Leuze DCR 80 Operating Instructions

DCR 80

Scan Engine

<![if ! IE]><![endif]>EN 2017/03 - 50129903 We reserve the right to make technical changes

O r i g i n a l o p e r a t i n g i n s t r u c t i o n s

© 2017

Leuze electronic GmbH + Co. KG In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199 http://www.leuze.com

Leuze electronic |

DCR 80 |

2 |

1 About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Used symbols and signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2.3 Competent persons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2.4 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3.1.1 The DCR 80 scan engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3.1.2 Stand alone operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3.3 Device construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 3.4 Connection technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Selecting a mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Voltage supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 5.2 Pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 Switching input/Switching output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 5.3.1 Switching input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 5.3.2 Switching output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 PC or terminal connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 5.5 Cable lengths and shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Configuration and diagnostic software - Sensor Studio . . . . . . . . . . . . . . . . . . . 15

6.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Installing Sensor Studio configuration software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 6.2.1 Downloading configuration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 6.2.2 Installing the Sensor Studio FDT frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 6.2.3 Install the communication DTM and device DTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 6.2.4 Connecting device to PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.3 Starting the Sensor Studio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 6.4 Exiting Sensor Studio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.5 Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 6.5.1 Control tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 6.5.2 Decode tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 6.5.3 Host interface tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 6.5.4 Diagnosis / Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 Starting up the device - Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 Measures to be performed prior to the initial commissioning . . . . . . . . . . . . . . . . . . . . . . 23

7.2 Starting the device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 7.2.1 Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 7.2.2 “Online commands”. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 7.2.3 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.3 Setting the communication parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Leuze electronic |

DCR 80 |

3 |

8 Online commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.1 Overview of commands and parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 8.2 General online commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Care, maintenance and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 9.2 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 9.3 Disposing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10 Service and support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10.1 What to do should servicing be required?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

11 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11.1 General specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 11.2 Reading fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 11.3 Dimensioned drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

12 Ordering information and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

12.1 Type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 12.2 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

13 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

14 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

14.1 Bar code samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

14.2 Configuration via configuration codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Leuze electronic |

DCR 80 |

4 |

About this document

1About this document

1.1Used symbols and signal words

Table 1.1: |

|

|

|

|

Warning symbols and signal words |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Symbol indicating dangers to persons |

|

|

|

|

|

|

|

NOTICE |

|

|

|

|

|

Signal word for property damage |

|

|

|

|

|

|

Indicates dangers that may result in property damage if the measures for dan- |

|

|

|

|

|

|

ger avoidance are not followed. |

|

|

|

|

|

|

|

Table 1.2: |

|

|

|

|

Other symbols |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Symbol for tips |

|

|

|

|

|

|

Text passages with this symbol provide you with further information. |

|

|

|

|

|

|

|

|

|

|

|

Symbols for action steps |

||

|

|

|

Text passages with this symbol instruct you to perform actions. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 1.3: |

|

|

|

|

Terms and abbreviations |

|

|

|

|

|

|

|

|

BCL |

|

|

|

|

|

Bar code reader |

|

|

|

|

|

|

|

CMOS |

|

|

|

|

|

Semiconductor process for implementing integrated circuits |

|

|

|

|

|

|

(Complementary Metal-Oxide-Semiconductor) |

|

|

|

|

|

|

|

DCR |

|

|

|

|

|

Image-based code reader |

|

|

|

|

|

|

(Dual Code Reader) |

|

|

|

|

|

|

|

DTM |

|

|

|

|

|

Software device manager |

|

|

|

|

|

|

(Device Type Manager) |

|

|

|

|

|

|

|

EMC |

|

|

|

|

|

Electromagnetic compatibility |

|

|

|

|

|

|

|

EN |

|

|

|

|

|

European standard |

|

|

|

|

|

|

|

FDT |

|

|

|

|

|

Software frame for management of device managers (DTM) |

|

|

|

|

|

|

(Field Device Tool) |

|

|

|

|

|

|

|

FE |

|

|

|

|

|

Functional earth |

|

|

|

|

|

|

|

GUI |

|

|

|

|

|

Graphical User Interface |

|

|

|

|

|

|

|

HID |

|

|

|

|

|

Device class for input devices with which users directly interact |

|

|

|

|

|

|

(Human Interface Device) |

|

|

|

|

|

|

|

IO or I/O |

|

|

|

|

|

Input/Output |

|

|

|

|

|

|

|

LED |

|

|

|

|

|

Light Emitting Diode |

|

|

|

|

|

|

|

PLC |

|

|

|

|

|

Programmable Logic Control |

|

|

|

|

|

|

|

Leuze electronic |

DCR 80 |

5 |

Safety

2Safety

This scan engine was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1Intended use

The DCR 80 scan engine is designed as an installation scanner with integrated decoder for all of the most popular 1D and 2D codes for automatic object recognition.

Areas of application

The DCR 80 scan engine is intended especially for the following areas of application:

•automatic analyzers

•For space-critical code reading tasks

•For installation in a housing or beneath covers

CAUTION

CAUTION

Observe intended use!

Only operate the device in accordance with its intended use.

Theprotectionofpersonneland thedevicecannotbeguaranteedifthedeviceisoperatedinamanner not complying with its intended use.

Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use.

Read these original operating instructions before commissioning the device. Knowledge of the original operating instructions is an element of proper use.

NOTICE

Comply with conditions and regulations!

Observethelocallyapplicablelegalregulationsandtherules oftheemployer'sliabilityinsuranceassociation.

2.2Foreseeable misuse

Any use other than that defined under “Intended use” or which goes beyond that use is considered improper use.

In particular, use of the device is not permitted in the following cases:

•Rooms with explosive atmospheres

•Circuits relevant to safety

•Operation for medical purposes

NOTICE

Do not modify or otherwise interfere with the device.

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way. There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

2.3Competent persons

Connection,mounting,commissioningandadjustmentofthedevicemustonlybecarriedoutbycompetent persons.

Leuze electronic |

DCR 80 |

6 |

Safety

Prerequisites for competent persons:

•They have a suitable technical education.

•They are familiar with the rules and regulations for occupational safety and safety at work.

•They are familiar with the technical description of the device.

•They have been instructed by the responsible person on the mounting and operation of the device.

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with relevant standards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3 (e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

2.4Disclaimer

Leuze electronic GmbH + Co. KG is not liable in the following cases:

•The device is not being used properly.

•Reasonably foreseeable misuse is not taken into account.

•Mounting and electrical connection are not properly performed.

•Changes (e.g., constructional) are made to the device.

Leuze electronic |

DCR 80 |

7 |

Device description

3Device description

3.1Device overview

3.1.1The DCR 80 scan engine

The code reader is based on a scan engine with CMOS imager with integrated decoder for all of the most popular 1D and 2D codes such as DataMatrix, Aztec, QR Code, 2/5 Interleaved, Code 39, Code 128, UPC/EAN etc.

The many possible configurations of the device allow it to be adapted to a multitude of reading tasks. Due to the small dimensions of the unit and the large reading field, the scan engine can also be used in highly constrained spaces.

Information on technical data and characteristics: see chapter 11.

3.1.2Stand alone operation

The scan engine is operated as a single “stand-alone” device. It is equipped with a 12-pin Molex plug connector for the power supply electrical connection, the interface, the trigger input and the switching output.

3.2Performance characteristics

•High-performance miniature CMOS imager scan engine

•Compact design for simple integration, even in constrained spaces

•Reading of extremely small high-density codes and recording of standard codes in a large reading area using a special optical system

•Reading of shiny surfaces using a gloss reduction process

•Excellent decoding characteristics

•Clearly visible alignment LED

•RS 232 interface, triggering input, switching output, buzzer output (GOOD READ)

Leuze electronic |

DCR 80 |

8 |

Device description

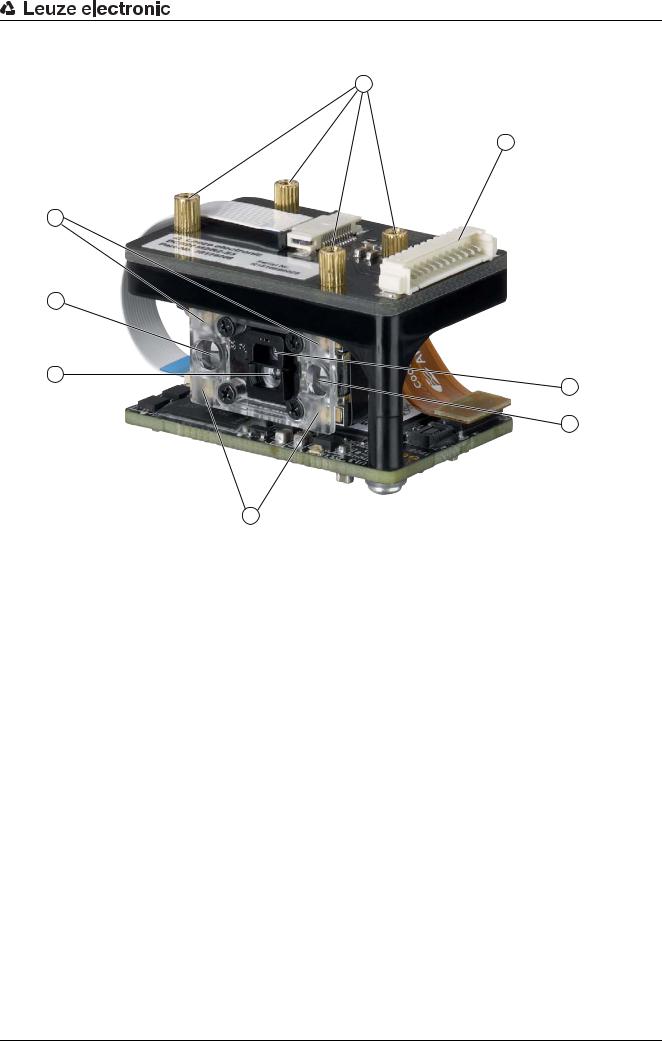

3.3Device construction

4

5

3

2

1

6

2

3

1 Wide-range reading field lens

2Alignment LEDs (blue light)

3LEDs for illumination (red light)

4 Studs for mounting, M2 internal thread

5 Molex connector (53398-1271), 12-pin

6 High resolution reading field lens

Figure 3.1: DCR 80 device construction

3.4Connection technology

Molex connector (53398-1271), 12-pin

Leuze electronic |

DCR 80 |

9 |

Mounting

4Mounting

The scan engine can be attached at four studs with an M2 internal thread.

4.1Selecting a mounting location

The size of the code module influences the maximum reading distance and the width of the reading field. Therefore, when selecting a mounting location and/or the code label, take into account the different reading characteristics of the scanner with various code modules.

NOTICE

Observe when choosing the mounting location!

Maintaining the required environmental conditions (temperature, humidity).

Possible soiling of the reading window due to liquids, abrasion by boxes, or packaging material residues.

Lowest possible chance of damage to the scanner by mechanical collision or jammed parts.

Possible extraneous light influence (no direct sunlight).

In order to select the right mounting location, several factors must be considered:

•Size, orientation, and position tolerance of the bar codes or Data Matrix codes on the objects to be scanned.

•The reading field of the scan engine depends on the code module width.

•the resulting minimum and maximum reading distance from the respective reading field; see figure 11.1.

•Scan engine alignment for avoiding reflections.

•Distance between scan engine and host system with respect to the interface.

It is advisable to use a transparent, double-sided anti-reflective coated material when installing the scan engine behind a pane of glass. Recommended pane thickness: 1 mm; optics as flush as possible with the glass.

The best read results are obtained when

•the reading distance lies in the middle area of the reading field.

•there is no direct sunlight and extraneous light is avoided.

•the bar code labels are of good print quality and have good contrast ratios.

•you do not use high-gloss labels.

•the bar code or the Data Matrix code is moved past the reading window with a rotational angle of 10° to 15°.

•the red light beam is narrowed down for its respective reading task in order to avoid reflections on shiny components.

The front beam exit of the scan engine is almost vertical to the optics. The code label must be rotated by > 10° to avoid a total reflection of the red light beam in the case of glossy labels.

Leuze electronic |

DCR 80 |

10 |

Mounting

γ

γ

β

β

α

αAzimuth angle

β Angle of inclination

γAngle of rotation

Recommended angle of rotation: γ > 10°

Figure 4.1: Definition of the reading angles

Leuze electronic |

DCR 80 |

11 |

Electrical connection

5Electrical connection

CAUTION

CAUTION

Safety notices

Before connecting the device, be sure that the supply voltage agrees with the value printed on the name plate.

Connection of the device and maintenance work while under voltage must only be carried out by a qualified electrician.

The power supply unit for the generation of the supply voltage for the bar code reader and the corresponding connection units must have a secure electrical insulation according to IEC 60742 (PELV). For UL applications: only for use in “class 2” circuits according to NEC.

If faults cannot be corrected, the device should be removed from operation and protected against possible commissioning.

5.1Voltage supply

The scan engine is designed for connection to a 5 V supply voltage.

•+5 V DC (pin 1)

•GND (pin 2)

An adapter circuit board with spring terminals, Molex plug connector and 9-pin SUB-D socket is available as an accessory; see chapter 12.2 "Accessories".

•With the adapter circuit board, the 12-pin plug connector of the scan engine can be contacted via a 150 mm long interconnection cable with a 12-pin Molex terminal strip and connected to the PC via the 9-pin SUB-D socket using an RS 232 interconnection cable.

•With the adapter circuit board, the voltage supply of 10 … 30 V DC can be fed in via spring terminals or, alternatively, 5 V DC can be fed in via a micro USB connector.

5.2Pin assignment

Pin |

Signal |

Description |

|

|

|

1 |

+5 V DC Power |

IN |

|

|

|

2 |

GND |

IN |

|

|

|

3 |

BUZZER |

OUT |

|

|

|

4 |

SWITCHING OUTPUT |

OUT |

|

|

|

5 |

TRIGGER |

IN |

|

|

|

6 |

RS 232 RxD |

IN |

|

|

|

7 |

RS 232 TxD |

OUT |

|

|

|

8 |

RS 232 RTS |

OUT |

|

|

|

9 |

RS 232 CTS |

IN |

|

|

|

10 |

--- |

not connected |

|

|

|

11 |

--- |

not connected |

|

|

|

12 |

--- |

not connected |

|

|

|

Leuze electronic |

DCR 80 |

12 |

Electrical connection

5.3Switching input/Switching output

The scan engine has a switching input and a switching output.

•The switching input is used to trigger reading.

•The switching output signals successful code reading.

•An additional BUZZER output supplies a modulated signal for connecting a buzzer. The buzzer signals successful code reading.

5.3.1Switching input

A read process can be triggered using the trigger input (pin 5) in the standard setting (low = active) via the connection to GND (pin 2). We recommend wiring a 2.2 kΩ “pull-up” resistor as defined cable termination; see figure 5.1.

1+ 5 V DC

3.3… 5.5 V DC

2.2k

5TRIGGER

GND |

2 |

GND |

|

||

|

|

Connection version NPN: standard setting (low = active)

Figure 5.1: Wiring example of the trigger input

5.3.2Switching output

TheNPNswitchingoutputconnectionbetweenswitchingoutput(pin 4)andGND(pin 2)switchesifacode is detected against GND.

1+ 5 V DC

3.3… 5.5 V DC

100 k

+ 5 V DC |

|

RL |

4 |

OUT |

|

|

|

||

max. 20 mA ! |

|

|

|

|

|

|

|

|

2 GND

GND

Figure 5.2: Switching output

NOTICE

Maximum loading of the switching output

Do not load the switching output of the scan engine with more than 20 mA at +5 … V DC!

5.4PC or terminal connection

Viatheserialinterface,youcanconfigurethescanenginebymeansofaPCorterminal.Forthis,youneed an RS 232 connection that establishes the RxD, TxD and GND connections between PC and scan engine.

Leuze electronic |

DCR 80 |

13 |

Electrical connection

The RS 232 connection can be established in the following ways:

•Direct connection of the plug connector of the scan engine to the PC or terminal via its own connector.

•Connection via an MA-CR adapter circuit board

To simplify the connection of the connection wires to the PC interface, an adapter circuit board (MACR) is available for implementing the 12-pin plug connector to SUB-D, 9-pin; see chapter 12.2.

2 |

1 |

3 |

10 |

11 |

|

|

|

|

8 |

|

|

9 |

|

4 |

|

|

5 |

6 |

7 |

1RS 232 connection

2 CR 50 or DCR 80 connection

3 CR 100 or CR 55 connection

4 Molex Micro-Fit, 6-pin

5USB connection

6 Connection to machine control, PLC, external voltage supply 5 VDC

7 |

External voltage supply 10 … 30 VDC |

8 |

SWINDIPswitch(levelfortriggerbutton;5 Vifthescanner highswitchinginputisactive,GNDifthe |

|

low input is active) |

9USB/PWR DIP switch (USB position if voltage is supplied via USB; PWR position if voltage is supplied via 7 )

10Trigger button

11Status LEDs

Figure 5.3: Connection options for MA-CR adapter circuit board

5.5Cable lengths and shielding

The maximum cable length is 3 m.

Should a cable extension be necessary, make certain that the cables of the RS 232 interface are shielded.

Leuze electronic |

DCR 80 |

14 |

Loading...

Loading...