Page 1

Network

Application Platforms

Hardware platforms for next generation networking infrastructure

HCP-72i1

V1.0

User's Manual

Release Date: 2015/06/19

www.lannerinc.com

Page 2

2

www.lannerinc.com

Overview

Icon Descriptions

The icons are used in the manual to serve as an

indication of interest topics or important messages.

Below is a description of these icons:

NOTE: This check mark indicates

that there is a note of interest and is

something that you should pay special

attention to while using the product.

WARNING: This exclamation point

indicates that there is a caution or

warning and it is something that could

damage your property or product.

Online Resources

The listed websites are links to the on-line product

information and technical support.

Resource Website

Lanner http://www.lannerinc.com

Product

Resources

http://www.lannerinc.com/downloadcenter/

RMA http://eRMA.lannerinc.com

Copyright and Trademarks

This document is copyrighted, © 2014 All rights are

reserved. The original manufacturer reserves the right to

make improvements to the products described in this

manual at any time without notice.

No part of this manual may be reproduced, copied,

translated or transmitted in any form or by any means

without the prior written permission of the original

manufacturer. Information provided in this manual

is intended to be accurate and reliable. However, the

original manufacturer assumes no responsibility for its

use, nor for any infringements upon the rights of third

parties that may result from such use.

Acknowledgement

Intel, Pentium and Celeron are registered trademarks of

Intel Corp.

Microsoft Windows and MS-DOS are registered

trademarks of Microsoft Corp.

All other product names or trademarks are properties of

their respective owners.

Compliances

CE

This product has passed the CE test for environmental

specifications. Test conditions for passing included

the equipment being operated within an industrial

enclosure. In order to protect the product from being

damaged by ESD (Electrostatic Discharge) and EMI

leakage, we strongly recommend the use of CEcompliant industrial enclosure products.

FCC Class A

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference

in which case the user will be required to correct the

interference at his own expense.

Safety Guidelines

Follow these guidelines to ensure general safety:

Keep the chassis area clear and dust-free during •

and after installation.

Do not wear loose clothing or jewelry that could •

get caught in the chassis. Fasten your tie or scarf

and roll up your sleeves.

Wear safety glasses if you are working under any •

conditions that might be hazardous to your eyes.

Do not perform any action that creates a potential •

hazard to people or makes the equipment unsafe.

Disconnect all power by turning off the power and •

unplugging the power cord before installing or

removing a chassis or working near power supplies

Do not work alone if potentially hazardous •

conditions exist.

Never assume that power is disconnected from a •

circuit; always check the circuit.

Page 3

3

www.lannerinc.com

LITHIUM BATTERY CAUTION:

Risk of Explosion if Battery is replaced by an incorrect

type. Dispose of used batteries according to the

instructions

Operating Safety

Electrical equipment generates heat. Ambient air

temperature may not be adequate to cool equipment to

acceptable operating temperatures without adequate

circulation. Be sure that the room in which you choose to

operate your system has adequate air circulation.

Ensure that the chassis cover is secure. The chassis design

allows cooling air to circulate effectively. An open chassis

permits air leaks, which may interrupt and redirect the

flow of cooling air from internal components.

Electrostatic discharge (ESD) can damage equipment

and impair electrical circuitry. ESD damage occurs when

electronic components are improperly handled and can

result in complete or intermittent failures. Be sure to

follow ESD-prevention procedures when removing and

replacing components to avoid these problems.

Wear an ESD-preventive wrist strap, ensuring that it

makes good skin contact. If no wrist strap is available,

ground yourself by touching the metal part of the

chassis.

Periodically check the resistance value of the antistatic

strap, which should be between 1 and 10 megohms

(Mohms).

EMC Notice

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference

in which case users will be required to correct the

interference at their own expense.

Consignes de sécurité

Suivez ces consignes pour assurer la sécurité générale :

Laissez la zone du châssis propre et sans poussière •

pendant et après l’installation.

Ne portez pas de vêtements amples ou de bijoux qui •

pourraient être pris dans le châssis. Attachez votre

cravate ou écharpe et remontez vos manches.

Portez des lunettes de sécurité pour protéger vos •

yeux.

N’effectuez aucune action qui pourrait créer un •

danger pour d’autres ou rendre l’équipement

dangereux.

Coupez complètement l’alimentation en éteignant •

l’alimentation et en débranchant le cordon

d’alimentation avant d’installer ou de retirer un

châssis ou de travailler à proximité de sources

d’alimentation.

Ne travaillez pas seul si des conditions dangereuses •

sont présentes.

Ne considérez jamais que l’alimentation est coupée •

d’un circuit, vérifiez toujours le circuit. Cet appareil

génère, utilise et émet une énergie radiofréquence

et, s’il n’est pas installé et utilisé conformément aux

instructions des fournisseurs de composants sans

fil, il risque de provoquer des interférences dans les

communications radio.

Avertissement concernant la pile au

lithium

Risque d’explosion si la pile est remplacée par une •

autre d’un mauvais type.

Jetez les piles usagées conformément aux •

instructions.

L’installation doit être effectuée par un électricien •

formé ou une personne formée à l’électricité

connaissant toutes les spécifications d’installation et

d’appareil du produit.

Ne transportez pas l’unité en la tenant par le câble •

d’alimentation lorsque vous déplacez l’appareil.

La machine ne peut être utilisée qu’à un lieu fixe •

comme en laboratoire, salle d’ordinateurs ou salle de

classe.

Sécurité de fonctionnement

L’équipement électrique génère de la chaleur. La •

température ambiante peut ne pas être adéquate

pour refroidir l’équipement à une température de

fonctionnement acceptable sans circulation adaptée.

Vérifiez que votre site propose une circulation d’air

adéquate.

Vérifiez que le couvercle du châssis est bien •

fixé. La conception du châssis permet à l’air de

refroidissement de bien circuler. Un châssis ouvert

laisse l’air s’échapper, ce qui peut interrompre et

rediriger le flux d’air frais destiné aux composants

internes.

Les décharges électrostatiques (ESD) peuvent •

endommager l’équipement et gêner les circuits

électriques. Des dégâts d’ESD surviennent lorsque

des composants électroniques sont mal manipulés et

peuvent causer des pannes totales ou intermittentes.

Suivez les procédures de prévention d’ESD lors du

retrait et du remplacement de composants.

- Portez un bracelet anti-ESD et veillez à ce qu’il soit

bien au contact de la peau. Si aucun bracelet n’est

disponible, reliez votre corps à la terre en touchant la

Page 4

4

www.lannerinc.com

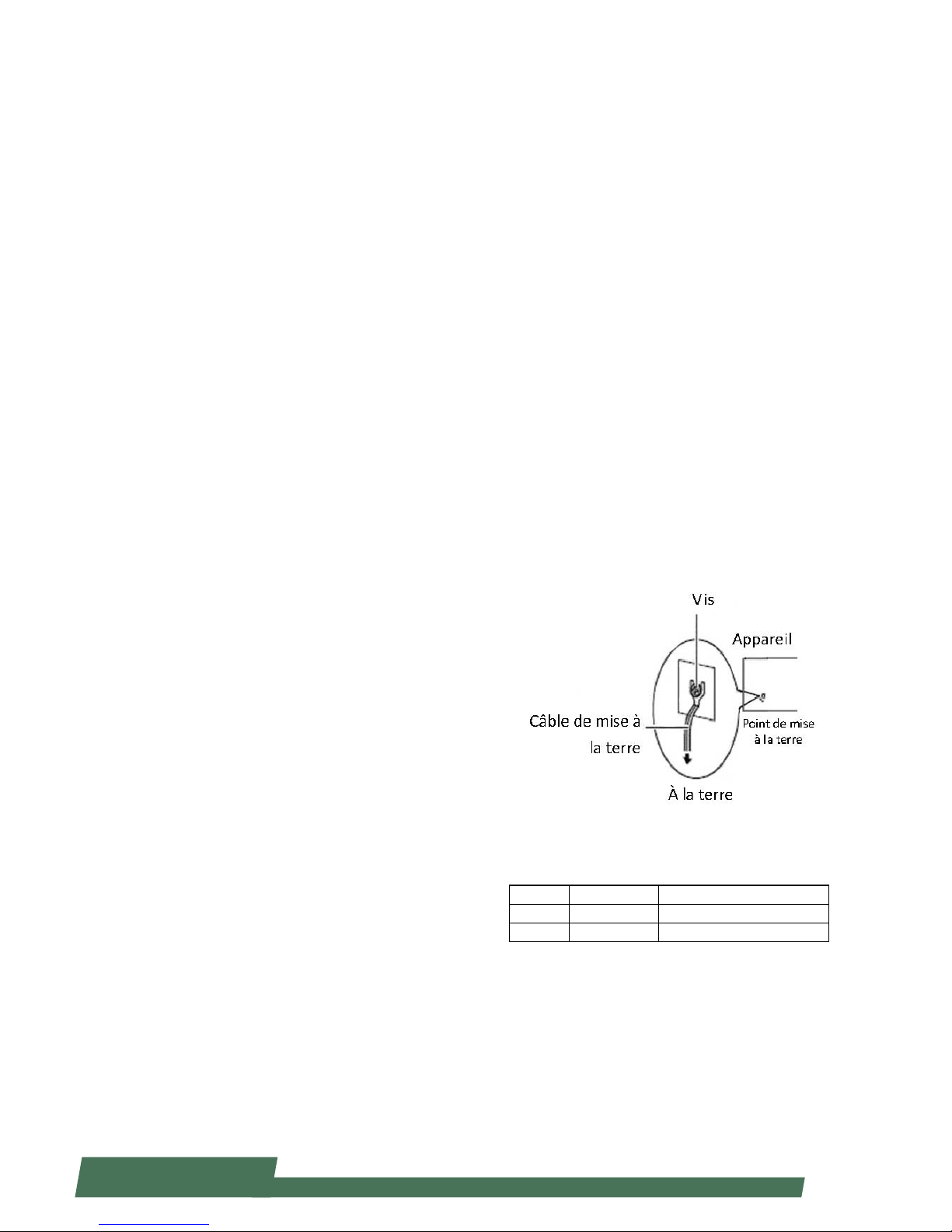

Consignes de sécurité électrique

Avant d’allumer l’appareil, reliez le câble de mise à la •

terre de l’équipement à la terre.

Une bonne mise à la terre (connexion à la terre) est •

très importante pour protéger l’équipement contre

les effets néfastes du bruit externe et réduire les

risques d’électrocution en cas de foudre.

Pour désinstaller l’équipement, débranchez le câble •

de mise à la terre après avoir éteint l’appareil.

Un câble de mise à la terre est requis et la zone •

reliant les sections du conducteur doit faire plus de 4

mm2 ou 10 AWG.

Procédure de mise à la terre pour source

d’alimentation CC Procédure de mise à la

terre pour source d’alimentation CC

Desserrez la vis du terminal de mise à la terre. •

Branchez le câble de mise à la terre à la terre.•

L’appareil de protection pour la source •

d’alimentation CC doit fournir 30 A de courant.

Cet appareil de protection doit être branché à la

source d’alimentation avant l’alimentation CC.

Revision History

Version Date Descriptions

V0.1 2014/12/09 Preliminary

V1.0 2015/06/19 Ocial release

partie métallique du châssis.

Vérifiez régulièrement la valeur de résistance du bracelet

antistatique, qui doit être comprise entre 1 et 10

mégohms (Mohms).

Consignes de sécurité électrique

Avant d’allumer l’appareil, reliez le câble de mise à la •

terre de l’équipement à la terre.

Une bonne mise à la terre (connexion à la terre) est •

très importante pour protéger l’équipement contre les

effets néfastes du bruit externe et réduire les risques

d’électrocution en cas de foudre.

Pour désinstaller l’équipement, débranchez le câble de •

mise à la terre après avoir éteint l’appareil.

Un câble de mise à la terre est requis et la zone reliant •

les sections du conducteur doit faire plus de 4 mm2 ou

10 AWG.

Procédure de mise à la terre pour source

d’alimentation CC Procédure de mise à la

terre pour source d’alimentation CC

Desserrez la vis du terminal de mise à la terre. •

Branchez le câble de mise à la terre à la terre.•

L’appareil de protection pour la source d’alimentation •

CC doit fournir 30 A de courant.

Cet appareil de protection doit être branché à la source

d’alimentation avant l’alimentation CC.

pour refroidir l’équipement à une température de •

fonctionnement acceptable sans circulation adaptée.

Vérifiez que votre site propose une circulation d’air

adéquate.

Vérifiez que le couvercle du châssis est bien fixé. La •

conception du châssis permet à l’air de refroidissement

de bien circuler. Un châssis ouvert laisse l’air s’échapper,

ce qui peut interrompre et rediriger le flux d’air frais

destiné aux composants internes.

Les décharges électrostatiques (ESD) peuvent •

endommager l’équipement et gêner les circuits

électriques. Des dégâts d’ESD surviennent lorsque

des composants électroniques sont mal manipulés et

peuvent causer des pannes totales ou intermittentes.

Suivez les procédures de prévention d’ESD lors du

retrait et du remplacement de composants.

- Portez un bracelet anti-ESD et veillez à ce qu’il soit bien

au contact de la peau. Si aucun bracelet n’est disponible,

reliez votre corps à la terre en touchant la partie

métallique du châssis.

Vérifiez régulièrement la valeur de résistance du bracelet

antistatique, qui doit être comprise entre 1 et 10

mégohms (Mohms).

Page 5

5

www.lannerinc.com

Table of Contents

Chapter 1: Introduction 10

System Specification 10

Package Contents 11

Block Diagram 12

Physical Architecture of Lanner’s HybridTCA 13

Chapter 2: System Components 15

Mechanical Drawings 15

Front Components 16

Rear Components 17

Chapter 3: Motherboard Information 19

An Internal Glance of HCP-72i1 19

Jumper and Connector Location 21

Connectors and Jumpers List 22

Jumper Settings & Connectors Pin Definitions 23

Chapter 4: Hardware Installation 27

Preparing the Hardware Installation 27

Accessing the Components 27

Installing CPU and the Heat Sink 28

Installing the System Memory 29

Installing IPMI Card on OPMA Socket 29

Installing HDD/SSD 30

Replacing Network I/O Modules 31

Replacing Power Supply Units 31

Page 6

6

www.lannerinc.com

Replacing Cooling Fans 32

Rack Mounting 33

Chapter 5: BIOS Setup 36

Main 37

Advanced 38

WHEA Configuration 40

CPU Configuration 41

SATA Configuration 46

USB Configuration 48

Hardware Monitor 51

LAN Module Hardware Monitor 52

LAN Boot Select 53

Serial Port Console Redirection 54

COM Console Redirection Settings 55

Chipset 60

IOH Configuration 61

Intel (R) VT for Directed I/O Configuration 62

Boot 68

Security 75

Save & Exit 76

Chapter 6: IPMI Navigation 78

Getting Started 78

Dashboard 79

Remote Control 79

Remote Control -- Launched 80

Introducing the Remote Control Functions 81

Page 7

7

www.lannerinc.com

Configuration 87

DNS Server Settings 87

Mouse Mode Settings 88

Network Settings 89

Network Link Configuration 90

NTP Settings 91

Services 91

SSL Certificate Configuration 92

User Management 93

Remote Control 94

Console Redirection 94

Server Power Control 95

Maintenance 95

Firmware Update 96

Restore Factory Defaults 96

System Administrator 96

Chapter 7: About the PCIe-Switch Feature of HCP-72i1 98

Brief 98

Default Settings of PCI Express Switch 99

Demonstrating the Switching Methods for the PCIe Switch 99

Initializing the System for Re-planning the Arrangement of PCI Bus ID 100

Scenario 1: Bottom Board as Management Port, Device 2/3 Taken by Bottom Board 101

Scenario 2: Bottom Board as Management Port, Device 2/3 Returned to Upper Board 104

Description of PLX8748 Register 105

Management of the Control Register 105

Secondary Bus Reset 105

Virtual Switch 105

Page 8

8

www.lannerinc.com

Appendix 1: About the Non-Transparent Bridge 106

Appendix 2: Programming Watchdog Timer 110

Appendix 3: Setting up Console Redirections 110

Appendix 4: Programming the LCM 111

Appendix 5: On Linux 114

Appendix 6: Terms and Conditions 115

Warranty Policy 115

RMA Service 115

Page 9

9

www.lannerinc.com

Chapter 1

Introduction

Page 10

10

www.lannerinc.com

Chapter 1:

Introduction

Thank you for choosing HCP-72i1. HCP-72i1 is a

2U rackmount network security appliance built

with Lanner’s unique Hybrid Telecommunications

Computing Architecture (HybridTCA™).

HCP-72i1 integrates control, management and data

processing in one system and is positioned as an ideal

solution for datacenters and telecommunications

carriers. It comes with two x86 mainboards, each

supporting two Intel Xeon E5-2600 series “Ivy Bridge EP”

processors on LGA2011.

HCP-72i1 can be fitted, via the three (max.) swappable

I/O blades, with up to 36 1GbE network ports or 24

10GbE network ports in an array of SFP or copper

combinations. This particular appliance also comes with

8 quad-channel DDR3 modules and 2 removable SAS/

SATA HDD bays, future-proofing most of the expansion

needs.

SFeatures:

Intel Sandy/Ivy Bridge EP Xeon® Processor E5-2697 •

v2 CPUs, with Patsburge-B 602 PCH

2 x86 CPU Blades in the rear, each blade support •

Ivy-Bridge E5-2600 v2 Family up to 130W CPU

Dual Mainboard Communication is through NTB •

port up to 20 Gbs bi-way

Each Blade Support 16x R-DIMM•

3 network I/O Blades on the front•

IPMI Port for Remote Management•

Removable Fan Module•

NEBS Ready Design•

2 x 2.5” HDD Bay•

Hinge LCD Module for Easy Diagnostics and •

Configuration

System Specification

Form Factor 2U Rackmount

Platform

Processor

Options

Intel Sandy / Ivy Bridge EP (Intel®

Xeon® Processor E5-2697 v2 (30M

Cache, 2.70 GHz)

Dual 2011 pin LGA sockets

Chipset Intel Patsburg-B 602

BIOS

64Mb Flash Memory with AMI®

BIOS

System

Memory

Technology

16 x 240-pin DIMM Sockets per

board

Max. Capacity

Up to 32GB DDR3 1600 ECC Registered DIMM

Socket 16 x 240-pin DIMM Sockets

OS Support

Supports 32-bit/64-bit

operating systems

Storage HDD Bays 2 x SATA 2.5” HDD/SSD

Networking

Outputs (per

board)

Management

Port

1 x RJ-45 Intel 82574L Gigabit

supports 10BASE-T,100BASE-T, and

1000BASE-T

SYNC Port 1 x SFP+ port

LOM Port

1 x RJ-45 at 10/100/1000 base-T

speeds

Console Port 1 x RJ-45 port

Ethernet

Expansion

3 x LAN I/O blades for network

modules. Each I/O slot supports PCIe

x8 Gen 3.0

I/O Interface

(per board)

Reset Button

1 x reset button

Software reset by default

Console 1 x RJ45

USB

1 x USB 2.0

1 x USB 2.0 pin header

ESD 1 x ESD jack

SATA

1 x internal SATA II connector

1 x mini PCIe connector (serving as

mSATA)

LCM

128 x 64 Graph LCM with 4 key pad

Hinge LCM

1 LED for power,1 LED for Status

and 1 LED for HDD

Expansion (per

board)

PCIe

3 x PCIe Gen3.0x8 (to front side

module)

1 x PCIe Gen 3.0x8 (NTB)

1 x PCIe Gen2.0x4 (for front I/O)

1 x PCIe Gen2.0 (for Mgmt port)

PCI N/A

Power supply

AC redundant 1,200W hot-plug,

auto-switching 85/264V, 13A

DC redundant 1,010W hot-plug,

auto-switching, -36 to -76V, 30A

System Cooling

5 x system fans each layer

Supports smart fan feature

Environment

Operating

Temperature

0º to 50º C

Operating

Humidity

5% to 95%

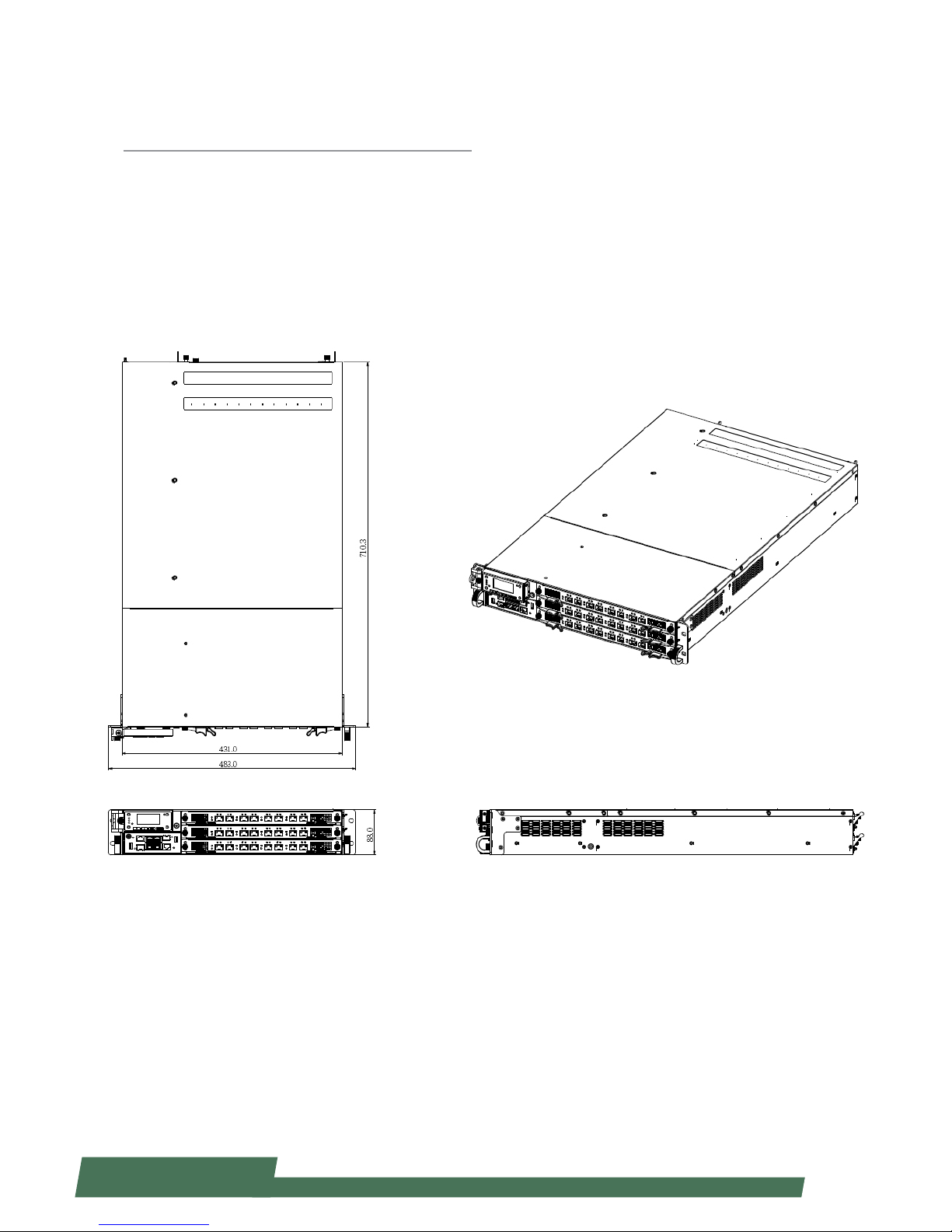

Dimensions W 431 xH 88 x D 720(mm)

Certication RoHS

Page 11

11

www.lannerinc.com

Package Contents

Your package contains the following items:

HCP-72i1 Network Security Platform•

4 passive CPU heatsink•

2 power cords•

2 SATA cables•

1 crossover Ethernet cable (1.8 meters)•

1 straight-through Ethernet cable (1.8 meters)•

1 RJ-45 to DB-9 female console cable•

Drivers and user’s manual CD.•

Ordering Information

HCP-72i1 HybridTCA. High-performance Network

Appliance with 4 x IntelR XeonR E5-2600

series, (Sandy/Ivy-Bridge-EP) processor

+ 2 bays for 2.5” HDD with 3 Ethernet

modules

Optional Accessories

NCM-BPGC01A 12 ports GbE RJ-45, Gen 2 Bypass

NCM-BPGC01B 12 ports GbE RJ-45, Without Bypass

NCM-BPSC01A 12 ports GbE SFP, Without Bypass

NCM-BPX402A 4 ports 10G SFP+, Without Bypass

TCM-IXT801A 8 ports 10G SFP+, Without Bypass

Page 12

12

www.lannerinc.com

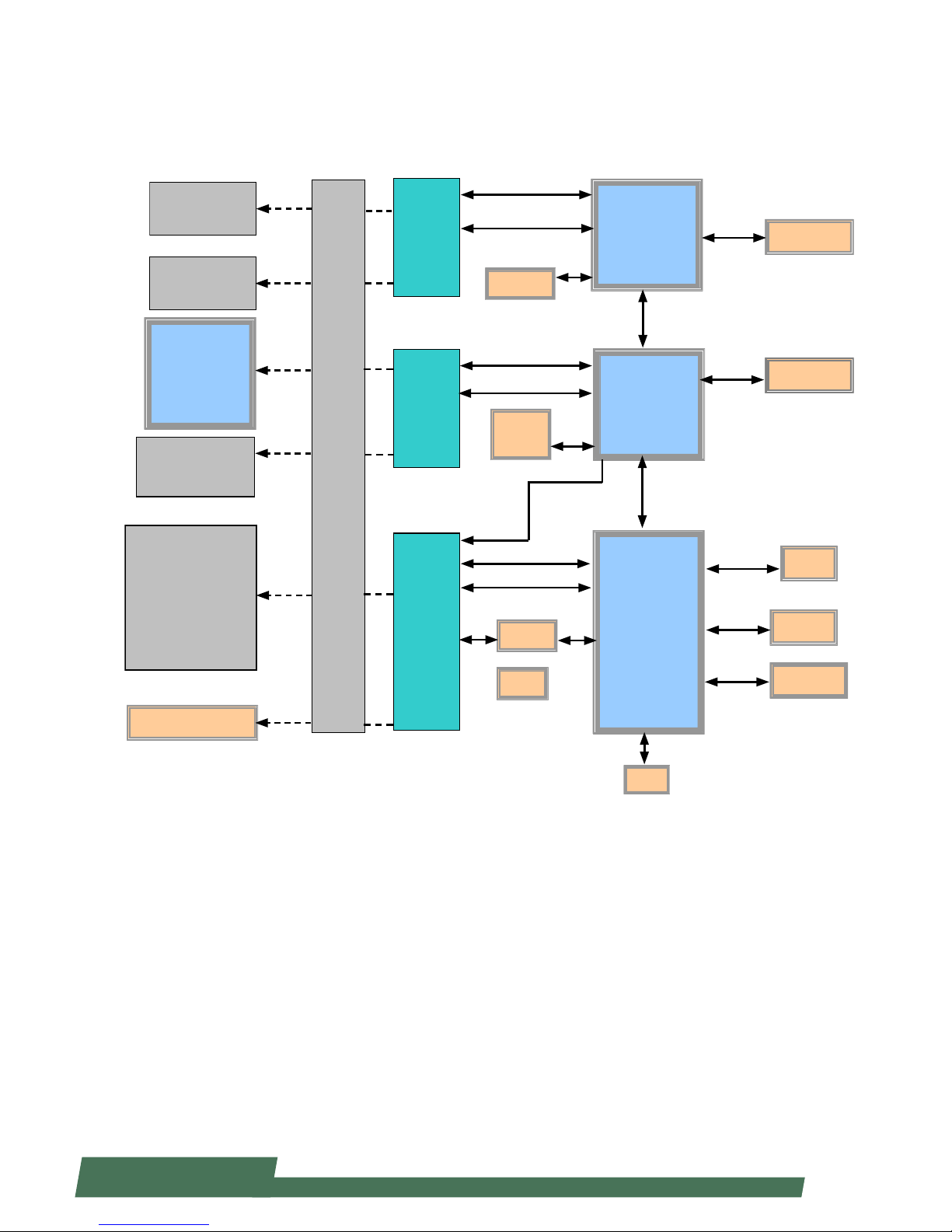

Molex

ZD

Conn

Molex

ZD

Conn

Molex

ZD

Conn

DDR3 x 8

DDR3 x 8

Intel Xeon

CPU1

Intel Xeon

CPU0

Patsburg

PCH

Back

plane

LAN Module

Bottom (Slot2)

LAN Module

Top (Slot0)

Intel Xeon

CPU0

(Another MB)

LAN Module

Middle (Slot1)

SATA HDD/SSD

Memory

Bus

Memory

Bus

QPI

DMI

USB

SATA

mSATA

USB2.0

SATA

OPMA

VGA

PCIEC1

PCIe x 8

PCIe x 8

PCIe x 8

I/O Board:

USB

Console

LOM

LAN controller

Cave

Creek

PCIe x 8 (NTB)

PCIe x 8

PCIe x 8

PCIe x 4

USB2.0

PCIe 1x

SPI

PCIe x1

MDI

Block Diagram

PCIe

Debug Pin Header

Page 13

13

www.lannerinc.com

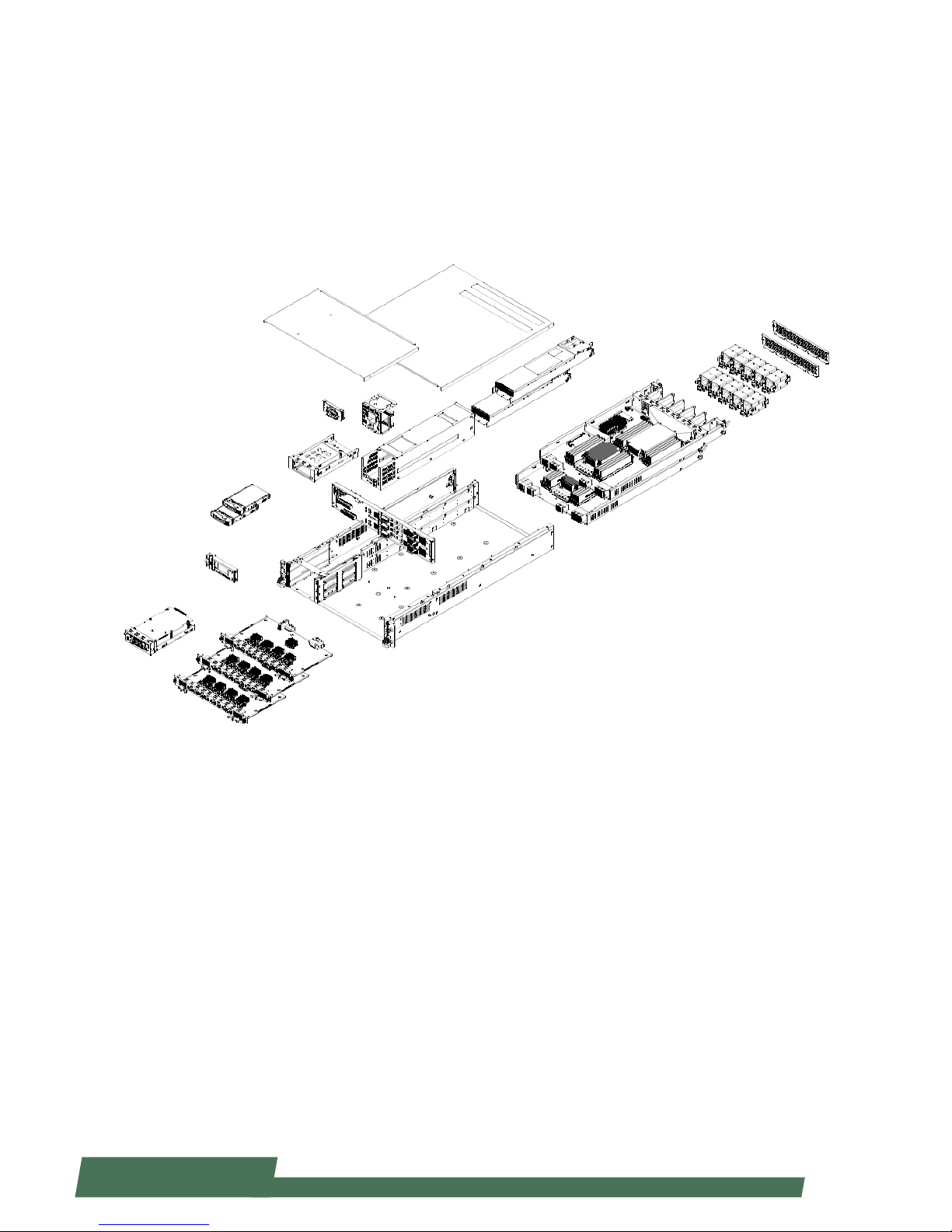

Physical Architecture of Lanner’s HybridTCA

The diagram presents all necessary components of Lanner’s Hybrid TCA

architecture applied for HCP-72i1.

Page 14

14

www.lannerinc.com

Chapter 2

System Components

Page 15

15

www.lannerinc.com

Chapter 2:

System Components

Mechanical Drawings

Unit: mm

Page 16

16

www.lannerinc.com

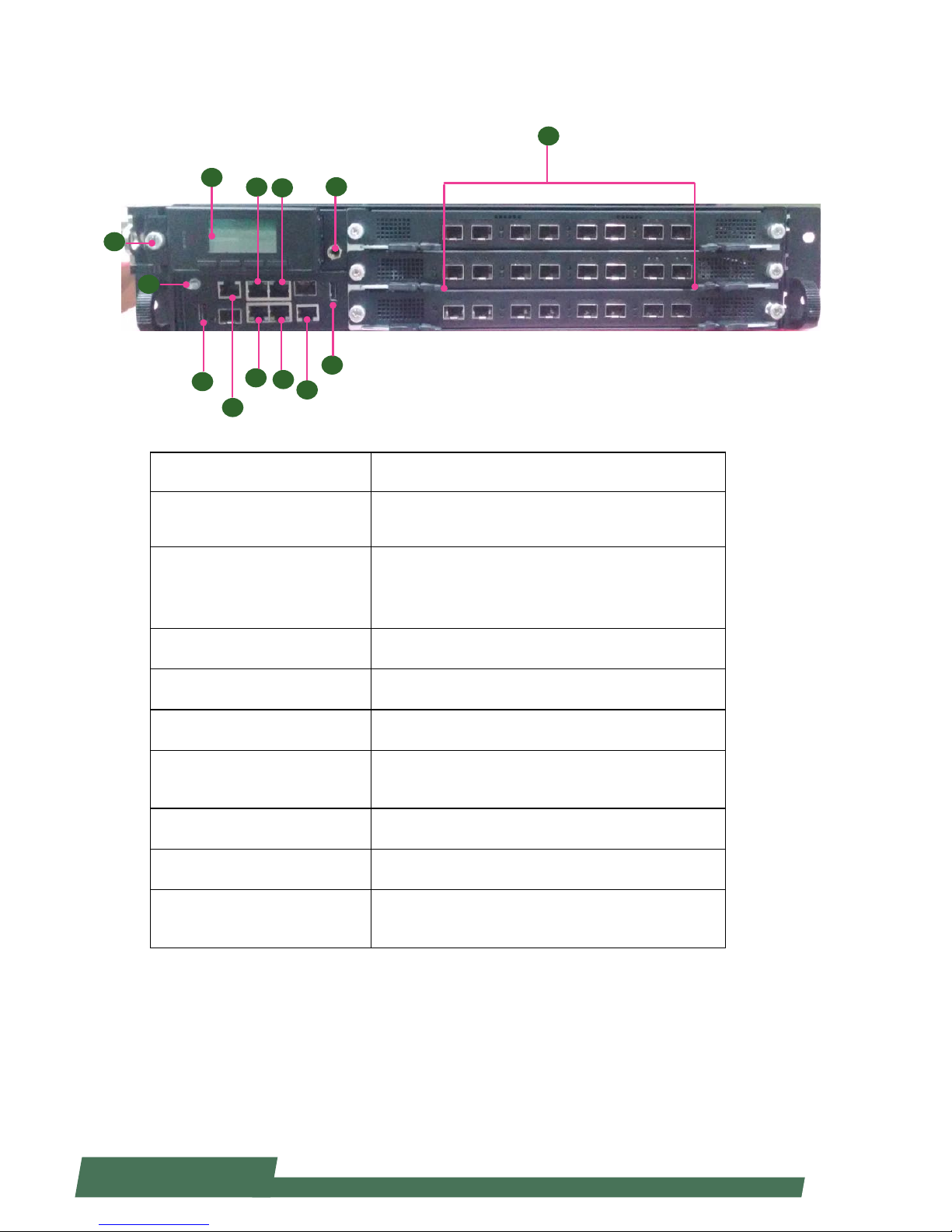

Front Components

Component Description

F1 Console

RJ-45 console port for connecting to a computer terminal

for local, out-of-band diagnostic or configuration

purpose.

F2 LCM

128 x 64 Graph LCM with 4 key pad•

Hinge LCM•

1 LED for power, 1 LED for Status and 1 LED for HDD•

F3 USB 2.0 Ports USB 2.0 type A connectors.

F4 Onboard Management Port RJ-45 onboard management port

F5 IPMI ports IPMI ports

F6 LCM Unlock Button

Push it to unlock LCM pad to access the two 2.5” drive

bays

F7 ESD Jack 1 x ESD Jack

F8 GND Ground

F9 Other RJ-45/SFP+ ports

Network ports (number and type of network ports may

vary depending on the modules installed)

F2

F1

F3

F1

F5

F4

F3

F6

F9

F7

F8

F5

F4

Page 17

17

www.lannerinc.com

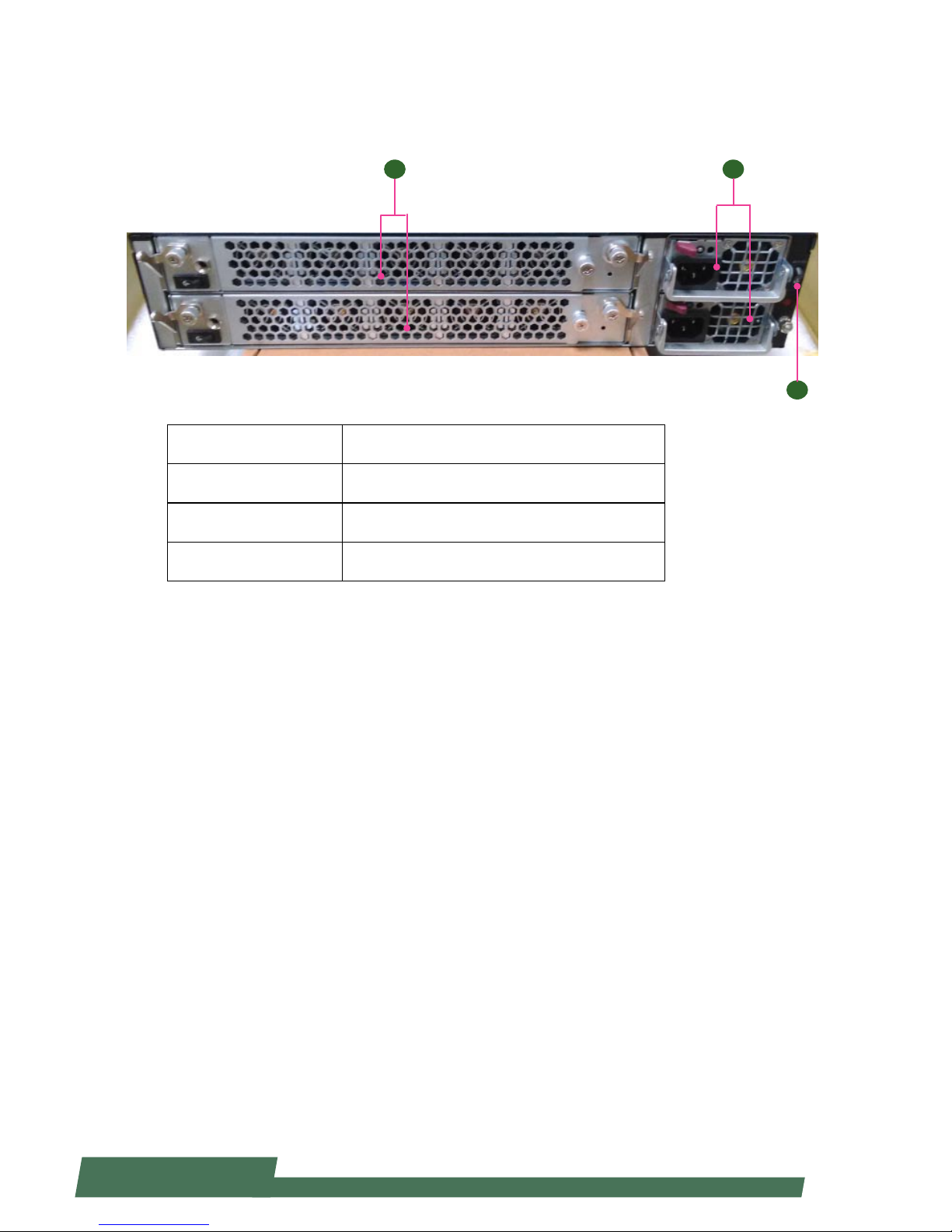

Rear Components

Component Description

R1 Cooling fans 5x cooling fans each layer

R2 Power supply Redundent power supply for each layer

R3 Power Switch Turn on/off of the system

R1 R2

R3

Page 18

18

www.lannerinc.com

Chapter 3

Motherboard Information

Page 19

19

www.lannerinc.com

An Internal Glance of HCP-72i1

The inside of HCP-72i1 is designed based on Lanner’s exclusive HybridTCA structure. This hybrid design integrates

two identical, high-performance motherboards for optimal system boost.

Chapter 3:

Motherboard Information

Upper Board

Bottom Board

Page 20

20

www.lannerinc.com

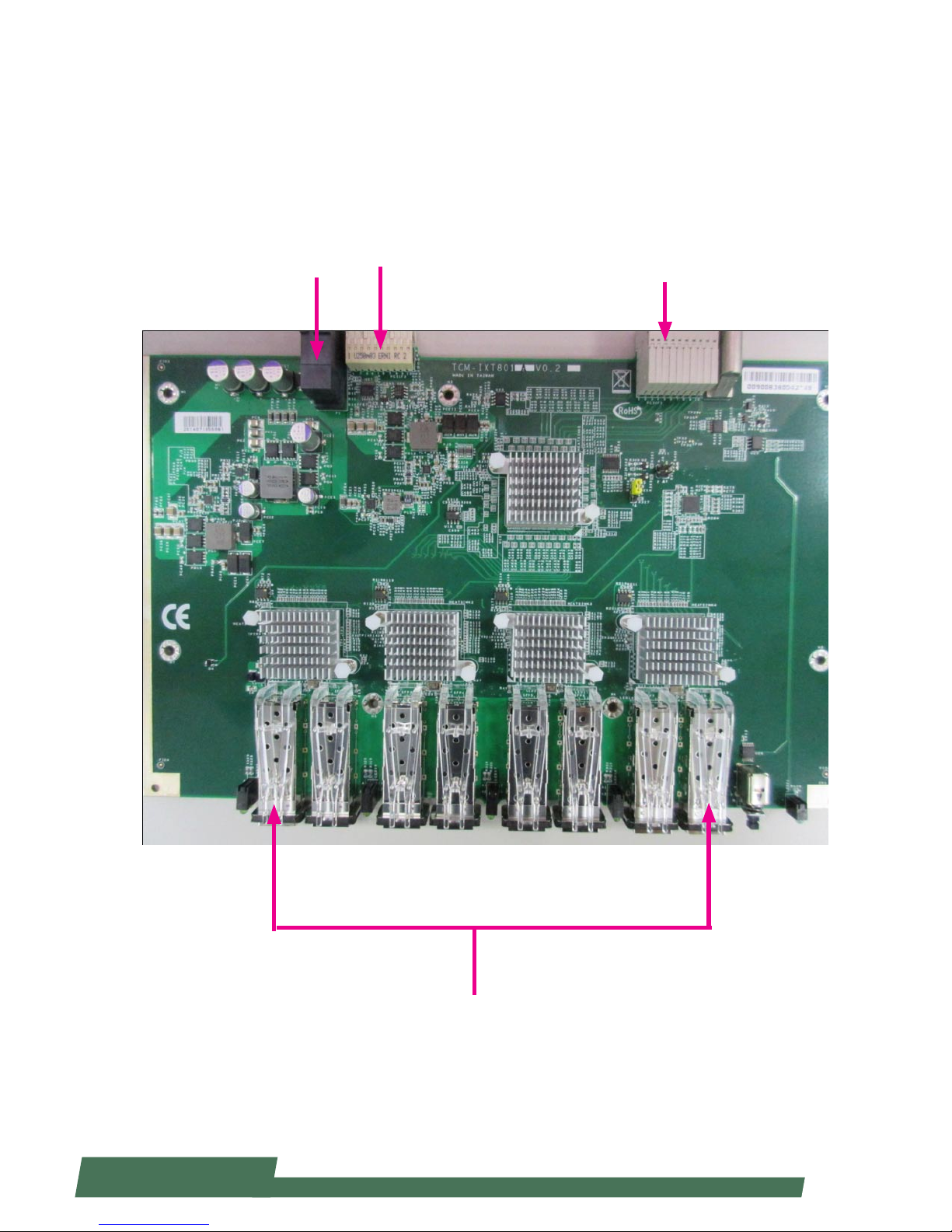

An Internal Glance of HCP-72i1

HCP-72i1 can be connected with up to 3 LAN modules for networking applications. The image below shows the

LAN module “TCM-IXT801A”.

SFP+ 10G ports

Power

PCIe Hot-Swap

PCIe

Page 21

21

www.lannerinc.com

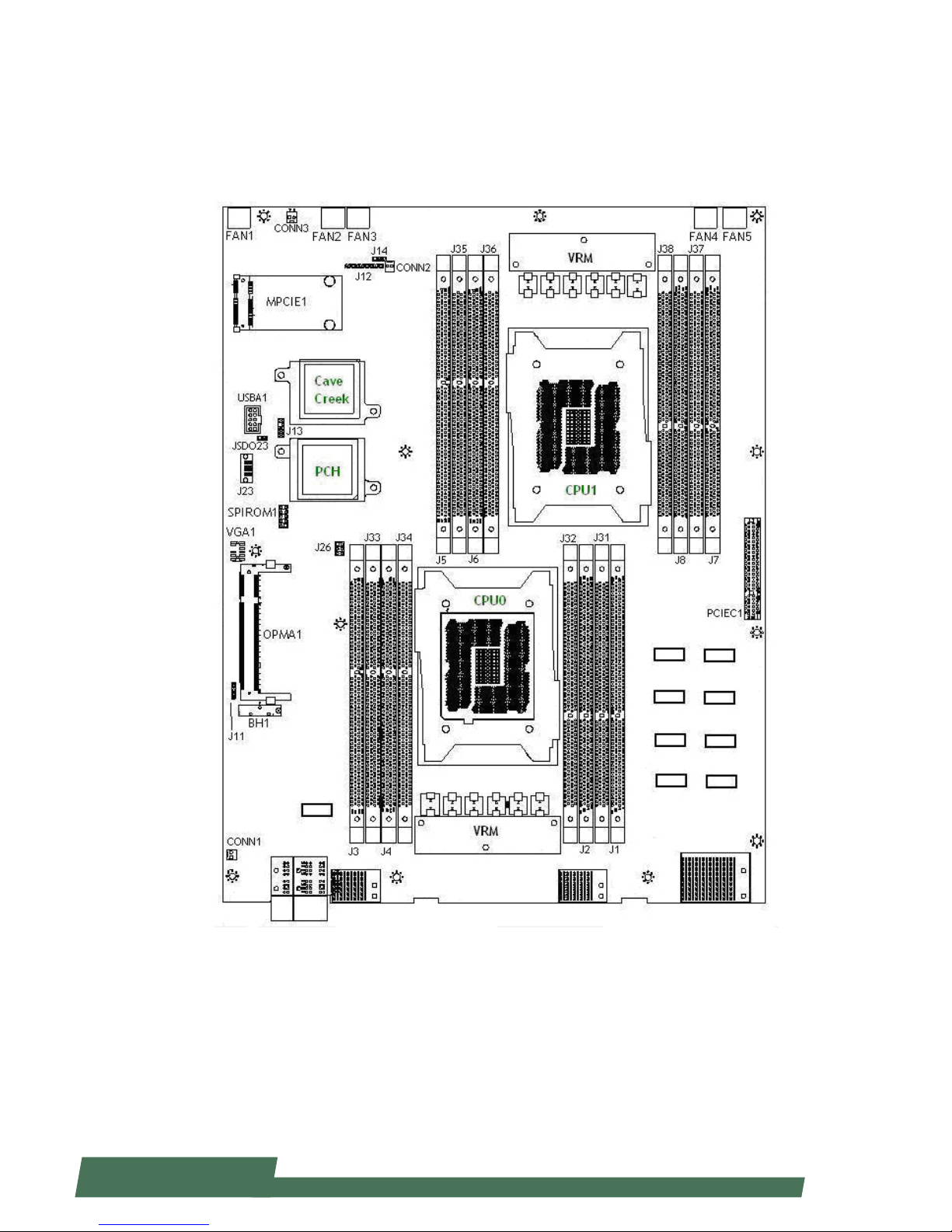

Jumper and Connector Location

The illustration below presents the jumper and

connector location of each board.

Page 22

22

www.lannerinc.com

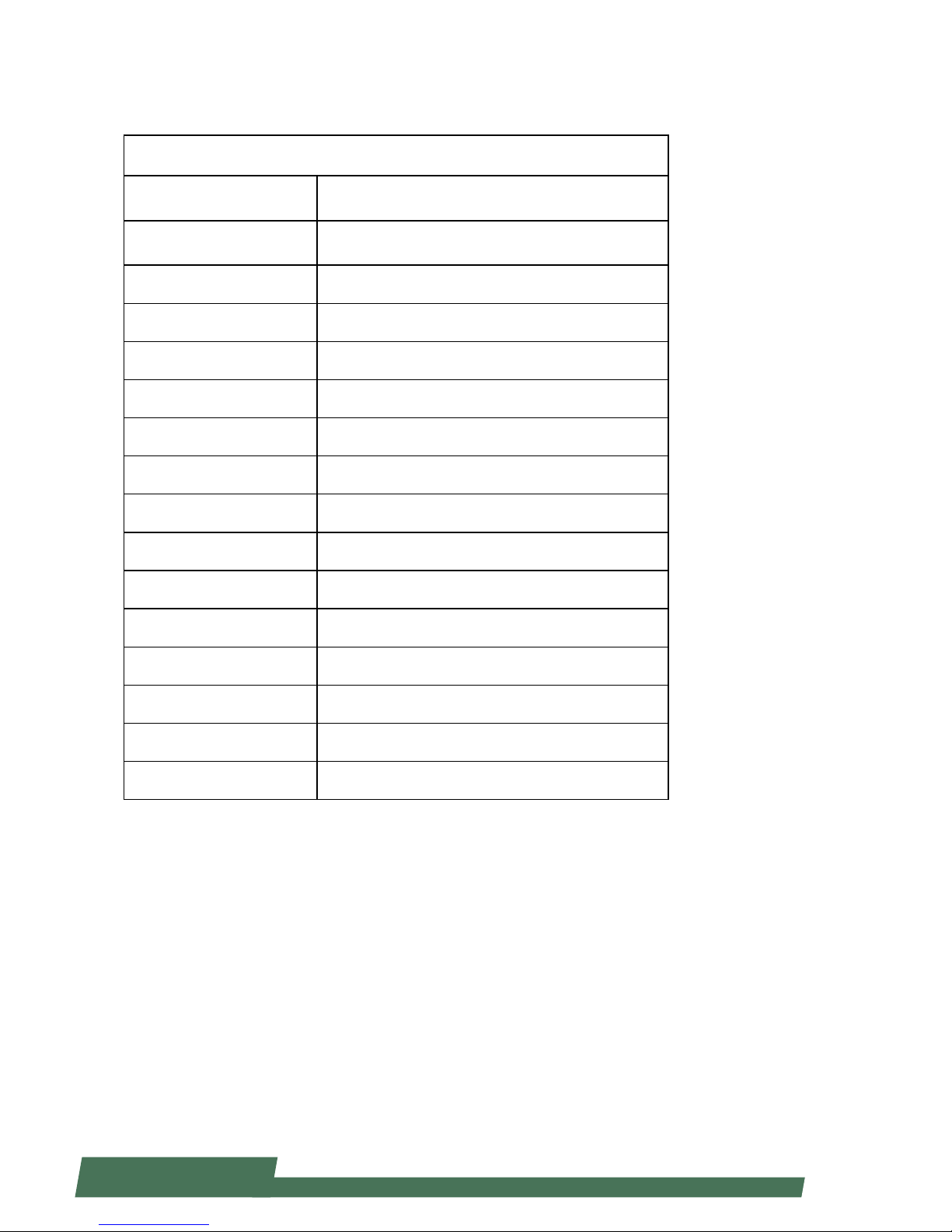

Connectors and Jumpers List

The tables below list the jumper and connector label of each board.

Labels Function

FAN1~5 FAN connectors

J14 Front Panel Reset Button Setting

CONN2 Power-On Button Pin Header

J12 CPLD Flash Pin Header

MPCIE1 Mini PCIe Socket

USBA1 USB connector

JSDO23 Security Override

J13 LPC Port 80

SPIROM1 SPI Flash ROM Update Pin Header

J23 SATA Connector

J26 SATA Re-driver Value Flash Pin Header

J11 CMOS clear

VGA1 VGA connector

CONN3 Hot Swap LED Pin Header

CONN1 Hot Swap MRL (Manual Retention Latch) Pin Header

Page 23

23

www.lannerinc.com

Jumper Settings & Connectors Pin

Definitions

FAN connectors (FAN1~5):

Five-pin FAN connectors

FAN1

Pin Description

1 HM_PWMOUT1

2 FAN_TECH_IN_FAN1

3 FAN_TECH_IN_FAN2

4 12V

5 GND

FAN2

Pin Description

1 HM_PWMOUT2

2 FAN_TECH_IN_FAN7

3 FAN_TECH_IN_FAN8

4 12V

5 GND

FAN3

Pin Description

1 HM_PWMOUT1

2 FAN_TECH_IN_FAN3

3 FAN_TECH_IN_FAN4

4 12V

5 GND

FAN4

Pin Description

1 HM_PWMOUT2

2 FAN_TECH_IN_FAN9

3 FAN_TECH_IN_FAN10

4 12V

5 GND

FAN5

Pin Description

1 HM_PWMOUT3

2 FAN_TECH_IN_FAN5

3 FAN_TECH_IN_FAN6

4 12V

5 GND

Front Panel Reset Button Setting(J14)

The jumper setting for selecting hardware reset or

software reset. Software reset is the default option.

Pin Description

1-2 Hardware reset

2-3 Software reset (default)

Power-On Button (CONN2)

Pin Description

1 GND

2 PWR_BUTTON

CPLD Flash Pin Header (J12):

Complex Programmable Logic Device can be used to

bridge JTAG and ash memory data interface

Pin Description

1 3.3V standby

2 JIAG_PLD_TDO

3 JTAG_PLD_TDI

4 NC

5 NC

6 JTAG_PLD_TMS

7 GND

8 JTAG_PLD_TCK

CONN2

1

2

Page 24

24

www.lannerinc.com

Mini-PCIe socket (MPCIE1):

Serves as mSATA storage socket

Pin Description Pin Description

1 NC 2 3.3V

3 NC 4 GND

5 NC 6 NC

7 NC 8 NC

9 GND 10 NC

11 PCIe Clock_N 12 NC

13 PCIe Clock_P 14 NC

15 GND 16 NC

Mechanical key

17 NC 18 3.3V

19 NC 20 NC

21 GND 22 PCIe Reset#

23 SATA_RX_N 24 3.3V

25 SATA_RX_P 26 GND

27 GND 28 NC

29 GND 30 NC

31 SATA_TX_N 32 NC

33 SATA_TX_P 34 GND

35 GND 36 NC

37 GND 38 NC

39 3.3V 40 GND

41 3.3V 42 NC

43 GND 44 NC

45 NC 46 NC

47 NC 48 NC

49 Active#/LED 50 GND

51 NC 52 3.3V

USB connector (USBA1)

Pin Description Pin Description

1 5V 2 5V

3 USB2- 4 USB35 USB2+ 6 USB3+

7 USB23GND 8 USB23GND

9 USB23GND 10 USB23GND

Security Override (JSDO23)

FLASH DESCRIPTOR SECURITY OVERRIDE WHEN HIGH

(Default Not Connect)

Port 80 (J13): This is the Port 80h, which is used as

BIOS debug port. Once the system is initialized, BIOS

will send POST (Power-On Self-Test) codes to Port 80.

If POST fails, the last generated POST code will be left

in Port 80. This is used for debug purpose. If a sevensegment display is connected, the hexadecimal BIOS

debug code will appear.

Pin Description Pin Description

1 CLK_33M_P80 2 LPC_LAD_1

3 RST_PORT80_N 4 LPC_LAD_0

5 LPC_FRAME_N 6 3.3V

7 LPC_LAD_3 8 X

9 LPC_LAD_2 10 GND

SPIROM1:

SPI ROM pin header

Pin Description Pin Description

1 No Connect 2 No Connect

3 Dual_CS00_N 4 3.3V

5 SPI_MISO_DUAL 6 SPI_HOLD0_L

7 No Connect 8 SPI_CLK_DUAL

9 GND 10 SPI_MOSI_DUAL

1 2 9

10

USBA1

J13

9

10

2

1

SPI-ROM1

9

10

2

1

Page 25

25

www.lannerinc.com

SATA (J23): used to connect SATA disk drive

Pin Description

1 GND

2 TX+

3 TX4 GND

5 RX6 RX+

7 GND

SATA Re-Driver value flash (J26)

SATA signal redriver and conditioner

Pin Description

1 PCIE_R_SDA2

2 3.3V

3 PCIE_R_SCL2

4 MOSI2

5 REST_MCU2#

6 GND

CMOS clear (J11): clear CMOS jumper

Pin Description

Short 1-2 (default) Normal

Short 2-3 Clear CMOS

VGA connector (VGA1): VGA display

Pin Description Pin Description

1 RED 2 GND

3 GREEN 4 GND

5 BLUE 6 GND

7 HSYNC 8 X

9 VSYNC 10 GND

11 DDC_DATA_CONT 12 DDC_CLK_CONT

Hot swap LED(CONN3)

Pin Description

1 LED_P

2 LED_N

Hot swap MRL(Manual Retention Latch) pin

header(CONN1)

Pin Description

1 Power Enable#

2 GND

CONN3

1

2

CONN1

1

2

Page 26

26

www.lannerinc.com

Chapter 4

Hardware Installation

Page 27

27

www.lannerinc.com

Chapter 4:

Hardware Installation

Preparing the Hardware Installation

To access some components and perform certain service

procedures, you must perform the following procedures

first.

WARNING:

1. To avoid the risk of personal injury, electric shock, or

damage to the equipment, please remove all power

connections as well as all power sources.

2. Please wear ESD gloves to avoid potential injury or

damage.

Accessing the Components

1. Due to the hybrid architecture of HCP-72i1, you may

access the Upper Board or the Bottom Board. First, locate

the rear lock-handles and lock-screws. There should be 2

pairs on each side: two for the Upper Board and the other

two for the Bottom Board.

2. To access the Bottom Board, loosen the two lockscrews and then pull the two lock-handles.

3. Pull the blade out while holding the lock-handles.

4. To return the bottom blade to its original place, simply

push it to the end and use the two lock-handles and lockscrews to secure it.

5. To access the Upper Board, use the same method from

Step 2 and 3.

6. Pull the top blade out while holding the lock-handles.

Page 28

28

www.lannerinc.com

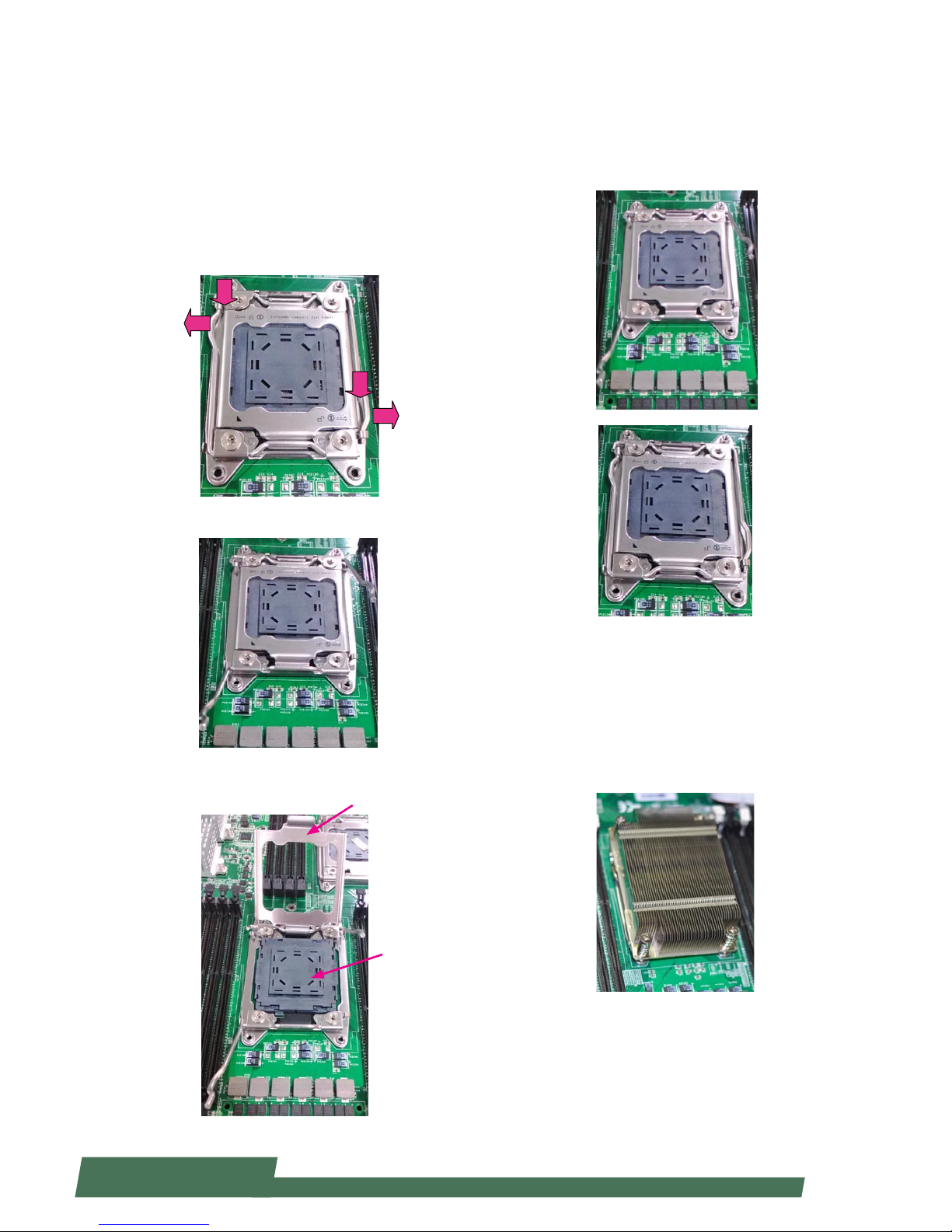

Installing CPU and the Heat Sink

Follow the procedures below for installing a CPU

1. Locate the CPU socket(s)

2. Press the left load lever down, move it out of the

retention tab. Then, do the same to the right. There are

two levers for each CPU socket.

3. Lift the load levers.

4. Open the load plate and also the protective cap.

Press down

Press down

Load plate

Protective cap

5. Align the CPU and the notch on the socket. The CPU should

fit perfectly into the socket. Note that the CPU fits in the

socket in only one direction.

6. Put the protective cap onto the CPU. Close the load plate

and push the load lever to lock it back to the retention tab.

7. Put the heat sink on the installed CPU and match the

screws with the screw holes on the board. Fasten two screws

which are opposite to each other at a time and then the other

two. It is easier this way to avoid the force of spring.

Place the heat sink cover on top of the installed heat sink and

fasten it with screws on the chassis.

Page 29

29

www.lannerinc.com

Installing IPMI Card on OPMA Socket

The motherboard of HCP-72I1 comes with a OPMA

socket for IPMI card installation.

1. Locate the OPMA socket.

2. Insert your IPMI card. Make sure the notches

between the card and the socket are aligned.

3. Your IPMI card may come with a display connector.

You may use a cable for connections.

Installing the System Memory

The motherboard supports DDR3 memory to meet the

higher bandwidth requirement of the latest operating

system and Internet applications. It comes with two

double data rate type three (DDR3) Small Outline Dual

Inline Memory Modules (SO-DIMM) sockets.

1. Power o the system

2. Locate the DIMM socket

3. Pull open the latches

4. Align the module and the socket and then insert

the module into the socket. Make sure the notches

are aligned. Press the module until it's fully seated and

close the latches.

Page 30

30

www.lannerinc.com

Installing HDD/SSD

The system is built to accommodate two 2.5” SATA disk

drives. Please follow instructions below.

1. The two 2.5” SATA disk drives are located behind the

hinge LCM. Rotate and loosen the lock-screw.

2. Open the hinge LCM and locate the HDD/SSD bays as

the images shown below.

3. Push the disk drive lock as the arrow of direction in the

image below. Then the disk drive bay will be released out.

4. Insert your HDD/SSD into the bay by aiming the SATA

connector of the drive as the arrow of direction in the

image shown below. Remember to use screws to fix both

sides of the disk drives.

SATA Connector direction

Page 31

31

www.lannerinc.com

Replacing Network I/O Modules

Please follow the instructions below to replace network

I/O modules. The images of network I/O modules below

are based on Lanner TCM-IXT801A model.

1. Loosen the lock-screw on two sides of the network I/O

module.

2. Hold and press the lock-handle as the arrow of direction in the image below. Remember to do it for both lockhandles at the same time.

3. While pressing both lock-handles as instructed in the

last step, then pull both lock-handles outwards at the

same time.

4. Continue to apply force when removing the module.

To install a module, just reverse the steps in this section.

Replacing Power Supply Units

Power supply units may have to be replaced when

they reach the end of their liftetime. Please follow the

instructions below to replace power supply units.

1. Locate the power supply units at the rear. Hold the

handle and press the lock as the arrow of direction in the

image below.

2. Pull the power supply unit out.

Page 32

32

www.lannerinc.com

Replacing Cooling Fans

Cooling fans may have to be replaced as they may reach

the end of their lifetime one day. Please follow the

instructions below to replace cooling fans.

1. Loosen the lock-screw on the cover of the cooling fans

array.

2. Slide the cover to the arrow of direction as shown in

the image below.

3. Apply forces onto the two clips and pull the fan out.

Page 33

33

www.lannerinc.com

3. Turn the slide rail upside down and push the black

arrow-shaped slide rail lock as the arrow of direction

below.

4. Press the security lock of the rail as well.

5. Separate the inner bracket from the slide rail.

6. Align the inner bracket to the side of the chassis.

Make sure the screw holes of the inner bracket match

with the ones on the side of the chassis.

7. Securely attach the inner bracket to the side of the

chassis by applying screws.

8. Repeat step 1 to 7 for another slide rail and for the

other side of the chassis.

Rack Mounting

Installation Precautions:

Elevated Operating Ambient - If installed in a closed 1.

or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater

than room ambient. Therefore, consideration should be

given to installing the equipment in an environment

compatible with the maximum ambient temperature

(Tma) specified by the manufacturer.

Reduced Air Flow - Installation of the equipment in 2.

a rack should be such that the amount of air flow

required for safe operation of the equipment is not

compromised. Mechanical Loading - Mounting of the

equipment in the rack should be such that a hazardous

condition is not created due to uneven mechanical

loading.

Circuit Overloading - Consideration should be given to 3.

the connection of the equipment to the supply circuit

and the effect that overloading of the circuits might

have on over-current protection and supply wiring.

Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern.

Reliable Earthing - Reliable earthing of rack-mounted 4.

equipment should be maintained. Particular attention

should be given to supply connections other than

direct connections to the branch circuit (e.g. use of

power strips).”

CAUTION :

Slide/rail mounted equipment is not to be used as a

shelf or a work space.

Prepare The Equipments

1. Prepare the slide rail equipments. In the package, you

should have two slide rails and 1 bag of screws.

2. Extend the inner bracket of each slide rail.

Page 34

34

www.lannerinc.com

Installing Slide Rails Onto the Rack

1. Install 2 cage nuts for both left and right of the rack,

as well as front and rear of the rack. Remember to leave

the middle hole open. You shall install a total number

of 8 cage nuts: 4 on the front (2 for the left and 2 for

the right), and 4 on the rear (2 for the left and 2 for the

right).

2. Install the slide rails to each side of the racket as the

image below. Make sure the screws are firmly applied.

Installing HCP-72i1 Onto the Rack

1. Inser the network appiance with the front facing

you. Make sure the chassis-attahced inner brackets accurately match the slide rails installed on the rack.

Notes: it is strongly recommended to conduct this action with two or more persons.

2. Make sure the inner brackets on the chassis match the

slide rails on the rack.

3. Gently push HCP-72i1 through the rails.

4. The device may be locked during the mid way. Remember to adjust the rail lock so that you can continue to psuh

the appliance to the end of the rack.

5. To bring the appliance out of the rack, use the two locks

on the rail circled in the image below. When sliding the

device out, remember to do it slowly.

Notes: it is strongly recommended to conduct this action

with two or more persons.

Page 35

35

www.lannerinc.com

Chapter 5

BIOS Setup

Page 36

36

www.lannerinc.com

Chapter 5:

BIOS Setup

To enter the BIOS setup utility, simply follow the steps below:

1. Boot up the system.

2. Press <Delete> during the boot-up if you connect a keyboard to HCP-72i1. But if you connect a PC to HCP-72i1

through console cable, then press <Tab>. Your system should be running POST (Power-On-Self-Test) upon booting

up.

About the POST Information of HCP-72i1:

HCP-72i1 is built based on HTCA structure with two motherboards. You may access either or both of the boards

depending on the connections established. You will see messages of whether you access the “Upper Board” or the

“Bottom Board” during the booting-up process.

3. Then you will be directed to the BIOS main screen.

4. Instructions of BIOS navigations:

[<--] [-->]: select a setup screen, for instance, [Main], [Advanced], [Chipset], [Boot], [Security], and

[Save & Exit]

[↑] [↓]: select an item/option on a setup screen

Enter: select an item/option or enter a sub-menu

ESC: exit the current screen

+/- = to adjust values for the selected setup item/option

F1 = to display General Help screen

F2 = to retrieve previous values, such as the parameters configured the last time you had entered BIOS.

F3 = to load optimized default values

F4 = to save configurations and exit BIOS

Notes: the images in the following section are for reference only.

Page 37

37

www.lannerinc.com

Main

The [Main] is the first setup screen when you enter BIOS. The [Main] displays general system and BIOS information

and you may configure the “System Language”, “System Date”, and “System Time”.

BIOS Information

BIOS Vendor: displays BIOS vendor information

Core Version: displays the BIOS core version

Compliancy: displays the BIOS compliancy

Project Version: displays BIOS project version

Build Date and Time: displays the date and time the BIOS was built.

Press “Enter” if you want to configure “System Language”, “System Date”, and “System Time”.

System Language: English

System Date: Day/Date/Year

System time: Hour/Minutes/Seconds

Access Level: Administrator by default

Page 38

38

www.lannerinc.com

Advanced

Use [<--] / [-->] to select [Advanced] setup screen. Under this screen, you may use [↑] [↓] to select an item you

want to configure.

Above 4G Decoding

This option enables or disables 64bit capable devices to be decoded in above 4G address space (only if the

system supports 64bit PCI decoding). You may select “Enabled” or “Disabled”.

Page 39

39

www.lannerinc.com

SRIOV

This option enables or disables SRIOV (Single Root I/O Virtualization) support. You may select “Enable” or “Disable”.

Set Pcie Driving By B

This option enables or disables PCIe driving by BIOS. You may select “Enabled” or “Disabled”.

Page 40

40

www.lannerinc.com

WHEA Configuration

This option allows you to conduct general WHEA (Windows Hardware Error Architecture) Configuration settings.

Press “Enter” to enter its setting menu.

Then you may select “Enabled” or “Disabled for WHEA support. The default is “Enabled”.

Page 41

41

www.lannerinc.com

CPU Configuration

This option allows you to access CPU configuration parameters. To access the sub menu, press “Enter” to access the

configuration parameters.

Socket 0/1 CPU Information - press “Enter” to display CPU0 information including CPU model name, signature,

microcode patch, maximum CPU speed, minimum CPU speed, processor cores, Intel HT Technology, Intel VT-x

Technology, L1 data cache, L1 code cache and L2/L3 cache.

Page 42

42

www.lannerinc.com

Hyper-threading: Hyper-threading is Intel’s multi-threading technology which improves computer multi-tasking

ability. This is frequently abbreviated as Intel® HT Technology. This enhancement design enables multiple threads to

run on each processor core. As a result, this will boost performance and throughput.

Active Processor Core: set the number of active processor cores.

Limit CPUID Maximum: When “Enabled”, the CPU will limit its maximum CPUID input value to 3 when the processor

is queried. When “Disabled”, the CPU will function with its actual maximum CPUID values. For this case, leave it as

“Disabled”.

Page 43

43

www.lannerinc.com

Execute Disable Bit: an Intel hardware-based protection against malicious code. It will detect the memory in which a

code can be executed or not. When enabled, it will prevent certain classes of malicious buffer overflow attacks when

combined with a supporting OS.

Hardware Prefetcher: when “Enabled”, it will activate the mid level cache L2 streamer prefetcher.

Adjacent Cache Line P: it is the Adjacent Cache-Line Prefetch. When “Enabled”, the CPU fetches Cache 1 & 2 for 128

bytes. If “Disabled”, the CPU only fetches one cache for just 64 byte. The default is “Enabled”.

Page 44

44

www.lannerinc.com

DCU Streamer Prefetch: When “Enabled”, it will activate the prefetch of next L1 Data Line based upon multiple loads

in same cache line.

DCU IP Prefetch: this allows you to enable prefetch of next L1 line based upon sequential load history.

Intel Virtualization: Enables or disables Intel Virtualization Technology. On a server or firewall/UTM/IPS operating mode,

it is recommended to enable this feature so that multiple operating systems and applications will run in independent

partitions.

Page 45

45

www.lannerinc.com

Local APIC Mode: select local APIC mode. If “Auto”, use x2APIC if required; otherwise, xAPIC mode. The xAPIC mode

will disable CPUs with APIC IDs greater than 254. Please be aware that some operating systems don’t support x2APIC

mode.

EIST: this option allows you to enable/disable Intel SpeedStep Technology.

Page 46

46

www.lannerinc.com

SATA Configuration

This option allows you to access SATA device configuration. Press “Enter” to access the sub-menu.

SATA Port 0 - 5: display SATA device information. If no device detected, it will show “Not Present”.

SATA Mode: select “IDE”, “AHCI”, or “RAID” mode for connected SATA storage devices. For RAID mode, your system

must be pre-programmed with RAID mode support.

Page 47

47

www.lannerinc.com

Aggressive Link Power: Aggressive Link Power Management for SATA devices complying with AHCI mode.

Port 0-5 Hot Plug: enable SATA hot plug for port 0-5.

Page 48

48

www.lannerinc.com

USB Configuration

This option allows you to access USB configuration parameters. Press “Enter” to access the sub-menu.

USB Module Version: displays USB module version information

USB Devices: displays USB device information

Legacy USB Support: enables legacy USB support. “Auto” option disables legacy support if no USB devices are

connected. “Disable” option will keep USB devices available only for EFT applications.

Page 49

49

www.lannerinc.com

EHCI Hand-off: this is a workaround for operating systems without EHCI hand-off support. The EHCI ownership

change should be claimed by EHCI driver.

USB Mass Storage Driv: this option allows you to enable or disable USB mass storage driver. The default is

“Enabled”.

Page 50

50

www.lannerinc.com

USB transfer time-out: set USB time-out value for control, Bulk and interrupt transfers.

Device reset time-out: set USB mass storage device Start Unit command time-out.

Device power-up delay: set the maximum time the device will take before it properly reports itself to the Host

Controller. “Auto” uses default value. For example, it is 100ms as a root port.

Page 51

51

www.lannerinc.com

Hardware Monitor

This option allows you to monitor hardware status. Press “Enter” to access the sub-menu.

Smart Fan Configuration: access smart fan parameters

CPU0/1 Temp: CPU(s) temperature

System Temp1/2: temperatures of system 1/2

FanXX Speed: the speed of each fan based on RPM

CPU0/1 Vcore: dispalys voltage information of CPU cores

Page 52

52

www.lannerinc.com

LAN Module Hardware Monitor

This option allows you to monitor hardware status of connected LAN modules. Press “Enter” to access the submenu.

Once entered, you may view PCIe layer information for the connected LAN modules.

Page 53

53

www.lannerinc.com

LAN Boot Select

This option allows you to select one of the onboard LAN PXE boot. Press “Enter” to access the sub-menu.

On Board LAN Boot: the default is “Enable”

Page 54

54

www.lannerinc.com

Serial Port Console Redirection

This option allows you to configure parameters about serial port console redirection. Press “Enter” to access the submenu.

Console Redirection: select “Enabled” or “Disable” for COM port console redirection. The default is “Enabled”.

Console Redirection Settings: select this item to enter the setting sub-menu.

Page 55

55

www.lannerinc.com

COM Console Redirection Settings

Terminal Type: the emulation configuration. Select “VT100”, “VT100+”, “VT-UTF8” or “ANSI”.

ANSI: Extended ASCII character set

VT100: ASCII character set

VT100+: extends VT100 to support color function keys

VT-UTF8: uses UTF8 encoding to map Unicode characters onto 1 or more

Bits per second: select “9600”, “19700”, “38400”, “57600”, or “115200” for bits per second. The Bps

will determine serial port transmision speed. The speed must be matched on the other side. Long or noisy lines may

require lower speeds.

Page 56

56

www.lannerinc.com

Data Bits: select the value for data bits. In this case, “7” or “8”.

Parity Bits: a parity bit can be sent with the data bits to detect some transmission errors. Select “None”, “Even”, “Odd”,

“Mark” or “Space”.

Page 57

57

www.lannerinc.com

Stop Bits: stop bits indicate the end of a serial data packet. The standard is 1 stop bit. Communication with slow

devices may require more than 1.

Flow Control: flow control can prevent data loss from buffer overflow. When sending data, if the receiving buffers

are full, a “stop” signal can be sent to stop the data flow. You may select “None” or “Hardware RTS/CTS”, depending on

the circumstances.

Page 58

58

www.lannerinc.com

VT-UTF8 Combo Key Support: this option enables/disables VT-UTF8 combination key support for ANSI/VT100

terminals.

Recorder Mode: on this mode, when “Enabled”, only text will be sent. This is to capture terminal data.

Resolution 100 x 31: select “Enable” or “Disable” for extended terminal resolution.

Page 59

59

www.lannerinc.com

Legacy OS Redirection Resolution: select “80x24” or “80x25”. The default for this case is “80x24”.

Putty KeyPad: select Function Key and Key Pad on Putty. You may select “VT100”, “LINUX”, “XTERMR6”, “SC0”, “ESCN”,

or “V1400”.

Redirection After BIOS POST: The settings specify if BootLoader is selected than Legacy console redirection is

disabled before booting to Legacy OS. Default value is “Always Enable” which means Legacy OS console redirection

is always enabled after BIOS.

Page 60

60

www.lannerinc.com

Chipset

Use [<--] / [-->] to select [Chipset] setup screen. Under this screen, you may use [↑] [↓] to select an item you

want to configure.

Restore AC Power Loss: This option specifies what state to go to when power is re-applied after a power failure (G3

state). You may select “Power Off”, “Power On” or “Last State”. The default is “Power On”.

Onboard SATA RAID Oprom/Driver: controls whether to enable the onboard SATA Option ROM or EFI Driver.

Page 61

61

www.lannerinc.com

IOH Configuration

Intel(R) NTB Configuration: press “Enter” to access the sub-menu for Intel Non-Transparent Bridge (NTB)

configurations.

Then, you may select “TB”, “NTB-NTR” or “NTB-RP” for the NTB configuration. Remember to set different NTB ports for

“Crosslink Control” for the Upper Board and the Bottom Board. For instance, as the image below, the crosslink control

is DSD/USP for the Upper Board while setting “USD/USP for the Bottom Board.

Page 62

62

www.lannerinc.com

Intel (R) VT for Directed I/O Configuration

This option is enabled by Intel’s virtualization technology. Press “Enter” to access the sub-menu.

Intel (R) VT-d: this option allows you to enable or disable Intel Virtualization Technology fo directed I/O. The default

is “Enabled” as this enhances server/firewall performance.

Page 63

63

www.lannerinc.com

Coherency Support: enable it to enhance operational coherency, but might lower system performance. Therefore,

this option is left as “Disabled” by default.

ATS Support: Address Translation Services. This function is enabled if “Intel(R) VT-d” is activated by default setting.

Enabling it will improve DMA performance.

Page 64

64

www.lannerinc.com

Intel (R) I/OAT:This option is enabled by Intel’s virtualization technology. Press “Enter” to access the sub-menu.

This is the Intel I/O Acceleration Technology option. Enable it to accelerate system performance in virtualization

operation. However, for considerations regarding possible data loss under Linux operating systems, this is “Disabled”

by default.

IOH Resource Selection: you may select “Auto” or “Manual” for your I/O hub (IOH) resource allocation. If you select

“Auto”, PCI resource allocation across multiple IOHs is optimized automatically based on the PCI devices present.

Therefore, the default is set as “Auto” instead of “Manual”.

Page 65

65

www.lannerinc.com

No Snoop Optimization: this option allows you to enable or disable Intel Virtualization Technology fo directed I/O.

The default is “Enabled” as this enhances server/firewall performance. This configuration requires that no snoop in PCI

Express settings is enabled. It is recommended that this option is left at default, which is “VC1”.

MMIOH Size:Configure the capacity size for memory-mapped I/O hub (MMIOH), from 1G to 128G.

Page 66

66

www.lannerinc.com

MMCFG BASE: select MMCFG Base values.

IOH PCIe port Bifurcation Control

IOU1-PCIe Port: functions visible based on these two options: “x4x4” (Function 0/1 visible) or “x8” (Function 1

visible)

Page 67

67

www.lannerinc.com

Port 1A/1B/2A Link Speed: select “GEN1”, “GEN2” or “GEN3” for the target link speed.

IOU2-PCIe Port: Functions visible based on the following options:

x4x4x4x4: functions 0/1/2/3 visible

x4x4x8: functions 0/2/3 visible

x8x4x4: functions 0/1/2 visible

x8x8: functions 0/2 visible

x16: function 0 visible

Page 68

68

www.lannerinc.com

Boot

Use [<--] / [-->] to select [Boot] setup screen. Under this screen, you may use [↑] [↓] to select an item you

want to configure.

Boot Configuration

Setup Prompt Timeout: number of seconds to wait for setup activation key. “65535 (0xFFFF)” means indefinite

waitings.

Bootup Numlock State: select the keyboard “Numlock” state

Page 69

69

www.lannerinc.com

Quiet Boot: this option allows you to enable or disable “Quiet Boot”. The default is “Disabled” based on Intel’s server

environment setting.

Fast Boot: select “Enabled” or “Disabled” for fast boot-up process. The default is “Disabled” based on Intel’s server

environment setting.

Set Boot Priority: the following allows you to configure the system boot sequence.

Page 70

70

www.lannerinc.com

CSM16 Parameters:

CSM16 Module Version

GateA20 Active: select “Upon Request” or “Always”.

Upon Request -- GA20 can be disabled using BIOS services.

Always -- do not allow disabling GA20: this option is useful when any RT code is executed above 1MB

Option ROM Message: select “Force BIOS” or “Keep Current”. This option sets display mode for Option ROM.

Page 71

71

www.lannerinc.com

INT19 Trap Response: Select “Immediate” or “Postponed”. This option sets BIOS reaction on INT19 Trapping by Option

ROM:

Immediate - execute the trap right away

Postponed - execute the trap during legacy boot

CSM Parameters

Launch CSM: this option controls if CSM will be launched

Page 72

72

www.lannerinc.com

Boot Option Filter: Select “UEFI and Legacy”, “Legacy only” or “UEFI only”. This option controls what devices system

can boot to.

Launch PXE OpROM Policy: this option controls the execution of UEFI and Legacy PXE OpROM

Launch Storage OpROM: select “Do not launch”, “UEFI only”, “Legacy only”, “Legacy first” or “UEFI first”. This option

controls the execution of UEFI and legacy storage OpROM.

Page 73

73

www.lannerinc.com

Boot Option Filter: select “Do not launch”, “UEFI only”, “Legacy only”, “Legacy first” or “UEFI first”. This option controls

the execution of UEFT and legacy video OpROM.

Other PCI device ROM: select “UEFI OpROM” or “Legacy OpROM”. For PCI devices other than network, mass storage

or video defines which OpROM to launch.

Page 74

74

www.lannerinc.com

NETWORK Device BBS Priorities

1st Boot: set boot priority

Page 75

75

www.lannerinc.com

Security

Use [<--] / [-->] to select [Security] setup screen. Under this screen, you may use [↑] [↓] to select an item you

want to configure.

Administrator Password: set administrator password. Once set, then this only limits access to Setup and is only

asked for when entering Setup.

User Password: set user password. Once set, then this is a power-on password and must be entered to boot or enter

Setup. In Setup, the user will have Administrator rights.

Page 76

76

www.lannerinc.com

Save & Exit

Use [<--] / [-->] to select [Save & Exit] setup screen. Under this screen, you may use [↑] [↓] to select an item you

want to configure.

Save Changes and Exit: exit system setup after saving the configuration changes

Discard Changes and Exit: exit system setup without saving the configuration changes

Save Changes and Reset: reset the system after saving the configuration changes

Discard Changes and Reset: reset the system without saving the configuration changes

Save Options

Save Changes: save the configuration changes

Discard Changes: discard all the configuration changes

Restore Defaults: restore to factory default setting

Save as User Defaults: save changes as the new user default

Restore User Defaults: restore the user default

Boot Override

Launch EFI Shell from filesystem device: launch Extensive Firmware Interface which will allow you to input Shell

commands

Page 77

77

www.lannerinc.com

Chapter 6

IPMI Navigation

Page 78

78

www.lannerinc.com

Chapter 6:

IPMI Navigation

IPMI, abbreviation of Intelligent Platform Management Interface, offers system administrators to manage and

monitor computing platforms with standardized interface and protocol. Due to its messaging and hardware-based

nature, IPMI works independently from the operating system, so that system administrators are able to remotely

manage and monitor computing platform status.

Lanner’s IPMI provides rich management features that will enable users to remote monitor their host machines,

while configuring control options. These include:

Remote control viewing options•

DNS configuration options•

SSL upload/generate/view options•

Network setting•

Firmware update•

User information management•

The following will provide a simple walkthrough of Lanner’s IPMI interface.

Reminder

The images shown in the following section are based on the latest version available at the time of this writing.

Therefore, the images may or may not look identical to the screens on your computing systems.

The following interface images are based on web browser operation.

Before You Start

Make sure the proper LAN connection to HCP-72i1. •

IPMI card has been properly installed.•

Prepare a desktop or laptop that is connecting to the same network. Start the computer. (Preferrably a laptop).•

Make sure JAVA is installed in the computer you are using.•

IP Configuration

Configure the IP address on the computer you are using. Please input “192.168.0.100:80”.•

Go to “JAVA” program, then go to “Exception Site List” and add a new location “192.168.0.100:80”.•

Getting Started

Open a web browser and input “192.168.0.100:80” to launch IPMI interface.

You will be required to enter “Username” and “Password”. The default username and password are “admin” for both.

Page 79

79

www.lannerinc.com

Dashboard

The “Dashboard” provides an overall information about the stauts of the device and remote server.

Device Information

Device Power Status: the power state of the monitored device

Firmware Revision: firmware revision information

Firmware Build Date: the date that the firmware was built

Network Information

MAC Address: displays MAC address information

V4 Network Mode: the status of V4 network

IPv4 Address: the IP address information

V6 Network Mode: the status of V6 network

Remote Control

Click the “Lanuch” bar to display the remote console, which is the host machine being monitored. The operating

system running on the host machine can be viewed as well.

Page 80

80

www.lannerinc.com

Remote Control -- Launched

Once you clicked the “Launch” bar, the remote control screen will be enlarged and the status of the remote console

can be viewed.

Launch bar

Page 81

81

www.lannerinc.com

Introducing the Remote Control Functions

The Remote Control interface comes with many handy functions for you to navigate the remote console operating

system.

Video

Click “Video” on the task bar to open menu for video related options

Pause Redirection: pause the console redirection

Resume Redirection: resume the console redirection

Refresh Video: refresh the video image of remote console status

Compression Mode: select compression mode

DCT Quantization Table: view DCT Quantization Table

Host Video Output: host machine video output option

Full Screen: to enable full screen viewing option

Exit: to exit

Page 82

82

www.lannerinc.com

Keyboard

Click “Keyboard” on the task bar to view keyboard related options:

Hold Right Ctrl Key

Hold Right Alt Key

Hold Left Ctrl Key

Hold Left Alt Key

Left Windows Key

Right Windows Key

Ctrl+Alt+Del

context Menu

Mouse

Click “Mouse” on the task bar to open menu for mouse related options

Show Cursor: enable or disable mouse cursor

Mouse Calibration: set mouse calibration

Mouse Mode:select mouse modes

Page 83

83

www.lannerinc.com

Options

Click “Options” on the task bar to view navigation options:

Bandwidth: set bandwidth

Keyboard/Mouse Encryption: enable or disable keyboard/mouse encryption

Zoom: set zooming options

Media

Click “Media” and the “Virtual Media” window will pop up. This will allow you to select and open .iso files from Floppy,

CD/DVD or Hard Disk/USB devices.

Page 84

84

www.lannerinc.com

Keyboard Layout

Click “Keyboard Layout” on the task bar to view keyboard layout options:

Auto Detect: enable or disable “Auto Detect”

SoftKeyboard: select and open virtual soft keyboard

VideoRecord

Click “VideoRecord” on the task bar to view video recording options

Start Record: start recording the current conditions of the operating remote console

Stop Record: stop the recording process

Settings: view and select Setting options

Power

Click “Power” on the task bar to view power related options

Reset Server: reset the remote server

Immediate Shutdown: shut down the system immediately

Orderly Shutdown: set shutdown order

Power On Server: power on the remote server

Power Cycle Server: the server will go through a cold boot and reset

Page 85

85

www.lannerinc.com

Active Users

Click “Active Users” on the task bar to view the number of active users. The information will be shown by user name

and IP address.

Help

Click “Help” on the task bar to view other options

About JViewer: displays information about the software program of this remote control

Page 86

86

www.lannerinc.com

Icons on the Task Bar

There are useful icons on the task bar to activate certain functions.

Play/Pause

Stop

USB/Floppy/CD-ROM

Mouse

Keyboard

Video Record

Hot keys

Page 87

87

www.lannerinc.com

Configuration

The “Configuration” provides setting options for “DNS”, “Mouse Mode”, “Network”, “Network Link”, “NTP”, “Services”,

“SSL”, and “Users”.

DNS Server Settings

Click “DNS” under “Configuration” to access DNS (Domain Name System) setting options

Page 88

88

www.lannerinc.com

Manage DNS Setting of the device

Host Settings: select “Automatic” or “Manual”

Host Name: the host name is automatically displayed if you choose “Automatic” for Host Setting

Domain Name Configurations

Domain Settings: select domain setting mode

Domain Name: you may have to specify the domain name if “Manual” is chosen for DNS Server Settings

IPv4 Domain Name Server Configurations

DNS Server Settings: select “Automatic” or “Manual”

Preferred DNS Server: enter the IP address for the preferred DNS server, such as 192.168.0.100

Alternate DNS Server: enter the IP address for an alternative DNS server

IPv6 Domain Name Server Configurations

DNS Server Settings: select “Automatic” or “Manual”

Preferred DNS Server: enter the IP address for the preferred DNS server, such as 192.168.0.100

Alternate DNS Server: enter the IP address for an alternative DNS server

Save: Save configuration changes

Reset: Reset configurations

Mouse Mode Settings

Click on “Mouse Mode Settings” under “Configuration to access redirection console mouse mode setting options.

Set Mode to Absolute (Recommended when server OS is Windows)

Set Mode to Relative (Recommended when server OS is Linux)

Select the mode based on the operating system of the remote console.

Page 89

89

www.lannerinc.com

Save: Save configuration changes

Reset: Reset configurations

Network Settings

Click on “Network Settings” under “Configuration” to manage network settings of the remote device.

LAN Interface: configure the LAN interface

LAN Settings: click to enable the support of LAN settings

MAC Address: displays the MAC address of the device. This cannot be modified.

IPv4 Configuration

Obtain an IP address automatically: tick to enable the use of DHCP to automatically obtain an IP address

IPv4 Address: enter the IP address for IPv4 network if DHCP is not enabled

Subnet Mask: enter the “Subnet Mask” if DHCP is not enabled

Default Gateway: enter the “Default Gateway” address if DHCP is not enabled

Page 90

90

www.lannerinc.com

IPv6 Configuration

IPv6 Settings: tick to enable IPv6 setting in order to enter values for IPv6 address, subnet prefix length and default

gateway. If IPv6 is not in use, simply skip this setting.

Obtain an IP address automatically: tick to enable the use of DHCP to automatically obtain an IP address

IPv4 Address: enter the IP address for IPv6 network if DHCP is not enabled

Subnet Mask: enter the “Subnet Mask” if DHCP is not enabled

Default Gateway: enter the “Default Gateway” address if DHCP is not enabled

Save: Save configuration changes

Reset: Reset configurations

Network Link Configuration

Click “Network Link Configuration” under “Configuration” to manage network link settings of the device.

LAN Interface: configure the LAN interface

Auto Negotiation: enable it to configure the service configurations automatically. If this is “OFF”, you may have to

manually configure “Link Speed” and “Duplex Mode”.

Link Speed: configure the link speed if “Auto Negotiation” is OFF

Duplex Mode: configure the Duplex Mode if “Auto Negotiation” is OFF

Save: Save configuration changes

Reset: Reset configurations

Page 91

91

www.lannerinc.com

NTP Settings

Click “NTP Settings” under “Configuration” to either configure the NTP server or view and modify the device’s date and

time.

Date: configure the device’s date setting

Time: configure the device’s time setting in hour/minute/second format

UTC Timezone: configure the device’s current time zone

NTP Server: configure the NTP (Network Time Protocol) server

You may tick on “Automatically synchronize Data & Time with NTP Server” so that the time and data information will

be automatically updated once a NTP server is configured.

Refresh: click it to refresh NTP information

Save: save the configuration changes

Reset: reset the NTP setting

Services

Click “Service” under “Configuration” to view and modify the list of services under BMC. The table presents current

status of available services. You may click “Modify” at the bottom right to modify the information.

Page 92

92

www.lannerinc.com

SSL Certificate Configuration

Click “SSL Certificate Configuration” under “Configuration” to configure SSL certificate into the BMC. With SSL, the

device can be accessed in a secured mode.

Upload SSL: upload SSL certificate and provide key file into the BMC

Generate SSL: generate SSL certificate based on configuration details

Page 93

93

www.lannerinc.com

View SSL: view the uploaded SSL

User Management

Click “User Management” under “Configuration” to access current list of available users. You may add, modify or delete

users on the list.

Page 94

94

www.lannerinc.com

Remote Control

Click “Remote Control” and you may choose “Console Redirection” or “Server Power Control” option.

Console Redirection

Click “Console Redirection” under “Remote Control”.

Press the button “Java Console” to launch the viewing of the remote console. This is the same as the “Launch” on the

“Dashboard” page. Please refer to “Dashboard” section for details.

Page 95

95

www.lannerinc.com

Server Power Control

Click “Server Power Control” under “Remote Control” to select power control options for the remote console.

You may choose the following actions to perform for the host machine.

Reset Server: reset the remote console server

Power Off Server-Immediate: this will power off the remote console server immediately

Power Off Server – Orderly Shutdown: this will power off the remote console server in an orderly way

Power On Server: this will power on the remote console server

Power Cycle Server: if this is activated, the remote console server will experience a cold boot, which will shut it down

first and then boot it up.

Maintenance

Click on “Maintenance” to view maintenance options, including “Firmware Update”, “Preserve Configuration”, “Restore

Factory Defaults” and “System Administrator”.

Page 96

96

www.lannerinc.com

Firmware Update

Click “Firmware Update” under “Maintenance” to update firmware.

Enter Update Mode: this will enable the device in update mode

Enter Preserve Configuration: this will preserve all configurations during firmware update process

Restore Factory Defaults

Click “Restore Factory Defaults” under “Maintenance”. This option will bring the device to original factory default

setting. Please note that all the currently running services or web pages will not work once this function is enabled.

All open widgets will close automatically. If the defautl restoring progress is cancelled during the process, the device

will reset.

System Administrator

This page allows the user to enable or disable access and change the password for the system administrator

account.

Page 97

97

www.lannerinc.com

Chapter 7

About the PCIe-Switch

Feature of HCP-72i1

Page 98

98

www.lannerinc.com

Chapter 7:

About the PCIe-Switch Feature of HCP-72i1

Brief

HCP-72i1 is built with TCM-IXT801A network device card, which is programmed with PCIe switch functionality.

Unlike traditional redundant system where one identical machine will take over the work from the main server until

the main server crashes, Lanner’s TCM-IXT801A will be able to avoid this indirect waste of efficiency of the backup

server.

To maximize the performance, TCM-IXT801A allows two identical servers to deal with their own network packets

separately in the normal condition. The network device(s) will be switched into the other system by dynamically

transferring PCI Express bus via PLX8748 PCI Express switch to keep on the original server task and shorten the

troubleshooting time while one machine is under malfunction. The network device(s) that has been switched will be

returned to the original system when the information staff restarts the crashed server.

The following presents the structure of the PCIe-Switch mechanism of HCP-72i1.

Page 99

99

www.lannerinc.com

Default Settings of PCI Express Switch

The following lists out the default settings of the PCI Express switch.

BIOS Version :

MB-7220(HCP-72I1) Ver.AA0 12/30/2014 Bottom Board

MB-7220(HCP-72I1) Ver.AA0 12/30/2014 Upper Board

PLX 8748 Virtual Switch Table :

VS0 : upstream port 0x0, downstream port 0x8 and 0x9

VS1 : upstream port 0x1, downstream port 0x10 and 0x11

Note:

Upstream Port : The port that PCI Express bridge upward connects to the root port.•

Downstream Port : The port that PCI Express bridge downward connects to the device.•

Kernel Patch Provided by Lanner :

Solve the issue of insufficient BAR size space for VS0 and VS1.1.

The setting of “Payload size = 256” for Intel 82599 will improve the performance.2.

Demonstrating the Switching Methods for the PCIe Switch

The following lists out the environmental setting for the demonstration:

PCI root port on the Bottom Board connects to Port ID 0x0 of VS0.•

PCI root port on the Upper Board connects to Port ID 0x1 of VS1.•

The default Management Port is Port ID 0x0, therefore, only the Bottom Board can control PCI Express Switch. •

Others can control individual Port ID only.

Port ID 0x8, 0x9, 0x10 and 0x11 connect one set of Intel 82599 PCI Express LAN device respectively.•

Device 0 and 1 connect VS0 to the Bottom Board.•

Device 2 and 3 connect VS1 to the Upper Board.•

Page 100

100

www.lannerinc.com

Initializing the System for Re-planning the Arrangement of PCI Bus ID

The Command for initializing the Bottom Board

~# sh ./pci_init.sh

The Command for initializing the Upper Board

~# sh ./pci_init.sh

Instructions of Commands:

<pci_init.sh>

Parameters: None

Function Description:

Re-plan the downstream Port BUS ID.

Main Commands of the Script:

~# remove ixgbe

~# echo 1 > /sys/bus/pci/devices/”downstream port bus ID”/remove

~# echo 1 > /sys/bus/pci/rescan

~# insmod ixgbe.ko

Loading...

Loading...