Page 1

LDEDS−CCU210B

.Jf$

Ä.Jf$ä

System Manual

LDEC

LDECBBF1xxxxxxHx

Carriage control systems for monorail overhead conveyors

l

Page 2

0Fig. 0Tab. 0

Page 3

Contents i

1 About this documentation 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Notes used 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety and application notes for Lenze control systems 7 . . . . . . . . . . . . . .

2.2 Residual hazards 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Device description 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Device features 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Overview 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Type code 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data and operating conditions 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Rated data 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Mechanical installation 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Important notes 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Dimensions 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Electrical installation 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Important notes 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Basic circuit diagram 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Mains connection 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Motor connection 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Control terminals 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Connection of system bus (CAN) 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Commissioning 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Before switching on 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Switch−on sequence 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Function library 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Important notes 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Operating mode 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Digital input signals 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 Description 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Connection logic 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 Assignment logic 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LDEDS−CCU210B EN 4.0

l 3

Page 4

Contentsi

8.4 Digital output signals 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Description 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Assignment logic 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Motor control 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 "Motor speed V1−V8" function 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.2 Stop functions 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.3 "Frequency limitation" function (speed limit) 54 . . . . . . . . . . . . . . . . . . . . .

8.5.4 "Open brake" function 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 Monitoring 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.1 Anti−collision sensor SensoPart 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.2 I2t monitoring 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.3 Non−equivalence monitoring 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.4 Motor temperature monitoring 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.5 Output stage temperature monitoring 63 . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.6 Parameter error 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.7 External error 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Infrared data transmission (IrDA) 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 IrDA positioning 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 Infrared remote control (IrRC) 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10 Half Wave Code (HWC) 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.11 Open and closed loop control 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.12 Status messages 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Troubleshooting and fault elimination 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Status display 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Fault messages 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Appendix 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Signal processing − overview 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Code table 86 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 4

LDEDS−CCU210B EN 4.0

Page 5

1 About this documentation

Contents

The System Manual provides full information on the intended use of the carriage control

system for monorail overhead conveyors.

, Information on customised designs can be found in a separate documentation

supplied with the product.

Validity

About this documentation

Document history

1

Type Type designation from hardware

LDEC carriage control LDECBBF1xxxxxxHW − V3.00

LDEC carriage control with

half−wave coding

Target group

This System Manual is directed to all persons dimensioning, installing, commissioning and

adjusting monorail overhead conveyors with carriage control systems.

I Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

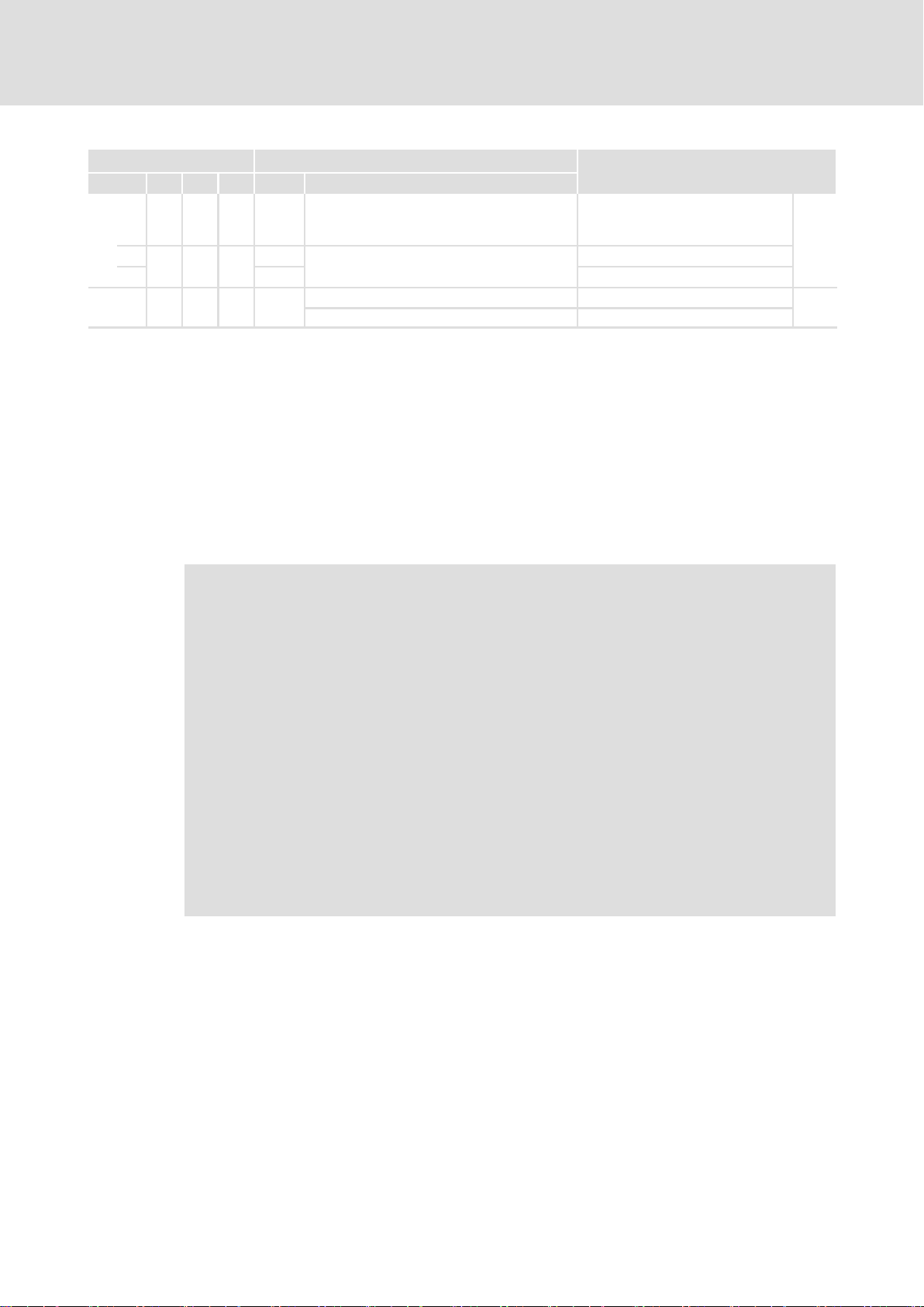

1.1 Document history

Material number Version Description

13202797 1.0 04/2007 TD00 First edition

13238907 2.0 02/2008 TD03 New product designation

13240731 2.1 03/2008 TD03 UL formulation has been removed from the

13285774 3.0 09/2009 TD03 Description of CAN interface added

version

from software version

LDECBBF1xxxxxxHC − V3.00

specification;

Spark suppressor has been replaced by freewheeling

diode

.Jf$ 4.0 09/2012 TD29 "Function library" chapter extended;

LDEDS−CCU210B EN 4.0

l

"Troubleshooting and fault indications" and "Code

list" chapters revised

5

Page 6

1

About this documentation

Conventions used

1.2 Conventions used

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Text

Program name » « PC software

Icons

Page reference ^ Reference to another page with additional

Documentation reference , Reference to another documentation with

language−dependentIn each case, the signs typical for the target

language are used as decimal separators.

For example: 1234.56 or 1234,56

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: ^ 16 = see page 16

additional information

For example: , EDKxxx = see

documentation EDKxxx

6

l

LDEDS−CCU210B EN 4.0

Page 7

About this documentation

Notes used

1

1.3 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

LDEDS−CCU210B EN 4.0

l

7

Page 8

2

Safety instructions

General safety and application notes for Lenze control systems

2 Safety instructions

2.1 General safety and application notes for Lenze control systems

(in accordance with Low−Voltage Directive 2006/95/EC)

General

Lenze controls can have live, even moving or rotating parts during operation − according

to their enclosure. Surfaces can be hot.

The unauthorised removal of the required cover, improper use, incorrect installation or

operation will risk serious personal injury and damage to property.

Additional information can be found in the documentation.

All work concerning transport, installation, commissioning and maintenance may only be

performed by qualified technical personnel (observe IEC 364 or CENELEC HD 384 or

DIN VDE 0100 and IEC report 664 or DIN VDE 0110 and national regulations for the

prevention of accidents).

Qualified technical personnel within these basic safety instructions are persons who are

familar with installation, assembly, commissioning and operation of the product and who

have the respective qualifications for their work.

The Hardware Manual contains important safety instructions and notes with regard to the

connection and commissioning of the control system, which you have to observe.

Therefore always keep the Hardware Manual near the control system.

The Hardware Manual always has to be complete and in a perfectly readable state.

8

l

LDEDS−CCU210B EN 4.0

Page 9

Safety instructions

General safety and application notes for Lenze control systems

Application as directed

The Lenze control system is designed for operation on a travelling drive (short−time brake

applications permissible only). Without protection of persons (optional) the control

system is not suitable for hoist applications!

Lenze control systems are components intended for installation in electrical systems or

machines. They are not household appliances, but are designed as components exclusively

for application for commercial or professional use according to EN 61000−3−2. The

documentation contains notes for maintaining the limit values to EN 61000−3−2.

If the control systems are installed in machines, commissioning (i.e. starting operation as

directed) is prohibited until it has been determined that the machine corresponds to the

regulations of EC Directive 98/37/EC (Machinery Directive); observe EN 60204.

The commissioning (i.e. starting the intended operation) is only allowed if the EMC

Directive (89/336/EEC) is met.

The Lenze control systems meet the requirements of Low−Voltage Directive 2006/95/EC.

The harmonised standards of the EN 61800−5−1, EN 61800−3, EN 61800−2 series are

applied to the Lenze control systems.

2

Technical data and connection requirement information appear on the nameplate and in

the documentation. They must be observed.

Warning: The control systems are products for the use in a second environment in

accordance with EN 61800−3 (industrial environment). These products can cause radio

interferences in residential areas. In this case it may be required for the operator to

implement corresponding measures.

Transport, storage

Observe the notes for transport, storage and proper handling.

Observe the climatic conditions according to EN 61800−2.

Installation

The control systems must be set up and cooled according to the regulations of the

accompanying documentation.

Ensure careful handling and avoid mechanical overload. Do not bend any components

during transport or handling or change insulation distances. Do not touch any electronic

components or contacts.

Lenze control systems contain electrostatic sensitive components that can easily be

damaged by improper handling. To avoid risks to health, do not damage or destroy any

electrical components!

LDEDS−CCU210B EN 4.0

l

9

Page 10

2

Safety instructions

General safety and application notes for Lenze control systems

Electrical connection

When working on live control systems, observe the applicable national regulations for the

prevention of accidents (e.g. VBG 4 in Germany).

Perform the electrical installation in accordance with applicable regulations (e.g. cable

cross−sections, fusing, PE connections). The documentation contains additional notes.

The documentation contains notes for EMC−compliant installation (shielding, earthing,

arrangement of filters and routing of cables). Also observe these notes for direct control

systems bearing the CE mark. The manufacturer of the system or machine is responsible

for maintaining the limit values required by EMC regulations.

Operation

You may have to fit additional monitoring and protection devices to systems with built−in

Lenze control systems in accordance with relevant safety regulations (e.g. law on technical

equipment, regulations for the prevention of accidents). You may adjust the Lenze control

systems to your application. Observe the notes in the documentation for this purpose.

Keep all protective covers closed during operation.

Service and maintenance

The Lenze control system is maintenance−free, provided that the prescribed operating

conditions are complied with.

Disposal

Send metals and plastics for recycling. Dispose of assembled PCBs properly.

Observe the product−specific safety and application notes in these instructions!

10

l

LDEDS−CCU210B EN 4.0

Page 11

2.2 Residual hazards

Protection of persons

ƒ The X1 power connector contacts (supply via flat connector field) can conduct

hazardous voltages if the control system is connected to the mains. Therefore

disconnect the control system before carrying out any work on it.

ƒ The X2 power connector contacts also conduct hazardous voltages. Depending on the

risk analysis of the machine/system, you may have to take additional protective

measures.

ƒ If the status LEDs and other display elements go out, this does not indicate that the

control system is disconnected from the mains and is deenergised.

ƒ During operation, the control system has to be closed.

ƒ The current collector may only be touched 3 minutes after disconnection from the

mains. Before carrying out any work on the control system, check whether all power

terminals are deenergised. The control system may not be short−circuited.

Safety instructions

Residual hazards

2

ƒ Operation at ambient temperatures > 50 °C:

– The operating temperature of the control system housing is > 60 °C.

– Depending on the risk analysis on the machine/system, you may have to use

additional protective covers.

Motor protection

ƒ The connected motor can overheat if

– motors that do not feature temperature monitoring with PTC thermistor (PTC) or

thermal contact (NC contact) are operated on the control system.

– the temperature monitoring with PTC thermistor (PTC) or thermal contact

(NCcontact) is not connected to the control system

– the temperature monitoring is switched off (C0120 = 0).

– the temperature monitoring is set to "Warning" (C0120 = 2).

LDEDS−CCU210B EN 4.0

l

11

Page 12

3

Device description

Device features

3 Device description

3.1 Device features

Vehicle control system Description

LDECBBF1xxxxxxHW

LDECBBF1xxxxxxHC

0.75/ 1.5/ 2.2 kW

l Travelling drive for monorail overhead conveyors (MOC),

frequency−controlled

l Energy supply 3/PE/PEN AC 360 V − 0 % ... 528 V + 0 %

l Connection of an external data memory to the control system

l Halve wave selection

l Halve wave feedback signal

l Display: 7−segment LED display red for status display, error messages, special

display

12

l

LDEDS−CCU210B EN 4.0

Page 13

Device description

Overview

3

3.2 Overview

Power 0.75 kW

Operational control and connections

Pos. Function Description

0 Important fault messages Short description of the most important fault

1 Status display of device (LED) Readiness for operation, error ^ 78

2

Infrared receiver ...

... for infrared data transmission

(IrDA)

... for infrared remote control (IrRC) Manual operation via infrared remote control ^ 68

3 4−digit 7−segment display Status display, error messages, warning signals ^ 79

4 On/Off switch Software deactivation, acknowledgement of errors

X1 Mains connection Connector: flat connector, 10−pole ^ 31

X2 Motor connection Connector: socket, Harting HAN−10B, 10−pole + PE ^ 32

X43 Digital inputs DIN1/DIN2 Connector: socket, 8−pole, M12 ^ 34

X44 Digital inputs DIN3/DIN4

Digital output DOUT1

X45 Digital inputs DIN5, DIN6

Digital output DOUT2

X50 Connection of external data

memory

X51 Connection of anti−collision sensor Connector: socket, 5−pole, M12, B−coded ^ 33

System bus (CAN) connection

X60

(behind the cover)

X61

messages

Parameter setting, manual operation and status

enquiries via PDA

Connector: socket, 4−pole, M12 ^ 34

Connector: socket, 4−pole, M12 ^ 35

Connector: socket, 8−pole, M12 ^ 33

RJ45 connector ^ 33

^ 81

^ 65

CCU210_002H

LDEDS−CCU210B EN 4.0

l

13

Page 14

3

Device description

Overview

Power 1.5 kW

Operational control and connections

Pos. Function Description

0 Important fault messages Short description of the most important fault

1 Status display of device (LED) Readiness for operation, error ^ 78

2

Infrared receiver ...

... for infrared data transmission

(IrDA)

... for infrared remote control (IrRC) Manual operation via infrared remote control ^ 68

3 4−digit 7−segment display Status display, error messages, warning signals ^ 79

4 On/Off switch Software deactivation, acknowledgement of errors

X1 Mains connection Connector: flat connector, 10−pole ^ 31

X2 Motor connection Connector: socket, Harting HAN−10B, 10−pole + PE ^ 32

X40 Digital inputs DIN3 ... DIN7

Digital output DOUT2

X41 Digital input DIN2

Digital output DOUT1

X42 Digital inputs DIN1, DIN8 Connector: socket, 4−pole, M12 ^ 34

X50 Connection of external data

memory

X51 Connection of anti−collision sensor Connector: socket, 5−pole, M12, B−coded ^ 33

System bus (CAN) connection

X60

(behind the cover)

X61

messages

Parameter setting, manual operation and status

enquiries via PDA

Connector: socket, 8−pole, M12 ^ 33

Connector: socket, 4−pole, M12 ^ 34

Connector: socket, 8−pole, M12 ^ 33

RJ45 connector ^ 33

^ 81

^ 65

CCU210_002A

14

l

LDEDS−CCU210B EN 4.0

Page 15

Power 2.2 kW

Device description

Overview

3

Operational control and connections

Pos. Function Description

0 Important fault messages Short description of the most important fault

1 Status display of device (LED) Readiness for operation, error ^ 78

2

Infrared receiver ...

... for infrared data transmission

(IrDA)

... for infrared remote control (IrRC) Manual operation via infrared remote control ^ 68

3 4−digit 7−segment display Status display, error messages, warning signals ^ 79

4 On/Off switch Software deactivation, acknowledgement of errors

X1 Mains connection Connector: flat connector, 10−pole ^ 31

X2 Motor connection Connector: socket, Harting HAN−10B, 10−pole + PE ^ 32

X40 Digital inputs DIN3 ... DIN7

Digital output DOUT2

X41 Digital input DIN2

Digital output DOUT1

X42 Digital inputs DIN1, DIN8 Connector: socket, 4−pole, M12 ^ 34

X50 Connection of external data

memory

X51 Connection of anti−collision sensor Connector: socket, 5−pole, M12, B−coded ^ 33

System bus (CAN) connection

X60

(behind the cover)

X61

messages

Parameter setting, manual operation and status

enquiries via PDA

Connector: socket, 8−pole, M12 ^ 33

Connector: socket, 4−pole, M12 ^ 34

Connector: socket, 8−pole, M12 ^ 33

RJ45 connector ^ 33

^ 81

^ 65

CCU210_002A

LDEDS−CCU210B EN 4.0

l

15

Page 16

3

Device description

Type code

3.3 Type code

This documentation is valid for LDEC carriage control systems as of nameplate data:

0 Manufacturer code

1 Product family

2 Equipment line

3 Generation

4 Design

5 Number of axes

Nameplate

LDE C B B F 1 xxx xxx Hx NN

Product

Order no.

Type

Input

Output

132341632

Serial No

Hans-Lenze-Strasse 1

D-31855 Aerzen

Material

ED

Brake

%

IP

CCU210_104

1

6 Power of first axis in W

7 Power of second axis in W

8 Communication

9 Power of third axis / variants, customer version

Further information

:

Product designation

; Order number

< Input data of frequency inverter

= Output data of frequency inverter

> Degree of protection

? Operating time in %

@ Brake

16

l

LDEDS−CCU210B EN 4.0

Page 17

Legend for LDECBBF1xxxxxxHW type code

0 Manufacturer code

LDE Lenze

1 Product family

L Local control unit

I Inductive control unit

C Conductive control unit

Z General accessories

2 Equipment line

B Baseline

S Stateline

H Highline

3 Generation

A 1st generation

B 2nd generation

4 Design

F Frequency inverter

M Motor starter

P Pole−changing control system

5 Number of axes

1 1 axis

2 2 axes

3 3 axes

S Special axes

6 Power of first axis in W

xxx e.g.

751= 75 x 10

7 Power of second axis in W

xxx e.g.

123 = 12 x 10

1

W = 750 W

3

W = 12kW

Device description

Type code

3

8 Communication

DB Rail bus

DN DeviceNet IN Inductive

EI Ethernet/IP PB Profibus

EP Ethernet Powerlink PW Powerwave

ER PROFInet RF Radio frequency

ET Ethercat SC Sercos

HC Half wave (HWC=half wave code) WL WLAN

HW Half wave

LDEDS−CCU210B EN 4.0

l

IB Interbus

17

Page 18

3

Device description

Type code

9 Power of third axis / variants, customer version

01 = 0.55kW

02 = 0.75kW

03 = 1.1kW

04 = 2.2kW

05 = 4.0kW

06 = 7.5kW

07 = 10.0kW

AA Labelling (variants_customer version)

Other characters

NN Not relevant

x For the entry of numbers

18

l

LDEDS−CCU210B EN 4.0

Page 19

General data and operating conditions

4 Technical data

4.1 General data and operating conditions

General data

Conformity and approval

Conformity

CE

Protection of persons and equipment

Degree of protection EN 60529

Earth leakage current EN 61800−5−1 < 3.5 mA

Insulation of control

circuits

Insulation resistance EN 61800−5−1

Protective measures Against motor overtemperature (input for PTC or thermal

2006/95/EC Low−Voltage Directive

93/68/EEC EMC Directive (basis 89/336/EEC)

EN 61800−5−1 Safe mains isolation by double (reinforced) insulation

Technical data

IP54

Cover all unused connectors with protective caps or dummy

plugs.

The cover over X60/X61 has to be available.

< 2000 m site altitude: overvoltage category III

> 2000 m site altitude: overvoltage category II

contact), overcurrent at output

4

EMC

Noise emission EN 61800−3

Noise immunity EN 61800−3 Compliance with the limit values for the 2. environment

Compliance with the limit values for the 2. environment

(industrial premises): category C3

(industrial premises): category C3

LDEDS−CCU210B EN 4.0

l

19

Page 20

4

Technical data

General data and operating conditions

Operating conditions

Ambient conditions

Climatic

Storage

Transport IEC/EN 60721−3−2 2K3 (−25 ... +70 °C)

Operation IEC/EN 60721−3−3 3K3 (0...+45 °C)

Pollution EN 61800−5−1 Degree of pollution 2

Site altitude < 4000 m amsl

Mechanic

Vibration resistance

Storage Germanischer Lloyd Vibration test 1

Transport EN 60721−3−2 2M2

Operation

Electric

Mains connection

Mains system

TT, TN

(earthed neutral)

IT Operation permitted without restrictions.

IEC/EN 60721−3−1

EN 60721−3−3 3M4

EN 60721−3−7 7M2

1K3 (−25 ... +70 °C) < 6 months

1K3 (−25 ... +40 °C) > 6 months

> +40 °C: reduce the rated output current by 2.5%/°C.

> 1000 m amsl: reduce the rated output current by

5 %/ 1000 m.

Operation permitted without restrictions.

> 2 years: form DC−bus

capacitors

Motor connection

Length of the motor

cable

Cable type Shielded servo cable (e. g. LAPP: Ölflex servo, FD−755−CP)

Mounting conditions

Mounting place On monorail overhead conveyors

Mounting position Vertically, control connections laterally on the right

Mounting clearances

at the top

at the bottom

to the sides

< 5 m from motor connector

Typically 150 mm

The actual free space is determined by the connectors used

and the cable bending radii.

20

l

LDEDS−CCU210B EN 4.0

Page 21

4.2 Rated data

) Note!

The frequency inverter is not suitable for permanent operation in generator

mode.

Mains voltage

Voltage range U

Frequency f

Fusing 10 A−T/AC 500 V

Frequency inverter (data for operation on 3/PE/PEN AC 400 V, switching frequency 8 kHz)

Starting current

Effektive I

Peak I

Rated power (typical MOC application)

Operating time 70 % PN [kW] 0.75 1.5 −

Operating time 50 % PN [kW] − − 2.2

Typical motor power

4−pole asynchronous motor, Y connection

Max. output power SN [kVA] 1.3 2.0 3.9

Output current

Duration I

For 60 s I

Switching frequency

Optionally f [kHz] 2, 4, 8

Lenze setting f [kHz] 8

Motor output frequency f [Hz] 0 ... 120 variable

Power loss at rated load P

Power loss in idle state (only half wave

power, 24V−sensors are not connected)

DC motor brake control

Brake voltage

Duration (U = UN x 0.45) U [V DC

Peak (U

Max. braking current I [A

Integrated switched−mode power supply (supply for external encoders and actuators)

Output voltage UA [V DC] +24 (21.6 ... 26.4 V DC)

Max. output current

(current−limited)

Weight

Control system complete, without counter

plug

= UN x Ö2) U

peak

Technical data

Rated data

N

N

[A] 4

eff

[A] 6

peak

PN [kW] − − 2.2

[A] 1.8 3.5 5.6

N

[A] 3.0 5.0 10

max

[W] 22 60 100

V

P

[W] 6 6 6

V

[V DC] 564 (for UN = 400 V AC)

peak

] 0.5 ± 10 %

eff

IA [A DC] 0.5 0.7 0.7

[approx. kg] 2.8 3.4 5.0

3/PE/PEN AC 360 V − 0 % ... 528 V + 0 %

45 Hz − 0 % ... 65 Hz + 0 %

] 185 (for UN = 400 V AC)

eff

4

LDEDS−CCU210B EN 4.0

l

21

Page 22

4

Technical data

Rated data

Half wave system

Control bar

Z system No

Number 2

Signal level

Reference voltage or switched

voltage

Rated voltage 400 ... 480 V AC,

Switching threshold 50 Hz: 270 V AC (243 ... 297 V AC)

Power consumption 1.5 W (400 V AC) for 1 x half wave

Message bar

Number 1

Signal level

Reference voltage or switched

voltage

Short−circuit protection PTC protection (500 W in series)

Reference voltage 400 ... 480 V

Switching current max. 28 mA AC

Sensor technology

Digital inputs

Number 8

Level

Input current Typ. 4 mA at 24 V DC

Digital outputs

Number 2

Level

Output current Max. 200 mA per

Serial interface RS485 SensoPart protocol

Parameter setting and configuration

IrDA interface Serial IrDA interface for parameter setting

CAN interface For parameter setting and configuration

Manual control

IR−RC interface Manual operation using infrared remote control

External data memory

Storage space Max. 2 kB Depending on the application

Full wave

Positive half wave

Negative half wave

L3

L1 possible with different hardware configuration

50−60 Hz

60 Hz: 330 V AC (297 ... 363 V AC)

Full wave

Positive half wave

Negative half wave

L3

L1 possible with different hardware configuration

HIGH +16 . +26.5 V DC

LOW 0 . 4 V DC

HIGH +19 . +26.4 V DC

LOW 0 . 4 V DC

output

Range typ. 300 mm

If inductive loads are switched,

external freewheeling diodes are

required!

22

l

LDEDS−CCU210B EN 4.0

Page 23

5 Mechanical installation

5.1 Important notes

ƒ Never install or commission damaged products. Please complain about damage

immediately to the forwarder.

ƒ Only mount the control system if the data on the nameplate of the control system

correspond to the voltage mains.

ƒ Ensure that the mounting location fulfils the following conditions:

– The ambient conditions mentioned in the technical data have to be fulfilled.

– No oils, acids, gases, vapours, radiation, etc.

– Protection against the permeation of fluid.

– Low−vibration and buckling resistant substructure.

Mechanical installation

Important notes

5

LDEDS−CCU210B EN 4.0

l

23

Page 24

5

5.2 Dimensions

Mechanical installation

Dimensions

Power 0.75 kW

CCU210_002H

24

l

LDEDS−CCU210B EN 4.0

Page 25

Power 1.5 kW

Mechanical installation

Dimensions

5

LDEDS−CCU210B EN 4.0

l

CCU210_002B

25

Page 26

5

Mechanical installation

Dimensions

Power 2.2 kW

26

l

CCU210_002_2_2kW

LDEDS−CCU210B EN 4.0

Page 27

6 Electrical installation

6.1 Important notes

{ Danger!

ƒ The contacts for the X1 and X2 power connectors can carry dangerous

voltages when the control system is connected to the mains. Therefore

deenergise the control system before working on it.

ƒ After the connection of a PTC thermistor or a thermal switch (NC contact),

all control terminals are only base−insulated (single isolating distance):

– Protection against accidental contact in case the isolating distance is

defective only is ensured by external measures, e. g. double insulation.

ƒ The control system must be earthed via X1 to prevent injuries to persons

and breakdown.

Electrical installation

Important notes

6

) Note!

ƒ Supplied plastic covers on the connectors for the control connections and

interfaces:

– Be absolutely sure to keep the plastic covers!

– You must cover unused connections during transport, storage and

operation with the plastic covers to guarantee the IP 54 enclosure.

ƒ Labels in the area of the control connections:

– Do not remove labels!

– The IP 54 enclosure is only guaranteed with the label.

LDEDS−CCU210B EN 4.0

l

27

Page 28

6

Electrical installation

Important notes

EMC−compliant wiring

) Note!

In order to ensure the trouble−free operation of Lenze control systems on

monorail overhead conveyors, an EMC−compliant installation is requried. This

includes the following:

ƒ Conduct the motor cable as described in the technical data.

ƒ Install the motor connection cables (connections U, V, W) separately from

the sensor cables:

– Do not use a common cable duct.

– Do not lay the cables in parallel over longer distances.

– Minimum distance 10 cm.

– Keep the motor cable as short as possible.

ƒ Lay the supply cables for the sliding contacts of the bars separately to the

sensor cables:

– Do not use a common cable duct.

– Do not lay the cables over longer distances.

– Minimum distance 20 cm.

ƒ Connect control and data cable shields at both ends.

ƒ Prevent the formation of loops of the sensor cables when cables are too

long:

– Conveniently trim the sensor cables or directly lay them in the wire

harness by folding them up and interconnecting them using a cable tie, in

order to avoid interferences and magnetic inductions.

ƒ Earth the MOC vehicle directly via the earthing brushgear:

– Connect all movable parts to the cross beam or the main beam in a

low−resistance manner.

2

– Use copper braid strap or drain wire 4 mm

ƒ Series connections of the earthing are allowed:

– If a movable part is earthed, the proximate movable part can be earthed

on the previous movable part.

– For instance in the case of carriages, you can like this establish a closed

and low−resistance connection from the cross beam to the main beam

which the control is connected to, via several PE connections from the

motor bracket, control beam, front and rear carriage.

ƒ The responsibility for the compliance with the EMC Directive in the machine

application lies with the user.

.

28

l

LDEDS−CCU210B EN 4.0

Page 29

6.2 Basic circuit diagram

Power 0.75 kW

Electrical installation

Basic circuit diagram

6

DIN6

DIN5 / DOUT2

1

2

3

X45

L1/AC 400 V

PE

L2/AC 400 V

SS1/AC 400 V

L3/AC 400 V

SS2/AC 400 V

N

MS1/AC 230 V

4

1

X44

LDECBBF1xxxxxxH W

C

IrDA

PDA Ir-RC

(DISPLAY)

REL-1 REL-2

DIN4

DIN3 / DOUT1

2

3

4

DIN1

DIN2

1

2

3

X43

4

B

R S485

SensoPart

A

R S485

12345

8

EXM ID1

X50 X51

X61

8

PC

System -

X60

C

(FU)

busad apter

0 Control cabinet

1234 7 10

X1

+

GND

3

1

J1

2

PE

F1 F2 F3

24 V DC

~

5 9 10

-

+

W1

V1

M

3~

U1

1234

Th

-

+

PE

X2

CCU210_105

LDEDS−CCU210B EN 4.0

l

29

Page 30

6

Electrical installation

Basic circuit diagram

Power 1.5 kW and 2.2 kW

DIN8

DIN6

DIN5

DIN3

DIN4

1

2

X40

3

DIN7

DOUT2

4

5

6

7

8

1

X41

DIN2

DOUT1

2

3

4

1

X42

DIN1

2

3

4

L1/AC 400 V

PE

L2/AC 400 V

SS1/AC 400 V

L3/AC 400 V

SS2/AC 400 V

N

MS1/AC 230 V

B

R S485

SensoPart

A

R S485

12345

LDECBBF1xxxxxxH W

C

IrDA

PDA Ir-RC

(DISPLAY)

REL-1 REL-2

C

(FU )

+

GND

3

1

J1

2

24 VDC

~

8

EXM ID1

X50 X51

X61

8

PC

adapter

X60

System bus

0 Control cabinet

1234 7 10

X1

PE

5 9 10

1234

+ -

W1

V1

M

3~

U1

Th

-

+

F1 F2 F3

PE

X2

CCU210_105

30

l

LDEDS−CCU210B EN 4.0

Page 31

6.3 Mains connection

Electrical installation

Mains connection

6

CCU210_002C

X1 − Mains connection

Pin Connection Description Data

Connector: FASTON 6.3 x 0.8 mm flat

connector, 10−pole

1 L1 Phase L1

2 L2 Phase L2

3 L3 Phase L3

4 + PE PE conductor

5 n.c. Not assigned

6 n.c. Not assigned

7 SS1 Control bar 1

8 n.c. Not assigned

9 n.c. Not assigned

10 MS1 Message bar 1

The SS2 control bar is assigned according to customer’s specifications. (see project documentation)

3/PE/PEN AC 360 V − 0 % ... 528 V + 0 %

45 Hz − 0 % ... 65 Hz + 0 %

LDEDS−CCU210B EN 4.0

l

31

Page 32

6

Electrical installation

Motor connection

6.4 Motor connection

X2 − Motor connection

Pin Connection Description Data

1 U Phase U

2 V Phase V

3 W Phase W

4 + brake Brake supply voltage

5 +PTC Motor temperature monitoring PTC thermistor (PTC) or thermal contact (NC

6 n.c. Not assigned

7 n.c. Not assigned

8 n.c. Not assigned

9 − brake Brake supply voltage

10 −PTC Motor temperature monitoring PTC thermistor (PTC) or thermal contact (NC

+ PE PE conductor

CCU210_002D

Connector: Socket, Harting HAN−10B

contact)

contact)

32

l

LDEDS−CCU210B EN 4.0

Page 33

6.5 Control terminals

Device in a power range of 1.5 kW and 2.2 kW Devices in a power range of 0.75 kW

Common control terminals

X50 − external data memory

Pin Signal Description Data

Electrical installation

Control terminals

CCU210_002E CCU_210_002G

EXMID1 Connector: socket, 8−pole, M12

Connection of external data

memory

Max. 2 kB Depending on the application

6

X51 – anti−collsion sensor for RS485 SensoPart forward travel

Pin Signal Description Data

Connector: socket, 5−pole, M12, B−coded

1 +24V Supply

2 A RS485 signal A

3 GND Reference potential

4 B RS485 signal B

5 n. c. Not assigned

− Shld Shield Applied to the connector housing

X60, X61 – CAN system bus connection

Pin Signal Description Data

Two CAN system bus terminals for

parameter setting and

configuration

Connector: RJ45

Control terminals for devices in a power range of 1.5 kW and 2.2 kW

X40 − digital inputs DIN3 ... DIN7/digital output DOUT2

Pin Signal Description Data

Connector: socket, 8−pole, M12

1 DIN3 Digital input 3 HIGH +16 .... +26.5 V DC

2 DIN4 Digital input 4 LOW 0 ... +4 V

3 DIN5 Digital input 5 4 mA Current per input for 24 V DC

4

5 +24V DC Supply

6 DIN7 Digital input 7

7 GND Reference potential

8 DOUT2 Digital output 2

DIN6 Digital input 6

max.

200 mA

Permissible current loading per

output

If inductive loads are switched,

use a freewheeling diode as

close to the inductive load as

possible!

LDEDS−CCU210B EN 4.0

l

33

Page 34

6

Electrical installation

Control terminals

X41 − digital input DIN2 / digital output DOUT1

Pin Signal Description Data

Connector: socket, 4−pole, M12

1 +24V DC Supply HIGH +16 .... +26.5 V DC

2 DOUT1 Digital output 1 LOW 0 ... +4 V

3

4

X42 − digital inputs DIN1/DIN8

Pin Signal Description Data

1 +24V DC Supply HIGH +16 .... +26.5 V DC

2 DIN8 Digital input 8 LOW 0 ... +4 V

3 GND Reference potential

4 DIN1 Digital input 1

GND Reference potential 4 mA Current per input for 24 V DC

DIN2 Digital input 2 max.

200 mA

Connector: socket, 4−pole, M12

4 mA Current per input for 24 V DC

Permissible current loading per

output

If inductive loads are being

switched, freewheeling diodes

are required. Place the diodes

as close to the inductor load as

possible!

Control terminals for devices in a power range of 0.75 kW

X43 − digital inputs DIN1/DIN2

Pin Signal Description Data

Connector: socket, 4−pole, M12

1 +24V DC Supply HIGH +16 .... +26.5 V DC

2 DIN1 Digital input 1 LOW 0 ... +4 V

3

4 DIN2 Digital input 2

X44 − digital inputs DIN3/DOUT1 − DIN4

Pin Signal Description Data

1 +24V DC Supply HIGH +16 .... +26.5 V DC

1)

2

3 GND Reference potential

4 DIN4 Digital input 4

1)

GND Reference potential 4 mA Current per input for 24 V DC

Connector: socket, 4−pole, M12

DIN3 Digital input 3 LOW 0 ... +4 V

DOUT1

DIN/DOUT cannot be used at the same time!

Digital output 1 4 mA Current per input for 24 V DC

max.

200 mA

Permissible current loading per

output

If inductive loads are being

switched, a spark suppressor

must be used at the output!

34

l

LDEDS−CCU210B EN 4.0

Page 35

Electrical installation

Control terminals

X45 − digital inputs DIN5/DOUT2 − DIN6

Pin Signal Description Data

Connector: socket, 4−pole, M12

1 +24V DC Supply HIGH +16 .... +26.5 V DC

1)

2

3

4 DIN6 Digital input 6

1)

DIN5 Digital input 5 LOW 0 ... +4 V

DOUT2

GND Reference potential

DIN/DOUT cannot be used at the same time!

Digital output 2 4 mA Current per input for 24 V DC

max.

200 mA

Permissible current loading per

output

If inductive loads are being

switched, a spark suppressor

must be used at the output!

6

LDEDS−CCU210B EN 4.0

l

35

Page 36

6

6.6 Connection of system bus (CAN)

Electrical installation

Connection of system bus (CAN)

The CAN interface enables communication between a PC and a CCU210B control system.

The CAN system bus has the following functions:

ƒ Exchange and change of parameter values

ƒ Display of status messages

Before using the CAN interface ...

... install the following software components on your PC:

ƒ the "Global Drive Control" program

I Tip!

The system requirements and the steps required for installing the program are

described in the Global Drive Control or Global Drive Control easy user

manuals.

ƒ the device description file (*.pdb) provided by Lenze. The PC uses this file to identify

the control system.

– To ensure that you will not have to repeatedly look for the device description file,

copy the "82S8219V_10.pdb" file into the PDB directory of the "Global Drive

Control" program, e.g. C:\Program Files\Lenze\GDC_4_100\PDB\049.

36

l

LDEDS−CCU210B EN 4.0

Page 37

Electrical installation

Connection of system bus (CAN)

Connection to the PC

After installing the "Global Drive Control" software program and the device description

file, you can connect the device to your PC.

1. Remove the black cover on the control end of the device.

Device in a power range of 1.5 kW and 2.2 kW Devices in a power range of 0.75 kW

6

CCU210_002A CCU210_002G

Fig. 6−1 Position of the RJ45 sockets for the CAN system bus

0 Cover

X60/X61 CAN system bus connections

2. Plug the cable into RJ45 socket X60 or X61.

X60

X61

Fig. 6−2 Connecting the device to the PC using a system bus adapter

3. Connect the Sub−D interface of the cable with the system bus adapter.

4. Connect the system bus adapter to the PC.

LDEDS−CCU210B EN 4.0

l

CAN_CCU210B

37

Page 38

7

Commissioning

Before switching on

7 Commissioning

7.1 Before switching on

Before initial switch−on, check ...

ƒ ... whether the drive is undamaged.

ƒ ... the entire wiring with regard to completeness, short circuit and earth fault.

ƒ ... whether the mains and the motor are connected in correct phase relation.

ƒ ... whether the control bars and message bars are connected in correct phase

relation.

ƒ ... whether the configuration saved is valid for the application.

ƒ ... whether the parameters loaded are optimally adapted to the motor.

l 38

LDEDS−CCU210B EN 4.0

Page 39

7.2 Switch−on sequence

) Note!

ƒ Disconnect the control system from the mains before you attach or remove

the external EXMID1 data memory!

ƒ If the external EXMID1 data memory is attached or removed during voltage

is applied, the data saved on it can be damaged:

– If data are damaged, the control system reports the error F008.

– ^ 81

) Note!

ƒ Carefully follow the switch−on sequence described.

ƒ In case of faults during commissioning, the chapter "Troubleshooting and

fault elimination" (^ 78) will help you.

Commissioning

Switch−on sequence

7

How to switch on the control system:

1. If the control system is equipped with an external EXMID1 data memory:

– Connect the external EXMID1 data memory to plug X50.

2. Switch on the mains:

– After approx. 1 s the control system is ready for operation.

3. The control system behaves according to the specifications parameterised (signals

on the digital inputs):

A The control system is ready for operation if the display shows the status display 00

or the current operating status.

B The control system is not ready for operation if the signal in the display is blinking:

– A fault is active.

– Eliminate the fault. (¶ 78)

LDEDS−CCU210B EN 4.0

l

39

Page 40

8

Function library

Important notes

8 Function library

8.1 Important notes

Linking signals correctly

To operate the controller or to output status messages, you can freely link internal digital

and analog signals to sources and targets.

You can avoid faults if you observe the following:

ƒ Always select the source from the target:

– Ask yourself, where the signal comes from.

– Like this, you can easily find the correct entry for the corresponding code.

ƒ A source can have several targets:

– Thus, when a target is assigned to a source, undesirable or duplicate assignments

that are mutually exclusive may occur.

– Ensure that a source is only linked to the desired targets.

ƒ A target can only have one source.

Code table and signal flow diagram as a quick overview

In the code table all functions are numerically listed in the form of a "reference book" with

short explanations. (¶ 87 et seqq.)

The signal flow diagram shows in which way the most important codes are integrated in

the internal signal processing. (¶ 85)

40

l

LDEDS−CCU210B EN 4.0

Page 41

Function library

Operating mode

8.2 Operating mode

The vehicle control system is operated in the "V/f characteristic control" operating mode.

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0015 RW EXT 4 0 Operating mode ^ 41

0 V/f characteristic control

1 Reserved

2 Reserved

C0016 RW EXT 4 400 Mains voltage ^ 41

0 {V} 480

C0017 RW EXT 4 0 Mains frequency ^ 41

0 50 Hz

1 60 Hz

C0018 Switching frequency of the inverter

in ...

1 RW EXT 4 2 8 kHz ... Parameter set 1

2 2 8 kHz ... Parameter set 2

Possible values

0 2 kHz

1 4 kHz

2 8 kHz

C0024 V/f characteristic – U-boost voltage

in ...

1 RW EXT 4 5.0 1 {%} 25.5 ... Parameter set 1

2 5.0 ... Parameter set 2

C0029 V/f characteristic – base frequency

in ...

1 RW EXT 4 50.0 0 {Hz} 120.0 ... Parameter set 1

2 50.0 ... Parameter set 2

^ 41

^ 41

^ 41

8

LDEDS−CCU210B EN 4.0

l 41

Page 42

8

8.3 Digital input signals

8.3.1 Description

Function library

Digital input signals

Description

The vehicle control system is equipped with digital inputs and a control bar evaluation to

evaluate digital input signals.

ƒ Basic circuit diagram: (¶ 29)

ƒ You can assign different switch−on and switch−off delays (C0406/C0407) to each

input signal.

ƒ The input signals can be logically linked (C0409) and assigned to internal control

functions via the assignment logic (C0410).

Digital inputs

There are 8 digital inputs to evaluate the sensors at the suspension gear of the monorail

overhead conveyor.

Additionally you can logically invert each input.

Control bar

Digital input signals via the control bar serve as a command specification by the

higher−level system control to the vehicle control system.

In the standard scope of supply the evaluation for a control bar is provided (SS1). On

customer request, the evaluation for a second control bar (SS2) can be activated.

For each control bar you can use the digital signals "positive half wave", "negative half

wave" and "full−wave" for function links.

) Note!

The reference phase in the Lenze setting is L3.

On customer request, the reference phase L1 can be supplied by adapting the

hardware.

42

l

LDEDS−CCU210B EN 4.0

Page 43

Function library

Digital input signals

Description

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0406 Switch−on delay of digital input

RW EXT 4

1

2 0 ... DIN2

3 0 ... DIN3

4 0 ... DIN4

5 0 ... DIN5

6 0 ... DIN6

7 0 ... DIN7

8 0 ... DIN8

9 0 ... SS1 positive half wave

10 0 ... SS1 negative half wave

11 0 ... SS1 full−wave

12 0 Reserved

13 0 ... SS2 positive half wave

14 0 ... SS2 negative half wave

15 0 ... SS2 full−wave

16 0 Reserved

C0407 Switch−off delay of digital input

RW EXT 4

1

2 0 ... DIN2

3 0 ... DIN3

4 0 ... DIN4

5 0 ... DIN5

6 0 ... DIN6

7 0 ... DIN7

8 0 ... DIN8

9 0 ... SS1 positive half wave

10 0 ... SS1 negative half wave

11 0 ... SS1 full−wave

12 0 Reserved

13 0 ... SS2 positive half wave

14 0 ... SS2 negative half wave

15 0 ... SS2 full−wave

16 0 Reserved

0 {ms} 10000

0

0 {ms} 10000

0

signals

LOW ð HIGH ...

... DIN1

signals

HIGH ð LOW ...

... DIN1

8

^ 42

^ 42

LDEDS−CCU210B EN 4.0

l

43

Page 44

8

Function library

Digital input signals

Connection logic

C0408

RW EXT 1 0 1 255

8.3.2 Connection logic

SelectionLenzeByte<ñòNo.

Possible values

0 No inversion

1 DIN1

2 DIN2

4 DIN3

8 DIN4

16 DIN5

32 DIN6

64 DIN7

128 DIN8

DescriptionPossible settingsCode

Level inversion for digital inputs

à inputs are LOW−active

Add values of the inverted inputs:

e. g. DIN1, DIN3 and DIN5 are

LOW−active à C0408 = 21.

^ 42

By means of the connection logic (C0409) you can logically link digital inputs and control

bar inputs to each other:

ƒ The linkages 1−8 (C0409/1 ... C0409/8) are permanently set as "OR" operations.

ƒ The linkages 8−16 (C0409/8 ... C0409/16) are permanently set as "AND" operations.

ƒ For further function assignments the linkage results are provided as digital signal

sources.

44

l

LDEDS−CCU210B EN 4.0

Page 45

Function library

Digital input signals

Connection logic

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0409 Logic operations of digital input

RW EXT 2

1

2 0 Link OR2

3 0 Link OR3

4 0 Link OR4

5 0 Link OR5

6 0 Link OR6

7 0 Link OR7

8 0 Link OR8

9 0 Link AND1

10 0 Link AND2

11 0 Link AND3

12 0 Link AND4

13 0 Link AND5

14 0 Link AND6

15 0 Link AND7

16 0 Link AND8

0 65535

0

Possible values

0 No linkage

1 DIN1

2 DIN2

4 DIN3

8 DIN4

16 DIN5

32 DIN6

64 DIN7

128 DIN8

256 SS1 positive half wave

512 SS1 negative half wave

1024 SS1 full−wave

2048 Reserved

4096 SS2 positive half wave

8192 SS2 negative half wave

16384 SS2 full−wave

31768 Reserved

signals

Link ORx = OR operation

Link ANDx = AND operation

Link OR1

Add values of the digital input

signals to define a linkage:

e. g. DIN1, SS1 full−wave and SS2

full−wave are to be assigned to link

OR2 (OR operation)

à C0409/2 = 17409.

8

^ 44

LDEDS−CCU210B EN 4.0

l

45

Page 46

8

Function library

Digital input signals

Assignment logic

8.3.3 Assignment logic

In the assignment logic (C0410) you assign digital signal sources, like for instance digital

inputs or linkage results, to the internal control functions. By this, you define the desired

control functions and responses to specific events.

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0410 Linking digital input signals to an

RW EXT 4

1

2 0 Not assigned ... Motor V2 (incl. brake)

3 0 Not assigned ... Motor V3 (incl. brake)

4 0 Not assigned ... Motor V4 (incl. brake)

5 0 Not assigned ... Motor V5 (incl. brake)

6 0 Not assigned ... Motor V6 (incl. brake)

7 0 Not assigned ... Motor V7 (incl. brake)

8 0 Not assigned ... Motor V8 (incl. brake)

9 0 Not assigned ... CW/CCW rotation of motor

10 0 Not assigned Reserved

11 0 Not assigned ... Set fault

12 0 Not assigned ...Acknowledge fault

13 0 Not assigned ... Frequency inverter: change over

14 0 Not assigned ... DC−injection braking

15 0 Not assigned ... Open brake

16 0 Not assigned ... Stop1

17 0 Not assigned ... Stop2

18 0 Not assigned ... Stop3

19 0 Not assigned ... Stop4

20 0 Not assigned ... Frequency limitation 1

21 0 Not assigned ... Frequency limitation 2

22 0 Not assigned ... Frequency limitation 3

23 0 Not assigned ... Frequency limitation 4

24 0 Not assigned ... SensoPart: change over

25 0 Not assigned ... Deactivate control

0 Not assigned ... Motor V1 (incl. brake)

internal device function ...

l CW rotation = LOW

l CCW rotation = HIGH

parameter set

l Parameter set 1 = LOW

l Parameter set 2 = HIGH

parameter set

l Parameter set 1 = LOW

l Parameter set 2 = HIGH

^ 46

46

l

LDEDS−CCU210B EN 4.0

Page 47

Function library

Digital input signals

Assignment logic

DescriptionPossible settingsCode

SelectionLenzeByte<ñòNo.

C0410 (Continuation)

Linking digital input signals to an

internal device function ...

Possible values

0 Not assigned

1 DIN1 Digital input DIN1

2 DIN2 Digital input DIN2

3 DIN3 Digital input DIN3

4 DIN4 Digital input DIN4

5 DIN5 Digital input DIN5

6 DIN6 Digital input DIN6

7 DIN7 Digital input DIN7

8 DIN8 Digital input DIN8

9 SS1 positive half wave Control bar 1 positive half wave

10 SS1 negative half wave Control bar 1 negative half wave

11 SS1 full−wave Control bar 1 full−wave

12 Reserved

13 SS2 positive half wave Control bar 2 positive half wave

14 SS2 negative half wave Control bar 2 negative half wave

15 SS2 full−wave Control bar 2 full−wave

16 Reserved

... ...

31 Reserved

32 Link OR1 Result of OR operation 1

33 Link OR2 Result of OR operation 2

34 Link OR3 Result of OR operation 3

35 Link OR4 Result of OR operation 4

36 Link OR5 Result of OR operation 5

37 Link OR6 Result of OR operation 6

38 Link OR7 Result of OR operation 7

39 Link OR8 Result of OR operation 8

40 Link AND1 Result of AND operation 1

41 Link AND2 Result of AND operation 2

42 Link AND3 Result of AND operation 3

43 Link AND4 Result of AND operation 4

44 Link AND5 Result of AND operation 5

45 Link AND6 Result of AND operation 6

46 Link AND7 Result of AND operation 7

47 Link AND8 Result of AND operation 8

48 Reserved

... ...

63 Reserved

8

^ 46

LDEDS−CCU210B EN 4.0

l

47

Page 48

8

Function library

Digital input signals

Assignment logic

DescriptionPossible settingsCode

SelectionLenzeByte<ñòNo.

C0410 (Continuation)

Linking digital input signals to an

internal device function

64 HWC match code 1 HWC match code 1

65 HWC match code 2 HWC match code 2

66 HWC match code 3 HWC match code 3

67 HWC match code 4 HWC match code 4

68 HWC match code 5 HWC match code 5

69 HWC match code 6 HWC match code 6

70 HWC match code 7 HWC match code 7

71 HWC match code 8 HWC match code 8

72 HWC match code 9 HWC match code 9

73 HWC match code 10 HWC match code 10

74 HWC match code 11 HWC match code 11

75 HWC match code 12 HWC match code 12

76 HWC match code 13 HWC match code 13

77 HWC match code 14 HWC match code 14

78 HWC match code 15 HWC match code 15

79 HWC match code 16 HWC match code 16

80 Reserved

... ...

95 Reserved

96 HWC−OR1 Result of HWC OR operation

97 HWC−OR2 Result of HWC OR operation

98 HWC−OR3 Result of HWC OR operation

99 HWC−OR4 Result of HWC OR operation

100 HWC−OR5 Result of HWC OR operation

101 HWC−OR6 Result of HWC OR operation

102 HWC−OR7 Result of HWC OR operation

103 HWC−OR8 Result of HWC OR operation

104 Reserved

... ...

252 Reserved

253 Fixed LOW Signal level always is LOW

254 Fixed HIGH Signal level always is HIGH

255 Not assigned

^ 46

48

l

LDEDS−CCU210B EN 4.0

Page 49

8.4 Digital output signals

8.4.1 Description

The vehicle control system is equipped with digital outputs and a message bar output to

provide digital output signals.

ƒ Basic circuit diagram: (¶ 29)

ƒ The internal status signals are assigned to the output signals via the assignment

logic (C0415).

Digital outputs

There are 2 digital outputs to control the actor technology at the suspension gear of the

monorail overhead conveyor.

Additionally you can logically invert each output.

Message bar

Function library

Digital output signals

Description

8

The digital output signals via the message bar serve as a feedback from the vehicle control

system to the higher−level system control.

A message bar output (MS1) is provided.

You can output the digital signals "positive half wave" and "negative half wave".

) Note!

The reference phase in the Lenze setting is L3.

On customer request, the reference phase L1 can be supplied by adapting the

hardware.

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0416

RW EXT 1 0 1 255

Possible values

0 No inversion

1 DOUT1

2 DOUT2

4 Reserved

8 Reserved

16 Message bar1 positive half wave

32 Message bar1 negative half wave

64 Reserved

128 Reserved

Level inversion for digital outputs

à outputs are LOW−active

Add values of the inverted outputs:

e. g. DOUT1 and message bar1

negative half wave are LOW−active

à C0416 = 33.

^ 49

LDEDS−CCU210B EN 4.0

l

49

Page 50

8

Function library

Digital output signals

Assignment logic

8.4.2 Assignment logic

In the assignment logic (C0415) you assign internal status signals to the message bar and

the digital outputs.

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0415 Linking internal status signals to

RW EXT 4

1

2 0 Not assigned ...Digital output DOUT2

3 0 Not assigned Reserved

4 0 Not assigned Reserved

5 0 Not assigned ... Message bar1 positive half wave

6 0 Not assigned ... Message bar1 negative half wave

0 Not assigned ...Digital output DOUT1

Possible values

0 Not assigned

1 Motor V1 active

2 Motor V2 active

3 Motor V3 active

4 Motor V4 active

5 Motor V5 active

6 Motor V6 active

7 Motor V7 active

8 Motor V8 active

9 Motor CCW rotation active

10 Reserved

11 Fault active

12 Reserved

13 Frequency inverter: parameter set 2

active

14 Reserved

15 Brake is open

16 Stop 1 active

17 Stop 2 active

18 Stop 3 active

19 Stop 4 active

20 Frequency limitation 1 active

21 Frequency limitation 2 active

22 Frequency limitation 3 active

23 Frequency limitation 4 active

24 SensoPart: parameter set 2 active

25 Reserved

... ...

29 Reserved

30 HWC code range active

31 Reserved

digital output signal ...

^ 50

50

l

LDEDS−CCU210B EN 4.0

Page 51

Function library

Digital output signals

Assignment logic

DescriptionPossible settingsCode

SelectionLenzeByte<ñòNo.

C0415 (Continuation)

Linking internal status signals to

digital output signal ...

Possible values

32 Motor is running

33 Reserved

34 Status On/Off: OFF active

35 Status On/Off: OFF active or fault

active

36 Status On/Off: OFF active or fault

active or Stop 1 active or manual Ir

operation active

37 Reserved

38 Stop 1, 2, 3, 4 active or SensoPart

active

39 Frequency limitation 1, 2, 3, 4 active

or SensoPart active

40 Reserved

41 Reserved

42 SensoPart: Stop active

43 SensoPart: frequency limitation

active

44 Reserved

... ...

50 Reserved

51 Start−up warning or fault active

52 Reserved

... ...

59 Reserved

60 IrDA positioning active

61 IrDA position reached

62 Reserved

... ...

252 Reserved

253 Fixed LOW Signal level always is LOW

254 Fixed HIGH Signal level always is HIGH

255 Not assigned

8

^ 50

LDEDS−CCU210B EN 4.0

l

51

Page 52

8

Function library

Motor control

"Motor speed V1−V8" function

8.5 Motor control

8.5.1 "Motor speed V1−V8" function

By the "Motor speed V1−V8" functions (C0410/1 ... C0410/8), 8 speed values for each

parameter set are provided.

ƒ The functions are activated via digital signal sources (e. g. digital inputs).

– The brake opens automatically.

– The motor is activated with the frequency (C0011/1 ... C0011/8) that is

parameterised respectively.

– If two speeds are activated at the same time, the higher stage has priority.

Example: If V2 and V5 are activated at the same time, V5 is used.

ƒ If a "Stop function" is active, the "Motor speed V1−V8" function is inhibited. The

motor control is stopped. The motor is braked to V0 via the deceleration ramp of the

stop function (C0434/1 ... C0434/4).

ƒ If the "Frequency limitation" function is active, the "Motor speed V1−V8" function is

interrupted. The motor is controlled with the corresponding frequency

(C0440/1 ... C440/4).

The acceleration and deceleration times for V1−V8 can be set individually for each drive

frequency (C0012/1 ... C0012/8 and C0013/1 ... C0013/8). The direction of rotation is

controlled via C0410/9. A second parameter set can be activated via C0410/13.

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0010 RW EXT 4 10000

0 {mm/min} 65535

C0011 Drive frequency for ...

RW EXT 4

1

2 0.0 ... V2

3 0.0 ... V3

4 0.0 ... V4

5 0.0 ... V5

6 0.0 ... V6

7 0.0 ... V7

8 0.0 ... V8

C0012 Acceleration time for ...

RW EXT 4

1

2 50 ... V2

3 50 ... V3

4 50 ... V4

5 50 ... V5

6 50 ... V6

7 50 ... V7

8 50 ... V8

0.0 {Hz} 120.0

0.0

1 {Hz/s} 255

50

Conversion factor: speed at 50 Hz

drive frequency

... V1

... V1

^ 52

^ 52

^ 52

52

l

LDEDS−CCU210B EN 4.0

Page 53

Function library

Motor control

"Motor speed V1−V8" function

DescriptionPossible settingsCode

SelectionLenzeByte<ñòNo.

C0013 Deceleration time for ...

RW EXT 4

1

2 50 ... V2

3 50 ... V3

4 50 ... V4

5 50 ... V5

6 50 ... V6

7 50 ... V7

8 50 ... V8

C0014 RW EXT 4 80

C0420 RW EXT 4 0

C0421 RW EXT 4 0

1 {Hz/s} 255

50

1 {Hz/s} 255

0 {ms} 20000

0 {ms} 20000

... V1

Deceleration time for quick stop

functions:

l On/Off switch

l Error

l SensoPart trip−out

Deceleration time:

start−up after mains connection

V0 ð Vx

Deceleration time:

start−up after On/Off switch to ON

V0 ð Vx

8

^ 52

^ 52

^ 52

^ 52

LDEDS−CCU210B EN 4.0

l

53

Page 54

8

Function library

Motor control

Stop functions

8.5.2 Stop functions

In order to interrupt the main functions "Motor V1−V8", you can use "Stop functions". For

this purpose, four independent functions are provided (C0410/16 ... C0410/19):

ƒ The functions are activated via digital signal sources (e. g. digital inputs).

ƒ For the deceleration of Vx to V0 separate deceleration ramps (C0434/1 ... C0434/4)

are provided.

ƒ For each function you can set deceleration times for the acceleration ramps

(C0432/1 ... C0432/4) and deceleration ramps (C0433/1 ... C0433/4).

ƒ You can set each function so that the stop function only is activated in the case of

one direction of rotation of the drive.

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0430 Configuration of function ...

RW EXT 4

1

2 3 ... Stop 2

3 3 ... Stop 3

4 3 ... Stop 4

C0432 delay time:

RW EXT 4

1

2 0 ... Stop 2

3 0 ... Stop 3

4 0 ... Stop 4

C0433 delay time:

RW EXT 4

1

2 0 ... Stop 2

3 0 ... Stop 3

4 0 ... Stop 4

C0434 Deceleration ramp Vx ð V0 for ...

RW EXT 4

1

2 50 ... Stop 2

3 50 ... Stop 3

4 50 ... Stop 4

3 ... Stop 1

Possible values

1 Stop x only active in the case of CW

2 Stop x only active in the case of CCW

3 Stop x active in the case of CW and

0 {ms} 20000

0

0 {ms} 20000

0

1 {Hz/s} 255

50

rotation

rotation

CCW rotation

start−up V0 ð Vx after ...

... Stop 1

start of deceleration ramp Vx ð V0

after command ...

... Stop 1

... Stop 1

^ 54

^ 54

^ 54

^ 54

54

l

LDEDS−CCU210B EN 4.0

Page 55

Function library

Motor control

"Frequency limitation" function (speed limit)

8

8.5.3 "Frequency limitation" function (speed limit)

In order to interrupt the main functions "Motor V1−V8", the "Frequency limitation"

function can be used. If the function is active, it limits the drive frequency to the maximum

value that is respectively set (C0441/1 ... C0441/4). For this purpose, four independent

functions are provided (C0410/20 ... C0410/23):

ƒ The functions are activated via digital signal sources (e. g. digital inputs).

ƒ For the deceleration of Vx to the limited speed VLx there are separate deceleration

ramps (C0444/1 ... C0444/4).

ƒ For each function you can set deceleration times for the acceleration ramps

(C0442/1 ... C0442/4) and deceleration ramps (C0443/1 ... C0443/4).

ƒ You can set each function so that the frequency limitation only is activated in the

case of one direction of rotation of the drive.

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0440 Configuration of function ...

RW EXT 4

1

2 3 ... Frequency limitation 2

3 3 ... Frequency limitation 3

4 3 ... Frequency limitation 4

C0441 Drive frequency for ...

RW EXT 4

1

2 0 ... Frequency limitation 2 (VL2)

3 0 ... Frequency limitation 3 (VL3)

4 0 ... Frequency limitation 4 (VL4)

C0442 delay time:

RW EXT 4

1

2 0 ... Frequency limitation 2

3 0 ... Frequency limitation 3

4 0 ... Frequency limitation 4

C0443 delay time:

RW EXT 4

1

2 0 ... Frequency limitation 2

3 0 ... Frequency limitation 3

4 0 ... Frequency limitation 4

3 ... Frequency limitation 1

Possible values

1 Frequency limitation only active in

2 Frequency limitation only active in

3 Frequency limitation active in the

0 {Hz} 120.0

0

0 {ms} 20000

0

0 {ms} 20000

0

the case of CW rotation

the case of CCW rotation

case of CW and CCW rotation

... Frequency limitation 1 (VL1)

acceleration VLx ðVx after

deactivation of ...

... Frequency limitation 1

start of deceleration ramp Vx ð VLx

after command ...

... Frequency limitation 1

^ 55

^ 55

^ 55

^ 55

LDEDS−CCU210B EN 4.0

l

55

Page 56

8

Function library

Motor control

"Open brake" function

DescriptionPossible settingsCode

SelectionLenzeByte<ñòNo.

C0444 Deceleration ramp Vx ð VLx for ...

RW EXT 4

1

2 50 ... Frequency limitation 2

3 50 ... Frequency limitation 3

4 50 ... Frequency limitation 4

1 {Hz/s} 255

50

... Frequency limitation 1

8.5.4 "Open brake" function

You can also open the motor brake via digital signal sources (C0410/15) without using the

"Motor V1−V8" functions.

In order to prevent an overload of the brake by triggering it for too long, a maximum

triggering time can be parameterised via C0451. After this time has elapsed, the brake

automatically engages even if a trigger signal is available.

If the "Motor V1−V8" functions are active, the motor brake always is open automatically.

^ 55

Codes for parameter setting

Code Possible settings Description

No. ñò < Byte Lenze Selection

C0450 RW EXT 4 0

0 Brake opens immediately Brake opens if C0410/15 = HIGH

1 Brake opens with delay Brake opens if C0410/15 = HIGH

C0451 RW EXT 4 0

0 {s} 1000 l C0451 = 0 s:

"Open brake" function:

configuration

and drive frequency = 0 Hz

"Open brake" function:

maximum activation time

– Brake opens if

C0410/15 = HIGH

– Brake closes if

C0410/15 = LOW

l C0451 > 0 s:

– Brake opens if

C0410/15 = HIGH

– Brake closes after the time set

if C0410/15 = HIGH

^ 56

^ 56

56

l

LDEDS−CCU210B EN 4.0

Page 57

8.6 Monitoring

8.6.1 Anti−collision sensor SensoPart

The SensoPart permanently measures the distance to a reflector on the vehicle ahead. The

distance is read out via a serial interface RS485 by the vehicle control system and is

evaluated according to the function parameterised.

Via a digital signal source (digital inputs, linkage result, etc…) you can switch over between

two SensoPart parameter sets (close−up range and long range, e. g. loaded or empty

vehicle).

For each parameter set, 2 distances, including hystereses in [mm], can be parameterised.

When an object is detected within the approach distance [mm] (speed limit), the speed is

limited to a freely parameterisable threshold [Hz].

The required braking distance towards the vehicle ahead, calculated via the speed [Hz] that

is currently travelled and the deceleration set [Hz/s], is added to the stopping distance