Page 1

Network

Application Platforms

Hardware platforms for next generation networking infrastructure

FW-8894

V1.0

User's Manual

Release Date: 2015/02/09

Page 2

Table of Contents

Overview 3

Chapter 1: Introduction 6

System Specifications 6

Package Contents 7

Ordering Information 7

Compatible Accessories 7

Front Panel Features 8

Rear Panel Features 9

Chapter 2: Motherboard Information 10

Block Diagram 10

Internal Jumper & Connectors 12

Chapter 3: Hardware Setup 16

Preparing the Hardware Installation 16

Installing the System Memory 18

Installing the CFast Card 19

Installing the Disk Drive(s) 19

Installing the NIC Modules 21

Replacing the Power Supply Units 22

Replacing the Cooling Fans 22

Rack Mounting 23

Installing the system to the rack 24

Appendix A: Programming Watchdog Timer 25

Appendix B: Setting up Console Redirections 25

Appendix C: Programming Generation 3 LAN Bypass 26

Appendix D: Programming the LCM 27

Appendix E: On Linux 30

Appendix F: Terms and Conditions 31

Page 3

Overview

Icon Descriptions

The icons are used in the manual to serve as an

indication of interest topics or important messages.

Below is a description of these icons:

NOTE: This check mark indicates

that there is a note of interest and is

something that you should pay special

attention to while using the product.

Online Resources

The listed websites are links to the on-line product

information and technical support.

Resource Website

Lanner http://www.lannerinc.com

Product Resources

RMA http://eRMA.lannerinc.com

WARNING: This exclamation point

indicates that there is a caution or

warning and it is something that could

damage your property or product.

http://www.lannerinc.com/

download-center/

Acknowledgement

Intel® Atom™, Pentium,® Celeron®, and Xeon® are

registered trademarks of Intel Corp.

Microsoft Windows and MS-DOS are registered

trademarks of Microsoft Corp.

All other product names or trademarks are properties of

their respective owners.

Compliances

CE

This product has passed the CE test for environmental

specifications. Test conditions for passing included

the equipment being operated within an industrial

enclosure. In order to protect the product from being

damaged by ESD (Electrostatic Discharge) and EMI

leakage, we strongly recommend the use of CEcompliant industrial enclosure products.

FCC Class A

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference

in which case the user will be required to correct the

interference at his own expense.

Copyright and Trademarks

This document is copyrighted © 2014. All rights are

reserved. The original manufacturer reserves the right to

make improvements to the products described in this

manual at any time without notice.

No part of this manual may be reproduced, copied,

translated or transmitted in any form or by any means

without the prior written permission of the original

manufacturer. Information provided in this manual

is intended to be accurate and reliable. However, the

original manufacturer assumes no responsibility for its

use, nor for any infringements upon the rights of third

parties that may result from such use.

Page 4

EMC Notice

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference

in which case users will be required to correct the

interference at their own expense.

Safety Guidelines

Follow these guidelines to ensure general safety:

Keep the chassis area clear and dust-free during and •

after installation.

Operating Safety

Electrical equipment generates heat. Ambient air •

temperature may not be adequate to cool equipment to

acceptable operating temperatures without adequate

circulation. Be sure that the room in which you choose to

operate your system has adequate air circulation.

Ensure that the chassis cover is secure. The chassis design •

allows cooling air to circulate effectively. An open chassis

permits air leaks, which may interrupt and redirect the flow

of cooling air from internal components.

Electrostatic discharge (ESD) can damage equipment and

impair electrical circuitry. ESD damage occurs when electronic

components are improperly handled and can result in complete

or intermittent failures. Be sure to follow ESD-prevention

procedures when removing and replacing components to avoid

these problems.

Wear an ESD-preventive wrist strap, ensuring that it makes •

good skin contact. If no wrist strap is available, ground

yourself by touching the metal part of the chassis.

Periodically check the resistance value of the antistatic •

strap, which should be between 1 and 10 megohms

(Mohms).

Do not wear loose clothing or jewelry that could get •

caught in the chassis. Fasten your tie or scarf and roll

up your sleeves.

Wear safety glasses if you are working under any •

conditions that might be hazardous to your eyes.

Do not perform any action that creates a potential •

hazard to people or makes the equipment unsafe.

Disconnect all power by turning off the power and •

unplugging the power cord before installing or

removing a chassis or working near power supplies

Do not work alone if potentially hazardous •

conditions exist.

Never assume that power is disconnected from a •

circuit; always check the circuit.

LITHIUM BATTERY CAUTION:

Risk of Explosion if Battery is replaced by an incorrect

type. Dispose of used batteries according to the

instructions.

Installation only by a trained electrician or only by •

an electrically trained person who knows all English

Installation and Device Specifications which are to

be applied.

Do not carry the handle of power supplies when •

moving to other place.

Rack Mounting Installation Environment Precaution

Elevated Operating Ambient - If installed in a closed 1.

or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than

room ambient. Therefore, consideration should be given

to installing the equipment in an environment compatible

with the maximum ambient temperature (Tma) specified

by the manufacturer.

Reduced Air Flow - Installation of the equipment in a rack 2.

should be such that the amount of air flow required for

safe operation of the equipment is not compromised.

Mechanical Loading - Mounting of the equipment in the

rack should be such that a hazardous condition is not

created due to uneven mechanical loading.

Mechanical Loading - Mounting of the equipment in the 3.

rack should be such that a hazardous condition is not

achieved due to uneven mechanical loading.

Circuit Overloading - Consideration should be given to 4.

the connection of the equipment to the supply circuit and

the effect that overloading of the circuits might have on

over-current protection and supply wiring. Appropriate

consideration of equipment nameplate ratings should be

used when addressing this concern.

Reliable Earthing - Reliable earthing of rack-mounted 5.

equipment should be maintained. Particular attention

should be given to supply connections other than direct

connections to the branch circuit (e.g. use of power strips).”

The machine can only be used in a fixed location •

such as labs or computer facilities.

Page 5

Revision History

Version Date Descriptions

V1.0 2015/02/09 Ocial release

Page 6

Chapter 1:

Introduction

Thank you for choosing Lanner FW-8894. The FW-8894

is the 1U version of our already launched powerful

platform of FW-8896. It leverages many technological

advancements as followed:

Dual Intel® Haswell-EP Xeon® E5-2600 v3 CPUs with •

C612 chipset

Driven by dual Intel® Xeon® E5-2600 v3 CPUs

with C612 chipset (codenamed “Grantley”),

this new platform delivers excellent efficiency

and performance. The architecture of this next

generation platform supports quad-channel

memory, up to 512GB of registered DDR4 RAM and

40 PCIe 3.0 lanes. Regarding the chipset, Intel® C612

PCH (codenamed “Wellsburg”) with ultra peripheral

connectivity supporting multiple PCIe lanes, SATA

ports, USB ports and IPMI/OPMA.

Intel® • QPI® links up to 9.6 GT/s

FW-8896 is built with dual Intel Xeon CPUs and

connected by the latest Intel QPI links up to 9.6 GT/s

to keep latency down to minimal even during heavy

workloads.

Up to Eight Ethernet modules with 32 GbE ports:•

Under 1U rackmount form factor, Lanner FW-8894

can fit in up to 4 Ethernet modules, with a total of up

to 32 GbE ports. The appliance also supports 1/10G

RJ-45 or 1/10/40G fiber Ethernet. NIC modules are

available for further expansion (optional).

Support hot-swappable cooling fans with smart fan •

control

Cooling fans are essential especially in rackmount

applications. The hot-swappable mechanism allows

easy replacement of worn-out fans to ensure

constant and reliable operations.

Intel• ® Coleto Creek 8925 acceleration engine

The integration of Intel Coleto Creek 8925 delivers up

to 25 Gbps throughput and provides optimal boost

to handle repetitive and large-scale mathematical

loads.

Intel• ® QuickAssist Technology

The Intel Grantley platform comes with Intel

QuickAssist Technology, accelerating security packet

and compression processes.

Watchdog Timer and Gen 2/3 LAN Bypass•

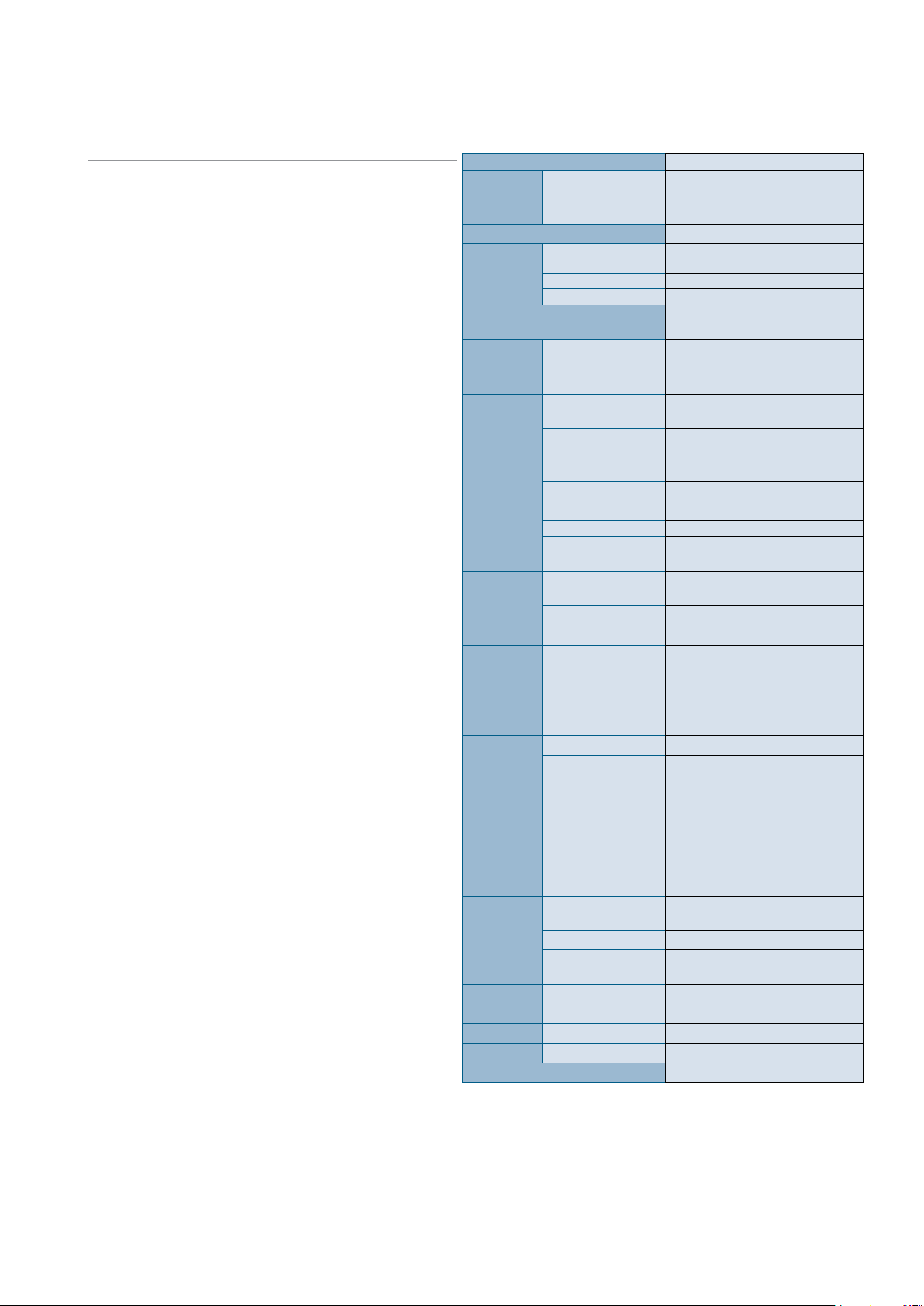

System Specifications

Form Factor 1U Rackmount

Platform

BIOS AMI BIOS 128Mb

System

Memory

OS Support

Storage

Networking

I/O Interface

Expansion PCIe

Cooling

Environmental

Parameters

Miscellaneous

Physical

Power Type / Watts 1+1 ATX 650W redundant PSUs

Certicate & Compliance CE Class A, FCC Class A, RoHS

Processor Options

Chipset Intel C612 chipset

Technology DDR4 2133 MHz registered DIMM

Max. Capacity 512 GB

Socket 16 x 288-pin DIMM

Drive Bays

NAND Flash 1 x CFast

Management Ports

Bypass

Controllers 1 x Intel® i210AT

Ethernet Modules up to 4 slim type modules

Security Acceleration Intel ColetoCreek 8925

LAN ports

Reset Button

USB 2 x USB 2.0

IPMI via OPMA slot OPMA socket

Processor 2 x CPU heat-sink (Passive)

System

Temperature, operating / storage

Humidity (RH),

operating / nonoperating

LCD Module

Watchdog Yes

Internal RTC with Li

Battery

Dimensions 438 x 44 x 630 unit:mm

Weight 18 kg

Input AC 90~264 V@47~63Hz

2 x Intel Xeon E5-2600 v3 Series

on LGA2011-R3 (Haswell-EP)

Windows 7, 2008 Server, Linux

kernel 2.6 or later

1 x 3.5” or 2 x 2.5” SATA HDD/

SSD

1 x RJ45 GbE port, shared with

IPMI

Depending on Ethernet module

specications

(support Lanner Gen 3 bypass)

Up to 32 GbE ports, depending on

modules installed

1 x reset button

Software reset by default

4x PCIe*8 connectors for front

NIC

2x PCIe*16 ZD connectors for

backplane

1x PCIe*8 connector for riser card

4 x independent hot-swappable

cooling fans with smart fan

control

0 ~ 40º C / -40~70º C

5~90%, non-condensing

1x character type LCM with 4

keypads (graphic optional)

Yes

Page 7

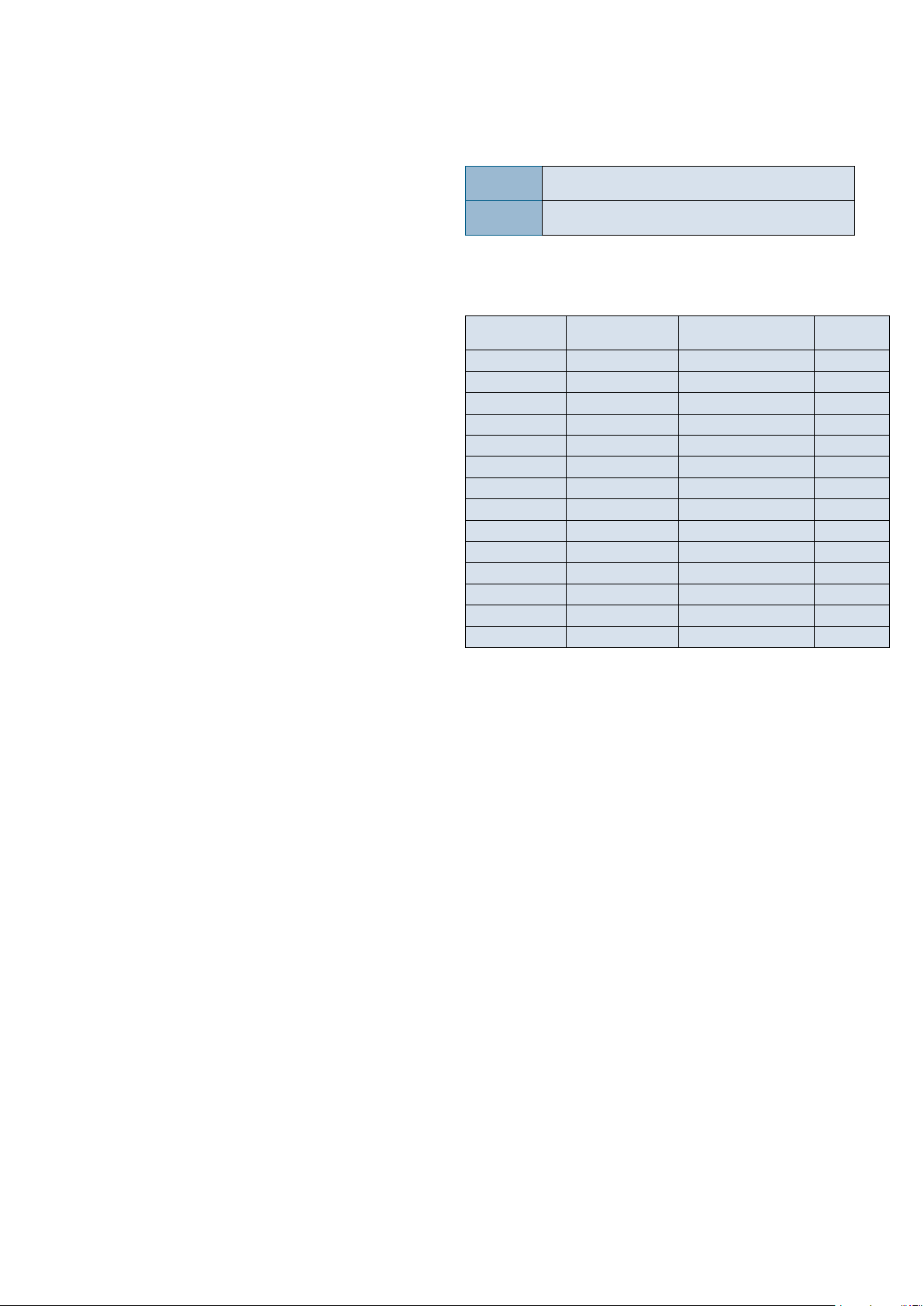

Package Contents

Ordering Information

Your package contains the following items:

FW-8894 Network Security Platform•

2 power cables•

1 Long Ear Rack mount kit with screws•

1 Console cable•

1 LAN cable (grey)•

Optional:

RC-8894 1A PCIe riser card (RC-8896 1A, brackets, •

and screws) 2U slide kit

IPMI Card: IAC-AST2300•

TPM Module: IAC-TPM01A / IAC-TPM01B•

Note: If any components is missing or damaged,

please contact your dealer immediately for

assistance.

FW-8894A

FW-8894B

4 Ethernet module slots & 2 hard drive bays, with

Coleto Creek 8925

4 Ethernet module slots & 2 hard drive bays, without

Coleto Creek 8925

Compatible Accessories

Models Specifications Chipset

NCS2-IGM428A 4 x GbE RJ45 Intel i350AM-4 2 pairs

NCS2-IGM428B 4 x GbE RJ45 Intel i350AM-4 N/A

NCS2-IGM806A 8 x GbE RJ45 Intel i350AM-4 4 pairs

NCS2-IGM806B 8 x GbE RJ45 Intel i350AM-4 N/A

NCS2-IGM808A 8 x GbE RJ45 Intel i210AT 4 pairs

NCS2-IGM808B 8 x GbE RJ45 Intel i210AT N/A

NCS2-ISM405A 4 x GbE SFP Intel i350AM-4 2 pairs

NCS2-ISM406A 4 x GbE SFP Intel i350AM-4 N/A

NCS2-ISM802A 8 x GbE SFP Intel i350AM-4 N/A

NCS2-IXM204A 2 x 10G SFP Intel 82599ES N/A

NCS2-IXM205A 2 x 10G SFP Intel 82599ES 1 pair

NCS2-IXM405A 4 x 10G SFP Intel 82599ESPLX8724 N/A

NCS2-IXM407 4 x 10G SFP+ Intel Fortville N/A

NCS2-IQM201 2 x 40G QSFP+ Intel Fortville N/A

Gen3

Bypass

Page 8

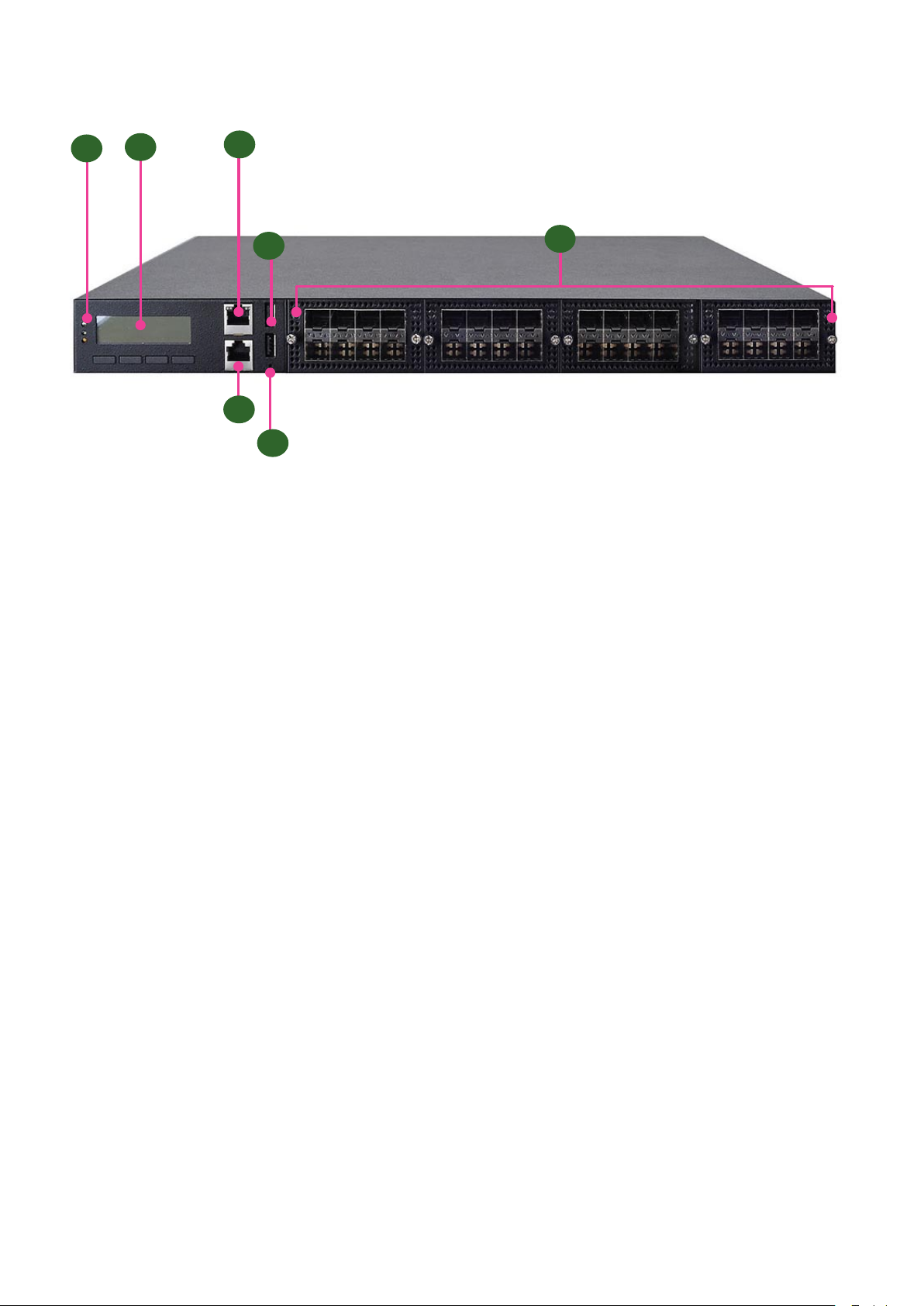

Front Panel Features

F1

F2

F3

F4

F5

F7

F6

F1 Power/Status/HDD LED

Power LED: If the LED is on, it indicates that the system is powered on. If it is off, it indicates that the system is powered

off.

Status LED: This LED indicator is programmable. You could program it to display the operating status with the

behaviors as followed:

If the LED is green, it indicates that the system’s operational state is normal. If it is red, it indicates that the system is

malfunctioning.

HDD: If this LED blinks, it indicates data access activities; otherwise, it remains off.

F2 LCD System Panel

F3 1 x Management Port

F4 1 x Console Port

F5 2 x USB ports

F6 1 x Reset switch

F7 Up to 4 Ethernet NIC modules

Page 9

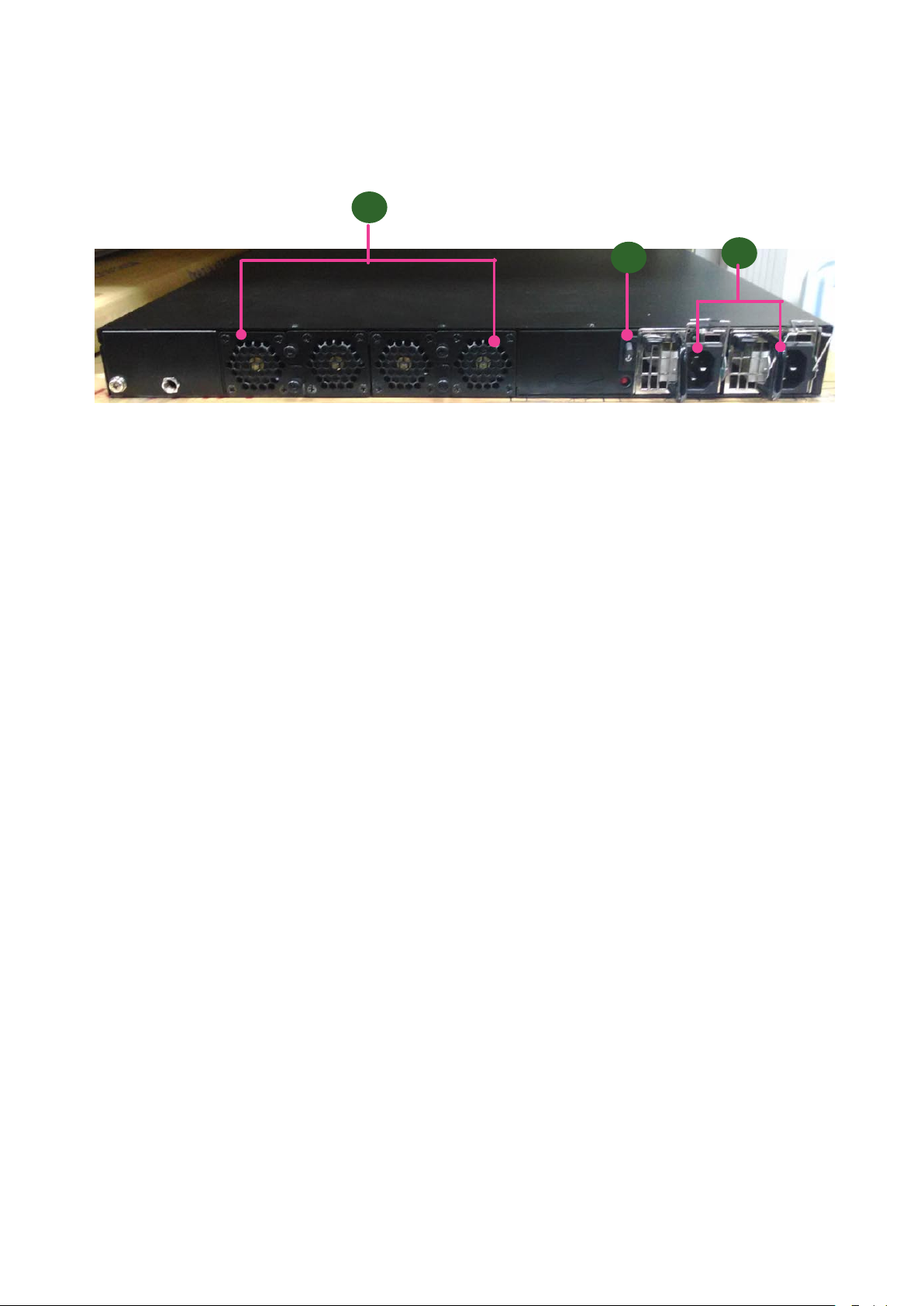

Rear Panel Features

R1

R1 4 x Cooling fans

R2 Power switch

R3 Power supply units for RPS (Redundent Power Supply)

R2

R3

Page 10

Chapter 2:

Motherboard Information

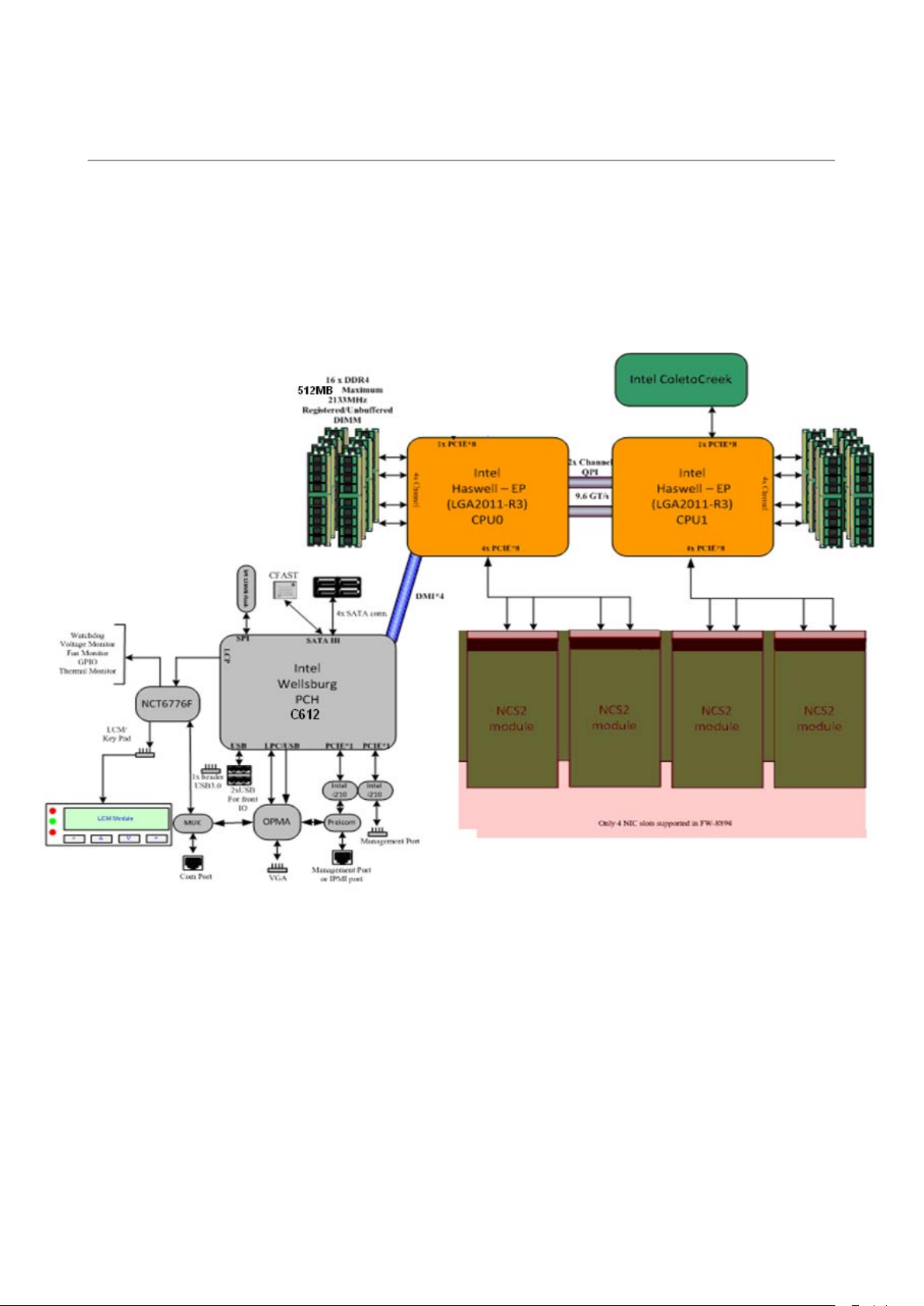

Block Diagram

The block diagram indicates how data flows among components on the motherboard. Please refer to the following

figure for your motherboard’s layout design.

Page 11

Motherboard Layout

The motherboard layout shows the connectors and

jumpers on the board. Refer to the following picture

as a reference of the pin assignments and the internal

connectors.

JDDR0-3

ATX5

CON3

J80PORT1

JVGA1

ATX3-4

JFAN1 JFAN3 JFAN4

JFAN2

CPU Socket

No.1

ATX1-2

JDDR4-11

JDDR12-15

CPU Socket NO. 2

MGT1

JRISER1

J23

JOPMA1

JUSB1

JCOMA1

J27

JOPEN1

COMB1

JPCIESL1

MGT2

JPCIESL2

OPEN2

SATA1-4

JUSB2

JGP1

JLCM1

JCMOS

CFast1

J25

JSPIROM1

JTPM1

JPCIESL4

JPCIESL3

Page 12

Internal Jumper & Connectors

2

10

9

1

USB_LCM

MGT1

11

12

2

1

MGT2

11

12

2

1

JLCM1: USB-type front LCD Message Display

Module (LCM).

Pin Description Pin Description

1 P5V_SB 2 P5V

3 USB20_N5 4

5 USB20_P5 6 HDD_LED#

7 GND 8 GND

9 NTXD2 10 NRXD2

MGT1: RJ 45 LAN management port connector by

Intel I210 LAN

Pin Description Pin Description

1 LAN2_MDX+0 2 LAN2_MDX-0

3 LAN2_MDX+1 4 LAN2_MDX-1

5 LAN2_MDX+2 6 LAN2_MDX-2

7 LAN2_MDX+3 8 LAN2_MDX-3

9 LAN2_100# 10 LAN2_ACTR#

11 LAN2_1000# 12 P3V3_AUX

ATX5: 24-Pin ATX Power Connector

23

21

19

1

Pin Description Pin Description

1 +3.3V 2 +3.3V

3 +3.3V 4 -12V

5 Ground 6 Ground

7 +5V 8 PSON-

9 Ground 10 Ground

11 +5V 12 Ground

13 Ground 14 Ground

15 Power Good 16 NC

17 Stand-By 5V 18 +5V

19 +12V 20 +5V

21 +12V 22 +5V

23 3.3V 24 GND

24

23

20

2

ATX1~4: 8-Pin ATX Power Connector

2

4

6

8

1

3

5

7

MGT2: RJ 45 LAN management port connector

Pin Description Pin Description

1 MGT_MDIP_0 2 MGT_MDIN_0

3 MGT_MDIP_1 4 MGT_MDIN_1

5 MGT_MDIP_2 6 MGT_MDIN_2

7 MGT_MDIP_3 8 MGT_MDIN_3

9 MGT_LAN_100# 10 MGT_LAN_ACT#

11 MGT_LAN_1G# 12 P3V3_AUX

Pin Description Pin Description

1 GND 2 +12V

3 GND 4 +12V

5 GND 6 +12V

7 GND 8 +12V

SATA1~4: SATA Connectors for SATA disk drives

7 6 5 4 3 2 1

SATA1

Pin Description

1 GND

2 TX_P

3 TX_N

4 GND

5 RX_N

6 RX_P

7 GND

Page 13

JFAN1~4: 5-Pin FAN Connector.

2

10

9

1

USB1

11

12

2

1

JUSB2: USB 2.0/3.0 Internal Connector

Pin Description

1 Ground

2 12V

3 RPM Sense

4 RPM Sense

5 PWM Status

J27: Jumper for Reset

Pin Description

Short Pin 1-2 Hardware reset

Short Pin 2-3 Software reset

JUSB1: USB 2.0 internal pin header

Pin Description Pin Description

1 2 USB20_L_P2

3 USB20_L_P3 4 USB20_L_N2

5 USB20_L_N3 6 USBGND02

7 USBGND02 8 USB30_TX2P_C_L

9 USB30_TX1P_C_L 10 USB30_TX2N_C_L

11 USB30_TX1N_C_L 12 USBGND02

13 USBGND02 14 USB30_RX2P_L

15 USB30_RX1P_L 16 USB30_RX2N_L

17 USB30_RX1N_L 18 P5V_USB2

19 P5V_USB2 20

JVGA1: VGA interface connector

Pin Function Pin Function

1 DAC_RO 2 Ground

3 DAC_GO 4 Ground

5 DAC_BO 6 Ground

7 HSYNC_O 8

9 VSYNC_O 10 Ground

11 DDC_DATA 12 DDC_CLK

Pin Description Pin Description

1 P5V_USB1 2 P5V_USB1

3 USB20_L_N0 4 USB20_L_N1

5 USB20_L_P0 6 USB20_L_P1

7 USBGND1 8 USBGND1

9 USBGND1 10 USBGND1

Page 14

OPMA1: OPMA interface. The OPMA connector is

2

10

9

1

COMA1

2

10

9

1

COMB1

for connecting the OPMA card. When the OPMA card is

connected, the management port will comply with the

Intelligent Platform Management Interface (IPMI) standard.

JCFast1: CFast card

Pin Function Pin Function

PC1 Tie to Pin17 S1 GND

PC2 GND S2 SATA_TX_P0

PC3 S3 SATA_TX_N0

PC4 S4 GND

PC5 S5 SATA_RX_N0

PC6 S6 SATA_RX_P0

PC7 GND S7 GND

PC8 LED_CFAST#

PC9

PC10

PC11

PC12

PC13 P3V3

PC14 P3V3

PC15 GND

PC16 GND

PC17 Tie to Pin1

JCOMA1: COM PORT Connector

Pin Description Pin Description

1 NDCD1 2 NDSR1

3 NRXD1 4 NRTS1

5 NTXD1 6 NCTS1

7 NDTR1 8 NRI1

9 GND 10 FP_RESET_N

COMB1: COM PORT Internal Connector

Pin Description Pin Description

1 NDCD2- 2 NDSR23 NRXD2 4 NRTS25 NTXD2 6 NCTS27 NDTR2 8 NRI29 GND 10

Page 15

J23: LCM

Pin Description Pin Description

1 VCC 2 GND

3 P_SLIN_N 4 VEE

5 P_AFD_N 6 P_INIT_N

7 LPD1 8 LPD0

9 LPD3 10 LPD2

11 LPD5 12 LPD4

13 LPD7 14 LPD6

15 LCD 16 VCC

17 KPA1 18 KPA2

19 KPA3 20 KPA4

21 FP_RESET# 22 CTR_GRN

23 CTR_YEW 24 HDD_LED#

CON3: PMBUS/TTL

Pin Description

1 PSU_TTL1

2 PSU_TTL2

3

4 GND

5

6 PMBUS_CLK

7 PMBUS_DAT

8 PMBUS_ALERT#

JOPEN2: MGT port SEL (IPMI/I210). This is the

management port function selection jumper.

Pin Description

1 MGT_SEL

2 IPMI_DETECT#

JCMOS: Clear CMOS

Pin Description

1 VRTC

2 PCH_RTCRST#

3 GND

J25: Burn CPLD (Complex Programmable Logic Device)

Pin Description Pin Description

1 VCC 5

2 JTAG_PLD_TPO 6 JTAG_PLD_TMS

3 JTAG_PLD_TD1 7 GND

4 8 JTAG_PLD_TCK

JGP1: External GPIO header

JOPEN1: Chassis Open Detect mainboard protection

jumper. (a short-pin cap will be connected to the top

compartment of the system chassis. When the top

compartment is lifted/removed, the board functions will

be disabled once the jumper cap is lifted along with the

top compartment. This is to protect the board from being

tampered by anyone who remove the top compartment.

Pin Description

1 GND

2 CSOPEN#

Pin Description Pin Description

1 GPO_B_1 6 GPI_B_3

2 GPI_B_1 7 GPO_B_4

3 GPO_B_2 8 GPI_B_4

4 GPI_B_2 9 GND

5 GPO_B_3 10 GND

JTPM1: TPM connector

Pin Description Pin Description

1 IRQ_SERIAL 2 LPC_FRAME#

3 LPC_LAD0 4 CLK_33M_PCI

5 LPC_LAD1 6 VCC

7 LPC_LAD2 8

9 LPC_LAD3 10 VCC

11 PLT_RST# 12 GND

Page 16

Chapter 3:

Hardware Setup

Preparing the Hardware Installation

WARNING: To reduce the risk of personal injury,

electric shock, or damage to the equipment,

remove the power cord to complete shut down

the device. The rear panel Power On button does

not completely shut off system power. Portions

of the power supply and some internal circuitry

remain active until AC power is removed.

Installing CPU and the Heat Sink

Follow the procedures below for installing a CPU

1. Locate the CPU socket(s)

2. Press the left load lever down, move it out of the

retention tab. Then, do the same to the right. There are

two levers for each CPU socket.

Press down

Power off FW-8894 and make sure the power cord is 1.

disconnected from the device.

Remove the 3 circled screws at the rear of the top 2.

compartment and 2 from each side.

Press down

3. Lift the load levers.

Gently pull the cover backward .3.

Open the cover from the side.4.

Page 17

4. Open the load plate and also the protective cap.

Load plate

Protective cap

5. Align the CPU and the notch on the socket. The CPU

should fit perfectly into the socket. Note that the CPU

fits in the socket in only one direction.

6. Put the protective cap onto the CPU. Close the load

plate and push the load lever to lock it back to the

retention tab.

7. Put the heat sink on the installed CPU and match the

screws with the screw holes on the board. Fasten two

screws which are opposite to each other at a time and

then the other two. It is easier this way to avoid the force

of spring.

Place the heat sink cover on top of the installed heat sink

and fasten it with screws on the chassis.

Note:

If you have only one CPU, install it on the left 1.

side (CPU socket No.1with the front panel

facing you). Failure to do so will result in boot

failure .

To protect the CPU socket pins, retain the CPU 2.

cap when the CPU is not installed.

8. Install rediation mounting-brackets as the image below.

Make sure to lock all the necessary screws.

Rediation mounting brackets

Rediation

mounting

brackets

Rediation mounting brackets

Page 18

Installing the System Memory

The motherboard supports DDR4 registered DIMM

memory for heavy-duty operations. Please follow the

steps below to install the DIMM memory modules.

Power off the system.1.

Pull open the DIMM slot latches2.

Align the DIMM module and make sure the notches 3.

of the module aligned with the socket keys in the slot.

The motherboard of FW-8894 is designed with 16 DDR

DIMM sockets. For users without 16 modules to ll up all

the sockets, it is recommended to start by the blue ones

for optimal performance.

Insert the module into the slot until it’s firmly seated.4.

Page 19

Installing the CFast Card

Installing the Disk Drive(s)

FW-8894 provides one CFast slot. Follow the procedures

below for installing a CFast card.

Locate the CFast socket.1.

Remove the protection cover.2.

Insert a CFast card until completed seated.3.

FW-8894 supports 1x3.5” or 2 x 2.5” SATA disk drives.

Please follow the steps below for instructions.

1. As shown in the image below, the disk drive bay is

located at the top right corner inside FW-8894.

2. Remove the 4 footing-screws to take out the HDD/SSD

bracket.

3. The disk drive bracket can be used as a 1 x 3.5” or 2 x

2.5” SATA HDD/SSD bay. The image below is to use it as a 1

x 3.5” SATA HDD/SSD bay.

Page 20

4. You may adjust it to be used for 2 x 2.5” SATA HDD/SSD.

Just relocate the side bracket as shown below.

5. Use SATA cables to connect your HDD/SSD with the

SATA connectors on the motherboard.

SATA Power Cable

SATA Signal Cable

4 x SATA connectors on the motherboard

Page 21

Installing the NIC Modules

FW-8894 series comes with 4 NIC Ethernet module slots

for network bandwidth expansion. Please follow the steps

for installation.

1. Select a NIC Ethernet module slot.

2. Rotate and loosen the two lock-screws of the selected

module slot.

4. Insert your NIC Ethernet module. (Note: the module

shown in the image below is for reference only).

5. Once the module is firmly seated, rotate and tighten the

two lock-screws.

3. Remove the door of the module slot and aim at the

PCIe socket for module insertion.

Page 22

Replacing the Power Supply Units

Replacing the Cooling Fans

Power supply units may wear down eventually. Please be

noted that FW-8894 series supports 650W depending on

the ordering preferences. Please prepare the power supply

units matching this capacity.

1. Locate the power supply units.

2. Pull the lock mechanism towards your left and hold the

handle backward t

Cooling fans may wear down eventually. Please refer to

the steps below for replacing cooling fans.

1. Locate the cooling fans at the rear panel.

2. Loosen the lock-screw of the fan you would like to

replace.

3. Hold onto the two lock-screws and pull it out.

3. Hold the handle and pull it out.

4. Prepare a new power supply unit (650W) and install it

back onto FW-8894.

4. Remove the screws that secure the fan.

Page 23

Rack Mounting

Installation Precautions:

Elevated Operating Ambient - If installed in a closed 1.

or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater

than room ambient. Therefore, consideration should be

given to installing the equipment in an environment

compatible with the maximum ambient temperature

(Tma) specified by the manufacturer.

Reduced Air Flow - Installation of the equipment in 2.

a rack should be such that the amount of air flow

required for safe operation of the equipment is not

compromised. Mechanical Loading - Mounting of the

equipment in the rack should be such that a hazardous

condition is not created due to uneven mechanical

loading.

Circuit Overloading - Consideration should be given to 3.

the connection of the equipment to the supply circuit

and the effect that overloading of the circuits might

have on over-current protection and supply wiring.

Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern.

Reliable Earthing - Reliable earthing of rack-mounted 4.

equipment should be maintained. Particular attention

should be given to supply connections other than

direct connections to the branch circuit (e.g. use of

power strips).”

CAUTION :

Mounting the outer rails to the rack

Slide/rail mounted equipment is not to be used as a

shelf or a work space.

Attaching the rails to the system

Page 24

Installing the system to the rack

Notes for Step 5: it is strongly recommended that installing the system

onto the rack is a 2-persons' job. Please avoid performing this task by

oneself.

Page 25

Appendix A:

Appendix B:

Programming Watchdog

Timer

A watchdog timer is a piece of hardware that can be

used to automatically detect system anomalies and reset

the processor in case there are any problems. Generally

speaking, a watchdog timer is based on a counter that

counts down from an initial value to zero. The software

selects the counter’s initial value and periodically restarts

it. Should the counter reach zero before the software

restarts it, the software is presumed to be malfunctioning

and the processor’s reset signal is asserted. Thus, the

processor will be restarted as if a human operator had

cycled the power.

For sample watchdog code, see watchdog folder on the

Driver and Manual CD

To execute the sample code: enter the number of

seconds to start count down before the system can be

reset. Press start to start the counter and stop to stop the

counter..

Dwd_tst --swt xxx (Set Watchdog Timer 1-255 seconds)

wd_tst[*] --start (Start Watchdog Timer)

wd_tst --stop (Stop Watchdog Timer)

For sample watchdog code, see watchdog folder on the

Driver and Manual CD

Setting up Console

Redirections

Console redirection lets you monitor and configure a

system from a remote terminal computer by re-directing

keyboard input and text output through the serial port.

This following steps illustrate how to use this feature. The

BIOS of the system allows the redirection of console I/O

to a serial port. With this configured, you can remotely

access the entire boot sequence through a console port.

Connect one end of the console cable to console 1.

port of the system and the other end to serial port of

the Remote Client System.

Configure the following settings in the BIOS Setup 2.

menu:

BIOS > Advanced > Remote Access Configuration >

Serial Port Mode > [115200, 8 , n ,1 ]

Configure Console Redirection on the client system. 3.

The following illustration is an example on Windows

platform:

A. Click the start button, point to Programs > a.

Accessories > Communications and select Hyper

Terminal.

B. Enter any name for the new connection and b.

select any icon.

Click OK.c.

From the “Connect to”. Pull-down menu, select the d.

appropriate Com port on the client system and

click OK.

Select 115200 for the Baud Rate, None. for Flow e.

contorl, 8 for the Data Bit, None for Parity Check,

and 1 for the Stop Bit.

Page 26

Appendix C:

Programming Generation

3 LAN Bypass

The bypass function is used to link two independent

Ethernet ports when the system crashes or powers

off. This means if your system is equipped with a LAN

Bypass function, a condition in your system will not

interrupt your network traffic. Different from the previous

two generations (Gen1 and Gen2), the Lanner Bypass

Gen 3 employs a programming method to control the

bypass function by software. There are typically two

communication status for the bypass function, one is

“Normal” and another is “Bypass” status. Furthermore, the

Lanner Bypass software is capable to control the bypass

status in the following 3 instances.

When the system powers off, it can be forced to 1.

enable the LAN Bypass function .

When the system is in the just-on state which is a 2.

brief moment when it powers up .

When the system is running3.

can use this timer to delay enabling the bypass in

just-on state.

For sample LAN bypass code and the Bypass Manual, see

the LAN_Bypass folder on the Driver and Manual CD or

the Lanner Support Website at http://www.lannerinc.com/

download-center/. And browse the download center and

look for Lanner LAN Bypass Watchdog User Manual under

the Accessories folder.

Fro a description of the physical LAN ports equipped

with this function, refer to Front Panel Features in Chapter

1 Introduction.

Please refer to the LAN_Bypass_Watchdog folder on the

Driver and Manual CD.

And the Lanner bypass possess the following features:

Communication through SMBUS (I2C)1.

Independent bypass status control for each pair up to 2.

a total of 4 pairs

Lanner Bypass Modules can bypass systems Ethernet 3.

ports on a host system during three instances: Just-on

(Just-on is the brief moment when the internal power

supply turns on and booting process starts), system

off, or upon software request (during run-time).

Software programmable bypass or normal mode4.

Software programmable timer interval:5.

- JUST-ON watchdog timer, used during JUST-ON, has

timer setting of 5~1275 seconds of timer interval.

- Run-Time watchdog timer, used during run-time, has

setting of 1~255 seconds of timer interval.

Multiple Watchdog Timers:6.

-Two for run-time: It is designed to give you a more

variety of controls of the bypass on port basis. By

using dedicated watchdogs for different pairs of

bypass, you have the flexibility to manage the bypass

status for them differently.

-One for just-on: It is designed to give you the

precise control of the bypass during this phase. You

Page 27

Appendix D:

Programming the LCM

The LCD panel module (LCM) is designed to provide

real-time operating status and configuration information

for the system. For sample LCM code, see LCM foler in

the Driver and Manual CD. The driver and the program

library can also be found in the folder.

The system supports the following 2 kinds of LCM:

Install

Install the driver and create a node in the /dev directory

by:

#insmod plcm_drv.ko

#mknod /dev/plcm_drv c 248 0

Parallel Text-based LCM: The LCM connects to the •

motherboard’s parallel port. The LCD screen can

display 2 lines, 16 (or 20) characters per line.

USB and Serial Text or Graphic-based LCM: Our next •

generation LCM. Lanner engineers design a common

source code to be deployed on these two differently

interfaced LCM modules. Jumpers are used to select

between text and graphic types. See next section.

For Parallel Text-based LCM

Build

To build program source code on Linux platform, please

use the following steps as a guideline:

1. Extract the source file:

# tar -xzvf plcm_drv_v0XX.tgz

(0XX is the version of the program.)

2. Change directory to the extracted folder:

# cd plcm_drv_v0XX

(0XX is the version of the program.)

Note:

If you cannot install the driver,

check whether you have enabled the

parallel port in the BIOS setting .

Once the message of “insmod: error

inserting ‘plcm_drv.ko’: -1 Input/output

error” appears, please check that whether

the major number is repeated or not.

The major number needed with the

mknod command varies with different

software versions; please look up

the Readme file for this value.

Execute

This section contains sample executable programs that

you could test on your platform. It demonstrates some

useful functionality that the LCM provides. Note that the

installation needs to be completed before proceeding

with these executions.

To execute, run the command:

Note: Apply our Parallel Text-based LCM to the

environment of virtualization, please use the version 013

or above of the program.

3. Type make to build source code:

# make

After compiling, the executable programs (plcm_test,

plcm_cursor_char, ppdev_test, Test) and the driver

(plcm_drv.ko) will appear in the program’s folder.

Note: The OS supported by Parallel Text-based LCM

function includes platforms based on Linux Kernel series

2.4.x, Linux Kernel series 2.6.x and Linux Kernel series

3.0.x or above.

#./plcm_test

Backlight Off/On turning off/on the backlight of the

LCM display

Display Off turning off the LCM display

Cursor Off/On NOT showing/showing the cursor on the

LCM display

Blinking off/On turning off/on the cursor blinking

Writing “Lanner@Taiwan” displaying the specific

sentences

Reading “Lanner@Taiwan” reading the specific sentence

CGram Test displaying the user-stored characters

Keypad Testing Get the keypad input: the 1st button is

read in as Left, the 2nd button is read in as Up, the 3rd

button is read in as Right, and the 4th button is read in as

Down)

Page 28

Corresponding Commands for plcm_test

Test

You can directly input the specic command to have its

corresponding function worked on your LCM. This

will be much more convenient once you would like to

merely execute the keypad testing.

-On

— Turn on the backlight of the LCM display.

— To execute, please type:

#./plcm_test -On

-O

— Turn o the backlight of the LCM display.

— To execute, please type:

#./plcm_test –O

-LCM1

— Writing “Lanner@Taiwan” in line1.

— To execute, please type:

#./plcm_test -LCM1

-LCM2

— Writing “2013-11-05” in line 2.

— To execute, please type:

#./plcm_test -LCM2

Keypad

— Get the keypad input: the 1st button is read in as Left,

the 2nd button is read in as Up, the 3rd button is read

in as Right, and the 4th button is read in as Down.

— To execute, please type:

#./plcm_test -Keypad

Commands for plcm_cursor_char

This Run this command for cursor shift & single text

update

# ./plcm_cursor_char

Please read the options below

Insert line select Item 1 to set the starting line as either

line 1 or line 2

Move cursor right select Item 2 to move the cursor to

the right

This program is a testing script and runs through the

following procedures in sequence:

—rmmod plcm_drv (remove the kernel mode driver

module)

— insmod plcm_drv.ko (install the kernel mode

driver module)

— ./plcm_test (execute the driver testing program)

— ./plcm_test -stop (stop executing the driver testing

program)

— rmmod plcm_drv (remove the kernel mode driver

module)

To execute, please type:

#./Test

Virtualization Implemented by Parallel

Port Pass Through

By the utilization of the parallel port pass through,

the Parallel Text-based LCM implements the following

three kinds of virtualization in the Guest OS.

- QEMU/KVM

- Xen

- VMWare Player

Here, we take the Fedora 20 x86_64 operation system

for instance to explain 3 virtualization respectively for

parallel port pass through. Use the procedures listed

below for step-by-step instructions separately based

on your case.

In case of QEMU/KVM or Xen, please use the following

steps as a guideline to implement the virtualization :

(1) Make sure that the Guest OS has been installed.

(2) Add the following 4 lines into the xml file (for

example, add to

/etc/libvirt/qemu/<yourvirtualmachine>.xml in linux

KVM) :

Move cursor left select Item 3 to move the cursor to the

left

Add a char select Item 4 to display a character on the

LCM screen

Clean display select Item 5 to clear up the LCM display

Leave select Item 6 to exit the program

<parallel type=’dev’>

<source path=’/dev/parport0’/>

<target port=’0’/>

</parallel>

Page 29

(3) Open a terminal in the Guest OS and then issue the

following commands to install linux kernel drivers.

# modprobe parport

# modprobe parport_pc

# modprobe ppdev

(4) Check that whether the /dev/parport0 exists or

not. You may not find proper /dev/parport0 in the

device list, please reconfirm the setup of xml file in the

Guest OS.

(5) Reboot the Guest OS.

Note: It is necessary for you to insmod parport.ko,

parport_pc.ko and ppdev.ko linux kernel drivers in

virtualization environment before executing the

ppdev_test testing program.

In case of VMWare Player, please use the following

steps as a guideline to implement the virtualization:

(1) Make sure that the Guest OS has been installed.

(2) To set up the parallel port pass through, please

enter VMWare Player’s --> Virtual Machine Setting -->

VMWare Player’s setting page to select /dev/parport0

as parallel port device.

(3) Open a terminal in the Guest OS and then issue the

following commands to install linux kernel drivers.

# modprobe parport

# modprobe parport_pc

# modprobe ppdev

4) Check that whether the /dev/parport0 exists or not.

You may not find proper /dev/parport0 in the device

list, please reconfirm the setup of VMWare Player’s

setting page described in Step 2.

(5) Reboot the Guest OS.

Note: It is still necessary for you to insmod parport.

ko, parport_pc.ko and ppdev.ko linux kernel drivers

in virtualization environment before executing the

ppdev_test testing program.

Page 30

Appendix E:

On Linux

Follow these instructions when installing the Intel®

LAN controller base driver for the in Red Hat® and Linux

operating system.

Insert the motherboard/system support CD to the 1.

optical drive and mount the optional drive in the

Linux platform.

Copy the base driver tar file from the motherboard/2.

system support CD to the directory of your local hard

disk. The Intel® LAN driver for Linux OS is located in

the following directory:

\Driver\LAN_Driver\PRO1000\LINUX. The name format

of driver file is “e1000-<Version>.tar.gz”. For example:

the file name of driver version 7.0.38 is “e1000-7.0.38.

tar.gz”.

Untar/unzip the archive, where <x.x.x> is the version 3.

number for the driver tar file:

tar zxf e1000-<x.x.x>.tar.gz

Change to the driver src directory on your system, 4.

where <x.x.x> is the version number for the driver tar:

Assign an IP address to the interface by entering the 8.

following, where <x> is the interface number:

ifconfig eth<x> <IP_address>

Verify that the interface works. Enter the following, 9.

where <IP_address> is the IP address for another

machine on the same subnet as the interface that is

being tested:

ping <IP_address>

cd e1000-<x.x.x>/src/

Compile the driver module by typing the following 5.

command:

make install

The binary will be installed as:6.

/lib/modules/<kernel_version>/kernel/drivers/

net/e1000.o

The install locations listed above are the default

locations. They might not be correct for certain Linux

distributions.

Load the module using either the insmod or 7.

modprobe command:

modprobe igb

insmod igb

Note that for 2.6 kernels the insmod command

can be used if the full path to the driver module is

specified. For example:

insmod /lib/modules/<KERNEL VERSION>/kernel/

drivers/net/igb/igb.ko

With 2.6 based kernels also make sure that older

igb drivers are removed from the kernel, before loading

the new module:

rmmod igb; modprobe igb

Page 31

Appendix F:

Terms and Conditions

Warranty Policy

All products are under warranty against defects in 1.

materials and workmanship for a period of one year

from the date of purchase.

The buyer will bear the return freight charges for 2.

goods returned for repair within the warranty period;

whereas the manufacturer will bear the after service

freight charges for goods returned to the user.

RMA Service

Requesting a RMA#

To obtain a RMA number, simply fill out and fax the 6.

“RMA Request Form” to your supplier.

The customer is required to fill out the problem code 7.

as listed. If your problem is not among the codes

listed, please write the symptom description in the

remarks box.

Ship the defective unit(s) on freight prepaid terms. 8.

Use the original packing materials when possible.

Mark the RMA# clearly on the box. 9.

The buyer will pay for repair (for replaced 3.

components plus service time) and transportation

charges (both ways) for items after the expiration of

the warranty period.

If the RMA Service Request Form does not meet the 4.

stated requirement as listed on “RMA Service,” RMA

goods will be returned at customer’s expense.

The following conditions are excluded from this 5.

warranty:

Improper or inadequate maintenance by the customer

Unauthorized modification, misuse, or reversed

engineering of the product Operation outside of the

environmental specifications for the product.

Note: Customer is responsible for shipping

damage(s) resulting from inadequate/loose

packing of the defective unit(s). All RMA# are

valid for 30 days only; RMA goods received after

the effective RMA# period will be rejected.

Loading...

Loading...