Leuze BCL34 Technical Description

BCL34

Barcode reader

GB 05-10/08 50038851

TECHNICAL DESCRIPTION

Nortécnica

S

. R. L

.

Tel. Int. + 54 1147 57-3129

Fax Int. + 54 1147 57-1088

Tel. Int. + 43 732 76460

Fax Int. + 43 732 785036

Balluff-Leuze Pty. Ltd.

Tel. Int. + 61 3 9720 4100

Fax Int. + 61 3 9738 2677

Leuze electronic nv/ sa

Tel. Int. + 32 2253 16-00

Fax Int. + 32 2253 15-36

ATICS

Tel. Int. + 359 2 847 6244

Fax Int. + 359 2 847 6244

Leuze electronic Ltda.

Tel. Int. + 55 11 5180-6130

Fax Int. + 55 11 5181-3597

Leuze electronic AG

Tel. Int. + 41 44 834 02-04

Fax Int. + 41 44 833 26-26

Imp. Tec. Vignola S.A.I.C.

Tel. Int. + 56 3235 11-11

Fax Int. + 56 3235 11-28

Leuze electronic Trading

(Shenzhen) Co. Ltd.

Tel. Int. + 86 755 862 64909

Fax Int. + 86 755 862 64901

Componentes Electronicas Ltda.

Tel. Int. + 57 4 3511049

Fax Int. + 57 4 3511019

Schmachtl CZ s.r.o.

Tel. Int. + 420 244 0015-00

Fax Int. + 420 244 9107-00

Desim Elektronik APS

Tel. Int. + 45 7022 00-66

Fax Int. + 45 7022 22-20

SKS-automaatio Oy

Tel. Int. + 358 20 764-61

Fax Int. + 358 20 764-6820

Leuze electronic sarl.

Tel. Int. + 33 160 0512-20

Fax Int. + 33 160 0503-65

Leuze Mayser electronic Ltd.

Tel. Int. + 44 14 8040 85-00

Fax Int. + 44 14 8040 38-08

UTECO A.B.E.E.

Tel. Int. + 30 211 1206 900

Fax Int. + 30 211 1206 999

Sensortech Company

Tel. Int. + 852 26510188

Fax Int. + 852 26510388

Leuze electronic OOO

Tel. Int. + 7 495 933

75

05

Fax Int. + 7 495 933

75

05

Leuze electronic AB

Tel. + 46 8 7315190

Fax + 46 8 7315105

Ingermark (M) SDN.BHD

Tel. Int. + 60 360 3427-88

Fax Int. + 60 360 3421-88

Leuze Lumiflex México, S.A. de C.V.

Tel. Int. + 52 8183 7186-16

Fax Int. + 52 8183 7185-88

Leuze electronic BV

Tel. Int. + 31 418 65 35-44

Fax Int. + 31 418 65 38-08

LA2P, Lda.

Tel. Int. + 351 214 447070

Fax Int. + 351 214 447075

Balluff Sp. z o. o.

Tel. Int. + 48 71 338 49 29

Fax Int. + 48 71 338 49 30

O`BOYLE s.r.l

Tel. Int. + 40 2 56201346

Fax Int. + 40 2 56221036

Elteco A/S

Tel. Int. + 47 35 56 20-70

Fax Int. + 47 35 56 20-99

Great Cofue Technology Co., Ltd.

Tel. Int. + 886 2 29 83 80-77

Fax Int. + 886 2 29 85 33-73

Countapulse Controls (PTY.) Ltd.

07/2008

Tel. Int. + 27 116 1575-56

Fax Int. + 27 116 1575-13

Schmachtl SK s.r.o.

Tel. Int. + 421 2 58275600

Fax Int. + 421 2 58275601

Tipteh d.o.o.

Tel. Int. + 386 1200 51-50

Fax Int. + 386 1200 51-51

Industrial Electrical Co. Ltd.

Tel. Int. + 66 2 6426700

Fax Int. + 66 2 6424249

Leuze electronic San.ve.Tic.Ltd.Sti.

Tel. Int. + 90 216 456 6704

Fax Int. + 90 216 456 3650

Balluff Asia pte Ltd

Tel. Int. + 65 6252 43-84

Fax Int. + 65 6252 90-60

Leuze electronic, Inc.

Tel. Int. + 1 248 486-4466

Fax Int. + 1 248 486-6699

SV Altera OOO

Tel. Int. + 38 044 4961888

Fax Int. + 38 044 4961818

C. illies & Co., Ltd.

Tel. Int. + 81 3 3443 4143

Fax Int. + 81 3 3443 4118

Profa-Tech Ltd.

Tel. Int. + 254 20 828095/6

Fax Int. + 254 20 828129

Leuze electronic Co., Ltd.

Tel. Int. + 82 31 3828228

Fax Int. + 82 31 3828522

KazPromAutomatics Ltd.

Tel. Int. + 7 7212 50 11 50

Fax Int. + 7 7212 50 11 50

Leuze electronic S.A.

Tel. Int. + 34 93 4097900

Fax Int. + 34 93 4903515

Logoprom ODO

Tel. Int. + 375 017 235 2641

Fax Int. + 375 017 230 8614

Schmachtl GmbH

SABROW HI-TECH E. & A. LTD.

Tel. Int. + 234 80333 86366

Fax Int. + 234 80333 84463518

Tipteh d.o.o. Beograd

Tel. Int. + 381 11 3131 057

Fax Int. + 381 11 3018 326

Leuze electronic S.r.l.

Tel. Int. + 39 02 26 1106-43

Fax Int. + 39 02 26 1106-40

Kvalix Automatika Kft.

Tel. Int. + 36 272 2242

Fax Int. + 36 272 2244

P.T. Yabestindo Mitra Utama

Tel. Int. + 62 21 92861859

Fax Int. + 62 21 6451044

Galoz electronics Ltd.

Tel. Int. + 972 3 9023456

Fax Int. + 972 3 9021990

Global- Tech (India) Pvt. Ltd.

Tel. Int. + 91 20 24470085

Fax Int. + 91 20 24470086

Tavan Ressan Co. Ltd.

Tel. Int. + 98 21 2606766

Fax Int. + 98 21 2002883

Tipteh Zagreb d.o.o.

Tel. Int. + 385 1 381 6574

Fax Int. + 385 1 381 6577

Tipteh d.o.o. Skopje

Tel. Int. + 389 70 399 474

Fax Int. + 389 23 174 197

Leuze electronic GmbH + Co. KG

P.O. Box 1111, D- 73277 Owen / Teck

Tel. +49(0) 70 21/ 573-0,

Fax +49(0 )7021 / 573-199

info@leuze.de • www.leuze.com

Sales Region East

Phone 035027/629-106

Fax 035027/629-107

Postal code areas

01000-19999

39000-39999

98000-99999

Sales Region North

Phone 07021/573-306

Fax 07021/9850950

Postal code areas

20000-38999

40000-65999

97000-97999

Sales Region South

Phone 07021/573-307

Fax 07021/9850911

Postal code areas

66000-96999

Sales and Service

Worldwide

AT (Austria)

AR (Argentina)

AU + NZ (Australia + New Zealand)

BE (Belgium)

BG (Republic of Bulgaria)

BR (Brasil)

CH (Switzerland)

CO (Colombia)

CZ (Czech Republic)

CL (Chile)

CN (People’s Republic of China)

DK (Denmark)

FI (Finland)

GB (United Kingdom)

GR (Greece)

HK (Hong Kong)

IT (Italy)

HU (Hungary)

ID (Indonesia)

IL (Israel)

IN (India)

IR (Iran)

FR (France)

RU (Russian Federation)

SE (Sweden)

MY (Malaysia)

MX (Mexico)

NL (Netherlands)

PT (Portugal)

PL (Poland)

RO (Romania)

NO (Norway)

TW (Taiwan)

ZA (South Africa)

SK (Slowakia)

SI (Slovenia)

TH (Thailand)

TR (Turkey)

SG + PH (Singapore +

Philippines)

US + CA (United States +

Canada)

UA (Ukraine)

JP (Japan)

KR (South Korea)

KZ (Republic of Kazakhstan)

ES (Spain)

BY (Republic of Belarus)

Germany

KE (Kenia)

NG (Nigeria)

RS (Republic of Serbia)

HR (Croatia)

MK (Macedonia)

© All rights reserved, especially the right of reproduction, distribution and translation. Copying or

reproductions in any form require the written consent of the manufacturer.

Changes reflecting technical improvements may be made.

Table of contents

1 General Information........................................................................................................... 5

1.1 Explanation of Symbols .......................................................................................................5

1.2 Declaration of conformity..................................................................................................... 5

2 Safety Notices ....................................................................................................................6

2.1 Safety Standards ................................................................................................................. 6

2.2 Intended use ........................................................................................................................ 6

2.3 Working Safely ..................................................................................................................... 7

3 Commissioning steps at a glance .................................................................................... 9

4 Description ....................................................................................................................... 13

4.1 On the barcode readers BCL 34........................................................................................ 13

4.2 Modular hoods with integrated connectors MS 34 103/MS 34 105.................................. 14

4.3 Modular Service Display MSD 1 101 ................................................................................. 15

5 Specifications................................................................................................................... 17

5.1 General specifications of the BCL 34 ................................................................................17

5.2 LED indicators.................................................................................................................... 18

5.3 Device Construction and Components.............................................................................. 19

5.3.1 Dimensioned and Connection Drawings..................................................................................... 19

5.4 Optical data ....................................................................................................................... 21

5.4.1 Type overview..............................................................................................................................21

5.4.2 Raster aperture............................................................................................................................ 22

5.4.3 Optics variants and reading fields............................................................................................... 22

5.5 Automatic reflector activation "AutoReflAct"..................................................................... 27

6 Accessories / Order Designation ................................................................................... 29

6.1 Accessories........................................................................................................................ 29

6.1.1 Modular Service Display MSD 1 101...........................................................................................30

6.1.2 Fastening Accessories.................................................................................................................32

6.1.3 Connection cable KB 034 2000...................................................................................................32

7 Installation ........................................................................................................................ 33

7.1 Storage, Transportation ..................................................................................................... 33

7.2 Mounting............................................................................................................................ 34

7.2.1 Arrangement of devices............................................................................................................... 35

7.3 Address setting.................................................................................................................. 37

7.4 Connection......................................................................................................................... 37

7.4.1 ConnectionBCL 34 ...................................................................................................................... 38

7.4.2 Ready-made PROFIBUS connection cable.................................................................................40

7.4.3 User-configurable PROFIBUS connectors.................................................................................. 42

7.4.4 Connection of switching inputs and outputs............................................................................... 43

7.5 Disassembling, packing, disposing ................................................................................... 43

Leuze electronic BCL 34 1

TNT 35/7-24V

Table of contents

8 PROFIBUS ........................................................................................................................ 44

8.1 General Information ........................................................................................................... 44

8.1.1 GSD File .......................................................................................................................................45

8.1.2 Permanently defined parameters (device parameters) ................................................................45

8.2 Structure of the project modules ....................................................................................... 47

8.2.1 Overview of the project modules .................................................................................................47

8.3 Description of the individual project modules ................................................................... 49

8.3.1 Code table extension: Modules 1-4.............................................................................................50

8.3.2 Multilabel: Module 5.....................................................................................................................50

8.3.3 Reading Gate Control: Module 6 .................................................................................................52

8.3.4 Check Digit: Module 7..................................................................................................................53

8.3.5 EAN designator: Module 8...........................................................................................................54

8.3.6 Laser control: Module 9 ...............................................................................................................55

8.3.7 Pharmacode Properties: Module 10 ............................................................................................56

8.3.8 Code Type Properties: Module 11...............................................................................................57

8.3.9 Data Formatting: Module 12 ........................................................................................................58

8.3.10 Switching input: Module 13 .........................................................................................................59

8.3.11 Switching output: Module 14.......................................................................................................60

8.3.12 AutoReflAct (automatic reflector activation) Module 15: ............................................................62

8.3.13 AutoControl: Module 16...............................................................................................................63

8.3.14 Reference Code Comparison: Module 17 ...................................................................................64

8.3.15 Activations: Module 18 ................................................................................................................69

8.3.16 Activations with ACK: Module 19.................................................................................................70

8.3.17 Decoding state: Module 20..........................................................................................................71

8.3.18 Decoding Result: Modules 21 to 27.............................................................................................71

8.3.19 Interlinked read result: Module 33 ...............................................................................................73

8.3.20 Fragmented Reading Result: Module 34 .....................................................................................74

8.3.21 Reading Gate Activations: Module 35 .........................................................................................75

8.3.22 Reading gate number: Module 36................................................................................................76

8.3.23 Number of scans per reading gate: Module 37 ...........................................................................76

8.3.24 Code Position: Module 38............................................................................................................77

8.3.25 Reading Security (Equal Scans): Module 39................................................................................78

8.3.26 Scans per barcode: Module 40....................................................................................................78

8.3.27 Scans With Information: Module 41.............................................................................................79

8.3.28 Decoding quality: Module 42 .......................................................................................................79

8.3.29 Code Direction: Module 43 ..........................................................................................................80

8.3.30 Number Of Digits: Module 44 ......................................................................................................80

8.3.31 Code type: Module 45 .................................................................................................................81

8.3.32 Alignment mode 1: Module 46.....................................................................................................82

8.3.33 Service: Module 47 ......................................................................................................................83

8.3.34 Alignment mode 2: Module 48.....................................................................................................84

8.3.35 Switching output expansion: Module 49 .....................................................................................85

8.3.36 RS 232: Module 50 ......................................................................................................................87

2 BCL 34 Leuze electronic

Table of contents

9 Example configurations................................................................................................... 88

9.1 Indirect Activation via the PLC........................................................................................... 88

9.1.1 Task .............................................................................................................................................88

9.1.2 Procedure ....................................................................................................................................88

9.2 Direct Activation via the Switching Input ........................................................................... 90

9.2.1 Task .............................................................................................................................................90

9.2.2 Procedure ....................................................................................................................................90

9.3 Direct Activation via the Switching Input ........................................................................... 92

9.3.1 Task .............................................................................................................................................92

9.3.2 Procedure ....................................................................................................................................92

10 Commissioning ................................................................................................................ 94

10.1 Measures to be performed prior to the initial commissioning ...........................................94

10.2 Function Test ..................................................................................................................... 94

10.2.1 Service Operating Mode..............................................................................................................95

11 Maintenance..................................................................................................................... 95

11.1 General Maintenance Information...................................................................................... 95

11.2 Repairs, servicing .............................................................................................................. 95

12 Appendix ........................................................................................................................... 96

12.1 EU Declaration of Conformity ............................................................................................ 96

Leuze electronic BCL 34 3

TNT 35/7-24V

Figures and tables

Figure 2.1: Attachment of the sticky labels with warning notices at the BCL 34.....................................................8

Figure 3.1: Beam exit and device arrangement of the BCL 34 ...............................................................................9

Figure 3.2: View of the inside of the MS 34 ......................................................................................................... 10

Figure 3.3: BCL 34 with MS 34 103/MS 34 105 - Connection PWR .....................................................................10

Figure 3.4: BCL 34 with MS 34 103/MS 34 105 - Connection HOST/BUS IN and BUS OUT...................................11

Figure 3.5: Example PROFIBUS manager ............................................................................................................. 11

Figure 3.6: BCL 34 with MS 34 103/MS 34 105 - Connection SW IN/OUT............................................................12

Figure 3.7: BCL 34 with MS 34 103/MS 34 105 - Connection SERVICE ............................................................... 12

Figure 4.1: BCL 34 device construction ............................................................................................................... 13

Figure 4.2: MS 34 103 ........................................................................................................................................14

Figure 4.3: MS 34 103 ........................................................................................................................................14

Figure 4.4: MSD 1 101 ........................................................................................................................................15

Table 5.1: General Specifications.......................................................................................................................18

Table 5.2: LED states MS 34 103 / MS 34 105...................................................................................................18

Figure 5.1: BCL 34 with MS 34 105 ....................................................................................................................19

Figure 5.2: Dimensioned drawing of the BCL 34..................................................................................................19

Figure 5.3: Dimensioned drawing MS 34 103 / MS 34 105 ................................................................................. 20

Table 5.3: Type overview BCL 34 without integrated heating .............................................................................21

Table 5.4: Type overview BCL 34 Devices with integrated heating .....................................................................21

Figure 5.4: BCL 34 … 100: Reading field, M optics (medium density, normal distance) ......................................22

Figure 5.5: BCL 34 … 100: Reading field, F optics (low density, normal distance)...............................................23

Figure 5.6: BCL 34 … 100: Reading field, L optics (low density, long distance)................................................... 23

Figure 5.7: BCL 34 … 100: Reading field, J optics (for ink-jet applications) ........................................................24

Figure 5.8: BCL 34 … 100 H: Reading field, M optics (medium density, normal distance) ................................... 25

Figure 5.9: BCL 34 … 100 H: Reading field, F optics (low density, normal distance) ...........................................25

Figure 5.10: BCL 34 … 100 H: Reading field, L optics (low density, long distance) ...............................................26

Figure 5.11: BCL 34…100 H: Reading field, J optics (for ink-jet applications) ....................................................... 27

Table 5.5: Examples of reflectors which may be used ........................................................................................ 28

Figure 5.12: Reflector arrangement for autoReflAct...............................................................................................28

Table 6.1: Accessories / Order Designation........................................................................................................30

Figure 6.1: Modular Service Display MSD 1 101 ..................................................................................................31

Figure 6.2: Mounting device BT 56......................................................................................................................32

Figure 7.1: Device name plate BCL 34 ................................................................................................................33

Figure 7.2: Mounting example BCL 34 ................................................................................................................ 34

Figure 7.3: Beam exit on BCL 34 ......................................................................................................................... 35

Figure 7.4: Application example "conveyor chain" ..............................................................................................36

Figure 7.5: View of the inside of the MS 34 ......................................................................................................... 37

Figure 7.6: Pin assignment BCL 34 with MS 34 103 / MS 34 105........................................................................38

Table 7.1: Pin assignments - PWR .....................................................................................................................39

Table 7.2: Pin assignment SW IN/OUT................................................................................................................ 39

Table 7.3: Pin assignment HOST/BUS IN / BUS OUT ...........................................................................................40

Table 7.4: Accessories / Order Designation........................................................................................................41

Figure 7.7: Cable structure of PROFIBUS connection cable .................................................................................. 41

Figure 7.8: Connection diagram switching inputs and outputs BCL 34.................................................................43

Table 8.1: "Common" Parameters .....................................................................................................................46

Table 8.2: Code type and code length, Tables 1-4..............................................................................................46

Table 8.3: Overview of the project modules .......................................................................................................47

Figure 8.1: Specifying switch-on and switch-off positions of the laser................................................................. 55

Figure 8.2: Relative position of the barcode in the scanner beam. .......................................................................77

Table 9.1: Device parameters for example configuration 2 ................................................................................. 90

Table 9.2: Device parameters for example configuration 3 ................................................................................. 93

Table 9.3: Module parameters for example configuration 3................................................................................93

4 BCL 34 Leuze electronic

1 General Information

U

L

US

C

LISTED

1.1 Explanation of Symbols

The symbols used in this operating manual are explained below.

Attention!

Pay attention to passages marked with this symbol. Failure to heed this information can lead

to injuries to personnel or damage to the equipment.

Attention Laser!

This symbol warns of possible danger through hazardous laser radiation.

Notice!

This symbol indicates text passages containing important information.

1.2 Declaration of conformity

The barcode reader BCL 34, the modular hoods with integrated connectors MS 34 103/

MS 34 105, and the optional modular service display MSD 1 101 have been developed and

manufactured under observation of the applicable European standards and directives.

The barcode reader models BCL 34 … 100 without integrated heating also fulfil the UL

requirements (Underwriters Laboratory Inc.) for the USA and Canada.

General Information

Notice!

You can find the corresponding declaration of conformity in the appendix of the manual.

The manufacturer of the product, Leuze electronic GmbH & Co KG in D-73277 Owen/Teck,

possesses a certified quality assurance system in accordance with ISO 9001.

Leuze electronic BCL 34 5

TNT 35/7-24V

Safety Notices

2 Safety Notices

2.1 Safety Standards

The barcode reader BCL 34, the modular hoods with integrated connectors MS 34 103/

MS 34 105, and the optional modular service display MSD 1 101 have been developed,

produced and tested subject to the applicable safety standards. They correspond to the

state of the art.

2.2 Intended use

Attention!

The protection of personnel and the device cannot be guaranteed if the device is operated

in a manner not corresponding to its intended use.

Bar code readers of the type BCL 34 are conceived as stationary, high-speed scanners

with integrated decoders for all current bar codes used for automatic object recognition.

The modular hoods with integrated connectors MS 34 103/MS 34 105 are intended for the

easy connection of barcode readers of type BCL 34 in a PROFIBUS system and for the

setting of the respective PROFIBUS address (see chapter 7.3 "Address setting").

The modular service display MSD 1 101, which is optionally available, displays operational

data of the BCL 34 and is used as a simple means of access to the service interface.

In particular, unauthorised uses include:

• rooms with explosive atmospheres

• operation for medical purposes

Areas of application

The barcode reader BCL 34 is intended especially for the following areas of application:

• labelling and packaging machines

• space-critical barcode reading tasks

• storage and conveying engineering, in particular for object identification on fastmoving conveyor belts

• pharmaceutical industry

6 BCL 34 Leuze electronic

2.3 Working Safely

Attention!

Access to or changes on the device, except where expressly described in this operating

manual, is not authorised.

Safety regulations

Observe the locally applicable legal regulations and the rules of the employer's liability

insurance association.

Qualified personnel

Mounting, commissioning and maintenance of the device must only be carried out by

qualified personnel.

Electrical work must be carried out by a certified electrician.

Attention, laser radiation!

WARNING: The barcode reader BCL 34 operates with a red light laser of class 2 acc.

to EN 60825-1. If you look into the beam path over a longer time period, the retina of

your eye may be damaged!

Never look directly into the beam path!

Do not point the laser beam of the BCL 34 at persons!

Safety Notices

When mounting and aligning the BCL 34, take care to avoid reflections of the laser

beam off reflective surfaces!

Heed the laser safety regulations according to DIN EN 60825-1 in their most current

version! The output power of the laser beam at the reading window is at most 1.8mW

acc. to EN 60825-1.

The BCL 34 uses a laser diode with low power in the visible red light range with an

emitted wavelength of 650 … 690nm.

CAUTION - the use of operating and adjusting devices other than those specified

here or carrying out of differing procedures may lead to dangerous exposure to radiation!

Leuze electronic BCL 34 7

TNT 35/7-24V

Safety Notices

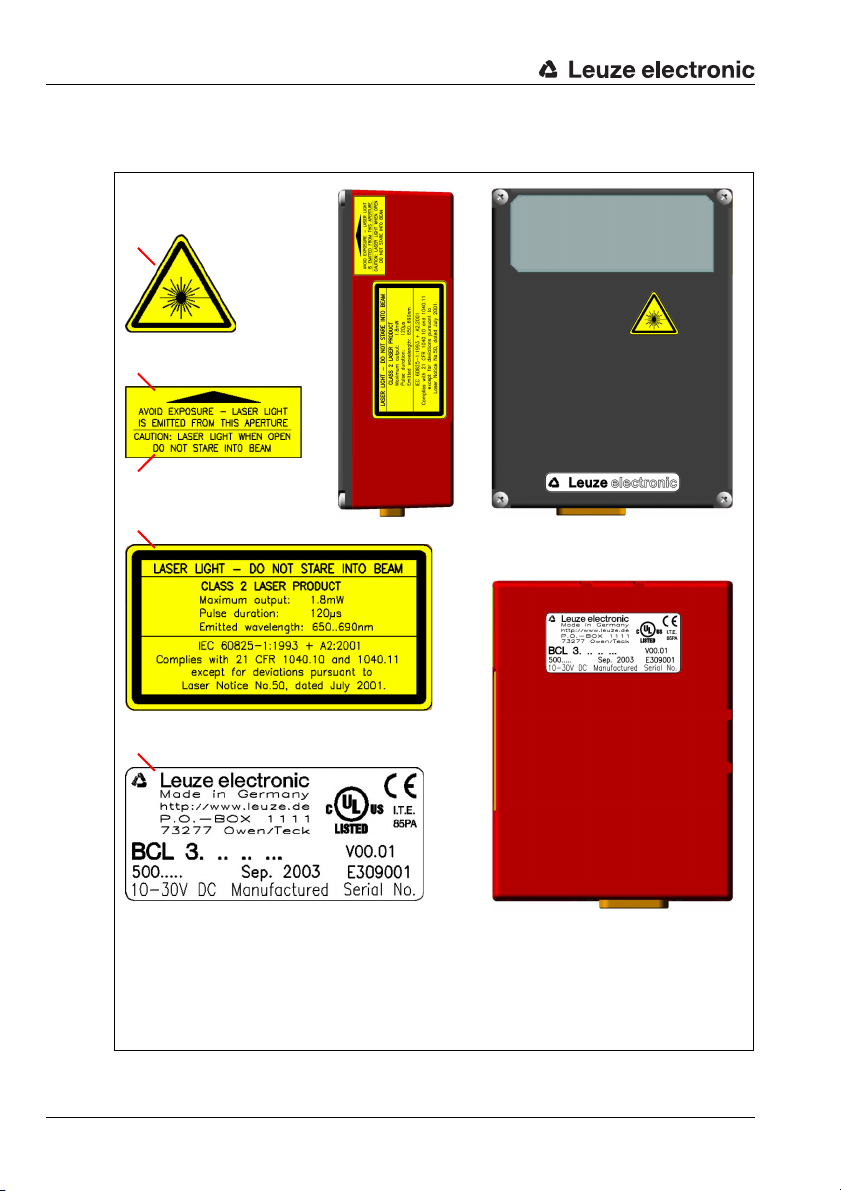

A

B

D

E

C

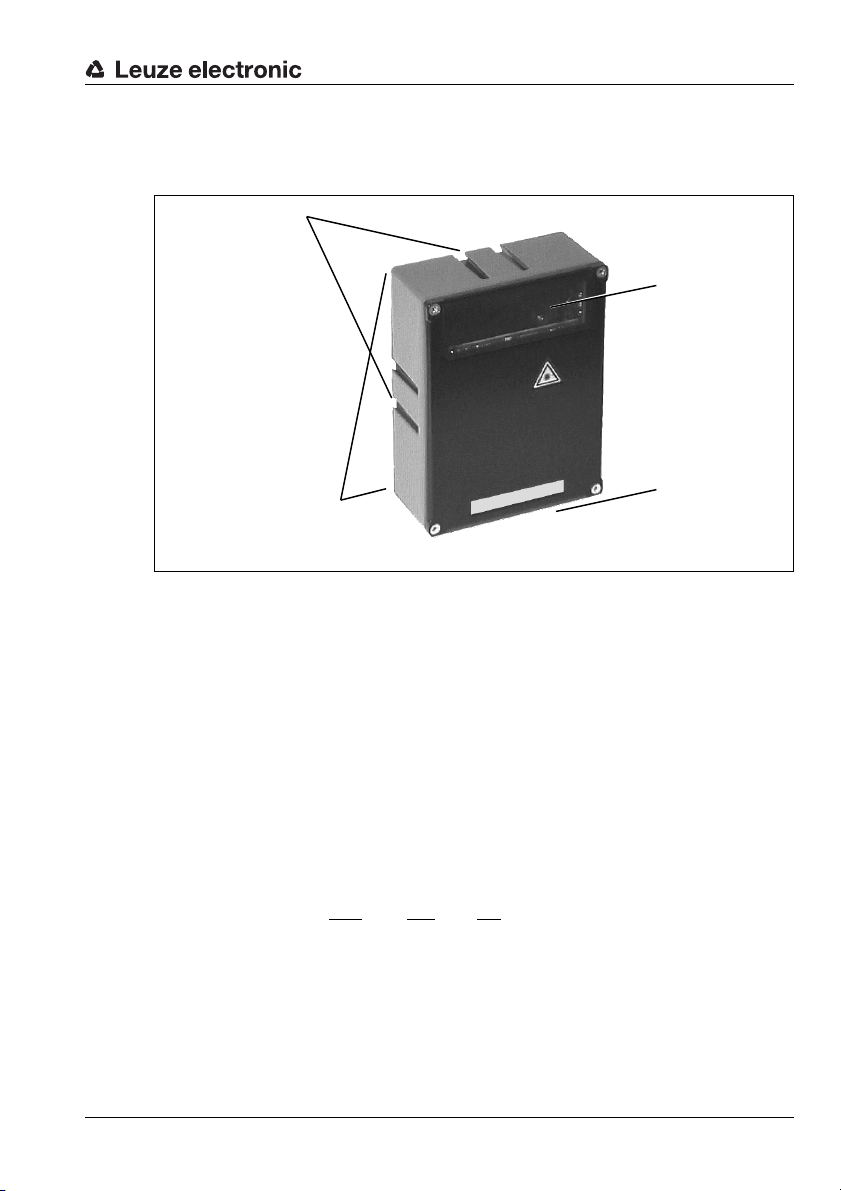

A Danger warning symbol

B Warning laser discharge

C Warning unlocked protective housing

D Warning and certification sign

E Name plate

The housing of the bar code reader BCL 34 is labelled on the side, below the scanner

window and on the rear with the following logotypes:

8 BCL 34 Leuze electronic

Figure 2.1: Attachment of the sticky labels with warning notices at the BCL 34

Commissioning steps at a glance

Read distance

Beam exit

all dimensions

in mm

Scanning beam(s)

3 Commissioning steps at a glance

Notice!

Below you will find a short description for the initial commissioning BCL 34of the barcode reader. Detailed explanations for all listed points can be found throughout the manual.

Mechanical design

Mounting the device BCL 34

There are two different types of mounting arrangements for the BCL 34:

1. Using 4 M4x6 screws on the rear of the device.

2. Using a mounting device (BT 56) on the dovetail fastening grooves.

Notice!

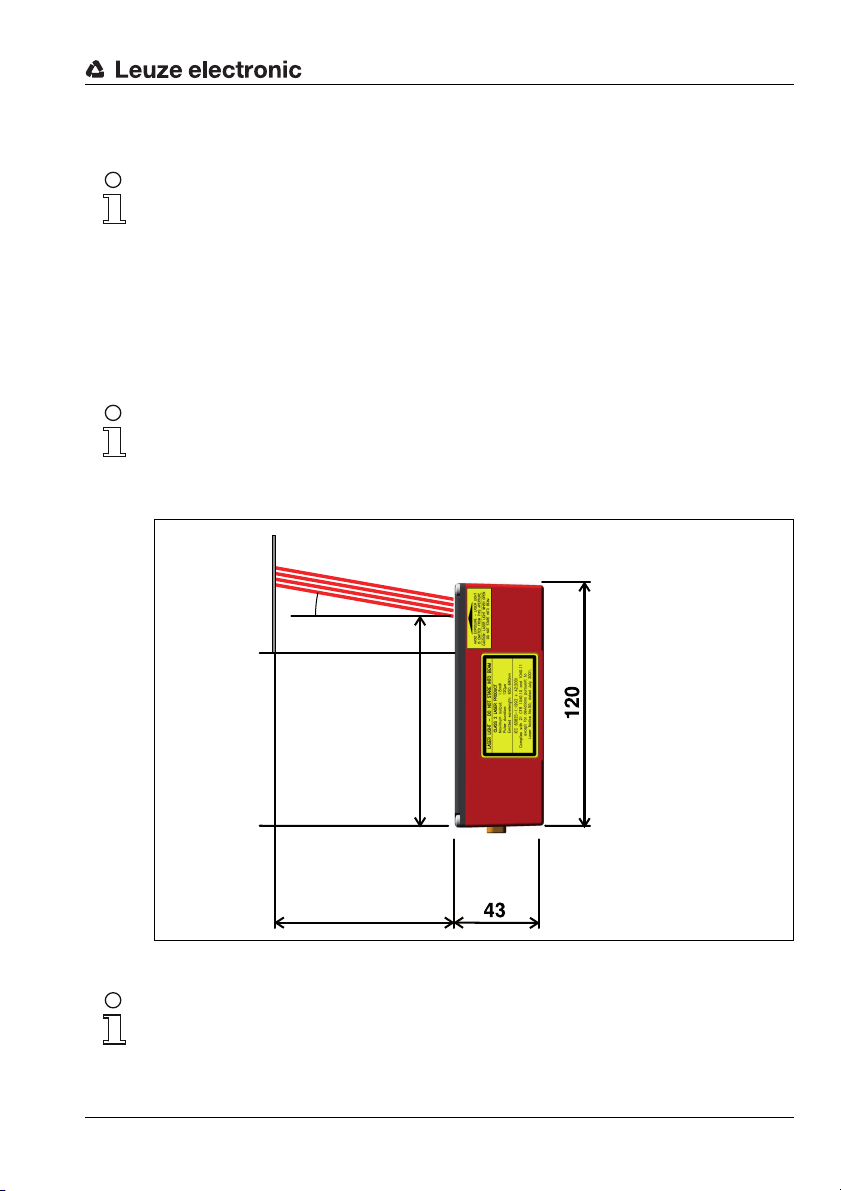

The installation dimensions listed in the following figure must absolutely be adhered to.

Optically, it must be ensured that the scanner has an unobstructed view of the barcode at

all times. The scanning beam's angle of incidence on the label of at least 10° must be adhered to.

10°

103 ± 2

Figure 3.1: Beam exit and device arrangement of the BCL 34

Notice!

During installation, the working range of the reading field curve must be taken into account.

Leuze electronic BCL 34 9

TNT 35/7-24V

Commissioning steps at a glance

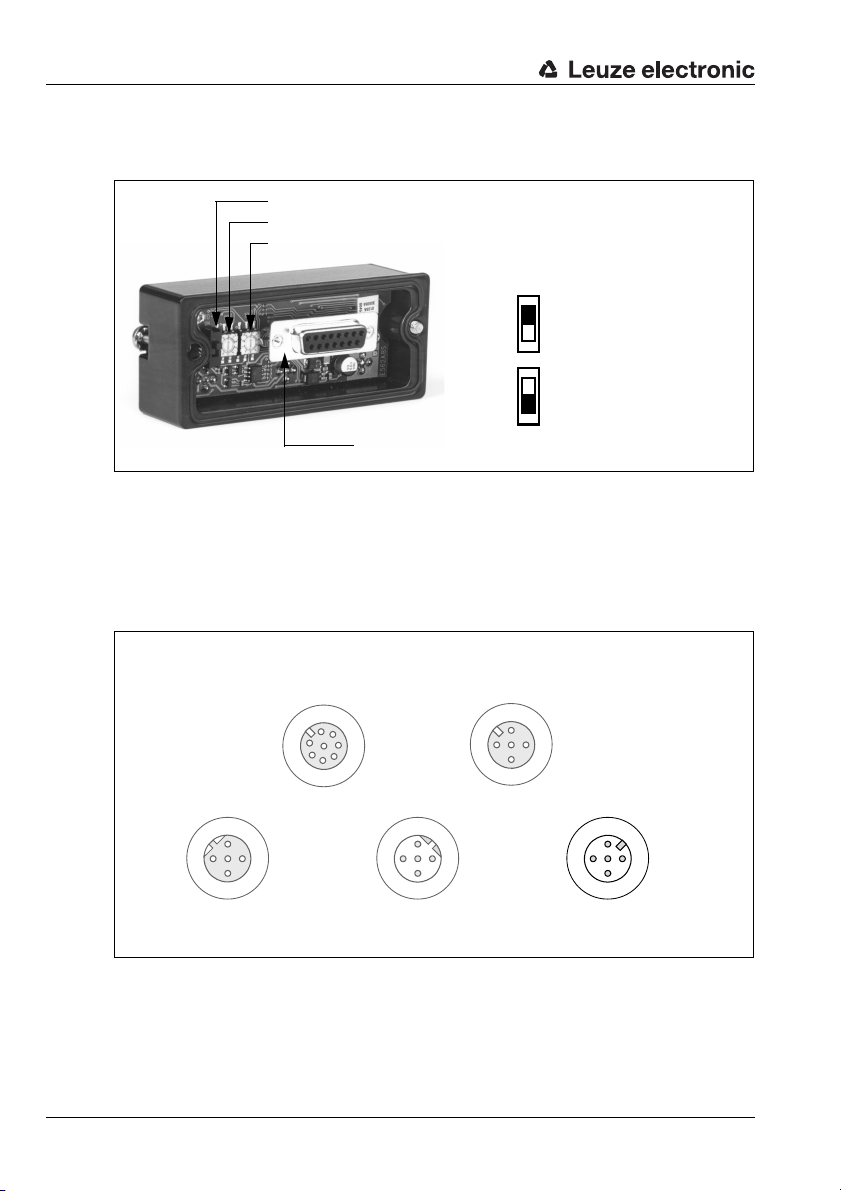

Slide switch for the hundreds (marked with 102)

Rotary switch for the tens (marked with 10

1

)

Rotary switch for the single digits (marked with 10

0

)

Connector to the BCL 34

Position of the slide

switch:

Top address

100 - 126

Bottom address

1 - 99

Socket connector

(A coded)

Socket connector

(A coded)

Socket connector

(B coded)

Plug connector

(B coded)

Plug connector

(A coded)

Setting the PROFIBUS address

The PROFIBUS address must be set in the MS 34 10x connector plug hood.

Figure 3.2: View of the inside of the MS 34

Connecting the voltage supply and PROFIBUS

The BCL 34, in combination with an MS 34 103 or MS 34 105, is connected via M 12

connectors.

Connecting the voltage supply

The voltage supply is connected via the PWR M12 connection.

SERVICE

VIN

TXD

2

/INT

/SERV

A (N)

2

4

B (P)

3

GND

GND

FE

BUS OUT HOST/BUS IN PWR

VCC

1

3

1

4

5

7

6

SDA

GND

RXD

SCL

3

FE

Figure 3.3: BCL 34 with MS 34 103/MS 34 105 - Connection PWR

10 BCL 34 Leuze electronic

SW IN/OUT

SWOUT

2

VOUT

1

4

A (N)

2

4

B (P)

SWIN

VCC

1

3

FE

GND

GND

FE

SWOUT

3

2

1

4

SWIN

VIN

Commissioning steps at a glance

Socket connector

(A coded)

Socket connector

(A coded)

Socket connector

(B coded)

Plug connector

(B coded)

Plug connector

(A coded)

1

2

3

4

5

6

7

/SERV

VIN

TXD

RXD

SCL

SDA

GND

/INT

SWIN

SWOUT

3

2

1

4

GND

VIN

FE

1

2

3

4

VOUT

FE

SWIN

SWOUT

GND

GND

3

2

1

4

FE

A (N)

B (P)

VCC

VCC

1

2

3

4

A (N)

B (P)

GND

FE

SW IN/OUT

BUS OUT HOST/BUS IN PWR

SERVICE

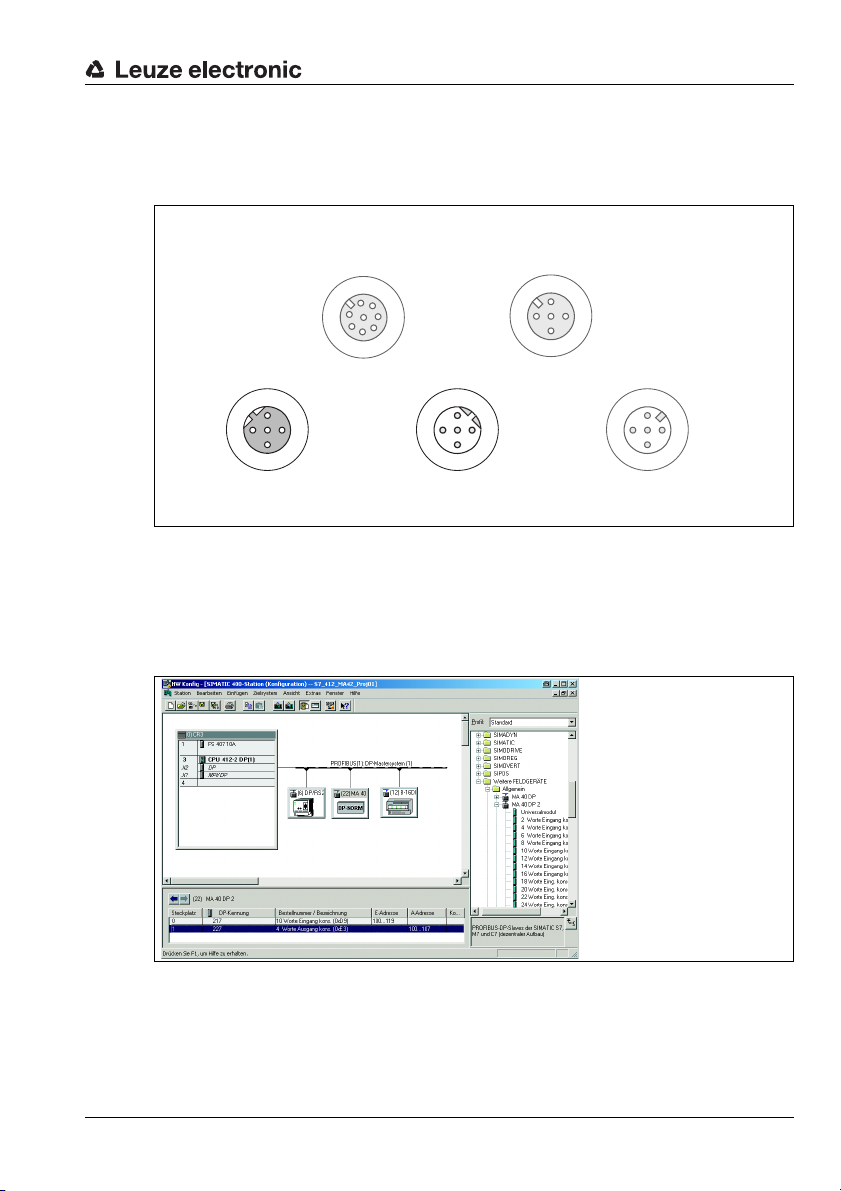

Connecting the PROFIBUS

The PROFIBUS is connected via HOST/BUS IN or, in the case of a continuing network, via

BUS OUT. If BUS OUT is not used, the PROFIBUS must be terminated at this point with

an M12 terminator plug (see "Accessories" on page 29.).

Figure 3.4: BCL 34 with MS 34 103/MS 34 105 - Connection HOST/BUS IN and BUS OUT

Configuration via the PROFIBUS hardware manager

PROFIBUS manager

Install the GSE file associated with the BCL 34 in the PROFIBUS manager of your control.

Activate the required modules, including at least one of the modules 20 … 27.

Figure 3.5: Example PROFIBUS manager

Leuze electronic BCL 34 11

Store the slave address for the BCL 34 in the PROFIBUS manager. Ensure that the address

is the same as the address configured in the device. As soon as the BCL 34 is addressed

and configured correctly and the PROFIBUS functions, the status LED at the MS 34 104 or

MS 34 105 lights up in green.

TNT 35/7-24V

Commissioning steps at a glance

Socket connector

(A coded)

Socket connector

(A coded)

Socket connector

(B coded)

Plug connector

(B coded)

Plug connector

(A coded)

Socket connector

(A coded)

Socket connector

(A coded)

Socket connector

(B coded)

Plug connector

(B coded)

Plug connector

(A coded)

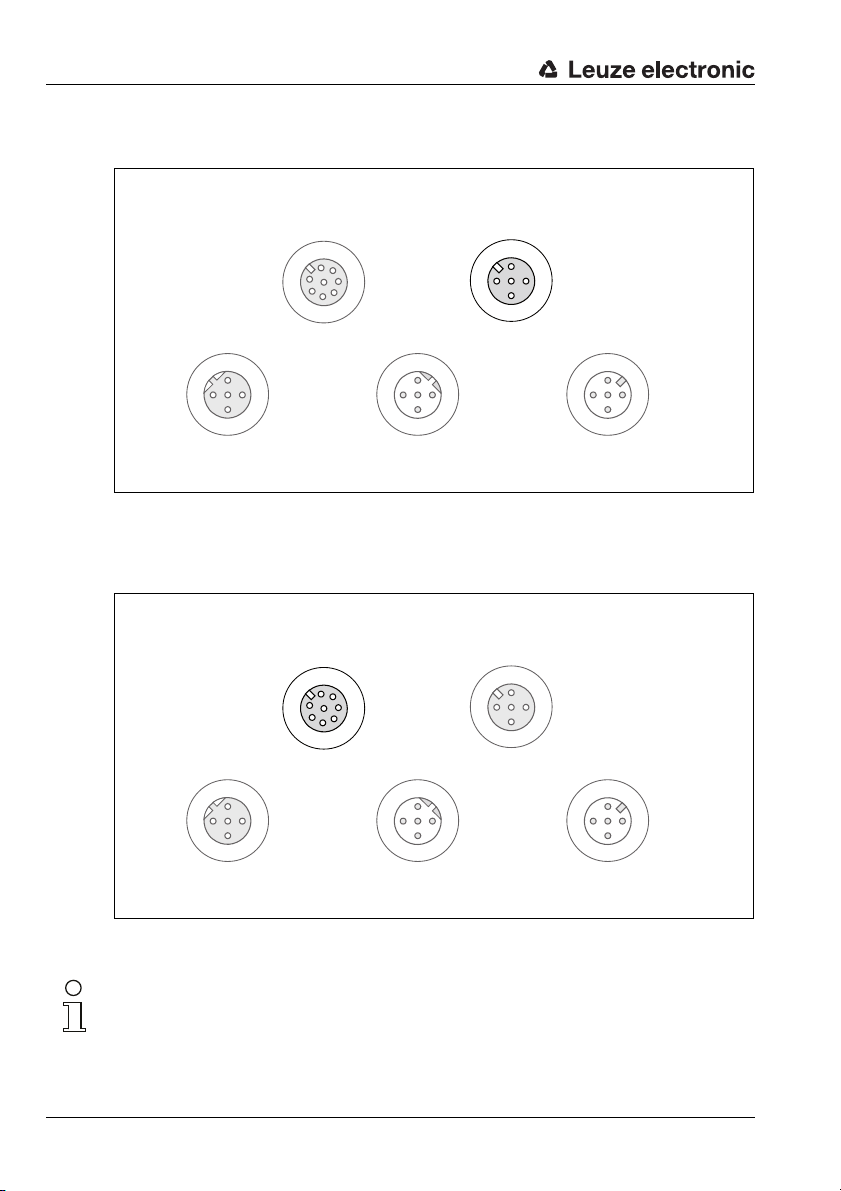

Connecting the switching input/switching output at the BCL 34

The switching input/switching output is connected via SW IN/OUT.

SERVICE

VIN

TXD

2

/INT

/SERV

A (N)

2

4

B (P)

3

GND

GND

FE

BUS OUT HOST/BUS IN PWR

VCC

1

3

SDA

RXD

4

5

SCL

6

3

GND

FE

1

7

A (N)

2

4

B (P)

SW IN/OUT

VOUT

VCC

1

SWOUT

1

SWIN

2

GND

3

4

FE

SWOUT

2

3

GND

FE

4

SWIN

VIN

1

Figure 3.6: BCL 34 with MS 34 103/MS 34 105 - Connection SW IN/OUT

Connecting the Modular Service Display MSD 1 101

The MSD 1 101 is connected via cable KB 034-2000 (M12 connection on SERVICE and

M12 connection on MSD 1 101, see "Connection cable KB 034 2000" on page 32. on ).

A (N)

2

4

B (P)

SW IN/OUT

VOUT

VCC

1

SWOUT

1

SWIN

2

GND

3

4

FE

SWOUT

2

3

GND

FE

4

SWIN

VIN

1

SERVICE

VIN

TXD

2

/INT

/SERV

A (N)

2

4

B (P)

3

GND

GND

FE

BUS OUT HOST/BUS IN PWR

VCC

1

3

1

4

5

7

6

SDA

GND

RXD

SCL

3

FE

Figure 3.7: BCL 34 with MS 34 103/MS 34 105 - Connection SERVICE

The BCL 34 can be accessed via the MSD 1 101 using the service interface.

Notice!

Changes which were made via the service interface on the BCL 34 are lost following initialisation on the PROFIBUS.

12 BCL 34 Leuze electronic

4 Description

Reading

window

4 fastening threads M4 x 6 on

the rear of the device

15-pin sub D connector on the underside of the unit

Dovetail fastening

grooves

4.1 On the barcode readers BCL 34

Description

BCL 34 device construction

Figure 4.1: BCL 34 device construction

The bar code readers BCL 34 are high-speed scanners with integrated decoder for all bar

codes currently in use, e.g. 2/5 Interleaved, EAN etc.

The many possible configurations of the device via PROFIBUS modules permit its adaptation to a multitude of reading tasks. Due to the small dimensions of the unit and the short

minimum reading distance, the BCL 34 may also be used in highly constrained spaces.

A special barcode reader with optics version J is available for all ink jet applications. This

reader has been optimised for low contrast barcodes that generally feature gaps. Furthermore, device variants with integrated heating are available.

Information on technical data and characteristics can be found in chapter 5.

TNT 35/7-24V

AutoReflAct

AutoReflAct stands for Automatic Reflector Activation and permits an activation without

additional sensors. This is achieved by directing the scanner with reduced scanning beam

towards a reflector mounted behind the conveyor path. As long as the scanner is targeted

at the reflector, the read gate remains closed. If, however, the reflector is blocked by an

object such as a container with a barcode label, the scanner activates the read procedure,

and the label on the container is read. When the path from the scanner to the reflector has

cleared, the read procedure has completed and the scanning beam is reduced and again

directed onto the reflector. The reading gate is closed.

Leuze electronic BCL 34 13

Description

4.2 Modular hoods with integrated connectors MS 34 103/MS 34 105

The modular hoods with integrated connectors are necessary accessories for connecting

a BCL 34 in a PROFIBUS system. They are used to feed through the PROFIBUS connections, set the PROFIBUS address, and supply voltage to the BCL 34.

MS 34 103

The MS 34 103 offers the following interfaces:

• PROFIBUS In (HOST/BUS IN)

•PROFIBUS Out (BUS OUT)

• Voltage supply (PWR) and 1 switching input and output each (SW IN/OUT)

Figure 4.2: MS 34 103

MS 34 105

In addition, the MS 34 105 offers the following interfaces:

• Service interface (SERVICE)

• 1 further switching input and output each (SW IN/OUT)

Figure 4.3: MS 34 103

Further information on the modular hoods with integrated connectors may be found in the

following chapters.

14 BCL 34 Leuze electronic

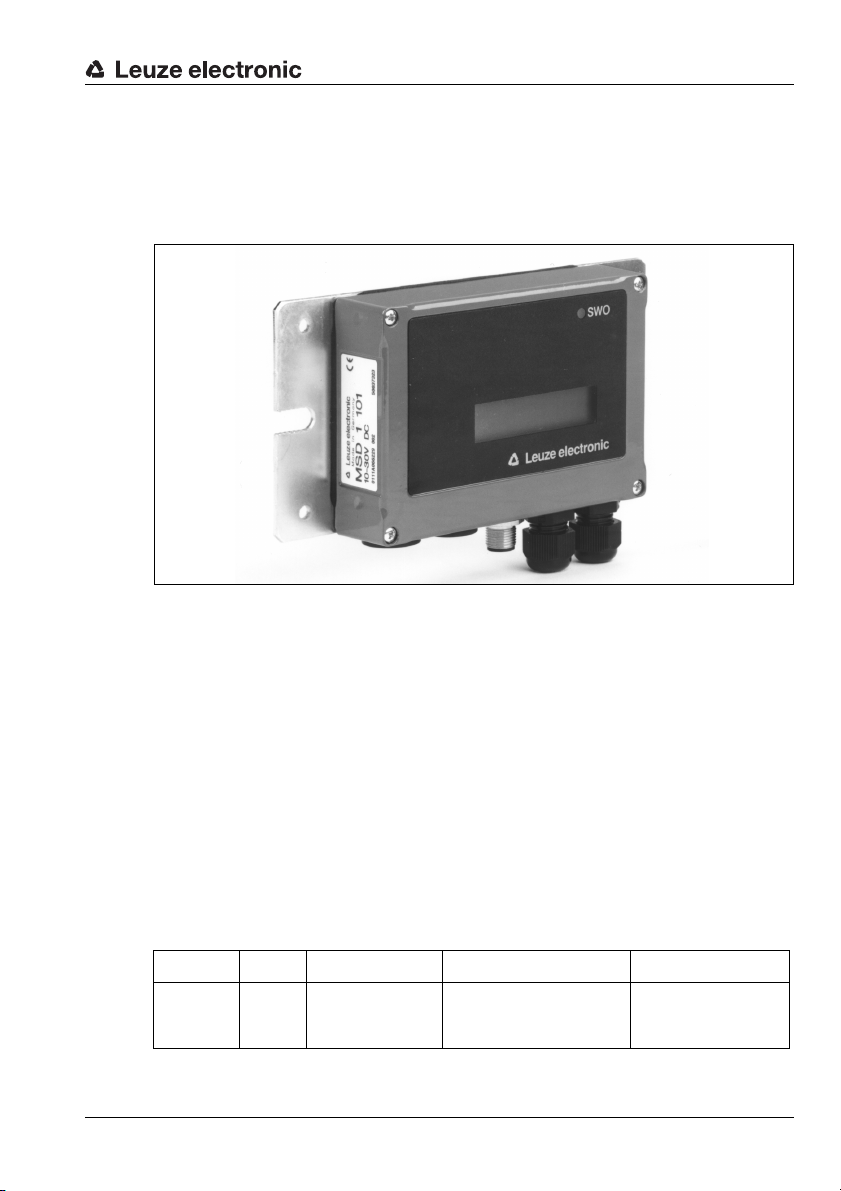

4.3 Modular Service Display MSD 1 101

The modular service display is used to display the reading and operational data on the one

hand, and as simple access to the service interface on the other. The RS 232 service interface of the BCL 34is tapped in this case and is made available at the 9-pin sub D connector

of the MSD (for further information see page 30).

Figure 4.4: MSD 1 101

To connect to the MS 34 105, an 8-pin cable (M12) with a length of 2 m is used (see

chapter 6 "Accessories / Order Designation").

The MSD can be operated in different display modes which are stored in the parameter set

of the BCL. The required parameter for setting up the display mode can be altered via the

service interface. The LCD display contains two lines with 16 characters each. There are

3 display modes:

1. Single line:

a result is output in one line. If the information is longer than 16 characters, the characters > 16 are cut off. This means that two results may be output on the LCD display.

2. Double line:

a result is displayed over both lines. Thus, only one result is visible in the display.

3. Depending on the size:

if a result is > 16 characters, both lines are used

if a result is < 16 characters, one line is used and two results are displayed

Description

TNT 35/7-24V

Address Size Designation Value Range Standard

161 Byte lcd_output_format

Leuze electronic BCL 34 15

1: single line (two results)

2: double line (one result)

0: depending on the size

2: double line

(one result visible)

Description

The input can be specified as a PT commentary or in the BCL Config parameter list, e.g.,

PT0001610x.

Using the maintenance display, new settings for the BCL can be tried quickly and easily,

without having to project these settings via the PROFIBUS. If these settings are to be

accepted for standard operation, these must be configured via PLC.

Notice!

With very few exceptions, the BCL 34 is configured via the PROFIBUS connection

group.Parameters which were set via the service interface are, therefore, overwritten in

PROFIBUS operation by the parameters stored in the project. If parameters in the project

were not explicitly changed, the corresponding default parameters are transferred.

In the BCLConfig configuration software, the parameter input fields which can be overwritten by the PROFIBUS are displayed with a blue background. Parameter input fields which

are not overwritten by the PROFIBUS are displayed with a white background.

If these parameters were changed, they are stored in one of the available parameter memories in the MS 34. They are, thus, safely stored even if a BCL 34 is replaced.

16 BCL 34 Leuze electronic

5 Specifications

5.1 General specifications of the BCL 34

Optical data

Light source laser diode 650 nm

Scanning rate BCL with M optics: 1000scans/s

BCL with F optics: 800 scans/s

BCL with L optics: 800 scans/s

BCL with J optics: 1000scans/s

Resolution BCL 3x xM 100: m = 0.2mm … 0.5mm

BCL 3x xF 100: m = 0.3mm … 0.8mm

BCL 3x xL 100: m = 0.35mm … 0.8mm

BCL 3x xJ 100: application-dependent

Reading distance see reading curve

Laser class 2 acc. to EN 60825-1,

II acc. to CDRH

Code types all common code types

Software features selectable output format, autoControl, autoReflAct, reference

code comparison, adjustment mode, diagnosis, reading gate

control, control of switching inputs and switching outputs, etc.

Electrical data

Interface type PROFIBUS DP

Service interface only in combination with MS 34 105: RS232 with fixed data

format,

8 data bits, no parity, 1 stop bit,

9.6kBd

Ports 1 switching output, 1 switching input

Operating voltage without heating: 10 … 30V DC

with heating: 22 … 26V DC

Power consumption without heating: 5W

with heating: max. 30W (of which window heating

accounts for: 1.5W)

Indicators

LED see chapter 5.2 "LED indicators"

Mechanical data

Protection class IP 65

BCL 34 MS 34

Weight without heating: 405g

with heating: 480g

Dimensions (W x H x D) without heating: 120 x 90 x 43mm

with heating: 120 x 90 x 52mm

Housing diecast aluminium diecast zinc

Specifications

TNT 35/7-24V

160g

38 x 90 x 39mm

Leuze electronic BCL 34 17

Specifications

Environmental data

Ambient temp. (operation/

storage)

Air humidity max. 90% rel. humidity, non-condensing

Vibration IEC 60068-2-6, test FC

Shock IEC 60068-2-27, test Ea

Electromagnetic

compatibility

Additional Functions

autoReflAct automatic reading activation via reflector

Table 5.1: General Specifications

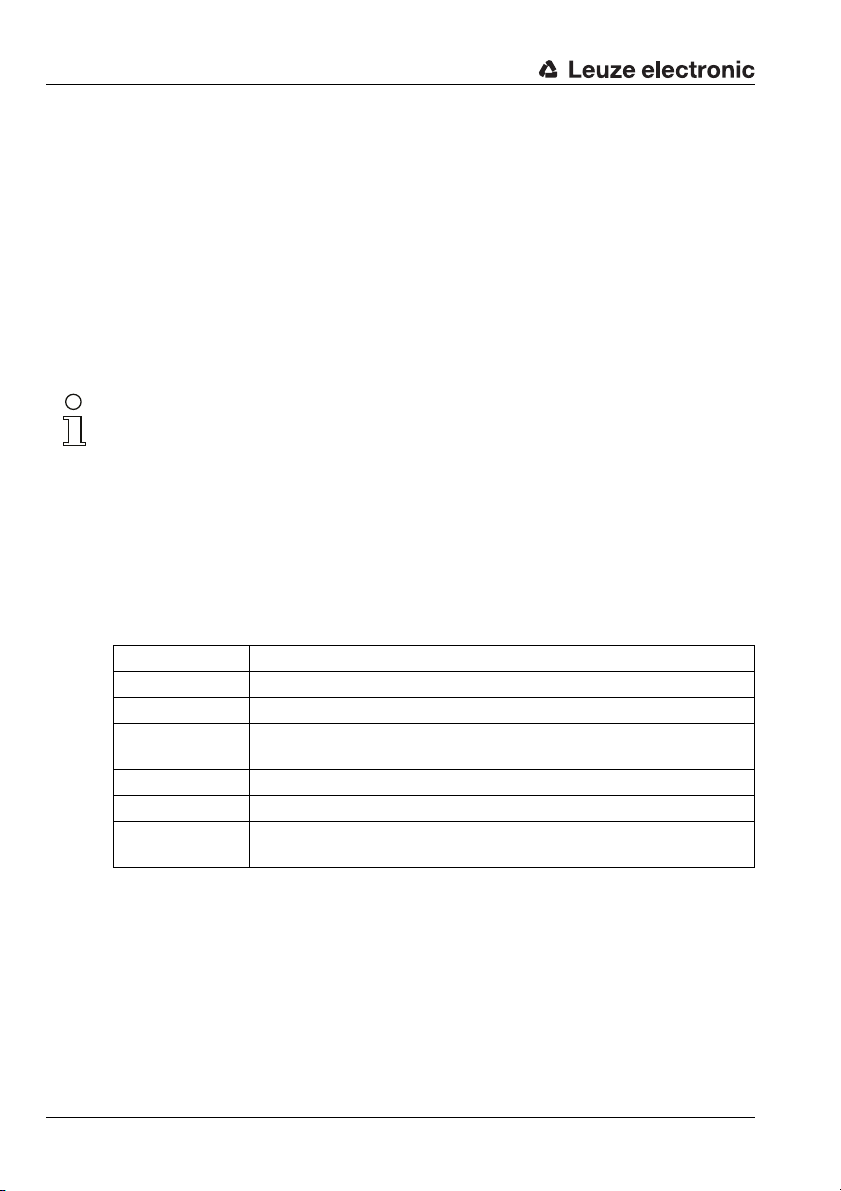

Notice!

The warm-up time before devices with integrated heating are ready for operation is

approx. 30min. (depending on the environmental conditions).

5.2 LED indicators

MS 34 103 / MS 34 105

On top of the modular hood with integrated connectors a red/green status LED is located

between the M12 connectors HOST/BUS IN and BUS Out. It indicates the state of the

PROFIBUS connection.

without heating: 0°C … +40 °C/-20 °C … +60 °C

with heating: -35°C … +30°C/-20°C … +60°C

EN 61326-1,

IEC 61000-4-2, -3, -4 and -6,

State Meaning

1)

off voltage off or device not yet recognised

by the PROFIBUS

green flashing initialisation of the device, establishment of the PROFIBUS communication

green, continuous

light

data operation

red, flashing error on the PROFIBUS, error can be resolved by a reset

red, continuous light error on the PROFIBUS, error cannot be resolved by a reset

orange, continuous

light

SERVICE operation active

Table 5.2: LED states MS 34 103 / MS 34 105

1) Note: The LED remains off until the BCL 34 is recognised by the PROFIBUS. Only after

the PROFIBUS has addressed the BCL 34 for the first time do the following status

descriptions apply.

18 BCL 34 Leuze electronic

5.3 Device Construction and Components

Plan view

(without heating)

Rear view

all dimensions in mm

Plan view

(with heating)

A modular hood of type MS 34 103 or MS 34 105 with integrated connectors is part of

every BCL 34. The two hoods with integrated connectors are used to connect the BCL 34

to the PROFIBUS. For this, they feature one HOST/BUS IN and BUS OUT connection each,

as well as an internal switch for address setting.

If only the connection to the PROFIBUS is intended, type MS 34 103 is sufficient.

If, in addition, switching input and output or a modular service display are to be connected,

an MS 34 105 is required. Although switching inputs and outputs are available on the

voltage supply connector, the switching inputs of the MS 34 105 have the advantage that

a standard sensor connector can be used.

Specifications

Figure 5.1: BCL 34 with MS 34 105

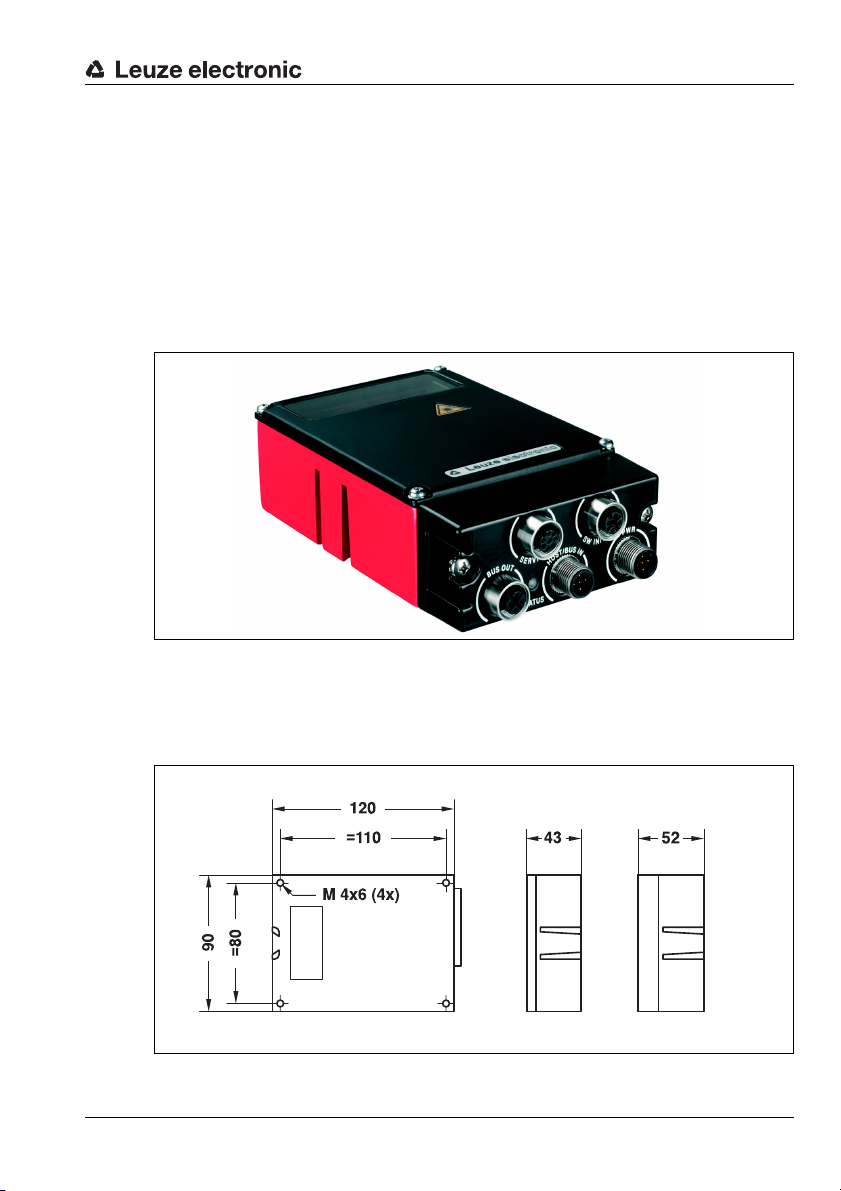

5.3.1 Dimensioned and Connection Drawings

BCL 34

Figure 5.2: Dimensioned drawing of the BCL 34

Leuze electronic BCL 34 19

TNT 35/7-24V

Specifications

A = Barcode reader

1)

1)

1) The total length of the barcode reader + hood with

integrated connectors + connection plug is approx.

all dimensions in mm

MS 34 103 / MS 34 105

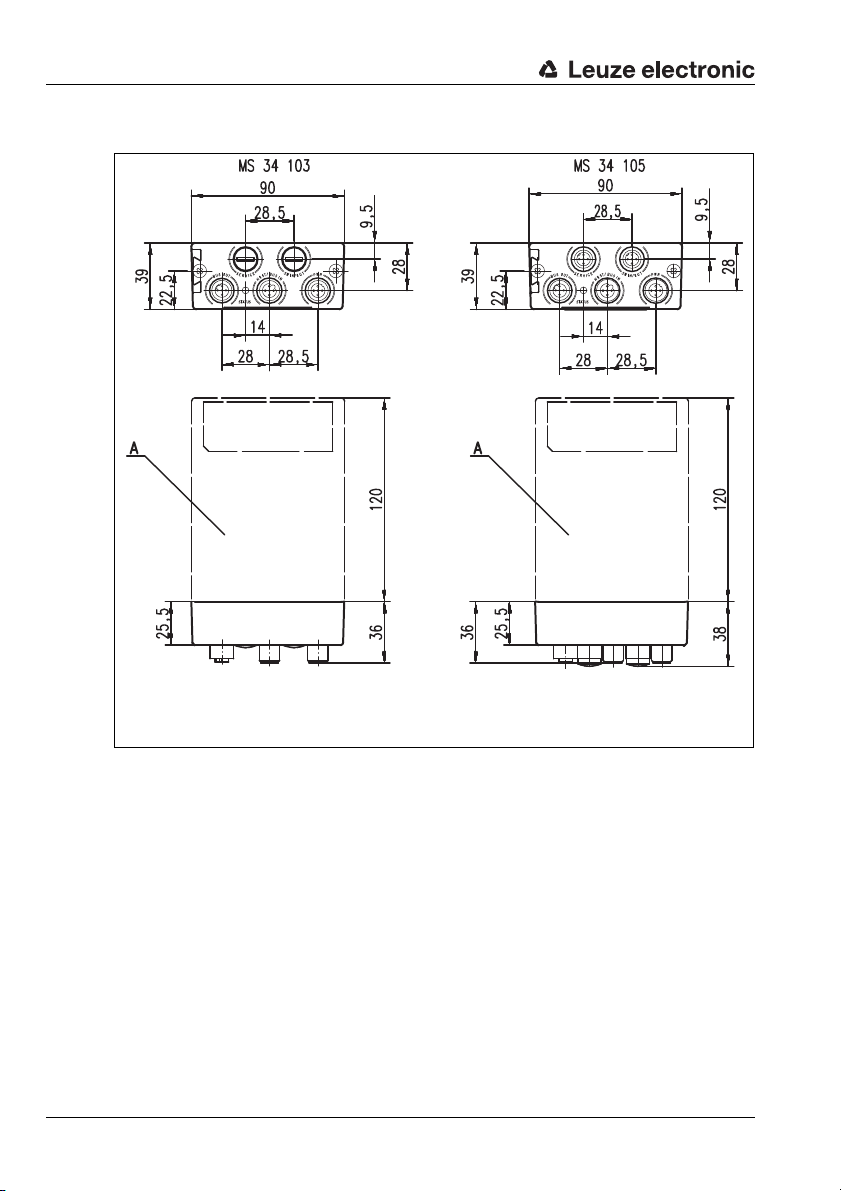

Figure 5.3: Dimensioned drawing MS 34 103 / MS 34 105

20 BCL 34 Leuze electronic

5.4 Optical data

Notice!

Please note that the size of the barcode module influences the maximum reading distance

and the width of the reading field. Therefore, when selecting a mounting location and/or the

barcode label, take into account the different reading characteristics of the scanner with

various barcode modules.

For different reading tasks, the BCL 34 is available in various versions, both as a raster

scanner and as a single line scanner. Please refer to the following table or the respective

scanning curves for ratings.

5.4.1 Type overview

Models without integrated heating

Specifications

Maximum

possible oper-

Model

BCL 34 S M 100

BCL 34 R1 M 100 Raster 500 37227

BCL 34 S F 100

BCL 34 R1 F 100 Raster 500 37226

BCL 34 S L 100

BCL 34 R1 L 100 Raster 500 41382

BCL 34 S J 100

BCL 34 R1 J 100 Raster 500 41801

Table 5.3: Type overview BCL 34 without integrated heating

ating range

up to 220mm 0.2 … 0.5 1000

up to 550mm 0.3 … 0.8 800

up to 750mm 0.35 … 0.8 800

up to 570mm 0.5 … 0.8 1000

Module/

resolution

(mm)

Scanning

rate

(scans/s)

Scanner type Order No.

Single line 500 37229

Single line 500 37228

Single line 500 41381

Single line 501 04023

Models with integrated heating

Maximum

possible oper-

Model

BCL 34 S M 100 H

BCL 34 R1 M 100 H Raster 500 39130

BCL 34 S F 100 H

BCL 34 R1 F 100 H Raster 500 39127

BCL 34 S L 100 H

BCL 34 R1 L 100 H Raster 501 01901

BCL 34 R1 J 100 H up to 550mm 0.5 … 0.8 1000 Raster 501 01902

Table 5.4: Type overview BCL 34 Devices with integrated heating

ating range

up to 210mm 0.2 … 0.5 1000

up to 550mm 0.3 … 0.8 800

up to 650mm 0.35 … 0.8 800

Module/

resolution

(mm)

Scanning

rate

(scans/s)

Scanner type Order No.

Single line 500 39129

Single line 500 39128

Single line 501 01903

TNT 35/7-24V

Leuze electronic BCL 34 21

Specifications

-70

-60

-50

-40

-30

-20

-10

0

10

20

30

40

50

60

70

0 20 40 60 80 100 120 140 160 180 200 220

m=0 ,2

m=0 ,3

m=0 ,5

Reading distance [mm]

Reading field width [mm]

5.4.2 Raster aperture

Raster aperture depending on various distances:

Scanner distance [mm] 50 100 200 300 400 450 700

Raster line field [mm] 15 21 32 44 55 61 84

5.4.3 Optics variants and reading fields

The BCL 34 is available with different optics. The optics differ in range and resolution (see

chapter 5.4.1).

•M optics:for small to medium modules

•F optics: for medium to large modules

•L optics: for medium to large modules

• J Optics: for ink-jet applications or if the barcodes are of low contrast or have gaps.

The following graphics display the ranges of the various BCL models.

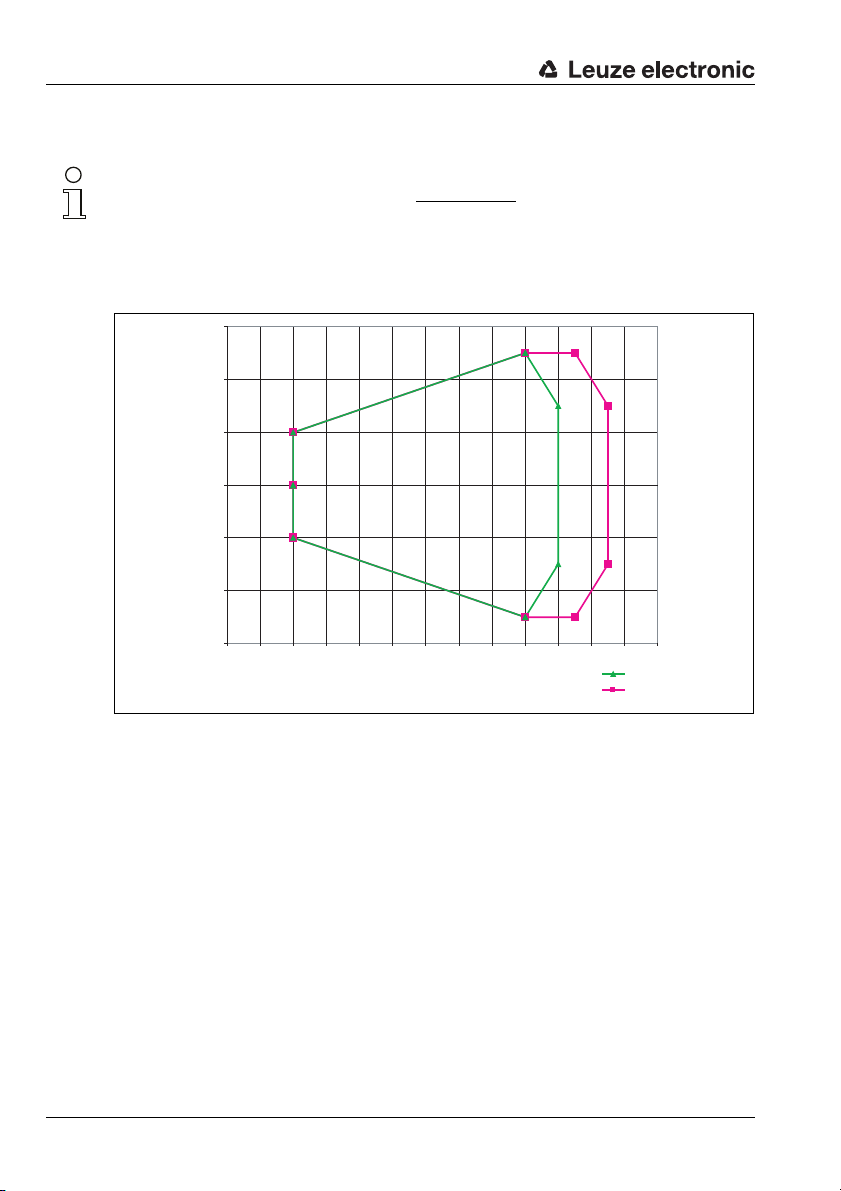

Notice!

Please notice that the real scanning curves are also influenced by factors such as labelling

material, printing quality, scanning angle, printing contrast etc., and may thus deviate from

the scanning curves specified here.

The reading curves specified here were determined under the following conditions:

code type 2/5 interleaved, ratio = 1:2.5, label class A.

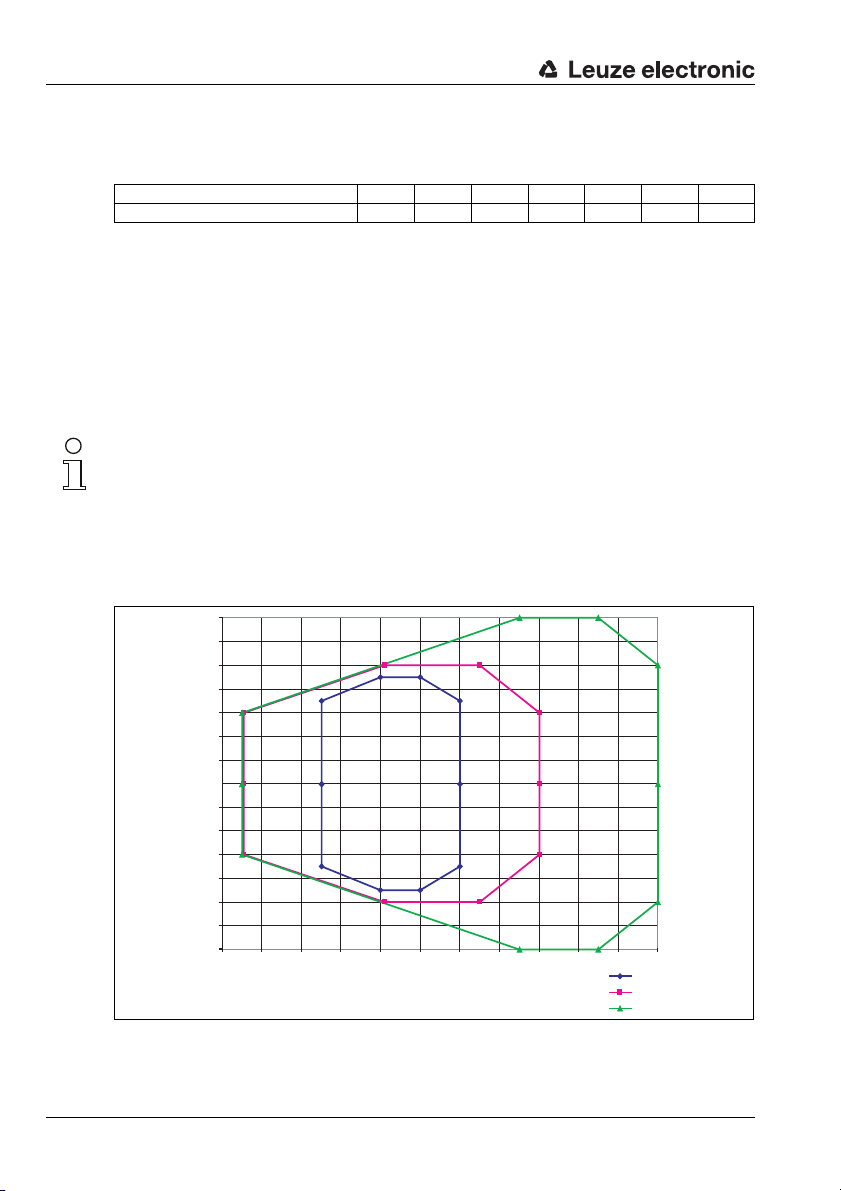

Reading curves BCL 34 without heating with M optics

Figure 5.4: BCL 34 … 100: Reading field, M optics (medium density, normal distance)

22 BCL 34 Leuze electronic

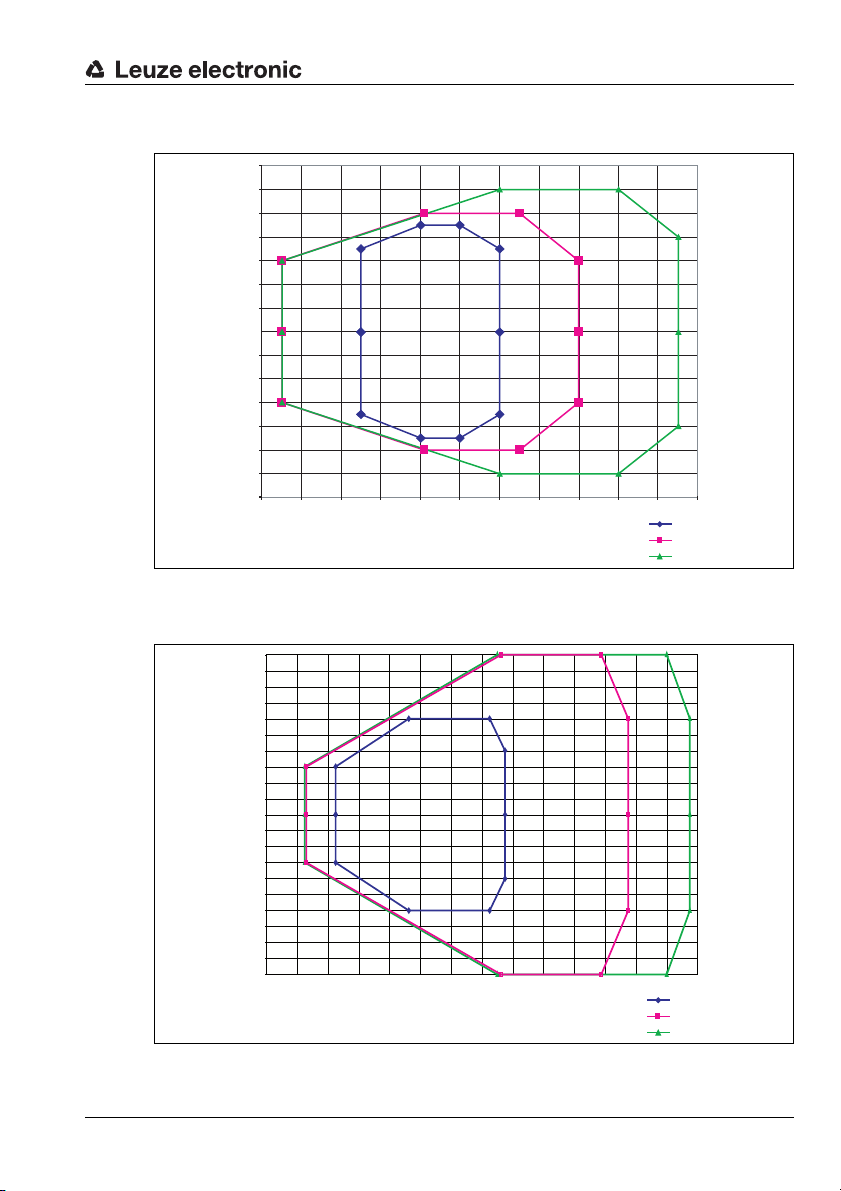

Reading curves BCL 34 without heating with F optics

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

10

20

30

40

50

60

70

80

90

100

0 40 80 120 160 200 240 280 320 360 400 440 480 520 560

m=0,3

m=0,5

m=0,8

Reading distance [mm]

Reading field width [mm]

-200

-150

-100

-50

0

50

100

150

200

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

m=0 ,3 5

m=0 ,5

m=0 ,8

Reading distance [mm]

Reading field width [mm]

Figure 5.5: BCL 34 … 100: Reading field, F optics (low density, normal distance)

Reading curves BCL 34 without heating with L optics

Specifications

Leuze electronic BCL 34 23

Figure 5.6: BCL 34 … 100: Reading field, L optics (low density, long distance)

TNT 35/7-24V

Specifications

m=0 ,5

m=0 ,8

-150

-100

-50

0

50

100

150

0 50 100 150 200 250 300 350 400 450 500 550 600 650

Reading distance [mm]

Reading field width [mm]

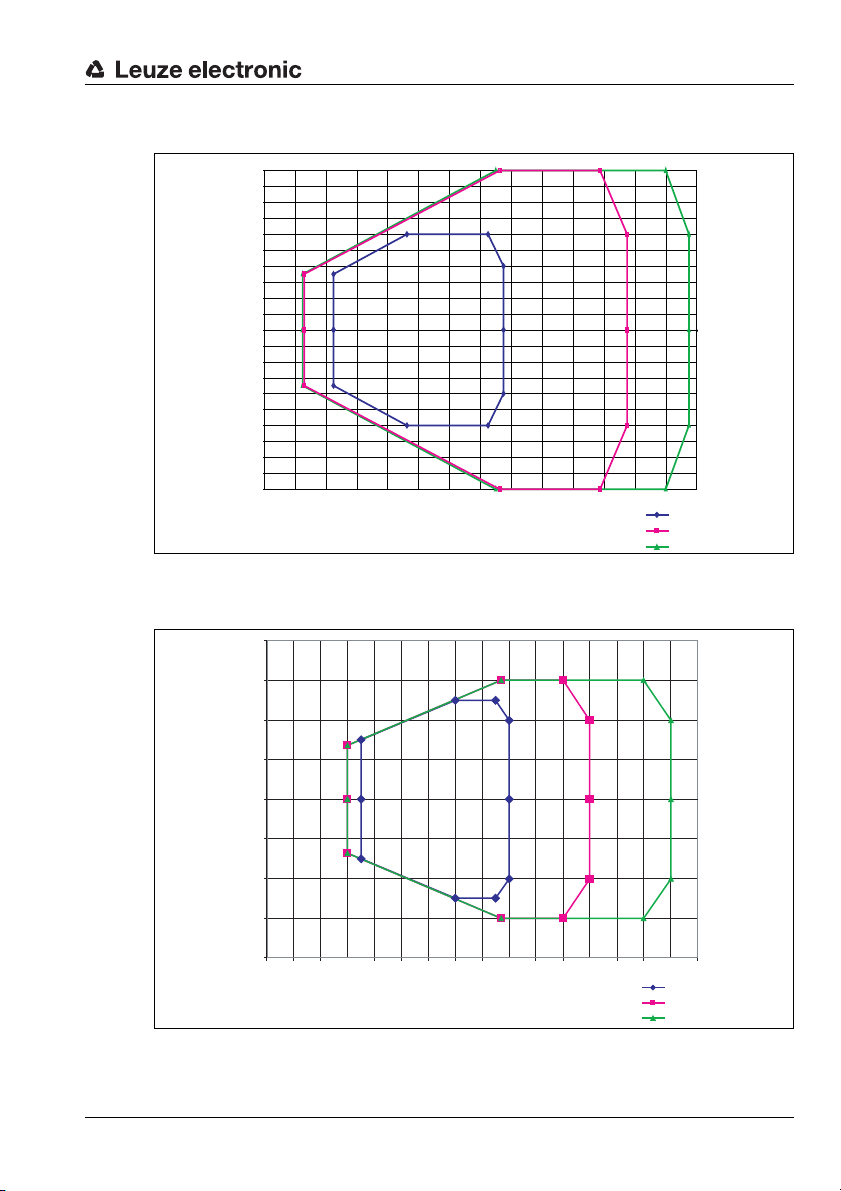

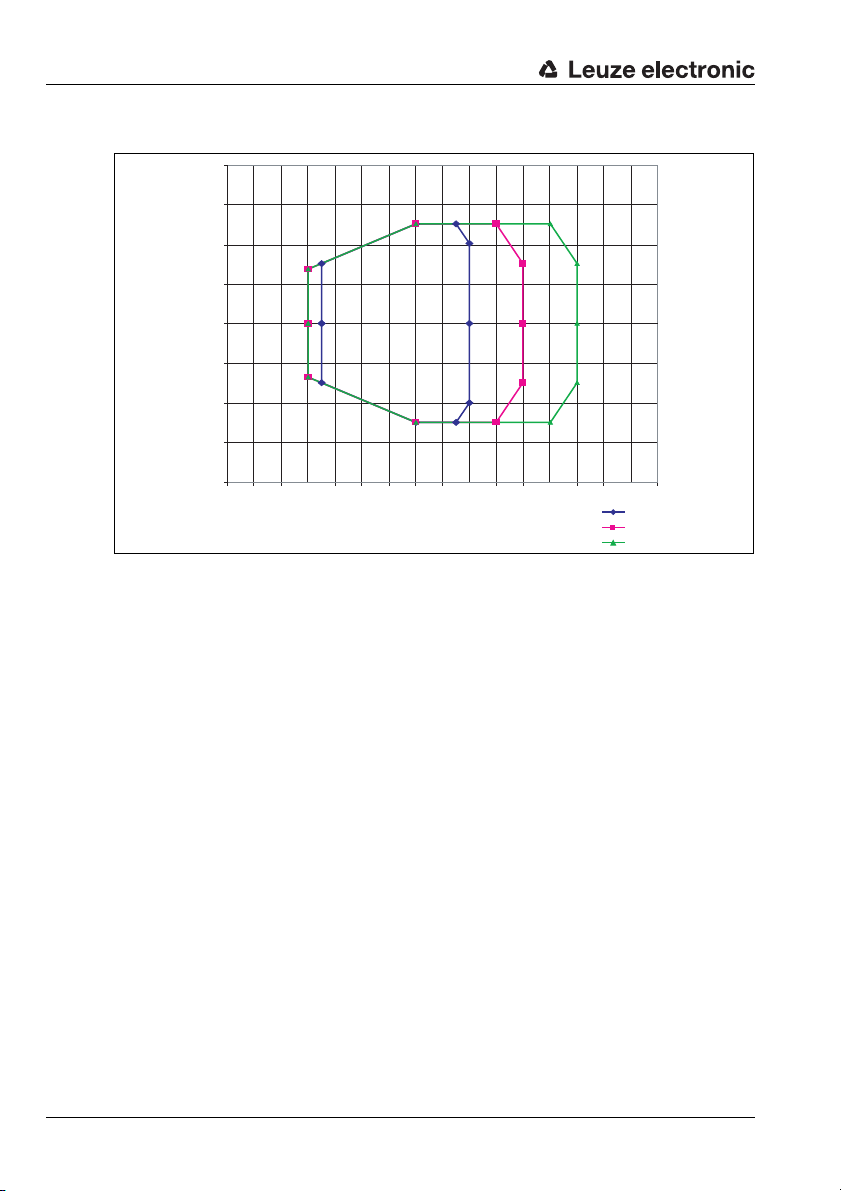

Reading curves BCL 34 without heating with J optics

Notice!

The specified reading curve applies to the standard case

black on white, sharp contours, homogeneously printed code.

The actual reading field for an ink-jet application must be checked for the respective

application.

:

Figure 5.7: BCL 34 … 100: Reading field, J optics (for ink-jet applications)

24 BCL 34 Leuze electronic

Specifications

Reading distance [mm]

Reading field width [mm]

m=0,3

m=0,5

m=0,8

Reading distance [mm]

Reading field width [mm]

Reading curves BCL 34 with heating with M optics

70

60

50

40

30

20

10

0

-10

-20

-30

-40

-50

-60

-70

0 20 40 60 80 100 120 140 160 180 200 220

Figure 5.8: BCL 34 … 100 H: Reading field, M optics (medium density, normal distance)

Reading curves BCL 34 with heating with F optics

100

90

80

70

60

50

40

30

20

10

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

0 40 80 120 160 200 240 280 320 360 400 440 480 520 560

m=0 ,2

m=0 ,3

m=0 ,5

TNT 35/7-24V

Figure 5.9: BCL 34 … 100 H: Reading field, F optics (low density, normal distance)

Leuze electronic BCL 34 25

Specifications

Reading distance [mm]

Reading field width [mm]

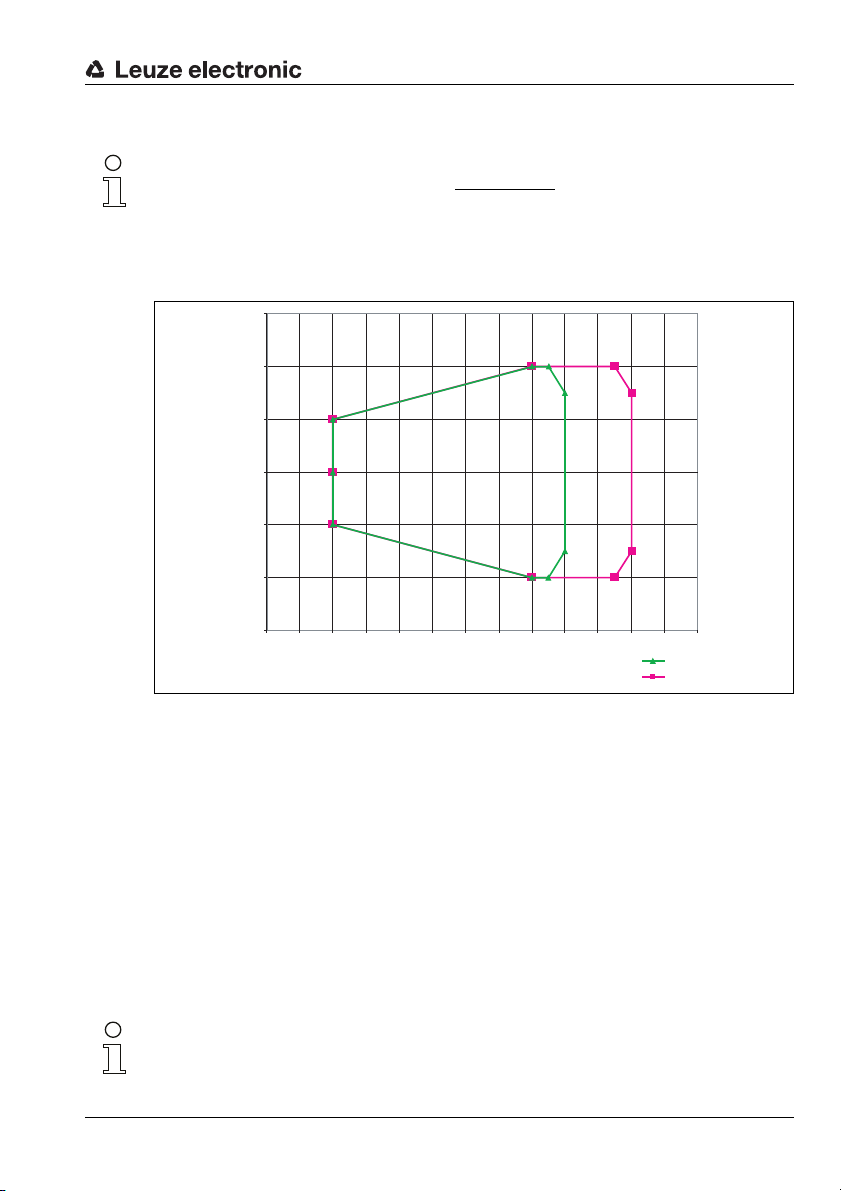

Reading curves BCL 34 with heating with L optics

Figure 5.10: BCL 34 … 100 H: Reading field, L optics (low density, long distance)

200

150

100

50

0

-50

-100

-150

-200

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

m=0 ,3 5

m=0 ,5

m=0 ,8

26 BCL 34 Leuze electronic

Specifications

Reading distance [mm]

Reading field width [mm]

Reading curves BCL 34 with heating with J optics

Notice!

The specified reading curve applies to the standard case

black on white, sharp contours, homogeneously printed code.

The actual reading field for an ink-jet application must be checked for the respective

application.

150

100

50

0

-50

-100

-150

0 50 100 150 200 250 300 350 400 450 500 550 600 650

:

m=0 ,5

m=0 ,8

Figure 5.11: BCL 34…100 H: Reading field, J optics (for ink-jet applications)

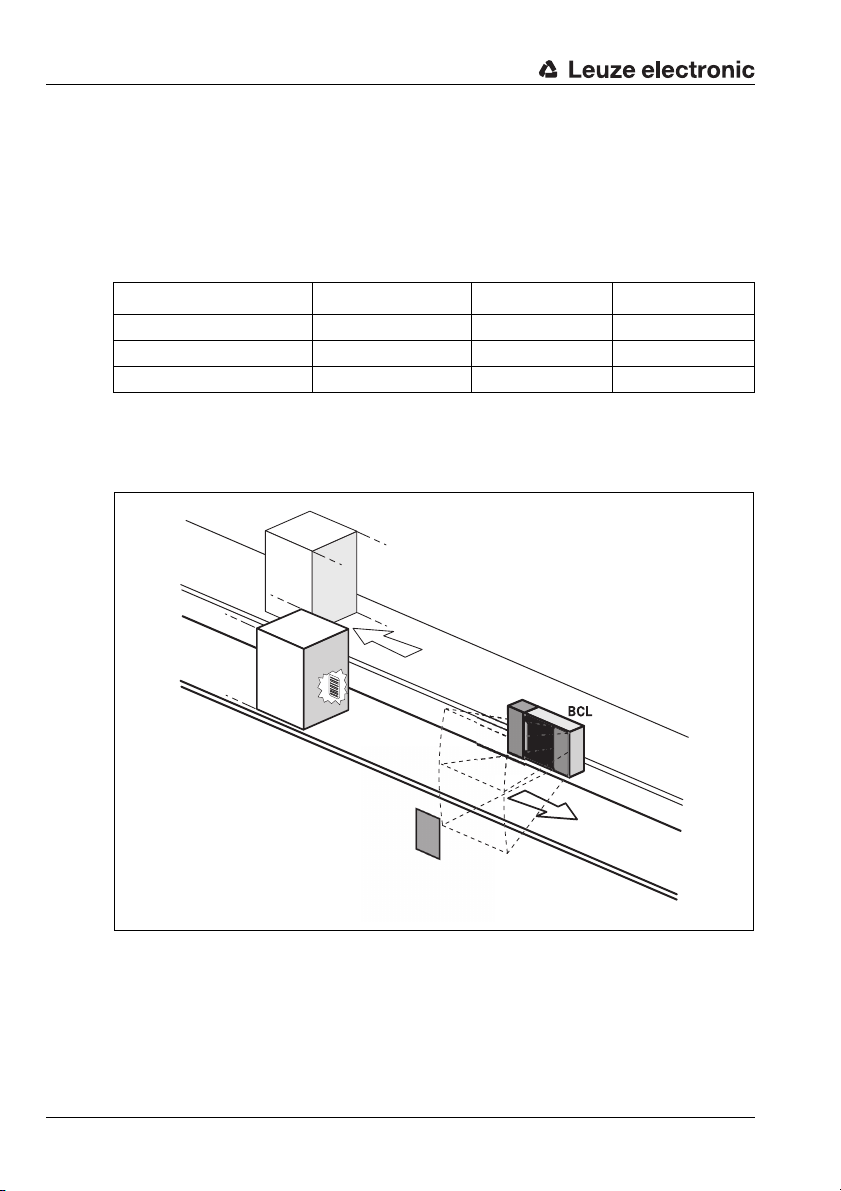

5.5 Automatic reflector activation "AutoReflAct"

The AutoReflAct function uses the scanning beam to simulate a photoelectric sensor and

thus permits an activation without additional sensory mechanism. This is achieved by

directing the scanner with reduced scanning beam towards a reflector mounted behind the

conveyor path.

As long as the scanner is targeted at the reflector, the read gate remains closed. If,

however, the reflector is blocked by an object such as a container with a bar code label,

the scanner activates the read procedure, and the label on the container is read. When the

path from the scanner to the reflector has cleared, the read procedure has completed and

the scanning beam is reduced and again directed onto the reflector. The reading gate is

closed.

Leuze electronic BCL 34 27

Notice!

autoReflAct does not function if the bar codes which are to be read are put on reflecting

surfaces, e.g. foils.

TNT 35/7-24V

Specifications

Reflector

Our recommendation:

• Use BCL 34 R1x100

• AutoRefl mode with or without reading gate control (single)

The maximum distances between the reflector and the BCL depend on the reflector used.

A summary is provided in the following table. The fundamental arrangement of reflector and

BCL is shown in figure 5.12.

Reflector type/reflective tape Max. distance (mm) Max. angle (°) Order No.

reflective tape no. 2 *) 1200 15 500 11523

TK 100x100 2000 20 500 03192

TKS 50x50 1000 20 500 22814

Table 5.5: Examples of reflectors which may be used

*) Reflective tape no. 2 is included

Application example: automatic reflector activation

Figure 5.12: Reflector arrangement for autoReflAct

28 BCL 34 Leuze electronic

Loading...

Loading...