Leeson DC Motors Catalog Page

<![endif]>Terms / Warnings Tech Information X-Ref / Index Options Accessories / Kits AC / DC Controls Gearmotors DC Motors IEC Motors

<![endif]>Mods / Factory

DC Motors

•NEMA DC, explosion proof, SUB-FHP, washdown, IEC and low voltage motors available

•Permanent magnet designs

•PWM or SCR rated and low voltage input voltage designs

•Removable bolt-on base

•Oversized brushes for long brush life

•Easy access to brushes

•Constant torque throughout speed range

•DC Controls available to change the speed of the motors

Applications:

DC motors are typically used is applications requiring motor speed adjustment, constant torque throughout the speed range and reversing capabilities. Applications would include: pumps, conveyors, turntables, textile machinery, treadmills, reeling equipment, sports equipment and medical equipment.

292

DC Motors

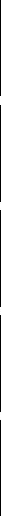

Mechanical/ Electrical Features:

•Brush holder design provides easy access to brushes

•Large oversized brushes assure long brush life

•Removable bolt-on base

•NEMA C face designs

•115 or 230 volt input power ratings –

90 / 180 volt output

•Capable of dynamic braking

•PWM or SCR type controller rated

•High starting torque

•Permanently lubricated sealed bearings

•LEESON SCR controls available to power motors

•High starting torque

•Higher HP and speed achievable using PWM type DC controls

•UL and CSA Listed

•Meets NEMA MG1 standards

•Dynamically balanced armatures

•30:1 constant torque operation

<![endif]>Factory / Mods

<![if ! IE]><![endif]>Warnings / Terms Information Tech Index / Ref-X Options Kits / Accessories Controls DC / AC Gearmotors Motors DC Motors IEC

293

<![endif]>Terms / Warnings Tech Information X-Ref / Index Options Accessories / Kits AC / DC Controls Gearmotors DC Motors IEC Motors

<![endif]>Mods / Factory

DC Motors

NEMA Frame - SCR Rated

TEFC - SCR Rated 90 & 180 Volts

NEMA 56C - C Face With Removable Base

|

Full |

|

|

<![if ! IE]> <![endif]>Stock |

|

|

|

|

App. |

Arm. |

Control |

F. L. |

"C" |

|

|

Load |

NEMA |

Catalog |

|

|

|

|

Wgt. |

Volts |

Volts AC |

Amps |

Dim. |

|

|

HP |

RPM |

Frame |

Number |

|

|

|

|

Model Number |

(lbs) |

DC |

Input |

DC |

(Inches) |

YNotes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/4 |

1750 |

SS56C |

098002.00 |

√ |

42D17FK2 |

19 |

90 |

115 |

2.5 |

10.81 |

S, US |

|||

|

1750 |

SS56C |

098003.00 |

√ |

|

|

42D17FK3 |

22 |

180 |

230 |

1.4 |

11.31 |

S, US |

|

1/3 |

1750 |

SS56C |

098004.00 |

√ |

|

|

42D17FK4 |

23 |

90 |

115 |

3.5 |

11.31 |

S, US |

|

|

1750 |

SS56C |

098005.00 |

√ |

|

|

42D17FK5 |

23 |

180 |

230 |

1.7 |

11.31 |

S, US |

|

|

1140 |

S56C |

109098.00 |

C/A |

|

|

4D11FK5 |

32 |

90 |

115 |

3.5 |

12.81 |

S, US |

|

1/2 |

2500 |

SS56C |

098006.00 |

√ |

|

|

42D28FK1 |

22 |

90 |

115 |

5.0 |

10.81 |

S, US |

|

|

2500 |

SS56C |

098007.00 |

√ |

|

|

42D28FK2 |

22 |

180 |

230 |

2.5 |

10.81 |

S, US |

|

|

1750 |

SS56C |

098000.00 |

√ |

|

|

42D17FK1 |

26 |

90 |

115 |

5.0 |

11.81 |

S, US |

|

|

1750 |

S56C |

108014.00 |

√ |

|

|

4D17FK1 |

29 |

90 |

115 |

5.0 |

12.82 |

S, US |

|

|

1750 |

SS56C |

098008.00 |

√ |

|

|

42D17FK6 |

25 |

180 |

230 |

2.5 |

11.81 |

S, US |

|

|

1750 |

S56C |

108015.00 |

√ |

|

|

4D17FK2 |

30 |

180 |

230 |

2.5 |

12.82 |

S, US |

|

|

1140 |

S56C |

109099.00 |

√ |

|

|

4D11FK6 |

40 |

90 |

115 |

5.0 |

14.32 |

S, US |

|

3/4 |

2500 |

SS56C |

098009.00 |

√ |

|

|

42D28FK3 |

26 |

90 |

115 |

7.6 |

11.81 |

S, US |

|

|

2500 |

S56C |

108016.00 |

√ |

|

|

4D28FK3 |

29 |

90 |

115 |

7.6 |

12.82 |

S, US |

|

|

2500 |

SS56C |

098010.00 |

√ |

|

|

42D28FK4 |

25 |

180 |

230 |

3.8 |

11.81 |

S, US |

|

|

2500 |

S56C |

108017.00 |

√ |

|

|

4D28FK4 |

29 |

180 |

230 |

3.8 |

12.82 |

S, US |

|

|

1750 |

SS56C |

098032.00 |

√ |

|

|

42D17FK7 |

36 |

90 |

115 |

7.6 |

13.81 |

S, US |

|

|

1750 |

S56C |

108018.00 |

√ |

|

|

4D17FK3 |

38 |

90 |

115 |

7.6 |

13.82 |

S, US |

|

|

1750 |

SS56C |

098069.00 |

√ |

|

|

42D17FK11 |

36 |

180 |

230 |

3.8 |

13.81 |

S, US |

|

|

1750 |

S56C |

108019.00 |

√ |

|

|

4D17FK4 |

35 |

180 |

230 |

3.8 |

13.82 |

S, US |

|

|

1140 |

S56C |

109100.00 |

√ |

|

|

4D11FK7 |

49 |

90 |

115 |

7.5 |

15.82 |

S, US |

|

1 |

2500 |

S56C |

108020.00 |

√ |

|

|

4D28FK5 |

34 |

90 |

115 |

10.0 |

13.32 |

S, US |

|

|

2500 |

S56C |

108021.00 |

√ |

|

|

4D28FK6 |

38 |

180 |

230 |

5.0 |

13.82 |

S, US |

|

|

1750 |

S56C |

108022.00 |

√ |

|

|

4D17FK5 |

47 |

90 |

115 |

10.0 |

14.82 |

S, US |

|

|

1750 |

S56C |

108023.00 |

√ |

|

|

4D17FK6 |

39 |

180 |

230 |

5.0 |

14.81 |

S, US |

|

|

1140 |

145TC |

128023.00 |

C/A |

|

|

C145D11FK1 |

82 |

90 |

115 |

11.0 |

18.84 |

S, US |

|

11⁄2 |

2500 |

S56C |

108265.00 |

√ |

|

|

4D28FK11 |

43 |

180 |

230 |

7.5 |

15.32 |

S, US |

|

|

1750 |

S56C |

108092.00 |

√ |

|

|

4D17FK10 |

53 |

180 |

230 |

7.6 |

16.82 |

S, US |

|

|

1750 |

S56/145TC |

108262.00 |

√ |

|

|

4D17FK19 |

54 |

180 |

230 |

7.6 |

17.39 |

S, US, 8 |

|

|

1750 |

145TC |

128000.00 |

√ |

|

|

C145D17FK2 |

70 |

180 |

230 |

7.5 |

18.34 |

S, US |

|

2 |

2500 |

S56/145TC |

108266.00 |

√ |

|

|

4D28FK12 |

51 |

180 |

230 |

8.6 |

17.89 |

S, US, 8 |

|

|

1750 |

145TC |

128010.00 |

√ |

|

|

C145D17FK3 |

83 |

180 |

230 |

9.5 |

19.34 |

S, US |

|

|

1750 |

182/145TC |

128001.00 |

√ |

|

|

C182D17FK3 |

84 |

180 |

230 |

9.5 |

19.34 |

S, US, 61 |

|

3 |

1750 |

182/145TC |

108502.00 |

√ |

|

|

182D17FK2 |

88 |

180 |

230 |

14.0 |

21.75 |

S, US, 61 |

|

If base is removed, do not reinstall bolts without using washers to |

Y Note listing on inside back flap |

compensate for thickness of base. |

|

C/A - Check Availability |

|

Specifications are subject to change without notice |

|

294

DC Motors

NEMA Frame - SCR Rated

TEFC - SCR Rated 90 & 180 Volts

NEMA 56C - C Face Less Base*

|

Full |

|

|

<![if ! IE]> <![endif]>Stock |

|

|

|

App. |

Arm. |

Control |

F. L. |

"C" |

|

|

Load |

|

Catalog |

|

|

|

Wgt. |

Volts |

Volts AC |

Amps |

Dim. |

|

|

HP |

RPM |

NEMA Frame |

Number |

|

|

Model Number |

(lbs) |

DC |

Input |

DC |

(Inches) |

YNotes |

|

1/4 |

1750 |

SS56C |

098377.00 |

√ |

|

|

42D17FC29 |

19 |

90 |

115 |

2.5 |

10.81 |

S, US |

1/3 |

1750 |

SS56C |

098378.00 |

√ |

|

42D17FC30 |

23 |

90 |

115 |

3.5 |

11.31 |

S, US |

|

1/2 |

1750 |

SS56C |

098379.00 |

√ |

|

42D17FC31 |

29 |

90 |

115 |

5.0 |

11.81 |

S, US |

|

3/4 |

1750 |

SS56C |

098380.00 |

√ |

|

42D17FC32 |

38 |

90 |

115 |

7.6 |

13.81 |

S, US |

|

1 |

1750 |

S56C |

109096.00 |

√ |

|

4D17FC42 |

47 |

90 |

115 |

10.0 |

14.82 |

S, US |

|

|

1750 |

S56C |

109097.00 |

√ |

|

4D17FC43 |

39 |

180 |

230 |

5.0 |

14.82 |

S, US |

|

No tapped holes provided for attaching a bolt-on base. |

Y Note listing on inside back flap |

|

|

Specifications are subject to change without notice |

|

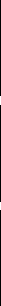

All necessary parts to mount listed tachometers to stock TEFC SCR motors. Consists of machined cast fan cover, coupling and hardware. Does not include tachometer. Tach adapter kit is not suitable for catalog number 108502.00.

Tachometer Mounting Kits For DC Motors

|

|

|

|

|

App. |

Tachometer |

NEMA |

IEC |

Catalog |

Wgt. |

|

Type |

Frame |

Frame |

Number |

(lbs) |

|

GE 5PY Series |

SS56 |

71 |

175156.00 |

|

5 |

|

56/145 |

— |

175158.00 |

|

5 |

Servo-tek |

SS56 |

71 |

175157.00 |

|

8 |

SA740 Series |

56/145 |

— |

175159.00 |

|

8 |

No Kit available for S56C motors

Specifications are subject to change without notice |

|

Motors with S56C or SS56C frame sizes may be |

DC motors in NEMA S56C frame may be |

converted to 42/48 C face using the following: |

converted to 48 base using the following: |

Modification Kits

Frame Catalog Number

SS56C 175182.00

S56C 175082.00* 175802.00*†

*Addition of base kit will result in non-NEMA BA dimension of 2 3/4”. Addition of C face kit will result in conduit box located at 1 o’clock facing lead end.

†For S56 frame endshield mounted brush cover motors

Specifications are subject to change without notice

Frame Catalog Number

S56C 175080.00*

*Additon of base kit will result in nonNEMA BA dimension of 2 3/4. Addition of C face kit will result in conduit box located at 1 o’clock facing lead end

†For S56 frame endshield mounted brush cover motors

Specifications are subject to change without notice

<![endif]>Factory / Mods

<![if ! IE]><![endif]>Warnings / Terms Information Tech Index / Ref-X Options Kits / Accessories Controls DC / AC Gearmotors Motors DC Motors IEC

295

<![endif]>Terms / Warnings Tech Information X-Ref / Index Options Accessories / Kits AC / DC Controls Gearmotors DC Motors IEC Motors

<![endif]>Mods / Factory

DC Motors

Explosion-Proof - SCR Rated

Application Notes:

These motors must be applied in accordance with the National Electrical Code, Article #500. For a listing of explosive agents, consult NFPA Publication 497M.

General Specifications:

•Approved for application in hazardous environments where certain explosive gases or materials are present

Features:

•Rugged mechanical construction

•Meets all safety requirements

•UL and CSA listed

•Leads exit thru 3/4”-14NPT Pipe nipple at top of frame opposite shaft end

•Conduit box optional - see below

•Pilot duty thermostats -standard (connect to SCR control)

•Thermostats rated for continuous duty with full wave SCR(thyristor) controls.

•Double shielded, pre lubricated ball bearings - standard

•Easy brush access for field service

Explosion-Proof - Class I, Groups C & D – Class II, Groups F & G 90 & 180 Volt - TEFC - C Face With Removable Base

|

Full |

|

|

<![if ! IE]> <![endif]>Stock |

|

|

|

App. |

Arm. |

Control |

F. L. |

"C" |

|

|

|

Load |

NEMA |

Catalog |

|

|

Wgt. |

Volts |

Volts AC |

Amps |

Dim. |

|

|

||

HP |

RPM |

Frame |

Number |

|

|

|

Model Number |

(lbs) |

DC |

Input |

DC |

(Inches) |

YNotes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/3 |

1750 |

S56C |

118015.00 |

√ |

|

|

C6D17EK1 |

27 |

90 |

115 |

3.5 |

13.41 |

S, US |

|

1/2 |

1750 |

S56C |

118016.00 |

√ |

C6D17EK2 |

30 |

90 |

115 |

4.7 |

14.41 |

S, US |

|||

|

1750 |

S56C |

118017.00 |

√ |

C6D17EK3 |

32 |

180 |

230 |

2.5 |

14.41 |

S, US |

|||

3/4 |

1750 |

S56C |

118018.00 |

√ |

C6D17EK4 |

40 |

90 |

115 |

7.1 |

16.41 |

S, US |

|||

|

1750 |

S56C |

118019.00 |

√ |

|

C6D17EK5 |

36 |

180 |

230 |

3.3 |

16.41 |

S, US |

|

|

Specifications are subject to change without notice |

|

|

|

|

Y Note listing on inside back flap |

|||||||||

UL and CSA listed for Class I, Group C & D, and Class II, Groups F & G locations. Has grounding screw and all hardware provided. Mounts to motor by 3/4”-14NPT opening at rear of box. For NEMA 56 frame motors only.

Explosion-Proof Conduit Box

Catalog |

|

|

Number |

|

App. Wgt. (lbs) |

|

|

|

175026.00 |

|

2 |

Specifications are subject to change without notice

296

DC Motors

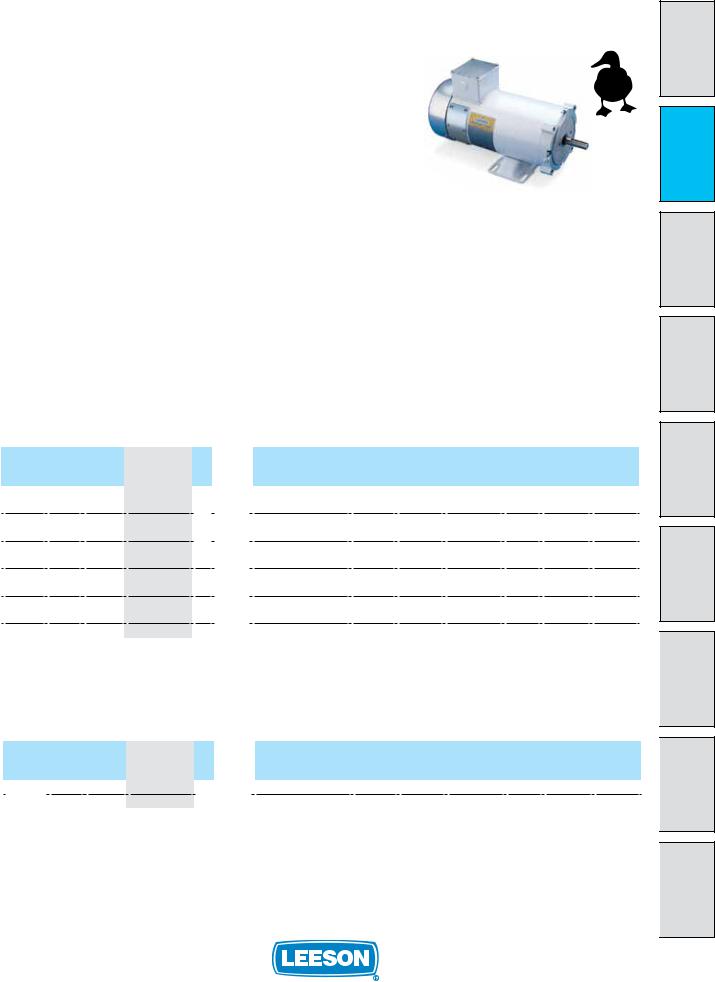

Nema Frame - Washguard® Duty - 90 & 180 Volts

General Specifications:

•Extended life in wet, high humid applications

•Design repels water from entering motor

•Internal components protected against rust and corrosion

•Frame, base, endshields, armature and interior components protected by enamel and polyester compounds of outstanding adhesion and resistance to moisture, acids, alkalies and oil

Features: |

• 304 stainless steel conduit box cover and fan |

|

• 303 Stainless steel shaft resists corrosion |

||

cover |

||

• Lubricated spring loaded contact seals prevent |

||

• Re-positionable drain plugs for use in |

||

moisture from entering the motor |

||

multiple mounting positions |

||

• Patented “V” ring forsheda seal deflects water |

||

• Nylon seals at bolt heads for superior sealing |

||

• Double sealed, Oversize bearings with high temp lubricant |

||

• Machined fits throughout |

||

• Exterior and interior components protected against |

• Stainless steel data plate |

moisture,acids, alkalies and oil |

• Chemically inert, static free fan with positive |

|

• Cast conduit box for superior sealing includes: |

||

mounting insures it wont move |

||

- Threaded entrance |

||

• Stainless steel fan guard |

||

- Drain holes |

||

• USDA Approved white epoxy finish |

||

- Nitrile gaskets |

||

|

90 & 180 Volts - Totally Enclosed - C Face With Removable Base

|

Full |

|

|

<![if ! IE]> <![endif]>Stock |

|

|

|

|

|

|

Control |

F. L. |

"C" |

|

|

Load |

NEMA |

Catalog |

|

|

|

|

App. |

Arm. |

Volts AC |

Amps |

Dim. |

|

|

HP |

RPM |

Frame |

Number |

|

|

|

|

Model Number |

Wgt. (lbs) |

Volts DC |

Input |

DC |

(Inches) |

YNotes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/4 |

1750 |

S56C |

108423.00 |

√ |

C4D17VK9 |

23 |

90 |

115 |

2.7 |

10.69 |

S, US |

|||

|

1750 |

S56C |

098375.00 |

CA |

|

|

C42D17VK1 |

21 |

180 |

230 |

1.4 |

10.22 |

S, US |

|

1/3 |

1750 |

S56C |

108424.00 |

√ |

|

|

C4D17VK10 |

26 |

90 |

115 |

3.5 |

11.69 |

S, US |

|

|

1750 |

S56C |

098376.00 |

C/A |

|

|

C42D17VK2 |

22 |

180 |

230 |

1.7 |

10.22 |

S, US |

|

1/2 |

1750 |

S56C |

108226.00 |

√ |

|

|

C4D17VK1 |

38 |

90 |

115 |

4.9 |

13.69 |

S, US |

|

|

1750 |

S56C |

108227.00 |

√ |

|

|

C4D17VK2 |

43 |

180 |

230 |

2.4 |

13.69 |

S, US |

|

3/4 |

1750 |

S56C |

108228.00 |

√ |

|

|

C4D17VK3 |

53 |

90 |

115 |

7.0 |

15.69 |

S, US |

|

|

1750 |

S56C |

108229.00 |

√ |

|

|

C4D17VK4 |

50 |

180 |

230 |

3.5 |

15.69 |

S, US |

|

1 |

1750 |

S56C |

108230.00 |

√ |

|

|

C4D17WK1 |

45 |

90 |

115 |

10.0 |

15.81 |

S, US |

|

|

1750 |

S56C |

108231.00 |

√ |

|

|

C4D17WK2 |

42 |

180 |

230 |

5.0 |

14.81 |

S, US |

|

1 1⁄2 |

1750 |

S56C |

108232.00 |

√ |

|

|

C4D17WK3 |

50 |

180 |

230 |

7.6 |

15.81 |

S, US |

|

C/A - Check Availability |

Y Note listing on inside back flap |

|

|

Specifications are subject to change without notice |

|

Washguard® - IEC Frame - TENV IP55

180 Volts - TENV - B5 Flange With Removable Base

|

Full |

|

|

<![if ! IE]> <![endif]>Stock |

|

|

|

|

|

|

Control |

F. L. |

"C" |

|

|

Load |

NEMA |

Catalog |

|

|

|

App. |

|

Arm. |

Volts AC |

Amps |

Dim. |

|

|

HP/kW |

RPM |

Frame |

Number |

|

|

|

Model Number |

Wgt. (lbs) |

Volts DC |

Input |

DC |

(Inches) |

YNotes |

|

1/2 - .37 |

1750 |

71 |

098040.00 |

C/A |

|

|

42D17VD1 |

22 |

|

180 |

230 |

2.5 |

10.69 |

S, US |

3/4 - .55 |

1750 |

80 |

108407.00 |

C/A |

|

4D17VD1 |

52 |

|

180 |

230 |

3.5 |

16.02 |

S, US |

|

If base is removed, do not reinstall bolts without using washers to compensate for the |

Y Note listing on inside back flap |

|||||||||||||

thickness of base. These WASHGUARD motors are modular design but stocked with B5 |

|

|

|

|

||||||||||

flange and B3 foot. The foot is removable. The B5 flange can be replaced with a B14 |

|

|

|

|

|

|||||||||

face or other diameter B5 flanges noted on page 306. |

|

|

|

|

|

|

|

|||||||

Specifications are subject to change without notice

<![endif]>Factory / Mods

<![if ! IE]><![endif]>Warnings / Terms Information Tech Index / Ref-X Options Kits / Accessories Controls DC / AC Gearmotors Motors DC Motors IEC

297

Loading...

Loading...