Page 1

50

20

4030

TPS300 Basic Series

User Manual Mining Application Program

English

Version 1.0

Page 2

The quick way to start with the TPS300 Mining Programs.

To use equipment in the permitted manner, please refer to the

detailed safety instructions in the TPS300 Basic Series User

Manual (English version).

© 2000 Leica Geosystems AG Heerbrugg, ® All rights reserved.

TPS300 Mining Manual-1.0.0en

2

The quick way to start

Page 3

Contents - Overview

Introduction......................................................................... 5

Peg Survey .......................................................................... 6

Front Line Peg .................................................................. 16

Grades................................................................................ 17

Offset.................................................................................. 23

Mining Editor..................................................................... 27

TPS300 Mining Manual-1.0.0en

3

Contents - Overview

Page 4

Contents

Introduction................................................5

How to use this manual ............................... 5

Symbols used in the sequence of operation 5

Peg Survey ................................................. 6

Introduction.................................................. 6

Before starting Peg Survey .......................... 7

Start and execution Peg Survey................... 8

Error messages ...........................................9

Proceeding Peg Survey ............................. 10

Results.......................................................13

Saving data ................................................15

Front Line Peg.......................................... 1 6

Introduction................................................ 16

Grades....................................................... 1 7

Introduction................................................ 17

Before starting Grades............................... 18

Start and execution Grades ....................... 18

Gradeline Marking......................................20

Results.......................................................21

Saving data ................................................22

TPS300 Mining Manual-1.0.0en

Offset.........................................................23

Introduction................................................ 23

Before starting Offset................................. 24

Start and execution Offset ......................... 24

Results.......................................................26

Mining Editor............................................27

Introduction................................................ 27

Installation on the PC.................................27

Program content ........................................ 27

Practical Examples .................................... 28

First Example

(Creating fixpoint files, define tolerances,

uploading) ..................................................29

Second Example

(Importing of fixpoints in ASCII format) ......31

4

Contents

Page 5

Introduction

How to use this manual

This manual describes the basic

operation of the TPS300 Mining

field programs. It shall be used

together with a TPS300

instrument.

For detailed description about

the whole functionality of the

TPS300 instrument please to

refer in the TPS300 User

Manual.

TPS300 Mining Manual-1.0.0en

Symbols used in the sequence of operation

Press the fixed key PROG

Press the fixed key ENTER

Navigation keys

Repeat operation

User input is necessary

Important paragraphs which must be adhered to in

practice as they enable the product to be used in a

technically correct and efficient manner.

5

Introduction

Page 6

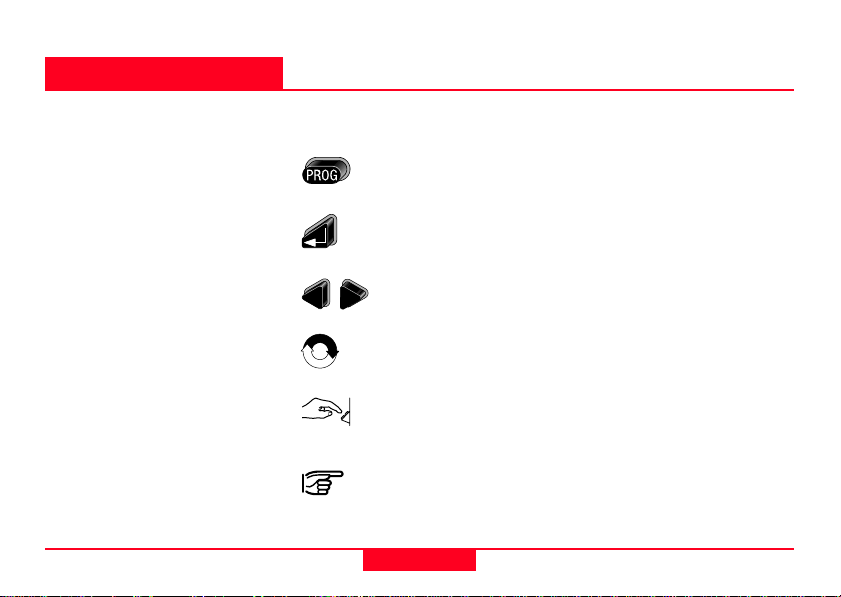

Peg Survey

Introduction

The application "Peg Survey" is

used to establish a forward peg

(point). It is used to control the

intermediate horizontal angle

between backsight and foresight

points. It also checks the

horizontal distances and heights

of the backsight and foresight

points. It computes the

coordinates of the foresight

point. "Peg Survey" allows users

to measure several sets in

different sequences. (The

quality of measurement is

controlled by the tolerances

which are set before starting

"Peg Survey").

TPS300 Mining Manual-1.0.0en

Backsight Point Station Foresight Point

Dist1

-hr

Hz1

Hz=0°00'00"

Known:

• Coordinates of station

Hz2

-hi

Unknown:

• Coordinates of foresight point

• Coordinates of backsight

point

6

-hr

Dist2

Mining_z01

Peg Survey

Page 7

Before starting Peg Survey

Data uploading using "Mining

Editor"

• Station coordinates

(East, North, Height,

Grade elevation)

• Backsight point coordinates

(East, North, Height,

Grade elevation)

• Tolerances, sequence,

number of sets

• Job definition

TPS300 Mining Manual-1.0.0en

Uploading of fixpoint

coordinates, tolerances,

sequence and number

of sets is mandatory to

enable the operation of

"Peg Survey".

7

To create new jobs on

board the instrument, a

set of tolerance must be

available.

Peg Survey

Page 8

Start and execution Peg Survey

Start "Peg Survey" from

the program menu.

Start-up menu:

PROGRAMS

PEG SURVEY

FLP

SETTING OUT

<EXIT>

Choose "Peg Survey" and press

.

> Step 1 Select a job.

> Step 2 Confirm the set of

tolerances.

TPS300 Mining Manual-1.0.0en

Sample dialog: > Step 4 <SET>

Set Point number

Input Station

PtID : 100

hi : -1.265 m

(PtID) and

instrument height

(hi).

<EXIT> Leaves "Input

<EXIT> <SET>

Station" and returns

to the start-up menu.

> Step 3 Choose "Start" and

press , then

enter point number

(PtID) and

instrument height

(hi) for the station.

The sign for the

instrument height

(hi) is normally

negative.

8

Peg Survey

Page 9

Error messages

Station or BS point has no

valid coords !

• The point number entered is

not available in the internal

memory or it has invalid

coordinates.

Re-enter point number

( > Step 3 ).

Sample dialog:

Survey will be

executed according to

the following settings:

No of Sets: 3

Sequence: BFFB

<OK>

TPS300 Mining Manual-1.0.0en

Number of sets:

One set means to measure two

times the backsight point and

two times the foresight point in

both faces.

The meaning of set is

described:

One Set

I Set

FSBS

Two Sets

II Set

I Set

FSBS

9

The user must complete

the number of sets as

preset in the tolerance

setting.

Mining_z02

Peg Survey

Page 10

Proceeding Peg Survey

Sequence:

It defines the measuring

sequence.

Options:

• BFFB

Backsight-ForesightForesight-Backsight

• BFBF

Backsight-ForesightBacksight-Foresight

• BBFF

Backsight-BacksightForesight-Foresight

<OK> Leaves this dialog

and proceed to the

next dialog.

TPS300 Mining Manual-1.0.0en

Sample dialog:

Set 1

of total 3

<OK>

Set 1 of total 3

Start with measurement first set

of three.

<OK> Leaves this dialog

and proceed to the

next dialog.

10

Sample dialog:

Measure Backsight Point

PtID: 150

<OK>

Measure Backsight Point

Information about which

backsight point the user has to

measure.

<OK> Leaves this dialog

and proceed to the

measure dialog.

Peg Survey

Page 11

Proceeding Peg Survey, continued

Sample dialog:

Backsight Point 1/3

PtID : 150

Hz : 98°12'45"

V : 99°45'23"

hr : -1.263 m

HD : ----.--- m

<EXIT> <SEARCH> <MEAS>

> Step 5 Enter the reflector

height (hr) for the

backsight point, if

required.

The sign for the

reflector height (hr)

is normally negative.

TPS300 Mining Manual-1.0.0en

> Step 6 Aim at backsight

point and measure.

<MEAS>, ALL or DIST/REC

Angle and distance

measurements are

triggered and stored

in the internal

memory.

<SEARCH>Allows users to

search and choose a

different backsight

point.

<EXIT> Terminates the

program and returns

to the start-up menu.

11

Sample dialog:

Measure Foresight Point

PtID: -----

<OK>

> Step 7 Enter a desired

foresight point

number (PtID).

<OK> Saves the foresight

point number and

proceed to the

measure dialog.

Peg Survey

Page 12

Proceeding Peg Survey, continued

Sample dialog:

Foresight Point 1/3

PtID : 151

Hz : 198°12'45"

V : 94°45'23"

hr : -1.632 m

HD : ----.--- m

<EXIT> <MEAS>

> Step 8 Enter the reflector

height (hr) for the

foresight point, if

required.

The sign for the

reflector height (hr)

is normally negative.

> Step 9 Aim at foresight

point and measure.

TPS300 Mining Manual-1.0.0en

<MEAS>, ALL, or DIST/REC

Angle and distance

measurements are

triggered and stored

in the internal

memory.

<EXIT> Terminates the

program and returns

to the start-up menu.

Repeat > Step 6

and > Step 9 until

all sets are

measured.

If the tolerances

after a set are not

met, the user has

the option to

continue with the

measuring or

rejecting the data.

12

<REJECT> Reject the

measurement and

measure the set

again.

<ACCEPT>Accept the result

and continue with

the next set.

Peg Survey

Page 13

Results

Sample dialog:

TOLERANCES MET ! (PAGE1)

dHz : 00°00'25"

TolHz : 00°00'50"

dHD BS: 0.001 m

dHD FS: 0.003 m

TolHD : 0.006 m

Page down

Sample dialog:

TOLERANCES MET ! (PAGE2)

dH BS : 0.003 m

dH FS : 0.001 m

TolH : 0.004 m

Set No: <ALL SETS>

<EXIT> <OK>

TPS300 Mining Manual-1.0.0en

Tolerances dialog:

• dHz: Residual on the

horizontal angle

• dHD: Residual on the

horizontal distance

• dH: Height residual

• TolHz, TolHD, TolH:

Tolerances horizontal angle, horizontal

distance and height

• Set No: Set number

13

<OK> Leaves this dialog

and proceed to the

result dialog.

<EXIT> Terminates the

measurement and

returns to the startup menu.

Peg Survey

Page 14

Results, continued

Sample dialog:

TRAVERSE RESULT (PAGE1)

mHz : 56°36'25"

mHDBS : 56.465 m

mHBS : 0.786 m

mHDFS : 46.632 m

mHFS : 1.236 m

Page down

Sample dialog:

TRAVERSE RESULT (PAGE2)

Pt BS : 101

Pt FS : 102

mHz : 56°36'25"

Seq : BFFB

Num : 2

<EXIT> <OK>

TPS300 Mining Manual-1.0.0en

Result dialog:

• mHz: Average

intermediate horizontal angle

between backsight point and

foresight point

• mHDBS/FS: Average

horizontal distance

(Backsight and Foresight)

Backsight Point Station Foresight Point

mHBS

mHz

mHDBS mHDFS

14

• mHBS/FS: Average height

(Backsight and Foresight)

• Pt BS/FS: Point number

(Backsight and Foresight)

• Seq: Sequence

• Num: Number of sets

mHFS

Mining_z03

Peg Survey

Page 15

Results, continued

Saving data

<OK> Quits the program.

<EXIT> Terminates the

measurement and

returns to the startup menu.

TPS300 Mining Manual-1.0.0en

The following result data are

stored in the internal memory:

Result:

mHz: Average

intermediate

horizontal angle

between backsight

point and foresight

point

mHD: Average horizontal

distance (backsight

and foresight)

mH: Average height

(backsight and

foresight)

15

Residual:

dHz: Residual on the

horizontal angle

dHD: Residual on the

horizontal distance

dH: Height residual

Coordinates foresight point:

E: Easting

N: Northing

H: Height point

GrEl: Grade Elevation

Peg Survey

Page 16

Front Line Peg

Introduction

The application "FLP" is used to

mark a new line peg (Front line

peg). This application is similar

to "Peg Survey" and there is

only one set of measurement

required.

For a more detail explanation of

"FLP", please refer to chapter

"Peg Survey".

TPS300 Mining Manual-1.0.0en

16

Front Line Peg

Page 17

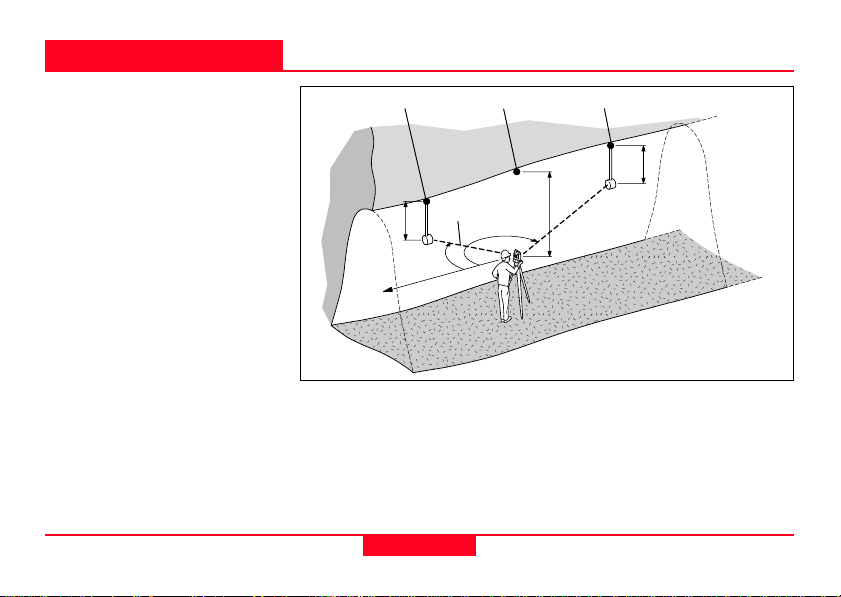

Grades

Introduction

"Grades" application is used to

mark gradelines along the side

walls of the mines (tunnels). It

allows users to input the slope

gradient and an offset

concerning the grade point. It

computes the stake out height

difference. The program allows

also to map the positions of the

grades points along the

gradelines.

Known:

• Coordinates and grade

elevation of station

• Coordinates and grade

elevation of backsight point

TPS300 Mining Manual-1.0.0en

Backsight Point Station Foresight Point

Mining_z04

3

2

1

New Gradeline

H

dHD

1A

2A

Unknown:

• Slope gradient (station until

foresight point)

• Height difference (dH)

between current gradeline

and new gradeline

• Stake out height difference

(dHgt) between measure

point and gradeline point

• Horizontal distance (dHD)

along the foresight line

17

4

dH

H

4A

3A

H = Current height of

gradeline above mine floor

dH = New height difference

input for new gradeline

Grades

Page 18

Before starting Grades

Start and execution Grades

• Station setup

• Application "FLP" is done

TPS300 Mining Manual-1.0.0en

Menu dialog of "FLP": Sample dialog:

CONTINUE WITH ...

GRADES

OFFSET

<EXIT>

Start "Grades" after "FLP"

(Front Line Peg) choose

<Grades> and press .

Grade : 1: 150

Height: 0.500 m

<EXIT> <SET>

If the slope gradient

(station until foresight

point) is the same like

the slope gradient

(backsight point until

station) then continue

direct with > Step 3 .

18

GRADES

Grades

Page 19

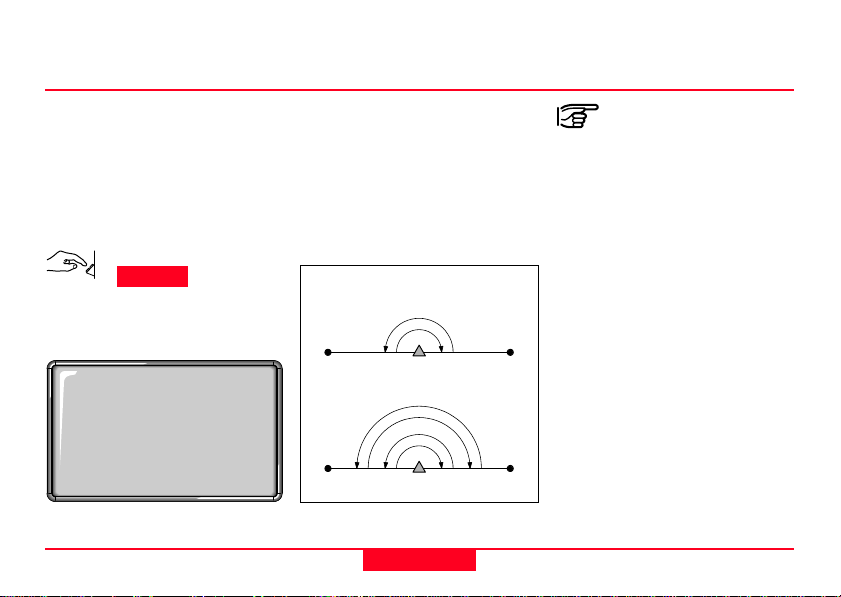

Start and execution Peg Survey, continued

> Step 1 Enter the slope

gradient

(proportion e.g.

1:150).

Slope gradient explained:

Gradeline

1

150

TPS300 Mining Manual-1.0.0en

> Step 2 Enter the height

difference.

Height difference explained:

Station Foresight Point

dH

New Gradeline

H

Mining_z05

H: Current height of

gradeline above

mine floor

dH: Height difference

19

> Step 3 <SET> Set the

entered values and

proceeds to the

gradeline marking

dialog.

<EXIT> Leaves the

application "Grades"

and return to the

menu dialog of

"FLP".

Mining_z06

Grades

Page 20

Gradeline Marking

Sample dialog:

GRADELINE MARKING

PtID : 100

dHgt : 0.552 m

dHD : 3.123 m

Hz : 126°56'23"

HD : 10.365 m

<EXIT> <PREV> <MEAS>

> Step 4 Enter a desired point

number (PtID).

> Step 5 Aim at target point

and measure.

<MEAS>, ALL or

DIST/REC

Measurement is

triggered and stored

in the internal

memory.

TPS300 Mining Manual-1.0.0en

<PREV> Returns to the start

of "Grades"

application.

For a new definition

of slope gradient

and height

difference repeat

> Step 1 until

> Step 3 .

20

<EXIT> Leaves the

application "Grades"

and return to the

menu dialog of

"FLP".

Grades

Page 21

Results

Grades computes the height difference (dHgt) between measure point and stake out point and the

horizontal distance (dHD) along the foresight line.

Height difference (dHgt) and horizontal distance (dHD) explained:

Station Foresight Point

Gradeline

TPS300 Mining Manual-1.0.0en

dHD

dHgt

21

dHD

Mining_z07

Foresight

Point

Station

New

Gradeline

point

Mining_z08

Grades

Page 22

Results, continued Saving data

If the sign is

negative the grade

point are above the

measure point.

If the sign is positive

the grade point are

below the measure

point.

> Step 6 Turn the telescope

until the height

difference (dHgt) is

zero, then repeat the

measurement

( > Step 5 ).

TPS300 Mining Manual-1.0.0en

The following result data are

stored in the internal memory:

Measurement data:

PtID: Point number

Hz: Horizontal angle

V: Vertical angle

HD: Horizontal distance

SD: Slope distance

dH: Height difference

22

Coordinates of new gradeline

point:

E: Easting

N: Northing

H: Height

Grades Result:

daH: Stake out height

difference

daHD: Horizontal distance

along the foresight

line

Grd: Slope gradient

GE: Grade elevation

Grades

Page 23

Offset

Introduction

"Offset" application is generally

used to obtain sections of the

tunnels for volume computation

as well as mapping of the

tunnels. It allows users to input

offset value (left, right, up and

down) and computes after

measurement the actual

coordinates of the tunnel walls.

TPS300 Mining Manual-1.0.0en

Backsight Point

Known:

• Coordinates of station

• Coordinates of backsight

point

• Offset value

Station Foresight Point

23

Up

Left

Right

Down

Mining_z09

Unknown:

• Point coordinates of the

tunnel walls

Offset

Page 24

Before starting Offset

Start and execution Offset

• Station setup

• Application "FLP" is done

TPS300 Mining Manual-1.0.0en

Menu dialog of "FLP":

CONTINUE WITH

GRADES

OFFSET

<EXIT>

Start "Offset" after "FLP" (Front

Line Peg) choose <OFFSET>

and press .

24

Sample dialog:

PtID : 100

Offset: 1.500 m

Hz : 123°12'36"

HD : -----.--- m

<EXIT> <MEAS>

OFFSET

LEFT

> Step 1 Enter a desired point

number (PtID) and

the offset value.

> Step 2 Using

for the offset

definition.

(Left, Up, Right, Down)

(Left, Down, Right, Up)

Offset

Page 25

Start and execution Offset, continued

Definition of offset explained:

Up

RightLeft

Down

Offset

Left

Offset

Right

Foresight

Point

Station

TPS300 Mining Manual-1.0.0en

> Step 3 Aim at target point

and measure.

<MEAS>, ALL or DIST/REC

Measurement is

triggered and stored

in the internal

memory.

<EXIT> Leaves the

application Offset

Mining_z10

and return to the

menu dialog of "FLP".

Mining_z11

25

After storing, the

program returns to

the measuring

dialog.

If you want to

measure a new point

repeat > Step 1

until > Step 3 .

Offset

Page 26

Results

Saving data

The following result data are

stored in the internal memory:

Measurement data:

PtID: Point number

Hz: Horizontal Angle

V: Vertical Angle

HD: Horizontal distance

SD: Slope distance

The measurement

data are already

corrected.

TPS300 Mining Manual-1.0.0en

Offset information:

Offset: Offset value

OffsetDir: Offset direction

(left, up, right, down)

26

Coordinates of new offset

point:

E: Easting

N: Northing

H: Height

Offset

Page 27

Mining Editor

Introduction

"Mining Editor" (PC Program

Package) is a Windows-based

program used for the data

exchange between the TPS300

Series and the PC.

TPS300 Mining Manual-1.0.0en

Installation on the PC

The installation program for the

"Mining Editor" can be found on

the CD-ROM supplied. Please

note that the "Mining Editor"

program can only be installed

under the operating systems MS

Windows 95, 98, NT4.0,

WINDOWS2000.

For the installation call program

"setup.exe" in the directory

"MiningEditor\Disk1" on the CDROM and follow the onscreen

instructions to complete the

installation.

27

Program content

The "Mining Editor" can be used

for the following purposes:

• Data Import & Export

Import and export fixpoint

files (ASCII format).

• Data Transfer between PC

and TPS300 instrument

Upload and download of

fixpoint files, upload of

tolerances, download of

measurement data and

conversion of measurement

data to various formats for

peg calculation and archiving.

Mining Editor

Page 28

Program content, continued

Practical Examples

• Define and upload

Tolerances

Defining tolerances, editing

tolerances (password

protected), uploading

tolerances

• Creating fixpoint files

Creating and editing of

fixpoint files (Coordinates)

TPS300 Mining Manual-1.0.0en

The following pages of the

manual describe the

functionality of "Mining Editor"

with two practical examples.

28

• Example1:

Creating fixpoint files, Define

tolerances, Uploading them

to the instrument

• Example2:

Importing of fixpoints in ASCII

format

Mining Editor

Page 29

First Example (Creating fixpoint files, define tolerances, uploading)

Creating fixpoint files

> Step 1 Open a new file:

> Step 2 Enter point number, coordinates,

backsight reference point, grade

elevation.

> Step 3 Save the created coordinate list:

File à Save As

In the fixpoint entry module, the

"Mining Editor" allows users to create,

view, modify and save coordinate lists.

TPS300 Mining Manual-1.0.0en

File à New

Define tolerances

> Step 1 Open tolerances:

Options à Tolerances à Edit

> Step 2 Enter a password.

Create a new password:

Options à Password

> Step 3 Select a measuring sequence

(BFFB, BFBF or BBFF).

(B = Backsight point and F= Foresight

point).

> Step 4 Enter number of sets.

29

Mining Editor

Page 30

First Example (Creating fixpoint files, define tolerances, uploading), continued

> Step 5

a)Select a tolerance type

(Primary, Secondary,

Tertiary).

b)Enter the values for:

• Horizontal Angle Limit

• Horizontal Distance Limit

• Height Limit

TPS300 Mining Manual-1.0.0en

Upload Fixpoints and

Tolerances to the instrument

Ensure that the unit

setting on the

instrument (Menu /

All Settings / Unit

Settings) is identical

to the units set in

the "Mining Editor"

(

Options

Settings

> Step 1 Open a fixpoint file:

à

).

File à Open

> Step 2 Choose Upload:

Data à Upload

> Step 3 Select a job.

30

> Step 4 Enter jobname,

operator and

comments.

Operator and

comments are

optional.

> Step 5 Select a tolerance

type.

Mining Editor

Page 31

Second Example (Importing of fixpoints in ASCII format)

Process import fixpoint files

The "Mining Editor" allows to import

fixpoint files in ASCII format.

> Step 1

TPS300 Mining Manual-1.0.0en

File à Open

> Step 2 ASCII-File search and select.

> Step 3 Open the selected file.

Follow the wizard onscreen

instructions to produce the correct

format.

> Step 4 Save the created file:

File à Save as

31

Mining Editor

Page 32

Leica Geosystems AG, Heerbrugg,

Switzerland, has been certified as

being equipped with a quality

system which meets the International Standards of Quality Management and Quality Systems (ISO

standard 9001) and Environmental

Management Systems

(ISO standard 14001).

Total Quality ManagementOur commitment to total customer

satisfaction

Ask your local Leica Geosystems

agent for more information about

our TQM program

723346-1.0.0en

Printed in Switzerland - Copyright

Leica Geosystems AG, Heerbrugg,

Switzerland 2000

Original text

Leica Geosystems AG

CH-9435 Heerbrugg

(Switzerland)

Phone +41 71 727 31 31

Fax +41 71 727 46 73

www.leica-geosystems.com

Loading...

Loading...