Page 1

Factory tips on the

M-Series Leicas

The M-series Leica is still the

standard of excellence among

rangefinder-type 35mm cameras. Yet

despite Leica's popularity and length

of time in service, there seems to be a

long-felt vacuum of factory

information in the repair field — at

least, so it appears from the

individual questions we've been

answering at National Camera.

So instructor Monty Witt ventured

forth to Leitz in hopes of obtaining

some first-hand factory servicing tips.

The notes he brought back from New

Jersey should be of prime interest to

CRAFTSMAN readers. And we'd like

to express our gratitude to Leitz for

their courtesy and assistance in

gathering this material.

Although Monty also received

bench training on the Leicaflex and

the Leica M5, we'll confine ourselves

this time to the notes he kept on the

M2, M3, and M4 ( mainly because of

the immediate availability of an M2

which was used for most of the

illustrations). We plan to pass along

the Leicaflex and M5 information in

future CRAFTSMAN articles.

In addition to Monty's notes, we'll

include some basic information on the

M-series Leicas. If you're already a

proficient Leica technician, please

stick with us — you should find

something new and useful besides

what may already be familiar.

Disassembly Steps For The

M-Series Leicas

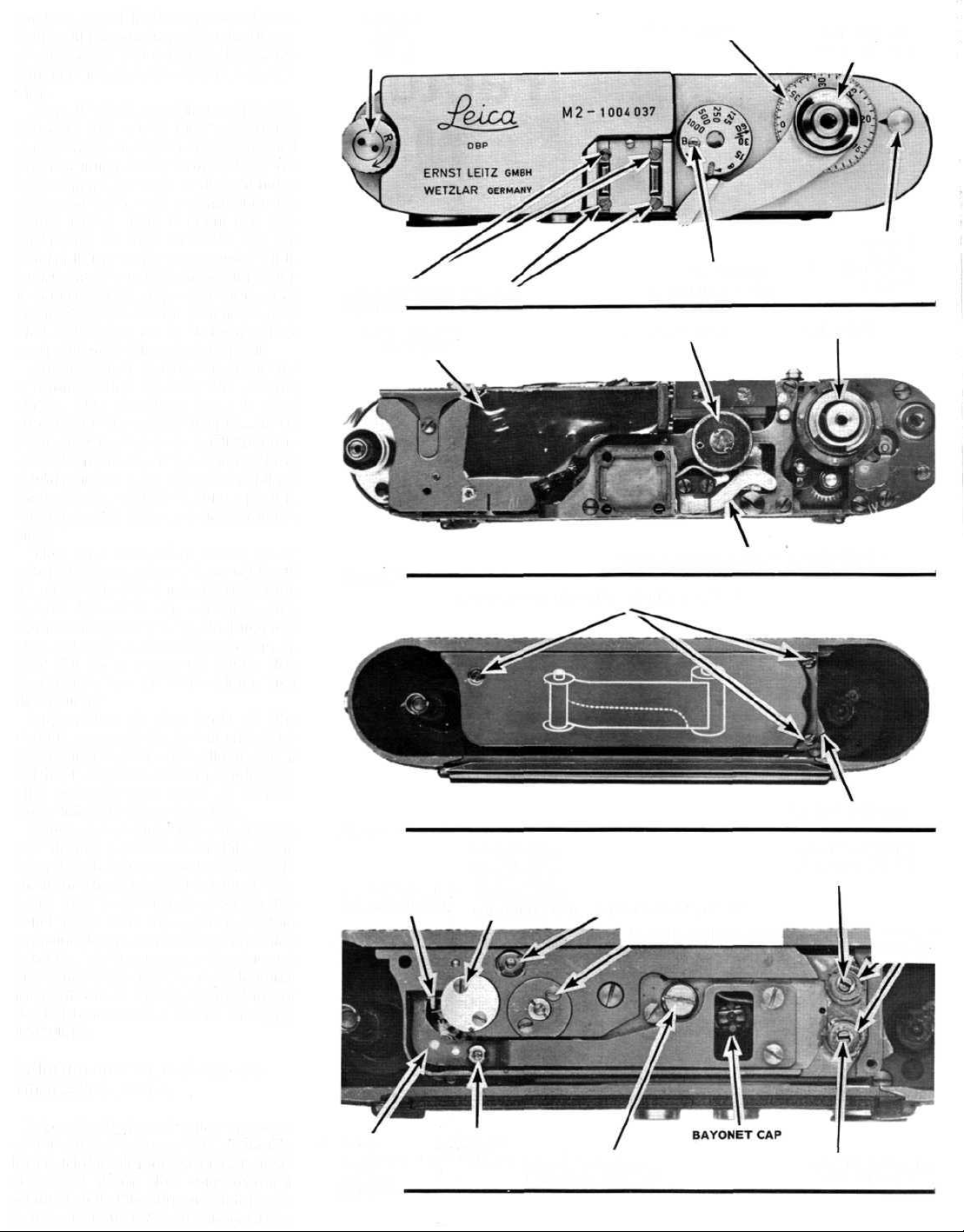

The Leica M2 illustrated in Fig. 1 is

a slightly simplified version of the

original M-series Leica, the M3. The

M3 set the design precedents for the

other M-series Leicas: the Ml

(further simplified from the M2) and

the MP (a special model for press

photographers quite similar to the

M2). More recently, the M4 (an

improved version of the M3) took over

the top roost. But all the Leica models

mentioned are nearly identical from

the technician's viewpoint. Only the

M5, which we'll not discuss here,

represents a radical departure from

the original design.

If you've been in the repair business

for any length of time, you can no

doubt take a Leica apart. But we find

that most technicians spend time

removing parts that could just as well

be left in place. So we'll outline the

disassembly techniques to reach the

adjustments and timing points of

concern.

Starting with the top cover plate

disassembly, remove the screw at the

top of the lens mounting ring, Fig. 1.

This screw is normally sealed with a

black locking agent. Since the screw

must be removed to pull either the top

cover plate or the body shell, you can

frequently tell from the condition of

the locking agent whether or not the

camera has previously been

disassembled.

Next, remove the camera's base

plate as you would for loading film.

The Leicas based on the M3 design

carry over the load-from-the-bottom

technique of the screw-mount Leicas.

But the M-series Leicas added a

hinged back to facilitate loading. You

can remove the hinged back by

pushing the release pin from left to

right in Fig. 2.

Reaching into the supply-spool

cavity, wedge the rewind fork to

prevent it from turning. Then, use a

Multispan wrench to unscrew the

cover screw that holds the rewind

knob, Fig. 3. An exception here is the

M4—the rewind knob in the M4 sits at

a convenient cant and is held by a

setscrew.

Probably one of the main

disassembly problems faced by the

technician is the removal of the wind

lever cover screw, Fig. 3. The wind

lever cover screw has a right-hand

thread, but it may be extremely tight.

To avoid scarring the polished

RANGEFINDER WINDOW

REWIND LEVER

Figure 1

COVER SCREW FOR

VERTICAL RANGEFINDER

ADJUSTMENT

FRAME LINE

MASK WINDOW

FRAME LINE SELECTOR LEVER

VIEWFINDER WINDOW

RELEASE PIN

Figure 2

Page 2

surface, use a Flexiclamp wrench or a

split collet to unscrew the wind lever

cover screw. You can then lift off the

wind lever and, in the M2, the counter

dial.

Also, if you're working on the M2,

remove the cover plate retaining

screw shown in Fig. 3. You won't find

this retaining screw in the M3 or the

M4 — instead, unscrew the retaining

ring accessible after removing the

wind lever. The reason for the

difference is that the AA2 has an

external, manually set counter dial.

But in the M3 and AA4, the counter dial

is underneath the top cover plate. The

spring-loaded counter dial in the M3

and AA4 automatically returns when

you pull out the film take-up spool.

Another tricky part to remove is the

retaining ring around the rewind

shaft. The problem here is that

standard tools can't do the job — there

isn't enough room for a Flexiclamp

wrench and there are no notches for a

Multispan wrench. So here's one place

that you may wish to design a special,

tubular tool that fits over the retaining

ring.

The remaining top cover plate

components are no problem. Take out

the speed knob retaining screw, Fig.

3, and lift off the speed knob. And

remove the four screws holding the

accessory shoe, also shown in Fig. 3.

Lift off the accessory shoe, the

accessory shoe pressure plate, and

the spring.

Proceeding to the back of the

camera, unscrew the two flash socket

cover rings and the two flash socket

bushings. If you're working on the M3,

also unscrew the eyepiece frame.

Now, lift off the top cover plate.

Before we go into the adjustments

and timing points now visible, we'll

complete the disassembly of the body

shell and the rangefinder, Fig. 4. You

may, however, wish to replace the

wind lever with its cover screw to

examine the operation at the top of the

camera. Then, turn over the camera

and remove the three screws holding

the bottom cover plate, Fig. 5. Lift off

the bottom cover plate and the base

lock plate.

REWIND

KNOB

COVER

SCREW

ACCESSORY SHOE SCREWS

Figure 3

RANGEFINDER

ASSEMBLY

Figure 4

BOTTOM COVER PLATE RETAINING SCREWS

Figure 5

PIVOT PLATE

FOR CURTAIN

END OF OPENING

CURTAIN LATCH

WIND GEAR

AND OPENING

CURTAIN LATCH

COUNTER DIAL

SPEED KNOB

RETAINING SCREW

SPEED SELECTOR

SAFETY SWITCH FOR "FP" SYNC CONTACTS

"X"-SYNC ADJUSTMENT

DRUM BEARING PLATE

WIND LEVER

COVER SCREW

WIND CAM

BASE LOCK PLATE

CLOSING CURTAIN

TAKE-UP ROLLER

COVER

PLATE

RETAINING

SCREW

LOCKING

COLLARS

Adjustments At The Bottom Of

The M-Series Leica

Several adjustment points are now

visible at the bottom of the camera,

Fig. 6. Notice that the M-series Leicas

departed from the conventional

methods of locking the curtain take-up

rollers. To adjust the curtain tensions,

FLAT

RELEASE

SPRING

Figure 6

SETSCREW

ADJUSTMENT

CLOSING CURTAIN

BRAKE ADJUSTMENT

OPENING CURTAIN

TAKE-UP ROLLER

Page 3

use a screwdriver with a blade

slightly wider than the slotted ends of

the take-up rollers central shafts.

Insert the screwdriver into the slotted

end of one central shaft and push

down — that depresses the locking

collar and frees the central shaft. You

can now turn the screwdriver to add

or let off tension.

Another departure from tradition is

the elimination of the interlockingstud arrangement common to the

drum-type focal-plane shutters. In the

shutter-cocked position, a slot in the

curtain wind gear clears the drum

gear at the bottom of the curtain

drum. Then, the opening curtain

latch, Fig. 6, drops into engagement

with the opening curtain cam

underneath the drum gear.

Depressing the release button

pushes the end of the flat release

spring against the opening curtain

latch. So the opening curtain latch,

pushed out of engagement with the

opening curtain cam, frees the

opening curtain. Simultaneously, the

flat release spring allows the closing

curtain latch, Fig. 7, to drop down and

engage the closing curtain cam.

meeting these specifications is the

setscrew on the flat release spring,

Fig. 6.

The "X"-sync adjustment is

another conveniently located

adjustment point visible in Fig. 6. The

collar with the Multispan notches

controls an eccentrically positioned

stud at the other side of the bottom

plate. And the stud, in turn, controls

the position of the fixed "X" contact.

Turning the collar corrects the "X"sync delay by setting the proper space

gap between the two contacts.

A second eccentric controls the

tension of the closing curtain brake

spring, Fig. 6. The brake spring,

which we'll see after removing the

body shell, engages a cam operated

by the closing curtain drum. And by

turning the eccentric from the bottom

of the camera, you can control the

amount of braking action.

Check the proper tension for the

closing curtain brake by first setting

the shutter to "bulb." Then, cock and

release the shutter. The closing

curtain should be stopped by the

brake spring before reaching the

extreme limit of its travel. So try

pulling the closing curtain in the

direction of its release movement —

you should be able to pull the curtain

an additional 0.1mm—0.5mm.

In some cameras, there's also an

eccentric adjustment for the opening

curtain brake; the opening curtain

brake eccentric is shown from a Leica

M3 in Fig. 8. Check the adjustment of

the opening curtain brake by holding

the shutter open at the "bulb" setting.

Now, looking from the front of the

focal-plane aperture, examine the

position of the opening curtain bar at

the right-hand side of the camera. If

the opening curtain brake is properly

adjusted, the edge of the opening

curtain bar should be 1.5mm —

2.5mm beyond the edge of the focalplane aperture.

Before moving too far away from

Fig. 6, we should point out the bayonet

cap in the focal-plane light shield. You

can remove the bayonet cap after

rotating it a partial turn. As you will

see a little later, removing the

bayonet cap uncovers an access hole

in the focal-plane light shield — a hole

which makes it easier to reach one of

the rangefinder retaining screws.

RELEASE BUTTON

CLOSING CURTAIN

RELEASE

ROD

FLAT

RELEASE

SPRING

OPENING CURTAIN

LATCH

RELEASE CYCLE

Figure 7 '

LATCH

DRUM GEAR

Leica's specifications here are that

the opening curtain should release

when you depress the release button

approximately 1.5mm. Once you let

up on the release button, the flat

release spring raises the closing

curtain latch above the closing curtain

cam. Checking the operation at

"bulb," the release button should

have an additional 0.2mm upward

travel after the closing curtain has

released. The adjustment point for

Figure 8

REWIND

LEVER

SCREW

Figure 9 •

LEICA M3 OPENING CURTAIN BRAKE ADJUSTMENT

BODY SHELL

SCREWS

RANGEFINDER CONTROL ARM

Page 4

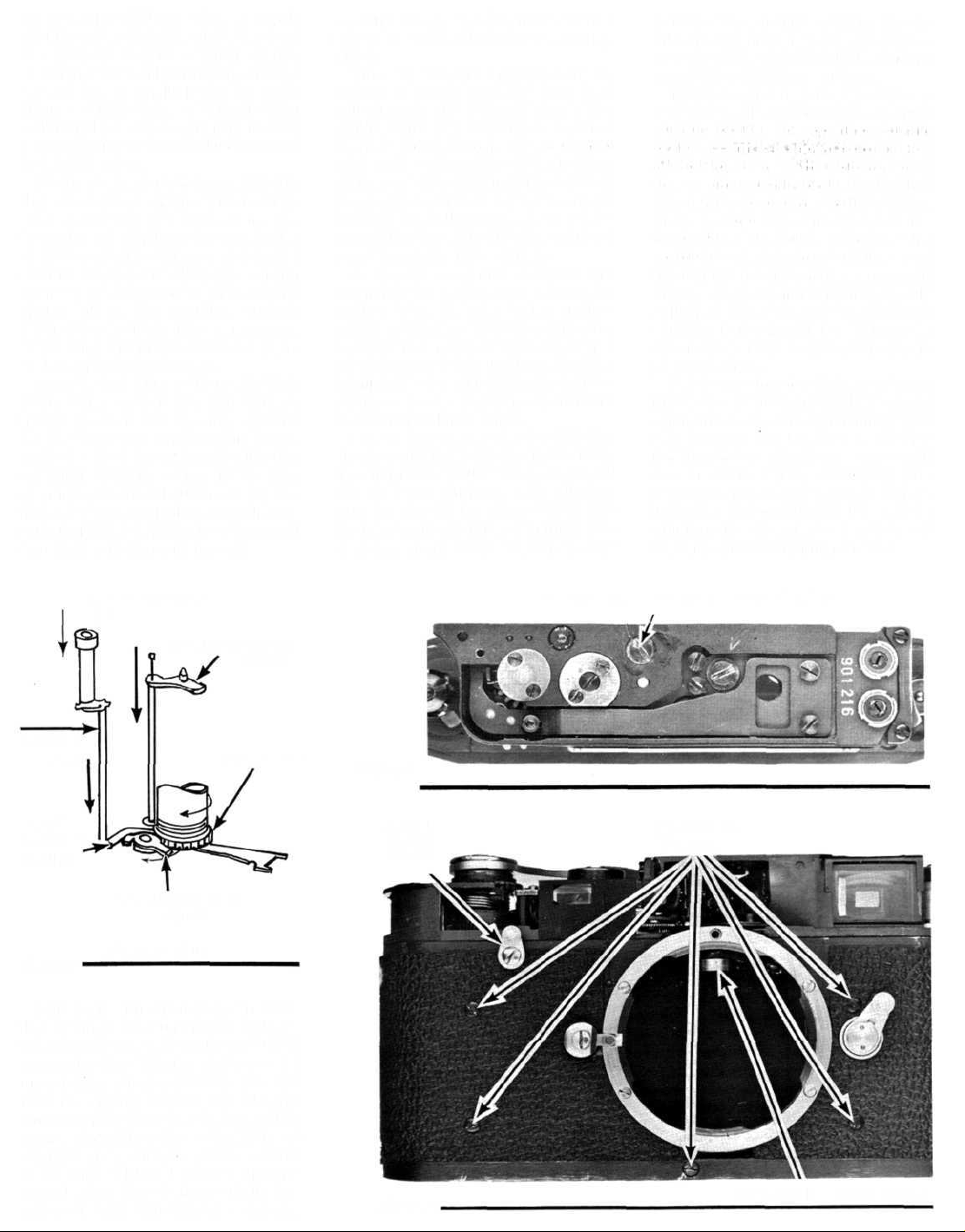

Removing The Body Shell

The next step is to separate the

body shell from the shutter

mechanism. First, take out the rewind

lever by removing its retaining screw,

Fig. 9. Then, remove the five screws

holding the body shell, also pointed

out in Fig. 9. You may find it

necessary to remove the frame line

selector lever to reach the upper bodyshell screw at the right of the lens

mounting ring.

The AA2 we used for the illustrations

does not have a self timer. But if

you've worked on M-series Leicas

before, you probably know that the

cocking lever in models with a self

timer has a left-hand thread. What

you may not have known is that you

don't have to remove the self-timer

cocking lever to pull the body shell —

just cock the self timer prior to

separating the body shell from the

shutter mechanism.

Some manipulation — but no

pressure — is now required to remove

the body shell. As you pull off the body

shell, push in the rangefinder control

arm (against its tension) for

clearance.

Rangefinder Adjustment Points

and Disassembly Procedure

We can now more easily point out

the rangefinder adjustments. Besides

the normal horizontal (infinity) and

vertical adjustments, there are

adjustments for the linearity at

different distances and for the

overtravel of the rangefinder control

arm.

Make your infinity and 10-meter

rangefinder adjustments by turning

the eccentric shaft on the rangefinder

control arm roller, Fig. 10. If the

rangefinder aligns properly at infinity

and 10 meters, check the alignment of

the superimposed images with a

target placed one meter from the

focal plane.

The adjustment point for the one-

meter target is the eccentric at the

other end of the rangefinder control

arm, Fig. 10. To turn the one-meter

eccentric, first loosen the rangefinder

control arm retaining screw. You may

have to alternate between the two

eccentrics, checking and adjusting at

the designated distances, to correct

the linearity for all distance settings.

In Fig. 10, the rangefinder control

arm has moved (via spring tension)

as far as it can go toward the front of

the camera. Here, the rangefinder

VERTICAL

ADJUSTMENT

OVERTRAVEL

ADJUSTMENT

Figure 10

THIS LIGHT SHIELD MAY

BE LOOSE

RANGEFINDER CONTROL

Figure 1 7

ARM SHAFT

stop arm comes against another

eccentric. This eccentric is the

overtravel adjustment for the

rangefinder control arm. In other

words, at the infinity setting the lens

pushes the rangefinder control arm

toward the back of the camera. But

the rangefinder control arm should

not touch the eccentric at infinity —

you should be able to push the

rangefinder control arm a slight

distance beyond infinity before it is

stopped by the eccentric.

The vertical rangefinder

adjustment, also shown in Fig. 10, is

still accessible after replacing the top

cover plate; just removing the screw

shown in Fig. 1 provides access to the

vertical adjustment point. So you can

make all rangefinder adjustments

with the camera assembled — the

distance adjustments are accessible

through the lens opening, and the

vertical adjustment is accessible

through the clearance hole in the top

cover plate.

Removing the rangefinder

assembly disturbs the setting of the

one-meter eccentric and could disturb

the overtravel eccentric. But you can

scribe the positions of the eccentrics

prior to disassembly. On reassembly,

aligning the scribe marks saves a lot

of time in the adjusting department.

INFINITY AND

10-METER

ADJUSTMENT

ONE-METER

ADJUSTMENT

RANGEFINDER

STOP ARM

FRAME LINE PIN

RANGEFINDER

ASSEMBLY

RETAINING

SCREWS

THIS LIGHT

SHIELD IS LOOSE

Now, remove the two rangefinder

assembly retaining screws shown in

Fig. 10. And, after scribing the onemeter eccentric's position, remove

the rangefinder control arm screw.

Take out the one-meter eccentric, the

rangefinder control arm, and the

rangefinder stop arm.

There's one more screw holding the

rangefinder assembly — the long

screw which passes through the

overtravel eccentric. But you may

find that this screw is a little difficult

to reach. So we've finally come to the

purpose behind removing the bayonet

cap in the focal-plane light shield.

Insert a long screwdriver through the

light shield access hole and unscrew

the overtravel eccentric retaining

screw.

Next, carefully lift off the

rangefinder assembly; as you can see

in Fig. 11, there's a loose light shield

at the bottom of the rangefinder. If

you do encounter a damaged

rangefinder, you'll usually have to

replace the complete assembly shown

in Fig. 11 — individual rangefinder

replacement parts are not available.

Although you may have reversed

the sequence in the past, it's easier to

remove the focal-plane light shield

after taking out the rangefinder

assembly. So remove the three

Page 5

FOCAL-PLANE LIGHT SHIELD RETAINING SCREWS

Figure 12

"FP" CONTACTS GROUND WIRE

WHEN SELF

TIMER IS USED,

IT IS HELD

BY THESE

TWO SCREWS

SAFETY SWITCH FOR

"X" SYNC CONTACTS

CURTAIN WIND GEAR

"FP" SYNC CONTACTS

"X" SYNC

CONTACTS

Figure 13

1/8 SECOND ADJUSTMENT

ACCESSORY SHOE MOUNTING PLATE SCREW

Figure 14

SPEED CONTROL BRIDGE

Figure 15

SPEEDS ESCAPEMENT

TUBE FOR ROUTING

WIRES TO "X" SYNC

CONTACTS AND

CURTAIN

DRUM

SPEEDS ESCAPEMENT ADJUSTMENT LEVER

SPEEDS ESCAPEMENT PIVOT SCREW

SAFETY SWITCH

screws shown in Fig. 12 and lift out the

focal-plane light shield.

Removing And Replacing The

Speeds Escapement

The present stage of disassembly

may be as far as you'll normally go

for routine cleaning and lubrication.

But there is one more recommended

step — the removal of the speeds

escapement at the top of the camera.

Fig. 13.

If this is your first encounter with an

M-series Leica, the speeds

escapement seems quite unique.

Varying amounts of retard

engagement are obtained by swinging

the entire escapement around a pivot

point. The speeds escapement

adjustment lever, Fig. 14, rides

against the slow-speed cam, one of the

cams moved by the speed selector.

The eccentric pointed out in Fig. 14

is your adjustment point for the slow

speeds. After making the high-speed

adjustments (which we'll discuss a

little later), turn the adjustment arm

eccentric to correct the exposure at

the 1/8 second setting.

To remove the speeds escapement,

first take out the screw holding the

accessory shoe mounting plate, Fig.

14. Now, lift aside the accessory shoe

mounting plate to expose the speeds

escapement pivot screw, Fig. 15.

Looking under the speed control

bridge, Fig. 15, locate the speeds

escapement pivot spring. The long

(upper) end of the spring hooks to a

post on the underside of the speed

control bridge, and the short end

hooks to a stud on the speeds

escapement.

Disconnect the long end of the pivot

spring from the hooking post. Then,

remove the pivot screw, Fig. 15, and

slide out the speeds escapement

toward the front of the camera.

As you've no doubt noticed, the

pivot screw is sealed — in this case,

the locking agent is used to hold the

pivot screw adjustment for the proper

freedom of the speeds escapement. So

let's take a moment to discuss the

reassembly of the speeds escapement

and the pivot screw adjustment

procedure.

First, set the speed selector to 1

second and push the pallet cam

follower toward the front of the

camera, Fig. 16. Place the pivot

spring on top of the speeds

escapement and slide the escapement

into place —make sure that the pallet

control lever (on top of the speeds

Page 6

escapement) is hooked behind the

pallet cam follower. Replace the pivot

screw and hook the pivot spring.

Now, to adjust the pivot screw, hold

the speeds escapement against its

spring tension — away from the speed

control cam stack. Tighten the pivot

screw until the speeds escapement

cannot move toward the speed control

cam stack under its own tension.

Then, back off the pivot screw until

the speeds escapement does swing

into contact with the speed control

cam stack.

Test your adjustment by pushing

down on the speed control bridge at

the point marked "X" in Fig. 15. The

speeds escapement should still move

freely while you're exerting pressure.

If it doesn't, slightly back off the pivot

screw. Finally, reseal the pivot screw

to hold your adjustment.

Slit-Width Adjustments

Since we mentioned the slow-speed

adjustment, let's look at the slit-width

adjustment at the back of the camera.

The slit-width adjustment is the

eccentric post on the closing curtain

latch, Fig. 17.

Say that you've just released the

shutter at one of the slit-width speeds.

You know that the opening curtain

starts across the aperture, but the

closing curtain is held back by the

closing curtain latch. It's up to the

opening curtain to disengage the

closing curtain latch at the proper

time for the desired slit width.

The part that disengages the closing

curtain latch is the disengaging lever,

Fig. 17. And the disengaging lever is

controlled by the release cam, a cam

that spins with the opening curtain

drum. So, once the opening curtain

has traveled a sufficient distance, the

release cam strikes the disengaging

lever. The disengaging lever, in turn,

strikes the eccentric post on the

closing curtain latch and frees the

closing curtain.

Turning the speed selector to the

different shutter speeds positions the

disengaging lever — that's how the

speed selector changes the release

point of the closing curtain for

different shutter speeds. From the

front of the camera, Fig. 16, you can

see the end of the disengaging lever

that rides against the high-speed cam.

The eccentric post on the closing

curtain latch is the adjustment point

for all the slit-width speeds. Turning

the eccentric post to correct 1/500

second and 1/250 second should bring

Figure 16

Figure 17

Figure 18

PALLET CAM FOLLOWER

DISENGAGING LEVER

1/1000 SECOND CONTROL SECTION OF HIGH-SPEED CAM

DISENGAGING LEVER

CLOSING CURTAIN LATCH

LATCH WHICH LIMITS THE FORWARD TRAVEL OF

THE WIND GEARS ON THE COCKING CYCLE

LATCH WHICH PREVENTS

SPROCKET BACKLASH

SLIT-WIDTH ECCENTRIC

ONE-WAY CLUTCH

FOR WIND STROKE

Page 7

in the remaining speeds as well. But if

the 1/1000 second is still out of

tolerance, you have a slotted

adjustment on the high-speed cam,

Fig. 16; reforming this section of the

high-speed cam affects only the 1/1000second setting. In fact, in the newer

versions of the M-series Leicas, the

high-speed cam is slotted at most of

the individual speeds to allow precise

adjustments throughout the speed

range. The slow-speed cam, which

controls the speeds escapement, also

has slotted adjustment points for

individual speeds.

Other Tests And Adjustments In

The M-Series Leicas

Although we've disassembled the

Leica as far as would normally be

necessary, we'll mention some of the

points to check in the event you go

further. For one, check the action of

the three wind latches: the latches

shown in Figs. 18 and 19 must all drop

into engagement simultaneously at

the end of the wind stroke.

Another timing point is shown in

Fig. 20. The curtain wind gear

engages the drum gear to advance the

curtains. If you'll cock the shutter —

and hold the wind lever fully

advanced — the first tooth in the

curtain wind gear (clockwise of the

slot in the gear, as seen from the top)

should center on the opening curtain

latch. You can remove the curtain

wind gear by taking out the pivot plate

from the bottom of the camera, Fig. 6.

So on reassembly, you must time the

curtain wind gear to meet the

condition just described.

The plentiful adjustment points are

true testimony to Leica quality. For

example, how many focal-plane

shutters allow you to adjust individual

shutter speeds within a range?

Another convincing example is the

alignment adjustment for the

curtains. In most focal-plane shutters,

you straighten a leaning curtain by

shimming the tapes. But most of the

M-series Leicas provide eccentric

bushings for the upper ends of the takeup rollers, Fig. 21. Correcting the

squareness of the curtain bars is just a

matter of turning the eccentric

bushings.

Perhaps the word of today is

"SLR," but many a connoisseur still

demands the comparative quiet and

convenience of the M-series Leica. So

we hope this article has been of some

help in giving the regal Leica the

quality field service it deserves.

LATCH WHICH

LATCHES THE

MAIN WIND

GEAR AT THE

END OF

ITS MOTION

Figure 19

CURTAIN WIND GEAR

Figure 20

ECCENTRIC BUSHINGS FOR TAKE-UP ROLLERS

Figure 21

OPENING CURTAIN LATCH

CLOSING CURTAIN BRAKE ASSEMBLY

Loading...

Loading...