LEESON SM4 User Manual

SPEEDMASTER®

Series Flux Vector

Series Flux Vector

and Manual

A Regal Brand

|

|

|

|

Contents |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1 |

Safety information.................................................................................... |

3 |

|

|

|

||||

2 |

Technical data........................................................................................... |

|

5 |

|

|

|

|||

|

2.1 |

Standards and application conditions...................................................................................... |

5 |

|

|

|

|||

|

2.2 |

Ratings.................................................................................................................................... |

|

6 |

|

|

|

||

|

|

|

|||||||

3 |

Installation |

|

8 |

|

|

|

|||

|

|

||||||||

|

3.1 |

Dimensions and mounting....................................................................................................... |

8 |

|

|

|

|||

|

|

3.1.1 NEMA 1 (IP31) Models.................................................................................................... |

8 |

|

|

|

|||

|

|

3.1.3 NEMA 4X (IP65) Models.................................................................................................. |

9 |

|

|

|

|||

|

3.2 |

Electrical installation............................................................................................................. |

10 |

|

|

|

|||

|

|

3.2.1 Power Connections....................................................................................................... |

10 |

|

|

|

|||

|

|

|

3.2.1.1 |

Mains Connection to 120VAX Single-Phase Supply........................................ |

10 |

|

|

|

|

|

|

|

3.2.1.2 |

Mains Connection to 240VAC Single-Phase Supply....................................... |

11 |

|

|

|

|

|

|

|

3.2.1.3 |

Mains Connection to Three-Phase Supply..................................................... |

11 |

|

|

|

|

|

|

|

3.2.1.4 |

Motor Connection......................................................................................... |

11 |

|

|

|

|

|

|

|

3.2.1.5 |

Installation Recommendations for EMC Compliance...................................... |

12 |

|

|

|

|

|

|

|

3.2.1.6 |

NEMA 4X (IP65) Input Terminal Block............................................................ |

12 |

|

|

|

|

|

|

|

3.2.1.7 |

Dynamic Brake Connections......................................................................... |

13 |

|

|

|

|

|

|

3.2.2 Fuses/cable cross-sections.......................................................................................... |

14 |

|

|

|

|||

|

|

3.2.3 |

Control terminals....................................................................................................... |

15 |

|

|

|

||

4 |

Commissioning....................................................................................... |

16 |

|

|

|

||||

|

4.1 |

Local Keypad & Display......................................................................................................... |

16 |

|

|

|

|||

|

4.2 |

Drive Displays and Modes of Operation................................................................................. |

19 |

|

|

|

|||

|

4.3 |

Parameter setting.................................................................................................................. |

20 |

|

|

|

|||

|

4.4 |

Electronic programming module (EPM).................................................................................. |

20 |

|

|

|

|||

|

4.5 |

Parameter menu................................................................................................................... |

21 |

|

|

|

|||

|

|

4.5.1 |

Basic Setup Parameters.............................................................................................. |

21 |

|

|

|

||

|

|

4.5.2 |

I/O Setup Parameters.................................................................................................. |

25 |

|

|

|

||

|

|

4.5.3 Advanced Setup Parameters........................................................................................ |

32 |

|

|

|

|||

|

|

4.5.4 |

PID Parameters........................................................................................................... |

37 |

|

|

|

||

|

|

4.5.5 Vector Parameters....................................................................................................... |

40 |

|

|

|

|||

|

|

4.5.6 |

Network Parameters.................................................................................................... |

43 |

|

|

|

||

|

|

4.5.7 |

Diagnostic Parameters................................................................................................ |

44 |

|

|

|

||

|

|

|

4.5.7.1 |

Terminal & Protection Status Display............................................................. |

46 |

|

|

|

|

|

|

|

4.5.7.2 |

Keypad Status Display.................................................................................. |

46 |

|

|

|

|

|

|

4.5.8 Onboard Communications Parameters 15-25 HP......................................................... |

47 |

|

|

|

|||

|

|

4.5.9 |

Sequencer Parameters................................................................................................ |

48 |

|

|

|

||

|

|

|

4.5.9.1 |

Sequencer Flow Diagram Left....................................................................... |

57 |

|

|

|

|

|

|

|

4.5.9.2 |

Sequencer Flow Diagram Right..................................................................... |

58 |

|

|

|

|

|

|

|

4.5.9.3 |

Sequencer Status......................................................................................... |

59 |

|

|

|

|

5 |

Troubleshooting and Diagnostics......................................................... |

60 |

|

|

|

||||

|

5.1 |

Status/Warning Messages..................................................................................................... |

60 |

|

|

|

|||

|

5.2 |

Drive Configuration Messages............................................................................................... |

62 |

|

|

|

|||

|

5.3 |

Fault Messages....................................................................................................................... |

|

6 |

|

|

|

||

Appendix A |

................................................................................................ |

|

66 |

|

|

|

|||

|

A.1 |

Permissable Cable Lengths................................................................................................... |

66 |

|

|

|

|||

1

About these instructions

This documentation applies to the SM2 and SM4 Vector frequency inverter, and contains important technical data and describes installation, operation, and commissioning.

These instructions are only valid for SM2 and SM4 Vector frequency inverters with software rev 20 (see drive nameplate).

Please read the instructions before commissioning.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

B |

|

|

|

C |

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type: |

|

|

INPUT: |

3~ |

(3/PE) |

|

OUTPUT: |

3~ |

(3/PE) |

For detailed information |

|

|||||

|

|

|

|

174621.00 |

|

|

|

400/480 V |

|

|

0 - 400/460 V |

refer to |

instruction |

|

|

|||||

|

|

|

|

Id-No: 00000000 |

|

2.9/2.5 A |

|

|

2.4/2.1 A |

Manual: |

SV06 |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

Made in USA |

|

|

|

|

|

|

|

50-60 HZ |

|

|

0.75 KW/1HP |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

0 - 500 HZ |

|

|

|

|

||||

|

Inverter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM2 Vector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V0115 |

|

|

A Certifications |

|

|

C Input Ratings |

|

|

|

|

|

|

|

|

||||||||

|

B Type |

|

|

D Output Ratings |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

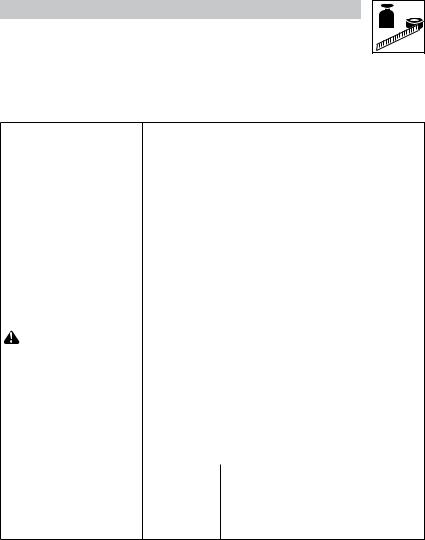

Scope of delivery |

|

|

Important |

|

|

|

|

|

|

|

|

|||||||||

|

|

|||||||||||||||||||

• 1 SM2 or SM4 Vector inverter |

After receipt of the delivery, check immediately whether the |

|||||||||||||||||||

|

with EPM installed |

|

|

items delivered match the accompanying papers. LEESON does |

||||||||||||||||

|

(see Section 4.4) |

|

|

not accept any liability for deficiencies claimed subsequently. |

||||||||||||||||

• 1 Operating Instructions |

|

|

Claim |

|

|

|

|

|

|

|

|

|||||||||

•visible transport damage immediately to the forwarder.

•visible deficiencies / incompleteness immediately to your

LEESON representative.

2

Safety information

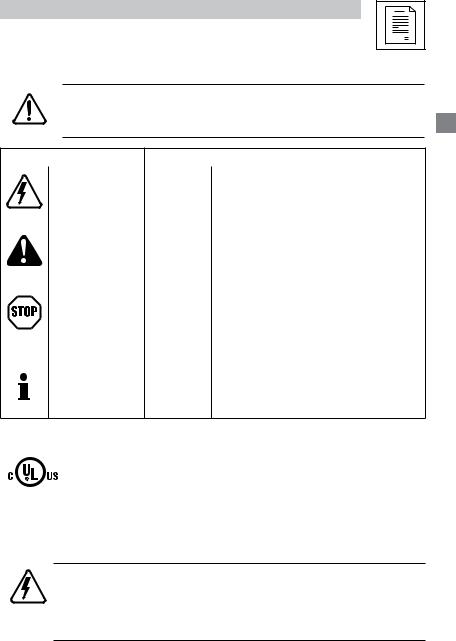

All safety information given in these Operating Instructions have the same layout:

Signal Word! (characterizes the severity of the danger)

Note (describes the danger and informs on how to proceed)

|

Icon |

Signal Words |

||

|

|

Warning of |

DANGER! |

Warns of imminent / impending danger. |

|

|

hazardous |

|

Consequences if disregarded: |

|

|

electrical voltage |

|

|

|

|

|

will result in Death or severe injuries. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning of a |

WARNING! |

Warns of potential, very hazardous situations. |

|

|

general danger |

|

Consequences if disregarded: |

|

|

|

|

could result in Death or serious injuries. |

|

|

|

|

|

|

|

Warning of damage |

STOP! |

Warns of potential damage to material and |

|

|

to equipment |

|

equipment. |

|

|

|

|

Consequences if disregarded: |

|

|

|

|

Damage to the controller/drive or its |

|

|

|

|

environment. |

|

|

|

|

|

|

|

Information |

Note |

Designates a general, useful note. |

|

|

|||

|

|

|

|

If you observe it, handling the controller/drive |

|

|

|

|

system is made easier. |

Note for UL approved system with integrated controllers: UL warnings are notes which apply to UL systems. The documentation contains special information about UL.

Warnings!

Operation

•Suitable for use on a circuit capable of delivering not more than 200,000 rms symmetrical amperes, at the maximum voltage rating marked on the drive.

•Use minimum 75 °C copper wire only.

•Shall be installed in a pollution degree 2 macro-environment.

Systems including controllers must be equipped with additional monitoring and protection devices according to the corresponding standards (e.g., technical equipment, regulations for prevention of accidents, etc.). The controller may be adapted to your application as described in this documentation.

DANGER!

•After the controller has been disconnected from the supply voltage, live components and power connection must not be touched immediately, since capacitors could be charged. Please observe the corresponding notes on the controller.

•Please close all protective covers and doors prior to and during operation.

•Do not cycle input power to the controller more than once every two minutes.

3

Safety information

1 Safety information

General

DANGER!

Some parts of LEESON controllers can be electrically live and some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation creates the risk of serious injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance must be carriedoutbyqualified,skilledpersonnelwhoarefamiliarwiththeinstallation,assembly,commissioning, and operation of variable frequency drives and the application for which it is being used.

Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components and do not change any insulation distances during transport, handling, installation or maintenance.

Do not touch any electronic components or contacts. This drive contains electrostatically sensitive components, which can easily be damaged by inappropriate handling. Static control precautions must be adhered to during installation, testing, service and repair of this drive and associated options. Component damage may result if proper procedures are not followed.

This drive has been tested by Underwriters Laboratory (UL) and is an approved component in compliance with UL508 Safety Standard.

This drive must be installed and configured in accordance with both national and international standards. Local codes and regulations take precedence over recommendations provided in this and other LEESON documentation.

The SM2 and SM4 Vector drive is considered a component for integration into a machine or process. It is neither a machine nor a device ready for use in accordance with European directives (reference machinery directive and electromagnetic compatibility directive). It is the responsibility of the end user to ensure that the machine meets the applicable standards.

Electrical connection

WARNING!

When working on live drive controllers, applicable national safety regulations must be observed.

The electrical installation must be carried out according to the appropriate regulations (e.g. cable cross-sections, fuses, protective earth [PE] connection). While this document makes recommendations in regard to these items, national and local codes must be adhered to.

The documentation contains information about installation in compliance with EMC (shielding, grounding, filters and cables). These notes must also be observed for CE-marked controllers.

The manufacturer of the system or machine is responsible for compliance with the required limit values demanded by EMC legislation.

Application

WARNING!

The drive must not be used as a safety device for machines where there is a risk of personal injury or material damage. Emergency Stops, over-speed protection, acceleration and deceleration limits, etc. must be made by other devices to ensure operation under all conditions.

The drive features many protection devices which are aimed at protecting the drive and the driven equipment by generating a fault and shutting the drive and motor down by removing power. Mains power variances can also result in shutdown of the drive. When the fault condition disappears or is cleared, the drive can be configured to automatically restart.It is the responsibility of the user and/ or OEM and/or integrator to ensure that the drive is configured for safe operation.

4

Technical data

2 Technical data

2.1Standards and application conditions

Conformity |

CE |

Low Voltage Directive (73/23/EEC) |

|

|

|

|

|||||

Approvals |

UL 508C |

Underwriters Laboratories - Power Conversion Equipment |

|

||

Input voltage phase imbalance |

< 2% |

|

|

|

|

|

|

|

– For central grounded systems, operation is |

|

|

Supported Power Systems |

TT |

|

permitted without restrictions. |

|

|

|

– For corner grounded 400/500V systems, operation |

|

|||

TN |

|

|

|||

|

|

is possible but reinforced insulation to control |

|

||

|

|

|

|

||

|

|

|

circuits is compromised. |

|

|

Humidity |

< 95% non-condensing |

|

|

||

|

Transport |

|

-25 … +70°C |

|

|

Temperature range |

Storage |

|

-20 … +70°C |

|

|

Operation |

|

-10 … +55°C (with 2.5%/°C current derating |

|

||

|

|

|

|||

|

|

above +40°C) |

|

||

|

|

|

|

||

Installation height |

0 … 4000m a.m.s.l. |

|

|

|

|

(with 5%/1000 m current derating above 1000m a.m.s.l.) |

|

|

|||

|

|

||||

Vibration resistance |

acceleration resistant up to 1.0g |

|

|||

WARNING! |

> 3.5 mA to PE |

|

|

|

|

Earth leakage current |

|

|

|

||

|

|

|

|

|

|

Max Permissable Cable Length (1) |

<=4.0 Hp (3.0 kW) |

30 meters shielded, 60 meters un-shielded |

|

|

|

=> 5.0 Hp (3.7 kW) |

50 meters shielded, 100 meters un-shielded |

|

|

||

|

|

||||

|

IP31 / NEMA 1 |

IP65/NEMA 4X |

|

|

|

Enclosure |

NEMA 1 and NEMA 4X model enclosures are plenun rated in accordance |

|

|||

|

with UL 508C and are suitable for installation in a compartment handling |

|

|||

|

conditioned air. |

|

|

|

|

Protection measures against |

short circuit, earth fault, phase loss, over voltage, under voltage, motor |

|

|||

stalling, over temperature, motor overload |

|

||||

|

|

||||

|

|

|

|

|

|

Compliance with EN 61000-3-2 |

< 0.5 kW |

|

with mains choke |

|

|

0.5 ... 1 kW |

|

with active filter |

|

|

|

Requirements (2) |

|

|

|||

|

> 1 kW |

|

without additional measures |

|

|

Compliance with EN 61000-3-12 |

16 ... 75 amp |

|

Additional measures required for compliance with |

|

|

Requirements (2) |

|

EN 61000-3-12 |

|

||

|

|

|

|||

Operation in public supply networks (Limitation of harmonic currents i.a.w. EN 61000-3-2, Electromagnetic Compatibiliy (EMC) Limits). Limits for harmonic current emissions (equipment input current up to 16A/phase).

(1)The stated cable lengths are permissiable at default carrier frequencies (refer to parameter P166).

(2)The additional measures described only ensure that the controller meets the requirements of the EN 61000-3-2. The machine/system manufacturer is responsible for the machine’s compliance with the regulations.

5

Technical data

2.2Ratings

120VAC Doubler / 240VAC Models

|

|

|

Power |

Mains |

|

|

|

|

Output Current |

SM2 |

SM4 |

|

|

|

Type |

[Hp/kW] |

Voltage(1) |

|

Iin (120V) |

Iin (240V) |

|

In |

CLimmax(2) |

Watts |

Watt |

|

|

|

|

|

Loss |

Loss |

||||||

|

174603 |

0.33 / 0.25 |

120 V Single-phase (1/N/PE) |

|

6.8 |

3.4 |

|

1.7 |

200 |

24 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174604- |

|

|

|

|

|

|

|

|

|

|

|

0.5 / 0.37 |

(90 … 132 V) |

|

9.2 |

4.6 |

|

2.4 |

200 |

32 |

32 |

||

|

|

174652 |

|

|

||||||||

|

|

OR |

|

|

|

|

|

|

|

|

||

|

|

174605- |

|

|

|

|

|

|

|

|

|

|

|

1 / 0.75 |

240 V Single-phase (2/PE) |

|

16.6 |

8.3 |

|

4.2 |

200 |

52 |

41 |

||

|

|

174653 |

|

|

||||||||

|

|

(170 … 264 V) |

|

|

|

|

|

|

|

|

||

|

|

174651- |

1.5 / 1.1 |

|

20.0 |

10.0 |

|

6.0 |

200 |

74 |

74 |

|

|

|

|

|

|||||||||

|

|

174654 |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

240VAC Models |

|

|

|

|

|

|

|

|

|

|

|

|

Type |

Power |

Mains |

|

|

|

|

Output Current |

SM2 |

SM4 |

|

|

|

[Hp/kW] |

Voltage(1) |

Iin 1~ (2/PE) |

Iin 3~ (3/PE) |

In |

CLimmax(2) |

Watts |

Watts |

|||

|

|

|

Loss |

Loss |

||||||||

|

|

174606 |

0.33 / 0.25 |

240 V Single Phase (2/PE) |

3.4 |

- |

|

1.7 |

200 |

20 |

|

|

|

|

174607-174655 |

0.5 / 0.37 |

|

5.1 |

2.9 |

|

2.4 |

200 |

27 |

30 |

|

|

|

174608-174656 |

1 / 0.75 |

240 V Single-phase (2/PE) |

8.8 |

5.0 |

|

4.2 |

200 |

41 |

42 |

|

|

|

174609-174657 |

1.5 / 1.1 |

OR |

12.0 |

6.9 |

|

6.0 |

200 |

64 |

63 |

|

|

240 V Three-phase (3/PE) |

|

||||||||||

|

|

174610-174658 |

2 / 1.5 |

(170 … 264 V) |

13.3 |

8.1 |

|

7.0 |

200 |

75 |

73 |

|

|

|

|

||||||||||

|

|

174611-174659 |

3 / 2.2 |

|

17.1 |

10.8 |

|

9.6 |

200 |

103 |

97 |

|

|

|

174612 |

1.5 / 1.1 |

|

- |

6.9 |

|

6.0 |

200 |

64 |

59 |

|

|

|

174613 |

2 / 1.5 |

|

- |

8.1 |

|

7.0 |

200 |

75 |

69 |

|

|

|

174614 |

3 / 2.2 |

240 V Three-phase (3/PE) |

- |

10.8 |

|

9.6 |

200 |

103 |

93 |

|

|

|

174615-174660 |

5 / 4.0 |

(170 V … 264 V) |

- |

18.6 |

|

16.5 |

200 |

154 |

139 |

|

|

|

|

||||||||||

|

|

174616-174661 |

7.5 / 5.5 |

|

- |

26 |

|

23 |

200 |

225 |

167 |

|

|

|

174617-174662 |

10 / 7.5 |

|

- |

33 |

|

29 |

200 |

274 |

242 |

|

|

|

174618 |

15 / 11 |

|

- |

48 |

|

42 |

180 |

485 |

468 |

|

|

|

174619 |

20 / 15 |

|

- |

59 |

|

54 |

180 |

614 |

591 |

|

(1)Frequency Range: 48 Hz … 62 Hz

(2)Current Limit (CLim) is a percentage of the output current, In. CLimmax is the maximum setting for P171.

6

480VAC Models |

|

|

Technical data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Power |

|

Mains |

|

|

|

|

|

Output Current |

SM2 |

|

SM4 |

|

|

|||||||||||||||||||

Type |

|

|

|

Iin |

|

|

In |

|

CLimmax(2) |

Watts |

|

Watts |

|

|

|||||||||||||||||||

|

[Hp/kW] |

Voltage(1) |

|

|

|

|

|

|

|

|

|

|

|

Loss |

|

Loss |

|

|

|||||||||||||||

|

400V |

|

480V |

|

400V |

|

480V |

400V |

|

480V |

|

|

|

||||||||||||||||||||

174620-174671 |

0.5 / 0.37 |

|

|

1.7 |

|

1.5 |

1.3 |

|

1.1 |

175 |

|

200 |

23 |

|

|

|

21 |

|

|

|

|||||||||||||

174621-174672 |

1 / 0.75 |

|

|

2.9 |

|

2.5 |

2.4 |

|

2.1 |

175 |

|

200 |

37 |

|

|

|

33 |

|

|

|

|||||||||||||

174622-174673 |

1.5 / 1.1 |

400 V Three-phase (3/PE) |

4.2 |

|

3.6 |

3.5 |

|

3.0 |

175 |

|

200 |

48 |

|

|

|

42 |

|

|

|

||||||||||||||

|

|||||||||||||||||||||||||||||||||

174623-174674 |

2 / 1.5 |

(340 … 440 V) |

4.7 |

|

4.1 |

4.0 |

|

3.5 |

175 |

|

200 |

57 |

|

|

|

50 |

|

|

|

||||||||||||||

OR |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

174624-174675 |

3 / 2.2 |

|

6.1 |

|

5.4 |

5.5 |

|

4.8 |

175 |

|

200 |

87 |

|

|

|

78 |

|

|

|

||||||||||||||

480 V Three-phase (3/PE) |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

174625-174676 |

5 / 4.0 |

(340 … 528 V) |

10.6 |

|

9.3 |

9.4 |

|

8.2 |

175 |

|

200 |

128 |

|

|

103 |

|

|

||||||||||||||||

174626-174677 |

7.5 / 5.5 |

|

|

14.2 |

|

12.4 |

12.6 |

|

11.0 |

175 |

|

200 |

178 |

|

|

157 |

|

|

|||||||||||||||

174627-174678 |

10 / 7.5 |

|

|

18.1 |

|

15.8 |

16.1 |

|

14.0 |

175 |

|

200 |

208 |

|

|

190 |

|

|

|||||||||||||||

174628 |

15 / 11 |

|

|

27 |

|

24 |

24 |

|

21 |

155 |

|

180 |

418 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

174629 |

20 / 15 |

|

|

35 |

|

31 |

31 |

|

27 |

155 |

|

180 |

493 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

174630 |

25 / 18.5 |

|

|

44 |

|

38 |

39 |

|

34 |

155 |

|

180 |

645 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

174991 |

30 / 22 |

|

|

52 |

|

45 |

46 |

|

40 |

155 |

|

180 |

709 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

174992 |

40 / 30 |

|

|

68 |

|

59 |

60 |

|

52 |

155 |

|

180 |

1020 |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

174710 |

50 / 37.5 |

|

|

85 |

|

74 |

75 |

|

65 |

155 |

|

180 |

1275 |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

174711 |

60 / 45 |

|

|

100 |

|

87 |

88 |

|

77 |

155 |

|

180 |

1530 |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

600 VAC Models |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power |

|

Mains |

|

|

|

|

|

Output Current |

|

SM2 |

|

|

|

SM4 |

|

|

||||||||||||||||

Type |

|

|

|

|

|

|

|

|

|

|

|

|

|

Watts |

|

Watts |

|

|

|||||||||||||||

[Hp/kW] |

Voltage |

(1) |

|

Iin |

|

|

|

In |

|

|

(2) |

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

CLimmax |

Loss |

|

Loss |

|

|

|||||||||||||||||||||

174631-174663 |

1 / 0.75 |

|

|

|

2.0 |

|

|

1.7 |

|

|

200 |

37 |

|

|

|

31 |

|

|

|

||||||||||||||

174632-174664 |

2 / 1.5 |

|

|

|

3.2 |

|

|

2.7 |

|

|

200 |

51 |

|

|

|

43 |

|

|

|

||||||||||||||

174633-174665 |

3 / 2.2 |

600 V Three-phase (3/PE) |

|

4.4 |

|

|

3.9 |

|

|

200 |

68 |

|

|

|

57 |

|

|

|

|||||||||||||||

174634-174666 |

5 / 4.0 |

(425 … 660 V) |

|

6.8 |

|

|

6.1 |

|

|

200 |

101 |

|

|

67 |

|

|

|

||||||||||||||||

174635-174667 |

7.5 / 5.5 |

|

|

|

10.2 |

|

|

9 |

|

|

200 |

148 |

|

|

116 |

|

|

||||||||||||||||

174636-174668 |

10 / 7.5 |

|

|

|

12.4 |

|

|

11 |

|

|

200 |

172 |

|

|

152 |

|

|

||||||||||||||||

174637 |

15 / 11 |

|

|

|

19.7 |

|

|

17 |

|

|

180 |

380 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

174638 |

20 / 15 |

|

|

|

25 |

|

|

22 |

|

|

180 |

463 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

174639 |

25 / 18.5 |

|

|

|

31 |

|

|

27 |

|

|

180 |

560 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

174993 |

30 / 22 |

|

|

|

36 |

|

|

32 |

|

|

180 |

640 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

174994 |

40 / 30 |

|

|

|

47 |

|

|

41 |

|

|

180 |

930 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

174712 |

50 / 37.5 |

|

|

|

59 |

|

|

52 |

|

|

180 |

1163 |

|

|

|

|

|

|

|

|

|

|

|

||||||||||

174713 |

60 / 45 |

|

|

|

71 |

|

|

62 |

|

|

180 |

1395 |

|

|

|

|

|

|

|

|

|

|

|

||||||||||

(1)Frequency Range: 48 Hz … 62 Hz

(2)Current Limit (CLim) is a percentage of the output current, In. CLimmax is the maximum setting for P171.

For 480VAC models, the CLimmax value in the 480V column of the table is used when P107 is set to 1. The CLimmax value in the 400V column is used when P107 is set to 0.

STOP!

Drive Derating

The SM2 and SM4 Vector Series drive is designed to operate at the Nominal Output Current (In)shown in the Ratings tables for most standard applications and industrial environments. The drive output current or operating temperature may need to be limited as described below:

• For installations above 1000m a.m.s.l., derate In by 5% per 1000m, do not exceed 4000m a.m.s.l.

• Operation above 40°C, derate In by 2.5% per °C, do not exceed 55°C.

• Carrier Frequency (P166):

- If P166=2 (8 kHz), derate In to 92% of drive rating or do not exceed 33°C ambient - If P166=3 (10 kHz), derate In to 84% of drive rating or do not exceed 27°C ambient

For combinations of the above, please consult LEESON applications support for proper derating.

7

|

Installation |

3 |

Installation |

3.1Dimensions and mounting

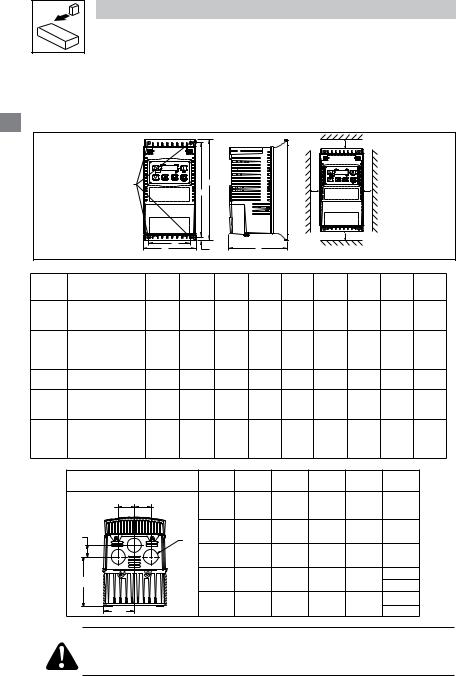

3.1.1NEMA 1 (IP31)

|

|

|

|

|

|

|

|

|

s2 |

|

|

|

|

|

Mounting |

|

|

|

|

|

|

|

|

|

|

|

|

|

Screws |

|

|

|

|

|

|

|

|

|

|

|

|

|

4 X #10 |

|

b |

|

|

|

|

|

|

|

|

|

|

|

18 lb-in |

|

|

|

|

|

|

|

|

|

|

||

|

|

b1 |

|

|

|

|

|

|

|

|

|

||

|

(420XNmM5) |

|

|

|

|

|

|

s1 |

s1 |

|

|

||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

s2 |

|

|

|

|

|

|

a a1 |

b2 |

|

|

|

c |

|

|

|

|

|

|

|

|

|

|

|

|

|

mm (in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V0102 |

|

|

Type |

a |

a1 |

|

b |

|

b1 |

b2 |

c |

s1 |

s2 |

m |

|

|

in (mm) |

in (mm) |

in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) |

lb (kg) |

|||||||||

|

|

||||||||||||

CH1 |

174603 - 174608, |

3.90 |

3.10 |

7.50 |

|

7.00 |

0.25 |

4.35 |

0.6 |

2.0 |

2.0 |

||

174620 - 174621, |

|

||||||||||||

|

174631 |

(99) |

(79) |

(190) |

(178) |

(6) |

(110) |

(15) |

(50) |

(0.9) |

|||

|

174609 - 174614, |

3.90 |

3.10 |

7.50 |

|

7.00 |

0.25 |

5.45 |

0.6 |

2.0 |

2.8 |

||

CH2 |

174622 - 174624, |

|

|||||||||||

174632 - 174633 |

(99) |

(79) |

(190) |

(178) |

(6) |

(138) |

(15) |

(50) |

(1.3) |

||||

|

174651 |

|

|

|

|

|

|

|

|

|

|

|

|

CH3 |

174615, 174625, |

3.90 |

3.10 |

7.50 |

|

7.00 |

0.25 |

5.80 |

0.6 |

2.0 |

3.2 |

||

174634 |

(99) |

(79) |

(190) |

(178) |

(6) |

(147) |

(15) |

(50) |

(1.5) |

||||

|

|||||||||||||

CH4 |

174616 - 174617, |

5.12 |

4.25 |

9.83 |

|

9.30 |

0.25 |

6.25 |

0.6 |

2.0 |

6.0 |

||

174626 - 174627, |

|

||||||||||||

|

174635 - 174636 |

(130) |

(108) |

(250) |

(236) |

(6) |

(159) |

(15) |

(50) |

(2.0) |

|||

|

174618 - 174619, |

6.92 |

5.75 |

12.50 |

11.88 |

0.31 |

8.09 |

0.6 |

2.0 |

13.55 |

|||

CH5 |

174628 - 174630, |

||||||||||||

174637 - 174639 (176) |

(146) |

(318) |

(302) |

(8) |

(205) |

(15) |

(50) |

(6.15) |

|||||

|

174991, 174993 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Conduit Hole Dimensions |

Type |

|

|

N |

P |

P1 |

Q |

S |

|

|||

|

in (mm) |

in (mm) |

in (mm) |

in (mm) |

in (mm) |

|

|||||||

|

|

|

|

|

|

||||||||

|

Q |

Q |

CH1 |

|

1.84 (47) |

1.93 (49) |

.70 (18) |

1.00 (25) |

.88 (22) |

|

|||

|

|

|

|

|

|||||||||

|

P1 |

|

CH2 |

|

1.84 (47) |

3.03 (77) |

.70 (18) |

1.00 (25) |

.88 (22) |

|

|||

|

|

S |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

CH3 |

|

1.84 (47) |

3.38 (86) |

.70 (18) |

1.00 (25) |

.88 (22) |

|

|||

|

P |

|

CH4 |

|

2.46 (62) |

3.55 (90) |

.13 (3) |

1.38 (35) |

1.13 (29) |

|

|||

|

|

|

.88 (22) |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

CH5 |

|

3.32 (84) |

4.62 (117) |

.73 (19) |

1.40 (36) |

1.31 (33) |

|

|||

|

N |

|

|

.88 (22) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

WARNING!

Drives must not be installed where subjected to adverse environmental conditions

8 such as: combustible, oily, or hazardous vapors or dust; excessive moisture; excessive vibration or excessive temperatures. Contact LEESON for more information.

Installation

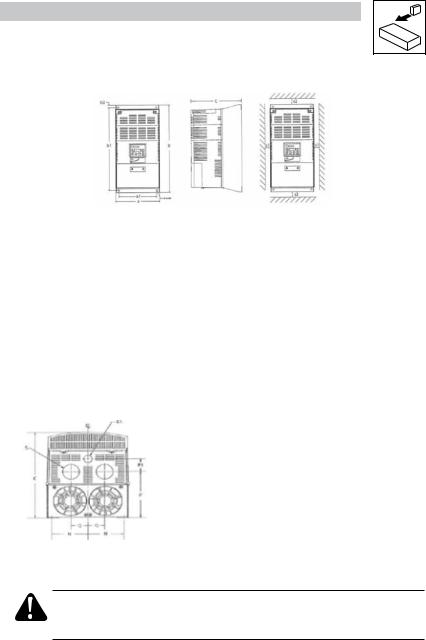

3.1.1NEMA 1 (IP31) Models > 30HP (22kW)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V0102 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type |

a |

a1 |

|

|

b |

|

b1 |

|

b2 |

|

c |

s1 |

s2 |

|

|

m |

|

|

|

|

|||

|

|

|

in (mm) |

in (mm) |

|

in (mm) |

in (mm) |

in (mm) |

in (mm) |

in (mm) |

in (mm) |

|

lb (kg) |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

CH6 |

174992 |

8.72 |

7.50 |

|

14.19 |

13.30 |

0.45 |

|

10.07 |

0.6 |

2.0 |

|

24.0 |

|

|

|

|

|||||||

|

|

174994 |

(221) |

(190) |

|

(360) |

|

(338) |

|

(11.4) |

|

(256) |

(15) |

(50) |

|

(10.9) |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

CH7 |

174710 |

8.72 |

7.50 |

|

17.19 |

16.30 |

0.45 |

|

10.07 |

0.6 |

2.0 |

|

31 |

|

|

|

|

|||||||

|

|

174712 |

(221) |

(190) |

|

(436) |

|

(414) |

|

(11.4) |

|

(256) |

(15) |

(50) |

|

(14.1) |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

CH8 |

174711 |

8.72 |

7.50 |

|

20.09 |

19.30 |

0.45 |

|

10.07 |

0.6 |

2.0 |

|

35 |

|

|

|

|

|||||||

|

|

174713 |

(221) |

(190) |

|

(513) |

|

(490) |

|

(11.4) |

|

(256) |

(15) |

(50) |

|

(15.9) |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Conduit Hole Dimensions |

|

Type |

|

|

|

N |

|

|

P |

|

P1 |

Q |

S |

|

S1 |

|

|||||||

|

|

|

|

|

in (mm) |

|

in (mm) |

in (mm) |

in (mm) |

in (mm) |

|

in (mm) |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH6 |

|

|

3.75 (95) |

|

5.42 (137) |

1.50 (38.1) |

1.75 (44.4) |

1.75 (44.4) |

|

0.875 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

(22.2) |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH7 |

|

|

3.75 (95) |

|

5.42 (137) |

1.50 (38.1) |

1.75 (44.4) |

1.75 (44.4) |

|

0.875 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

(22.2) |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CH8 |

|

|

3.75 (95) |

|

5.42 (137) |

1.50 (38.1) |

1.75 (44.4) |

1.75 (44.4) |

|

0.875 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

(22.2) |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING!

Drives must not be installed where subjected to adverse environmental conditions such as: combustible, oily, or hazardous vapors or dust; excessive moisture; excessive vibration or excessive temperatures. Contact LEESON for more information.

9

Installation

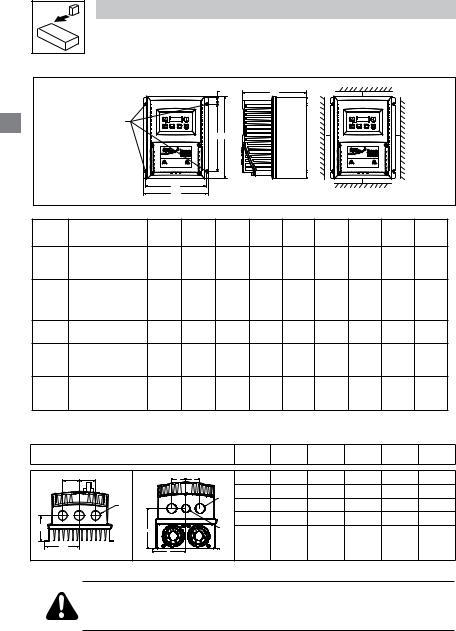

3.1.3NEMA 4 (IP65)

|

|

|

|

b2 |

|

c |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

s2 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

Mounting Screws |

|

|

|

|

|

|

|

|

|

|

|

|

4 x #8-32 |

|

|

|

|

|

|

|

|

|

|

|

|

10 lb-in |

|

|

|

|

|

|

|

|

|

|

|

|

(1.24 x NmM4 ) |

|

|

b1 b |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

s1 |

|

s1 |

|

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

s2 |

|

|

|

|

|

a1 |

|

|

|

|

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V0102 |

|

|

Type |

a |

a1 |

b |

b1 |

|

b2 |

c |

s1 |

s2 |

m |

|

|

in (mm) |

in (mm) |

in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) |

lb (kg) |

||||||||

|

|

|||||||||||

CH1 |

174652 - 174656, |

6.28 |

5.90 |

8.00 |

6.56 |

0.66 |

4.47 |

2.00 |

2.00 |

3.6 |

||

174671 - 174672, |

(160) |

(150) |

(203) |

(167) |

(17) |

(114) |

(51) |

(51) |

(1.63) |

|||

|

174663 |

|

|

|

|

|

|

|

|

|

|

|

CH2 |

174657 - 174658, |

6.28 |

5.90 |

8.00 |

6.56 |

0.66 |

6.31 |

2.00 |

2.00 |

5.9 |

||

174673 - 174675, |

(160) |

(150) |

(203) |

(167) |

(17) |

(160) |

(51) |

(51) |

(2.68) |

|||

|

174664 - 174665 |

|||||||||||

CH3 |

174659 |

7.12 |

6.74 |

8.00 |

6.56 |

0.66 |

6.77 |

2.00 |

2.00 |

7.1 |

||

(181) |

(171) |

(203) |

(167) |

(17) |

(172) |

(51) |

(51) |

(3.24) |

||||

|

174661 - 174662, |

|||||||||||

CH4 |

8.04 |

7.56 |

10.00 |

8.04 |

0.92 |

8.00 |

4.00 |

4.00 |

10.98 |

|||

174678 |

(204) |

(192) |

(254) |

(204) |

(23) |

(203) |

(102) |

(102) |

(4.98) |

|||

|

174668 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

174660 |

8.96 |

8.48 |

10.00 |

8.04 |

0.92 |

8.00 |

4.00 |

4.00 |

11.58 |

||

CH5 |

174676-174677 |

|||||||||||

(228) |

(215) |

(254) |

(204) |

(23) |

(203) |

(102) |

(102) |

(5.25) |

||||

|

174666-174667 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

Conduit Hole Dimensions |

|

|

Type |

|

N |

P |

Q |

S |

S1 |

||

|

|

|

in (mm) |

in (mm) |

in (mm) |

in (mm) |

in (mm) |

|||||

|

|

|

|

|

|

|||||||

Q |

Q |

Q |

Q |

|

CH1 |

|

3.14 (80) |

2.33 (59) |

1.50 (38) |

.88 (22) |

n/a |

|

|

|

|

|

S |

CH2 |

|

3.14 (80) |

4.18 (106) |

1.50 (38) |

.88 (22) |

n/a |

|

|

|

|

|

CH3 |

|

3.56 (90) |

4.63 (118) |

1.50 (38) |

.88 (22) |

n/a |

||

|

S |

|

|

|

|

|||||||

|

|

|

|

|

CH4 |

4.02 (102) |

5.00 (127) |

1.85 (47) |

1.06 (27) |

n/a |

||

P |

|

P |

|

S1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

N |

|

|

|

|

CH5 |

4.48 (114) |

5.00 (127) |

1.85 (47) |

1.06 (27) |

n/a |

||

|

|

N |

|

|

|

|

|

|

|

|

|

|

WARNING!

Drives must not be installed where subjected to adverse environmental conditions such as: combustible, oily, or hazardous vapors or dust; excessive moisture; excessive vibration or excessive temperatures. Contact LEESON for more information.

10

Installation

3.2Electrical installation

Installation After a Long Period of Storage

STOP!

Severe damage to the drive can result if it is operated after a long period of storage or inactivity without reforming the DC bus capacitors.

If input power has not been applied to the drive for a period of time exceeding three years (due to storage, etc.), the electrolytic DC bus capacitors within the drive can change internally, resulting in excessive leakage current. This can result in premature failure of the capacitors if the drive is operated after such a long period of inactivity or storage.

In order to reform the capacitors and prepare the drive for operation after a long period of inactivity, apply input power to the drive for 8 hours prior to actually operating the motor.

3.2.1Power Connections

DANGER!

Hazard of electrical shock! Circuit potentials are up to 600 VAC above earth ground. Capacitors retain charge after power is removed. Disconnect power and wait at least three minutes before servicing the drive.

STOP!

• Verify mains voltage before connecting to drive.

• Do not connect mains power to the output terminals (U,V,W)! Severe damage to the drive will result.

• Do not cycle mains power more than once every two minutes. Damage to the drive will result.

|

|

|

|

|

|

|

|

Mains and Motor Terminations |

|

|

||

|

|

|

Type |

|

|

|

|

|

|

Torque |

Strip Length |

|

|

|

|

174991, 174992 |

|

|

|

|

24 lb-in (2.7 Nm) |

7/16 in (10mm) |

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

174710, 174711 |

|

|

|

|

27 lb-in (3.05 Nm) |

0.75 in (19mm) |

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

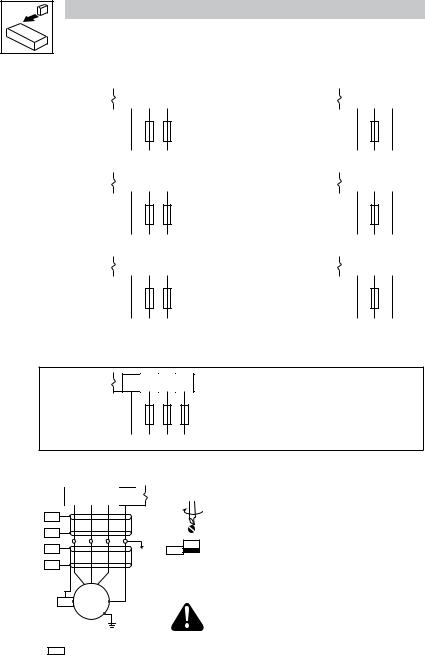

3.2.1.1 Mains connection to 120VAC Single-Phase Supply |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

174603 |

|

|

|

|

|

|

|

|

|

||

|

|

PE |

L1 |

L2 |

N |

|

|

|

|

|||

|

174604 |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||

|

174605 |

|

|

|

|

|

|

|

|

|

||

|

174651 |

|

|

|

|

|

|

|

|

|

||

|

174652 |

|

|

|

|

|

|

|

|

|

||

|

174653 |

|

|

|

|

|

|

|

|

|

||

|

174654 |

|

PE L1 |

N |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

Installation

3.2.1.2Mains connection to 240VAC Single-Phase Supply

|

174603 |

|

|

|

|

|

174603 |

|

|

|

|

|

|

|

|

174604 |

|

PE |

L1 |

L2 |

N |

174604 |

|

PE |

L1 |

L2 |

N |

|

|

|

|

174605 |

|

|

|

|

|

174605 |

|

|

|

|

|

|

|

|

174651 |

|

|

|

|

|

174651 |

|

|

|

|

|

|

|

|

174652 |

|

|

|

|

|

174652 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

174653 |

|

|

|

|

|

174653 |

|

|

|

|

|

|

|

|

174654 |

|

PE |

L1 |

L2 |

|

174654 |

|

PE |

L1 |

N |

|

|

|

|

174607 |

|

|

|

|

|

174607 |

|

|

|

|

|

|

|

|

174608 |

|

PE |

L1 |

L2 |

L3 |

174608 |

|

PE |

L1 |

L2 |

L3 |

|

|

|

174609 |

|

|

|

|

|

174609 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

174610 |

|

|

|

|

|

174610 |

|

|

|

|

|

|

|

|

174611 |

|

|

|

|

|

174611 |

|

|

|

|

|

|

|

|

|

(2/PE AC) |

|

PE |

L1 |

L2 |

|

(1/N/PE AC) |

|

PE |

L1 |

N |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

174606 |

|

|

|

|

|

174606 |

|

|

|

|

|

|

|

|

|

|

PE |

L1 |

L2 |

|

|

PE |

L1 |

L2 |

|

|

||

|

|

(2/PE AC) |

|

|

(1/N/PE AC) |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

PE |

L1 |

L2 |

|

|

PE |

L1 |

N |

|

|

||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.2.1.3Mains connection to Three-Phase Supply

All

three-phase PE L1 L2 L3 models

(3/PE AC)

PE L1 L2 L3

3.2.1.4Motor Connection

U/T1 V/T2 W/T3 PE |

||

PES |

|

|

PES |

PE |

|

PES |

||

|

||

PES |

|

|

PES |

M |

|

3~ |

||

|

||

|

PE |

|

PES = Protective Earth Shielding

Mains and Motor Terminations

12 lb-in (1.3 Nm)

0.25 in (6mm)

SM4 Cover Screws Torque 6-7 lb-in

WARNING!

Leakage current may exceed 3.5 mA AC. Minimum size of the protective earth conductor shall comply with local safety regulations for high leakage current equipment.

12

Installation

3.2.1.5Installation Recommendations for EMC Compliance

For compliance with EN 61800-3 or other EMC standards, motor cables, line cables and control or communications cables must be shielded with each shield/screen clamped to the drive chassis. This clamp is typically located at the conduit mounting plate.

Motor cable should be low capacitance (core/core <75pF/m, core/shield <150pF/m). Filtered drives can meet the class A limits of EN 55011 and EN 61800-3 Category 2 with this type of motor cable up to 10 meters. NOTE: Refer to Appendix A for recommended cable lengths. Any external line filter should have its chassis connected to the drive chassis by mounting hardware or with the shortest possible wire or braid.

Enclosure / Backplate

External

Control

Circuits

Control and signal cabling |

should be separated from |

power cables by |

a minimum of 300mm |

360° shield termination to |

backplate using saddle clamp |

From |

Motor |

From

AC Supply

Screened motor cable: core/core <75pF/M core/shield <150pF/M

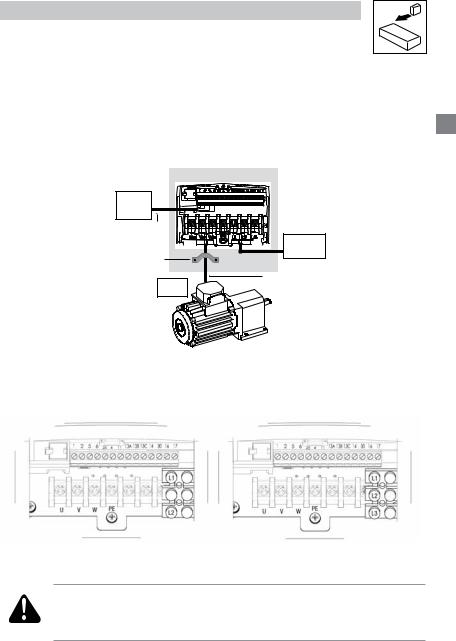

3.2.1.6NEMA 4X (IP65) Input Terminal Block

For NEMA 4X (IP65) models with integrated EMC filter and/or integrated line disconnect, the input terminal block is located on the right-hand side of the SM4 inverter in the NEMA 4 X (IP65) enclosure. The single and three phase models are illustrated herein. Refer to paragraph 3.2.3 Control Terminals for pin out information.

Single Phase (2/PE) |

Three Phase (3/PE) |

With Filter and/or integrated line disconnect |

With Filter and/or integrated line disconnect |

WARNING

Power remains present for up to 3 minutes on power input terminals (L1, L2 and L3) and output terminals (U, V and W) even when the disconnect switch is in the OFF position. Remove input power ahead of the drive and wait 3 minutes before removing the terminal cover.

13

Installation

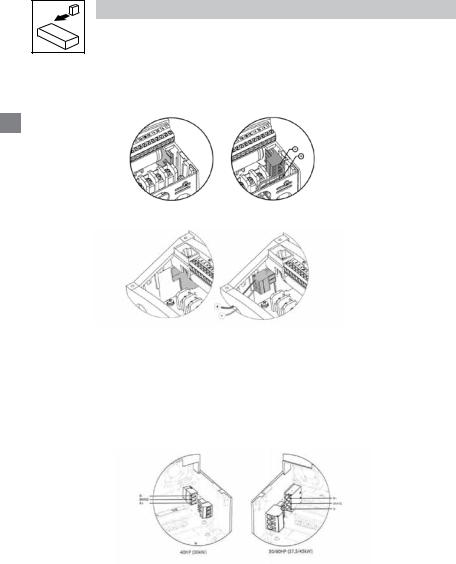

3.2.1.7Dynamic Brake Connections

For NEMA 1 and NEMA 4X Drives rated up to 25 HP the Dynamic Brake connections are made as illustrated herein. Refer to the SM2 and SM4 Dynamic Brake instructions for complete information.

NEMA 1 (IP31) up to 30 HP

NEMA 4 (IP65) up to 10 HP

The 40...40HP (30...45kW) models include a dynamic brake transitor as standard and only require the connection of an external resistor kit for dynamic braking operation. The dynamic brake resistor connections for 40...60HP (30...45kW) drives are standard built-in connections as illustrated in the diagram below. In the 40HP (30kW) model drives, the dynamic brake connector is on the right-hand side of the drive and the terminals from top to bottom are B-, BRAKE and B+. In the 50/60HP (37.5/45kW) model drives, the dynamic brake connector is on the left-hand side of the drive and the terminals from top to bottom are B+, BRAKE and B-.

14

Installation

3.2.2Fuses/cable cross-sections

Note

Observe local regulations.

Local codes may supersede these recommendations

|

|

|

Recommendations |

|

|||

|

Type |

Fuse |

Miniature |

Fuse (2) or |

Input Power Wiring |

||

|

|

circuit |

Breaker(3) |

(L1, L2, L3, PE) |

|||

|

|

|

breaker(1) |

(N. America) |

[mm²] |

[AWG] |

|

120V |

174603 |

M10 A |

C10 A |

10 A |

1.5 |

14 |

|

1~ |

174604, 174652.00 |

M16 A |

C16 A |

15 A |

2.5 |

14 |

|

(1/N/PE) |

174605, 174653.00 |

M25 A |

C25 A |

25 A |

4 |

10 |

|

|

174603, 174604,174652, 174653 |

M10 A |

C10 A |

10 A |

1.5 |

14 |

|

240V |

174607, 74606 |

||||||

174605, 174608 |

M16 A |

C16 A |

15 A |

2.5 |

14 |

||

1~ |

|||||||

174609, 174651, 174654, 174657 |

M20 A |

C20 A |

20 A |

2.5 |

12 |

||

(2/PE) |

|||||||

174610, 174658 |

M25 A |

C25 A |

25 A |

2.5 |

12 |

||

|

174611, 174659 |

M32 A |

C32A |

32 A |

4 |

10 |

|

|

174607, 174608, 174606 |

M10 A |

C10 A |

10 A |

1.5 |

14 |

|

|

174609, 174610, 174612, 174613 |

M16 A |

C16 A |

12 A |

1.5 |

14 |

|

240V |

174651, 174654, 174657, 174658 |

||||||

174611, 174614, 74659 |

M20 A |

C20 A |

20 A |

2.5 |

12 |

||

3~ |

|||||||

174615, 174660 |

M32 A |

C32 A |

32 A |

4.0 |

10 |

||

(3/PE) |

|||||||

174616, 174661 |

M40 A |

C40 A |

35 A |

6.0 |

8 |

||

|

|||||||

|

174617, 174662 |

M50 A |

C50 A |

45 A |

10 |

8 |

|

|

174618 |

M80 A |

C80 A |

80 A |

16 |

8 |

|

|

174619 |

M100A |

C100A |

90 A |

16 |

8 |

|

|

174620, 174624, 174671, 174675 |

M10 A |

C10 A |

10 A |

1.5 |

14 |

|

|

174625, 174676 |

M16 A |

C16 A |

20 A |

2.5 |

14 |

|

|

174626, 174677 |

M20 A |

C20 A |

20 A |

2.5 |

14 |

|

400V |

174627, 174678 |

M25 A |

C25 A |

25 A |

4.0 |

10 |

|

174628 |

M40 A |

C40 A |

40 A |

4 |

8 |

||

or 480V |

174629 |

M50 A |

C50 A |

50 A |

10 |

8 |

|

3~(3/ |

174630 |

M63 A |

C63 A |

70 A |

10 |

6 |

|

PE) |

|||||||

174991 |

M80 A |

C80 A |

80 A |

16 |

6 |

||

|

|||||||

|

174992 |

M100 A |

C100 A |

100 A |

25 |

4 |

|

|

174710 |

M125 A |

C125 A |

125 A |

35 |

2 |

|

|

174711 |

M180 A |

C160 A |

150 A |

35 |

1 |

|

|

174631, 174632, 174633, |

M10 A |

C10 A |

10 A |

1.5 |

14 |

|

|

174663, 174665 |

||||||

|

174634, 174666 |

M16 A |

C16 A |

12 A |

1.5 |

14 |

|

|

174635, 174667 |

M16 A |

C16 A |

15 A |

2.5 |

14 |

|

600V |

174636, 174668 |

M20 A |

C20 A |

20 A |

2.5 |

12 |

|

174637 |

M32 A |

C32 A |

30 A |

4 |

10 |

||

3~(3/ |

174638 |

M40 A |

C40 A |

40 A |

4 |

8 |

|

PE) |

174639 |

M50 A |

C50 A |

50 A |

6 |

8 |

|

|

174993 |

M63 A |

C63 A |

60 A |

10 |

8 |

|

|

174994 |

M80 A |

C80 A |

70 A |

16 |

6 |

|

|

174712 |

M100 A |

C100 A |

90 A |

16 |

4 |

|

|

174713 |

M125 A |

C125 A |

110 A |

25 |

2 |

|

(1)Installations with high fault current due to large supply mains may require a type D circuit breaker.

(2)UL Class CC or T fast-acting current-limiting type fuses, 200,000 AIC, preferred. Bussman KTK-R, JJN or JJS or equivalent.

(3)Thermomagnetic type breakers preferred.

15

Installation

Observe the following when using Ground Fault Circuit Interrupters (GFCIs):

•Installation of GFCI only between supplying mains and controller.

•The GFCI can be activated by:

-capacitive leakage currents between the cable screens during operation (especially with long, screened motor cables)

-connecting several controllers to the mains at the same time

-RFI filters

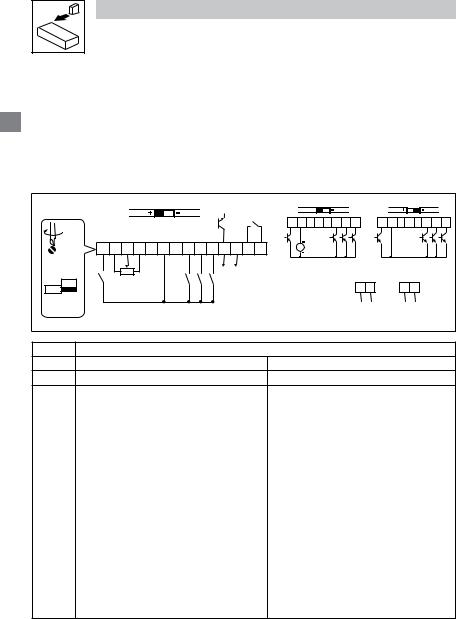

3.2.3Control terminals

Control Terminal Strip for 0.33-10HP (0.25-7.5 kW): |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

ALsw |

COM |

|

|

|

ALsw |

|

|

ALsw |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COM |

|

+10 V |

|

|

|

1 |

2 |

4 |

13A 13B 13C |

1 |

2 |

4 |

13A 13B 13C |

|

|

|

AIN |

AIN |

|

|

|

|

+15V |

|

|

COM |

|

|||

4.5 lb-in |

|

|

|

|

|

PNP |

|

|

|

NPN |

|

|||||

1 |

2 |

5 |

6 |

25 4 11 13A13B13C 14 30 16 |

17 |

|

|

|

|

|

||||||

(0.5 Nm) |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

+12 VDC - 0 % |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

… |

|

|

|

|

|

0.25 in (6 mm) |

|

2k … 10k |

|

DIGOUT |

AOUT |

+30 VDC + 0 % |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

2 |

5 |

2 |

25 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||||||

AWG 26…16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

0 … 10 V |

4 … 20 mA |

|||||

(<1mm²) |

|

|

|