LEESON Micro Series Compact Inverters User Manual

SPEEDMASTER®

Series Compact

Installation

Operation Manual

A Regal Brand

TABLE OF CONTENTS |

|

|

1.0 |

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

PRODUCT CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . |

|

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

RECEIVING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . |

|

CUSTOMER MODIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 4 |

2.0 |

MICRO SERIES SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

4.0 |

MICRO SERIES DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

5.0 |

MICRO SERIES RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

6.0 |

THEORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

DESCRIPTION OF AC MOTOR OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

DRIVE FUNCTION DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

7.0 |

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

8.0 |

INPUT AC REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

9.0 |

VOLTAGE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 2 |

10.0 |

POWER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

11.0 |

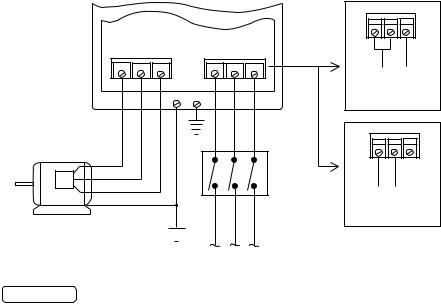

MICRO SERIES POWER WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 26 |

12.0 |

INITIAL POWER UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

13.0 |

KEYPAD CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

KEYPAD FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . |

|

MICRO SERIES DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

14.0 |

CONTROL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

START/STOP AND SPEED CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . |

15.0 |

MICRO SERIES CONTROL WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

MICRO SERIES TERMINAL STRIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

TWO-WIRE START/STOP CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

41 |

|

THREE-WIRE START/STOP CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

|

SPEED POT AND PRESET SPEED CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

16.0 |

PROGRAMMING THE MICRO SERIES DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

|

PROGRAMMING THE PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

|

PARAMETER ACCESS USING SPEED DIAL . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 46 |

17.0 |

PARAMETER MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

18.0 |

DESCRIPTION OF PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

1

TABLE OF CONTENTS (cont’d.)

19.0MICRO SERIES PID SET POINT CONTROL . . . . . . . . . . . . . . 77

FEEDBACK DEVICES .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

77 |

THE SYSTEM - DIRECT AND REVERSE ACTING . . . . . . . . . . . . . . . . . . . . . . . . |

78 |

PID CONTROL - DIRECT AND REVERSE ACTING .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

78 |

SET POINT REFERENCE SOURCES . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . |

TUNING THE PID CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

79 |

MICRO SERIES DISPLAY IN PID MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

80 |

20.0TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . 81

21.0 |

USER SETTING RECORD . . . . . . . . . . . . . . . . . . . . . . 83 |

NOTE!

The manual covers software version M108314 and above.

See parameter 63 for the software version of the drive you are working with.

If you are working with an earlier software release, you will not have all of the functionality described in this manual, but the functionality of the drive is fulled documented in this manual.

If you are working with M108313 or earlier, parameters 69 and 70 are described in this manual as parameters 98 and 99.

2

IMPORTANT NOTICE

The following  DANGER ,

DANGER ,  WARNING and

WARNING and  CAUTION information is supplied to you for your protection and to provide you with many years of trouble free and safe operation of your LEESON Electric product..

CAUTION information is supplied to you for your protection and to provide you with many years of trouble free and safe operation of your LEESON Electric product..

DANGER

DANGER

WARNING

WARNING

CAUTION

CAUTION

• Hazard of electrical shock! Capacitors retain charge after power is removed. Disconnect incoming power and wait until the voltage between terminals B+ and B- is 0 VDC before servicing the drive..

• Hazard of electrical shock! Wait three minutes after disconnecting incoming power before servicing drive.. Capacitors retain charge after power is removed..

• Automatic starting of equipment may cause damage to equipment and / or injury to personnel! Automatic start should only be used on equipment that is inaccessible to personnel.

• DRIVES MUST NOT BE INSTALLED WHERE SUBJECTED TO ADVERSE

ENVIRONMENTAL CONDITIONS SUCH AS: COMBUSTIBLE, OILY, OR HAZARDOUS VAPORS OR DUST; EXCESSIVE MOISTURE OR DIRT; VIBRATION; EXCESSIVE AMBIENT TEMPERATURES. . CONSULT LEESON ELECTRIC FOR MORE INFORMATION ON THE SUITABILITY OF A DRIVE TO A PARTICULAR ENVIRONMENT..

•Severe damage to the drive can result if it is operated after a long period of storage or inactivity without reforming the DC bus capacitors!

•Do not connect incoming AC power to output terminals T1, T2, or T3. Severe damage to the drive will result..

•When operating in JOG mode, the STOP key WILL NOT stop the drive.. To stop the drive, the contact between TB-13B and TB-2 must be opened..

•Do not continuously cycle input power to the drive more than once every two minutes. Damage to the drive will result..

•The availability of controllers is restricted according to EN 61800-3. These products can cause radio interference in residential areas.. In this case, special measures can be necessary..

•Consult qualified personnel with questions. All electrical repairs must be performed by trained and qualified personnel only.

Resale of Goods:

In the event of the resale of any of the goods, in whatever form, Resellers/Buyers will include the following language in a conspicuous place and in a conspicuous manner in a written agreement covering such sale:

The manufacturer makes no warranty or representations, express or implied, by operation of law or otherwise, as the merchantability or fitness for a particular purpose of the goods sold hereunder. Buyer acknowledges that it alone has determined that the goods purchased hereunder will suitably meet the requirements of their intended use. In no event will the manufacturer be liable for consequential, incidental or other damages.

Even if the repair or replacement remedy shall be deemed to have failed of its essential purpose under Section

2-719 of the Uniform Commercial Code, the manufacturer shall have no liability to Buyer for consequential damages..

Resellers/Buyers agree to also include this entire document including the warnings and cautions above in a conspicuous place and in a conspicuous manner in writing to instruct users on the safe usage of the product..

3

1.0GENERAL

1.1This manual covers the LEESON MICRO Series Inverters..

1.2PRODUCT CHANGES

LEESON Electric reserves the right to discontinue or make modifications to the design of its products without prior notice, and holds no obligation to make modifications to products sold previously. LEESON Electric also holds no liability for losses of any kind which may result from this action.

1.3WARRANTY

LEESON Electric warrants the SPEEDMASTER MICRO Series AC motor control to be free of defects in material and workmanship for a period of twelve months from the date of sale to the user, or two years from the date of manufacture, which ever occurs first. . Any control component, which under normal use, becomes defective, within the stated warranty time period shall be returned to LEESON Electric, freight prepaid, for examination. Contact Leeson’s Warranty Dept. for a return authorization number and shipping instructions. LEESON Electric reserves the right to make the final determination as to the validity of a warranty claim, and sole obligation is to repair or replace only components which have been rendered defective due to faulty material or workmanship. No warranty claim will be accepted for components which have been damaged due to mishandling, improper installation, unauthorized repair and/or alteration of the product, operation in excess of design specifications or other misuse, or improper maintenance. LEESON Electric makes no warranty that its products are compatible with any other equipment, or to any specific application, to which they may be applied and shall not be held liable for any other consequential damage or injury arising from the use of its products.

This warranty is in lieu of all other warranties, expressed or implied. No other person, firm or corporation is authorized to assume, for LEESON Electric, any other liability in connection with the demonstration or sale of its products.

NOTE 1: LEESON will match mode of transportation if drive is repaired under warranty. . Customer will be invoiced for shipping if no problem is found, if the repair is non-warranty, or if the return mode is different..

NOTE 2: There is a minimum inspection fee of $100..00 if no problem is found.. There is an additional charge of 25% for Rush Service..

1.4RECEIVING

Inspect all cartons for damage which may have occurred during shipping. Carefully unpack equipment and inspect thoroughly for damage or shortage.. Report any damage to carrier and/or shortages to supplier.. All major components and connections should be examined for damage and tightness, with special attention given to PC boards, plugs, knobs and switches.

1.5CUSTOMER MODIFICATION

LEESON Electric, its sales representatives and distributors, welcome the opportunity to assist our customers in applying our product. . LEESON Electric cannot assume responsibility for any modifications not authorized by its engineering department.

4

2.0MICRO SERIES SPECIFICATIONS

Storage Temperature

Ambient Operating Temperature

(With 2.5 and 8 kHZ carrier, derate for higher carriers)

Ambient Humidity

Maximum Altitude

Input Line Voltages

Input Voltage Tolerance

Input Frequency Tolerance

Output Wave Form

Output Frequency

Carrier Frequency

Frequency Stability

Service Factor

Efficiency

Power Factor (Displacement)

Overload Current Capacity

Speed Reference Follower

Control Voltage

Analog Outputs

Digital Outputs

-20° to 70° C |

|

Chassis |

-10° to 55° C |

Type 1 (IP 31) |

-10° to 50° C |

Type 4 (IP 65) |

-10° to 40° C |

Type 12 (IP 54) |

-10° to 40° C |

Less than 95%

(non-condensing)

3300 feet (1000 meters) above sea level

240/120 Vac, 240/200 Vac,

480/400 Vac, and 590/480 Vac

+10%, -15%

48 to 62 Hz

Sine Coded PWM

0-120 Hz, Optional up to 1000 Hz

2.5 kHz to 14 kHz

+/-0.00006%/ C

1..00

>97% throughout speed range

>0.96

150% of drive output rating for one minute

180% of drive output rating for 30 seconds

0-10 VDC, or 4-20 mA

15 VDC

0 - 10 VDC, or 2 - 10 VDC Proportional to speed or load

Form C relay: 2 A at 28 VDC or 120 Vac

Open-collector outputs: 40 mA at 30 VDC

5

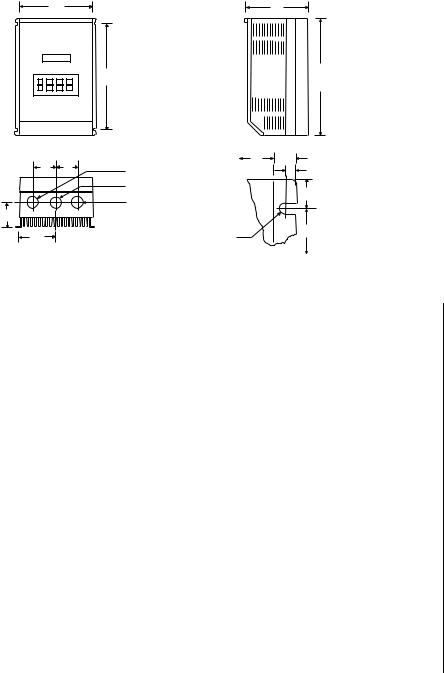

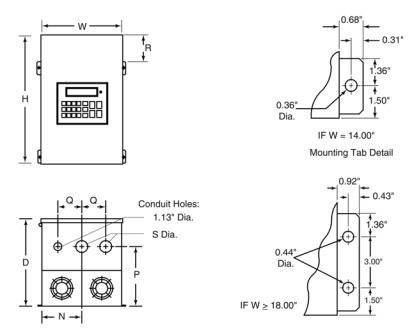

4.0MICRO SERIES DIMENSIONS

4.1TYPE 1 ENCLOSED

W D

R H

Q Q |

Conduit Holes: |

W |

U |

IF W ≤ 7.86" |

S Dia. |

|

V |

||

|

0.88" Dia. |

|

|

T = 0.20" |

|

|

1.00" |

U = 0.34" |

|

|

S Dia. |

|

||

P |

|

|

V = 0.19" |

|

|

|

|

IF W ≥ 10.26" |

|

|

|

|

R |

|

N |

|

T |

T = 0.28" |

|

|

|

|||

|

|

Dia. Slot |

|

U = 0.44" |

|

|

Mounting Tab Detail |

V = 0.24" |

|

|

|

|

||

HP |

INPUT |

CATALOG |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(kW) |

VOLTAGE |

NUMBER |

H |

|

W |

D |

|

N |

P |

Q |

|

R |

|

S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0. .25 |

240/120 |

174930 |

7. |

.50 |

4. |

.70 |

3. |

.33 |

2. |

.35 |

1. |

.60 |

|

1. |

.37 |

5 |

|

(0.18) |

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0. .5 240/120 |

174997 |

7. |

.50 |

6. |

.12 |

3. |

.63 |

3. |

.77 |

1. |

.80 |

|

1. |

.37 |

5 |

||

(0.37) |

240/200 |

174914 |

7.50 |

|

4.70 |

3.63 |

|

2.35 |

1.90 |

1.37 |

|

5.50 |

|

0.88 |

|

|

|

1 |

240/120 |

174931 |

7. |

.50 |

6. |

.12 |

4. |

.22 |

3. |

.77 |

2. |

.40 |

|

1. |

.37 |

5 |

|

(0.75) |

240/200 |

174915 |

7.50 |

|

4.70 |

4.33 |

|

2.35 |

2.60 |

1.37 |

|

5.50 |

|

0.88 |

|

|

|

|

480/400 |

174920 |

7. |

.50 |

4. |

.70 |

3. |

.63 |

2. |

.35 |

1. |

.90 |

|

1. |

.37 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

174925 |

7. |

.50 |

4. |

.70 |

3. |

.63 |

2. |

.35 |

1. |

.90 |

|

1. |

.37 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. .5 240/120 |

174932 |

7. |

.50 |

6. |

.12 |

4. |

.22 |

3. |

.77 |

2. |

.40 |

|

1. |

.37 |

5 |

||

(1.1) |

240/200 |

174916 |

7.50 |

|

4.70 |

4.33 |

|

2.35 |

2.60 |

1.37 |

|

5.50 |

|

0.88 |

|

|

|

2 |

240 |

174933 |

7. |

.50 |

6. |

.12 |

5. |

.12 |

3. |

.77 |

3. |

.30 |

|

1. |

.37 |

5 |

|

(1.5) |

240/200 |

174917 |

7.50 |

|

6.12 |

5.12 |

|

3.77 |

3.30 |

1.37 |

|

5.50 |

|

0.88 |

|

|

|

|

480/400 |

174921 |

7. |

.50 |

6. |

.12 |

4. |

.22 |

3. |

.77 |

2. |

.40 |

|

1. |

.37 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

174926 |

7. |

.50 |

6. |

.12 |

4. |

.22 |

3. |

.77 |

2. |

.40 |

|

1. |

.37 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

240 |

174934 |

7. |

.50 |

6. |

.12 |

5. |

.12 |

3. |

.77 |

3. |

.30 |

|

1. |

.37 |

5 |

|

(2.2) |

240/200 |

174918 |

7.50 |

|

6.12 |

5.12 |

|

3.77 |

3.30 |

1.37 |

|

5.50 |

|

0.88 |

|

|

|

|

480/400 |

174922 |

7. |

.50 |

6. |

.12 |

5. |

.12 |

3. |

.77 |

3. |

.30 |

|

1. |

.37 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

174927 |

7. |

.50 |

6. |

.12 |

5. |

.12 |

3. |

.77 |

3. |

.30 |

|

1. |

.37 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

240/200 |

174919 |

7. |

.88 |

7. |

.86 |

5. |

.94 |

5. |

.13 |

3. |

.95 |

|

1. |

.50 |

5 |

|

(4) |

480/400 |

174923 |

7.50 |

|

6.12 |

5.12 |

|

3.77 |

3.30 |

1.37 |

|

5.50 |

|

0.88 |

|

|

|

|

590 |

174928 |

7. |

.50 |

6. |

.12 |

5. |

.12 |

3. |

.77 |

3. |

5.30 |

.5 |

01.. |

.88.37 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6

W D

R H

|

|

Conduit Holes: |

W |

U |

IF W ʺ 7.86" |

Q |

Q |

|

V |

||

S Dia. |

|

||||

|

|

|

|

T = 0.20" |

|

|

|

0.88" Dia. |

|

1.00" |

U = 0.34" |

|

|

S Dia. |

|

|

V = 0.19" |

P |

|

|

|

R |

IF W ʺ 10.26" |

|

|

|

T |

T = 0.28" |

|

|

|

|

|

||

N |

|

|

Dia. Slot |

|

U = 0.44" |

|

|

Mounting Tab Detail |

V = 0.24" |

||

|

|

|

|||

|

|

|

|

||

HP |

INPUT |

CATALOG |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(kW) |

VOLTAGE |

NUMBER |

H |

|

W |

D |

N |

|

P |

|

Q |

|

R |

|

S |

|

|

|

7. .5 240/200 |

174545 |

7. |

.88 |

7. |

.86 |

5. |

.95 |

5. |

.13 |

3. |

.95 |

|

1. |

.80 |

5 |

|||

(5.5) |

480/400 |

174924 |

7.88 |

|

7.86 |

5.94 |

5.13 |

3.95 |

|

1.50 |

|

5.88 |

|

1.13 |

|

|

|

|

|

590 |

174929 |

7. |

.88 |

7. |

.86 |

5. |

.94 |

5. |

.13 |

3. |

.95 |

|

1. |

.50 |

5 |

||

10 |

240/200 |

174551 |

11. .257. .86 |

6. |

.84 |

3. |

.93 |

4. |

.19 |

2. |

.00 |

|

|

7. |

||||

(7.5) |

480/400 |

174552 |

9.38 |

|

7.86 |

6.84 |

3.93 |

4.19 |

|

2.00 |

|

5.88 |

|

1.13 |

|

|

|

|

|

590 |

174553 |

9. |

.38 |

7. |

.86 |

6. |

.84 |

3. |

.93 |

4. |

.19 |

|

2. |

.00 |

5 |

||

15 |

240/200 |

174557 |

12. .757. .86 |

6. |

.84 |

3. |

.93 |

4. |

.19 |

2. |

.00 |

|

|

9. |

||||

(11) |

480/400 |

174558 |

11.25 |

|

7.86 |

6.84 |

3.93 |

4.19 |

|

2.00 |

|

7.75 |

|

1.38 |

|

|

|

|

|

590 |

174559 |

12. .757. .86 |

6. |

.84 |

3. |

.93 |

4. |

.19 |

2. |

.00 |

|

|

9. |

||||

20 |

240/200 |

174560 |

12. .7510. .267. |

.74 |

5. |

.13 |

5. |

.00 |

2. |

|

.50 |

9. |

|

.25 |

||||

(15) |

480/400 |

174561 |

12.75 |

|

7.86 |

6.84 |

3.93 |

4.19 |

|

2.00 |

|

9.25 |

|

1.38 |

|

|

|

|

|

590 |

174562 |

12. .757. .86 |

7. |

.40 |

3. |

.93 |

4. |

.19 |

2. |

.00 |

|

|

9. |

||||

25 |

240/200 |

174569 |

15. .7510. .26 |

8. |

.35. .13 |

5. |

.00 |

2. |

.50 |

12. |

|

.25 |

1. |

|

.38 |

|||

(18.5) |

480/400 |

174563 |

12.75 |

|

10.26 |

7.74 |

5.13 |

5.00 |

|

2.50 |

|

9.25 |

|

1.38 |

|

|

|

|

|

590 |

174564 |

12. .7510. .267. |

.74 |

5. |

.13 |

5. |

.00 |

2. |

|

.50 |

9. |

|

.25 |

||||

30 |

240/200 |

174571 |

15. .7510. .26 |

8. |

.35. .13 |

5. |

.00 |

2. |

.50 |

12. |

|

.25 |

1. |

|

.38 |

|||

(22) |

480/400 |

174565 |

12.75 |

|

10.26 |

7.74 |

5.13 |

5.00 |

|

2.50 |

|

9.25 |

|

1.38 |

|

|

|

|

|

590 |

174598 |

15. .7510. .26 |

7. |

.745. |

.13 |

5. |

.00 |

2. |

.50 |

12. |

|

.25 |

1. |

|

.38 |

||

40 |

480/400 |

174567 |

12. .7510. .268. |

.35 |

5. |

.13 |

5. |

.00 |

2. |

|

.50 |

9. |

|

.25 |

||||

(30) |

590 |

174599 |

15.75 |

|

10.26 |

8.35 |

5.13 |

5.00 |

|

2.50 |

|

12.25 |

|

1.38 |

|

|

|

|

50 |

480/400 |

174593 |

19. .7510. .26 |

8. |

.55. .13 |

5. |

.75 |

2. |

.50 |

16. |

|

.25 |

1. |

|

.75 |

|||

(37) |

590 |

174594 |

19.75 |

|

10.26 |

8.55 |

5.13 |

5.75 |

|

2.50 |

|

16.25 |

|

1.75 |

|

|

|

|

60 |

480/400 |

174572 |

19. .7510. .26 |

8. |

.55. .13 |

5. |

.75 |

2. |

.50 |

16. |

|

.25 |

1. |

|

.75 |

|||

(45) |

590 |

174573 |

19.75 |

|

10.26 |

8.55 |

5.13 |

5.75 |

|

2.50 |

|

16.25 |

|

1.75 |

|

|

|

|

7

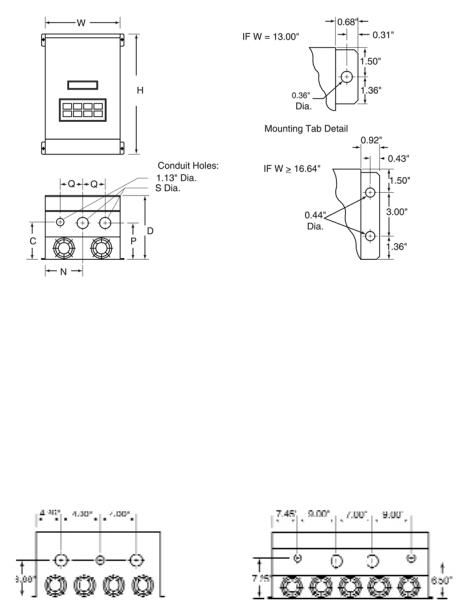

4.2TYPE 1 DIMENSIONS FOR MODELS RATED ABOVE 30 HP AT 240/200 Vac and 60 HP at 590/480/400 Vac

HP |

INPUT |

|

H |

|

W |

D |

|

N |

|

C |

P |

|

Q |

|

|

S |

|

|

(kW) |

VOLTAGE |

MODEL |

|

|

|

|

|

|

|

|

||||||||

40/30 |

240 / 200 |

174576 |

25. .0013. |

.0010. .505. |

.56 |

6. |

.50 |

6. |

|

.50 |

|

2. |

. |

62 |

||||

60/45 |

240 / 200 |

174578 |

47..00 |

16..64 |

11..85 |

|

|

See below |

|

|

|

|

|

|

||||

75/55 |

480 / 400 |

174580 |

29. .0016. |

.6411. |

.857. |

.14 |

6. |

.88 |

6. |

|

.88 |

|

3. |

. |

12 |

|||

100/75 |

480 / 400 |

174582 |

29. |

.00 |

24. |

.42 |

11. |

.85 |

117. . .12.25 |

6. |

.50 |

4. |

.50 |

2. |

|

.50 |

|

|

125/90 |

480 / 400 |

174584 |

29. |

.00 |

24. |

.42 |

11. |

.85 |

117. . .12.25 |

6. |

.50 |

4. |

.50 |

2. |

|

.50 |

|

|

150/110 |

480 / 400 |

174586 |

29..00 |

36..66 |

11..85 |

|

|

See below |

|

|

|

|

|

|

||||

CONDUIT HOLES FOR 174578 |

|

|

|

|

|

CONDUIT HOLES FOR 174586 |

|

|

|

|||||||||

Conduit Holes: Large holes = 1.75” |

Conduit Holes: Large holes = 3.00” |

Small holes = 1.13” |

Small holes = 1.13” |

8

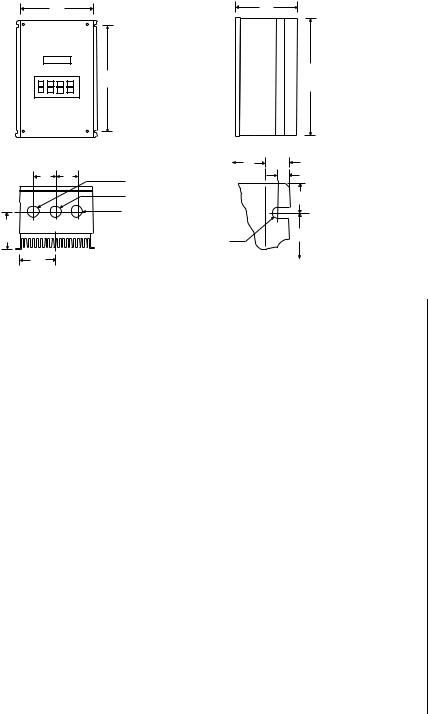

4.3WASHGUARD NEMA 4/12, 12, & 4X

W D

R H

|

|

|

Q |

Q |

Conduit Holes: |

|

|

W |

|

U |

|

IF W ʺ 7.86" |

|

|

|

|

|

||

|

|

|

S Dia. |

|

|

|

|

|

V |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

T = 0.20" |

|

|

|

|

|

||

|

|

|

|

|

0.88" Dia. |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

1.00" |

U = 0.34" |

|

|

|

|

|

||||

|

|

|

|

|

S Dia. |

|

|

|

|

|

|

|

V = 0.19" |

|

|

|

|

|

|

|

P |

|

|

|

|

|

|

|

|

|

R |

|

IF W ʺ 10.26" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

T = 0.28" |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

N |

|

|

|

Dia. Slot |

|

|

|

U = 0.44" |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Mounting Tab Detail |

|

V = 0.24" |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HP |

|

|

INPUT |

CATALOG |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(kW) |

|

VOLTAGE |

NUMBER |

H |

W |

|

D |

|

N |

P |

Q |

|

R |

S |

|

|

|

||

0. |

.25 |

240/120 |

174996 |

7. |

.88 |

6. |

.12 |

3. |

.63 |

3. |

.06 |

2. |

.00 |

1. |

.37 |

5 |

|||

(0.18) |

|

|

|

174519** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

0. |

|

.5 |

240/120 |

174998 |

7. |

.88 |

7. |

.86 |

3. |

.75 |

4. |

.80 |

2. |

.10 |

1. |

.37 |

5 |

||

(0.37) |

|

|

|

174520** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

240/200 |

174935 |

7. |

.88 |

6. |

.12 |

4. |

.35 |

3. |

.06 |

2. |

.70 |

1. |

.37 |

5 |

|||

|

|

|

|

|

174527** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

240/120 |

174999 |

7. |

.88 |

7. |

.86 |

3. |

.75 |

4. |

.80 |

3. |

.25 |

1. |

.37 |

5 |

|||

(0.75) |

|

|

|

174521** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

240/200 |

174936 |

7. |

.88 |

6. |

.12 |

4. |

.35 |

3. |

.06 |

2. |

.70 |

1. |

.37 |

5 |

|||

|

|

|

|

|

174528** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

480/400 |

174939 |

7. |

.88 |

6. |

.12 |

4. |

.35 |

3. |

.06 |

2. |

.70 |

1. |

.37 |

5 |

|||

|

|

|

|

|

174532** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

|

174943 |

7. |

.88 |

6. |

.12 |

4. |

.35 |

3. |

.06 |

2. |

.70 |

1. |

.37 |

5 |

||

|

|

|

|

|

174536** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. |

.5 |

240/120 |

174515 |

7. |

.88 |

7. |

.86 |

4. |

.90 |

4. |

.80 |

3. |

.25 |

1. |

.37 |

5 |

|||

(1.1) |

|

|

|

174517** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

240/200 |

174482 |

7. |

.88 |

6. |

.12 |

5. |

.25 |

3. |

.06 |

3. |

.60 |

1. |

.37 |

5 |

|||

|

|

|

|

|

174529** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

240 |

|

174475 |

7. |

.88 |

7. |

.86 |

4. |

.90 |

4. |

.80 |

3. |

.25 |

1. |

.37 |

5 |

||

(1.5) |

|

|

|

174525** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

240/200 |

174937 |

7. |

.88 |

7. |

.86 |

4. |

.90 |

4. |

.80 |

3. |

.25 |

1. |

.37 |

5 |

|||

|

|

|

|

|

174530** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

480/400 |

174940 |

7. |

.88 |

7. |

.86 |

4. |

.90 |

4. |

.80 |

3. |

.25 |

1. |

.37 |

5 |

|||

|

|

|

|

|

174533** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

|

174944 |

7. |

.88 |

7. |

.86 |

4. |

.90 |

4. |

.80 |

3. |

.25 |

1. |

.37 |

5 |

||

|

|

|

|

|

174537** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*= NEMA 12 Only

**= NEMA 4X Others are NEMA 4/12

9

W D

R H

|

Q |

Q |

Conduit Holes: |

|

|

W |

U |

|

IF W ʺ 7.86" |

|

|

|

|

|

|||

|

S Dia. |

|

|

|

|

V |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

T = 0.20" |

|

|

|

|

|

|||

|

|

|

0.88" Dia. |

|

|

|

1.00" |

U = 0.34" |

|

|

|

|

|

||||

|

|

|

S Dia. |

|

|

|

|

|

|

V = 0.19" |

|

|

|

|

|

||

|

P |

|

|

|

|

|

|

R |

|

IF W ʺ 10.26" |

|

|

|

|

|

||

|

|

|

|

|

T |

|

|

T = 0.28" |

|

|

|

|

|

||||

|

N |

|

|

|

Dia. Slot |

|

|

|

U = 0.44" |

|

|

|

|

|

|||

|

|

|

|

|

Mounting Tab Detail |

|

V = 0.24" |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HP |

INPUT |

CATALOG |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(kW) |

VOLTAGE |

NUMBER |

H |

W |

|

D |

N |

P |

|

Q |

|

R |

S |

|

|

|

|

3 |

240 |

174729 |

7. |

.88 |

7. |

.86 |

5. |

.90 |

4. |

.80 |

4. |

.25 |

1. |

.37 |

5 |

||

(2.2) |

|

174526** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

240/200 |

174938 |

7. |

.88 |

7. |

.86 |

5. |

.90 |

4. |

.80 |

4. |

.25 |

1. |

.37 |

5 |

||

|

|

174531** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

480/400 |

174941 |

7. |

.88 |

7. |

.86 |

4. |

.90 |

4. |

.80 |

3. |

.25 |

1. |

.37 |

5 |

||

|

|

174534** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

174945 |

7. |

.88 |

7. |

.86 |

4. |

.90 |

4. |

.80 |

3. |

.25 |

1. |

.37 |

5 |

||

|

|

174538** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

240/200 |

174730 |

7. |

.88 |

7. |

.86 |

4. |

.90 |

4. |

.80 |

3. |

.25 |

1. |

.37 |

5 |

||

(4) |

|

174732** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

480/400 |

174942 |

7. |

.88 |

7. |

.86 |

5. |

.90 |

4. |

.80 |

4. |

.25 |

1. |

.37 |

5 |

||

|

|

174535** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

174946 |

7. |

.88 |

7. |

.86 |

5. |

.90 |

4. |

.80 |

4. |

.25 |

1. |

.37 |

5 |

||

|

|

174539** |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. .5 |

240/200 |

174734 |

11. .7510. .268. |

.35 |

5. |

.13 |

5. |

|

.75 |

2. |

.00 |

9. |

|

.75 |

|||

(5.5) |

|

174735** |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

480/400 |

174548 |

8. .3810. .266. |

.90 |

5. |

.13 |

5. |

|

.25 |

2. |

.00 |

6. |

|

.38 |

|||

|

|

174745** |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

174549 |

9. .7510. .267. |

.20 |

5. |

.13 |

5. |

|

.25 |

2. |

.00 |

7. |

|

.75 |

|||

|

|

174759** |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

240/200 |

174737 |

13. .7510. |

.26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

11. |

.75 |

1. |

|

.38 |

|

(7.5) |

|

174738** |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

480/400 |

174554 |

11. .7510. .268. |

.35 |

5. |

.13 |

5. |

|

.75 |

2. |

.00 |

9. |

|

.75 |

|||

|

|

174747** |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

174556 |

11. .7510. .268. |

.35 |

5. |

.13 |

5. |

|

.75 |

2. |

.00 |

9. |

|

.75 |

|||

|

|

174761** |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

240/200 |

174740 |

15. .7510. |

.26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

13. |

.75 |

1. |

|

.38 |

|

(11) |

|

174741** |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

480/400 |

174749 |

13. .7510. |

.26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

11. |

.75 |

1. |

|

.38 |

|

|

|

174750** |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

174763 |

13. .7510. |

.26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

11. |

.75 |

1. |

|

.38 |

|

|

|

174764** |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*= NEMA 12 Only

**= NEMA 4X Others are NEMA 4/12

10

4.4TYPE 12 DIMENSIONS FOR MODELS RATED ABOVE 30 HP AT 240/200 Vac AND 60 HP AT 590/480/400 Vac

HP |

INPUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(kW) |

VOLTAGE |

MODEL |

H |

|

W |

D |

|

N |

P |

Q |

|

R |

|

|

S |

|

75/55 |

480 / 400 |

174581 |

37. .0018. .0013. |

.307. |

.50 8. |

.00 |

|

3. |

.13 |

|

7. . |

14 |

||||

100/75 |

480 / 400 |

174583 |

39. |

.00 |

26. |

.00 |

13. |

.30 |

119. . .50.00 |

4. |

.50 |

9. |

.14 |

2. |

.50 |

|

125/90 |

480 / 400 |

174585 |

39. |

.00 |

26. |

.00 |

13. |

.30 |

119. . .50.00 |

4. |

.50 |

9. |

.14 |

2. |

.50 |

|

11

W D

R H

Q |

Q |

Conduit Holes: |

W |

U |

IF W ʺ 7.86" |

S Dia. |

|

V |

|||

|

|

|

|

T = 0.20" |

|

|

|

0.88" Dia. |

|

|

|

|

|

|

1.00" |

U = 0.34" |

|

|

|

S Dia. |

|

|

V = 0.19" |

P |

|

|

|

R |

IF W ʺ 10.26" |

|

|

T |

|

T = 0.28" |

|

|

|

|

|

||

N |

|

Dia. Slot |

|

|

U = 0.44" |

|

Mounting Tab Detail |

V = 0.24" |

|||

|

|

||||

|

|

|

|||

HP |

INPUT |

CATALOG |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(kW) |

VOLTAGE |

NUMBER |

H |

W |

|

D |

N |

|

P |

|

Q |

|

R |

S |

|

|

20 |

240/200 |

174743* |

15. |

.7510. |

.26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

11. |

.75 |

1. |

.38 |

(15) |

480/400 |

174752 |

15. |

.7510. |

.26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

11. |

.75 |

1. |

.38 |

|

|

174753** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

590 |

174766 |

15. |

.7510. |

.26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

13. |

.75 |

1. |

.38 |

|

|

174767** |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

240/200 |

174595* |

20. .2510. .26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

16. |

.25 |

1. |

.38 |

||

(18.5) |

480/400 |

174755* |

15.75 |

10.26 |

|

8.35 |

5.13 |

|

5.75 |

|

2.00 |

|

11.75 |

1.38 |

|

.38 |

|

590 |

174769* |

15. .7510. .26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

11. |

.75 |

1. |

|||

30 |

240/200 |

174596* |

20. .2510. .26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

11. |

.75 |

1. |

.38 |

||

(22) |

480/400 |

174757* |

15.75 |

10.26 |

|

8.35 |

5.13 |

|

5.75 |

|

2.00 |

|

11.75 |

1.38 |

|

.38 |

|

590 |

174597* |

15. .7510. .26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

11. |

.75 |

1. |

|||

40 |

480/400 |

174513* |

20. .2510. .26 |

8. |

.35. |

.13 |

5. |

.75 |

2. |

.00 |

16. |

.25 |

1. |

.38 |

||

(30) |

590 |

174512* |

20.25 |

10.26 |

|

8.35 |

5.13 |

|

5.75 |

|

2.00 |

|

16.25 |

1.38 |

|

|

50 |

480/400 |

174511* |

21. .0013. .72 |

8. |

.35. |

.13 |

6. |

.10 |

2. |

.00 |

16. |

.25 |

1. |

.38 |

||

(37) |

590 |

174510* |

21.00 |

13.72 |

|

8.35 |

5.13 |

|

6.10 |

|

2.00 |

|

16.25 |

1.38 |

|

|

60 |

480/400 |

174574* |

21. .0013. .72 |

8. |

.35. |

.13 |

6. |

.10 |

2. |

.00 |

16. |

.25 |

1. |

.38 |

||

(45) |

590 |

174575* |

21.00 |

13.72 |

|

8.35 |

5.13 |

|

6.10 |

|

2.00 |

|

16.25 |

1.38 |

|

|

*= NEMA 12 Only

**= NEMA 4X Others are NEMA 4/12

12

5.0MICRO SERIES RATINGS

115/230 & 230V (SINGLE PHASE) VOLT MICRO SERIES RATINGS

|

MODEL |

|

|

|

INPUT |

|

|

|

|

|

OUTPUT |

|

|||||

|

|

|

(120/240 Vac, 50-60 Hz) |

|

|

(0-230 Vac) |

|

||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

NOMINAL |

|

|

|

|

|

|

|

|

||

|

FOR MOTORS |

|

CURRENT |

|

|

|

NOMINAL |

|

|

||||||||

CATALOG |

|

RATED |

|

|

INPUT |

(AMPS) |

|

|

POWER |

CURRENT |

POWER |

||||||

NUMBER |

HP |

|

kW |

PHASE |

(NOTE 1) |

|

|

(KVA) |

(AMPS) |

|

(KVA) |

||||||

174930 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174996* |

0. |

.25 |

|

0. |

.18 |

1 |

6. |

.0/3. |

.0 |

|

0. |

.7 |

1. |

.4/1. |

.4 |

0. |

.6 |

174519** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174997 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174998* |

. |

.50 |

|

0. |

.37 |

1 |

9. |

.2/4. |

.6 |

|

1. |

.1 |

2. |

.2/2. |

.2 |

0. |

.9 |

174520** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174391 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174999* |

1 |

|

0. |

.75 |

1 |

16. |

.2/8. |

.1 |

|

1. |

.9 |

4. |

.0/4. |

.0 |

1. |

.6 |

|

174521** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174932 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174515* |

1. |

.5 |

|

1. |

.1 |

1 |

21. .0/10. .4 |

2. |

.5 |

5. |

.2/5. |

.2 |

2. |

.1 |

|||

174517** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MODEL |

|

|

|

INPUT |

|

|

|

|

|

OUTPUT |

|

|||||

|

|

|

(200/240 Vac, 50-60 Hz) |

|

(0-200/230 Vac) |

||||||||||||

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174933 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174475* |

2 |

|

1. |

.5 |

1 |

17. .1/14. . |

9 |

3. |

.6 |

7. |

.8/6. |

.8 |

2. |

.7 |

|||

174525** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174934 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174729* |

3 |

|

2. |

.2 |

1 |

24/21 |

|

|

5. |

.0 |

11. |

.0/9. |

.6 |

3. |

.8 |

||

174526** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE 1: For 115/230 Vac, the higher current rating is for 120 Vac input and the lower current rating is for 240 Vac input.. NOTE 2: See Section 8..0 for recommended fuse type..

*= NEMA 4/12 ENCLOSURE

**= NEMA 4X ENCLOSURE OTHERS ARE NEMA 1 ENCLOSURE

13

230 VOLT MICRO SERIES RATINGS

|

MODEL |

|

|

|

INPUT |

|

|

|

|

|

|

OUTPUT |

|

|||||

|

|

|

(200/240 Vac, 50-60 Hz) |

|

|

(0-200/230 Vac) |

||||||||||||

|

|

|

|

|

|

|

|

|||||||||||

|

FOR MOTORS |

|

NOMINAL |

|

|

|

NOMINAL |

|

|

|||||||||

CATALOG |

|

RATED |

|

|

INPUT |

CURRENT |

|

POWER |

CURRENT |

POWER |

||||||||

NUMBER |

HP |

|

kW |

PHASE |

(AMPS) |

|

|

(KVA) |

|

(AMPS) |

|

(KVA) |

||||||

174914 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174935* |

. .50 |

|

0. |

.37 |

3 |

3. |

.1/2. |

.7 |

|

1. |

.1 |

|

2. |

.5/2. |

.2 |

0. |

.88 |

|

174527** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174915 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174936* |

1 |

|

|

0. |

.75 |

3 |

5. |

.5/4. |

.8 |

|

2. |

.0 |

|

4. |

.6/4. |

.0 |

1. |

.6 |

174528** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174916 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174482* |

1. |

.5 |

|

1. |

.1 |

3 |

7. |

.1/6. |

.2 |

|

2. |

.6 |

|

6. |

.0/5. |

.2 |

2. |

.1 |

174529** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174917 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174937* |

2 |

|

|

1. |

.5 |

3 |

9. |

.3/8. |

.1 |

|

3. |

.4 |

|

7. |

.8/6. |

.8 |

2. |

.7 |

174530** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174918 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174938* |

3 |

|

|

2. |

.2 |

3 |

13. .0/11. . |

3 |

4. |

.7 |

|

11. |

.0/9. |

.6 |

3. |

.8 |

||

174531** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174919 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174730* |

5 |

|

|

3. |

.7 |

3 |

20. .0/17. . |

7 |

7. |

.4 |

17. .5/15. .2 |

6. |

.1 |

|||||

174732** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174545 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174734* |

7. |

.5 |

|

5. |

.5 |

3 |

30/26 |

|

|

10. |

.6 |

|

25/22 |

|

8. |

.8 |

||

174735** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174551 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174737* |

10 |

|

|

7. |

.5 |

3 |

37/32 |

|

|

13. |

.2 |

|

32/28 |

|

11. |

.2 |

||

174738** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174557 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174740* |

15 |

|

|

11 |

3 |

55/48 |

|

|

19. |

.8 |

|

48/42 |

|

16. |

.7 |

|||

174741** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174560 |

20 |

|

|

15 |

3 |

70/61 |

|

|

25. |

|

.3 |

62/54 |

|

21. |

|

|||

174743* |

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174569 |

25 |

|

|

18. |

|

.5 3 |

89/77 |

|

|

32. |

|

.0 |

78/68 |

|

27. |

|

||

174595* |

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174571 |

30 |

|

|

22 |

3 |

104/90 |

|

|

37. |

|

.6 |

92/80 |

|

31. |

|

|||

174596* |

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174576 |

40 |

|

|

30 |

3 |

119/99 |

|

|

41. |

.0 |

|

120/104 |

|

41. |

.4 |

|||

174578 |

60 |

|

|

45 |

3 |

174/145 |

|

|

60. |

.5 |

|

177/154 |

|

61. |

.3 |

|||

.5

.1

.9

NOTE See Section 8..0 for recommended fuse type..

*= NEMA 4/12 or 12 ENCLOSURE

**= NEMA 4X ENCLOSURE OTHERS ARE NEMA 1 ENCLOSURE

14

|

|

|

|

460 VOLT MICRO SERIES RATINGS |

|

|

|

|

|

|

|

|

|||||

|

MODEL |

|

|

|

INPUT |

|

|

|

|

|

OUTPUT |

|

|

||||

|

|

|

(400/480 Vac, 50-60 Hz) |

|

|

|

(0-400/460 Vac) |

|

|||||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

FOR MOTORS |

|

NOMINAL |

|

|

NOMINAL |

|

|

|

||||||||

CATALOG |

RATED |

|

|

INPUT |

CURRENT |

POWER |

CURRENT |

POWER |

|

||||||||

NUMBER |

HP |

|

kW |

PHASE |

(AMPS) |

|

(KVA) |

|

(AMPS) |

|

(KVA) |

|

|||||

174920 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174939* |

1 |

|

0. |

.75 |

3 |

2. |

.8/2. |

.4 |

2. |

.0 |

|

2. |

.3/2. |

.0 |

1. |

.6 |

|

174532** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174921 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174940* |

2 |

|

1. |

.5 |

3 |

4. |

.7/4. |

.1 |

3. |

.4 |

|

3. |

.9/3. |

.4 |

2. |

.7 |

|

174533** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174922 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174941* |

3 |

|

2. |

.2 |

3 |

6. |

.8/5. |

.7 |

4. |

.7 |

|

5. |

.5/4. |

.8 |

3. |

.8 |

|

174534** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174923 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174942* |

5 |

|

3. |

.7 |

3 |

10. |

.2/8. |

.9 |

7. |

.3 |

|

8. |

.7/7. |

.6 |

6. |

.1 |

|

174535** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174924 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174548* |

7. .5 |

|

5. |

.5 |

3 |

14. .7/12. .8 |

10. |

.6 |

12. .6/11. .0 |

8. |

.8 |

|

|||||

174745** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174552 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174554* |

10 |

|

7. |

.5 |

3 |

18. .3/15. .9 |

13. |

.2 |

16. .0/14. .0 |

11. |

.2 |

|

|||||

174747** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174558 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174749* |

15 |

|

11 |

3 |

28/24 |

|

19. |

.8 |

|

24/21 |

|

16. |

.7 |

|

|||

174750** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174561 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174752* |

20 |

|

15 |

3 |

36/31 |

|

25. |

.3 |

|

31/27 |

|

21. |

.5 |

|

|||

174753** |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174563 |

25 |

|

18. |

|

.5 3 |

44/38 |

|

31. |

|

.9 |

39/34 |

|

27. |

|

.1 |

||

174755* |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174565 |

30 |

|

22 |

3 |

52/45 |

|

37. |

|

.6 |

46/40 |

|

31. |

|

.9 |

|||

174757* |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174567 |

40 |

|

30 |

3 |

68/59 |

|

49. |

|

.0 |

60/52 |

|

44. |

|

.0 |

|||

174513* |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174593 |

50 |

|

37 |

3 |

85/74 |

|

61. |

|

.5 |

75/65 |

|

51. |

|

.8 |

|||

174511* |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174572 |

60 |

|

45 |

3 |

100/87 |

|

72. |

|

.3 |

88/77 |

|

61. |

|

.3 |

|||

174574* |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174580 |

75 |

|

55 |

3 |

109/91 |

|

75. |

|

.5 |

110/96 |

|

76. |

|

.5 |

|||

174581* |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174582 |

100 |

|

75 |

3 |

139/116 |

|

96. |

|

.4 |

143/124 |

|

98. |

|

.8 |

|||

174583* |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174584 |

125 |

|

90 |

3 |

175/146 |

|

121. |

|

.4 |

179/156 |

|

124. |

|

.3 |

|||

174585* |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

174586 |

150 |

|

110 |

3 |

202/168 |

|

139. |

.7 |

|

207/180 |

|

143. |

.4 |

|

|||

NOTE See Section 8..0 for recommended fuse type..

*= NEMA 4/12 or 12 ENCLOSURE

**= NEMA 4X ENCLOSURE OTHERS ARE NEMA 1 ENCLOSURE

15

575 VOLT MICRO SERIES RATINGS

|

MODEL |

|

INPUT |

|

OUTPUT |

|||

|

(480/590 Vac, 50-60 Hz) |

(0-460/575 Vac) |

||||||

|

|

|

|

|||||

|

FOR MOTORS |

|

NOMINAL |

|

NOMINAL |

|

||

CATALOG |

|

RATED |

INPUT |

CURRENT |

POWER |

CURRENT |

POWER |

|

NUMBER |

HP |

|

kW |

PHASE |

(AMPS) |

(KVA) |

(AMPS) |

(KVA) |

174925 |

|

|

|

|

|

|

|

|

174943* |

1 |

|

0..75 |

3 |

1..9 / 1..9 |

1..9 |

1..6 / 1..6 |

1..6 |

174536** |

|

|

|

|

|

|

|

|

174926 |

|

|

|

|

|

|

|

|

174944* |

2 |

|

1..5 |

3 |

3..3 / 3..3 |

3..4 |

2..7 / 2..7 |

2..7 |

174537** |

|

|

|

|

|

|

|

|

174927 |

|

|

|

|

|

|

|

|

174945* |

3 |

|

2..2 |

3 |

4..6 / 4..6 |

4..7 |

3..9 / 3..9 |

3..9 |

174538** |

|

|

|

|

|

|

|

|

174928 |

|

|

|

|

|

|

|

|

174946* |

5 |

|

3..7 |

3 |

7..1 / 7..1 |

7..3 |

6..1 / 6..1 |

6..1 |

174539** |

|

|

|

|

|

|

|

|

174929 |

|

|

|

|

|

|

|

|

174549* |

7..5 |

|

5..5 |

3 |

10..5 / 10..5 |

10..7 |

9..0 / 9..0 |

8..8 |

174759** |

|

|

|

|

|

|

|

|

174553 |

|

|

|

|

|

|

|

|

174556* |

10 |

|

7..5 |

3 |

12..5 / 12..5 |

12..8 |

11..0 / 11..0 |

11..0 |

174761** |

|

|

|

|

|

|

|

|

174559 |

|

|

|

|

|

|

|

|

174763* |

15 |

|

11 |

3 |

19..3 / 19..3 |

19..7 |

17..0 / 17..0 |

16..9 |

174764** |

|

|

|

|

|

|

|

|

174562 |

|

|

|

|

|

|

|

|

174766* |

20 |

|

15 |

3 |

25 / 25 |

25..4 |

22 / 22 |

21..5 |

174767** |

|

|

|

|

|

|

|

|

174564 |

25 |

|

18..5 |

3 |

31 / 31 |

31..2 |

27 / 27 |

26..9 |

174769* |

|

|||||||

|

|

|

|

|

|

|

|

|

174566 |

30 |

|

22 |

3 |

36 / 36 |

37..1 |

32 / 32 |

31..9 |

174597* |

|

|||||||