Page 1

Intel

LEC-2010 Fanless Embedded System User’s Manual

LEC-2010 Series

®

Atom N270 (1.6Ghz) CPU onboard

Fanless Embedded System

User’s Manual

1

Page 2

LEC-2010 Fanless Embedded System User’s Manual

LEC-2010 Series

User’s Manual

Version 1.1

© Copyright 2009, Lanner Electronics, Inc. All rights reserved. This document contains

proprietary information that is protected by copyright. No part of this document may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form by any means without the written express of Lanner Electronics, Inc.

The author and Lanner Electronics, Inc. have used their best efforts in preparing this manual.

However, the author and Lanner Electronics, Inc. make no warranties of any kind, expressed

or implied, with re gard to the informatio nal content, docume ntation, or files con tained in this

manual, and shall not be liable for technical or editorial errors or omissions contained herein.

In no event shall the author or publisher be responsible or liable for any incidental or

consequential damages resulting from the furnishing, performance, or use of this material.

TRADEMARKS Internet Explorer, Windows Explorer, and Windows are trademarks or

registered trademarks of Microsoft Corporation. Other products mentioned herein may be

trademarks/or registered trademarks of their respective owners.

2

Page 3

LEC-2010 Fanless Embedded System User’s Manual

Safety Guidelines

Follow these guidelines to ensure general safety:

Keep the chassis area clear and dust-free during and after installation.

Do not wear loose clothing or jewelry that could get caught in the chassis. Fasten your

tie or scarf and roll up your sleeves.

Wear safety glasses if you are working under any conditions that might be hazardous to

your eyes.

Do not perform any action that creates a potential hazard to people or makes the

equipment unsafe.

Disconnect all power by turning off the power and unplugging the power cord before

installing or removing a chassis or working near power supplies

Do not work alone if potentially hazardous conditions exist.

Never assume that power is disconnected from a circuit; always check the circuit.

LITHIUM BATTERY CAUTION:

Risk of Explosion if Battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

Operating Safety

Electrical equipment generates heat. Ambient air temperature may not be adequate to

cool equipment to acceptable operating temperatures without adequate circulation. Be

sure that the room in which you choose to operate your system has adequate air

circulation.

Ensure that the chassis cover is secure. The chassis design allows cooling air to

circulate effectively. An open chassis permits air leaks, which may interrupt and

redirect the flow of cooling air from internal components.

Electrostatic discharge (ESD) can damage equipment and impair electrical circui try. ESD

damage occurs when electronic components are improperly handled and can result in

complete or intermittent failures. Be sure to follow ESD-prevention procedures when

removing and replacing components to avoid these problems.

Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. If no

wrist strap is available, ground yourself by touching the metal part of the chassis.

Periodically check the resistance value of the antistatic strap, which should be between

1 and 10 megohms (Mohms).

3

Page 4

LEC-2010 Fanless Embedded System User’s Manual

EMC Notice

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case users will be required to correct the

interference at their own expense.

Class A Notice for FCC

Modifying the equipment without the authorization of Lanner Electronics, Inc. may result in

the equipment no longer complying with FCC requirements for Class A digital devices. In that

event, your right to use the equipment may be limited by FCC regulations, and you may be

required to correct any interference to radio or television communications at your own

expense.

This equipment is in compliance with the essential requirements and other relevant

provisions of Directive 1999/5/EC.

4

Page 5

LEC-2010 Fanless Embedded System User’s Manual

Contents

Safety Guidelines..........................................................................3

EMC Notice ..................................................................................4

Contents......................................................................................5

Document History .........................................................................6

1. Product Overview.....................................................................7

1.1 Product Introduction .............................................................7

1.2 Features and Benefits............................................................7

1.3 Specifications.......................................................................8

1.4 Block Diagram......................................................................9

1.5 Package Contents............................................................... 10

1.6 Technical Assistance ...........................................................11

2. System Components...............................................................12

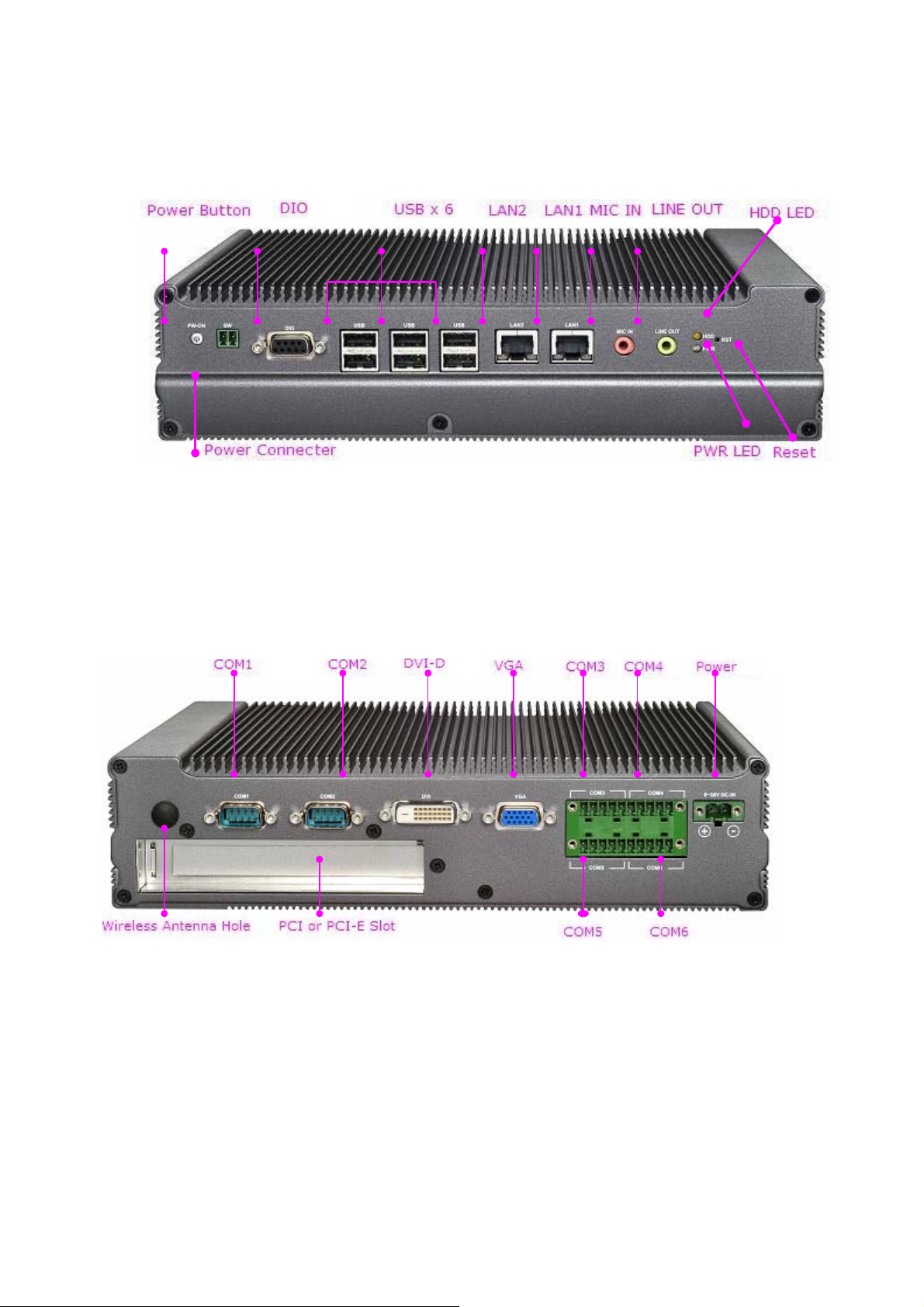

2.1 LEC-2010 Embedded System Mechanisms.............................. 12

2.1.1 Front View ......................................................................13

2.1.2 Rear View.......................................................................13

2.2 LEB-2010 System Board.................................................... 14

2.2.1 Board View .....................................................................15

2.2.2 Jumper Settings and I/O Connectors .................................... 16

2.2.3 Connector Pin Assignments ...............................................17

3. Hardware Installation Guide..................................................... 42

3.1 LEC-2010 Embedded System ............................................... 42

3.1.1 Begin Installation............................................................. 43

3.1.2 System Memory Installation ..............................................45

3.1.3 CompactFlash Card Installation.......................................... 45

3.1.4 PCI Module Installation..................................................... 46

3.1.5 LEC-2010 Hard Disk Installation......................................... 49

3.1.6 System Installation is now Complete ..................................52

3.2 Mounting Kits ....................................................................55

3.2.1 Wall Mount View .............................................................. 55

3.2.2 Wall Mount Package and Ordering Information..................... 55

A. Appendix A: LED Indicators ..................................................... 56

A.1 LAN Port LED......................................................................56

A.2 Power-on Button LED........................................................... 56

A.3 HDD LED............................................................................ 57

A.4 POWER LED........................................................................ 57

B. Appendix B: Watchdog Timer................................................... 58

B.1 Introduction ....................................................................... 58

B.2 Detail Register Descriptions ..................................................58

B.2.1 To use the watch-dog timer .............................................. 58

C. Appendix C: DIO.................................................................... 61

C.1 To use the DIO ................................................................... 61

Terms and Conditions..................................................................65

Warranty Policy ..........................................................................65

RMA Service :.............................................................................65

Requesting a RMA#.....................................................................65

5

Page 6

LEC-2010 Fanless Embedded System User’s Manual

Document History

Date Revision Comment

2009/10/5 V1.1

Modify USBG1 Pin assignment (Pin 5)

Adding MIC IN/LINE OUT pin assignment

6

Page 7

LEC-2010 Fanless Embedded System User’s Manual

1. Product Overview

1.1 Product Introduction

Figure 1 – LEC-2010 Outlook

The Lanner LUGE LEC-2010 is a fanless embedded system designed for intelligent

industrial and commercial applications. It features extensive I/O interfaces, PCI or PCI

Express expansion slot, and an onboard Intel® Atom™ embedded processor for

exceptional performance with very low heat generation and minimal cooling

requirements, resulting in improved stability and longevity, and providing a higher

return on investment.

1.2 Features and Benefits

Fanless embedded system

Intel Atom 1.6GHz onboard CPU

VGA, DVI-D video out

6 COM ports, 7 USB port

Supports up to 2GB DDR2 memory

Dual GbE LAN

PCI or PCI-E expansion slot

CompactFlash Type I/II and SATA HDD support

7

Page 8

LEC-2010 Fanless Embedded System User’s Manual

1.3 Specifications

Feature Description

Form Factor Fanless Embedded System

Processor Onboard Intel® Atom™ 1.6 GHz

Platform

System Memory

Storage Interface

Display

Audio

Networking

Front I/O

Rear I/O

Internal I/O

Expansion

Hardware

Monitoring

OS Supported

Environmental

Parameters

Mounting Wall mounting kit

Power

Note: All specifications and images are subject to change without notice.

Chipset Intel 945GSE+ICH7M

BIOS AMIBIOS with 8Mbit BIOS Flash

Technology 533 MHz DDR2 SDRAM

Socket 200P SODIMM x1

Onboard Memory 1GB DDR2 onboard

Maximum Capacity 2GB (1GB DDR2 onboard + 1GB DDR2 module)

CompactFlash I/II 1

SATA Port 2

VGA D-Sub 15-pin connector

Interface

Codec ALC888 HD Codec

Lan Ports 2

Speed 10/100/1000 Mbps

Digital I/O DB9 Female 4 in 4 Out

USB 2.0 6 (Total: 7; External x 6 , Internal x 1)

LAN 2 x RJ45 GbE

Mic In / Line Out 1/1

COM RS-232 x 4; RS-232/422/485 selectable x 2 ports(COM2& 3)

DVI 1

VGA 1

USB 2.0 1 (Pin header)

Lan Ports PCI x 1 (LEC-2010P)

Lan Ports PCIe x 1 (LEC-2010E)

Speed Mini-PCIe x 1

Controller Winbond W83627UHG integrated hardware monitor

Watchdog timer Reset supported, 1~255 level

Temperature, ambient

operating

Humidity (RH), ambient

operating

Storage Temperature -20°~80°C

Dimensions 268(W) x 65(H) x 190(D) Physical Dimensions

Net Weight 2.6Kg

Input DC +9V~36V (ATX Mode)

Adapter 75W (+19V)

DVI-D

Linux kernel 2.4.16 or above, XPE/Win

XP-32 bit, Win CE 6.0

-5~45°C (with 2.5” commercial HDD)

-10°~55°C (with industrial components - CF card, HDD,

Memory, adapter)

Extended Operating Temperature:

-20°C: 24 hours bootable;

70° C: 72 hours full-loading operating

10~95% relative humidity, non-condensing

8

Page 9

LEC-2010 Fanless Embedded System User’s Manual

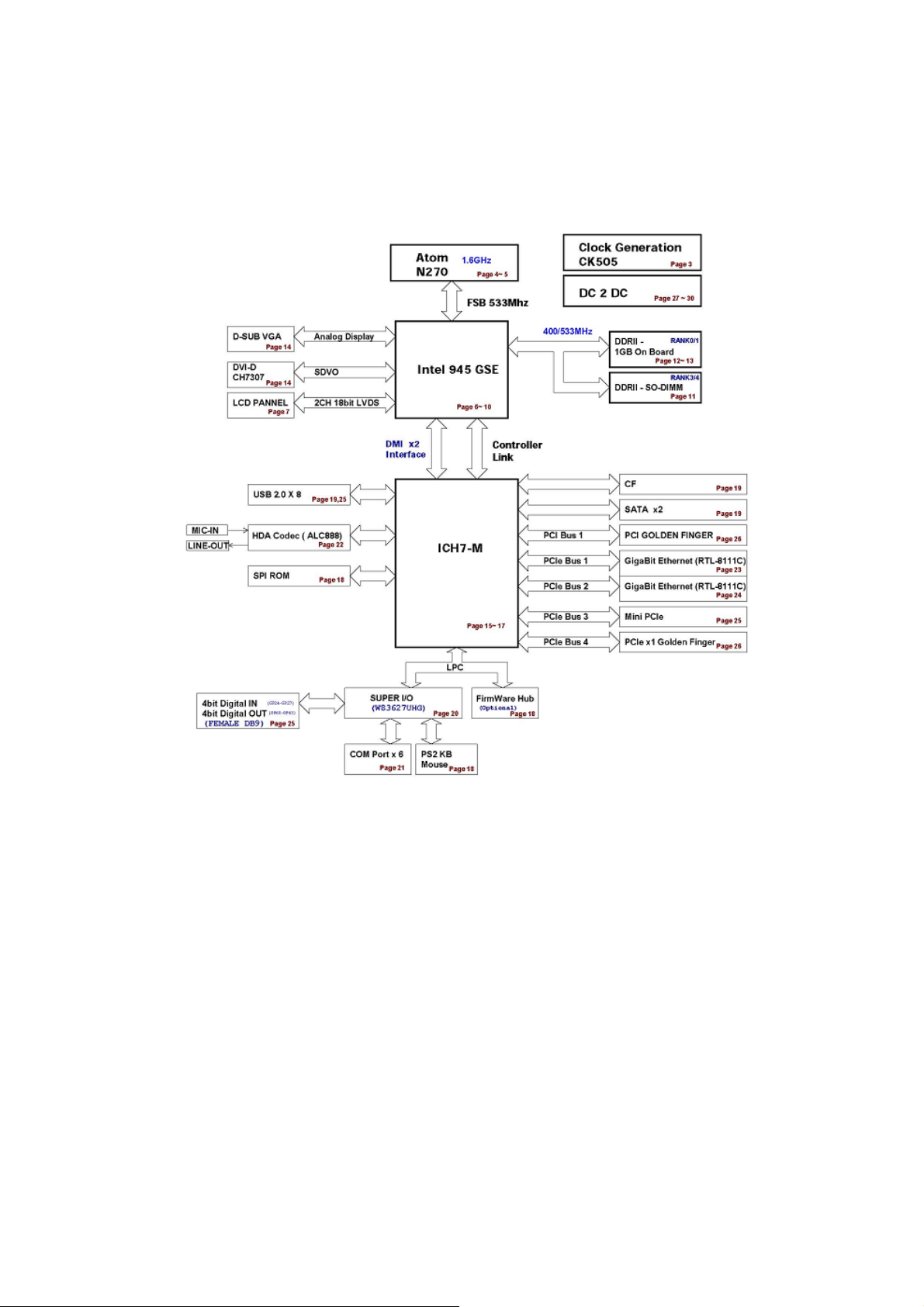

1.4 Block Diagram

Figure 2 – Block Diagram

9

Page 10

LEC-2010 Fanless Embedded System User’s Manual

1

1

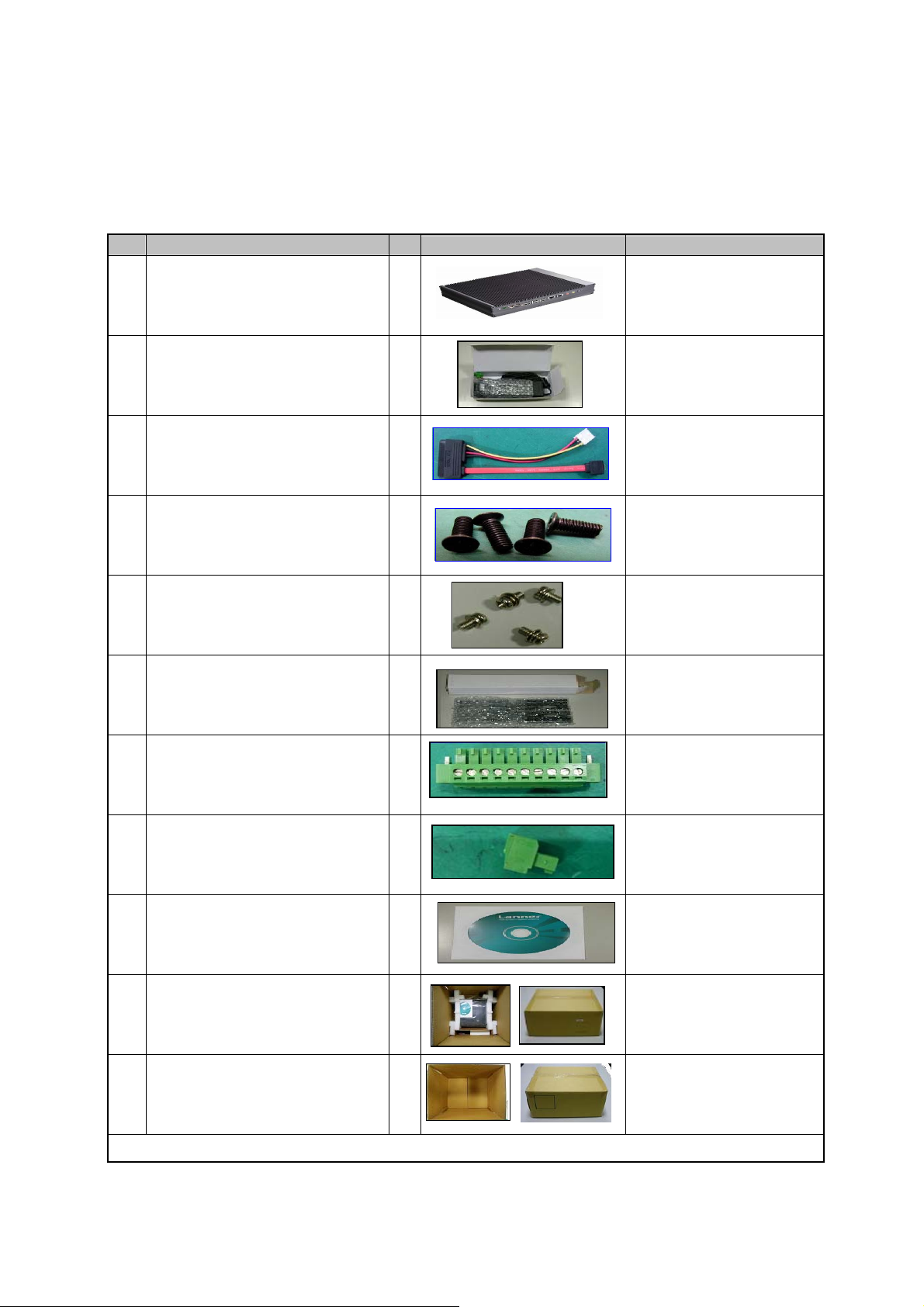

1.5 Package Contents

Carefully unpack your package and make sure that you have the following items:

Item

1 LEC-2010 Embedded System 1

2 DC+19V 75W Power Adapter 1

3 Serial ATA/Power Cable 1

Package Contents Q'ty

Photo Ordering Information

*LEC-2010P

(for PCI Riser card)

*LEC-2010E

(for PCIe Riser card)

*P/N:0P0W075190001

*P/N:080W1N2201001

4 HDD Screw ( M3x8) 4

5 Wall Mount Screw (M3x6 Ni) 4

Wall Mount Kits

6

(Please check chapter 3.2.1)

7 Terminal Block (10 pin) 2

8 Terminal Block (2 pin) 1

9 Drivers and User’s Manual CD 1

Carton(Inside)

10

(Dimension:359x333x164mm)

*P/N:070W102400801

*P/N:070W103000601

1

*P/N:SE9ESA829R110

*P/N:04AW20101O101

*P/N:04AW20024E101

*LEC-2010 CD

*P/N:085W002204107

11 Carton(Outside)

(Dimension:370x351x191mm)

*Total Weight of packing: NW:2.62kgs ; GW: 4kgs

Note: If you should find any components missing or damaged, please contact your dealer

immediately for assistance.

10

*P/N:085W002104239

Page 11

LEC-2010 Fanless Embedded System User’s Manual

1.6 Technical Assistance

Should you have any questions or problems with your product, please contact the Lanner

sales team.

Phone: 886-2-8692-6060

Fax: 886-2-8692-6101

E-mail:

Prior to contacting us, we ask that you first check the electronic product documentation for

assistance. Should you still have questions, we recommend you have the following

information on hand in order to expedite the process:

1. LEC-2010 model name

2. Serial number

3. Local network configuration details

support@lannerinc.com

4. Abnormal behavior and/or error messages reported by your network system

5. Your questions, or a description of the problem you are experiencing

11

Page 12

LEC-2010 Fanless Embedded System User’s Manual

2. System Components

2.1 LEC-2010 Embedded System Mechanisms

This section of the manual describes the mechanical and device nomenclature of the

LEC-2010.

Figure 3 – LEC-2010 System

12

Page 13

LEC-2010 Fanless Embedded System User’s Manual

2.1.1 Front View

Figure4 – LEC-2010 Front View

2.1.2 Rear View

Figure 5– LEC-2010 Rear View

13

Page 14

LEC-2010 Fanless Embedded System User’s Manual

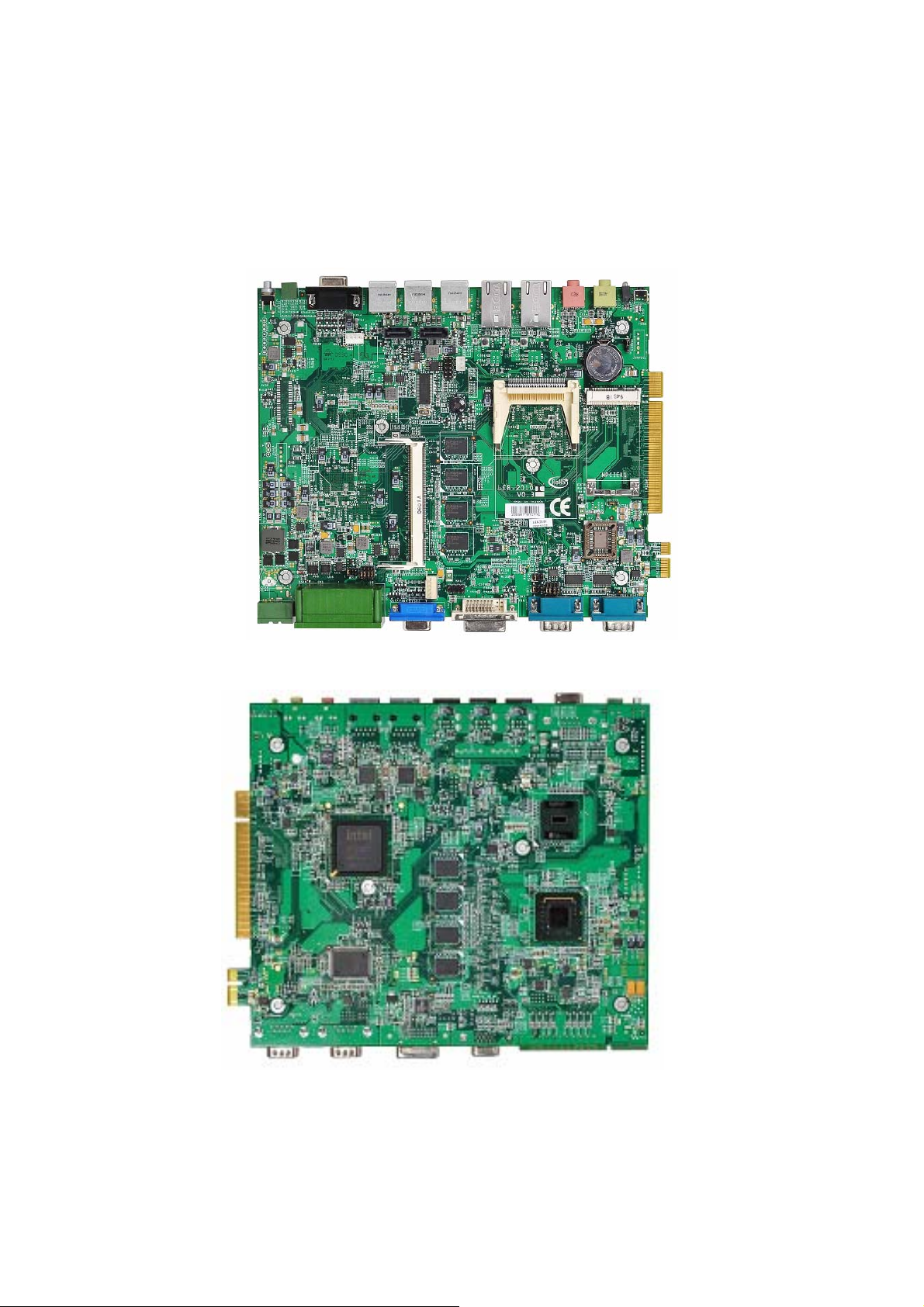

2.2 LEB-2010 System Board

LEB-2010 is the system board bundled with the LEC-2010 Fanless Embedded System

platform. The succeeding sections list LEB-2010 related jumper settings and connector pin

assignments.

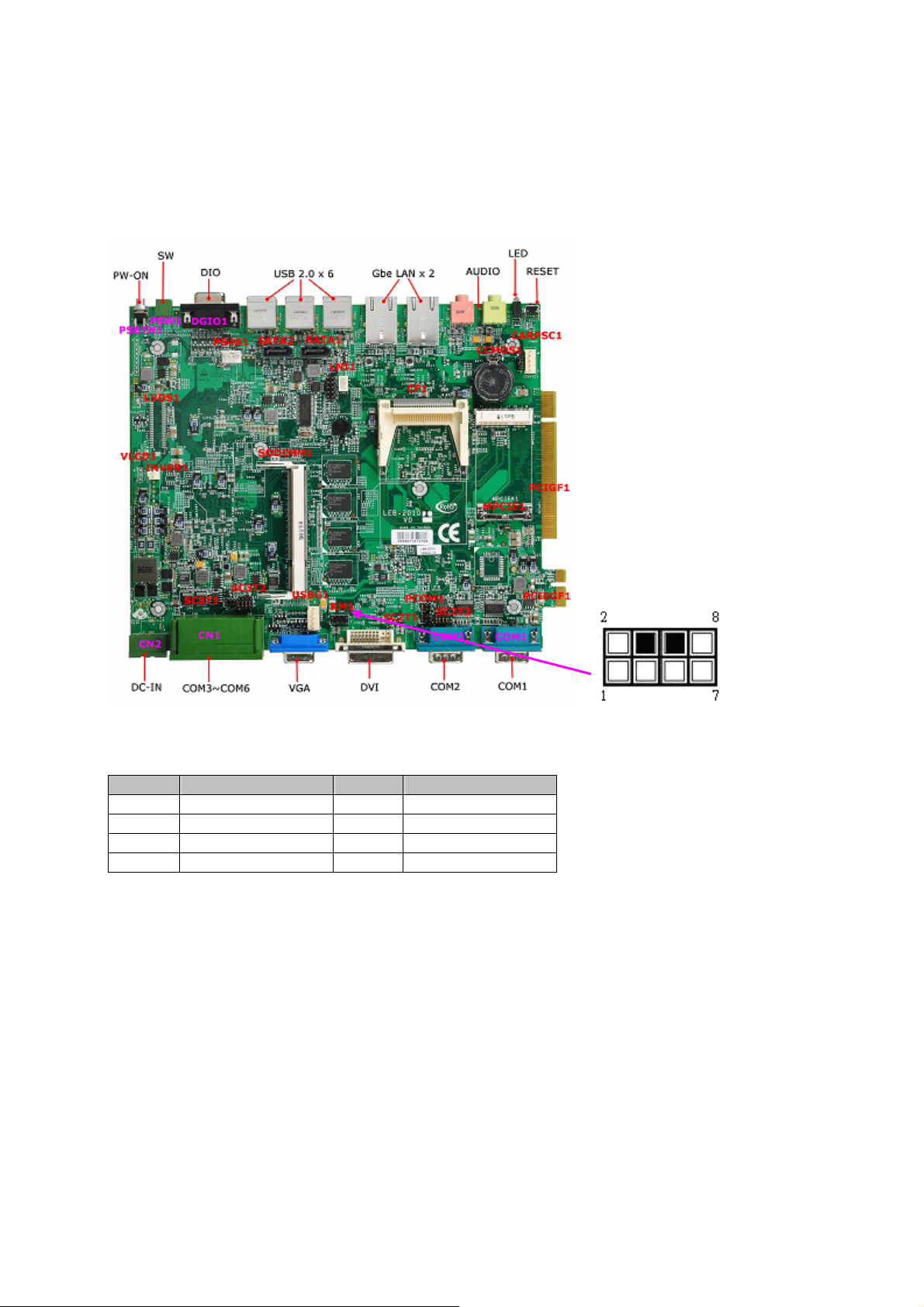

Figure 6 – LEB-2010 System Board

14

Page 15

LEC-2010 Fanless Embedded System User’s Manual

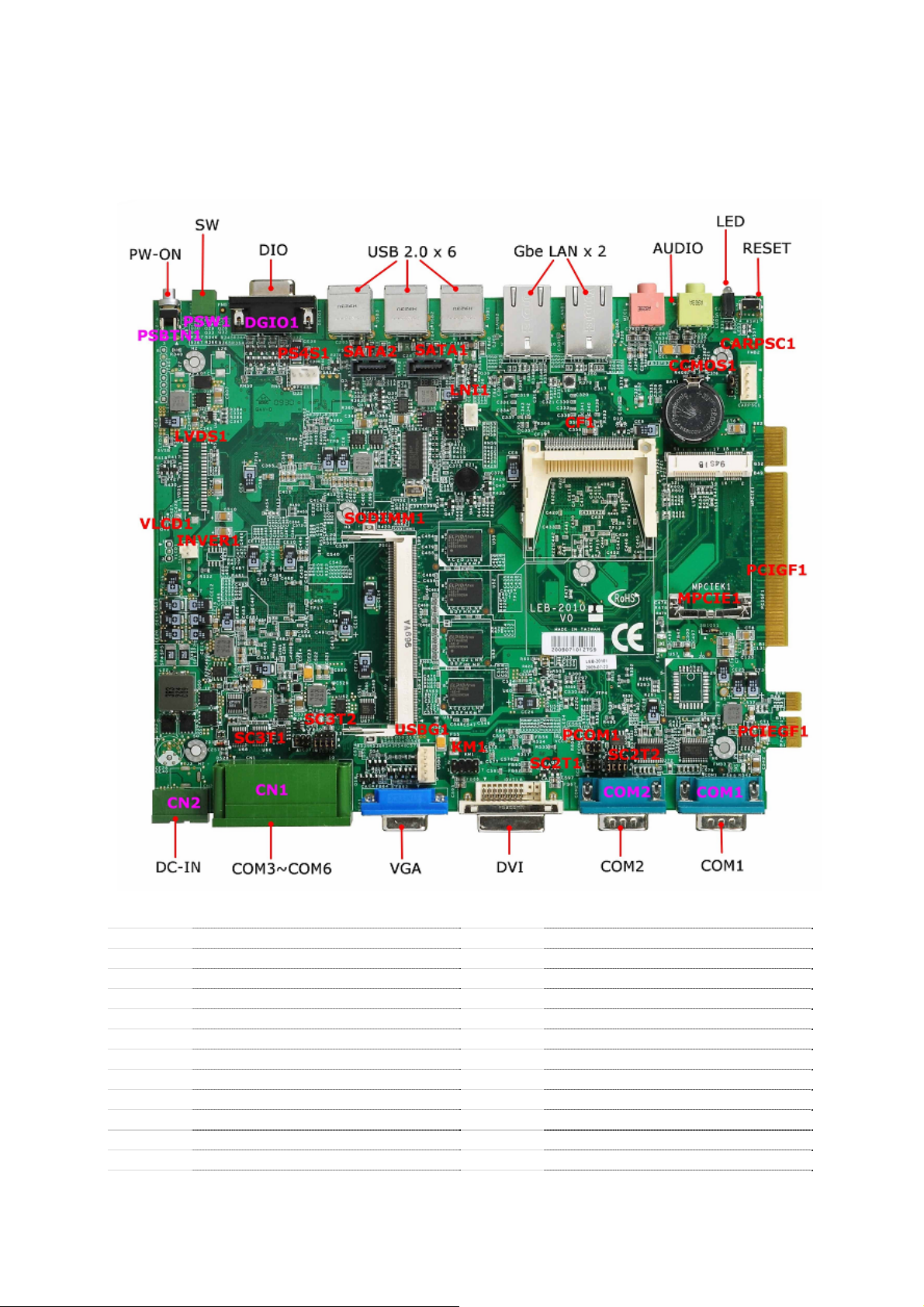

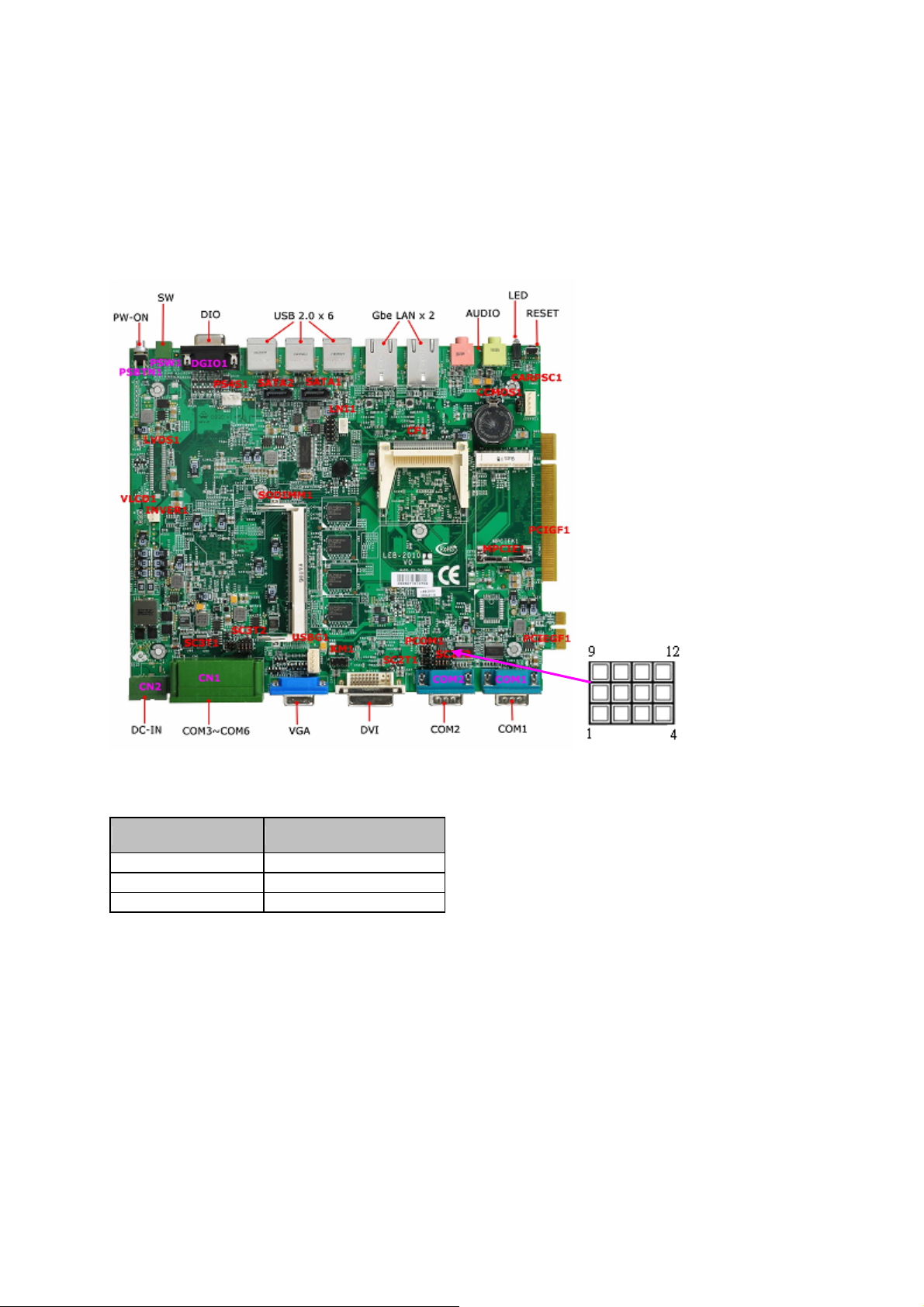

2.2.1 Board View

SC2T2 Select COM2 Type Jumper CF1 Compact Flash Connector

SC2T1 Select COM2 Type Jumper CCMOS1 Clear CMOS Data Jumper

PCOM1 Select COM1 Pin9 Signal Jumper CARPSC1 Car Application 5-Pin Power Connector

KM1 Keyboard/Mouse Connector Header MPCIE1 Mini PCI Express 1X Connector

USBG1 USB Port#7 5-Pin Power Connector PCIGF1 120 Pin PCI Golden Finger

SODIMM1 200 PIN DDR2 SODIMM Socket PCIEGF1 PCI Express 1x Golden Finger

SC3T2 Select COM3 Type Jumper COM1/2 Serial Port COM1/2 Connector

SC3T1 Select COM3 Type Jumper CN1 COM3 ~ 6 Connector

VLCD1 Select Panel Voltage Header CN2 DC-IN Connector

INVER1 7 Pin LCD INVETER Connector DGIO1 DIO Connector

LVDS1 LVDS Connector PSW1 SW Connector

PS4S1 4-Pin Power Connector PSBTN1 PW-ON Button

SATA2 Serial ATA-SATA Socket MIC1 MIC IN Connector

SATA1 Serial ATA-SATA Socket LNO1 LINE OUT Connector

Figure 6 – LEB-2010 Board View

15

Page 16

LEC-2010 Fanless Embedded System User’s Manual

2.2.2 Jumper Settings and I/O Connectors

The jumper settings and I/O connectors of the LEC-2010 have been arranged at the factory.

Any changes to the schematic or design of these connectors may cause damage to your unit.

Jumper Settings and I/O Connector Summary for LEC-2010 is as below:

CHAPTER JUMPER FUNCTION

2.2.3.1 SC2T2 Select COM2 Type Jumper

2.2.3.2 SC2T1 Select COM2 Type Jumper

2.2.3.3 PCOM1 Select COM1 Pin9 Signal Jumper

2.2.3.4 KM1 Keyboard/Mouse Connector Header

2.2.3.5 USBG1 USB Port#7 5-Pin Power Connector (5P Male)

2.2.3.6 SODIMM1 200 PIN DDR2 SODIMM Socket

2.2.3.7 SC3T2 Select COM3 Type Jumper

2.2.3.8 SC3T1 Select COM3 Type Jumper

2.2.3.9 VLCD1 Select Panel Voltage Header (Reserved)

2.2.3.10 INVER1 7 Pin LCD INVETER Connector (Optional)

2.2.3.11 LVDS1 LVDS Connector (Optional)

2.2.3.12 PS4S1 4-Pin Power Connector (4P Male )

2.2.3.13 SATA2 Serial ATA-SATA Socket (Port 2)

2.2.3.13 SATA1 Serial ATA-SATA Socket (Port 1)

2.2.3.14 LNI1 Line In 3Pin Connector

2.2.3.15 CF1 Compact Flash Connector

2.2.3.16 CCMOS1 Clear CMOS Data Jumper

2.2.3.17 CARPSC1 Car Application 5-Pin Power Connector (5P Male)

2.2.3.18 MPCIE1 Mini PCI Express 1X Connector

2.2.3.19 PCIGF1 120 Pin PCI Golden Finger

2.2.3.20 PCIEGF1 PCI Express 1x Golden Finger

2.2.3.21 COM1/2 Serial Port COM1/2 Connector (D-SUB9 Male)

2.2.3.22 CN1 COM3 – 6 Connector

2.2.3.23 CN2 DC-IN Connector (9 ~ 36V)

2.2.3.24 DGIO1 DIO Connector ( D-SUB9 Female)

2.2.3.25 PSW1 SW Connector (ATX Power Switch Connector)

2.2.3.26 PSBTN1 PW-ON Button

2.2.3.27 MIC1 MIC IN Connector

2.2.3.28 LNO1 LINE OUT Connector

16

Page 17

LEC-2010 Fanless Embedded System User’s Manual

2.2.3 Connector Pin Assignments

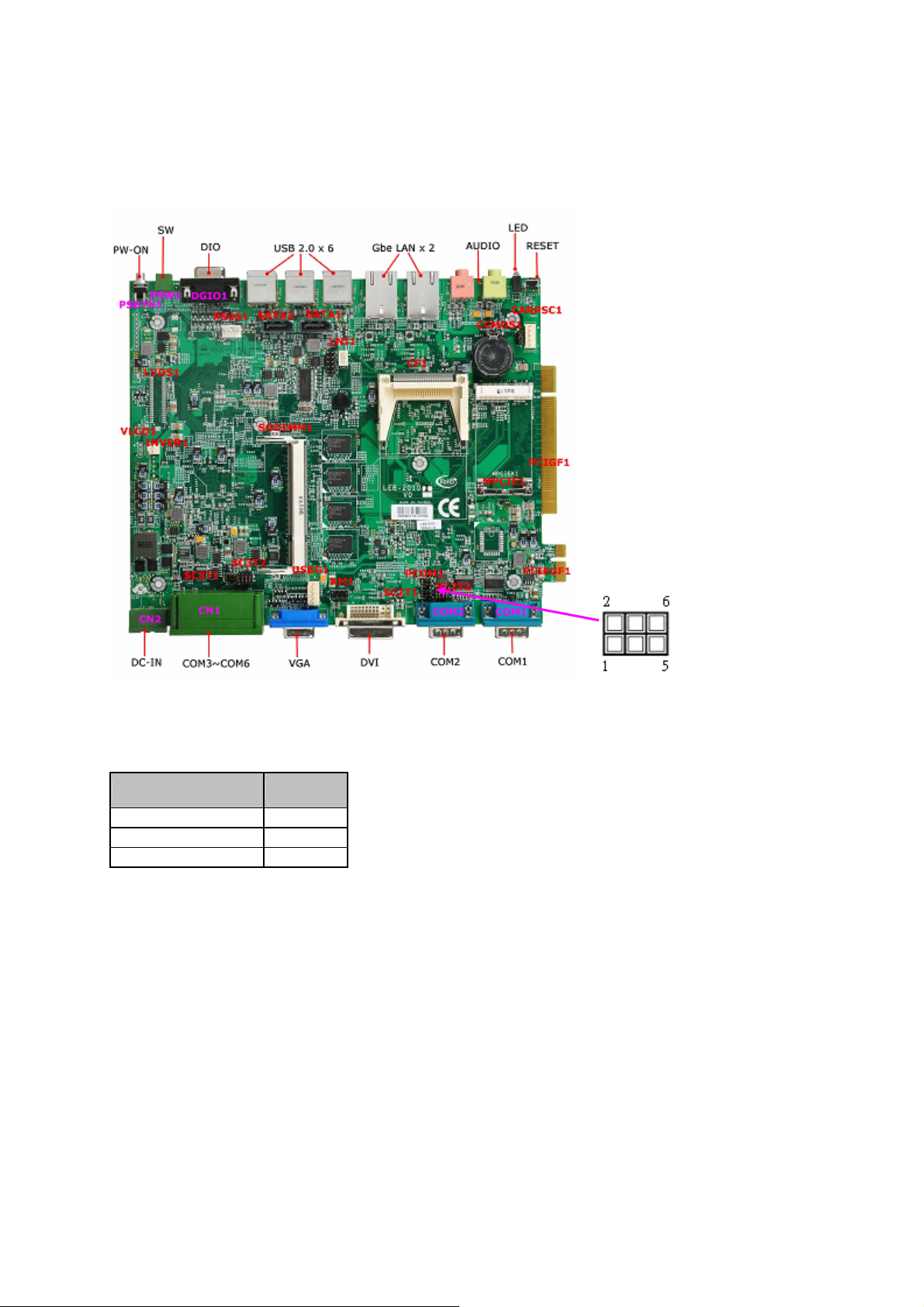

2.2.3.1 SC2T2: Select COM2 Type Jumper

COM2 TYPE SC2T2

RS-232 (Default) 1-5,2-6,3-7,4-8

RS-422 5-9,6-10,7-11,8-12

RS-485 5-9,6-10,7-11,8-12

17

Page 18

LEC-2010 Fanless Embedded System User’s Manual

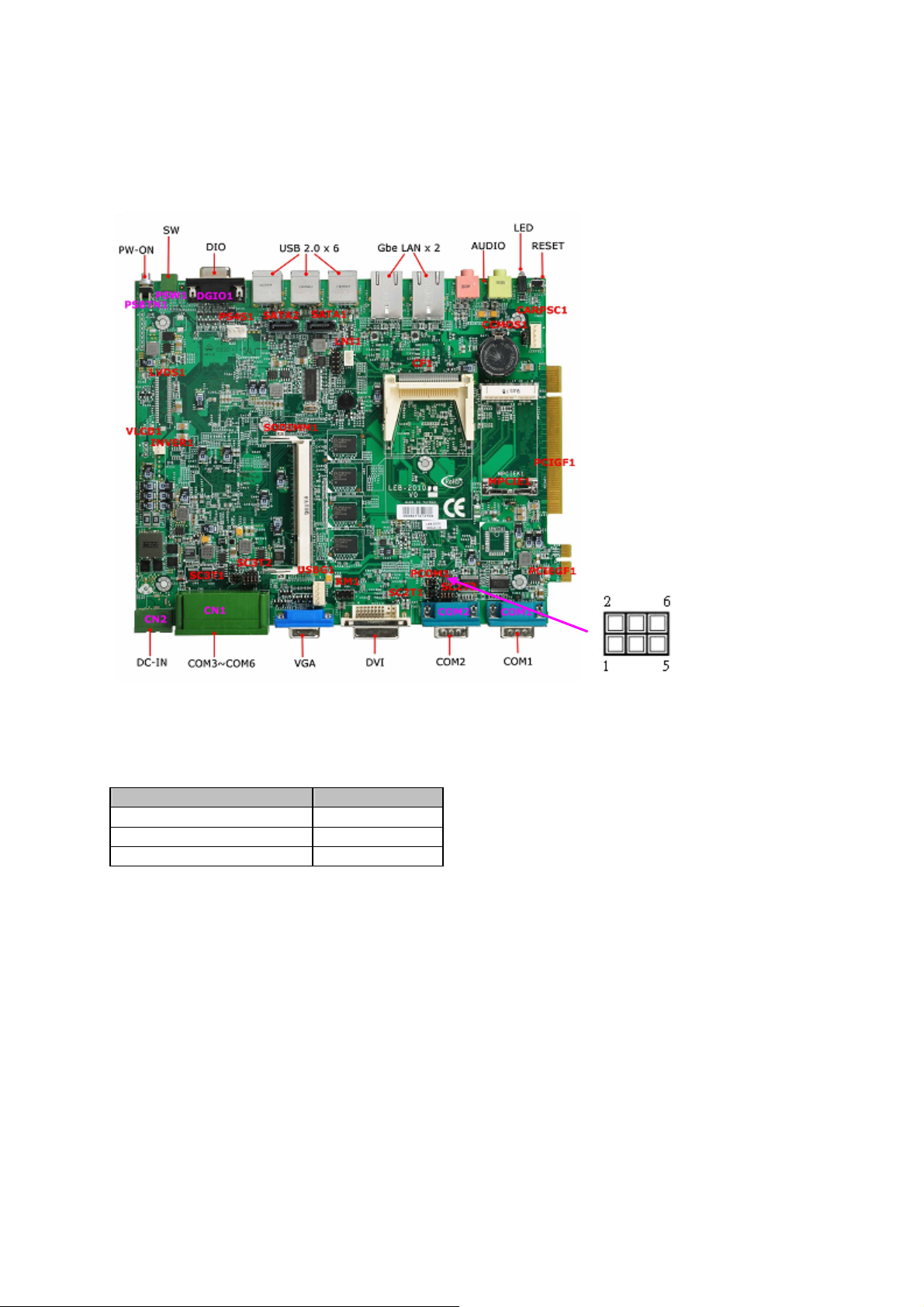

2.2.3.2 SC2T1: Select COM2 Type Jumper

COM2 TYPE SC2T1

RS-232 (Default) 1-2

RS-422 3-4

RS-485 5-6

18

Page 19

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.3 PCOM1 : Select COM1 Pin9 Signal Jumper

Description PCOM1

Ring In 1-2 (Default)

+5V 3-4

+12V 5-6

19

Page 20

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.4 KM1:Keyboard/Mouse Connector Header

(for Factory test only)

Pin No. Description Pin No.

1 +5V 2 MSCLK

3 MSDATA 4 KEY

5 KBDAT 6 KEY

7 GND 8 KBCLK

Description

20

Page 21

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.5 USBG1: USB Port#7 5-Pin Power Connector (5P Male)

Pin No. Description

1 USB_VCC

2 USBD0-

3 USBD0+

4 Ground

5 NG

21

Page 22

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.6 SODIMM1: 200 PIN DDR2 SODIMM SOCKET

Pin No Signal Pin No Signal Pin No

1 VREF 2 VSS46 3 VSS47 4 DQ4

5 DQ0 6 DQ5 7 DQ1 8 VSS15

9 VSS37 10 DM0 11 DQS#0 12 VSS5

13 DQS0 14 DQ6 15 VSS48 16 DQ7

17 DQ2 18 VSS16 19 DQ3 20 DQ12

21 VSS38 22 DQ13 23 DQ8 24 VSS17

25 DQ9 26 DM1 27 VSS49 28 VSS53

29 DQS#1 30 CK0 31 DQS1 32 CK0#

33 VSS39 34 VSS41 35 DQ10 36 DQ14

37 DQ11 38 DQ15 39 VSS50 40 VSS54

41 VSS18 42 VSS20 43 DQ16 44 DQ20

45 DQ17 46 DQ21 47 VSS1 48 VSS6

49 DQS#2 50 NC3 51 DQS2 52 DM2

53 VSS19 54 VSS21 55 DQ18 56 DQ22

57 DQ19 58 DQ23 59 VSS22 60 VSS24

61 DQ24 62 DQ28 63 DQ25 64 DQ29

65 VSS23 66 VSS25 67 DM3 68 DQS#3

69 NC4 70 DQS3 71 VSS9 72 VSS10

73 DQ26 74 DQ30 75 DQ27 76 DQ31

77 VSS4 78 VSS8 79 CKE0 80 CKE1

81 VDD7 82 VDD8 83 NC1 84 A15

85 A16_BA2 86 A14 87 VDD9 88 VDD11

Signal Pin No

Signal

22

Page 23

LEC-2010 Fanless Embedded System User’s Manual

Pin No Signal Pin No Signal Pin No

89 A12 90 A11 91 A9 92 A7

93 A8 94 A6 95 VDD5 96 VDD4

97 A5 98 A4 99 A3 100 A2

101 A1 102 A0 103 VDD10 104 VDD12

105 A10/AP 106 BA1 107 BA0 108 RAS#

109 WE# 110 S0# 111 VDD2 112 VDD1

113 CAS# 114 ODT0 115 S1# 116 A13

117 VDD3 118 VDD6 119 ODT1 120 NC2

121 VSS11 122 VSS12 123 DQ32 124 DQ36

125 DQ33 126 DQ37 127 VSS26 128 VSS28

129 DQS#4 130 DM4 131 DQS4 132 VSS42

133 VSS2 134 DQ38 135 DQ34 136 DQ39

137 DQ35 138 VSS55 139 VSS27 140 DQ44

141 DQ40 142 DQ45 143 DQ41 144 VSS43

145 VSS29 146 DQS#5 147 DM5 148 DQS5

149 VSS51 150 VSS56 151 DQ42 152 DQ46

153 DQ43 154 DQ47 155 VSS40 156 VSS44

157 DQ48 158 DQ52 159 DQ49 160 DQ53

161 VSS52 162 VSS57 163 NCTEST 164 CK1

165 VSS30 166 CK1# 167 DQS#6 168 VSS45

169 DQS6 170 DM6 171 VSS31 172 VSS32

173 DQ50 174 DQ54 175 DQ51 176 DQ55

177 VSS33 178 VSS35 179 DQ56 180 DQ60

181 DQ57 182 DQ61 183 VSS3 184 VSS7

185 DM7 186 DQS#7 187 VSS34 188 DQS7

189 DQ58 190 VSS36 191 DQ59 192 DQ62

193 VSS14 194 DQ63 195 SDA 196 VSS13

197 SCL 198 SA0 199 VDD(SPD) 200 SA1

Signal Pin No

Signal

23

Page 24

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.7 SC3T2: Select COM3 Type Jumper

COM3 TYPE SC3T1 SC3T2

RS-232 (Default) 1-2 1-5,2-6,3-7,4-8

RS-422 3-4 5-9,6-10,7-11,8-12

RS-485 5-6 5-9,6-10,7-11,8-12

24

Page 25

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.8 SC3T1: Select COM3 Type Jumper

COM3 TYPE SC3T1 SC3T2

RS-232 (Default) 1-2 1-5,2-6,3-7,4-8

RS-422 3-4 5-9,6-10,7-11,8-12

RS-485 5-6 5-9,6-10,7-11,8-12

25

Page 26

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.9 VLCD1: Select Panel Voltage Header (Reserved)

Panel Voltage VLCD1

+3.3V ( Default ) 1-2

+5V 2-3

26

Page 27

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.10 INVER1:7 Pin LCD INVETER Connector (Optional)

Pin No. Description

1 +5V

2 GND

3 +12V

4 +12V

5 GND

6 Bright

7 ENBKL

27

Page 28

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.11 LVDS1: LVDS Connector (2Channel 18bits 2x20 1.25mm

Connector /Optional)

Description Description

Pin No.

1 PVDD 2 +12V

3 LCDAD0# 4 LCDBD0#

5 LCDAD0 6 LCDBD0

7 PVDD 8 +12V

9 LCDAD1# 10 LCDBD1#

11 LCDAD1 12 LCDBD1

13 GND 14 GND

15 LCDAD2# 16 LCDBD2#

17 LCDAD2 18 LCDBD2

19 GND 20 GND

21 NC 22 NC

23 NC 24 NC

25 LACLK1# 26 LBCLK2#

27 LACLK1 28 LBCLK2

29 ENBLD1 30 BLCTR

31 GND 32 GND

33 NC 34 NC

35 NC 36 GND

37 NC 38 SPDAT

39 GND 40 SPCLK

LEB-2010I PANEL

Pin No.

LEB-2010I PANEL

28

Page 29

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.12 PS4S1: 4-Pin Power Connector (4P Male)

Pin No. Description

1 +5V

2 GND

3 GND

4 +12V

Note: Only support one 2.5” HDD.

29

Page 30

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.13 SATA1/2: Serial ATA-SATA Socket

Pin No. Description

1 GND

2 TX+

3 TX4 GND

5 RX6 RX+

7 GND

Note: When you connect SATA cable, the Pin 7 of cable will automatically switch to GND.

(Normal Pin7 is +5V for SATA-DOM)

30

Page 31

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.14 LNI1:Line In 3Pin Connector

Pin No. Description

1 LIN-L

2 CO_GND

3 LIN-R

31

Page 32

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.15 CF1:Compact Flash Connector

Pin No. Description Pin No.

1 GND 26 CD12 DATA3 27 DATA11

3 DATA4 28 DATA12

4 DATA5 29 DATA13

5 DATA6 30 DATA14

6 DATA7 31 DATA15

7 CE1# 32 CE2#

8 A10 33 VS1#

9 OE# 34 IOR#

10 A9 35 IOW#

11 A8 36 WE#

12 A7 37 READY#

13 CFVCC3 38 CFVCC3

14 A6 39 CSEL

15 A5 40 VS2#

16 A4 41 RESET

17 A3 42 WAIT#

18 A2 43 INPACK#

19 A1 44 REG#

20 A0 45 DASP#

21 DATA0 46 DIAG#

22 DATA1 47 DATA8

23 DATA2 48 DATA9

24 WP 49 DATA10

25 CD2- 50 GND

Description

32

Page 33

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.16 CCMOS1 : Clear CMOS Data Jumper

Description CCMOS1

Normal (Default) 1-2

Clear CMOS 2-3

33

Page 34

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.17 CARPSC1: Car Application 5-Pin Power Connector

(5P Male/ Reserve for LEC-5011)

Pin No. Description

1 Button-

2 Ground

3 SYS_RST#

4 Ground

5 VCC5

34

Page 35

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.18 MPCIE1: Mini PCI Express 1X Connector

Pin No. Description Pin No. Description

1 WAKE# 2

3 RSV1 4

5 RSV2 6 +1.5V

7 CLKREQ# 8 UIM_PWR

9 Ground 10 UIM_DATA

11 REFCLK- 12 UIM_CLK

13 REFCLK+ 14 UIM_RESET

15 GND3 16 UIM_VPP

KEY KEY

17 RSV3 18 Ground

19 RSV4 20 W_DISABLE#

21 GND5 22

23 PERn0 24

25 PERp0 26 Ground

27 Ground 28 +1.5V

29 Ground 30

31 PETn0 32

33 PETp0 34 Ground

35 Ground 36 USB_D37 RSV5 38

39 RSV6 40

41 RSV7 42 LED_WWAN#

43

45

47 RSV10 48 +1.5V

49 RSV11 50 Ground

51

RSV8

RSV9

RSV12

44 LED_WLAN#

46

52 +3.3V

+3.3V

Ground

PERST#

+3.3Vaux

SMB_SLK

SMB_DATA

USB_D+

Ground

LED_WPAN#

35

Page 36

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.19 PCIGF1: 120 Pin PCI G Golden Finger

No.

-12V TRST# (Ground) 32

1

TCK (Ground) +12V 33

2

3 Ground TMS (Ground) 34 Ground FRAME#

4 TDO TDI (Ground) 35 IRDY# Ground

5 +5V +5V 36 +3.3V TRDY#

6 +5V INTA# 37 DEVSEL# Ground

7 INTB# INTC# 38 Ground STOP#

8 INTD# +5V 39 LOCK# +3.3V

9 PRSNT1# Reserved 40 PERR# SDONE (SMBclk)

Reserved(PREQ-1)

10

11 PRSNT2# Reserved 42 SERR# Ground

12 Ground Ground 43 +3.3V PAR

Ground Ground 44

13

Reserved(PCLK2) 3.3Vaux/PGNT-1 45

14

Ground RST# 46

15

CLK

16

Ground GNT# (PGNT-0) 48

17

REQ# (PREQ-0) Ground 49

18

VI/O(NC)

19

AD﹝31﹞ AD﹝30﹞

20

AD﹝29﹞

21

Ground

22

AD﹝27﹞ AD﹝26﹞

23

AD﹝25﹞

24

+3.3V

25

C/BE﹝3﹞#

26

AD﹝23﹞

27

Ground

28

AD﹝21﹞ AD﹝20﹞

29

AD﹝19﹞

30

+3.3V

31

System Environment System Environment Pin

Side B Side A

VI/O(NC)

VI/O(NC)

PME#

+3.3V

AD﹝28﹞

Ground 55

AD﹝24﹞

IDSEL (AD16) 57

+3.3V 58

AD﹝22﹞

Ground 61

AD﹝18﹞

Pin

No.

AD﹝17﹞ AD﹝16﹞

C/BE﹝2﹞#

41

+3.3V SBO# (SMBdata)

C/BE﹝1﹞# AD﹝15﹞

AD﹝14﹞

Ground

47

AD﹝12﹞ AD﹝11﹞

AD﹝10﹞

M66EN (Ground)

KEY KEY

50

51

KEY KEY

52

AD﹝08﹞ C/BE﹝0﹞#

53

AD﹝07﹞

54

+3.3V

AD﹝05﹞ AD﹝04﹞

56

AD﹝03﹞

Ground

AD﹝01﹞ AD﹝00﹞

59

VI/O(NC) VI/O(NC)

60

ACK64# REQ64#

+5V +5V

+5V +5V

62

Side B Side A

+3.3V

+3.3V

AD﹝13﹞

Ground

AD﹝09﹞

+3.3V

AD﹝06﹞

Ground

AD﹝02﹞

36

Page 37

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.20 PCIEGF1: PCI Express 1x Golden Finger

Pin No. Side B Side A

1 12V PRSNT1#

2 12V 12V

3 12V 12V

4 Ground Ground

5 SMBCLK JTAG2

6 SMBDATA

7 Ground

8 +3.3V

9 JTAG1 +3.3V

10 +3.3VAUX +3.3V

11 WAKE# PCIE_RESET KEY KEY

12 Reserved Ground

13 Ground DEFCLK+

14 PE_TX0+ DEFCLK-

JTAG3

JTAG4

JTAG5

15 PE_TX0- Ground

16 Ground PE_RX0+

17 PRSNT2# PE_RX018 Ground Ground

37

Page 38

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.21 Serial Port COM1/2 Connector (COM1, COM2)

Pin No. Description

TYPE RS-232 RS-422 RS-485

1 Data Carrier Detect ( DCDA # ) 422TX+ DATA+

2 Receive Data ( RXDA ) 422TX- DATA3 Transmit Data ( TXDA ) 422RX+

4 Data Terminal Ready ( DTRA # ) 422RX-

5 Ground ( GND )

6 Data Set Ready ( DSRA # )

7 Request To Send ( RTSA # )

8 Clear To Send ( CTSA # )

9 Ring Indicator ( RIA # )

Note: COM1:RS-232 Only; COM2:RS-232,RS422,RS485

2.2.3.22 COM3 ~ 6 Connector (CN1)

COM3 COM4

Pin No. 20 19 18 17 16 15 14 13 12 11

RS-232 RTS3# SIN3 SOUT3

RS-422 TX+ TX- RX+ RX- GND

RS-485 4-wire TX+ TX- RX+ RX- GND

RS-485 2-wire DATA+ DATA- NC NC GND

COM5 COM6

Pin No. 10 9 8 7 6 5 4 3 2 1

RS-232 RTS5# SIN5 SOUT5 CTS5# GND RTS6# SIN6 SOUT6 CTS6# GND

CTS3# GND RTS4# SIN4 SOUT4 CTS4# GND

Note: Only COM3 can select RS-232/RS-422/RS-485

Pin1~5: COM6 , Pin6~10: COM5 , Pin11~15: COM4 , Pin16~20: COM3

38

Page 39

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.23 DC-IN Connector (CN2)

Pin No. Description

1 GND

2 DC IN

2.2.3.24 DIO Connector/D-SUB9 Female (DGIO1)

Pin No. Description

1 Digital IN 0

2 Digital IN 1

3 Digital IN 2

4 Digital IN 3

5 Ground

6 Digital Out 0

7 Digital Out 1

8 Digital Out 2

9 Digital Out 3

39

Page 40

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.25 SW Connector (PSW1)

Pin No. Description

1 Button2 GND

Note: ATX Power Switch Connector

2.2.3.26 PW-ON Button (PSBIN1)

Pin No. Description PIN Description

PAD1 Ground PAD2 Ground

1 Ground 3 BUTTON2 Ground 4 BUTTON-

L1

PWR_LED+ /

STB_LED-

L2

PWR_LED- /

STB_LED+

Note: Power ON: Green LED ; Standby: Red LED

40

Page 41

LEC-2010 Fanless Embedded System User’s Manual

2.2.3.27 MIC IN Connector/5Pin-PHONE Jack (MIC1)

Pin No. Description

1 CO_GND

2 MIC_INL

3 CO_GND

4 MIC-JDET

5 MIC_INR

2.2.3.28 LINE OUT Connector/5Pin-PHONE Jack (LNO1)

Pin No. Description

1 CO_GND

2 LINOUT-L

3 CO_GND

4 LINOUT-JDET

5 LINOUT- R

41

Page 42

LEC-2010 Fanless Embedded System User’s Manual

3. Hardware Installation Guide

3.1 LEC-2010 Embedded System

Figure 7 – LEC-2010 Embedded System Outlook

42

Page 43

LEC-2010 Fanless Embedded System User’s Manual

3.1.1 Begin Installation

1. Unscrew the 5 thumbscrews and 2 spacers at the rear bezel

2. Remove the rear Bezel

3. Unscrew the 5 thumbscrews and 8 spacers at the front bezel

43

Page 44

LEC-2010 Fanless Embedded System User’s Manual

4. Remove the rear Bezel

5. Unscrew the 6 thumbscrews at the bottom cover than remove the bottom cover

Note: For Safety reasons, please ensure that the power cord is disconnected

before opening the case.

44

Page 45

LEC-2010 Fanless Embedded System User’s Manual

3.1.2 System Memory Installation

Insert the memory module into the socket and push firmly until it is fully seated.

Note: The maximum capacity of DDR2 memory module is 1GB.

3.1.3 CompactFlash Card Installation

Carefully insert the CompactFlash card into the slot as shown in the illustration above.

45

Page 46

LEC-2010 Fanless Embedded System User’s Manual

3.1.4 PCI Module Installation

1. Replace the front bezel on the system and than refasten the 2 thumbscrews

2. Unscrew the screw and than remove the PCI bezel

46

Page 47

LEC-2010 Fanless Embedded System User’s Manual

3. Installing PCI module into PCI riser card

4. Refasten the screw

47

Page 48

LEC-2010 Fanless Embedded System User’s Manual

5. PCI module installation is now complete

48

Page 49

LEC-2010 Fanless Embedded System User’s Manual

3.1.5 LEC-2010 Hard Disk Installation

*HDD packing:

Spacer x 4

HDD Screw x 4

Serial ATA/Power Cable x 1

HDD Screw

Note: Please install 2.5” HDD

1. Invert Bottom Aluminum cover (Inverted )

*Inside View of the bottom cover

49

Page 50

LEC-2010 Fanless Embedded System User’s Manual

2. Position the Hard Disk on the bottom cover properly so that the screw holes of the Hard

Disk can match the holes with the cover for installation.

3. Begin to secure the hard disk with the 4 HDD screws on the right side of the bottom

cover

*Secure with 4 HDD screws on the right side of bottom cover

50

Page 51

LEC-2010 Fanless Embedded System User’s Manual

4. Connect the Serial ATA/Power Cable to the HDD

*Serial ATA/Power Cable

5. Plug the Serial ATA cable to the SATA Connector (SATA1 or SATA2)

*Plug the Serial ATA cable to the SATA Connector

51

Page 52

LEC-2010 Fanless Embedded System User’s Manual

6. Plug the Power cable to the 4-Pin Power Connector (PS4S1)

3.1.6 System Installation is now Complete

1. Replace the bottom cover

(Please don’t refasten the thumbscrews at bottom cover)

52

Page 53

LEC-2010 Fanless Embedded System User’s Manual

2. Replace the front bezel on the system

3. Refasten the 5 thumbscrews and 8 spacers at the front bezel

4. Replace the rear bezel on the system

53

Page 54

LEC-2010 Fanless Embedded System User’s Manual

5. Refasten the 5 thumbscrews and 2 spacers at the rear bezel

6. Refasten the 6 thumbscrews at the bottom cover than the LEC-2010 Embedded System

Installation is completed

**Note: Please load the optimized BIOS values ***

54

Page 55

LEC-2010 Fanless Embedded System User’s Manual

3.2 Mounting Kits

3.2.1 Wall Mount View

Figure 9 – LEB-2010 System Board

3.2.2 Wall Mount Package and Ordering Information

Package Contents Q'ty Photo Ordering Information

Wall Mount Screw (M3x6 Ni) 4

Wall Mount Kits 1

55

*P/N:070W103000601

*P/N:SE9ESA829R110

Page 56

LEC-2010 Fanless Embedded System User’s Manual

A. Appendix A: LED Indicators

A.1 LAN Port LED

Link/Active (Left LED )

Status Description LED/Color

On LAN is link to 10 or 100 or 1000Mbps Yellow

Blink LAN port is receiving and transmitting packets. Yellow

Speed (Right LED)

Status Description LED/Color

Off LAN is link to 10Mbps Dark

On LAN is link to 100Mbps Green

On LAN is link to 1000Mbps Yellow

A.2 Power-on Button LED

Color Status

Red Standby

Green Power-on

56

Page 57

LEC-2010 Fanless Embedded System User’s Manual

A.3 HDD LED

Color Status

Yellow Storage Access

A.4 POWER LED

Color Status

Yellow Storage Access

57

Page 58

LEC-2010 Fanless Embedded System User’s Manual

B. Appendix B: Watchdog Timer

B.1 Introduction

systems need to be self-reliant. If an error should occur it is typically not possible to wait for

the system to be rebooted manually. In some cases, such as space probes, the system is

simply not accessible to human operators. If such systems should ever hang, they would be

permanently disabled. In other cases, the speed at which a human operator would reset the

system would be too slow to meet the uptime requirements of the product.

A watchdog timer is a piece of hardware that can be used to automatically detect system

anomalies and reset the processor in the case any problems are found. Generally speaking,

a watchdog timer is based on a counter that counts down from an initial value to zero. The

software selects the counter's initial value and periodically restarts it. Should the counter

reach zero before the software restarts it, the software is presumed to be malfunctioning,

and the processor's reset signal is asserted. Thus, the processor will be restarted as if a

human operator had cycled the power.

B.2 Detail Register Descriptions

A watchdog action consists of a series of watchdog instructions. A watchdog instruction is

the operation on a register region. This section describes the detail register in LPD I/O

(W83697UHG)

B.2.1 To use the watch-dog timer

For DOS system:

Execute the WD.EXE file under DOS (WD.EXE and CWSDPMI.EXE should be placed on same

directory), then key-in 0~255. The system will reboot automatically according to the

time-out you set.

Watch Dog sample code:

#include <stdio.h>

#include <string.h>

#include <dos.h>

#include <stdlib.h>

#include <inlines/pc.h>

#define INDEX_PORT 0x2e

#define DATA_PORT 0x2f

void help()

{

printf("Watchdog timer control for EM-9345\n\n");

printf("wd.exe -wr xxx (1-255 sec)(Watchdog Control - SYSTEM RESET)\n");

printf("\n");

}

int main(int argc, char *argv[])

{

int temp, time;

if( argc < 2 )

{

58

Page 59

LEC-2010 Fanless Embedded System User’s Manual

help();

return -1;

}

if( strcmp(argv[1], "-wr") == 0 )

{

if( argc != 3 )

{

help();

return -1;

}

write_w83627_reg(0x8, 0xf6, 0); //LDN=8, CRF6, stop timer first

//clear status bit

write_w83627_reg(0x8, 0xf7, read_w83627_reg(0x8, 0xf7) & 0xef);

time = atoi(argv[2]);

printf("Setting Watchdog timer for System Reset...\n");

set_watchdog(time);

return 0;

}

else

{

help();

return -1;

}

return 0;

}

int set_watchdog(int time)

{

int temp;

outportb(INDEX_PORT, 0x87);

delay(1);

outportb(INDEX_PORT, 0x87); //Entering

W83627HF Configuration

temp = read_w83627_reg(0, 0x2b); //LDN=0, CR2B

temp &= 0xf3;

temp |= 0x04;

write_w83627_reg(0, 0x2b, temp); //set watchdog pin

write_w83627_reg(0x8, 0xf6, 0); //LDN=8, CRF6, stop timer first

write_w83627_reg(0x8, 0xf5, read_w83627_reg(0x8, 0xf5) & 0xf7); //;set

second

write_w83627_reg(0x8, 0xf7, read_w83627_reg(0x8, 0xf7) & 0xef); //;clear

status

write_w83627_reg(0x8, 0x30, read_w83627_reg(0x8, 0x30) | 0x01); //;enable

LDN8

temp = time;

write_w83627_reg(0x8, 0xf6, temp); //LDN=8, CRF6, set

watchdog timer time-out value

outportb(INDEX_PORT, 0xaa); //Exit W83627HF

Configuration

return 0;

}

int read_w83627_reg(int LDN, int reg)

{

outportb(INDEX_PORT, 0x07); //LDN register

delay(1);

outportb(DATA_PORT, LDN);

delay(1);

outportb(INDEX_PORT, reg);

delay(1);

return inportb(DATA_PORT);

}

59

Page 60

LEC-2010 Fanless Embedded System User’s Manual

int write_w83627_reg(int LDN, int reg, int value)

{

outportb(INDEX_PORT, 0x07); //LDN register

delay(1);

outportb(DATA_PORT, LDN);

delay(1);

outportb(INDEX_PORT, reg);

delay(1);

outportb(DATA_PORT, value);

return 0;

}

Note: The watchdog function is from the WINBODN 83627UHG.. Lanner provides sample codes in the

Manual/ Driver CD under the path: LEC-2010 Driver / LEC-2010 Utility/WatchDog

60

Page 61

LEC-2010 Fanless Embedded System User’s Manual

C. Appendix C: DIO

C.1 To use the DIO

For DOS system:

Execute the DIO.EXE file under DOS (DIO.EXE and CWSDPMI.EXE should be placed on same

directory).

DIO sample code:

#include <stdio.h>

#include <dos.h>

/* This program assume 4 Input and 4 output */

/* Digital Input=GP24,25,26,27==> mapping to OUT0~3 */

/* Digital Output=GP60,61,62,63 ==> mapping to IN0~3 */

#define SUPERIO_INDEX 0x2e

#define SUPERIO_DATA 0x2f

#define BANK_REG 0x07

#define GPIO0 0x01

#define GPIO1 0x02

#define GPIO2 0x04

#define GPIO3 0x08

#define GPIO4 0x10

#define GPIO5 0x20

#define GPIO6 0x40

#define GPIO7 0x80

int print_help(char *argv[])

{

printf("using: %s [i/o] [value]\n", argv[0]);

printf("Note:all data in hexadecimal format\n");

printf("eg: %s i ==>read Digital Input pin(3 2 1 0)\n");

printf(" %s o 8 ==>write 1000 to Output pin(3 2 1 0)\n");

printf(" %s o 0 ==>write 0000 to Output pin(3 2 1 0)\n");

printf(" %s o f ==>write 1111 to Output pin(3 2 1 0)\n");

printf("Program terminated !!!\n");

exit(1);

}

void enter_sio_config()

{

outportb(SUPERIO_INDEX, 0x87);

delay(1); //delay some time

outportb(SUPERIO_INDEX, 0x87);

}

void exit_sio_config()

{

outportb(SUPERIO_INDEX, 0xaa);

}

unsigned char read_sio_reg(unsigned char bank_no, unsigned char reg_no)

{

unsigned char reg_data;

61

Page 62

LEC-2010 Fanless Embedded System User’s Manual

enter_sio_config();

outportb(SUPERIO_INDEX, BANK_REG);

delay(1);

outportb(SUPERIO_DATA, bank_no);

delay(1);

outportb(SUPERIO_INDEX, reg_no);

delay(1);

reg_data=inportb(SUPERIO_DATA);

exit_sio_config();

return reg_data;

}

void write_sio_reg(unsigned char bank_no, unsigned char reg_no, unsigned char

write_data)

{

enter_sio_config();

outportb(SUPERIO_INDEX, BANK_REG);

delay(1);

outportb(SUPERIO_DATA, bank_no);

delay(1);

outportb(SUPERIO_INDEX, reg_no);

delay(1);

outportb(SUPERIO_DATA, write_data);

exit_sio_config();

}

unsigned char Get_DIO_Input_value()

{

unsigned char temp1;

temp1 = (read_sio_reg(0x08,0xE5) & 0x0F);

return temp1;

}

void Set_DIO_Output_value(unsigned char temp1)

{

write_sio_reg(0x09,0xE5, (read_sio_reg(0x09,0xE5) & 0x0F) | temp1);

}

void Init_GPIO(void) {

write_sio_reg(0x09,0x30,0x02); //;enable GPIO2

function

write_sio_reg(0x08,0x30,0x04); //;enable GPIO6

function

write_sio_reg(0x09,0xE4,(read_sio_reg(0x09,0xE4) &

~(GPIO4+GPIO5+GPIO6+GPIO7))); //;set GPI024,25,26,27=output

write_sio_reg(0x08,0xE4,(read_sio_reg(0x08,0xE4) |

(GPIO0+GPIO1+GPIO2+GPIO3))); //;set GPI060,61,62,63=input

}

main(int argc, char *argv[])

{

int io_mode; //0: read 1:write

char *ptr;

unsigned char tmp;

unsigned char Input_value, Output_value;

printf("===============================================\n");

printf(" Digital IO test program for LEB-2010I Ver:1.0\n" );

printf("===============================================\n");

Init_GPIO();

if ((argc<2)||(argc>4))

{

print_help(argv); //;The parameter over or not enough

62

Page 63

LEC-2010 Fanless Embedded System User’s Manual

}

if((*argv[1]=='i')|(*argv[1]=='I')) {

io_mode=0; //;0 for read

} else {

if((*argv[1]=='o')|(*argv[1]=='O')) {

io_mode=1; //;1 for write

// try to get the value which want to be write

ptr=argv[2];

tmp=*ptr;

switch (tmp)

{

case '0':

Output_value = 0;

break;

case '1':

Output_value = 1;

break;

case '2':

Output_value = 2;

break;

case '3':

Output_value = 3;

break;

case '4':

Output_value = 4;

break;

case '5':

Output_value = 5;

break;

case '6':

Output_value = 6;

break;

case '7':

Output_value = 7;

break;

case '8':

Output_value = 8;

break;

case '9':

Output_value = 9;

break;

case 'a':

case 'A':

Output_value = 10;

break;

case 'b':

case 'B':

Output_value = 11;

break;

case 'c':

case 'C':

Output_value = 12;

break;

case 'd':

case 'D':

Output_value = 13;

break;

case 'e':

case 'E':

Output_value = 14;

break;

case 'f':

case 'F':

63

Page 64

LEC-2010 Fanless Embedded System User’s Manual

Output_value = 15;

break;

default:

print_help(argv);

}

}

else {

print_help(argv);

}

}

if(io_mode==0) {

Input_value = Get_DIO_Input_value();

printf(" The Input pin of Digital IO = 0x%x\n", Input_value);

} else {

Set_DIO_Output_value(Output_value <<4); // use bit3~0 map to GPO24~27

printf(" write done...\n");

}

}

Note: The DIO function is from the WINBODN 83627UHG. Lanner provides samp le codes in the Manual/

Driver CD under the path: LEC-2010 Driver / LEC-2010 Utility/4bit-DIO

64

Page 65

LEC-2010 Fanless Embedded System User’s Manual

Terms and Conditions

Date:2007.03.19

Warranty Policy

1. All products are under warranty against defects in materials and wor kmanship for

a period of one year from the date of purchase.

2. The buyer will bear the return freight charges for goods returned for repair within

the warranty period; whereas the manufacturer will bear the after service freigh t

charges for goods returned to the user.

3. The buyer will pay for repair (for replaced components plus service time) and

transportation charges (both ways) for items after the expiration of the warranty

period.

4. If the RMA Service Request Form does not meet the stated requirement as listed

on “RMA Service,” RMA goods w ill be ret urned at customer’s expense.

5. The following conditions are excluded from this warranty:

Improper or inadequate maintenance by the customer

Unauthorized modification, misuse, or reversed engineering of the product

Operation outside of the environmental specifications for the product.

RMA Service :

Requesting a RMA#

1. To obtain a RMA number, log on to the leRMA web interface at

http://erma.lannerinc.com . Use you user name and password as supplied to you

from your Lanner account manager.

2. Once you have logged on, follow the onscreen instructions to complete the RMA

process.

3. Ship the defective unit(s) on freight prepaid terms. Use the original packing

materials when possible.

4. Mark the RMA# clearly on the box.

Note: If you have any issues with the eRMA system, email support@lannerinc.com for

assistance.

65

Loading...

Loading...