Page 1

BA 11.1031

Show/Hide Bookmarks

453 985 EN

Operating Instructions

Simplabelt

Compact Units

Page 2

What is new / what has changed ?

Show/Hide Bookmarks

Material No. Edit ion Important Content s

00 178 416 1.0 06/94 TD09 1st edition First edition for pilot series

00 390 299 1.0 01/96 TD09 1st edition

Replaces 178 415

00 390 299 2.0 07/97 TD09 2nd edition

Replaces 1st edition

00 453 985 1.0 05/02 TD09 1st edition

Replaces 390 299

E 1998 - 2001 Lenze Drive Systems GmbH

No part of this documentation may be re produced or made accessible to third parties without written consent by Lenze Drive Systems GmbH.

All indications given in these Operating instructions have been selected carefully. We will include necessary corrections in subsequent editions.

Completely revised

Product key completed

Chapter 3.3.2 Ambient media: new

Chapter 6.4 Spare parts new

Chapter 3.1.2: Item numbers of spare parts list adapted

Chapter 6.1: Maintenance intervals completed

Chapter 6.4: Order form completed

BA 11.1031

Author: Lenze Drive Systems GmbH

Edition: 1.0 05/02

2

BA S’belt KEEN 1.0

l

Page 3

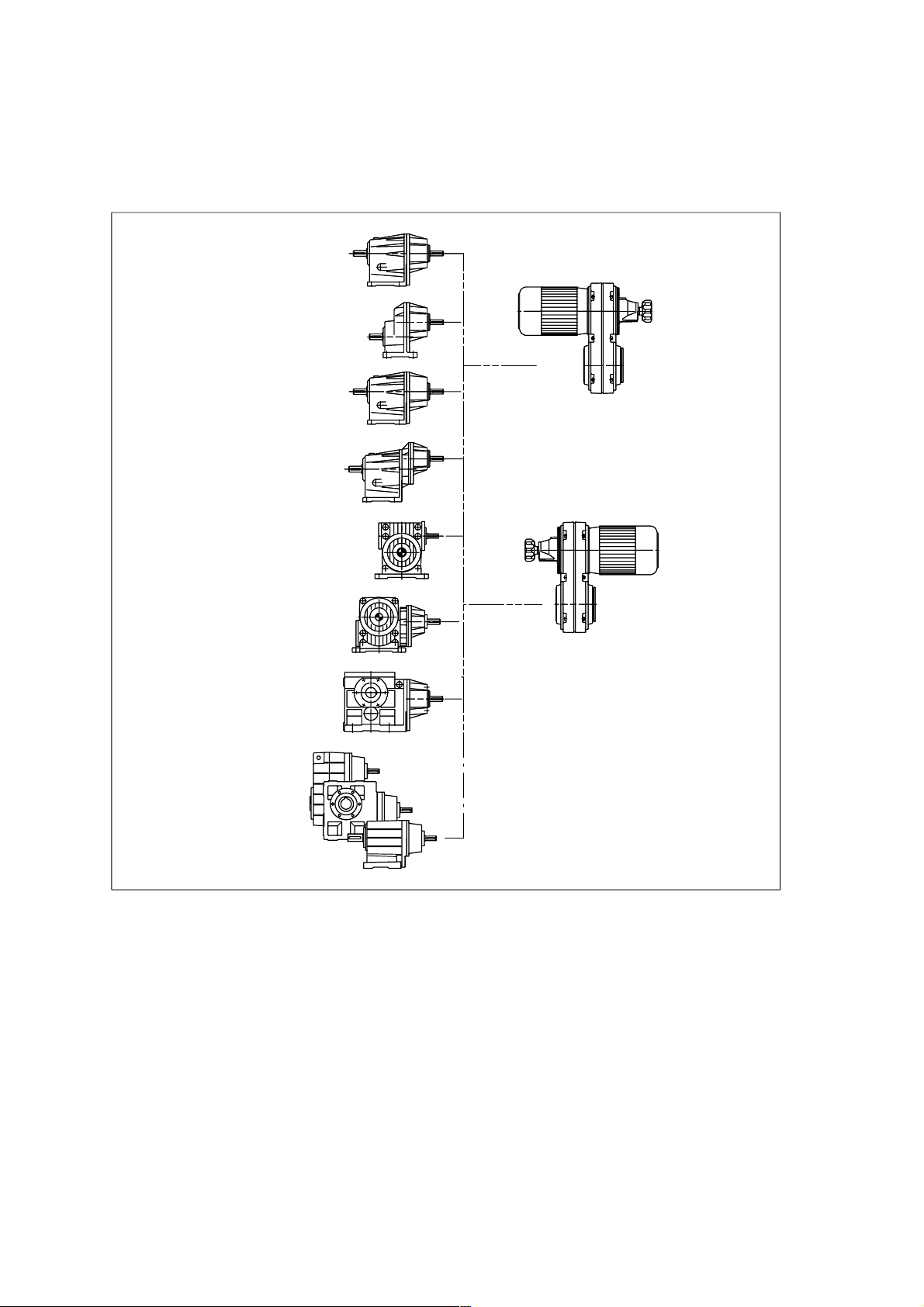

System overview

Show/Hide Bookmarks

12.600.LL

12.601.LL

12.602.LL

12.603.LL

!

&

52.154.LL

"

52.116.LL

#

12.503.LL

$

%

GLL

Helical gearbox i=1 # Helical worm gearbox

Single-stage helicalgearbox $ Helical bevel gearbox

Two-stage helical gearbox % Series GLL gearboxes

'

K11.0311/1

! Three-stage helical gearbox & Simplabelt variable speed drive for

" Wormgearbox compactunits inU-design

l

' Simplabelt variable speed drive for

compact units in Z-design

BA S’belt KEEN 1.0

3

Page 4

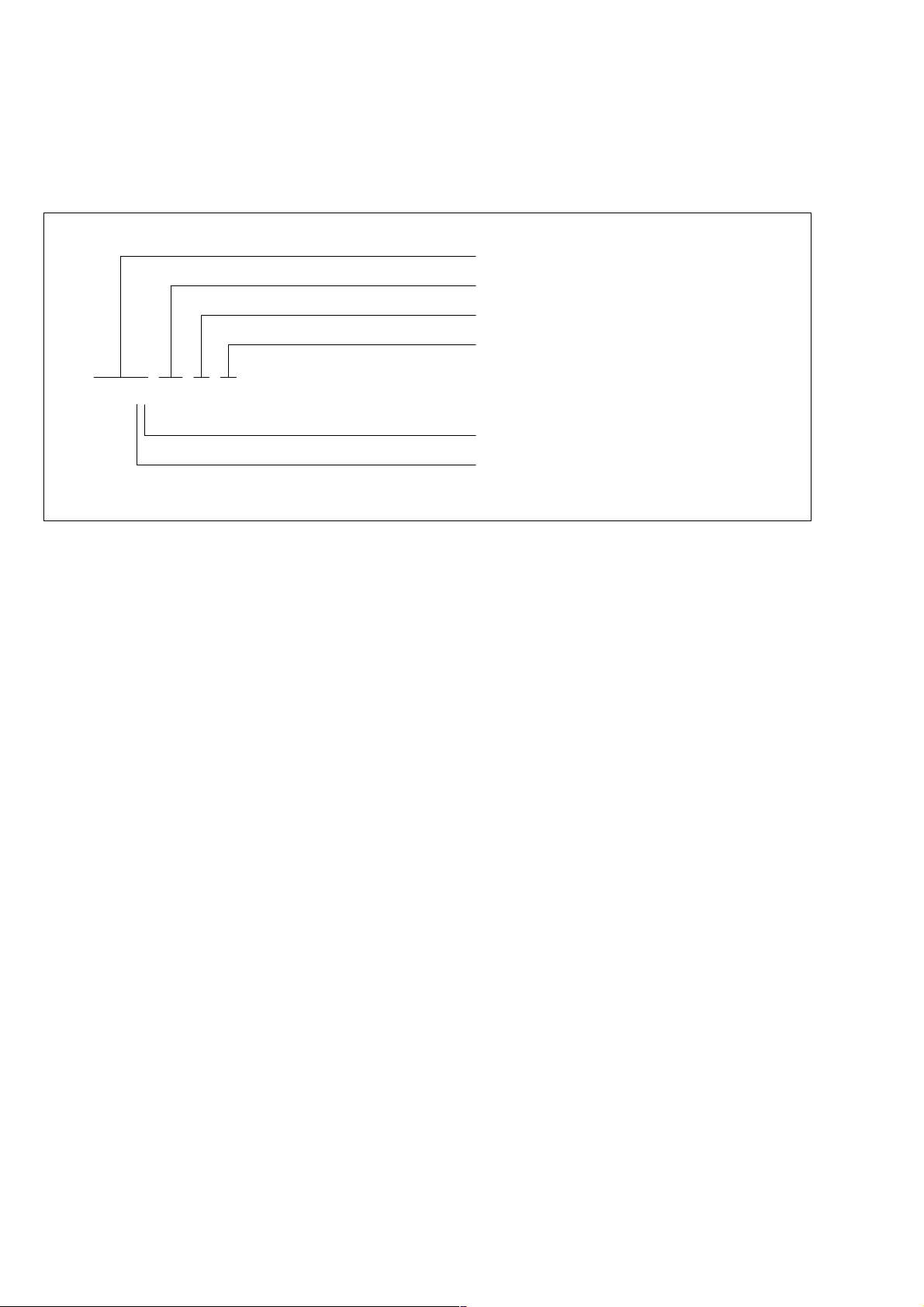

Type code

Show/Hide Bookmarks

11. 432 . 20 . 16 . 2

Type 11.432 (example)

Compact unit in U-design with two-stage helical gearbox

Sizes of the compact unit 10, 13, 16, 20, 25, 31, 40

Reduction gearbox sizes

!!!!

""""

####

Helical gearboxes 08, 10, 12, 16, 20, 25, 32

Worm gearboxes 04, 05, 06, 08, 10, 12

Helical worm gearboxes 15, 19, 24, 30

! Motor code

" Reduction gearbox design

0 = Helical gearbox i=1

1 = Single-stage helical gearbox

2 = Two-stage helical gearbox

3 = Three-stage helical gearbox

5 = Worm gearbox

6 = Helical worm gearbox

7 = Helical bevel gearbox

# Design of the compact unit

3=U-design

4=Z-design

Nameplate

The nameplate for the whole drive is attached to the housing of the modular unit.

4

BA S’belt KEEN 1.0

l

Page 5

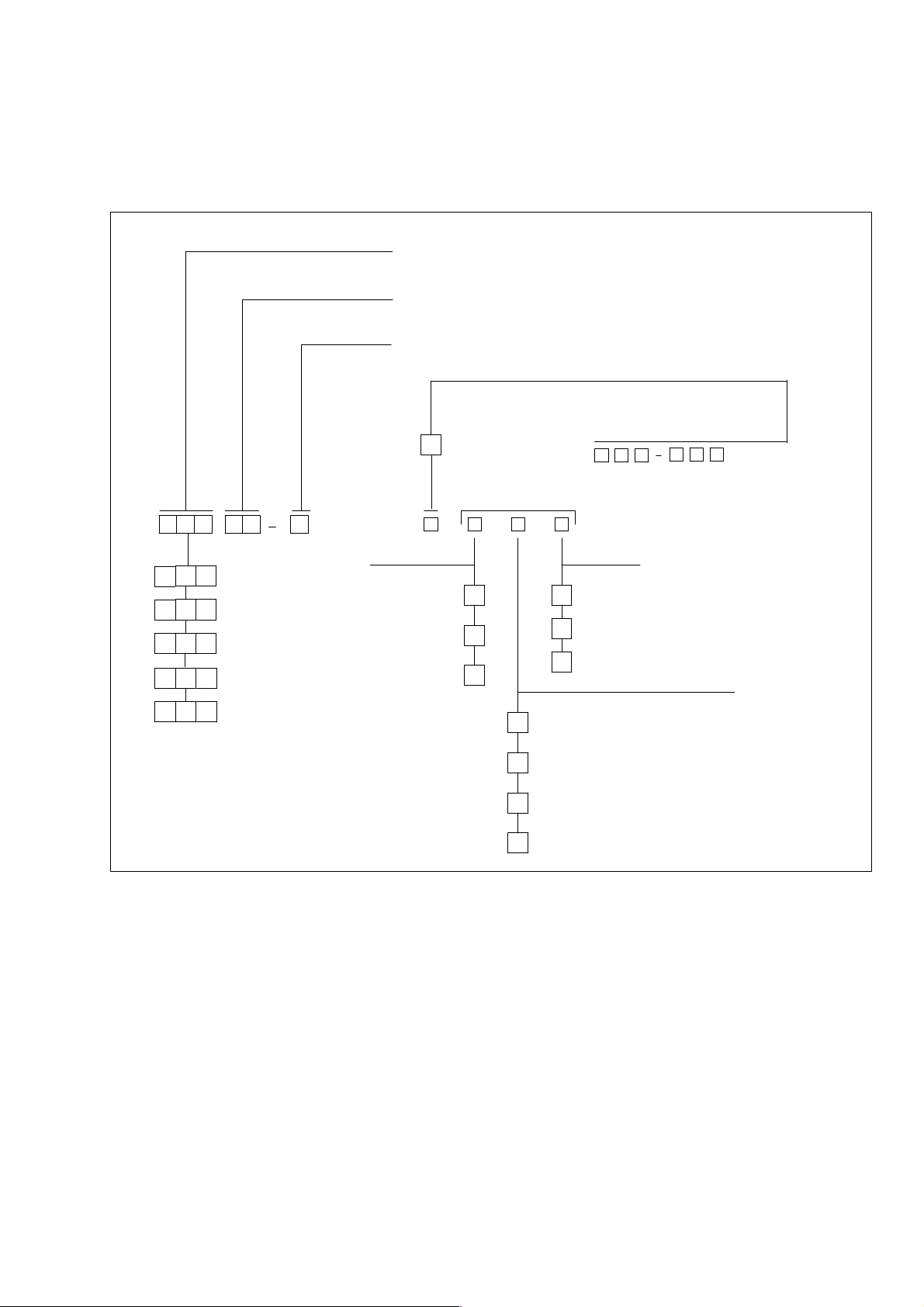

Product key

Show/Hide Bookmarks

Gear box t ype

Gear box si ze

Number of stag es

Input design

K12.0546

G

G

G

G

G

S

K

S

F

K

Helical gearbox

T

Low- profile gearbox

L

Helical-bevel gearbox

S

Bevel gearbox

R

Helical-wormgearbox

S

K

Shaf t

Solid shaft

Hollow shaft

Hollow shaft with

shrink di sk

Compact Units

Output design

V

H

S

A

B

C

D

R

K

Drive size

Output

wit hout fl ange

wit h fla nge (trough- holes)

L

wit h fla nge (thre aded-hol es)

Housin g w ith pitch circle

wit h centering and foot

wit h foot (without ce nteri ng)

wit h centering (without f oot)

wit hout centeri ng (without foot )

*

Product key with gearboxes of product family GLL

* according to product family

l BA S’belt KEEN 1.0

5

Page 6

Contents

Show/Hide Bookmarks

1 Preface and general information 8...........................................

1.1 How to use these Operating Instructions 8................................................

1.1.1 Terminology used 8.........................................................

1.2 Contents of delivery 8...............................................................

1.3 Lenze-drive systems 9..............................................................

1.3.1 Labelling 9................................................................

1.3.2 Application as directed 9.....................................................

1.3.3 Legal regulations 9..........................................................

2 Safety information 10......................................................

2.1 Personnel responsible for safety 10......................................................

2.2 General safety information 10..........................................................

2.3 Layout of the safety information 11......................................................

3 Technical data 12.........................................................

3.1 Product features 12.................................................................

3.1.1 Design 12.................................................................

3.1.2 Method of operation 12.......................................................

3.2 Weights 14........................................................................

3.3 Operating conditions 14..............................................................

3.3.1 Temperatures 14............................................................

3.3.2 Ambient conditions 14........................................................

4 Installation 15............................................................

4.1 Storage 15........................................................................

4.2 Installation 15......................................................................

4.2.1 Preparation after long storage 15................................................

4.2.2 General information on the assembly of drive systems 15..............................

4.3 Electrical connection 16..............................................................

4.3.1 Connection of the main motor 16................................................

4.3.2 Connection of the remote-control motor 16.........................................

4.3.3 Connection of the speed measuring unit 17.........................................

5 Commissioning and operation 19.............................................

5.1 Before you start 19..................................................................

5.2 During operation 19.................................................................

6

BA S’belt KE EN 1.0

L

Page 7

Contents

Show/Hide Bookmarks

6 Maintenance 20..........................................................

6.1 Maintenance intervals 20.............................................................

6.2 Maintenance operations 20............................................................

6.2.1 Replacing the V-belt 20.......................................................

6.2.2 Adjustment of output speed 21..................................................

6.2.3 Replacing the lubricant at gearboxes 22...........................................

6.3 Repair 23.........................................................................

6.4 Spare-parts list 254..................................................................

6.5 Order form 25......................................................................

7 Troubleshooting and fault elimination 26.......................................

8 Waste disposal 26.........................................................

Manufacturer’s Certification

Service addresses

L BA S’belt KE EN 1.0

7

Page 8

Preface and general information

Show/Hide Bookmarks

1 Preface and general information

1.1 How to use these Operating Instructions

l These operating instructions are intended for safety-relevant operations on and with the

Simplabelt compact units. They contain safety information which must be observed.

l All personnel working on and with the compact units must have the Operating Instructions

available and observe the information and notes which are relevant for them.

l The Operating Instructions must always be complete and perfectly readable.

1.1.1 Terminology used

Compact unit

For ”Simplabelt compact unit” the term ”compact unit” will be used in the following text.

Drive system

Fordrivesystemswith Simplabelt compactunits and other Lenzedrivecomponentstheterm”drive

system” willbe used in thefollowing text.

1.2 Contents of delivery

l The drive systems are combined individuallyaccording to a modular design. The contents of

delivery can be obtained from the pertinent papers.

l After receipt of the supply, check immediately whether the contents of delivery correspond to

the accompanying papers. Lenze does not grant any warranty for subsequent claims.

Immediately claim:

– visible transport damages to the forwarder

– visible defiencies/incompleteness to the responsible Lenze branch office or agency.

8

BA S’belt KEEN 1.0

l

Page 9

Preface and general information

Show/Hide Bookmarks

1.3 Lenze-drive systems

1.3.1 Labelling

l Lenze drive systems are uniquely designated by the content of their nameplates.

l Manufacturer:

Lenze GmbH & Co KG

Postfach 10 13 52

D-31763 Hameln

1.3.2 Application as directed

l Lenze drive systems

– are intended for use in machineryand systems

– must only be used for the purposes ordered and confirmed

– must only be operated under the ambient conditions prescribed in these operating

instructions

– must not be operated beyond their corresponding power limits

Anyother use shall be deemed inappropriate!

1.3.3 Legal regulations

Liability

l The information, data, and notes in the Operating Instructions were on the state of the art at

the time of printing. Claims about drive systems already supplied cannot be made from the

information, illustrations, and descriptions.

l We do not accept any liability for damages and operating interference caused by:

– inappropriate use

– unauthorized modifications to the drive system

– improper working on and with the drive system

– operating mistakes

– disregarding the Operating Instructions

Warranty

l Conditions of warranty: see terms of sale and delivery of Lenze Drive Systems GmbH.

l Warranty claims must be made to Lenze immediately after detecting the deficiency or fault.

l The warranty is void where liability claims cannot be also made either.

l BA S’belt KEEN 1.0

9

Page 10

Safety information

Show/Hide Bookmarks

2 Safety informat ion

2.1 Personnel responsibl e for safety

Operator

l An operator is any natural or legal person who uses the drive system or on behalf of whom

the drive system is used.

l The operator or his safety officer must ensure

– that all relevant regulations, instructions and legislation are observed.

– that only qualified personnel works with and on the drive system.

– that the personnel have the operating instructions available for all corresponding

operations.

– that non-qualified personnel are prohibited from working with and on the drive system.

Skilled personnel

Skilled personnel are persons who are - because of their education, experience, instructions, and

knowledge about corresponding standards and regulations, rules for the prevention of accidents,

and operatingconditions- authorizedbythepersonresponsibleforthe safetyof theplant toperform

the required actions and who are able to recognize potential hazards

(seeIEC364, definition for skilled personnel) .

2.2 General safety information

l This safety information is not claimed to be complete. In case of questions and problems

please contact your Lenze representative.

l At the time of supply thedrive system meets the state of the art and ensures basically safe

operation.

l The drive system is a source of danger for persons, for thedrive system itself, and for other

material assets of the operator, if

– non-qualified personnel work with and on the drive system.

– the drive system is used inappropriately.

l The drive systems must be designed such that they perform their functions after proper

installation and with application as directed in non-interfered operation and that they do not

cause hazards for persons. This also applies for their interaction with the complete plant.

l Make sure by appropriate measures that in case of failure of the drive system no material

damage is caused.

l Operate the drive system onlywhen in proper state.

l Retrofittings, modifications, or redesigns of the drive system are basically prohibited. In any

case, Lenze must be contacted.

l The compact units must not be adjusted in standstill.

10

BA S’belt KEEN 1.0

L

Page 11

2.3 Layout of the safety information

electricalvoltage

Conse

quencesifdisregarded:

d

r

o

rmo

dange

r

C

o

ifd

isr

r

ded

Show/Hide Bookmarks

l All safety information in these operating instructions has a uniform design:

Signalwort!

Hinweistext

– The icon designates the kind of danger.

– The signal word designates the severeness of the danger.

– The notes describe the danger and suggest how to avoid the danger.

Warning of personal injury

Icons used Signal words

Warning of ha zardous

Danger Wa r n s o f imminant danger.

Safety information

Warning of a general

ange

Warning of a general

danger

Warning! Wa r n s o f a potential, very hazardous situation.

Caution! Wa r n s o f a potential, hazardous situation.

Warning of material damage

Icons used Signal words

Stop! Wa r n s o f potential material damage.

Other information

Icons used Signal words

Note! Designates a general, useful note .

Death or most severe injuries

Consequences if disregarded:

Death

Light or minor injuries.

Consequences if disregarded:

Damage fo t he drive syste m/device or its e nvironment.

If you observe it, handling of the drive system/device is made easier.

nsequences

st severeinjuries

ega

:

L BA S’belt KEEN 1.0

11

Page 12

Technical data

Show/Hide Bookmarks

3 Technical data

l The most important data are indicated on the nameplate.

l Further technical data are listed in the product catalogues.

3.1 Product features

3.1.1 Design

Drive systems have a modular design. They consist of:

l Simplabelt attachment units

l Reduction gearboxes (helical gearboxes, worm gearboxes, helical worm gearboxes, or

helical bevel gearboxes)

l Three - phase AC motors to IEC standard

l Adjustment facilities

l Speed displays

3.1.2 Method of operation

(seeFig. 1 and Fig. 2 )

The three-phase AC motor (11BA)drives the mechanically adjustable variable speed pulley (1BA)

whichdrives the spring-loaded variablespeed pulley( 2BA)via theV-belt (3BA). Thispulley is fitted

onto thedrivingshaft of thereduction gearbox (12BA). Thevariablespeed pulleysandthe V-belt are

covered by the housings (4BA and 5BA).

The speed is adjusted via the adjustment facilities (6BA, 7BA, 8BA), i.e. by turning the handwheel

or operating the adjusting motor to move thepulley flange of themechanically adjustable variable

speed pulley(1BA)inthe axialdirection. The speed is indicated bymeans of thespeed indicatorin

the handwheel or a DC tacho or an impulse recorder and a display.

12

BA S’belt KEEN 1.0

L

Page 13

Technical data

Show/Hide Bookmarks

2 11BA 1.16 1.15 1BA 6BA 7BA 8BA

1

3BA

12BA 2BA 4BA 5BA

Fig. 1 Simplabelt compact unit, U-design

8BA 7BA 6BA 1BA 1.15 1.16 11BA 2

K11.0365/1

1

3BA

Fig. 2 Simplabelt compact unit, Z-design

L BA S’belt KEEN 1.0

12BA

4BA 5BA 2BA

K11.0365/1

13

Page 14

Technical data

Show/Hide Bookmarks

3.2 Weights

Compact Units Weight [kg] Compact Units Weight [kg]

11.4L1.10

11.4L2.10

11.4L3.10

11.4L5.10

11.4L1.13

11.4L2.13

11.4L3.13

11.4L5.13

11.4L6.13

11.4L7.13

11.4L1.16

11.4L2.16

11.4L3.16

11.4L5.16

11.4L6.16

11.4L7.16

11.4L1.20

11.4L2.20

11.4L3.20

11.4L5.20

11.4L6.20

11.4L7.20

<25

<25

<40

<25

<60

<60

<80

<60

<60

<60

< 100

< 100

< 125

< 100

< 100

<125

< 100

< 125

< 250

< 150

< 150

< 200

11.431.25

11.432.25

11.433.25

11.435.25

11.436.25

11.437.25

11.431.31

11.432.31

11.433.31

11.437.31

11.431.40

11.432.40

11.437.40

< 200

< 500

< 400

< 250

< 300

<400

< 400

< 400

< 500

< 500

< 1000

< 1000

< 1000

3.3 Operating conditions

3.3.1 Temperatures

The permissible temperature range is determined by the following:

l Thetorquetobetransmitted(→ dimensioning).

l The lubricant specification of the gearbox considering the oil temperature expected during

operation (see nameplate and/or Operating Instructions of the gearbox).

l The thermal class of the motor considering the motor temperature expected during operation

(seenameplate and Operating Instructions of the motor).

The operating temperature is determined by the power loss, the ambient temperature and the

cooling system!

3.3.2 Ambient conditions

l Gearboxes are protected against dust and spray water.

l Motors according to their enlosure (seenameplate and/or Operating Instructions of the

motor).

l Ambient media - especially chemically aggressive - can destroy shaft seals and coatings

(plastics) . Abrasive media may endanger shaft seals.

14

BA S’belt KEEN 1.0

L

Page 15

4 Installation

Show/Hide Bookmarks

Caution!

Transport the driveonly with transport equipment or hoistswhich are suitable for this load. Ensure

asafefixing.Avoidshocks!

The units in Z-design are not stable! Ensure proper support!

4.1 Storage

If you do not install the gearbox immediately, ensure the appropriate storage conditions.

l Up to one year:

Without special measures in dry, dust-free rooms which are protected against sunlight.

– Store gearbox with ventilation so that the breather screw is located at the top.

– Shafts and bright surfaces are delivered with protection against corrosion.

l Remove V-belts when storing the units for more than three months.

l More than a year:

Please contact the factory.

Installation

4.2 Installation

4.2.1 Preparation after long storage

Carefully remove the anti-corrosion agents from output shafts and flange surfaces.

4.2.2 General information on the assemblyof drive systems

l Take the necessary safety measures prior to any operations:

– Disconnect the machine from the mains, ensurestandstill of the machine and avoid any

machine movement.

– Check the proper state of the drive system. Never install and set-up damaged drive

systems.

– Check the combination of drive function and machine function. Check the direction of

rotation.

l The mounting surfaces must be even, without torsion, and free of vibrations.

l Align the drive system on the mounting surfaces exactly with themachine shaft to be driven.

l Ensurethat the assembly is without torsion, to avoid additional load.

l Compensate minor misalignment by using suitable flexible couplings.

l Upport the reaction torque appropriately.

l Fixings of accessories and attachments must be secured against loosening.

l We recommend bonding screw connections.

L BA S’belt KEEN 1.0

15

Page 16

Installation

Show/Hide Bookmarks

Stop!

Thelubricant filling is adapted to themounting position. To avoid damages to thegearbox, do not

change the mounting position indicated on the nameplate.

Caution!

Compact units in Z-design are not stable. Ensure propper support.

4.3 Electrical connection

Danger!

Electrical connections must only be carried out by skilled personnel!

4.3.1 Connection of the main motor

Connect the motor of your drive system according to the notes in the terminal box and the motor

operating instructions.Pleaseobserve the technicaldataonthemotornameplatepos. 2(Fig. 1and

Fig. 2).

4.3.2 Connection of the remote- control motor

Stop!

The remote-control motor must only be operated when the main motor is running. For testing the

functions at standstill, the momentary-contact switches must only be touched briefly.

1. Connect the remote-control motor according to the circuit diagram ( Fig. 3).

2. Check the direction of rotation in inching mode:

– Touch switch S1: the contact pin must move towards the flange.

– Touch switch S2: the contact pin must move in theopposite direction.

– If the pin does not move as indicated, reverse the motor polarity.

3. Check the limit switch:

– Actuate limit switch S3 (n

– Actuate limit switch S4 (n

– The contact pin must not move in either cases.

16

)and touch S1.

2max

)and touch S2.

2min

BA S’belt KEEN 1.0

L

Page 17

F1 Fuse

Show/Hide Bookmarks

K1, K2 Combined contactor relay for phase reversion

(CW or CCW rotation of the adjusting motor)

M1 Remote-control motor

Q1 Main switch

Q2 Motor circuit breaker

S1 Momentary-contact switch “faster”

S2 Momentary- contact switch “slower”

S3 Limit switch (highest spe ed limit)

S4 Limit speed (lowest speed limit)

① Drive motor

② Control phase of drive motor

③ faster

④ slower

Installation

①①①①

②②②②

③③③③

④④④④

K11.0252

Fig. 3 Connection diagram for the electrical remote control

4.3.3 Connection of the speed measuring unit

You can select the speed measuring units. They all can be retrofitted. The speed measuring units

aredelivered withconnectioncables. They are connected according to the user’s application orto

the requirements of the Lenze display units.

Three-phase AC tacho w ith rectification

Thethree-phase AC tacho with rectification generates a voltage which depends on thespeed and

the input resistance of the evaluating unit. The generated voltage can be evaluated via a

superimposed control or Lenze display units.

Suitable Lenze display units:

Analog voltmeter VSC 96 (approx. 5000Ω)

Digital voltmeter Fdi 635-F( > 100 kΩ)

1 Complete tacho

2Cover

3 Tightenning screw

4 Sealing washer

5 Allen screw

6 Stator (must be adjusted concentrically, gap “a”

must not change)

7Cable,1m

25

4

3

6

Fig. 4 Three-phase AC tacho with rectification

L BA S’belt KEEN 1.0

1

7

K11.0340

17

Page 18

Installation

Show/Hide Bookmarks

Fig. 5 Output voltage of the three-phase AC tacho with rectification as a function of the speed and the input resistance of the

display unit

Pulse recorder

The contactless speed measuring works with a rotating punched disk and a fixed pulse recorder.

In connection with a NAMUR input the pulse recorder generates a digital signal.

Suitable Lenze display units:

Analog voltmeter VSC 96 (approx. 5000 Ω)with digital-to-analog converter

Digital display unit ELTA 2000 A

1 Pulse recorder

2 Punched disk

3 Fixing screw

4Cover

K11.0249/1

Fig. 6 Pulse recorder

Technical data:

Housing Stainless steel

Connection cable 2.5 m PVC cable 2 x 0.14mm max. 300 m should be connected

Control circuit DIN 19234 or NAMUR

Auxiliary power/rated value 8.2 V ” 0.5 V / R

Signal volt age >1,2V

18

BA S’belt KEEN 1.0

ss

=1kΩ ”50Ω

i

L

Page 19

5 Commissioning and operation

Show/Hide Bookmarks

Stop!

The drive must only be commissioned by skilled personnel!

5.1 Before you start

Ensurethat the driveis not connected to mains and does not rotateunintentionally . Please check:

l Is the mechnical fixing o.k.?

l Are the electrical connections o.k.?

l For gearboxes with ventilation:

Is the plug removed from the breather screw?

Commissioning

5.2 During operation

Check the drive periodically during operation and take special note of unusual noises or

temperatures, leakages, loose fastening elements, and the state of the electrical cables. If any

interference occurs, proceed according to the troubleshooting list in chapter 7. If it is not possible

to eliminate the interference, please contact the Lenze Service.

Stop!

Never adjust the speed at standstill!

Otherwise, the compact unit will be damaged!

L BA S’belt KE EN 1.0

19

Page 20

Maintenance

Show/Hide Bookmarks

6 Maintenance

6.1 Maintenance intervals

Stop!

With drivesystems: Please observethe maintenance intervals of theother drive components, too!

l Wide V-belts have a natural wear which depends on several factors:

–On-time

– Load type

– Speeds

– Ambient temperature

As a guide value Lenze recommends to check the wide V-belt for wear and fissures every 4 to 6

months and replace it, if necessary.

l Variable speed pulleys are maintenance-free.

Note!

While checking thewide V-belt Lenze recommends to inspect visually the variable speed pulleys.

Check if themovabledisc canbe moved and the state of the disc face. Run-in grooveson the disc

face caused by wear reduces the belt life.

6.2 Maintenance operations

6.2.1 Replacing the V-belt

Stop!

Only use original Simplabelt V-belts!

Disassembly with U-design (see Fig. 1):

1. Activate the drive and accelerate it to max. speed, then switch off the drive and disconnect it

from mains.

2. Loosen 6 screws (1.16; 1.15)and remove the cover (5BA).

3. Completely open the variable speed pulleys (1BA), pull the V-belt (3BA)over the front edge of

the variable speed pulley (1BA)and remove it when turning the variable speed pulley.

20

BA S’belt KEEN 1.0

L

Page 21

Maintenance

Show/Hide Bookmarks

Disassembly with Z-design (see Fig. 2):

1. Activate the drive and accelerate it to max. speed, then switch off the drive and disconnect it

from the mains.

2. Loosen 6 screws (1.16; 1.15). Then push aside the covers (5BA and 4BA) to remove the V-belt

(3BA)from the variable speed pulley (1BA). The three-phase AC motor (5.0)must be

supported.

Assembly (U-design and Z-design)

Note!

With sizes 31 and 40, thespring-loaded variablespeed pulley can be opened by screwing a screw

into the flange (Fig. 7).

Remove the screw after assembly!

only with sizes 31 and 40

Required screw dimensions

Size 31: M6 x 40 (DIN933)

Size 40: M12 x 45 (DIN933)

Fig. 7 Variable speed pulley

1. First place the new V-belt onto the mechanically adjustable variable speed pulley (1BA)and

then draw it over the spring-loaded variable speed pulley (2BA)(see Fig. 1 and Fig. 2).

2. Refix housing (6 screws).

3. Start test running and check the speed limitating and the adjustment of the speed indicators

by means of a hand tacho. A readjustment may be necessary (see chap. 6.2.2).

K11.0265

6.2.2 Adjustment of output speed

L BA S’belt KEEN 1.0

The limit for the output speeds n

indication on the nameplate (pos. 1) may be necessary in the event of increased wear or after the

change of the V-belt (Fig. 1 and Fig. 2).

2min

and n

are factory-set. A readjustment according to the

2max

21

Page 22

Maintenance

Show/Hide Bookmarks

6.2.3 Replacing the lubricant at gearboxes

See Gearbox Operating Instructions.

Stop!

Never adjust the speed at standstill!

Otherwise, the compact unit will be damaged!

It must be observed that the V-belt

l does not run on the hub base (clearly audible running noises).

l does not run over the edge of the variable speed pulley.

Non-observance may lead to damage of the drive (bearing damage, belt damage).

Procedure of electric remote adjustment (Fig. 3)

1. Switc h on the drive motor.

2. First adjust the upper speed limit (n

– Check speed with hand tacho, increase speed to max with switch S1.

– Move limit switch S3 towards the contact pin until it switches audibly.

– Tighten the fixing screws of the limit switch.

3. Afterwards adjust the lower speed limit in the same way (momentary-contact switch S2 and

limit switch S4).

2max

).

Procedure of front and angle adjustment (Fig. 8 and Fig. 9)

1. Switc h on the drive motor.

2. Remove the bottom cover (4)of the adjustment unit.

3. Increase speed to its maximum indicated on the nameplate (pos. 1) (F ig. 1 and Fig. 2) by

means of the handwheel and the hand tacho.

4. Bolt (6)must be screwed in as an end limit.

5. Adjust the minimum speed in the same way and use bolt (5)as a limitation.

6. Remount the cover (4).

Afterwards check with the hand tacho whether the display values of the position indicator at the

handwheel correspond to the actual speed value. If not:

Adjust position indicator

7. Loosen setscrew (7)and remove the position indicator (9).

8. Turn the position indicator (9)until the display value corresponds to the actual value, ensure

that the scale is in position.

9. Refit the position indicator (9)in the handwheel (8)and secure it with the setscrew (7) .

22

BA S’belt KEEN 1.0

L

Page 23

4Cover

Show/Hide Bookmarks

5 Fixing screw

6Bolt

7Setscrew

8 Handwheel

9 Position indicat or

Maintenance

Fig. 8 Front adjustment

4Cover

5 Fixing screw

6Bolt

7Setscrew

8 Handwheel

9 Position indicat or

0 drawing turned by 90°

Fig. 9 Angle adjustment

K 11.0263

K 11.0263/2

6.3 Repair

L BA S’belt KEEN 1.0

Lenze recommends that repairs are carried out by Lenze Service.

23

Page 24

24

Show/Hide Bookmarks

6.4 Spare-parts list

11BA

BA S’belt KEEN 1.0

1BA

3BA

6BA

7BA

9BA

8BA

10BA

Maintenance

L

Fig. 10 Compact unit module

12BA 4BA 5BA 2BA

Page 25

L BA S’belt KEEN 1.0

Show/Hide Bookmarks

6.5 Order form

Recipient: Lenze

Postal code/City:___________________

Fax-no.: ___________________

all G

LL

Sende r

Company __________________________ Customer no. __________________

Street / P.O. Box __________________________ Orderno. ___________________

Postal code/City __________________________ Issued by ___________________

Delivery address __________________________ Phone ___________________

__________________________ Fax ___________________

Invoice recipient*__________________________ Date of delivery_________________

Date _____________ Signature ___________________

* Please indicate if othe r than sender

Item Name Pieces

1BA Variable spe ed pulley (mech. adjustabl e)

2BA Variable speed pulley (spring-loaded)

3BA V- bel t

4BA Housing (gea rbox side)

5BA Housing

6BA Front control

7BA Angula r control

8BA Electric front control

9BA Three -phase tacho

10BA Impulse gene rator

11BA Three-pase motor (see Ope rating Intructions Motor)

12BA Gearbox (see Operating Intructions Gearbox)

Maintenance

LENZE type number: ______________

Order number: ______________

25

Page 26

Troubleshooting and fault elimination

r

d

Show/Hide Bookmarks

7 Troubleshooting and fault elimination

If any disturbance should occur during operation of the drive system, please check the possible

causes using the following table. If the fault cannot be eliminated by means of one of the listed

measures, please contact Lenze Service.

Fau lt Possible cause Remedy

Drive does not start No or faulty connection of main motor Check motor conne ction

Clearly audible running noise V-belt runs on hub base, wrong adj ustment of spee d

Speeds indicated on the nameplate cannot be

eache

Position indicat ed on handwheel does not correspond

to output speed

Motor of electric remotecontrol does not rota te Adjustment spindle is stalling To do t his, re move the plastic plug at the rear side of

limit

Wrong adjustment of spe ed limit Correct adjustment of speed limit

Wrong V-belt Use V-belt which corresponds to compact unit

Wrong assembly of posi tion indicator Assemble position indicator a t adjustment of max.

Correct adjustment of speed limit

output spe ed

the adjustment motor.Loosen via the central thread

of the motor shaft.

26

BA S’belt KEEN 1.0

L

Page 27

Waste disposal

Show/Hide Bookmarks

8 Waste disposal

Help to protect the environment! Packing material can be recycled.

Material? Wh ere t o d isp os e?

Transport material Pallets Return to the manufacturer or forwarder

Packing material Cardboa rd boxes to waste pa per

Lubrica nts Oil, grease Dispose a ccording to the valid regulations

Components Housing: grey ca st iron

Bearings, shafts, gear wheels: steel

Seals/V-belts: special waste

disposal

Plastic to plastic recycling or waste material

Reuse or dispose of wood sha ving

Separate va luable substa nces a nd dispose

L BA S’belt KE EN 1.0

27

Page 28

Manufacturer’s Certification

Show/Hide Bookmarks

M anufacturer’sCertification

Weherewith certify that the below listed products are intended for assembly into

a machine or for assembly with other elements to form a machine.

Commissioning of the machine is prohibited before it is proven that it

corresponds to the EC regulation 98/37/E C.

Product : Type :

Low-profile gearboxes and geared motors GFL

Helical gearboxes and geared motors GST, 12.6LL

Helical bevel gearboxes and geared motors GKS, 12.5LL

Bevel gearboxes and geared motors GKR

Helical worm gearboxes and geared motors GSS, 52.1LL

Gear box es

Lenze GmbH & Co KG

Postfach 10 13 52

D-31763 Hameln

Site : Bösingfeld

Breslauer Straße 3

D-32699 Extertal

Telephone (05154) 82-0

Telefax (05154) 82-15 75

Variable speed belt drives and geared motors G LL-K

11.1LL, 11.2LL, 11.4LL

Variable speed drives with/without gearbox GLL-D

11.7LL

Shaft-mounted gearboxes 12.4LL

Worm gearboxes and geared motors 52.3LL, 52.4LL, 52.5LL

Applied standards and regulations:

EN 292 part 1

EN 292 part 2

Hameln, October 18, 2001

(i. V. Dr. K ie l)

Head of R&D dept. gearboxes

28

BA S’belt KEEN 1.0

l

Page 29

Notes

Show/Hide Bookmarks

L BA S’belt KEEN 1.0

29

Page 30

Notes

Show/Hide Bookmarks

30

BA S’belt KEEN 1.0

L

Loading...

Loading...