Page 1

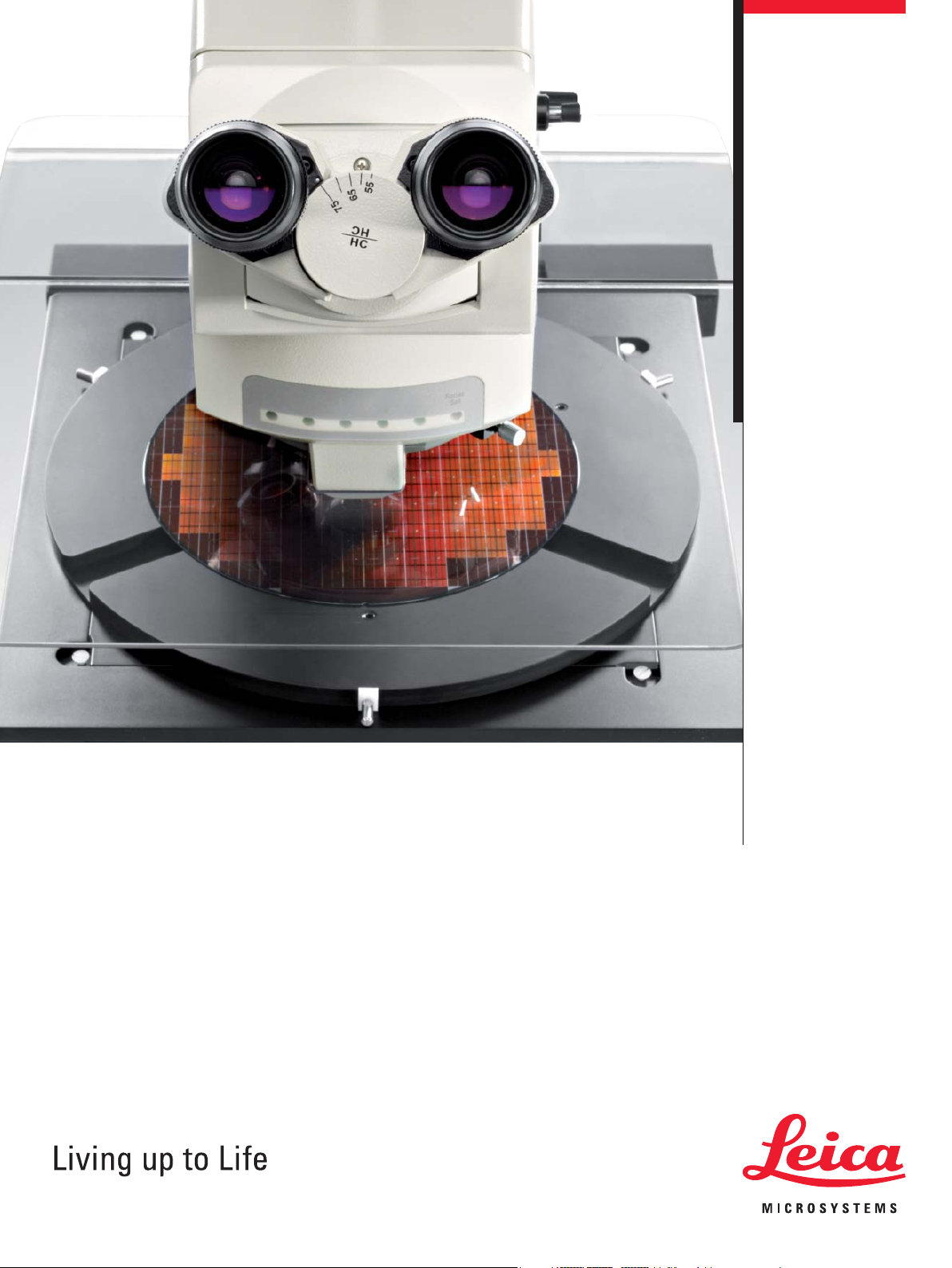

Leica DM8000 M & DM12000 M

See More, Detect Faster – Higher Productivity

Convincing Technical Details

Page 2

High-throughput Inspection Systems

Inspection, process control and defect analysis of wafers or LCDs and TFTs

has to be fast, accurate and ergonomic. The Leica DM8000 M and DM12000 M

optical inspection microscopes provide an innovative yet cost-effective system

solution for mastering present and future manual inspection challenges with

confi dence. Beside extreme large overview capabilities and high resolution optics

these systems are incorporated in a highly ergonomic design with fully integrated

LED illumination allowing the sample to be illuminated from different angles.

2

Page 3

Larger field of view

Highest resolution

for faster inspection

The Leica DM8000 M and the Leica DM12000 M

feature an integrated macro mode, which gives

you four times the fi eld of view of conventional

scanning objectives. Seeing more means faster

throughput.

from every angle

The new Oblique UV (OUV) mode combines

oblique illumination with UV light, which enables you to view a sample in high resolution

from any angle – and enhances the accuracy

of the inspection results.

Higher quality

due to ergonomic design

An ergonomic design enables users to work in

comfort, enhancing their performance and ultimately improving the quality of their work.

The Leica DM8000 M/DM12000 M are specifi cally

designed to provide comfort for long hours at the

microscope, and are intuitively operated and easy

to adapt to different users’ microscopy skill levels.

LED illumination

for a cleaner environment

The LED illumination integrated in the

Leica DM8000 M/DM12000 M optimizes

the airfl ow and creates a cleaner cleanroom.

With their long lifetimes and low power

consumption, LEDs also have a lower cost

of ownership.

3

Page 4

Optic – Excellent Image Quality

To achieve fast and reliable results during manual inspection within a very short time, the optical performance of the microscope is a

key element. With the Leica DM8000 M and DM12000 M, Leica Micro systems has developed a series of innovative features that support

the operator in completely new ways.

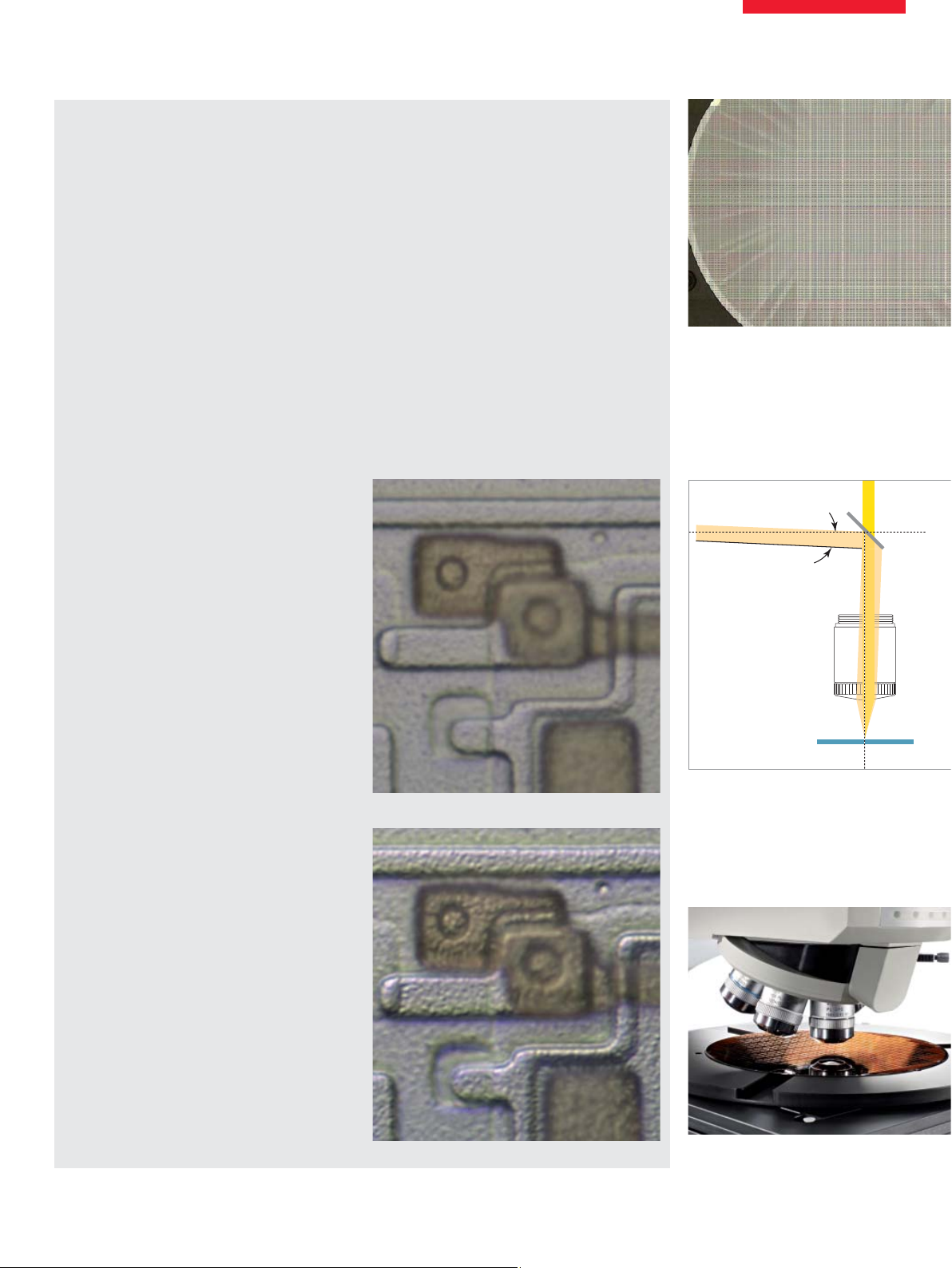

Macro overview

allows a fi eld of

approx. 40 mm

for fast inspection

work

1

6/7/8

High resolution optics incl.

PL APO 150x/0.95 for inspections in BF, DF, DIC, POL, OBL,

UV and OUV

Refl ected light axis, incl.

5

automated aperture disk

with 17 openings, motorized or manual contrast

change and integrated

LED illumination

Integrated oblique

illumination

4

2

3

Fast switchable OUV contrast

e.g. for edge inspections with

high resolution

4

Transmitted light

axis with fully integrated

power LED

Page 5

1.

1. Macro

Overview

In the motorized versions of the Leica

DM8000 M and DM12000 M the micro/macro

option for rapid scanning of large components can be integrated. The macro objective,

which is fully parfocal with all other inspection

objectives, captures an object fi eld of approx.

40 mm on the sample – that’s almost four times

more than with conventional scanning objectives. With the Leica macro mode you detect

defects that are invisible using conventional

light microscopes, such as insuffi cient development at the edge or within the center

of a wafer. Uneven radial fi lm thicknesses are

made visible using the macro overview mode.

The entire scan area can be accurately

checked for possible defects in a fraction of

the time. If you want to take a closer look,

simply press a single button to switch from

macro to micro mode and inspect the defect

in the required contrast mode.

3. Fast Switchable UV

and OUV Contrast

Achieving a higher resolution of the sample

image is done with a single button click using

the Leica DM8000 M and DM12000 M. Pressing the UV button the visible light is cut and

the sample is illuminated in less than a second with UV light of 365 nm wavelength, thus

reducing the resolvable structure sizes down

to 0.14 µm. Just one additional button click

gives a completely new visual experience –

the OUV mode, an adjustable UV illumination

beam that allows high resolution edge inspection, for example.

With the Leica macro mode, you detect

defects that are invisible using conventional light microscopes, such as

insuffi cient development at the edge.

2.

Half transparent mirror

α

Brightfield objective

2. Integrated Oblique

Illumination

For a quick inspection of edges, e.g. of transparent fi lms or solar cells, the oblique illumination is integrated with every Leica DM8000 M

and DM12000 M. By pressing the OBL button, oblique illumination is activated and the

operator can decide which deviation angle α

(see picture 2) of the beam path is applied to

inspect the sample in the best way – fast, reliable, and with topographic information. The

oblique illumination is combined with visible

light contrast modes such as BF or DIC, but

also with UV light in the OUV mode.

PL FLUOTAR 100x/0.90 – brightfi eld

PL FLUOTAR 100x/0.90 – oblique illumination

Sample

Edges of transparent layers are inspected

using the oblique illumination mode.

3.

A single button click switches from visible

to UV light within 1 second.

5

Page 6

5.

The illumination with powerful LEDs is fully

integrated with the Leica DM8000 M and

DM12000 M stands.

4. Transmitted

Light Axis

The transmitted light axis (TL) is equipped

with a fully integrated LED illumination in the

same way as the refl ected light axis. With the

integrated LED illumination samples such as

transparent LCD panels are inspected with

brightfi eld or with polarized light.

For high precision inspection of semitranslucent devices, a single button click is enough

to activate refl ected light (RL) and transmitted

light (TL) simultaneously. Intensity, aperture,

and even contrast mode can be switched

independently for RL and TL. To inspect microscratches, for example, you can have the

OBL mode in RL and polarized light in TL at the

same time and adjust intensity and aperture

of both axes separately. This saves time during inspection and allows additional information to be gathered from the sample.

5. Fully Integrated

LED Illumination

The LED illumination is integrated within the

microscope. Without a lamphousing in the

way, there is an optimal airfl ow around the

microscope. A clean solution for the cleanroom. The powerful LEDs with a color temperature of 4,000 K have a very long lifetime

of up to 25,000 hours yet extremely low power

consumption with the highest illumination

power. For BF, DF or DIC in refl ected light the

powerful LEDs are used in the same way as

for UV illumination or transmitted light inspections. The long lifetime of the LEDs reduces

the downtime of the instrument signifi cantly

as there is no need for bulb exchange. Keep

your environment clean while saving money

and increasing productivity at the same time.

6. Multi-functional

a

150x BF

150x UV

Plan APO 150x/0.90

Top of the line of the inspection objectives is the

multi-functional Plan APO 150x/0.90 objective.

With this single objective, which is fully parfocal with all other inspection objectives, the user

works in BF, DF, DIC, POL, OBL, UV and OUV.

a

b

Multi-functional objective: HCX Plan APO 150x/0.90LCD panel in (a) transmitted light only and

(b) transmitted and refl ected light simultaneously

150x OUV

6

Page 7

7. In-depth

Darkfield

Increased intensity and a higher resolution

combined with a longer working distance

characterize the new in-depth darkfi eld Plan

FLUOTAR objectives. Compared to conventional darkfi eld objectives, the image brightness has improved signifi cantly while the

working distance has nearly doubled, thus

keeping the sample safe and providing even

more image information.

8. Dedicated Inspection

Objective Series

8.

a

Macro

b

To attain faster and more accurate sample

analysis without damaging the sample, the

PL FLUOTAR LWD and PL APO objectives series are used. While the inspection objectives

of the PL FLUOTAR LWD series feature extra

long working distances for sample protection, the high resolving power and high image

sensitivity of the PL APO objective allow fast,

precise analysis and decisions on the results

viewed.

20x

c

20x

d

Dedicated objectives for the inspection of microelectronic components

20x

Quick macro mode scan (a),

brightfi eld (b), in-depth darkfi eld (c),

differential interference mode (d).

It takes less than a second to switch

contrast modes.

7

Page 8

Ergonomics – Clean Design

The Leica DM8000 M and DM12000 M inspection microscopes make routine work as comfortable and effortless as possible. Using

these microscopes, which are specifi cally designed for inspection of microelectronics parts, only a few moments are required to adjust the instrument to the operator’s seated height, posture, arm length, and hand size. Microscopy has never been more comfortable,

enabling fast and precise inspection work.

17

Integrated focus fi nder

Ergo tube

with upright image;

tilt angle 0°–35°;

beamsplitting 0/100%

and 100/0%

9

14/15/16

Support functions

such as the integrated

contrast manager or the

illumination manager

Objective revolver,

6-fold, motorized;

for BD objectives (M32);

with integrated

illumination manager

High precision focus drive

Manual version: 3-gear drive,

height adjustable focus knobs,

sample protection

Motorized version with

magnifi cation related speed

selection and integrated

parfocality function

10

11

13

LED status display

integrated in each

automated version;

indications for contrast

modes, focus setting

and travel speed

12

Freely programmable

function keys, e.g. for

contrast modes BF, DF,

DIC or RL/TL switch or

OBL activation

8

Page 9

9.

9. Upright Image

Ergo Tube

With an adjustment angle from 0–35°, the

upright image ergo tube fi ts any body shape

and delivers in the version with a 100/0%

(eyepiece/camera) and 0/100% or in the version 0/100% and 50/50% excellent images at

both the eyepieces and the camera port. For

UV and VIS imaging a separate upright image

ergo tube is used, ensuring that no UV light

passes the eyepieces.

10. Fast, Smooth-moving

Objective Nosepiece

Overview inspections with the macro objective, edge inspection with a 5x or 10x magnifi cation or review of small details with 100x

or 150x magnifi cation – all these steps of an

exemplary inspection workfl ow often need to

be performed in less than a minute, requiring

highest parcentration accuracy. Especially

developed for use in a cleanroom environment, the sealed 6-fold BD (M32) objective

revolver integrates two separate motors, one

for rotation and the other for fi ne movement,

resulting in fast yet completely smooth movement that is an audible sign of its long-life

quality. Comfortable use even with cleanroom

gloves is ensured by easy to reach control

buttons at the front of the instrument.

11. Focus Drive

The manual Leica DM8000 M and DM12000 M

inspection microscopes feature a precision

3-gear system, a sample protection stop, a

torque adjustment mechanism, and heightadjustable focus knobs. A total travel range of

35 mm can be adjusted in the coarse mode,

the fi ne mode or the super-fi ne mode. The

automated Leica DM8000 M and DM12000 M

inspection microscopes are outfi tted with a

motorized focus drive having a travel range of

35 mm with a minimal step size of 3.6 nm and

a maximum speed of 5 mm/sec. The electronically controlled focus drive has fi ve speeds.

Parfocal compensation can be set easily for

all objectives, which eliminates the need for

individual refocusing after objective change.

Height-adjustable

Focus Knobs

No two hands are alike. And so the manual

Leica DM8000 M and DM12000 M microscope versions enable every hand to rest

on the table while reaching the focus knobs

in complete comfort. The vertical position of

the focus knobs can be precisely adjusted to

fi t the individual user’s hand. This prevents

hand, arm, and shoulder tension and ensures

a comfortable, fatigue-free grip – without

additional arm supports.

Tilting trinocular tube with upright image

to suit any viewing position

10.

Fast, smooth and reliable long-life

objective change

11.

Height-adjustable focus knobs fi t every

operator’s hand size.

9

Page 10

12.

The easy to reach variable function

buttons allow a reduction of inspection

time of up to 10%.

13.

Easy to read feedback with the integrated

LED display

12. Programmable

Function Buttons

Inspection routines can differ from sample to

sample. With the introduction of programmable function buttons, the speed of operation

can be signifi cantly increased without harming the quality of inspection. Three of the conveniently arranged buttons with integrated

feedback LED are located on the front of each

Leica DM8000 M or DM12000 M microscope.

Semi-motorized or motorized stands feature

4 additional buttons behind the focus knobs

to provide easy, fast access to the functions used most. Additional function buttons

are available on the external Leica STP6000

SmartTouch Panel, on the joystick or on the

Leica SmartMove remote control.

13. LEDs Displaying

Microscopy Status

Immediate feedback of the current contrast

mode, the focus setting or the x, y, z travel

speed (coarse or fi ne mode) is provided for

the user of a motorized and semi-motorized

Leica DM8000 M or DM12000 M microscope

with the integrated LED status display.

14. Motorized Aperture

Diaphragm

All Leica DM8000 M and DM12000 M feature a

motorized disk with 17 stops of various sizes,

which are saved separately for every objective. This allows aperture openings from 5%

to 100% to be approached enabling a 100%

reproducibility of the imaging conditions. Together with the light intensity this aperture

information is stored when saving an image

and can be reproduced at any time. This high

reproducibility is especially important for the

review and classifi cation of critical defects.

15. Illumination

Manager

All Leica DM8000 M and DM12000 M inspection

microscopes feature automatic Köhler light

management. This fully integrated illumination

control system detects the selected objective

and automatically sets the user defi ned values

for aperture and light intensity. This reduces

inspection time and signifi cantly supports less

experienced operators. The user can change

these illumination values according to the

requirements of the sample at any time. The

modifi ed settings are automatically saved and

used as the new default values.

The 17-position aperture disk

allows 100% reproducibility.

10

14.

The illumination manager automatically adjusts intensity

and aperture.

Page 11

17.

16. Contrast Manager

The contrast manager which is integrated

in motorized (and semi-motorized) Leica

DM8000 M or DM12000 M microscopes allows

an easy and very fast change of the contrast

mode: just press one of the programmable

function buttons and all required adjustments

of the light path for the selected contrast are

automatically set. Toggle between brightfi eld

and DF or have the UV and even the OUV

contrast adjusted within less than a single

second. This naturally covers more than just

setting the appropriate refl ector cubes on the

integrated 4 position refl ector turret; it also

includes automatic adjustment of aperture

diaphragm and light intensity.

17. Integrated Focus

Finder

of the user interface with the requirements of

the individual inspection workfl ow.

a

b

Easy focusing of even highly refl ective

surfaces with the focus fi nder

18.

Easy focusing even on highly refl ective surfaces, such as mirror-like bare wafers, is achieved

with the integrated focus fi nder. With just a 90°

rotation of the focus fi nder knob a round shaped

diaphragm is inserted into the refl ected light

beam path. The correct focus position is easily

found by focusing on the edge of the projected

circle. Fast, easy and reliable.

18. Leica STP6000

SmartTouch Panel

The automated functions of the Leica

DM8000 M or DM12000 M can be controlled

directly on the microscope or on external remote devices provided by Leica such as a joystick for x, y control (incl. 4 additional function

buttons), the Leica SmartMove for x, y and z

control (incl. 4 additional function buttons) or

the Leica STP6000 SmartTouch Panel for x, y

and z control (incl. 12 additional function buttons). This selection provides a perfect match

c

Accurate detection in all types of illumination: (a) brightfi eld, (b) in-depth darkfi eld, (c)

DIC (Differential Interference Contrast). With

the contrast manager of the motorized Leica

DM8000 M or DM12000 M microscopes it

takes less than a second to switch modes,

and support operators with little experience

using the system.

The large, clearly arranged display

of the Leica STP6000 shows all settings

at a glance.

18.

Leica SmartMove remote control is used

to control the x, y, and z settings.

11

Page 12

Serving the Highest Standards

Protecting your investment and your samples

The innovative solutions incorporated into the Leica DM8000 M and DM12000 M go well beyond just the optical and mechanical performance of the inspection microscopes. Listening to our customers, we also integrated an innovative service concept, ESD protection

and further measures allowing you to be compliant with the most important industrial standards.

Service interval indicator

19

on back

23

Compliance with

SEMI S2 and S8

20

Fully integrated

electronics

(control and

power supply)

22

Anti-static

protection

21

Precision inspection

stage: travel ranges of

8”x8” or 12”x12”; manual

version with fast adjustment handle or motorized

version with precision

4 mm lead screw pitch

12

Page 13

19.

19. Service Interval

Indicator

In addition to design features such as the

long-life objective nosepiece or the integrated LED illumination the Leica DM8000 M and

DM12000 M inspection microscopes support

the user with information concerning the service status. A service-interval indication LED

is integrated on the back of each 8” or 12” instrument.

This allows you to plan preventative maintenance well in advance and further reduces

the risk of downtime of the instrument, even

in very demanding applications.

20. Fully Integrated

Electronics

The entire electronics required for control of

nosepiece, illumination, contrasting and xyz

movement for the LED illumination of TL and RL

axis and also for the control of intensity and aperture are fully integrated into the stand of the

microscope. Without the need for control boxes

or power supplies the space around the inspection microscope is kept empty and clean.

21. Precision Inspection

and Review Stages

Depending on the requirements and the

sample size different stages are available.

The manual 8“ or 12“ inspection stages are

equipped with a fast adjustment handle. The

positioning of the coaxial drive allows onehand operation for the control of x, y and z

movement.

Both the motorized 8“ and 12“ review stages

feature a spindle drive with a ball screw pitch

of 4 mm, allowing a fast travel speed of up to

240 mm/sec and at the same time a resolution

of 0.01µm in x and y direction.

Using the motorized review stage, a point of

interest selected in the Leica Application Suite

(LAS) live image shown on the monitor is immediately positioned in the center of the fi eld

of view. For live image measurements or image analysis, this function is a key element.

A variety of different inserts for the manual

and the motorized 8“ or 12“ stages is used

depending on the size and the type of sample.

Wafer holders (chucks) for 6-8“ or for 8-12“ diameters, both with or without vacuum fi xation

or mask holders, steel plates or glass plates –

the user has a wide selection to choose from.

Due to the same internal dimensions of the

stages all inserts fi t each stage and are fully

interchangeable.

The service LED indicates the service

status.

20.

All control elements including electronics

are integrated, leaving space around the

microscope.

a

d

Glass plate (a), metal plate (b), mask holders in different sizes (c), 8-12“ wafer holder (d), 6-8“ wafer holder (e),

6-8“ vacuum wafer holder (f)

b

e

c

f

21.

High precision positioning with dedicated

inspection stages

13

Page 14

inside a cleanroom as well as special

.

22.

Leica DM8000 M with contamination

protection

22. Anti-static

Protection

For the entire microscope frame including the

tube or the optional adaptable contamination

protection an antistatic coating is applied to

prevent each type of microelectronic component being destroyed during inspection.

23. Compliance with

SEMI S2 and S8

All Leica DM8000 M and DM12000 M inspection and review microscopes are in accordance with SEMI S2-0706 and SEMI S8-0705,

CE and other industry standards. The assembly inside a cleanroom as well as special

cleanroom packaging are keys for a high level

leanroom packaging are keys for a high level

of reliability of these systems in the same way

reliability of these systems in the same way

as their ergonomic design or the integrated

s their ergonomic design or the integrated

long-lifetime and safety precautions.

long-lifetime and safety precautions

24. System Integration –

Single-source Supply

With the Leica DM8000 M/DM12000 M, you

have a complete system: the microscope, the

Leica DFC camera and the Leica Application

Suite (LAS) software are perfectly matched.

Or upgrade the Leica DM8000 M/DM12000 M

to an inspection system by choosing a wafer

loader, matching accessories such as vacuum

wafer chucks, and by installing a dedicated

inspection software.

14

Fast but safe wafer handling is achieved with the adaptation of a wafer loader to the Leica DM8000 M, thus increasing

the throughput of the system signifi cantly. Different versions are combinable to the microscope ranging from load-only

function to systems with integrated visual macro front- and back side inspection capabilities.

Page 15

Selection Overview

Leica DM8000 M

manual focus

Contrast modes

BF

, OBL

DF, DIC

UV/OUV

Macro mode –

LED illumination

Illumination manager

Contrast manager

Stage

Manual version

Motorized (stage control integrated)

Stage control

Joystick

Leica SmartMove

Leica DM8000 M

motorized focus

+

{

{

+

{

{

{

Leica DM12000 M

manual focus

+

{

{

–

Leica DM12000 M

motorized focus

+

{

{

{

++++

++++

{

+ {

–

–

+

+

{

{

{

+

+

{

+

–

–

{

{

Leica STP6000

RL axis

Manual contrast selection

Contrast manager

Focus fi nder

LED status display

6-position nosepiece mot., M32

TL axis

LED illumination

Integrated polarizer

Tube

Ergo trinocular tube w. upright image

Fixed trinocular tube w. upright image

Focus

3-gear manual focus drive

Electronic focus drive

Height adjustable knobs

Parfocality adjustment

–

+

{

+

{

+

{

+

+

{

{

+

–

+

–

{

{

+

+

+

+

{

+

+

{

{

–

+

–

+

–

+

{

+

{

+

{

+

+

{

{

+

–

+

–

{

{

+

+

+

+

{

+

+

{

{

–

+

–

+

+ integrated as standard

{ optional

– not available

15

Page 16

Technical Specifications

Systems Leica DM8000 M Leica DM12000 M

Optical systems HC optics (infi

Observation tube Trinocular ergo tube with image erection

Switching positions (eyepiece/camera):

Macro imaging Super-widefi eld overview image of up to 40 mm of the sample*

Illumination system Refl ected light illumination system with LED; observation methods:

brightfi eld, darkfi eld, DIC, qualitative POL, oblique, UV, OUV

Integrated automatic aperture diaphragm

Transmitted light illumination system with LED; observation methods: brightfi eld, qualitative POL

4-position refl ector turret (manual/motorized use)

Status feedback Front status display*

Service interval indicator (on back)

Support systems Integrated light manager

Revolving nosepiece Motorized, brightfi eld/darkfi eld (M32), 6-positions with slider slot for DIC

Magnifi cation change via front side control panel or external remote control unit

(Joystick, Leica SmartMove, Leica STP6000)

Stages Manual inspection stage 8 x 8” ; 202 x 202 mm trav-

el range, fast adjustment handle; for refl ected and

transmitted light observation

nity corrected optical system)

100/0% and 0/100%

100/0% and 50/50%

Integrated contrast manager*

Manual inspection stage 12 x 12” ; 302 x 302 mm

travel range, fast adjustment handle; for refl ected

and transmitted light observation

Scanning stage 8 x 8” ; 202 x 202 mm travel range,

motorized, 4 mm spindle pitch; for refl ected and

transmitted light observation*

Repeatability*: < 1 m (bi-directional, measured according to VDI / DGQ 3441)

Accuracy: +/- 5 m

Resolution: 0.01 m (smallest step size)

Orthogonality: < 10 arc sec

Max. travel speed: 240 mm/s, 4 mm ball screw pitch

Stage inserts 6–8” wafer holder w/wo vacuum, 8–12” wafer holder w/wo vacuum, mask holders, RL plate, glass plate

Control units Joystick with 4 freely programmable positions

Leica SmartMove, x, y, z control with 4 freely programmable positions

Leica STP6000 SmartTouch x, y, z control with full remote control of instrument

Focusing mechanism High rigidity manual 2-gear focus; 35 mm stroke; height adjustable focusing knobs

High precision manual 3-gear focus; 35 mm stroke; height adjustable focusing knobs

Motorized 2-gear focus; 35 mm stroke; high repeatability; parfocality adjustment

Electrical system Input rating: 100–120/220–240 V AC, 50/60 Hz, P max = 100 W

Weight approx. 41 kg (microscope approx. 29 kg) approx. 52 kg (microscope approx. 31 kg)

Operation environment For use in industrial environment for EMC performance (class A device).

Use in residential environment may affect other equipment in the environment

Amb. temperature: 15°C–35°C

Relative humidity: 80% for temperatures up to 33°C (without condensation)

Supply voltage fl uctuations: +/- 10%

Installation (overvoltage) category: II ref. IEC60664

Polution degree: 2 ref. IEC60664

16

Scanning stage 12 x 12” ; 302 x 302 mm travel

range, motorized, 4 mm spindle pitch; for refl ected

and transmitted light observation*

* Motorized versions only

Page 17

Dimensions (in mm)

Leica DM8000 M

Leica DM12000 M

17

Page 18

System Overview

Leica DM8000 M

Leica DM12000 M

Status: November 2010

Leica DFC cameras

11 543 706

C-mount

1/2

1x

11 543 702

B-mount

1/2

Sony

Leica DFC cameras

1x

33000097

UV-filter kit

11541510

1x

C-mount-adapter 1x

11565026

Tube top with 2 camera ports 50/50

1 port VIS / 1 port UV

11565024

Ergo tube with image erection

0/100 or 100/0 VIS

11565040

Laser autofocus for adaption to

manual focus drive

0.35x

0.55x

C-mount-adapter HC

0.7x

11541512

11541545

115650245

Ergo tube with image erection

0/100 or 100/0 VIS, UV

0.70x

11541544

11541543

1x

11541510

0.33–1.6x

11541517

11888741

RL illumination VIS

11888743

RL axis manual

Microelectronics 4-fold turret,

6-fold mot. nosepiece (M32),

Rear plane with electronics

11888747

Basic stand DM8000 M, manual version, 2 gear

focus drive without TL illumination

11888748

with TL illumination

11888744

RL axis manual

Materials 4-fold turret,

6-fold mot. nosepiece (M32),

Rear plane with electronics

3

11565027

Contamination protection

11888745

RL axis motorized

Microelectronics 4-fold turret,

6-fold mot. nosepiece (M32),

Rear plane with electronics

3

2

11888749

Basic stand DM8000 M, motorized version,

without TL illumination

11888750

with TL illumination

11888742

RL illumination VIS/UV

1111

11888746

RL axis motorized

Materials 4-fold turret,

6-fold mot. nosepiece (M32),

Rear plane with electronics

Leica DM8000 M

18

Page 19

1

Special objectives

2

Remote controls

11565041

Joystick

Remote control

11505180

Leica SmartMove

Remote control

11501598

Fixed tube 20° with image erection

0/100 or 100/0 VIS

11505252

Manual magnification changer, VIS

1x, 1.5x, 2x

Tubes

Leica DM1000-6000

11888763 Macro overview

11566204 PL APO 150x/0.95 IVIS BD

3 4

8“ stages

11888755

Manual 8“ stage

with fast

2

Inserts and holders

5

Wafer chuck, manual

with vacuum

11565035 8“-12“

Wafer chuck, manual

11565033 8“-12“

adjustment handle

11888757

8“ Scanning stage

5 5

Wafer chuck, manual

with vacuum

11565034 6“-8“

afer chuck, manual

W

11565031 5“-6“

11565032 6“-8“

Mask holder

11565037 4“ x 4“

11565038 5“ x 5“

2

11501255

Leica STP6000

Remote control

12“ stages

11888756

Manual 12“ stage

with fast

adjustment handle

11888758

12“ Scanning stage

11565036

Glass

stage insert

11565029

Metal

stage insert

11888764

RL axis semi-mot

Microelectronics 4-fold turret,

6-fold mot. nosepiece (M32),

Rear plane with electronics

11888762

Basic stand DM8000 M, semi-mot version,

3-gear focus drive, with controls, without TL illumination

11888761

with TL illumination

11888765

RL axis semi-mot

Materials, 4-fold turret,

6-fold mot. nosepiece (M32),

Rear plane with electronics

3

11888751

Basic stand DM12000 M, manual version,

2 gear focus drive without TL illumination

11888752

with TL illumination

11888745

RL axis motorized

Microelectronics 4-fold turret,

6-fold mot. nosepiece (M32),

Rear plane with electronics

4

Leica DM8000 M semi mot Leica DM12000 M

11 11

11888746

RL axis motorized

Materials 4-fold turret,

6-fold mot. nosepiece (M32),

Rear plane with electronics

4

2

11888753

Basic stand DM12000 M, motorized version,

without TL illumination

11888754

with TL illumination

19

Page 20

“With the user, for the user”

Leica Microsystems

Leica Microsystems operates globally in four divi sions,

where we rank with the market leaders.

Life Science Division

•

The Leica Microsystems Life Science Division supports the

imaging needs of the scientifi c community with advanced

innovation and technical expertise for the visualization,

measurement, and analysis of microstructures. Our strong

focus on understanding scientifi c applications puts Leica

Microsystems’ customers at the leading edge of science.

Industry Division

•

The Leica Microsystems Industry Division’s focus is to

support customers’ pursuit of the highest quality end result.

Leica Microsystems provide the best and most innovative

imaging systems to see, measure, and analyze the microstructures in routine and research industrial applications,

materials science, quality control, forensic science investigation, and educational applications.

Biosystems Division

•

The Leica Microsystems Biosystems Division brings histopathology labs and researchers the highest-quality,

most comprehensive product range. From patient to pathologist, the range includes the ideal product for each

histology step and high-productivity workfl ow solutions

for the entire lab. With complete histology systems featuring innovative automation and Novocastra™ reagents,

Leica Microsystems creates better patient care through

rapid turnaround, diagnostic confi dence, and close customer collaboration.

Medical Division

•

The Leica Microsystems Medical Division’s focus is to

partner with and support surgeons and their care of patients with the highest-quality, most innovative surgi cal

microscope technology today and into the future.

The statement by Ernst Leitz in 1907, “with the user, for the user,” describes the fruitful collaboration

with end users and driving force of innovation at Leica Microsystems. We have developed fi ve

brand values to live up to this tradition: Pioneering, High-end Quality, Team Spirit, Dedication to

Science, and Continuous Improvement. For us, living up to these values means: Living up to Life.

Active worldwide

Australia: North Ryde Tel. +61 2 8870 3500 Fax +61 2 9878 1055

Austria: Vienna Tel. +43 1 486 80 50 0 Fax +43 1 486 80 50 30

Belgium: Groot Bijgaarden Tel. +32 2 790 98 50 Fax +32 2 790 98 68

Canada: Richmond Hill/Ontario Tel. +1 905 762 2000 Fax +1 905 762 8937

Denmark: Ballerup Tel. +45 4454 0101 Fax +45 4454 0111

France: Nanterre Cedex Tel. +33 811 000 664 Fax +33 1 56 05 23 23

Germany: Wetzlar Tel. +49 64 41 29 40 00 Fax +49 64 41 29 41 55

Italy: Milan Tel. +39 02 574 861 Fax +39 02 574 03392

Japan: Tokyo Tel. +81 3 5421 2800 Fax +81 3 5421 2896

Korea: Seoul Tel. +82 2 514 65 43 Fax +82 2 514 65 48

Netherlands: Rijswijk Tel. +31 70 4132 100 Fax +31 70 4132 109

People’s Rep. of China: Hong Kong Tel. +852 2564 6699 Fax +852 2564 4163

Portugal: Lisbon Tel. +351 21 388 9112 Fax +351 21 385 4668

Singapore Tel. +65 6779 7823 Fax +65 6773 0628

Spain: Barcelona Tel. +34 93 494 95 30 Fax +34 93 494 95 32

Sweden: Kista Tel. +46 8 625 45 45 Fax +46 8 625 45 10

Switzerland: Heerbrugg Tel. +41 71 726 34 34 Fax +41 71 726 34 44

United Kingdom: Milton Keynes Tel. +44 800 298 2344 Fax +44 1908 246312

USA: Buffalo Grove/lllinois Tel. +1 847 405 0123 Fax +1 847 405 0164

and representatives in more than 100 countries

by Leica Microsystems CMS GmbH, Wetzlar, Germany, 2011

©

Order no.: English 914 734 • III/11 • Copyright

LEICA and the Leica Logo are registered trademarks of Leica Microsystems IR GmbH.

www.leica-microsystems.com

Loading...

Loading...