Leica DM4500 P User manual

Leica DM4000 B

Leica DM4000 M

Leica DM4500 P

Leica DM5000 B

Operating Manual

Bedienungsanleitung

1

Published September 2007 by:

Herausgegeben September 2007 von:

Leica Microsystems CMS GmbH

Ernst-Leitz-Straße

D-35578 Wetzlar (Germany)

Responsible for contents:

Verantwortlich für den Inhalt:

Dr. Jasna Roeth, Stefan Motyka

(Marketing CM, Compound Microscopy, Product Management)

(Marketing CM, Compound Microscopy, Produktmanagement)

Holger Grasse

(Safety Officer according to MPG §30)

(Sicherheitsbeauftragter nach MPG §30)

In case of questions, please contact the hotline:

Bei Fragen wenden Sie sich bitte an die Hotline:

2

Phone +49(0)64 41-29 2286

Fax +49(0)64 41-2922 55

E-Mail: MQM-Hotline@leica-microsystems.com

Leica DM4000 B

Leica DM4000 M

Leica DM4500 P

Leica DM5000 B

Operating Manual

3

Copyrights

Copyrights

All rights to this documentation are held by

Leica Microsystems CMS GmbH. Reproduction

of text or illustrations (in whole or in part) by

print, photocopy, microfilm or other method

(including electronic systems) is not allowed

without express written permission from Leica

Microsystems CMS GmbH.

The term "Windows" may appear in the following

text without further identification. It is, however,

a registered trademark of Microsoft Corporation. The names of companies and products

used herein may be trademarks of their respective owners.

The instructions contained in the following documentation reflect state-of-the-art technology

and knowledge standards. We have compiled

the texts and illustrations as accurately as possible. Nevertheless, no liability of any kind may

be assumed for the accuracy of this manual’s

contents. Still, we are always grateful for comments and suggestions regarding potential mistakes within this documentation.

The information in this manual is subject to modification at any time and without notification.

4

Contents

Contents

1. Important notes about this manual ....... 7

2. Intended purpose of the microscope .... 8

3. Safety notes................................................ 9

3.1 General safety notes................................. 9

3.2 Electrical safety ......................................... 10

3.3 Disposal....................................................... 11

4. Overview of the instrument .................... 12

5. Unpacking the microscope..................... 17

6. Assembling the microscope ................... 19

6.1 Specimen stage ......................................... 19

6.2 Condenser ................................................... 21

6.3 Tube and eyepieces .................................. 22

6.4 Objectives ................................................... 23

6.5 Light sources for the transmitted

light axis ...................................................... 23

6.6 Light sources for the incident

light axis ...................................................... 25

6.7 Equipping the incident light

turret disk .................................................... 30

6.8 Polarizer and analyzer .............................. 31

6.9 DIC prisms ................................................... 32

6.10 Optional accessories ................................ 33

6.11 Connection to the power supply ............ 34

6.12 Connecting to the CTR5000

electronics box .......................................... 34

7. Startup ......................................................... 35

7.1 Functional principle .................................. 35

7.2 Switching on the unit ................................ 38

7.3 The display

(DM4000 B/4500 B/4000 M/4500 P)......... 39

7.4 The function keys ...................................... 40

7.5 Köhler illumination .................................... 41

7.5.1 Transmitted light ............................. 41

7.5.2 Incident light.................................... 42

7.6. Checking the phase contrast rings ........ 44

7.7 Setting the motorized polarizer

(DM4500 P/DM5000 B) .............................. 45

7.8 Adjusting the light sources...................... 45

8. Operation .................................................... 51

8.1 Switching on the unit ................................ 51

8.2 Stages and object displacement............ 51

8.3 Focusing ...................................................... 53

8.4 Tubes....................................................... 53

8.5 Eyepieces .................................................... 55

8.6 Objectives ................................................... 55

8.7 Magnification changer ............................. 58

8.8 HC P 1x/1.6x tube optics........................... 58

8.9 Light sources .............................................. 59

8.10 Aperture diaphragm and

field diaphragm .......................................... 59

5

Contents

9. Contrast methods for

Leica DM4000 B/DM4500 B/

DM4500 P/DM5000 B ................................ 60

9.1 Transmitted light ........................................ 60

9.1.1 Bright field ......................................... 60

9.1.2 Phase contrast.................................. 60

9.1.3 Dark field............................................ 61

9.1.4 Polarization........................................ 61

9.1.4.1 Manual method............................. 61

9.1.4.2 DM4500 P - examinations

in polarized transmitted light...... 62

9.1.4.3 Motorized method ........................ 68

9.1.4.4 Combined methods....................... 68

9.1.5 Differential interference

contrast ............................................ 68

9.1.5.1 DM4500 B/DM4500 P .................... 68

9.1.5.2 DM5000 B........................................ 69

9.2 Fluorescence.............................................. 70

10. Contrast methods for

Leica DM4000 M ........................................ 71

10.1 Incident light .............................................. 71

10.1.1 Bright field ....................................... 71

10.1.2 Dark field.......................................... 71

10.1.3 Polarization...................................... 72

10.1.4 Interference contrast .................... 73

10.2 Transmitted light ........................................ 73

10.2.1 Bright field ....................................... 73

10.2.2 Polarization...................................... 73

11. Troubleshooting......................................... 74

12. Care of the microscope ........................... 77

12.1 Dust cover ................................................... 77

12.2 Cleaning ....................................................... 77

12.3 Handling acids and bases ....................... 78

13. Essential wear and spare parts ............. 79

14. Abbreviations and pictograms ............... 80

15. Index ............................................................ 81

16. EU Declaration of Conformity................. 82

6

1. Important notes about this manual

1. Important notes about this manual

Caution!

This operating manual is an essential component of the microscope, and must be read

carefully before the microscope is assembled and put into operation.

Text symbols, pictograms and their meanings:

(1.2)

→ p.20

!

This operating manual contains important instructions and information for the operational

safety and maintenance of the microscope and

accessories. It must therefore be kept safely for

future reference.

Numbers in parentheses, such as "(1.2)", correspond to illustrations (in the example, Figure 1,

Item 2).

Numbers with pointer arrows (for example →

p.20), point to a certain page of this manual.

Caution!

Special safety instructions within this manual are indicated with the triangle symbol

shown here, and have a gray background.

Caution! The microscope and accessories can

be damaged when operated incorrectly.

Explanatory note.

Instructions on disposing of the microscope,

accessory components and consumables.

Item not contained in all configurations.

*

7

2. Intended purpose of the microscope

2. Intended purpose of the microscope

The DM4000 – DM5000 microscopes to which

these operating instructions belong, and which

have the identifying letter B, are intended for

biological routine and research applications.

This includes examining specimens taken from

the human body for the purpose of gaining information about physiological or pathological conditions or inborn anomalies, or testing for safety

and compatibility for potential recipients, or for

monitoring therapeutic measures.

The microscopes that have the identifying letters M or P are intended for materials science,

geological or mineralogical examinations.

The manufacturer assumes no liability for

damage caused by, or any risks arising from

using the microscopes for other purposes

than those for which they are intended or

not using them within the specifications of

Leica Microsystems CMS GmbH.

In such cases the declaration of conformity

shall cease to be valid.

Caution!

Caution!

The above-named microscopes comply with the

Council Directive 98/79/EEC concerning in vitro

diagnostics. They also conform to the Council

Directives 73/23/EEC concerning electrical apparatus and 89/336/EEC concerning electromagnetic compatibility for use in an industrial environment.

8

These (IVD) instruments are not intended for

use in the patient environment defined by

DIN VDE 0100-710. Nor are they designed to

be combined with medical instruments in

accordance with EN 60601-1. If a

microscope is electrically connected to a

medical instrument in accordance with

EN 60601-1, the requirements defined in

EN 60601-1-1 shall apply.

3. Safety notes

3.1 General safety notes

This safety class 1 device was built and tested

in accordance with the safety regulations for

electrical measuring, control, regulating and

laboratory devices in accordance with

EN 61010-2-101:2002

EN 61010-1:2001

IEC 1010-1:2001

Caution!

3. Safety notes

Caution!

The devices and accessories described in

this operating manual have been tested for

safety and potential hazards.

The responsible Leica affiliate or the main

plant in Wetzlar, Germany, must be consulted whenever the device is altered, modified

or used in conjunction with non-Leica

components that are outside of the scope of

this manual.

In order to maintain this condition and to ensure safe operation, the user must follow the

instructions and warnings contained in this

operating manual.

Unauthorized alterations to the device or

noncompliant use shall void all rights to any

warranty claims and void product liability!

9

3. Safety notes

3.2 Electrical safety

General specifications

Leica CTR5000 electronics box (for DM5000 B)

For indoor use only.

Supply voltage:

Frequency:

Power input:

Fuses:

90-250 V~

50-60 Hz

max. 290VA

T6.3 A

(IEC 60127-2/3)

Ambient temperature:

Relative humidity:

Overvoltage category:

Pollution degree:

15-35°C

max. 80% to 30°C

II

2

Microscope

For indoor use only.

Supply voltage:

Frequency:

90-250 V~

50-60 Hz

Power input:

DM4000

DM4500

DM5000

max. 180 VA

max. 180 VA

max. 290VA

Fuses:

DM4000

DM4500

DM5000

Ambient temperature:

Relative humidity:

Overvoltage category:

Pollution degree:

T6.3 A (IEC 60127-2/3)

T6.3 A (IEC 60127-2/3)

See CTR5000

15-35°C

max. 80% to 30°C

II

2

ebq 100 supply unit*

For indoor use only.

Supply voltage:

Frequency:

Power input:

Fuses:

Ambient temperature:

Relative humidity:

Overvoltage category:

Pollution degree:

90-250 V~

50-60 Hz

max. 155VA

2xT2A (IEC 127)

10-36°C

max. 80% to 30°C

II

2

(see enclosed manual)

Caution!

The power plug may only be plugged into an

outlet equipped with a grounding contact.

Do not interfere with the grounding function by using an extension cord without a

ground wire. Any interruption of the ground

wire inside or outside of the device, or release of the ground wire connection, can

cause the device to become hazardous.

Intentional ground interruption is not permitted!

Caution!

Through connection to the grounding connection, ancillary equipment with its own

and/or extra power supply may be brought

to the same ground wire potential. For connections without a ground connector, Leica

Service must be consulted.

10

Caution!

Never use any fuses as replacements other

than those of the types and the current ratings listed here. Bypassing fuse holders is

not permitted.

Caution!

The microscope’s electrical accessory components are not protected against water.

Water can cause electric shock.

Caution!

Protect the microscope from excessive temperature fluctuations. Such fluctuations can

lead to the accumulation of condensation,

which can damage the electrical and optical components.

Operating temperature: 15-35°C

3. Safety notes

3.3 Disposal

Once the product has reached the end of its service life, please contact Leica Service or Sales

about disposal.

Please observe and comply with the national

and federal laws and regulations that are equivalent to EU guidelines such as WEEE.

Note!

Like all electronic devices, the microscope,

its accessory components and consumables

must never be disposed of with general

household waste.

Caution!

Before exchanging the fuses or lamps, be

absolutely certain to switch off the main

power switch and remove the power cable.

11

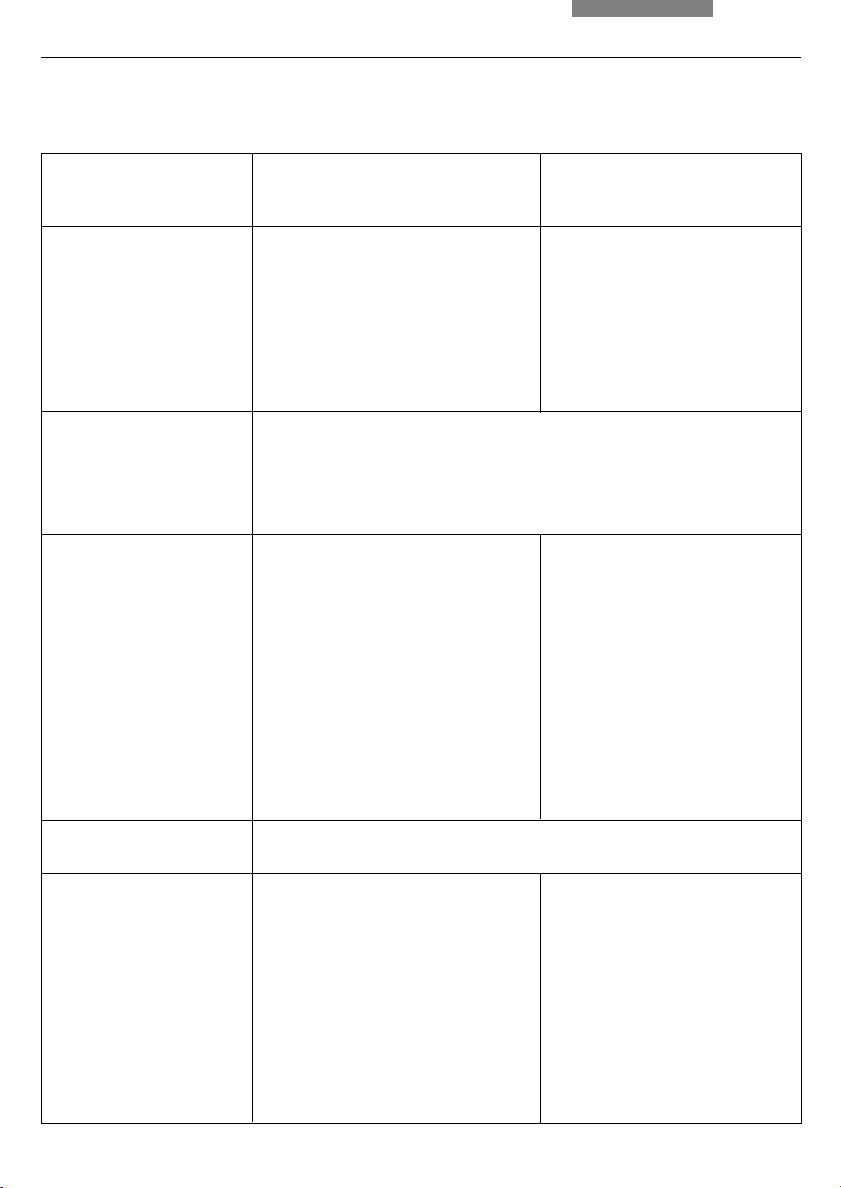

4. Overview of the instrument

4. Overview of the instrument

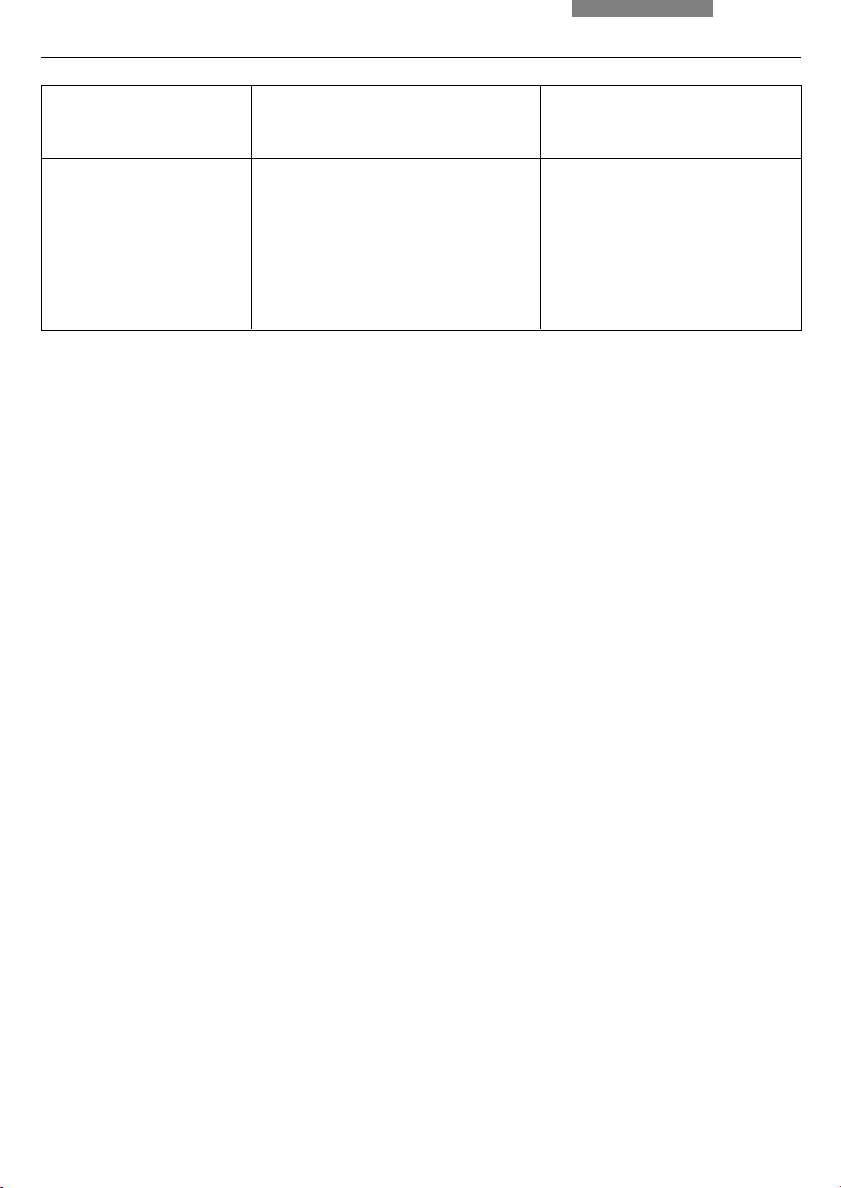

Specification

Contrast methods

Transmitted light axis

Incident light axis

Leica DM4000 B

Leica DM5000 B

• Transmitted light:

DM4000 B: BF, DF, PH, Pol

DM5000 B: and ICT (mot.)

• Incident light: Fluorescent

• Automatic illumination manager (mot. aperture diaphragm

and field diaphragm, mot. intensity control)

• Automatic constant-color intensity control

• Motorized shutter

• Integrated into the stand

• Motorized 5x filter turret disk

(DM5000 B 8x optional)

• With FIM (fluorescence intensity manager) for reducing the light intensity in 5 increments

• Mechanical booster lens for

increasing fluorescence intensity

• Motorized shutter

Leica DM4000 M

Leica DM4500 P

• Transmitted light:

DM4000 M: BF, DF, PH, ICT,

Pol

DM4500 P: BF, DF, PH, ICT,

Pol (conoscopy)

• Incident light:

BF, DF, ICR, Pol, Fluo

• Integrated into the stand

• Motorized 4x filter turret

disk

• Automatic

illumination manager

• DM4000 M: motorized

shutter

Z pinion

Objective turret

12

• Manual

• Manual, fully encoded

• DM4000 B: 6x/7x with

M25 thread

DM5000 B: 7x (M25)

DM5000 B: With object prism

disk (3 positions)

• Manual, fully encoded

• DM4000 M: 6x with

M32 thread

DM4500 P: 6x with

M25 thread, centerable,

encoded

• Receptacle for DIC prisms

and Pol compensators

(for DM4000 M: optional)

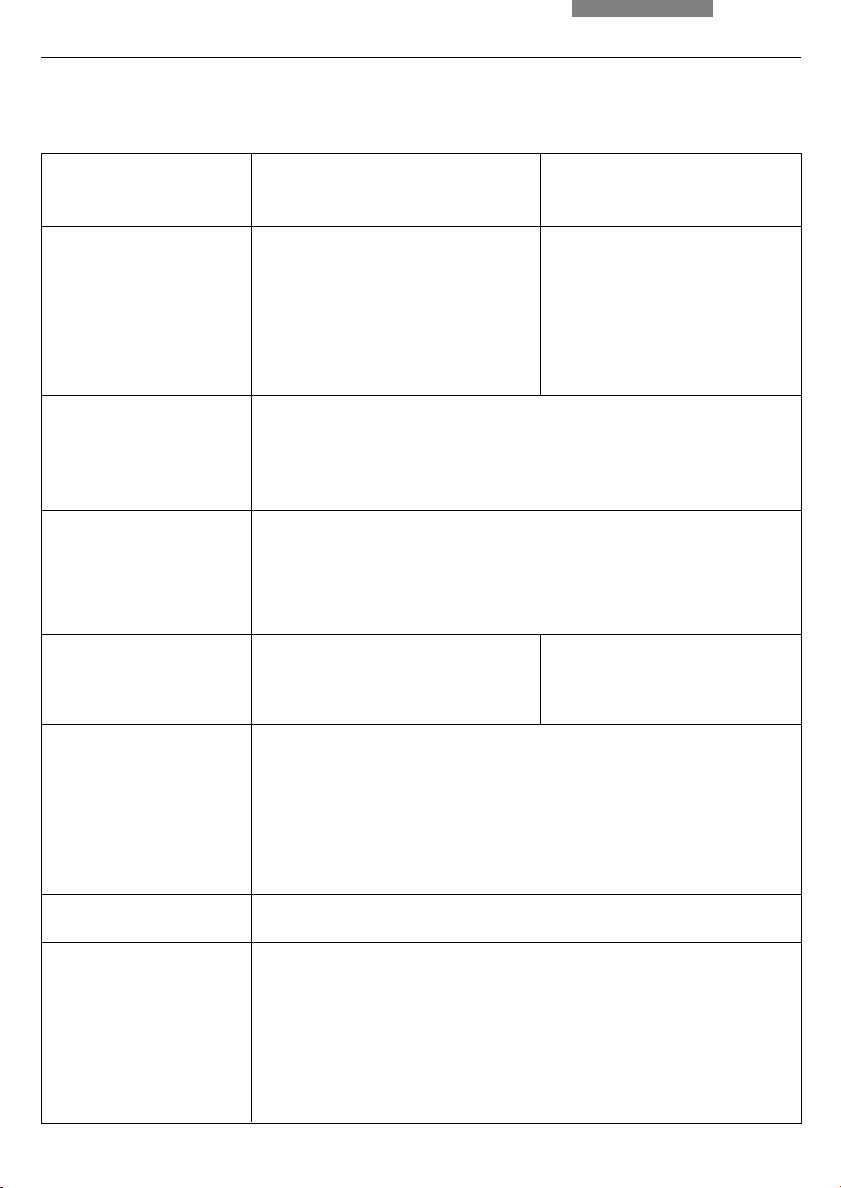

4. Overview of the instrument

Specification

X/Y stage

Tube

Condenser

Magnification changer

(optional)

Controls

Leica DM4000 B

Leica DM5000 B

• Manual

• Replaceable specimen stage

• Coaxial drive length: 155 mm

Leica DM4000 M

Leica DM4500 P

• Manual

• DM4000 M:

Replaceable specimen stage

•

•

Coaxial drive length: 140 mm

DM4500 P:

• Replaceable Pol stage

• Manual or motorized (DM4500P: manual)

• Optionally with one or two camera outputs

• DM4500 P: conoscopy module

(tube optics HC P1x/1.6x with Bertrand lens, encoded)

• Motorized condenser head

• Condenser disk for the light ring, DF-Stop, DIC prisms

• Automatic Köhler illumination

• Optional polarizer (integrated and motorized)

• Manual

• 3x fully encoded

• 1x; 1.25x; 1.6x

• Manual

• 3x fully encoded

• 1x; 1.5x; 2x

• Operating buttons on the stand for all motorized

microscope functions

• Additional variable multifunction keys

• Focus wheels

• LCD

• DM5000 B with Leica SmartTouch

Computer interface

Software tools

• USB2.0

• Leica Application Suite (LAS)

TM

for Windows

2000, XP, Vista

• With plug-ins for:

• Microscope and camera configuration

• Microscope and camera control

• Image acquisition

13

4. Overview of the instrument

Specification

Electronics box

Leica CTR5000

Leica DM4000 B

Leica DM5000 B

Only for the Leica DM5000 B:

Separate operating unit with a

power supply for 100 W halogen

lamps. See → p.10

(Electrical safety)

Leica DM4000 M

Leica DM4500 P

14

14

4. Overview of the instrument

1

2

3

4

5

6

13

12

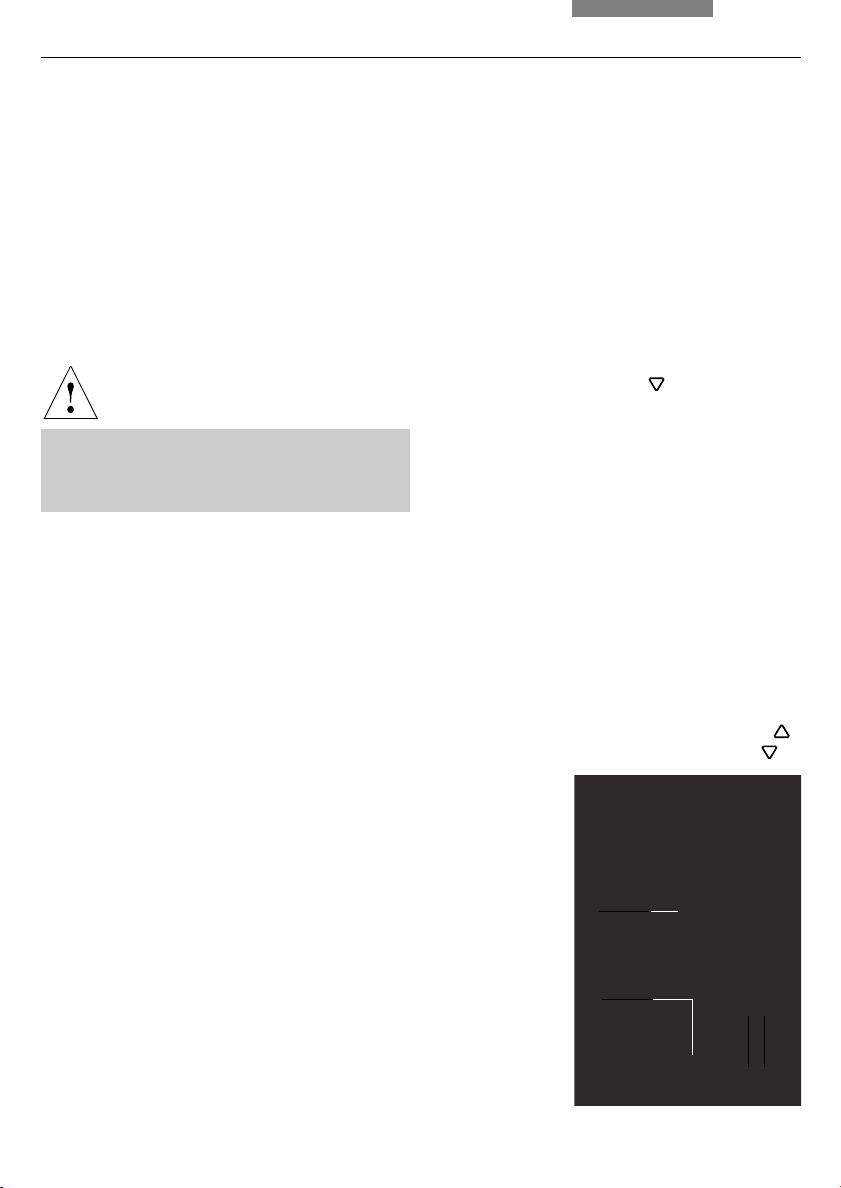

Fig. 1 Left side of the stand with the advanced AET22 ErgoTube

1 Eyepiece

2 Eyepiece tube

3 Tube

4 Objective turret with objectives

5 Specimen stage with specimen holder

6 Condenser

7 LCD

8 Field diaphragm operating buttons

9 Transmitted light / incident light switch

10 Aperture diaphragm operating buttons

11 Brightness adjustment buttons

12 Focus wheel with coarse and fine adjustment

13 Variable function keys (preset at the factory)

14 Lamp adjustment window

7

891011

15

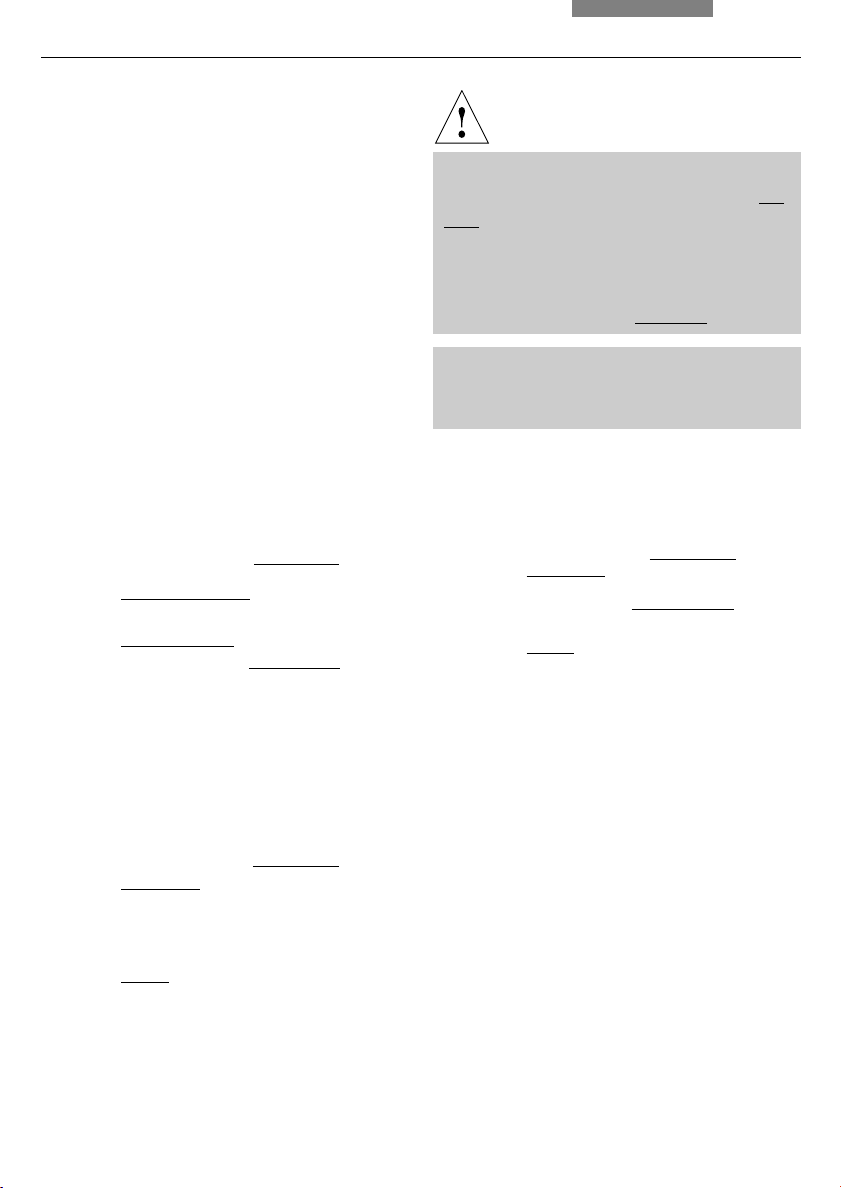

4. Overview of the instrument

22

15

16

21 20 19 18 17

Fig. 2 Right side of the stand with the advanced ErgoTube AET22

15 Lamp housing for incident light

16 Lamp housing for transmitted light

17 Transmitted light filter, optional

18 Transmitted light filter, optional

19 Variable function keys (preset at the factory)

20 x/y coaxial drive, adjustable height

21 Handwheel for fine focus

22 Motorized filter block exchanger

16

5. Unpacking the microscope

5. Unpacking the microscope

The microscope is delivered in two packages.

The stand package contains the following com-

ponents:

• Stand with integrated incident light axis and

objective turret

• Specimen stage with stage bracket

• Power cable and PC connecting cable

• CD with Leica Application Suite (LAS) software package

• Instructions and list of microscope default

settings

The system package contains the microscope’s

accessories:

• Tube

• Eyepieces

The external ebq 100 supply unit* is delivered in

a separate package.

For the Leica DM5000 B microscope:

The Leica CTR5000 electronics box is delivered

in a separate package.

First, carefully remove all components from the

transportation and packaging materials.

Note:

If at all possible, avoid touching the lens surfaces of the objectives. If fingerprints do appear on

the glass surfaces, remove them with a soft

leather or linen cloth. Even small traces of finger

perspiration can damage the surfaces of optical

devices in a short time. See the chapter on "Care

of the microscope" →

structions.

Caution!

p. 77 for additional in-

• Objectives

• Condenser

• Lamp housings with accessories

• Assembly tools

• Additional microscope accessories such as

filter cubes, etc. depending on product configuration

Do not connect the microscope or peripherals to an AC power source at this time

under any circumstances!

17

5. Unpacking the microscope

Installation location

Work with the microscope should be performed

in a dust-free room, which is free of oil vapors

and other chemical vapors, as well as extreme

humidity. At the workstation, large temperature fluctuations, direct sunlight and vibrations

should be avoided. These conditions can distort

measurements and micrographic images.

Allowable ambient conditions

Temperature 15-35°C

Relative humidity maximum 80% up to 30°C

Microscopes in warm and warm-damp climatic

zones require special care in order to prevent

the build up of fungus.

See the chapter on "Care of the microscope" →

p. 77 for additional instructions.

Caution!

Electrical components must be assembled at

least 10 cm away from the wall and from

flammable substances.

Transport

For shipping or transporting the microscope

and its accessory components, the original

packaging should be used.

As a precaution to prevent damage from vibrations, the following components should be disassembled and packaged separately:

• Unscrew the objectives.

• Remove the condenser.

• Remove the specimen stage.

• Remove the lamp housings.

• Disassemble the burner of 106 z lamp housing.

• Remove all moving or loose parts.

18

6. Assembling the microscope

6. Assembly

The microscope components are logically assembled in this order:

• Specimen stage

• Condenser with condenser head

• Tube

• Eyepieces

• Objectives

• Lamp housings with light sources

• Equipment for the incident light turret disk*

Only a few commonly used screwdrivers and

keys are necessary for assembly; these are included in the delivery package.

When using intermediate systems and optical

accessories, the sequence may vary.

In this case, read chapter,

"6.10 Optional accessories" →

p.33

6.1 Specimen stage

!

Caution:

Never install objectives before assembling the

stage.

• Place the specimen holder on the stage and

fasten it with the two screws (3.1).

• Using the condenser height adjuster (3.2), turn

the condenser holder completely upwards,

i.e. as close to the stage as possible.

• Loosen the stage clamp (3.3) slightly.

Fig. 3 Mechanical object stage

1 Locking screws for specimen holder

2 Condenser height adjuster

3 Stage clamp

1

23

19

6. Assembly

• From above, set the stage clamp onto the

dovetail guide (4.2) and push the stage downwards until the upper end of the dovetail

guide is tightly fastened to the upper end of

the stage clamp.

• Firmly tighten the stage clamp (4.1).

Note:

For thicker specimens (Leica DM4000 M) the

stage can be set to a correspondingly lower level.

Fig. 4 Assembling the stage

1 Stage clamp

2 Dovetail guide

• Only for DM4500 P:

Pol attachable mechanical stage*

Adjust the attachable mechanical stage so

that the fastening screw is visible below the

holes (4a.1). Set the attachable mechanical

stage in the guide holes on the rotating stage

and tighten the fastening screw using the

hexagonal key.

Attachable mechanical stage*

The attachable mechanical stage can be installed on the left, on the right or on the front

(not pictured). The two clamping screws fasten it into place.

Fig. 4a Pol rotating stage* and Pol 3 attachable mechanical stage*

1 Holes for the fastening screw.

2 Lever for the holder for glass slides of various formats,

which can be turned inward and outward

3 Storage for the centering key

4 Locking button pair

5 45° click stop

6 Clamping system for the stage rotation

20

4

3

1

1

2

5

2

6

6.2 Condenser

6. Assembly

• Screw the condenser head into the condenser.

• Using the condenser height adjuster (5.4), turn

the condenser holder (5.1) downward as far

as it will go.

• Unscrew the clamping screw for the condenser (5.3) far enough so that the condenser

can be inserted from the front.

• From the front, insert the condenser into the

condenser holder as far as it will go. On the

underside of the condenser, there is an orientation pin (6.1) that must be locked into place

in the guiding notch (7.1).

• Tighten the condenser’s clamping screw (5.3)

until the condenser locks into place.

• Connect the condenser over the connection

(8.1) with the stand.

Note:

The condenser must be centered before using

the microscope.

Köhler illumination p. 41.

→

Fig. 6

Underside of condenser

1 Orientation pin

Fig. 7 Condenser holder

1 Guiding groove

1

1

Fig. 5 Condenser holder

1 Condenser holder

2 Condenser centering

3 Clamping screw for the condenser

4 Condenser height adjuster

1

23 4

Fig. 8 Condenser connection

1 Condenser cable socket

1

21

6. Assembly

6.3 Tube and eyepieces

The tube is mounted on the stand either directly

or with the use of intermediate modules. The

side clamping screw fastens it into place (9b.1).

For the MBDT motorized tube only:

•

Remove the transport anchor (9a.1) on the underside of the tube.

• Partially unscrew the clamping screw (9b.1).

• Insert the tube into the circular receptacle

(dovetail ring).

• Retighten the clamping screw (9b.1).

For the MBDT motorized tube only:

•

Connect the tube to the stand with the connector bushing (10.1).

• The eyepieces are inserted into the eyepiece

tubes on the tube.

For the BDTP tube only:

•

The Pol eyepieces are inserted into the eyepiece tubes (using the locking groove).

Fig. 9b Fastening the tube

1 Clamping screw

1

Fig. 9a Underside of the tube

1 Transport anchor

1

22

Fig. 10 Motorized tube connection

1 Connector socket

1

6. Assembly

6.4 Objectives

The receptacles on the objective turrets are

numbered (Fig. 11). Based on your equipment,

the individual objectives have already been assigned to specific positions at the factory.

For details on the exact positions of the objectives, please refer to the enclosed identification sheet.

!

Caution:

Close vacant threads in the turret with dust protection caps!

Fig. 11

Objective turret with engraved objective receptacles

6.5 Light sources for the transmitted light axis

Caution!

Ensure that the lamp housing has been disconnected from the power supply. Unplug

the power plug and the power supply during

assembly.

Caution!

Light sources pose a potential irradiation risk

(glare, UV-radiation, IR-radiation). Therefore,

lamps have to be operated in closed housings.

Lamp housing 107/2

This lamp housing is used with a 12 V 100 W

halogen lamp, which is already mounted.

In case the lamp has to be removed:

• Remove the fastener screw on the housing

(Fig. 12).

• Remove the housing by pulling it upwards.

• Remove the lamp.

23

6. Assembly

• Insert the new 12 V 100 W lamp (13.1) with the

dust cover straight into the socket until it

stops. Be sure that the lamp is inserted

straight.

• Remove the lamp’s dust cover.

Caution!

Do not remove the lamp’s dust cover until after you have installed the lamp. Avoid fingerprints on the lamp.

• Replace the housing and fasten it in place using the fastening screw.

Fig. 12

Lamp housing 107/2

Releasing the

fastening screw

• Place the lamp housing in the transmitted

light lamp housing receptacle (14.2) and fasten it with the clamping screw on the side.

• Connect the lamp housing to the power supply

for transmitted light (symbol:

Fig. 14 Rear view of the stand

1 Incident light lamp housing receptacle

2 Transmitted light lamp housing receptacle

3 12 V 100 W connection for transmitted light (symbol: )

4 12 V 100 W connection for incident light (symbol: )

) (14.3).

Fig. 13

Lamp housing 107/2

opened

1 Mount with

halogen bulb

2 Collector

24

1

1

2

2

34

6. Assembly

6.6 Light sources for the incident light axis

Caution!

Light sources pose a potential irradiation

risk (glare, UV-radiation, IR-radiation).

Therefore, lamps have to be operated in

closed housings.

Ensure that the lamp housing has been disconnected from the power supply. Unplug

the power plug and the power supply during

assembly.

During assembly work on xenon burners,

always wear the protective gloves and face

protection supplied (Fig. 15) (risk of explosion).

Never touch the glass parts of the burner

with bare hands.

Never look directly into the beam path

(blinding hazard).

Lamp housing 106/106 z

This lamp housing is suitable for use with a 12 V

100 W halogen lamp or a variety of gas discharge

lamps.

Caution!

Make sure to follow the instructions and

safety notes of the lamp supplier.

Before changing lamps allow it to cool down

for at least 30 min.!

Fig. 16 106/106 z lamp housing (on the side, open)

1 Cover raised

2 Collector

3 12 V 100 W lamp or

gas discharge lamp in mount

4 Reflector (mirror)

5, 6, 7 Adjusting screw for x-y reflector

8 Fastening screw for the lamp mount

9 Socket for contact plug

Fig. 15

Protective gloves and mask

1

2

4

5

3

6

7

898

25

6. Assembly

Inserting the 12 V 100W halogen bulb into the

106/106 z lamp housing

• Unscrew the fastening screws of the cover

and flip the cover up (16.1).

• Unscrew the fastening screws of the lamp

mount (16.8) and pull out the mount (Fig. 17).

• Insert the lamp with the dust cover straight

into the socket until it stops.

Caution!

Do not remove the lamp’s dust cover until after you have installed the lamp. Avoid fingerprints on the lamp.

• Remove the dust cover.

Fig. 17 Lamp mount with 12 V 100 W halogen bulb

• Insert the lamp mount, with the burner installed, into the lamp housing and tighten it

with the screws (16.8).

• Close the lamp housing and retighten the fastening screws.

• Place the lamp housing in the incident light

lamp housing receptacle (18.1) and fasten it

with the clamping screw on the side.

• Connect the lamp housing to the power supply

for incident light (symbol:

Fig. 18 Rear view of stand

1 Incident light lamp housing receptacle

2 Transmitted light lamp housing receptacle

3 12 V 100 W connection for transmitted light (symbol: )

4 12 V 100 W connection for incident light (symbol: )

) (18.4).

26

1

2

34

6. Assembly

Inserting gas discharge lamps (Hg and Xe) into

the 106/106z lamp housing

Hg and Xe lamps are powered by separate supply units.

Please also read the separate instruction manual provided with these supply units.

The following gas discharge lamps may be used

and require different power supplies and lamp

mounts (Fig. 19):

Type Typical bulb life*

50 W high-pressure mercury burner (alternating current) 100 hrs.

100 W high-pressure mercury burner (direct current) 200 hrs.

100 W high-pressure mercury burner (direct current, type 103 W/2) 300 hrs.

75 W high-pressure xenon burner (direct current) 400 hrs.

* Please observe the data sheets of the lamp manufacturer.

27

6. Assembly

• To open the 106 z lamp housing, unscrew the

fastening screws on the cover.

Caution!

• Remove the transport anchor (red plastic rod

in place of the burner) in the lamp mount. To

do so, remove the lower clamp (19.1). Pull up

the cooling element (19.3) and turn it to the

side. Detach the lower clamp system (19.2)

and remove the transport anchor.

• Install the burner in reverse order.

Fig. 19 a-c Lamp mounts for gas discharge lamps

1 Upper clamping system, 2 Lower clamping system, 3 Cooling element

4 Melt nipple for the Hg 50 arc lamp, 5 Dust cover for the Xe 75 arc lamp

Hg 50

1

4

a

3

2

Hg 50 burner:

After installation, the labeling must be

right.

If a glass melt nipple is present (19a.4), position it by turning the burner so that the

nipple does not impede the beam path later,

but instead is positioned

Xe 75 burner:

Remove the burner’s dust cover (19b.5) after

you have installed the burner.

Xe 75

up-

sideways.

b

3

1

5

2

28

Hg 100

1

2

c

3

• Insert the lamp mount, with the burner installed, into the lamp housing and tighten it

with the screws (20.8).

6. Assembly

• Close the lamp housing and retighten the fastening screws.

• Place the lamp housing in the incident light

lamp housing receptacle (21.1) and fasten it

with the clamping screw on the side.

• Connect the lamp housing to the external

power supply (22.1).

Fig. 21 Rear view of the stand

1 Incident light lamp housing receptacle

2 Transmitted light lamp housing receptacle

3 12 V 100 W connection for transmitted light (symbol: )

4 12 V 100 W connection for incident light (symbol: )

Fig. 20 106/106 z lamp housing (on the side, open)

1 Cover raised

2 Collector

3 12 V 100 W lamp or

gas discharge lamp in mount

4 Reflector (mirror)

5, 6, 7 Adjusting screw for x-y reflector

8 Fastening screw for lamp mount

9 Socket for contact plug

1

2

3

898

4

5

6

7

Fig. 22 Rear panel of the ebq 100 supply unit

1 Lamp connection

1

1

2

34

29

6. Assembly

6.7 Equipping the incident light turret disk

The positions in the turret disk are numbered.

Depending on how they are equipped, the individual filter and/or reflector cubes are set in

pre-assigned positions at the factory. For

details, check the identification sheet included

with your order.

Insert the filter and reflector cubes in the following manner:

• Never fit the incident light turret disk while

the microscope is in operation.

• Remove the face plate from the upper part of

the microscope (Fig. 25). Press the locking pin

(25.2) to turn the turret disk. When the locking

pin is released, the turret disk locks into place

again.

• With the holder facing you squarely, insert the

filter cube or reflector cube into the holder as

described in the identification sheet provided.

To do so, place the filter or reflector cube on

the right side and press it toward the left into

the mounting (Fig. 26).

Fig. 23 Filter cube,

front side

Fig. 25 Removing the front panel

1 Filter receptacle

2 Locking pin

3 Front panel

Fig. 24 Filter cube,

back side

1

2

3

• Press the locking pin (25.2) and turn the filter

turret to the next click stop.

• Make sure that the turret engages (the locking pin springs forward) and insert the next filter and/or reflector cube as described above.

• When all filters and reflector cubes have been

inserted, close the front cover plate again.

30

Fig. 26 Inserting the filter or reflector cubes

1 Mounting

1

1

Loading...

Loading...