrid Ports (MJ3-1,2), keep the above pin assignment. Otherwise, the DKT or

SLT will not operate normally.

MBUB MJ3-3, 4 (EXTENSION)

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ45

1,2,3 Reserved

4,5 SLT-R, SLT-T

6,7,8 Reserved

TERMINAL DKT

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ11

1-2 RESERVED

3 TIP

4 RING

5-6 RESERVED

TERMINAL SLT

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ11

1-2 RESERVED

3 TIP

4 RING

25

Page 30

IP LDK-20 Installation Manual Board Installation

5-6 RESERVED

3.2.1.3 MJ4 Pin Assignment

MBUB

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ45

1,2 Relay1-R, Relay1-T

3,4 Relay2-R, Relay2-T

5,6 EXT_PAGE-R, EXT_PAGE-T

7,8 Alarm-R, Alarm-T

3.2.1.4 SW3 Functions and LED Indications

SWITCH FUNCTION OFF ON(DEFAULT)

3-1 Administration Programming Access Disable Enable

3-2 Command/Event Trace (The purpose of testing software) Enable Disable

3-3 SMDI (Simplified Message Desk Control –Voice Mail ) SMDI ON SMDI OFF

3-4 Database default on power up Disable Enable

Before programming the system, switch 3-4 should be placed in the ON position and power cycled-OFF and –ON to

initialize the system database to default. Once the database has been initialized, switch 3-4 should be placed in the

OFF position to protect the database.

After putting the lithium battery switch (SW1) into ON to protect RAM/RTC data, install the option boards to the MBUB.

CAUTION

• The DIP switch, SW1 should be turned ON to protect system data in case of a power failure.

• The system will not function properly if the battery is incorrectly replaced. Replace only with the same or

equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer

instructions.

• The 4th pole (switch 4) of SW3 should be OFF to protect the features being programmed in Admin

programming after the system power up and initialization.

LED INDICATIONS

LED MEANING

LD1 (RED) Periodic toggle – ON: 2 sec., OFF: 100m sec.

LD2 (RED) Periodic toggle – ON: 2 sec., OFF: 100m sec.

LD3 (RED) Timer, Flashing every 100msec

LD4 (RED) LCD active updating, Flashing every 300msec

LD5 (GREEN) The status of PLL for 32Mhz clock synchronization (ON : ACT, OFF : INACT)

LD6 (RED) The status of Main SYSTEM Power

STATUS

LINE NO. REMARK

IDLE 1 BRI

IDLE 2 BRI

26

LD7

LD8

LED

RED ERROR

GREEN IN-USE

RED ERROR

ON OFF

Page 31

IP LDK-20 Installation Manual Board Installation

GREEN IN-USE

3.2.1.5 CN22 Pin assignment

MBUB

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RS-232C

PC

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RS-232C

※ NOTE : The MBUB does not support hardware flow control.

1 RESERVED

2 TD Transmitted Data

3 RD Received Data

4 DSR Not used

5 SG Signal Ground

6 DTR Not used

7 CTS Not used

8 RTS Not used

9 RESERVED

1 RESERVED

2 RD Received Data

3 TD Transmitted Data

4 DTR Not used

5 SG Signal Ground

6 DSR Not used

7 RTS Not used

8 CTS Not used

9 RESERVED

27

Page 32

IP LDK-20 Installation Manual Board Installation

28

Page 33

IP LDK-20 Installation Manual Board Installation

3.3 Installation of the CO Line Board

BOARD PORT

LCOB

2 ports

(4 LCO)

CONNECTOR

TYPE

RJ45 Loop Start CO Line Interface 2 wire

DESCRIPTION CABLE REMARK

STIB

CBIB

2 ports

(2 BRI)

2 ports

( 1 BRI+2 LCO)

RJ45 ISDN Basic Rate Interface (2B+D) 4 wire

RJ45

ISDN Basic Rate Interface (2B+D)

+ Loop Start CO Line Interface

4 wire (Port 1)

2 wire (Port 2)

Switched

T or S

T mode

only.

3.3.1 LCOB (CID Loop Start CO line Interface Board)

Description

The LCOB can be installed on the LCOB/STIB/CBIB connector, and provides 4 CO/PBX Loop Start CO Line

interfaces that support Pulse/DTMF signaling. Each Interface contains ring and loop current detection circuits, A/D

and D/A conversions, and pulse signaling circuitry.

LCOB can be optionally equipped with add-on boards: CPCU4 (FSK CID, Polarity Reversal & Call Progress Tone

detection Unit 4) to detect FSK signal for the incoming Caller-ID, polarity reversal and call progress tone; PRCPTU4

(Polarity Reversal & Call Progress Tone detection Unit 4) to monitor polarity reversal and call progress tone; or PRU4

(Polarity Reversal detection Unit 4) to monitor polarity reversal.

※ NOTE

The PRU4, PRCPTU4 and CPCU4 can not be mounted on the LCOB at the same time. Select the

appropriate board for your application to install and use.

PRU4

PRCPTU4

CPCU4

Figure 3.3.1 LCOB

29

Page 34

IP LDK-20 Installation Manual Board Installation

3.3.1.1 Pin Assignment

LCOB

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ45

CONNECTOR FUNCTIONS

CONNECTOR FUNCTION REMARK

CN2 and CN3 PRCPTU4 or PRU4 connection

CN1, CN2 and CN3 CPCU4 connection

MJ1 2 ports RJ45 type CO line connection.

1,2 CO-R, CO-T

3 Reserved

4,5 CO-R, CO-T

6,7,8 Reserved

3.3.1.2 Add-On Boards

PRU4 (Polarity Reversal detection Unit)

Description

The PRU4 can be optionally mounted on LCOB, and provides Polarity Reversal detection for call metering.

Figure 3.3.1.2a PRU4

30

Page 35

IP LDK-20 Installation Manual Board Installation

PRCPTU4 (PR and CPT detection Unit)

Description

The PRCPTU4 can be optionally mounted on LCOB, and provides four polarity reversal detection for call metering,

four call progress tone detection to support ACNR feature (Automatic Called Number Redial).

Figure 3.3.1.2b PRCPTU4

CPCU4 (FSK CID, PR and CPT detection Unit)

Description

The CPCU4 can be optionally mounted on LCOB, and provides 4 Polarity Reversal detection for call metering, 4 call

progress tone detection to support the ACNR feature (Auto Called Number Redial) and four FSK CID signal detection.

Figure 3.3.1.2c CPCU4

31

Page 36

IP LDK-20 Installation Manual Board Installation

3.3.2 STIB (Basic Rate Interface Board: Selectable S/T interface)

Description

STIB should be installed on the LCOB/STIB/CBIB connector, and supports T-interface or S-interface. The 1st BRI port

can be operated to T-mode and S-mode and the 2nd port can only be set to T-mode.

Figure 3.3.2 STIB

S/T Interface selection on BRI1 (Port 1): Default = T Interface

- SW2 : Default = all OFF position

- SW4 : Default = 1, 2 pins ON position and 3, 4 pins OFF position

BRI2(Port 2): Default = T Interface only.

- SW1: Default = ON position

32

Page 37

IP LDK-20 Installation Manual Board Installation

)

R

R

3.3.2.1 Pin assignment

T MODE

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RJ45

R

R

1 2

1

2

3

TX+

6

TX

4

5

RX

Max. 1000 meters

3

6

4

RX+

5

RX

Interface

T

ON

OFF

1 2

RJ45 type jack

S

STIB Port2

Only T

Interface

RJ45 type jack

Figure 3.3.2.1a T Mode(Basic STIBI Line Connector and Terminating Resistors)

4

3

SW4

ON

OFF

SW2

OFF : T mode

ON

OFF

ON : Termination

1,2,7,8 Reserved

3 TX+ Transmit Data

4 RX+ Receive Data

5 RX- Receive Data

6 TX- Transmit Data

NT1(NT

RX+

+

-

+

-

-

RX

TX+

TX

RX+

RX

TX+

TX

3

6

4

5

NT1(NT

3

6

4

5

BOX

-

BOX)

-

From/to PX

From/to PX

33

Page 38

IP LDK-20 Installation Manual Board Installation

)

y

R

R

S MODE

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RJ45

Figure 3.3.2.1b S Mode(Basic STIBI Line Connector and Terminating Resistors)

LED INDICATIONS

STIB Port1 Onl

Interface

S

ON

1 2

RJ45 type jack

T

S

CN1

3 4

SW4

ON

ON : S mode

3

6

4

5

1 2

SW2

1,2,7,8 Reserved

3 RX+ Receive Data

4 TX+ Transmit Data

5 TX- Transmit Data

6 RX- Receive Data

RX+

RX

-

TX+

TX

-

Max. 1000 meters

TX+

TX

RX+

RX

TE1(or TA

3

6

4

5

-

LED1

LED2

LED

RED ERROR

GREEN IN-USE

RED ERROR

GREEN IN-USE

ON OFF

STATUS

LINE NO. REMARK

IDLE 1 STIB

IDLE 2 STIB

34

Page 39

IP LDK-20 Installation Manual Board Installation

3.3.2.2 Line Connector and Terminating Resistors

SW 1 AND SW4’S 1, 2 PIN SETTING : DEFAULT = ALL ON POSITION

LINE NO RJ45 TYPE JACK

Line 1 MJ1 SW4 Termination Open

Line 2 MJ1 SW1 Termination Open

T OR S SWITCH SET T IN G

LINE

NO

Line 1

Line 2 T Only

MODE

S ON ON

T OFF OFF

SWITCH AND CONNECTOR

SW4

PIN 3, 4

SW2 CN1

TERMINATING RESI ST OR S

SWITCH PIN1, 2 ON PIN3, 4 OFF

REMARK

T

S

T

S

Default

REMARK

※NOTE

- SW4(Pin 3, 4 : -40V Power Feeding.

- SW2: The mode Change of the BRI transceiver.

- CN1: Set four 2pin jumpers like the above figure according to each mode.

35

Page 40

IP LDK-20 Installation Manual Board Installation

3.3.3 CBIB (CID Loop Start CO line + Basic Rate Interface Board)

Description

The CBIB can be installed on the LCOB/STIB/CBIB connector, and provides 2 CO/PBX Loop Start CO Line interfaces

that support pulse/DTMF signal and ISDN BRI T-mode interface. CO Interface contains ring and loop current

detection circuits, A/D and D/A conversions, and pulse signaling circuit.

The CO port of the CBIB can be optionally equipped with add-on boards (Figure 3.3.3): CPCU2 (FSK CID, Polarity

Reversal & Call Progress Tone detection Unit 2) to detect FSK signal for the incoming Caller-ID, polarity reversal and

call progress tone; PRCPTU2 (Polarity Reversal & Call Progress Tone detection Unit 2) to monitor polarity reversal

and call progress tone; or PRU2 (Polarity Reversal detection Unit 2) to monitor polarity reversal.

Figure 3.3.3 CBIB

※NOTE

- SW1: The default is ON position.

- The PRU2, the PRCPTU2 and the CPCU2 can not be mounted on the CBIB at the same time. Select the

board that is appropriate for your application to install and use.

36

Page 41

IP LDK-20 Installation Manual Board Installation

3.3.3.1 Pin Assignment

CBIB 1’ST PORT FOR BRI T-MODE

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RJ45

CBIB 2’ND PORT FOR LCO

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ45

VARIOUS CONNECTORS FUNCTIONS

1,2,7,8 Reserved

3 TX+ Transmit Data

4 RX+ Receive Data

5 RX- Receive Data

6 TX- Transmit Data

1,2 CO-R, CO-T

3 Reserved

4,5 CO-R, CO-T

6,7,8 Reserved

CONNECTOR FUNCTION REMARK

CN2 and CN3 PRCPTU2 or PRU2 connection

CN1, CN2 and CN3 CPCU2 connection

MJ1 2 ports RJ45 type CO line connection.

37

Page 42

IP LDK-20 Installation Manual Board Installation

3.3.3.2 Add-On Boards

PRU2 (Polarity Reversal detection Unit)

Description

The PRU2 can be optionally mounted on CBIB, and provides Polarity Reversal detection for call metering. It also

provides four on-hook connection paths for SMS.

PRCPTU2 (PR and CPT detection Unit)

Description

The PRCPTU2 can be optionally mounted on CBIB, and provides four polarity reversal detection for call metering,

four call progress tone detection to support the ACNR feature (Automatic Called Number Redial). It also provides four

on-hook connection paths for SMS.

CPCU2 (FSK CID, PR and CPT detection Unit)

Description

The CPCU2 can be optionally mounted on CBIB, and provides four polarity reversal detection units for call metering,

four call progress tone detection to support the ACNR feature (Auto Called Number Redial), and four FSK CID signal

detection. It also provides four on-hook connection paths for SMS.

Figure 3.3.3.2 CPCU4

38

Page 43

IP LDK-20 Installation Manual Board Installation

3.4 Installation of the Extension Board

BOARD PORT CONNECTOR TYPE REMARK

DTIB4 4 DKT ports RJ45 Digital Terminal Interface : 4 ports

DTIB8 8 DKT ports RJ45 Digital Terminal Interface : 8 ports

SLIB4 4 SLT ports RJ45 Single line telephone Interface : 4 ports

SLIB8 8 SLT ports RJ45 Single line telephone Interface : 8 ports

3.4.1 DTIB4 (Digital Terminal Interface Board)

Description

DTIB4 can be installed on the SLIB/DTIB connector, and provides 4 Digital Keyset ports. It also provides 2-wire

connections for Digital Keysets. It has a module connector, MJ1, which is used to connect Digital Keyset lines to the

DTIB4.

Figure 3.4.1 DTIB4

3.4.1.1 Pin assignment

DTIB4

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RJ45

DKT

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ11

1,2,3,6,7,8 Reserved

4 DKT_R RING

5 DKT_T TIP

1-2 RESERVED

3 TIP

4 RING

5-6 RESERVED

39

Page 44

IP LDK-20 Installation Manual Board Installation

3.4.2 DTIB8 (Digital Terminal Interface Board)

Description

DTIB8 can be installed on the SLIB/DTIB connector, and provides 8 Digital Keyset ports. It also provides 2-wire

connections to Digital Keysets. It has module connectors, MJ1 and MJ2, that are used to connect Digital Keyset lines

to the DTIB8.

Figure 3.4.2 DTIB8

3.4.2.1 Pin assignment

DTIB8

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RJ45

DKT

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ11

1,2,3,6,7,8 Reserved

4 DKT_R RING

5 DKT_T TIP

1-2 RESERVED

3 TIP

4 RING

5-6 RESERVED

40

Page 45

IP LDK-20 Installation Manual Board Installation

3.4.3 SLIB4 (Single Line Interface Board)

Description

SLIB4 can be installed on the SLIB/DTIB connector, and provides 4 SLT ports, and 2 DTMF receivers. The SLIB4 and

SLT are connected with a RJ45 Modular Jack, MJ3.

Figure 3.4.3 SLIB4

3.4.3.1 Pin assignment

SLIB4

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ45

SLT

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ11

1,2,3,6,7,8 Reserved

4 SLT_RING

5 SLT-TIP

1-2 RESERVED

3 TIP

4 RING

5-6 RESERVED

41

Page 46

IP LDK-20 Installation Manual Board Installation

3.4.4 SLIB8 (Single Line Interface Board)

Description

SLIB8 can be installed the SLIB/DTIB connector, and provides the 8 SLT ports and 2 DTMF receivers. The SLIB8 and

SLT are connected with a RJ45 Modular Jack, MJ2 & MJ3.

Figure 3.4.4 SLIB8

3.4.4.1 Pin assignment

SLIB8

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ45

SLT

CONNECTOR PIN NUMBER NO SIGNAL NAME

RJ11

1,2,3,6,7,8 Reserved

4 SLT_RING

5 SLT-TIP

1-2 RESERVED

3 TIP

4 RING

5-6 RESERVED

42

Page 47

IP LDK-20 Installation Manual Board Installation

3.5 Other Board Installations

3.5.1 VMIBE (Voice Mail Interface Board Enhanced)

Description

The VMIBE can be installed on the VMIB/AAFB connector, and provides system announcement, ACD/UCD

announcement, and User Greeting.

Figure 3.5.1 VMIBE

ITEM RECORD/PLAY MOH

Channel 3 channels 1 channel

Max record time:

System/time stamp

User record time

Max. Number of User voice message 800 EA

※ NOTE

- User Greeting is not lost by system power OFF or reset because the message is stored in FLASH memory.

- MBUB SW3-4 controls the protection of recorded messages.

- LD1 gets turned on when any RECORD/PLAY channel is activated.

200 Min

28 Min

172 Min

60 Sec.

43

Page 48

IP LDK-20 Installation Manual Board Installation

3.5.2 AAFBE(Auto Attendant Function Board Enhanced)

Description

The AAFBE can be installed on the VMIB/AAFB connector, and provides system announcement and ACD/UCD

announcement.

Figure 3.5.2 AAFBE

ITEM RECORD/PLAY MOH

Channel 3 channels

Max record time:

System/time stamp

User record time

※ NOTE

- LD1 gets turned on when any RECORD/PLAY channel is activated.

28 Min

28 Min

Not Possible

-

-

44

Page 49

IP LDK-20 Installation Manual Board Installation

3.5.3 LANU (LAN interface Unit)

Description

LANU should be installed on the LANU connector, and provides 1 LAN port of 10Base-T networking. RJ45 Modular

Jack, MJ1, is used to interface with the Wide Area Network (WAN) or PC, and has two LEDs that indicate the

operational state of the LAN port.

Figure 3.5.3 LANU

3.5.3.1 Pin Assignment

LANU

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RJ45

PC

CONNECTOR PIN NUMBER NO SIGNAL NAME FUNCTION

RJ45

THE LED INDICATION OF MJ1

LED MEANING

LED1 (Green) OFF: No Link ON: Link, Toggle: Data Transfer

LED2 (Orange) OFF: Link and activity at 10MBps ON: Link and activity at 100MBps

4,5,7,8 RESERVED

1 TX+ Transmit Data

2 TX- Transmit Data

3 RX- Receive Data

6 RX+ Receive Data

4,5,7,8 RESERVED

1 TX+ Transmit Data

2 TX- Transmit Data

3 RX- Receive Data

6 RX+ Receive Data

45

Page 50

IP LDK-20 Installation Manual Board Installation

3.5.4 MODU (MODEM function Unit)

Description

MODU should be installed on the MODU connectors, and provides an analog modem connection. It supports Bell,

ITU-T, V.34, V.32BIS, V.90 Protocol at 300bps, up to 33Kbps speed rate, and automatic rate negotiation.

Figure 3.5.4 MODU

46

Page 51

IP LDK-20 Installation Manual Board Installation

SECTION 4. EXPANSION MODULE INSTALLATION

IPLDK-20 provides three kinds of expansion modules, VOIM, DTIM and SLIM.

MODULE PORT

VOIM 1 port RJ45 Voice Over Internet Protocol interface 4 wire

SLIM 4 ports RJ45 Single Line Telephone interface: 8 SLT 4 wire 2SLT/port

DTIM 4 ports RJ45 Digital Terminal interface: 8 DKT 4 wire 2 DKT/port

4.1 Unpacking

Open the box and verify the items shown in Figure 4.1 are included:

VOIM

DTIM/SLIM

CONNECTOR

TYPE

Module Screw

Module Screw Fuse

Figure 4.1 Unpacking

DESCRIPTION CABLE REMARK

Power Cord

Battery Cable

47

Page 52

IP LDK-20 Installation Manual Board Installation

4.2 Opening and closing the front cover

4.2.1 Opening the front cover

1. Turn the screw counter-clockwise to loosen as shown in Figure 4.2.1.

2. Lift the front cover in the direction of the arrow as shown:

.

Figure 4.2.1 Opening the front cover

48

Page 53

IP LDK-20 Installation Manual Board Installation

4.2.2 Closing the front cover

1. Insert the front cover into the slot on a module as show in Figure 4.2.2.

2. Then put the front cover down on a module in the direction of the arrow, as shown.

3. Turn the screws clockwise to tighten, as in the Figure.

Figure 4.2.2 Closing the front cover

※

NOTE

For safety reasons, close the front cover and tighten the screws prior to operating the IP LDK-20 System.

49

Page 54

IP LDK-20 Installation Manual Board Installation

4.3 Opening and closing the front cover

4.3.1 Connecting Expansion Module to KSU

1. Insert the expansion module into the slot of basic KSU as show in Figure 4.3.1.

2. Turn the screws clockwise to tighten, as in the Figure.

Figure 4.3.1 Connecting an expansion module

50

Page 55

IP LDK-20 Installation Manual Board Installation

4.3.2 Wall mounting

The KSU with an expansion module is mounted on the wall in the same way with basic KSU and an expansion

module itself is not mounted on the wall as shown in Figure 4.3.2.

Figure 4.3.2 Wall mounting of KSU with an expansion module

※ Note : Be careful not to drop the KSU.

51

Page 56

IP LDK-20 Installation Manual Board Installation

4.3.3 Rack Mounting

1. Attach the rack bracket to the bottom of an expansion module as shown in Figure 4.3.3.1.

Figure 4.3.3.1 Rack bracket

2. Attach it to an module securely by tightening the screws clockwise, as in the Figure.

Figure 4.3.3.2 Tightening Rack bracket

52

Page 57

IP LDK-20 Installation Manual Board Installation

3. To attach an expansion module to the rack, affix the bracket with the 4 screws provided (Figure 4.3.3.4).

4. Connect an expansion module with the basic KSU by a flat cable packed in the package type2, as in the Figure.

Figure 4.3.3.4 Module Rack Mounting

※ Note: The flat cable is supplied with expansion module package type2.

Package type1 for wall mounting doesn’t include flat cable.

53

Page 58

IP LDK-20 Installation Manual Board Installation

4.4 External backup batteries connection

In case of power failure, the external backup batteries automatically maintain uninterrupted power for the IP LDK-20

system. The external batteries must provide 24 Volts DC. This is generally accomplished by connecting two 12 Volt

batteries in a series arrangement.

Figure 4.4 External Back Up Battery Installation

※

Note : The cable for connecting the batter y is supp lied with an expan sion mo dule.

Backup batteries for the basic KSU a re used in parallel with an expansion module.

The IP LDK-20 MBUB will provide charging current to the batteries during normal AC power operation at a maximum

of about 100mA. During battery operation, the battery operation of MBUB and an Expansion Module will be stopped if

the AC power re-applied or the battery voltage is too low to maintain full-system operation.

The external batteries can maintain system operation as needed depending on several elements such as, battery

charge status, condition and capacity of the batteries, and system configuration (number of station ports).

CAUTION

• There is not the battery charging circuit in an expansion module.

• It is recommended to use a fuse (5A @250V) between battery and system.

• Recommended battery capacity is 24V/10AH MF battery; the IP LDK-20 system should operate more than 3

hours with batteries that are in good condition.

• Carefully check the battery polarity with cable colors (RED and BLUE) when connecting the battery to the

system.

• Make sure that you do not short-out the external backup batteries or cables.

• There is a danger of explosion if external backup batteries are incorrectly replaced. Replace only with the

same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

54

Page 59

IP LDK-20 Installation Manual Board Installation

4.5 VOIM (Voice over Internet Protocol Interface Module) installation

Description

The VOIM can be installed on the basic KSU and provides the Ethernet interface for S/W applications and VoIP

features with optional VoIP daughter board.

The VOIM has the capacity for maximum 8 channels with one(1) VOIU, and VOIU provides four(4) VoIP channels.

Item Specification

LAN Interface 10 / 100 Base-T Ethernet(IEEE 802.3)

Speed 10 Mbps or 100 Mbps(Auto-Negotiation)

Duplex Half Duplex or Full Duplex(Auto-Negotiation)

VoIP Protocol H.323 Revision 3

Voice Compression G.711/G.726/G729/G.723.1

Voice/Fax Switching T.38

Echo cancellation G.165

.

Figure 4.5.1 VOIM

55

Page 60

IP LDK-20 Installation Manual Board Installation

Figure 4.5.2 VOIB

The VOIB is installed in the VOIM and provides various kinds of connectors and RJ45 modular jacks for the

connection of peripheral boards and miscellaneous functions (refer to the following Table).

Various switches and connectors functions

Switch / Connector Functions Remark

SW1

SW2 VOIB Reset Switch for CPU (S32500C)

SW3 Pole1: Trace function disable, others: reserved Default: ON

CN1 JTAG(Joint Test Action Group) for debug

CN2 VOIU Board Connection

CN3 VOIU Board Connection

CN4 Basic KSU Connection

CN6

MJ1 Network(RJ-45) Cable Connection

Watch dog reset enable Default: Off

RS232C Trace Tool Connection

56

Page 61

IP LDK-20 Installation Manual Board Installation

LED indications

LED Functions Remark

LD1

LD2

LD3 Channel8 Seize indication LED (ON: Busy, OFF: Idle)

LD4 Channel7 Seize indication LED (ON: Busy, OFF: Idle)

LD5 Channel6 Seize indication LED (ON: Busy, OFF: Idle)

LD6 Channel5 Seize indication LED (ON: Busy, OFF: Idle)

LD7 Channel4 Seize indication LED (ON: Busy, OFF: Idle)

LD8 Channel3 Seize indication LED (ON: Busy, OFF: Idle)

LD9 Channel2 Seize indication LED (ON: Busy, OFF: Idle)

LD10 Channel1 Seize indication LED (ON: Busy, OFF: Idle)

LD11 VOIB DSP operation status LED (ON: Normal, OFF: Fail)

LD12 VOIU DSP operation status LED (ON: Normal, OFF: Fail)

MJ1-LD1 Link Status LED (ON: Link, Toggle: Data transfer)

MJ1-LD2 Speed Status LED (ON: 100Mbps operation, OFF: 10Mbps)

DSP HINT interrupt LED (ON: Active, OFF: Idle)

Periodic toggle – ON: 1 sec., OFF: 1 sec.

4.5.1 Pin assignment

Connector Pin Number NO SIGNAL NAME FUNCTION

RJ45

4,5,7,8 RESERVED

1 TX+ Transmit Data

2 TX- Transmit Data

3 RX- Receive Data

6 RX+ Receive Data

※

NOTE

- 10BASE-T runs on Category 3 UTP or higher.

- 100BASE-TX runs only on Category 5 UTP cable.

57

Page 62

IP LDK-20 Installation Manual Board Installation

4.5.2 VOIU(Voice over Internet Protocol Interface Unit)

Description

The VOIU can be installed on the VOIB through CN2 and CN3 and provides the Ethernet interface for S/W

applications and 4 VoIP channels.

Figure 4.5.2.1 VOIU Installation

58

Page 63

IP LDK-20 Installation Manual Board Installation

4.6 SLIM(SLT Interface Module) Installation

Description

The SLIM provides the eight (8) ports of SLT interface and two DTMF receivers. The connection between the SLIM

and Single Line Telephone is performed through RJ45 Modular Jacks, MJ1.

SLIM can be installed on basic KSU.

Figure 4.6.1 SLIM

4.6.1 Pin assignment

SLIM

Connector Pin Number NO SIGNAL NAME

RJ45

SLT

Connector Pin Number NO SIGNAL NAME

RJ11

1,2

3 Reserved

4,5 SLT-R, SLT-T

6,7,8 Reserved

1-2

3 TIP

4 RING

5-6 RESERVED

SLT-R, SLT-T

RESERVED

59

Page 64

IP LDK-20 Installation Manual Board Installation

4.7 DTIM(Digital Terminal Interface Module)

Description

The DTIM provides Digital terminal interface of 8 ports. It also provides 2-wire connection to Digital Keysets. It has

module connectors, MJ1, which is used to connect Digital Keyset lines to the DTIM.

DTIM can be installed on basic KSU.

Figure 4.7.1 DTIM

4.7.1 Pin assignment

DTIM

Connector Pin Number NO SIGNAL NAME

RJ45

1,2

3 Reserved

DKT-R, DKT-T

4,5 DKT-R, DKT-T

6,7,8 Reserved

DKT

Connector Type Pin Number NO SIGNAL NAME

RJ11

1-2

3 TIP

4 RING

5-6 RESERVED

60

RESERVED

Page 65

IPLDK-20 Installation Manual Terminal Connect ion

SECTION 5. TERMINAL CONNECTION

5.1 Terminal Models

Various types of digital terminals are used with IP LDK-20 MBUB/DTIB4/DTIB8 as listed and shown below:

MODEL DESCRIPTION

LDP-7004N 8 Flexible Button Normal

LDP-7004D 4 Flexible Button Display

LDP-7008D 8 Flexible Button Display

LDP-7016D 16 Flexible Button Display

LDP-7024D 24 Flexible Button Display

LDP-7024LD 24 Flexible Button Large Display

LDP-7048DSS 48 Button DSS Console

LDP-7004N LDP-7004D

LDP-7008D LDP-7016D

LDP-7024D LDP-7024LD

61

Page 66

IPLDK-20 Installation Manual Terminal Connect ion

5.2 Terminal Cabling Distance

Figure 5.2 Terminal Cabling Distance

62

Page 67

IPLDK-20 Installation Manual Terminal Connect ion

5.3 Keyset Connection

5.3.1 Digi tal Keyset

The following illustrates how to connect the Digital Keyset to your system:

Figure 5.3.1 Digital Keyset Connection

5.3.1.1 Pin Assignment

CONNECTOR TYPE PIN NUMBER NO SIGNAL NAME

RJ11

1-2 RESERVED

3 TIP

4 RING

5-6 RESERVED

5.3.2 SLT

The following illustrates how to connect the SLT to your system:

Figure 5.3.2 SLT Connection

5.3.2.1 Pin Assignment

CONNECTOR TYPE PIN NUMBER NO SIGNAL NAME

RJ11

1-2 RESERVED

3 TIP

4 RING

5-6 RESERVED

63

Page 68

IPLDK-20 Installation Manual Terminal Connect ion

5.4 Connecting Additional Terminals

MBUB provides connections for 1 external music source, 1 external page port, 2 relay contacts, and an alarm/doorbell input monitor through the PJ1 audio jack and a MJ4 RJ45 Modular Jack.

Figure 5.4.1 Additional Terminal Connection

5.4.1 External M u si c Source wiring

MBUB accommodates 1 port of external music source through a PJ1 (RED) audio Jack.

5.4.2 Relay Con t acts

MBUB provides 2 relay contacts that are used for loud bell or external paging through pin No. 1-2 & 3-4 of MJ4.

5.4.3 External Paging wiring

MBUB supports 1 external paging port through Pin No.5-6 (paging port) of MJ4.

5.4.4 Alarm Det ec tion wiring

MBUB provides an external alarm detection input, which can be used to transmit notification to extensions when the

external switch is closed or opened (programmable through Admin Programming). This alarm detection input is

provided through pin No.7-8 of MJ4.

64

Page 69

IPLDK-20 Installation Manual Starting the IP LDK-20 System

SECTION 6. STARTING THE IPLDK-20 SYSTEM

6.1 Before Starting the IP LDK-20 System

The DIP switch (SW1) of Memory Backup Battery should be turned ON before installing the MBUB, to protect system

data in the case of a power failure. To prepare for preprogramming, perform the following Steps:

1. Set the DIP switch (SW3) on the MBUB to ON.

To initialize all the data in Admin Programming, the 4th pole of SW3 should be set to ON.

Plug the AC power cord into the IP LDK-20 System and AC outlet.

Program the Country Code as applicable.

Reset the IP LDK-20 System.

Set the 4th pole of SW3 on the MBUB to OFF when the system operates normally. The 4th pole of SW3 is set to OFF,

to protect the various features addressed by Admin Programming after system power-up and initialization.

6.2 Basic Preprogramming

The IP LDK-20 System can be programmed to meet an individual customer's need. There are two ways to perform

ADMIN Programming:

- PC ADMIN : Refer to the PC ADMIN Programming Manual.

- DKTU : In this manual we explain DKTU (Station 10) in ADMIN Programming.

6.2.1 DKTU (Station 10) programming

All programming is done at Station 10 (Station port # 00) using the LDP-7024D digital key telephone.

Additional programming stations may be assigned (PGM 113 – FLEX 1), but only 1 DKTU can be active in the

programming mode at any one time.

When in programming mode, Station 10 does not operate as a normal telephone, but instead works as a

programming instrument with all of the buttons redefined. The keys of the dial pad are used to enter the various data

fields and to enter numerical information:

- Flexible Buttons

The 24 buttons located at the top of the phone are used to indicate a specific data field and to enter information.

- SPEED Button and * Key

Are sometimes used to delete data or to indicate the end of data input.

- REDIAL Button

Could be used to delete one digit or character from the end of entered digits or characters.

65

Page 70

IPLDK-20 Installation Manual Starting the IP LDK-20 System

6.2.1.1 Button explanation

There are many kinds of DKTUs capable of connecting to the IP LDK-20 system. Figure 6.2.1 shows a model of the

LDP-7024D and illustrates each button. Detailed DKTU information for this and other keysets is described in the

DKTU User Guide and Installation Manual.

Speaker phone

3 Soft Button

Fixed button

LCD

Figure 6.2.1 Description of LDP-7024D Buttons

Ring LED

Navigation button

FLEX 1

FLEX 13

.

.

.

.

.

.

.

FLEX 24

MIC

Flexible button

66

Page 71

IPLDK-20 Installation Manual Starting the IP LDK-20 System

6.2.2 Entering programming mode

To enter Programming Mode, perform the following Steps:

Lift the handset

OR

Press the [MON] button on the ADMIN station, and hear ICM dial tone.

1. Press the [TRANS/PGM] button and dial *# .

2. Confirmation tone should be heard.

3. Enter the ADMIN password if the password has been set.

4. A confirmation tone should be heard indicating that the station is in ADMIN Programming mode.

5. Each program is accessed by pressing the [TRANS/PGM] button, the following should display:

6. Dial the desired three-digit program number. If an error is made while entering data, the [TRANS/PGM] button

will return to the previous status.

※ NOTE

To return to the parent state while ADMIN programming, press the [CONF] button. Pressing the [CONF] button

clears temporary data fields.

ENTER PGM NUMBER

6.2.2.1 Permanent Update Procedure

To accept changes while programming, perform the following Steps:

1. Press the [HOLD/SAVE] button when all changes have been entered to store the data permanently.

A confirmation tone should be heard when pressing the [HOLD/SAVE] button if all data was entered correctly. If there

were any errors in the entry, then an error tone is presented and data is not stored in the permanent memory.

6.2.2.2 Resetting the System

To reset the system, perform the following Steps:

1. Enter [PGM] + 450 then [FLEX] + 15 and press the [HOLD/SAVE] button.

OR

Press [PGM] + 100 then [FLEX] + 1 (Nation Code Assign) to automatically reset the system.

67

Page 72

IPLDK-20 Installation Manual Starting the IP LDK-20 System

6.2.3 Pre-programming

Location PGM-Nation Code & Site Name (PGM100)

※ NOTE : The 4th pole of the DIP switch (SW 3) on the MPB must be turned ON.

Procedure

Nation Code

To program the Nation code, perform the following Steps:

1. Press [Trans/PGM] + PGM Number(100), then [Flex1] + 7.

Press [HOLD/SAVE] to accept change.

※ NOTE : Press the reset button after setting the nation code to restart the system

Site Name

1. Press [Trans/PGM] + Enter Site Name (use the following Keyset Map, Max. 24 digits allowed), then [Flex2].

Press [HOLD/SAVE] to accept change.

[Keyset Map]

Q – 11

Z – 12

. – 13

1 – 10

G – 41

H - 42

I - 43

4 – 40

P - 71

R - 72

S - 73

Q - 7*

7 – 70

*1 - Blank

*2 - :

*3 - ,

A - 21

B - 22

C - 23

2 - 20

J - 51

K - 52

L - 53

5 - 50

T - 81

U - 82

V - 83

8 - 80

0-00 #

D - 31

E - 32

F - 33

3 - 30

M - 61

N - 62

O - 63

6 - 60

W - 91

X - 92

Y - 93

Z - 9#

9 - 90

68

Page 73

IPLDK-20 Installation Manual Starting the IP LDK-20 System

International Calling Codes

NATION CODE NATION CODE NATION CODE

America 1 Argentina 54 Australia 61

Bahrain 973 Bangladesh 880 Belgium 32

Bolivia 591 Brazil 55 Brunei 673

Burma 95 Cameroon 237 Chile 56

China (Taiwan) 886 CIS 7 Colombia 57

Costa Rica 506 Cyprus 357 Czech 42

Denmark 45 Ecuador 593 Egypt 20

El Salvador 503 Ethiopia 251 Fiji 679

Finland 358 France 33 Gabon 241

Germany 49 Ghana 233 Greece 30

Guam 671 Guatemala 502 Guyana 592

Haiti 509 Honduras 504 Hong Kong 852

India 91 Indonesia 62 Iran 98

Iraq 964 Ireland 353 Israel 972

Italy 39 Japan 81 Jordan 962

Kenya 254 Korea 82 Kuwait 965

Liberia 231 Libya 218 Luxembourg 352

Malaysia 60 Malta 356 Mexico 52

Monaco 377 Morocco 212 Netherlands 31

New Zealand 64 Nigeria 234 Norway 47

Oman 968 Pakistan 92 Panama 507

P.N.G 675 Paraguay 595 Peru 51

Philippines 63 Portugal 351 Qatar 974

Saudi Arabia 966 Senegal 221 Singapore 65

South Africa 27 Spain 34 Sri Lanka 94

Swaziland 268 Sweden 46 Switzerland 41

TELKOM *27 Thailand 66 Tunisia 216

Turkey 90 U.A.E. 971 United Kingdom 44

Uruguay 598 Venezuela 58 Y.A.R. 967

TELSTRA *61

69

Page 74

IPLDK-20 Installation Manual Starting the IP LDK-20 System

6.2.3.1 RACK SLOT ASSIGNMENT (PGM 101)

1. Press [Trans/PGM] + 101

2. Enter slot number(2 digits).

3. Press [FLEX1]

4. Enter Board Type code(2 digits).

Press [HOLD/SAVE] to accept change.

STA CODE COL CODE STA & COL CODE Etc CODE

DTIB4

DTIB8

SLIB4

SLIB8

11

12

13

14

Board type of basic MBU(Slot 1, Slot5) and VMIB slot (slot 7) can not be changed.

- Slot 1: Hybrid on MBU.

- Slot 2-3: not used.

- Slot 4: optional STA board.

- Slot 5: CO board on MBU.

- Slot 6: optional CO slot.

- Slot 7: VMIB slot.

- Slot 8: SLIM/DTIM slot.

- Slot 9: VOIM slot.

LCOB2

LCOB4

CBIB

33

34

54

STIB2