Page 1

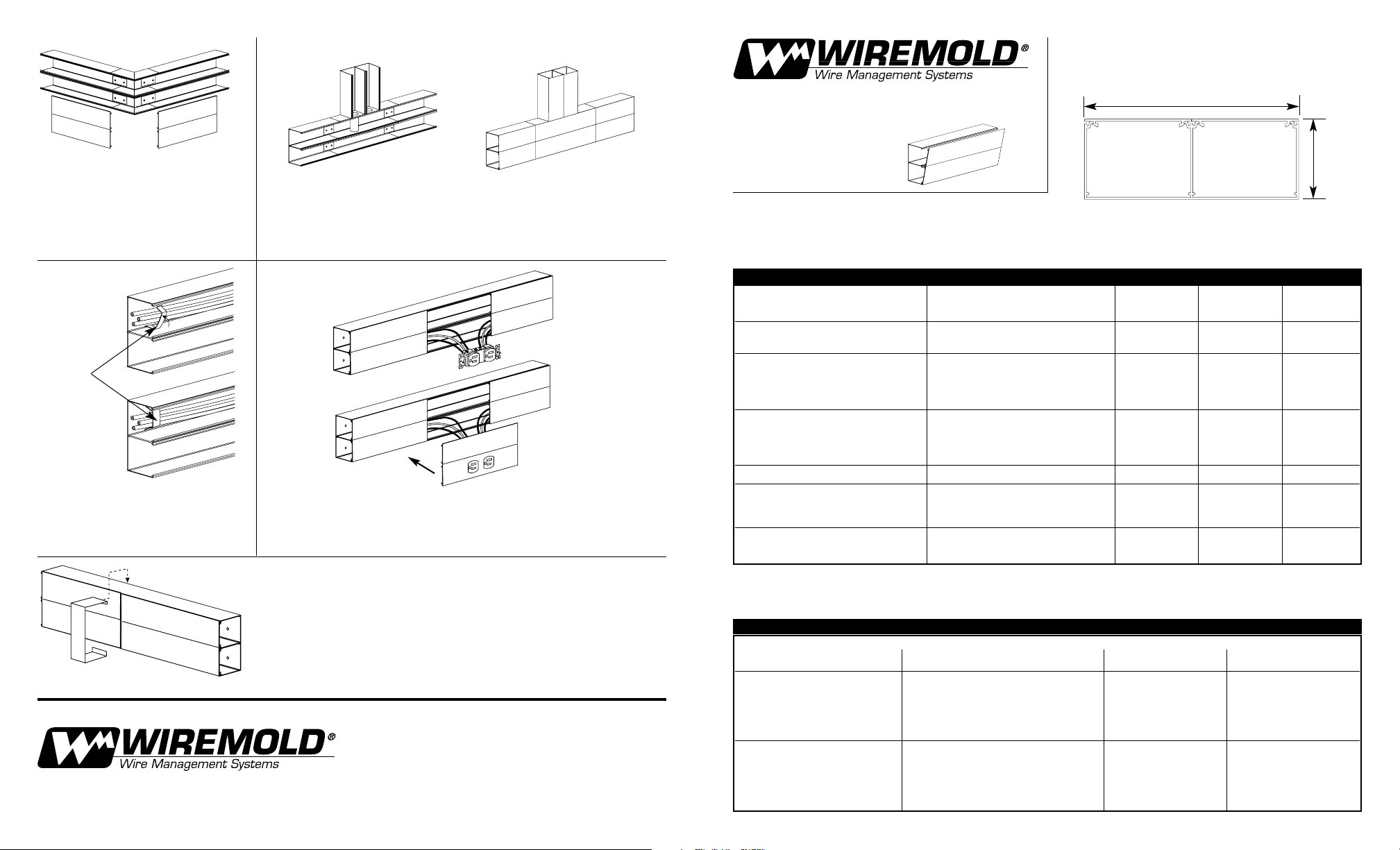

ALA4800 ALUMINUM RACEWAY

Installation

Instructions

The ALA4800 is a permanent two-channel raceway that is versatile

enough to accomodate power, data or telecommunication wiring.

NOTE: Cross-sectional area of each compartment indicated.

Wiremold Electrical Systems conform with, and should be installed and properly grounded in compliance with requirements of the current

National Electrical Code or codes administered by local authorities.All electrical products may represent a possible shock or fire hazard if improperly installed or used.Wiremold electrical products are UL listed, made for interior use in a dry location and should be installed by qualified electrical people in conformance with current local and/or the National Electrical Code.

At 90° Outside Corner, position ALA4818

External Elbow at end of ALA4800B-10

Base. Slide other base section to other end

of ALA4818. Center couplings on joints

and tighten screws. After wiring system,

snap on ALA4818 mitered covers.

For retaining wires in long raceway

runs, snap-in ALAWC Series Wire Clips

into ALA4800B-10 Base as required.

Snap ALA4806 Cover Clip over

joints in either ALA4800B Base or

ALAC-5 Cover sections.

ALA4815 Tee: Position fitting at end of ALA4800B-10 Base. Install

other base sections to other ends of the fitting. Center couplings on

joints and tighten screws. Install fitting covers after wiring.

ALAWC

ALA4815

The Wiremold Company

In U.S.:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062

In Canada:

850 Gartshore Street • Fergus, Ontario N1M 2W8

1-800-741-7957 • FAX 519-843-5980

41238R1 1197©1997 The Wiremold Company

For Device Plates (ALA-BL, ALA-E, ALA-DR, ALA-G, ALA-J, ALA-N, ALA-LPB,

ALA-MAB, ALA-SG, ALA-2A, and ALA-Z), install wiring to devices as required.

Attach devices to plate (using #6 screws and "Keps" nuts as required.) Snap

device plate onto ALA4800B-10 Raceway Base.

*Capacity range is calculated at 20% to 40% of raceway area as stated in a proposed revisions to the Commercial Building Standard for

Telecommunication Pathways & Spaces, EIA/TIA-569. Actual wire fill capacity may vary based on applications, cable types, and number, as well as

type of fittings. (Fittings may cause additional variances to the fill capacity.)

CABLE/WIRE SIZE O.D. 20% FILL 40% FILL

INCHES [MM]

UNSHIELDED TWISTED PAIR 4-Pair, 24 AWG Cat. 5 0.220 [5.6] 31 62

4-Pair, 24 AWG Cat. 3 0.190 [4.8] 41 83

TELEPHONE 2-Pair, 24 AWG 0.140 [3.6] 77 154

3-Pair, 24 AWG 0.150 [3.8] 67 134

4-Pair, 24 AWG 0.190 [4.8] 41 83

25-Pair, 24 AWG 0.410 [10.4] 8 17

COAXIAL CABLES RG58/U 18 0.195 [5.0] 39 79

RG59/U 22 0.242 [6.1] 25 51

RG62/U 20 0.242 [6.1] 25 51

RG6/U 22 0.270 [6.9] 20 41

TWINAXIAL 100 Ohm 0.330 [8.4] 13 27

SHIELDED TWISTED PAIR TYPE 1 0.390 [9.9] 9 19

TYPE 2 0.465 [11.8] 6 13

TYPE 3 0.245 [6.2] 25 50

FIBER OPTIC Two Strand (Duplex) 0.190 [4.8] 41 83

Multimode 62.5/125 µm

WIRE SIZE THHN/THWN O.D. 40% FILL

INCHES [MM]

6 AWG 0.257 [6.5] 41

POWER WIRING 8 AWG 0.218 [5.5] 56

WITHOUT DEVICES 10 AWG 0.153 [3.9] 98

12 AWG 0.122 [3.1] 156

14 AWG 0.105 [2.7] 214

6 AWG 0.257 [6.5] 30

POWER WIRING 8 AWG 0.218 [5.5] 42

WITH DEVICES 10 AWG 0.153 [3.9] 73

12 AWG 0.122 [3.1] 116

14 AWG 0.105 [2.7] 159

ALA4800 Raceway Cable Fill Capacity for Power

ALA4800 Raceway Cable Fill Capacity for Data/Communication

6"

[151mm]

2 1/4"

[57mm]

Page 2

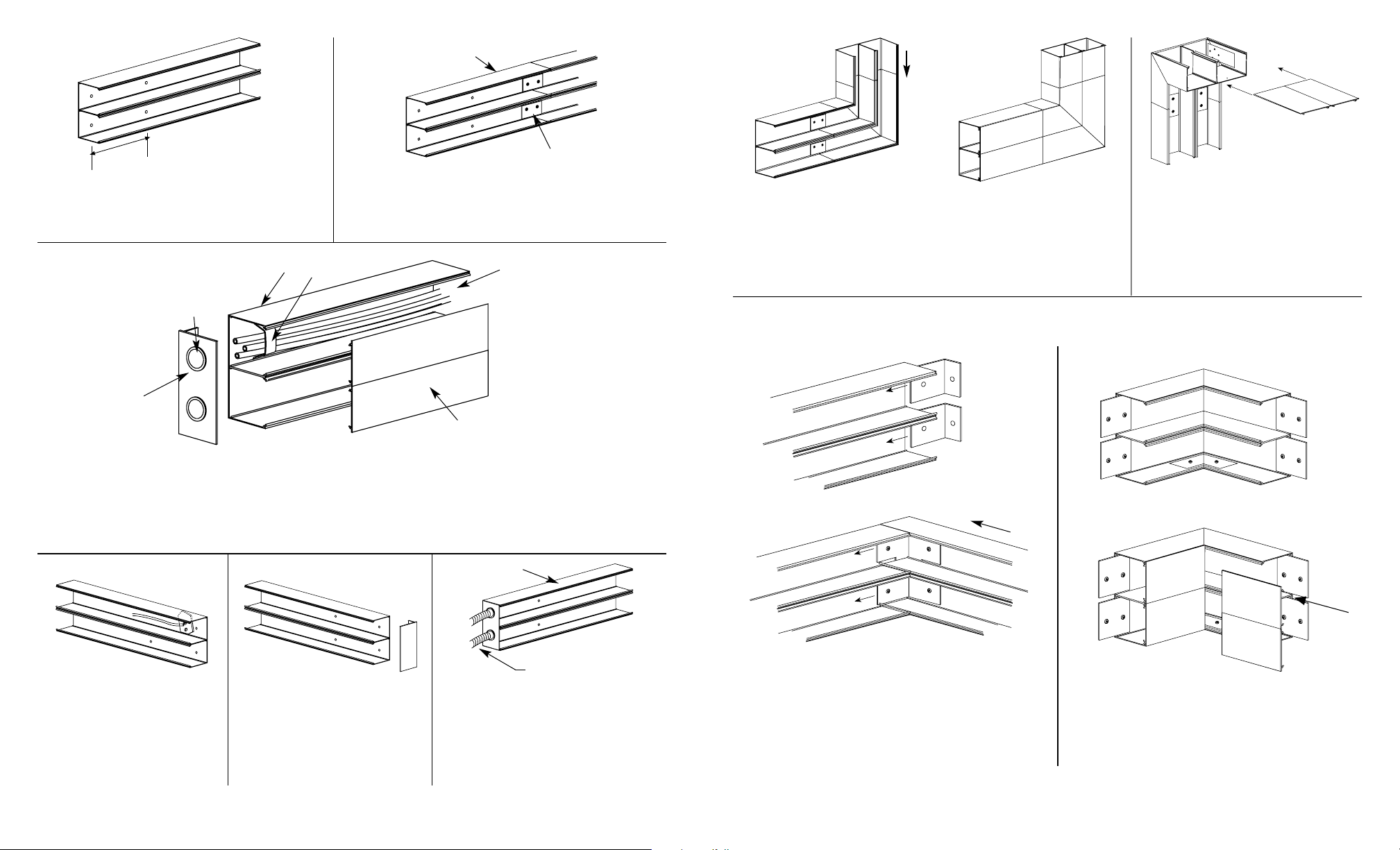

ALA4800B Base

(ALA4810B2 shown)

1/2" [12.7mm] or

3/4" [19.1mm] Conduit

End-feeding: ALA4810B2 Series End Fittings

have concentric 1/2" [12.7mm] and 3/4"

[19.1mm] trade size KOs in end. Provide

electrical feed through KOs. Insert fitting into

end of raceway base. Secure in place by

tightening two screws.

3

4

6

5

1

2

1 - Provide electrical feed through 1/2" [12.7mm] or 3/4"

[19.1mm] KOs in ALA4810B2 End Cap.

2 - Attach base section to mounting surface by drilling

9/32" [7.14mm] holes in the base then fastening with

#8 flat head screws.

3 - Secure conductors in place with ALAWC Wire Clip.

4 - Join additional raceway sections with two ALA01 Couplings.

5 - Close ends with ALA4810B2 End Caps.

6 - Snap ALAC-5 Cover into ALA4800B-10 Base to

complete installation.

To attach ALA4800B-10 Series Base sections to mounting

surface; drill 9/32" [7.14mm] holes in the base (approx.

18" [457mm] O.C.). Fasten Base with #8 flat head screws.

18"

[457mm]

At end of ALA4800B-10 Raceway

run: slide ALA4810B Blank End

Fitting in last base section. Secure in

place by tightening two screws.

ALA01

ALA4800B-10

Base Sections

At ALA4800B-10 Base section butt joints: slide two ALA01

Couplings into first base section. Mount next base to surface.

Center couplings on joint. Tighten locking screws.

Position ALA09 Ground Clamp

into ribs in ALA4800B-10 Base.

Fasten mounting screw. Attach

ground wire using brass cup

washer & green hex nut to

ground lug.

At 90° turn on same surface, position ALA4811 Flat Elbow at end of

ALA4800B Base. Position next base section onto other end of ALA4811.

Center couplings over base joints and tighten screws. Install ALA4811 Covers

and ALA4800 Series Covers as shown after wiring.

For connecting a vertical run of

ALA4800B with a horizontal overhead

run with its cover facing up. Assemble

ALA4817N to raceway bases with

ALA01 Couplings included.

Install one side of ALA417A Internal Coupling,

BEFORE mounting raceway base. Fasten first base section to wall, then slide adjoining base onto coupling

legs. Tighten all four coupling screws.

Install ALA4817 to first raceway base, BEFORE mount-

ing raceway base. Fasten base section to surface. Butt

next section of base. Center couplings over base joints,

tighten set screws.

ALA4811

ALA4811 With Cover

ALA17A Internal Corner Coupling

ALA4817 Internal Elbow

Options for 90° Internal Corners:

System Layout

ALA4817N

Loading...

Loading...