Page 1

BA 13.0011−EN

.CD(

Ä.CD(ä

Operating Instructions

SDS..

SDSGS

Synchronous servo motors

l

Page 2

, Please read these instructions before you start working!

Follow the enclosed safety instructions.

0Fig. 0Tab. 0

2

l

BA 13.0011−EN 1.0

Page 3

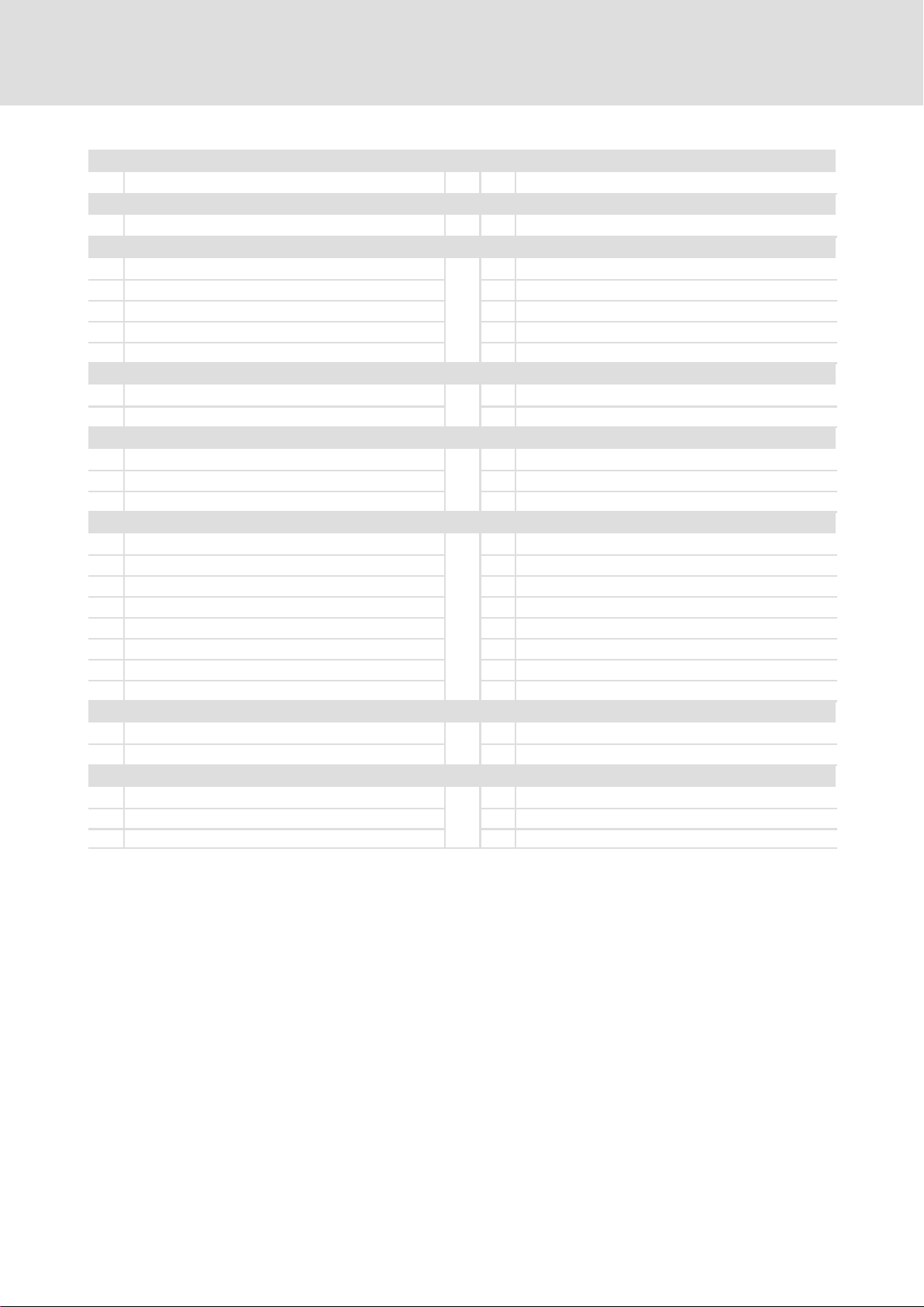

Contents i

1 About this documentation 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Abbreviations used 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Terminology used 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Notes used 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety instructions for drive components 8 . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Application as directed 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Improper use 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Residual hazards 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Identification 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Nameplate 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Product key 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data and operating conditions 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 General data 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Operating conditions 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Dimensions 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Rated data 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Rated data 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 Shaft loads 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Mechanical installation 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Preparation 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Assembly of built−on accessories 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Installation 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Holding brake (option) 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Important notes 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Permanent magnet holding brakes 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 Spring−applied holding brakes 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Electrical installation 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Important notes 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Wiring according to EMC 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Connection plan 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BA 13.0011−EN 1.0

l 3

Page 4

Contentsi

7 Commissioning and operation 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Important notes 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Before switching on 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Servo motor parameters 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Functional test 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Functional test 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 During operation 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Maintenance/repair 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Important notes 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Maintenance intervals 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Repair 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Troubleshooting and fault elimination 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 4

BA 13.0011−EN 1.0

Page 5

1 About this documentation

Contents

ƒ The present operating instructions are intended for safe working on and with the

motors. They contain safety instructions that must be observed.

ƒ All personnel working on and with the motors must have the operating instructions

available during work and observe the information and notes relevant for them.

ƒ The operating instructions must always be complete and in a perfectly readable

state.

If the information and notes provided in this documentation do not meet your

requirements, please refer to the controller and/or gearbox documentation.

I Tip!

Documentation and software updates for further Lenze products can be found

on the Internet in the "Services & Downloads" area under

http://www.Lenze.com

About this documentation

Document history

1

Validity

This documentation is valid for synchronous servo motors:

Type Designation

SDSGSLL

035, 047, 056, 063

Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the product.

1.1 Document history

Material no. Version Description

13314243 1.0 07/2009 TD09 First edition of the operating instructions, separate

Synchronous servo motors

from three−phase AC motors

BA 13.0011−EN 1.0

l

5

Page 6

1

About this documentation

Conventions used

1.2 Conventions used

This documentation uses the following conventions to distinguish different types of

information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Warnings

UL warnings

Icons

Page reference ^ Reference to another page with additional

1.3 Abbreviations used

Point In general, the decimal point is used.

For instance: 1234.56

J

Are only provided in English.

information

For instance: ^ 16 = see page 16

Abbreviations

P

r

M

I

r

U Rated voltage m

F Rated frequency N max. speed

J Moment of inertia M max. torque

w Angular velocity M

I

tot

Q Friction energy W Energy

U Resulting supply voltage L Cable length

U

L

phase

Rated power F

Rated torque F

n

Rated current n

Total moment of inertia M

Rated voltage of the brake I

B

Phase inductance R

1.4 Terminology used

Term In this text used for

Motor Synchronous motor, versions according to product key, ^ 15

Controller Any servo inverter

Drive system Drive systems with servo motors and other Lenze drive components

r1/Fr2

a

r

Mot

K

L

B

UV

Permissible radial load

Permissible axial load

Rated speed

Motor weight (mass)

Characteristic torque

Load torque

Rated current of the brake

Stator resistance

6

l

BA 13.0011−EN 1.0

Page 7

About this documentation

Notes used

1

1.5 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Special safety instructions and application notes for UL

Pictograph and signal word Meaning

J Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety note or application note for operating UL approved

devices in UL approved systems.

The operation of the drive system may not be UL compliant if

the corresponding measures are not taken.

BA 13.0011−EN 1.0

l

7

Page 8

2

Safety instructions

General safety instructions for drive components

2 Safety instructions

2.1 General safety instructions for drive components

(in accordance with Low−Voltage Directive 2006/95/EC)

At the time of dispatch, the drive components are in line with the latest state of the art and

can be regarded as operationally safe.

Scope

The following safety instructions generally apply to Lenze drive components.

The product−specific safety and application notes given in this documentation must be

observed!

General hazards

} Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

ƒ Lenze drive components ...

... must only be applied as directed.

... must never be commissioned if visibly damaged.

... must never be technically modified.

... must never be commissioned if incompletely mounted.

... must never be operated without the required covers.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation as well as for achieving the specified

product features.

ƒ Only qualified, skilled personnel is permitted to work on and with Lenze drive

components.

According to IEC 60364 / CENELEC HD 384, these are persons who ...

... are familiar with the installation, mounting, commissioning, and operation of the

product.

... have the qualifications required for their occupation.

... know and are able to apply all national regulations for the preventions of accidents,

directives and laws applicable on site.

8

l

BA 13.0011−EN 1.0

Page 9

Safety instructions

General safety instructions for drive components

Transport, storage

ƒ Transport and storage in a dry, low−vibration environment without aggressive

atmosphere; preferably in the packaging provided by the manufacturer.

2

– Protect against dust and shocks

– Comply with climatic conditions according to the technical data.

ƒ Before transport

– Check that all transport locking devices are mounted.

– Tighten all transport aids.

.

) Note!

Do not apply extra loads to the product as the transport aids (such as eye bolts

or bearing plates) are designed for the weight of the motor only (refer to the

catalogue for the weight).

Mechanical installation

ƒ Install the product according to the regulations of the corresponding

documentation. In particular observe the section "Operating conditions" in the

chapter "Technical data".

ƒ Provide for a careful handling and avoid mechanical overload. During handling

neither bend components, nor change the insulation distances.

Electrical installation

ƒ Carry out the electrical installation according to the relevant regulations (e. g. cable

cross−sections, fusing, connection to the PE conductor). Additional notes are

included in the documentation.

ƒ The documentation contains notes for the EMC−compliant installation (shielding,

earthing, arrangement of filters and installation of the cables). The manufacturer of

the system or machine is responsible for the compliance with the limit values

required in connection with EMC legislation.

ƒ For compliance with the limit values for radio interference emission at the site of

installation, the components − if specified in the technical data − have to be mounted

in housings (e. g. control cabinets). The housings have to enable an EMC−compliant

installation. In particular observe that for example control cabinet doors preferably

have a circumferential metallic connection to the housing. Reduce openings or

cutouts through the housing to a minimum.

ƒ Only plug in or remove pluggable terminals in the deenergised state!

Commissioning

ƒ If required, you have to equip the system with additional monitoring and protective

devices in accordance with the respective valid safety regulations (e. g. law on

technical equipment, regulations for the prevention of accidents).

ƒ Before commissioning remove transport locking devices and keep them for later

transports.

BA 13.0011−EN 1.0

l

9

Page 10

2

2.2 Application as directed

Safety instructions

Application as directed

Low−voltage machines are no household appliances, they are designed as components for

industrial or professional use in terms of IEC/EN 61000−3−2 only.

They comply with the harmonised standards of the series IEC/EN60034.

Low−voltage machines are components for installation into machines as defined in the

Machinery Directive 2006/42/EC. Commissioning is prohibited until the conformity of the

end product with this directive has been established (follow i. a. IEC/EN 60204−1).

It is only permissible to use low−voltage machines with IP23 protection or less outdoors if

special protective measures are taken.

The integrated brakes must not be used as safety brakes. It cannot be ruled out that

interference factors which cannot be influenced cause a brake torque reduction.

ƒ Drives

– ... must only be operated under the operating conditions and power limits

specified in this documentation.

– ... comply with the protection requirements of the EC Low−Voltage Directive.

Any other use shall be deemed inappropriate!

2.3 Improper use

ƒ Do not operate the motors

– ... in explosion−protected areas

– ... in aggressive environments (acid, gas, vapour, dust, oil)

– ... in water

– ... in radiation environments

10

l

BA 13.0011−EN 1.0

Page 11

Safety instructions

Residual hazards

2

2.4 Residual hazards

Protection of persons

ƒ Do not use the integrated brakes as fail−safe brakes. It cannot be ruled out that

certain disruptive factors that cannot be influenced such as oil ingress due to a

defective shaft sealing ring at the drive end may reduce the braking torque.

Motor protection

ƒ Integrated temperature sensors do not provide full protection for the machine. If

necessary, limit the maximum current. Parameterise the controller so that the

motor will be switched off with I > I

there is a risk of blocking.

ƒ If deviations from normal operation occur, e.g. increased temperature, noise,

vibration, determine the cause and, if necessary, contact the manufacturer. If in

doubt, switch off the low−voltage machine.

ƒ Overload protection does not protect against overloading under all conditions.

after a few seconds of operation, especially if

r

BA 13.0011−EN 1.0

l

11

Page 12

3

Product description

Identification

Nameplate

3 Product description

3.1 Identification

3.1.1 Nameplate

12

l

LKA−SDSGS−001.iso

BA 13.0011−EN 1.0

Page 13

Product description

Identification

Nameplate

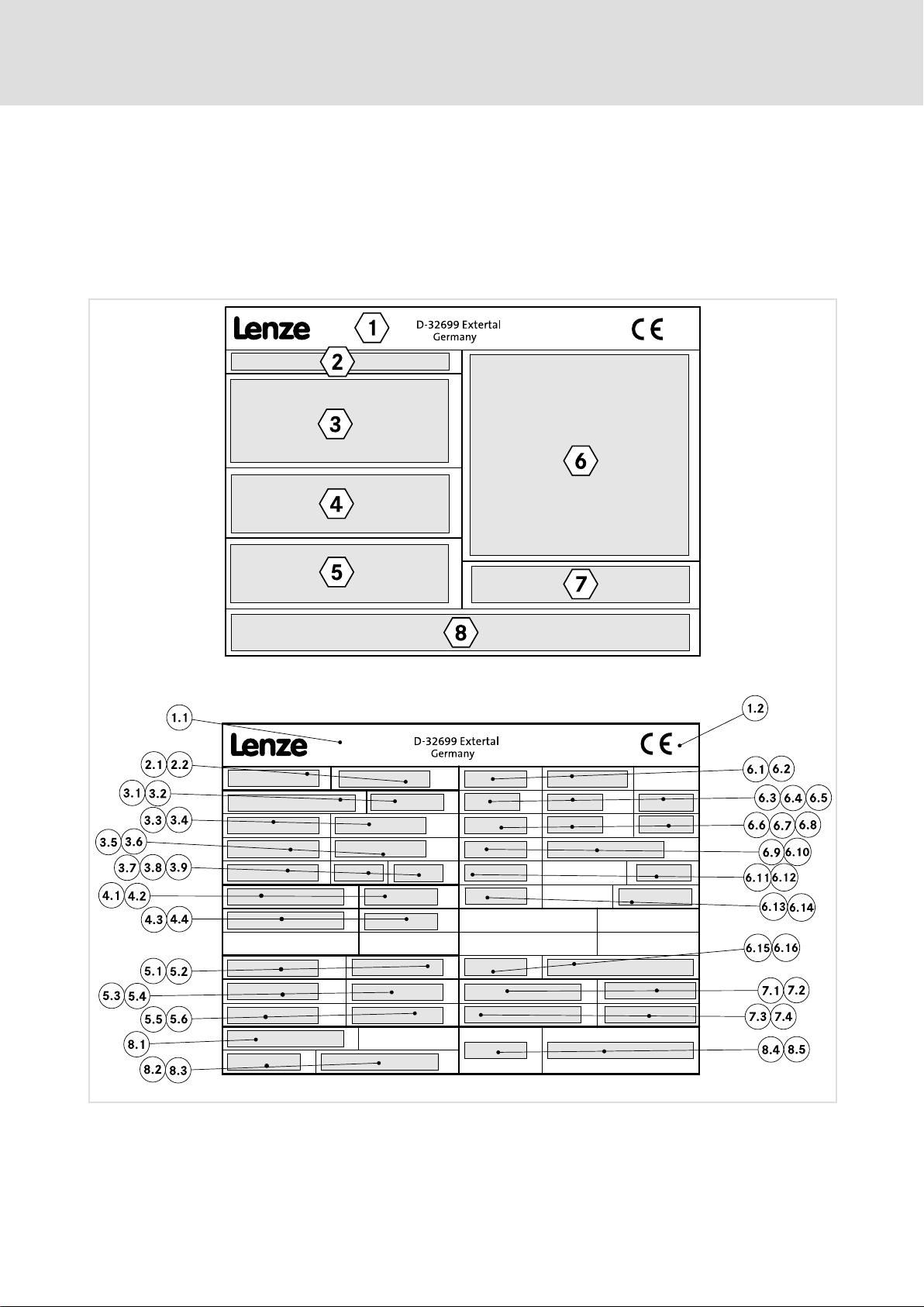

1 General information

1.1 Manufacturer 1.2 Applicable conformity declarations and approvals

2 Data on the complete drive system

2.1 Drives 2.2 Type of drive

3 Inverter data

3.1 Inverter 3.6 Voltage / I=I

3.2 Type of inverter 3.7 Fieldbus

3.3 FW 3.8 RS232

3.4 HW 3.9 I/O

3.5 Input

4 Encoder data

4.1 Encoder / feedback 4.3 Encoder voltage

4.2 Type of encoder 4.4 Indicated voltage

5 Gearbox data

5.1 Gearbox 5.4 Ratio

5.2 Gearbox type 5.5 Lubricant

5.3 Torque M2 [Nm] 5.6 Type of lubricant

6 Motor data

6.1 Motor 6.9 n

6.2 Motor type 6.10 C86 code

6.3 Motor type 6.11 Circuit, rated voltage

6.4 Rated power [kW] 6.12 Rated frequency

6.5 Degree of protection 6.13 Rated current

6.6 Rated torque 6.14 Rated speed

6.7 Operating mode 6.15 Insulation class of the winding

6.8 cos j 6.16 Temperature sensor

7 Brake data

7.1 Brake 7.3 Voltage, current, braking torque

7.2 Type of brake 7.4 Material number

8 Production data

8.1 Customer order number 8.4 Serial number

8.2 Year of manufacture 8.5 Bar code

8.3 Ident no. of the drive

max

max

(mechanical)

3

BA 13.0011−EN 1.0

l

13

Page 14

3

Product description

Identification

Nameplate

Gearbox

Pos. Contents

1 Manufacturer

2 Gearbox type

3 Manufacturing date

4 Commission number

5 Torque M2 [Nm]

6 Ratio

7 CE designation

Brakes

Reference to installed brake

Pos. Contents

1 Type / size of brake

2 Voltage [V] DC

3 Electrical power [W]

4 Braking torque [Nm]

5 Material number

14

l

BA 13.0011−EN 1.0

Page 15

Product description

Identification

Product key

3

3.1.2 Product key

Synchronous servo motors S D S G S LL LLL − L L

0

1

2

3

4

5

6

7

8

Product key legend

0 Product group S Small drives

1 Current type D Three−phase AC current

2 Ventilation S Self ventilation (cooling by convection and radiation)

3 Design/housing G Smooth and round housing

4 Machine type S Synchronous machine

5 Built−on accessories RS

6 Frame size 035, 047, 056, 063

7 Overall length 1

8 Number of pole pairs 2

Resolver

AG

Absolute value encoder

BA

Brake and sin/cos absolute value encoder

BS

Brake and resolver

short

2

medium

3

long

BA 13.0011−EN 1.0

l

15

Page 16

4

Technical data

General data and operating conditions

General data

4 Technical data

4.1 General data and operating conditions

4.1.1 General data

Conformity and approval

Conformity

CE

Approvals

UL/CSA File no. E210321

Protection of persons and equipment

Degree of protection

Earth leakage current IEC/EN 61800−5−1 > 3.5 mA Observe stipulations and safety

Total fault current < 100 mA

Thermal class F (155 °C) IEC 60034 Exceeding the temperature limit weakens or destroys the

Insulation resistance IEC/EN 61800−5−1

Protective measures Short circuit on the motor side, earth fault when switching on

Permissible voltage IEC/EN 60034−25 1.5 kV peak value

Vibration Up to 2.0 g (20 m/s2) without resonance excitation, e.g. of the

2006/95/EC Low−Voltage Directive

See nameplate

Degrees of protection only apply to horizontal installation

All unused plug−in connections must be sealed with

protective caps or dummy connectors.

instructions!

Earth−leakage circuit breakers of type B can be used.

insulation

< 2000 m site altitude: overvoltage category III

> 2000 m site altitude: overvoltage category II

the mains and during operation, motor overtemperature

(input for PTC or thermal contact, I

10 kV/ms speed of increase

fan.

2

t monitoring)

16

EMC

Noise emission

Noise immunity

IEC/EN 61800−3

l

Depending on the controller, see documentation for the

controller.

BA 13.0011−EN 1.0

Page 17

4.2 Operating conditions

Ambient conditions

Climatic

Transport IEC/EN 60721−3−2 2K3 (−20 ... +70 °C)

Storage IEC/EN 60721−3−1

Operation IEC/EN 60721−3−3

Site altitude < 1000 m amsl − without power reduction

Humidity Average relative humidity 85 %, without condensation

Electrical

The motor connection type depends on the controller

Length of motor cable

Length of cable for speed feedback

Technical data

General data and operating conditions

General data

1K3 (−20 ... +60 °C) < 3 months

1K3 (−20 ... +40 °C) > 3 months

Without brake −15 °C ... +40 °C

With brake −10 °C ... +40 °C

> +40 °C With power reduction see,

> 1000 m amsl < 4000m amsl with power reduction, see

catalogue

See inverter instructions

Without power reduction

catalogue

4

Mounting conditions

Mechanical

Mounting positions

Motor Suitable for all mounting positions

Geared motor Only for the ordered mounting position, see nameplate

ƒ Other application conditions require a power derating or torque reduction using the

factors listed in table 2 and 3 (see below).

Power derating

Power derating for other application conditions

Cooling air temperature [°C] 40 45 50 55 60

Power derating [kυ

Installation height above sea level

[m]

Power derating [k

Tab. 1

]

h]

1.00 0.95 0.90 0.83 0.77

1000 2000 3000 4000 5000

1.00 0.92 0.83 0.77 0.67

BA 13.0011−EN 1.0

l

17

Page 18

4

Technical data

Dimensions

General data

4.3 Dimensions

Motor type Frame size a1 b1

SDSGSLL 035−22 IEC56C80 79 50 12 9 M3 65 2.5 65 95 58 20 224

SDSGSLL 047−22 IEC56C80 79 50 12 9 M3 65 2.5 75 101 58 20 253

SDSGSLL 047−22 IEC63C90 89 60 12 11 M4 75 2.5 75 101 58 23 256

SDSGSLL 056−22 IEC63C90 89 60 12 11 M4 75 2.5 85 106 58 23 271

SDSGSLL 063−22 IEC71C105 104 70 12 14 M5 85 2.5 95 111 58 30 283

Motor type Frame size k1 k3 k4 L l1 l2 s1 t U X Weight

RS AG XX BS BA approx.

SDSGSLL 035−22 IEC56C80 169 180 138 204 225 20 3 14 M5 10.2 3 95 1.9 − 2.9

SDSGSLL 047−22 IEC56C80 189 200 156 233 244 20 3 14 M5 10.2 3 115 3.0 − 4.0

SDSGSLL 047−22 IEC63C90 489 200 156 233 244 23 3 18 M5 12.5 4 115 3.0 − 4.0

SDSGSLL 056−22 IEC63C90 196 207 163 248 260 23 3 18 M5 12.5 4 120 4.0 − 5.5

SDSGSLL 063−22 IEC71C105 199 214 168 253 268 30 2.5 25 M6 16 5 130 5.3 − 6.7

Tab. 2 Dimensions in mm

j7

c1 d

d2 e1 f1 G g1 g2 i2 K

k6

BS

kg

18

l

BA 13.0011−EN 1.0

Page 19

4.4 Rated data

ƒ The most important rated data of the motor are indicated on the nameplate.

– Further technical data can be obtained from the catalogues.

ƒ The indicated torques and weights are guide values for the selection of the

transmission elements and foundations.

ƒ The rated data indicated on the nameplate refer to operation with Lenze servo

inverters of the 9300 and 9400 series at an inverter input voltage (mains voltage) of

400 V.

) Note!

ƒ The motors can also be connected to inverters others than servo inverters of

Technical data

Rated data

General data

the 9300 and 9400 series:

– Depending on the modulation and control performance of the inverter it

might be necessary to derate the power if excessive temperatures are

detected (see Tab. 1).

4

BA 13.0011−EN 1.0

l

19

Page 20

4

Technical data

Rated data

General data

4.5 Rated data

SDSGSLL 035−22

Rated power [W] 140 140 140 140 140

Rated frequency [Hz] 100 100 100 100 100

Rated current [A] 8.4 4.4 4.0 0.56 0.36

Power factor cosj 1 1 1 1 1

Rated speed [rpm] 3000 3000 3000 3000 3000

Rated torque [Nm] 0.45 0.45 0.45 0.45 0.45

Degree of protection 54/55 54/55 54/55 54/55 54/55

Thermal class F F F F F

Maximum current [A] 47.5 26.5 22 3.3 2.05

Demagnetising current [A] 86 48 40 6.0 3.8

Maximum torque [Nm] 1.6 1.15 2.0 2.46 2.15

Maximum speed [rpm] 6000 6000 6000 6000 6000

RUV at 20°C [W] 0.22 0.72 1.10 46.6 116.4

L

phase

Moment of inertia [kg cm2] 0.221 0.221 0.221 0.221 0.221

Unit

13 25 30 210 360

[mH] 0.18 0.59 0.85 37.6 96.3

Rated voltage [V] AC

SDSGSLL 047−22

Unit

25 30 210 360

Rated power [W] 170 210 250 250

Rated frequency [Hz] 67 83 100 100

Rated current [A] 6.2 6.2 1.1 0.71

Power factor cosj 1 1 1 1

Rated speed [rpm] 2000 2500 3000 3000

Rated torque [Nm] 0.8 0.8 0.8 0.8

Degree of protection 54/55 54/55 54/55 54/55

Thermal class F F F F

Maximum current [A] 31 31 5.5 3.55

Demagnetising current [A] 41 41 7.5 4.8

Maximum torque [Nm] 2.0 2.4 3.9 3.9

Maximum speed [rpm] 6000 6000 6000 6000

RUV at 20°C [W] 0.61 0.61 18.6 46.8

L

phase

Moment of inertia [kg cm2] 0.301 0.301 0.301 0.301

[mH] 0.846 0.846 25.7 63.85

Rated voltage [V] AC

20

l

BA 13.0011−EN 1.0

Page 21

SDSGSLL 056−22

Technical data

Rated data

General data

4

Unit

30 210 360

Rated power [W] 450 500 500

Rated frequency [Hz] 100 100 100

Rated current [A] 12.5 1.93 1.2

Power factorcosj 1 1 1

Rated speed [rpm] 3000 3000 3000

Rated torque [Nm] 1.6 1.6 1.6

Degree of protection 54/55 54/55 54/55

Thermal class F F F

Maximum current [A] 62.5 9.65 6

Demagnetising current [A] 146 14.6 9.1

Maximum torque [Nm] 3.0 8.6 8.52

Maximum speed [rpm] 6000 6000 6000

RUV at 20°C [W] 0.19 6.92 17.8

L

phase

Moment of inertia [kg cm2] 1.337 1.337 1.337

[mH] 0.28 10.85 27.8

Rated voltage [V] AC

Characteristics SDSGSLL 063−22

Unit

Rated power [W] 700 700

Rated frequency [Hz] 100 100

Rated current [A] 2.45 1.54

Power factor cosj 1 1

Rated speed [rpm] 3000 3000

Rated torque [Nm] 2.2 2.2

Degree of protection 54/55 54/55

Thermal class F F

Maximum current [A] 12.5 7.7

Demagnetising current [A] 14.0 8.4

Maximum torque [Nm] 11.5 11.8

Maximum speed [rpm] 6000 6000

RUV at 20°C [W] 3.98 10.4

L

phase

Moment of inertia [kg cm2] 2.032 2.032

[mH] 7.9 22.1

Rated voltage [V] AC

210 360

BA 13.0011−EN 1.0

l

21

Page 22

4

Technical data

Rated data

Shaft loads

4.5.1 Shaft loads

The permissible loads listed in the table (Tab. 3) are either radial forces or axial forces.

Fig. 1 Points of action of radial and axial loads

Motor type F

SDSGSLL

Tab. 3 Radial and axial forces

Permissible axial load

F

a

F

Permissible radial load, acts on the middle of the shaft

r1

F

Permissible radial load, acts on the end of the shaft

r2

F

r1 /

r2

N

035−22 350/300 250

047−22 560/530 430

056−22

063−22 / 32

650/605 510

Ref. to the nominal bearing

service life of 10,000 h

KL−SDS−001

F

a

N

22

l

BA 13.0011−EN 1.0

Page 23

5 Mechanical installation

5.1 Preparation

Remove the corrosion protection from the shaft ends and flanges. If necessary, remove dirt

using standard cleaning solvents.

( Stop!

Bearings or seals must not come into contact with the solvent − material

damages.

After a long storage period (> 1 year) you have to check whether moisture has entered

the motor. For this purpose, measure the insulation resistance (measuring voltage

500 VDC). In case of values £1kWper volt of rated voltage, dry the winding.

Mechanical installation

Preparation

5

5.2 Assembly of built−on accessories

) Note!

Follow these instructions carefully. Please note that the warranty and product

liability will become void in the event of impermissible alterations or

modifications to the motors.

Follow the instructions below carefully. Please note that, in the event of impermissible

alteration or modification of the motor, you will lose all entitlements to make claims under

warranty and to benefit from product liability obligations.

ƒ Mount the transmission elements:

– Shocks and impacts must be avoided! They could destroy the motor.

– Always use the centre bore in the motor shaft (in accordance with DIN 332, design

D) for mounting.

– Tolerances of the shaft ends:

£ Æ 50 mm: ISO k6, > Æ 50 mm: ISO m6.

ƒ Only use an extractor for the disassembly.

ƒ When using belts for torque/power transmission:

– Tension the belts in a controlled manner.

– Provide protection against accidental contact! During operation, surface

temperatures of up to 140°C are possible.

BA 13.0011−EN 1.0

l

23

Page 24

5

5.3 Installation

Mechanical installation

Installation

Important notes

ƒ The mounting surface must be dimensioned for the design, weight and torque of

the motor.

ƒ The foot and flange faces must rest flat on the mounting surface.

– Incorrect motor alignment reduces the service life of the roller bearings and

transmission elements.

Impacts on shafts can cause bearing damage.

ƒ Do not exceed the permissible range of ambient operating temperature

(¶ chapter 4.1).

ƒ Fasten the motor securely.

ƒ Ensure that the ventilation is not impeded. The exhaust air, also the exhaust air of

other machines next to the drive system, must not be taken in immediately.

ƒ During operation, surfaces are hot, up to 150 °C! Ensure that guard preventing

accidental contact is in place!

Ensure an even surface, solid foot/flange mounting and exact alignment if a direct clutch

is connected. Avoid resonances with the rotational frequency and double mains frequency

which may be caused by the assembly.

Use appropriate means to mount or remove transmission elements (heating) and cover

belt pulleys and clutches with a touch guard. Avoid impermissible belt tensions.

5.4 Holding brake (option)

5.4.1 Important notes

As an option, the motors can be fitted with a brake. The installation of brakes (in or on the

motor) increases the length of the motor.

) Note!

The brakes used are not fail−safe because interference factors, which cannot

be influenced (e.g. oil ingress), can lead to a reduction in torque.

The brakes are used as holding brakes and serve to hold the axes at standstill or in the

deenergised state.

Emergency stops at higher speeds are possible, but high switching energy increases wear

on the friction surfaces and the hub (see wear of brakes, page 27 and 28).

24

The brakes operate according to the closed−circuit principle, i.e. the brake is closed in the

deenergised state. The brakes for DC supply can be fed with a bridge−rectified DC voltage

(bridge rectifier) or with a smoothed DC voltage. Information on the permissible voltage

tolerance is provided in the respective motor catalogue.

l

BA 13.0011−EN 1.0

Page 25

Mechanical installation

Holding brake (option)

Important notes

If long motor supply cables are used, pay attention to the ohmic voltage drop along the

cable and compensate for it with a higher voltage at the input end of the cable.

The following applies to Lenze system cables:

5

U*+UB )

0.08W

ƪ

m

@L@I

ƫ

B

U* [V] Resulting supply voltage

UB [V] Rated voltage of the brake

l [m] Cable length

IB [A] Rated current of the brake

( Stop!

If no suitable voltage (incorrect value, incorrect polarity) is applied to the

brake, the brake will be applied and can be overheated and destroyed by the

motor continuing to rotate.

The shortest operating times of the brakes are achieved by DC switching of the voltage and

a suppressor circuit (varistor or spark suppressor). Without suppressor circuit, the

operating times may increase. A varistor/spark suppressor limits the breaking voltage

peaks. It must be ensured that the power limit of the suppressor circuit is not exceeded.

This limit depends on the brake current, brake voltage, disengagement time and the

switching operations per time unit.

Furthermore, the suppressor circuit is necessary for interference suppression and also

increases the service life of the relay contacts (external, not integrated in the motor).

, Please refer to the catalogue for servo motors for detailed information about

holding brakes.

) Note!

The brake cannot be readjusted. When the wear limit is reached, the brake has

to be replaced.

BA 13.0011−EN 1.0

l

25

Page 26

5

5.4.2 Permanent magnet holding brakes

Mechanical installation

Holding brake (option)

Permanent magnet holding brakes

These brakes are used as holding brakes and serve to hold the axes without backlash at

standstill or in the deenergised state.

When activating the brake, it must be ensured that the brake is released or engaged at zero

speed to avoid unnecessary and rapid wear of the brake.

When used solely as holding brakes, the brakes are virtually wear free on their friction

surfaces. If the max. permissible switching energy per emergency stop (see catalogue) is

not exceeded, at least 2000 emergency stop functions from a speed of 3000 rpm are

possible.

W +½@J

The holding torques specified in the catalogue only apply when the motor is at standstill.

In the case of a slipping brake, the dynamic braking torque always applies which depends

on the speed.

ges

@ w

2

W [J] Energy

J

[kgm2] Total moment of inertia

tot

w [1/s] Angular velocity w=2p n/60, n= speed [rpm]

( Stop!

The holding brake is only designed for a limited number of emergency stops.

Utilisation as a working brake, e.g. to decelerate a load, is not permissible.

) Note!

The brakes are maintenance−free and cannot be adjusted. In the event of wear,

e.g. through emergency stops, the brakes must be replaced.

These brakes operate according to the closed−circuit principle, i.e. the brake is closed in the

deenergised state.

Brakes with a rated voltage of DC 24 V are designed for smoothed DC voltages with a ripple

of <1 %. It must be ensured that the connector on the motor side is supplied with the

minimum voltage of DC 24 V −10 %. If necessary, the voltage drop in the cable should also

be considered. If the maximum voltage DC 24 V + 5 % is exceeded, the brake can close

again. Supplying the brake with bridge−rectified DC voltage (bridge rectifier without

additional smoothing) or a DC voltage with a ripple of >1 % can lead to a malfunctioning

of the brake or an increase in the engagement and disengagement times.

26

Brakes with a rated voltage of DC 205 V are designed for bridge−rectified DC voltage, i.e. for

supply via a bridge rectifier from the 230 V mains (half−wave rectifiers are not permissible).

Supplying the brake with smoothed DC voltage can lead to malfunctioning or an increase

in the engagement and disengagement times. With regard to the minimum and

maximum voltages, the same conditions apply as for brakes with 24 V, i.e. the permissible

voltage tolerance is 205 V DC +5 %, −10 %.

l

BA 13.0011−EN 1.0

Page 27

Mechanical installation

Holding brake (option)

Permanent magnet holding brakes

Wear of permanent magnet brakes

If applied as directed (application as holding brakes), the permanent magnet brakes of the

servo motors are wear free and intended for long operating times. The wear on the friction

lining is due to e.g. emergency stops.

The table below describes the different reasons for wear and their impact on the

components of the permanent magnet brakes.

Component Effect Influencing factors Cause

Friction lining /

friction surface at

the armature plate

and external pole

Springs Fatigue failure of the springs Number of switching

Permanent magnet Useless brake Temperature, overvoltage Excessive overvoltages /

Wear on the friction lining

Applied friction energy

operations of the brake

Braking during operation

(impermissible, holding

brakes!)

Emergency stops

Overlapping wear when the

drive starts and stops

Active braking by the drive

motor with the help of the

brake (quick stop)

Axial duty cycle of the

springs

temperatures

5

( Stop!

In case of wear above the maximum air gap (^ brake operating instructions),

application of the brake cannot be ensured. In this case, no braking process is

carried out.

BA 13.0011−EN 1.0

l

27

Page 28

5

Mechanical installation

Holding brake (option)

Spring−applied holding brakes

5.4.3 Spring−applied holding brakes

These brakes are used as holding brakes and serve to hold the axes without backlash at

standstill or in the deenergised state.

For permissible operating speeds and characteristics, please see the respective valid motor

catalogue. Emergency stops at higher speeds are possible, but high switching energy

increases wear on the friction surfaces and the hub.

( Stop!

The friction surfaces must always be free from oil and grease because even

small amounts of grease or oil will considerably reduce the braking torque.

The formula below provides a simplified way to calculate friction energy per switching

cycle which must not exceed the limit value for emergency stops that depends on the

operating frequency (^ motor catalogue; Lenze drive solutions: Formulas, dimensioning,

and tables).

Q +½@J

@ Dw2 @

ges

M

K

MK* M

Q [J] Friction energy

J

[kgm2] Total mass inertia (motor + load)

tot

L

Dw [1/s] Angular velocity w=2p n/60, n= speed [rpm]

MK [Nm] Characteristic torque

ML [Nm] Load torque

Depending on the operating conditions and possible heat dissipation, the surface

temperatures can be up to 130 °C.

The spring−applied brakes operate according to the closed−circuit principle, i.e. the brake is

closed in the deenergised state. The brakes can be fed with a bridge−rectified DC voltage

(bridge rectifier) or with a smoothed DC voltage. The permissible voltage tolerance is

±10%.

, For more information on spring−applied brakes, please refer to the

corresponding catalogues and operating instructions of the brakes.

Wear on spring−applied brakes

Spring−applied brakes are wear−resistant and designed for long maintenance intervals.

However, the friction lining, the teeth between the brake rotor and the hub, and also the

braking mechanism are naturally subject to wear due to the way in which the equipment

functions. In order to ensure safe and problem−free operation, the brake must therefore be

checked regularly and, if necessary, replaced.

28

If the brake is used purely as a holding brake, the amount of wear on the friction surfaces

is only very small. Emergency stops increase wear on the friction surfaces.

The following table describes the different causes of wear and their effect on the

components of the spring−applied brake. In order to calculate the service life of the rotor

and brake and determine the required maintenance intervals, the relevant influencing

factors must be quantified. The most important factors are the applied friction energy, the

starting speed of braking and the switching frequency. If several of the indicated causes of

wear on the friction lining occur in an application, their effects are to be added together.

l

BA 13.0011−EN 1.0

Page 29

Mechanical installation

Holding brake (option)

Spring−applied holding brakes

Component Cause Effect Influencing factors

Friction lining

Armature plate and

flange

Teeth of the brake

rotor

Armature plate

bracket

Springs Axial load cycle and shearing stress

Emergency stops Wear on the

friction lining

Overlapping wear when the drive

starts and stops

Active braking by the drive motor

with the help of the brake (quick

stop)

Starting wear if motor is mounted

in a position with the shaft vertical,

even if the brake is open

Rubbing of the brake lining Running−in of armature

Relative movement and impacts

between brake rotor and brake hub

Load changes and impacts due to

reversal error during interaction

between armature plate, cap

screws and guide bolts

on the springs due to radial

reversed error of the armature plate

plate and flange

Teeth wear (primarily at

the rotor end)

Armature plate, cap

screws and bolts are

deflected

Fatigue failure

of the springs

Applied friction energy

Number of start−stop

cycles

Applied friction energy

Number of start−stop

cycles,

level of the braking

torque

Number of start−stop

cycles,

level of braking torque

Number of switching

operations of the brake

5

BA 13.0011−EN 1.0

l

29

Page 30

6

Electrical installation

Important notes

6 Electrical installation

6.1 Important notes

{ Danger!

Hazardous voltage on the power connections even when disconnected from

mains: residual voltage >60 V!

Before working on the power connections, always disconnect the drive

component from the mains and wait until the motor is at standstill.

Verify safe isolation from supply!

( Stop!

Electrical connections must be carried out in accordance with the national and

regional regulations!

ƒ The connection must ensure a permanent and safe electrical supply, i.e.

– no loose wire ends,

– use assigned cable end fittings,

– establish a safe PE conductor connection,

– Tighten the plug−in connector to the limit stop.

ƒ The smallest air gaps between uncoated, live parts and against earth must not fall

below the following values:

Minimum requirements for basic

insulation according to IEC/EN

60664−1 (CE)

3.87 mm 6.4 mm < 178 mm

ƒ All unused cable entries must be sealed against dust and water.

Voltage supply

ƒ Inverter−optimised motors

– must be supplied by inverters.

– connect the encoders mounted to the motor with the corresponding connections

of the inverter.

ƒ Holding brake (as option)

Higher requirements for UL design Motor diameter

30

ƒ Follow the Operating Instructions for the inverter used to connect it.

l

BA 13.0011−EN 1.0

Page 31

Electrical installation

Wiring according to EMC

Cable cross−section

ƒ Select appropriate connection cables to avoid impermissible heating (DIN

57100/VDE 0100 T523).

ƒ When extremely long cables are used, we recommend to use the next cable cross

section up to reduce the power losses. Observe the minimum cross sections to DIN

VDE 0298−4.

ƒ Establish the electrical connection as shown in the circuit diagram attached to each

motor. The circuit diagrams for the standard designs can be found in chapter 6.3.

Motor protection

ƒ The motor cable cannot be protected by temperature monitorings or PTC thermistors

in the motor winding:

– Take measures to DIN 57100 / VDE 0530.

ƒ The inverter changes current and voltage such that the output current can be

considerably higher than the input current. The motor cable cannot be protected via

the mains input fuses of the inverter:

– Take measures to DIN 57100 / VDE 0530.

6

ƒ Ensure careful earthing of the motor housing!

– If the motor is inverter driven, high−frequency voltages may be capacitively

transferred to the motor housing.

6.2 Wiring according to EMC

The EMC−compliant wiring of the motors is described in detail in the Operating

Instructions for the Lenze controllers.

ƒ Use of metal EMC cable glands with shield connection.

ƒ Connect the shielding to the motor and to the device.

BA 13.0011−EN 1.0

l

31

Page 32

6

Electrical installation

Connection plan

6.3 Connection plan

... for motor and brake

SDSGSLL − Pin No. Connection name

1 Y1

035−22

047−22

056−22

063−22

063−22/32

... for resolver and thermal contact

SDSGSLL − Pin No. Connection name

035−22

047−22

056−22

063−22

063−22/32

2 Y2

PE PE

4 U

5 V

6 W

1 + Ref

2 − Ref

3

4 + cos

5 − cos

6 + sin

7 − sin

8

9

10

11 +

12 −

Connection to:

Brake

Circuit breaker

Motor phase

Connection to:

Resolver

Resolver

KTY/thermal switch

Pin assignment

Pin assignment

... for absolute value encoder and thermal contact

SDSGSLL − Pin No. Connection name

1 B

2 A

3 A

4 + 5V

035−22

047−22

056−22

063−22

063−22/32

5 GND

6 Z

7 Z

8

9 B

10

11 + KTY

12 − KTY

Connection to:

Track B /

+ SIN

Track A inverted / − COS

Track A

Supply + 5V + 8V

Earth

Zero track inverted /

− RS485

Zero track / + RS485

Not assigned

Track B inverted / − SIN

Not assigned

Thermal detector +

Thermal detector −

Pin assignment

32

l

BA 13.0011−EN 1.0

Page 33

Commissioning and operation

7 Commissioning and operation

7.1 Important notes

( Stop!

ƒ Ensure that the drives are disconnected from the power supply when

working on them!

ƒ The drive must only be commissioned by qualified personnel!

ƒ Do not use the drive in rooms exposed to explosion danger!

ƒ Danger of fire! Do not use flammable detergents or solvents to clean the

drive.

ƒ Avoid overheating! Deposits and dirt on the drives impede the necessary

heat dissipation and must be removed frequently.

Ensure that no foreign particles ingress into the motor!

7

Important notes

For trial run without output elements, lock the featherkey. Do not deactivate the

protective devices, not even in a trial run.

Check the correct operation of the brake before commissioning motors with brakes.

BA 13.0011−EN 1.0

l

33

Page 34

7

Commissioning and operation

Before switching on

Servo motor parameters

7.2 Before switching on

) Note!

Before switch−on, you must ensure that the motor starts with the intended

direction of rotation.

Lenze motors rotate CW (looking at the driven shaft) if a clockwise three−phase

field L1 W U1, L2 WV1, L3 W W1 is applied.

Before initial commissioning, before commissioning after an extended standstill period, or

before commissioning after an overhaul of the motor, the following must be checked:

ƒ Measure the insulation resistance, in case of values £1 kWper volt of rated voltage, dry

the winding.

ƒ Have all screwed connections of the mechanical and electrical parts been firmly

tightened?

ƒ Is the unrestricted supply and removal of cooling air ensured?

ƒ Has the PE conductor been connected correctly?

ƒ Have the protective devices against overheating (temperature sensor evaluation)

been activated?

ƒ Is the controller correctly parameterised for the motor?

(^ Controller operating instructions)

ƒ Are the electrical connections o.k.?

ƒ Does the motor connection have the correct phase sequence?

ƒ Are rotating parts and surfaces which can become very hot protected against

accidental contact?

ƒ Is the contact of good electrical conductivity if a PE connection on the motor housing

is used?

7.2.1 Servo motor parameters

Motor

SDSGSLL

035−22

047−22

056−22

063−22

Mains voltage / AC current C86

210 V AC 1409

360V AC 1413

210 V AC 1410

360V AC 1414

210 V AC 1411

360V AC 1415

210 V AC 1412

360V AC 1416

Code for 9300 and 9400

34

l

BA 13.0011−EN 1.0

Page 35

7.3 Functional test

7.4 Functional test

ƒ Check all functions of the drive after commissioning:

ƒ Direction of rotation of the motor

– Direction of rotation in the disengaged state (see chapter "Electrical connection").

ƒ Torque behaviour and current consumption

ƒ Function of the feedback system

7.5 During operation

Commissioning and operation

Functional test

7

( Stop!

ƒ Fire hazard! Do not clean or spray motors with flammable detergents or

solvents.

ƒ Avoid overheating! Deposits on the drives impede the heat dissipation

required and have to be removed regularly.

} Danger!

During operation, motor surfaces may not be touched. According to the

operating status, the surface temperature for motors can be up to 150°C. For

the protection against burn injuries, provide protection against contact, if

necessary. Observe cooling−off times!

Perform regular inspections during operation. Check the drives approx. every 50 operating

hours. Pay particular attention to:

ƒ Unusual noises

ƒ Oil spots on drive end or leakages

ƒ Irregular running

ƒ Increased vibration

ƒ Loose fixing elements

BA 13.0011−EN 1.0

ƒ Condition of electrical cables

ƒ Speed variations

ƒ Impeded heat dissipation through:

– Deposits on the drive system

In case of irregularities or faults: ^ chapter 9.

l

35

Page 36

8

Maintenance/repair

Important notes

8 Maintenance/repair

8.1 Important notes

{ Danger!

Hazardous voltage on the power connections even when disconnected from

mains: residual voltage >60 V!

Before working on the power connections, always disconnect the drive

component from the mains and wait until the motor is at standstill.

Verify safe isolation from supply!

Shaft sealing rings and rolling−contact bearings have a limited service life.

8.2 Maintenance intervals

Inspections

ƒ If the machine is exposed to dirt, clean the air channels regularly.

ƒ Check the power supply cables on a regular basis.

Motor

ƒ Only the bearings and shaft sealing rings become worn.

– Check bearings for noise (after approx. 15,000 h at the latest).

ƒ In order to prevent overheating, remove dirt deposits on the drives regularly.

ƒ We recommend carrying out an inspection after the first 50 operating hours. In this

way, you can detect and correct any irregularities or faults at an early stage.

36

l

BA 13.0011−EN 1.0

Page 37

Maintenance/repair

Repair

Holding brake

The brakes need to be checked on a regular basis to ensure safe and trouble−free operation.

The necessary maintenance intervals primarily depend on the stress to which the brake is

subjected in an application. When a maintenance interval is being calculated, all causes of

wear must be taken into account (see notes "Wear on spring−applied brakes"). In the case

of brakes which are subjected to low levels of stress, e.g. holding brakes with emergency

stop function, regular inspections at a fixed time interval are recommended. In order to

reduce the amount of work involved in maintenance, perform the inspection at the same

time as other maintenance work carried out cyclically on the machine if possible.

If the brakes are not properly serviced, operating faults, production outages or damage to

machinery can occur. A maintenance concept adapted to the operating conditions and the

stresses to which the brakes are subjected must therefore be drawn up for every

application. For brakes, the maintenance intervals and servicing work listed in the

following table are necessary.

8

Maintenance interval for holding brake with

emergency stop

At least every 2 years

After 1 million cycles at the latest

Shorter intervals in the case of frequent emergency

stops!

8.3 Repair

ƒ It is recommended to have all repairs performed by Lenze Service.

Maintenance work

Inspection of the brake integrated in the motor:

l Check ventilation function and

activation/deactivation

BA 13.0011−EN 1.0

l

37

Page 38

Troubleshooting and fault elimination9

9 Troubleshooting and fault elimination

If faults occur during operation of the drive system:

ƒ First check the possible causes of malfunction according to the following table.

) Note!

Also observe the corresponding chapters in the operating instructions to the

other components of the drive system.

If the fault cannot be remedied using one of the listed measures, please contact the Lenze

Service.

} Danger!

ƒ Only work on the drive system when it is in a deenergised state!

ƒ Hot motor surfaces of up to 150 °C. Observe cooling times!

ƒ Remove loads acting on motors or secure loads acting on the drive!

38

l

BA 13.0011−EN 1.0

Page 39

Troubleshooting and fault elimination 9

Fault Cause Remedy

Motor does not start

Motor suddenly stops and

does not restart

Incorrect direction of

rotation of the motor, correct

display on the controller

Motor rotates slowly in one

direction and cannot be

influenced by the controller

Motor does not rotate,

gearbox output is not

running

Irregular running

Vibrations

Running noises

Surface

temperature > 150 °C

Voltage supply interrupted l Check error message at the controller

l Check electrical connection (chapter 6)

Controller inhibited l Check display at drive controller

l Check controller enable

Resolver cable is interrupted l Check error message at the controller

l Check resolver cable

Brake does not release

Drive blocks Check components for easy movement, remove foreign particles if

Overtemperature protector

switch is activated

Overload monitoring of the

inverter is activated

Reversed motor cable and

resolver cable

Polarity reversal of motor or

resolver cable

Defective wheel−hub

connection

Toothing worn out Repair by manufacturer

Insufficient shielding of

motor or resolver cable

Drive controller gain too

large

Insufficiently balanced

coupling elements or

machine

Poor alignment of the drive

train

Loose fixing screws Check and tighten screw connections

Foreign particles inside the

motor

Bearing damage Repair by manufacturer, if necessary

Overload of the drive Check load and, if necessary, reduce load by prolonging the

Heat dissipation impeded by

deposits

Check electrical connection

Check continuity of magnetic coil

necessary

l Let motor cool down

– Reduce the load by prolonging the acceleration times

l Check controller settings

l Reduce the load by prolonging the acceleration times

Exchange 2 phases of the motor cable

and

the +COS/−COS connections of the resolver

Exchange 2 phases of the motor cable

or

the +COS/−COS connections of the resolver

Check the connection, replace the keyway, if necessary, repair by

the manufacturer

Check shielding and grounding (chapter 6)

Adjust the gains of the controllers (see Drive controller operating

instructions)

Rebalance

Realign machine unit, check foundation if necessary

Repair by manufacturer, if necessary

acceleration times

Clean surface and cooling fins of the drives

BA 13.0011−EN 1.0

l

39

Page 40

F

(

Ê

ü

© 07/2010

Lenze Drives GmbH

Postfach 10 13 52

D−31763 Hameln

Germany

+49(0)5154/ 82−0

+49(0)5154/ 82−28 00

Lenze@Lenze.de

www.Lenze.com

Service Lenze Service GmbH

Breslauer Straße 3

D−32699 Extertal

Germany

(

Ê

008000/ 2446877 (24 h helpline)

+49(0)5154/ 82−13 96

Service@Lenze.de

BA 13.0011−EN § .CD( § § 1.0 § TD35

10987654321

Q

Loading...

Loading...