Page 1

Network

Application Platforms

Hardware platforms for next generation networking infrastructure

FW-7565

>>

User's Manual

Publication date:2010-09-01

Page 2

About

About

Overview

Icon Descriptions

The icons are used in the manual to serve as an indication

of interest topics or important messages. Below is a

description of these icons:

NOTE: This check mark indicates that

there is a note of interest and is something

that you should pay special attention to

while using the product.

Online Resources

The listed websites are links to the on-line product

information and technical support.

Resource Website

Lanner http://www.lannerinc.com

P r o d u c t

Resources

RMA http://eRMA.lannerinc.com

WARNING: This exclamation point

indicates that there is a caution or

warning and it is something that could

damage your property or product.

http://assist.lannerinc.com

Acknowledgement

Intel, Pentium and Celeron are registered trademarks of

Intel Corp.

Microsoft Windows and MS-DOS are registered trademarks

of Microsoft Corp.

All other product names or trademarks are properties of

their respective owners.

Compliances

CE

This product has passed the CE test for environmental

specifications. Test conditions for passing included the

equipment being operated within an industrial enclosure.

In order to protect the product from being damaged by

ESD (Electrostatic Discharge) and EMI leakage, we strongly

recommend the use of CE-compliant industrial enclosure

products.

FCC Class A

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required

to correct the interference at his own expense.

Safety Guidelines

Copyright and Trademarks

This document is copyrighted, © 2010. All rights are

reserved. The original manufacturer reserves the right to

make improvements to the products described in this

manual at any time without notice.

No part of this manual may be reproduced, copied,

translated or transmitted in any form or by any means

without the prior written permission of the original

manufacturer. Information provided in this manual is

intended to be accurate and reliable. However, the original

manufacturer assumes no responsibility for its use, nor for

any infringements upon the rights of third parties that

may result from such use.

Network Application Platforms

Follow these guidelines to ensure general safety:

Keep the chassis area clear and dust-free during and after •

installation.

Do not wear loose clothing or jewelry that could get •

caught in the chassis. Fasten your tie or scarf and roll up

your sleeves.

Wear safety glasses if you are working under any •

conditions that might be hazardous to your eyes.

Do not perform any action that creates a potential hazard •

to people or makes the equipment unsafe.

Disconnect all power by turning off the power and •

unplugging the power cord before installing or removing a

chassis or working near power supplies

Do not work alone if potentially hazardous conditions •

exist.

Never assume that power is disconnected from a circuit; •

always check the circuit.

i

Page 3

About

LITHIUM BATTERY CAUTION:

Risk of Explosion if Battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions

Operating Safety

Electrical equipment generates heat. Ambient air temperature

may not be adequate to cool equipment to acceptable

operating temperatures without adequate circulation. Be sure

that the room in which you choose to operate your system has

adequate air circulation.

Ensure that the chassis cover is secure. The chassis design

allows cooling air to circulate effectively. An open chassis

permits air leaks, which may interrupt and redirect the flow of

cooling air from internal components.

Electrostatic discharge (ESD) can damage equipment and

impair electrical circuitry. ESD damage occurs when electronic

components are improperly handled and can result in complete

or intermittent failures. Be sure to follow ESD-prevention

procedures when removing and replacing components to avoid

these problems.

Wear an ESD-preventive wrist strap, ensuring that it makes

good skin contact. If no wrist strap is available, ground yourself

by touching the metal part of the chassis.

Periodically check the resistance value of the antistatic strap,

which should be between 1 and 10 megohms (Mohms).

About

EMC Notice

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause

harmful interference in which case users will be required

to correct the interference at their own expense.

Network Application Platforms

ii

Page 4

TTaTTable of Contentsbeable of Contents

Chapter 1: Introduction 1

System Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Front Panel Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2: Hardware Setup 5

Preparing the Hardware Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the System Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing a CompactFlash Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing 3G SIM Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing Wireless 3G Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Din-Rail Rack Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Inner Rail Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Outer Rail Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the system to the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ear Bracket Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3: Motherboard Information 10

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Motherboard Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Chapter 4: BIOS Settings 15

Updating the BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Accessing the BIOS menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Navigating the BIOS menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

The Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Advanced Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Boot Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Security Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Exit Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Appendix A: Programming Watchdog Timer 40

Appendix B: Setting up Console Redirections 41

Appendix C: Programming the LCM 42

iii

Page 5

TTaTTable of Contentsbeable of Contents

Appendix D: Programming LAN Bypass 43

Appendix E: Driver Installation 44

LAN Adapters Driver Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Windows Operating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Linux. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

VGA Driver Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Windows Operating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Appendix F: Terms and Conditions 46

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

RMA Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

iv

Page 6

Chapter 1

Introduction

Chapter 1: Introduction

Thank you for choosing the FW-7565. The FW-7565 is a 1U

network communication appliance which is built on Intel®

Pineview™ embedded processor, the next-generation in

the Intel ® Atom™ family. The FW-7565 comes with either

6 or 8 ports of Gigabit Ethernet connection. Both options

can come with two pairs of ports supporting abnormal

state bypass.

The “Pineview” Atoms bring their memory controllers and

graphics cores on-die, saving on power and board size,

this makes

with power saving.

Please refer to the chart below for a summary of the

system’s specifications.

the FW-7565 an ideal choice for a compact system

System Specification

FEATURE DESCRIPTION

Form Factor

Processor

Platform

OS Support

Storage

Networking

I/O Interface

Expansion

Cooling

Environmental

Parameters

Miscellaneous

Physical

Dimensions

Power

Chipset Intel 82801 BHM (ICH8M)

BIOS AMI BIOS

Onboard

Socket

HDD Bay(s) 1 x 2.5” or 3.5”

Storage Interface

Ethernet Ports 6 or 8 GbE

Chipset

Console RJ45 x 1

USB 2.0 2

Mini PCIe

Processor CPU passive heatsink

Power Fan 1

System Fan 2

Temperature,

ambient operating

/ storage

Humidity (RH),

ambient operating

and non-operating

LCD Module Serial LCM

Watchdog Yes

Internal RTC with

Li Battery

Dimensions (WxHxD)

Weight 7 kg

Type / Watts Single 100W Power Supply

1U Rackmount

Supports Pineview Intel Atom

D-510 or D-410

512 MB/1 GB

onboard DDRII

667MHz SDRAM

(optional)

200 pin DDR II

667 MHz SODIMM

Windows (2000, 2003, XP) 32 or

64 bit,

Linux Kernal 2.4 or up

1 x SATA HDD

1 x CompactFlash

1 x Intel 82574L LAN Chip

5 x Intel 82583V LAN Chip

2 x Intel 82541 PI LAN Chip (models B & D)

1 (USB interface) for 3G / WiFi

module

0ºC ~40ºC / -20ºC~70ºC

5 ~ 95%, non condensing

Yes

430 x 277 x 45mm / 14.1” x 9.1”

x 1.5”

Maximum

capacity:

3GB

Network Application Platforms

1

Page 7

Chapter 1

Introduction

Approvals &

Compliance

Ordering

Information

FW-7565A

FW-7565B

FW-7565C

FW-7565D

FW-7565E

CE Emission, FCC Class A, RoHS

Intel Pineview D-410 (Single Core)

Processor,

6 x GbE ports with 2 pair of

Bypass

Intel Pineview D-510 (Dual Core)

Processor,

8 x GbE ports with 2 pair of

Bypass

Intel Pineview D-410 (Single Core)

Processor,

6 x GbE ports without bypass

Intel Pineview D-510 (Dual Core)

Processor,

8 x GbE ports without bypass

Intel® Pineview-D 510 (Dual Core)

Processor,

6 x GbE Ports with 2 pair Bypass

Package Contents

Your package contains the following items:

FW-7565 Network Security Platform•

Power cable•

1 crossover Ethernet cable (1.8 meters)•

1 straight-through Ethernet cable (1.8 meters)•

1 RJ-45 to DB-9 female console cable•

Serial-ATA hard drive cable •

1 threaded screw set•

1 ear bracket set•

Drivers and user’s manual CD.•

Network Application Platforms

2

Page 8

Chapter 1

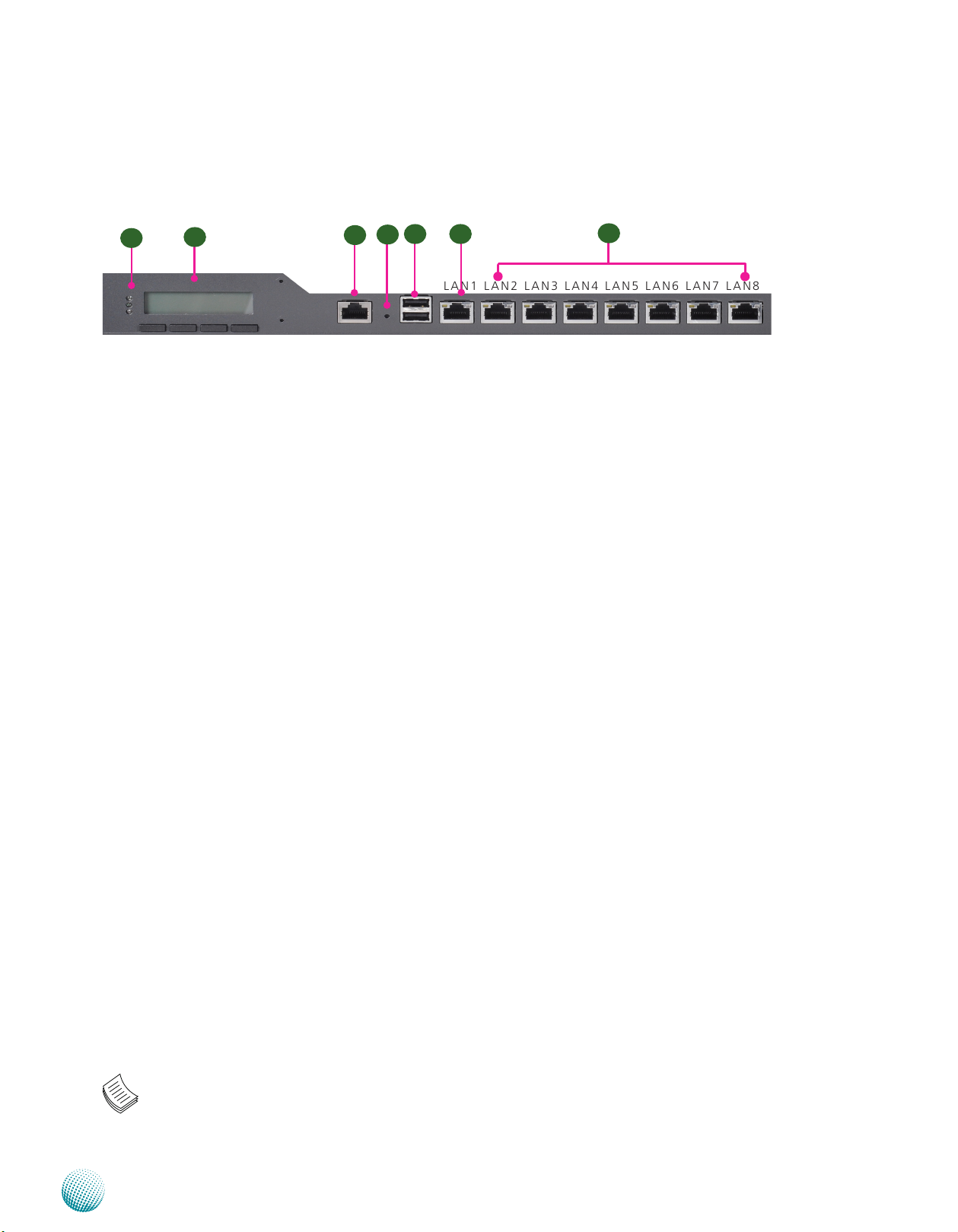

Front Panel Features

Introduction

F1

F2

F3

Management

LAN1 LAN2 LAN3 LAN4 LAN5 LAN6 LAN7 LAN8

F6

F5

F4

F7

F1 Power/Status/HDD LED

Power: If the LED is on it indicates that the system is powered on. If it is off, it indicates that the system is powered off.

Status: If the LED is green, it indicates that the system’s operational state is normal. If it is red, it indicates that the system is

malfunctioning.

HDD: If the LED is on, it indicates that the system’s storage is functional. If the LED blinks, it indicates data access activities.

If it is off, it indicates that there is no hard disk present or functional

F2 System Panel: LCD System Panel

The LCD System Panel can be programmed to display operating status and configuration information. For more details or

sample programming code, please refer to the Appendix C.

F3 Console Port

By using suitable rollover cable or RJ-45 to DB-9 Female (Cisco console cable), you can connect to a computer terminal for

diagnostic or configuration purpose. The default terminal Configuration Parameters: 115200 baud, 8 data bits, no parity, 1

stop bit , no flow control.

F4 Reset Switch

The reset switch can be used to reboot the system without turning off the power.

F5 Two USB 2.0 Ports

It connects to any USB devices, for example, a flash drive. The system supports two additional USB 2.0 ports in the form of

internal pin headers.

F6 Management Port (Optional)

This FastEthernet port can be connected for configuration or troubleshooting purpose. A conformity with IPMI (Intelligent

Platform Management Interface) can be implemented on this interface.

F7 8 Gigabit LAN ports

Right LED:If the LED is orange, it indicates that the connection speed is 1000Mbps. If the LED is green, it indicates that the

connection speed is 100Mbps. And if it is off, it indicates that the speed is 10Mbps.

Left LED: If the LED is on, it indicates that the port is active. If it blinks, it indicates there is traffic.

Using suitable RJ-45 cable, you can connect FW-7565 System to a computer, or to any other piece of equipment that has an

Ethernet connection, for example, a hub or a switch. Moreover, 2 pairs (LAN1-LAN2, LAN3-LAN4) can be configured as LAN

Bypass when failure events occur. This feature is implemented in hardware using watch dog timer functionality. Refer to your

Driver and Manual CD for a sample implementation of this feature.

Note:

The availability of LAN Bypass varies depending on the model.1.

The number of LAN ports varies depending on the model.2.

Network Application Platforms

3

Page 9

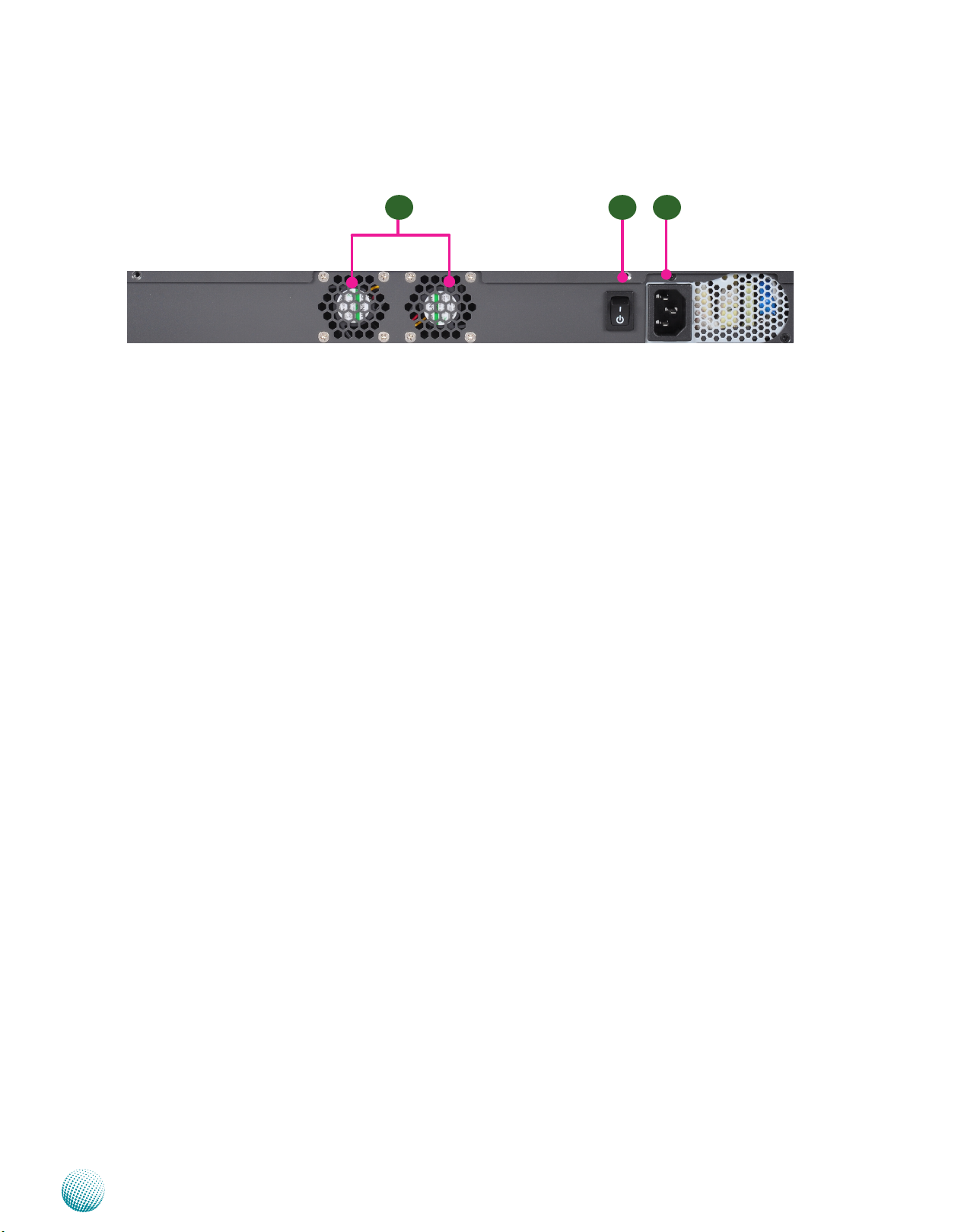

Chapter 1

Rear Panel Features

Introduction

R1

R1 System Fans 1 and 2

R2 Power-on Switch

It is a switch to turn on or off the power.

R3 AC Power-in socket

It is a power socket from a100-240 AC Power Supply.

R2 R3

Network Application Platforms

4

Page 10

Chapter 2

Introduction

Chapter 2: Hardware Setup

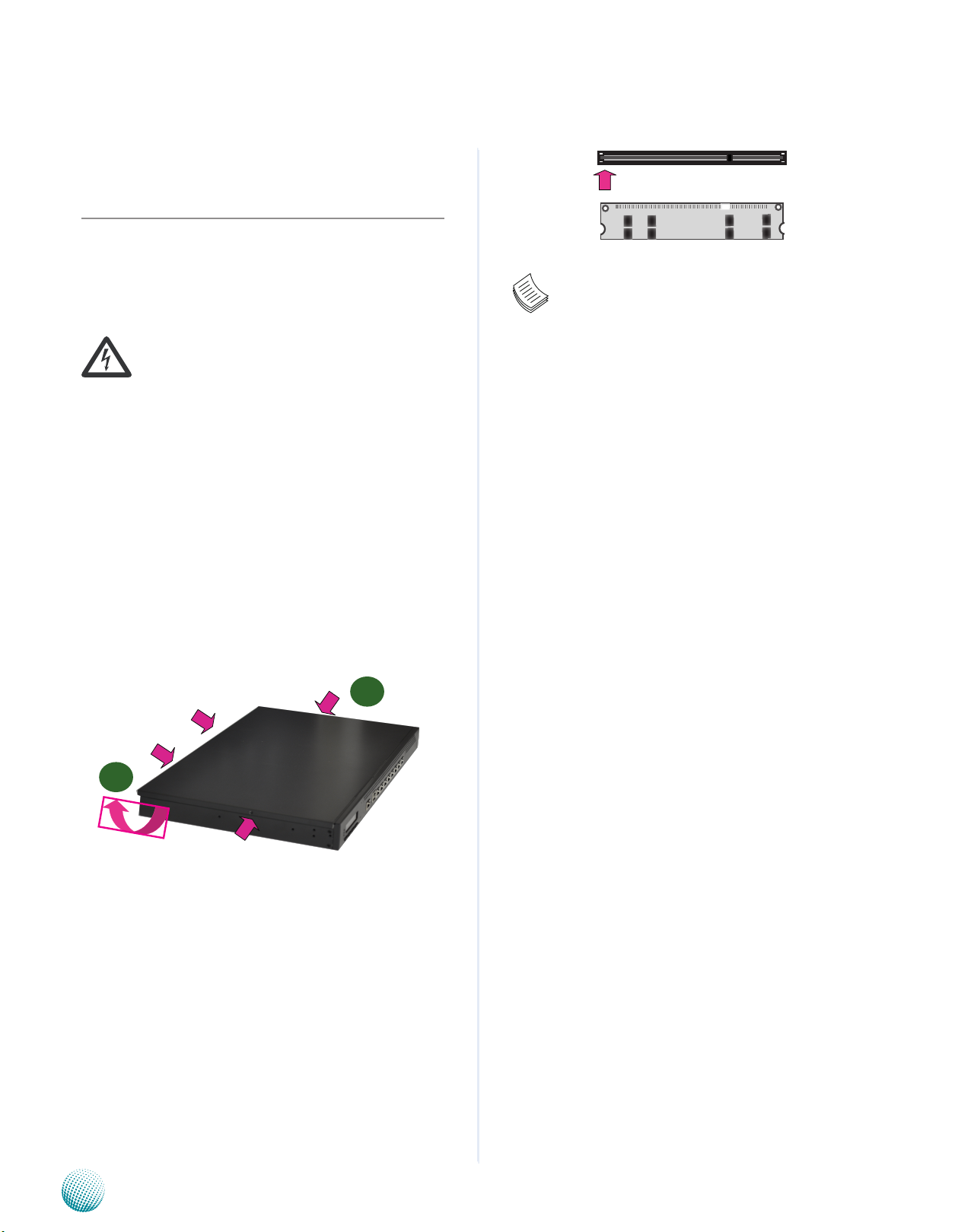

Preparing the Hardware Installation

To access some components and perform certain service

procedures, you must perform the following procedures

first.

WARNING: To reduce the risk of personal injury,

electric shock, or damage to the equipment,

remove the power cord to remove power from the

device. The Power On/Standby button on the back

panel does not completely shut off system power.

Portions of the power supply and some internal

circuitry remain active until AC power is removed.

Unpower the FW-7565 and remove the power cord.1.

Unscrew the 2 threaded screws from the two sides and 2.

2 screws from the rear of the top cover of the FW-7565

System.

Slide the cover backwards and lift cover upwards to 3.

open it.

2

Notch

Cutout

Note:

SO-DIMM installed must meet the following 1.

speed requirement: DDR2 667 or 800 MHz. Do

not install DIMMs with different speeds.

The motherboards can accommodate on-board 2.

memory of 512MB or 1GB DDR2 memory. With

the additional 2GB support from SO-DIMM , it

can support a total memory capacity of 3 GB in

maximum.

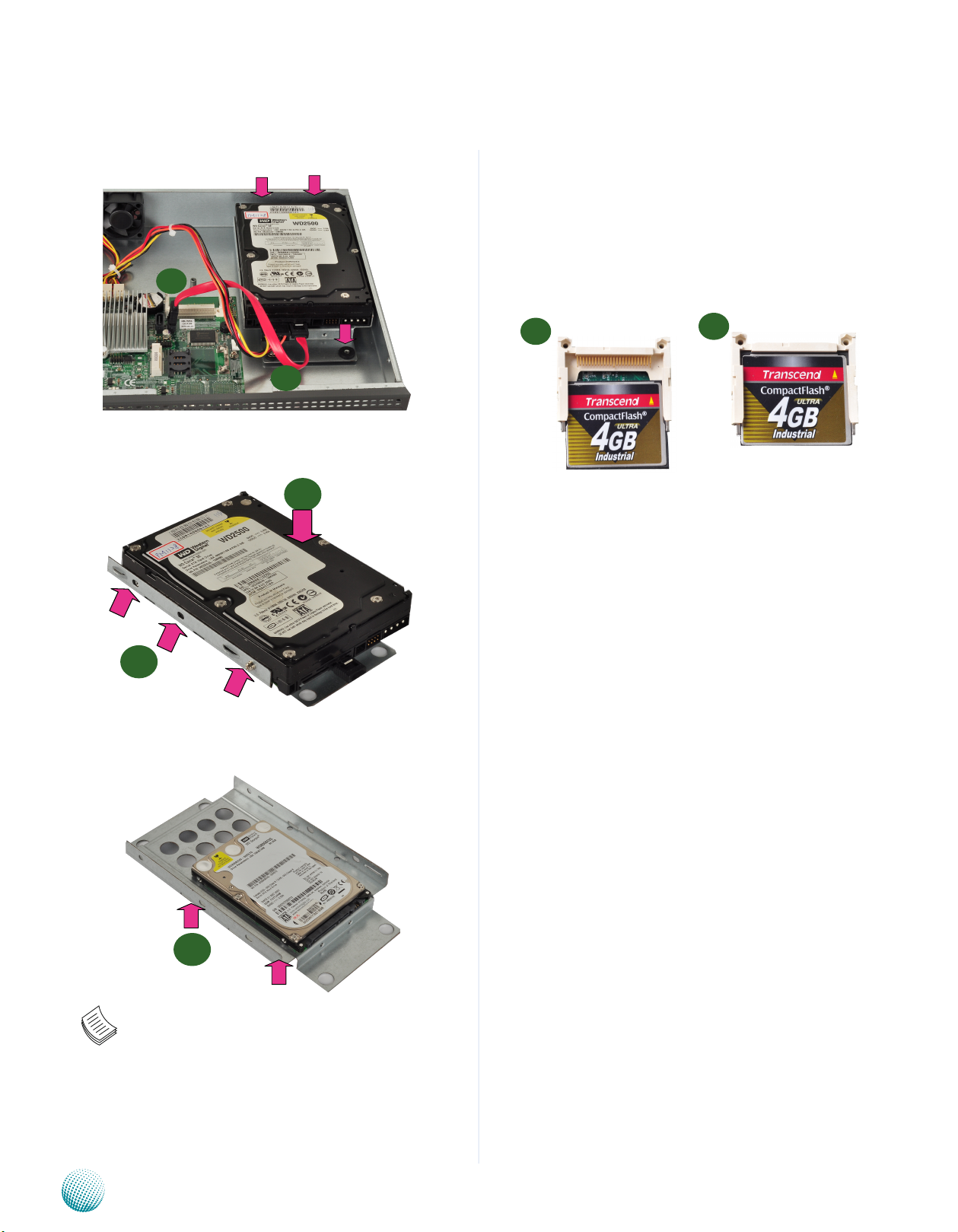

Installing the Hard Disk

The system can accommodate one Serial-ATA disk (2.5” or

3.5”). Follow these steps to install a hard disk into the FW7565:

Unscrew the 4 screws on the hard disk tray to take out 1.

the hard disk tray from the system.

Place hard disk on the hard disk tray and align the holes 2.

of the hard disk with the mounting holes on the tray.

Secure the hard disk with 4 mounting screws on the 3.

hard disk tray.

3

Installing the System Memory

The motherboard supports DDR2 memory that features

data transfer rates of 667 or 800 MHz to meet the higher

bandwidth requirements of the latest operating system

and Internet applications. It comes with one Double Data

Rate(DDR2) Small Outline Dual Inline Memory Modules

(SO-DIMM) socket.

Align the memory module’s cutout with the the SO-1.

DIMM’s slot notch.

Install the SO-DIMM.2.

Network Application Platforms

Connect the Serial-ATA power from the ATX power 4.

supply unit and hard disk cables to the hard disk’s

power and hard drive connectors respectively.

Plug the Serial-ATA cable to the Serial-ATA Connector 5.

on the main board.

Put the hard disk tray with the installed hard disk back 6.

to the system and secure it with the mounting screws.

5

Page 11

Chapter 2

3

5

Introduction

Installing a CompactFlash Card

FW-7565 provides one CompactFlash slot(CN1). Follow

the procedures bellow to install a CompactFlash card.

Align CompactFlash card and the card slot with the 1.

arrow pointing toward the connector.

Push the card to insert into the connector.2.

1

4

2

2

3

Note: To Secure a 2.5” hard disk on the tray, use

the mounting holes on the back .

Network Application Platforms

6

Page 12

Chapter 2

Installing 3G SIM Card

Unlock the SIM card tray.1.

Align the SIM card and the tray with the cut-off 2.

angle.

Insert the SIM card into the tray.3.

Close the tray and lock it on the board.4.

3

4

Introduction

Note: To remove the SIM card, unlock the tray first

by sliding it outward.

Installing Wireless 3G Module

Align the wireless module’s cutout with the Mini-PCIe 1.

slot notch.

Insert the wireless module into the connector 2.

diagnoally.

Push the other end of the wireless module to be 3.

tightened with the latch.

2

3

Note1. : To remove the module from the system,

release the latch first by slightly bending it inward.

Network Application Platforms

7

Page 13

Chapter 2

Introduction

Din-Rail Rack Mounting

Installation environment precaution:

Elevated Operating Ambient - If installed in a closed 1.

or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater

than room ambient. Therefore, consideration should be

given to installing the equipment in an environment

compatible with the maximum ambient temperature

(Tma) specified by the manufacturer.

Reduced Air Flow - Installation of the equipment in 2.

a rack should be such that the amount of air flow

required for safe operation of the equipment is not

compromised. Mechanical Loading - Mounting of the

equipment in the rack should be such that a hazardous

condition is not created due to uneven mechanical

loading.

Circuit Overloading - Consideration should be given to 3.

the connection of the equipment to the supply circuit

and the effect that overloading of the circuits might

have on over-current protection and supply wiring.

Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern.

Reliable Earthing - Reliable earthing of rack-mounted 4.

equipment should be maintained. Particular attention

should be given to supply connections other than

direct connections to the branch circuit (e.g. use of

power strips).”

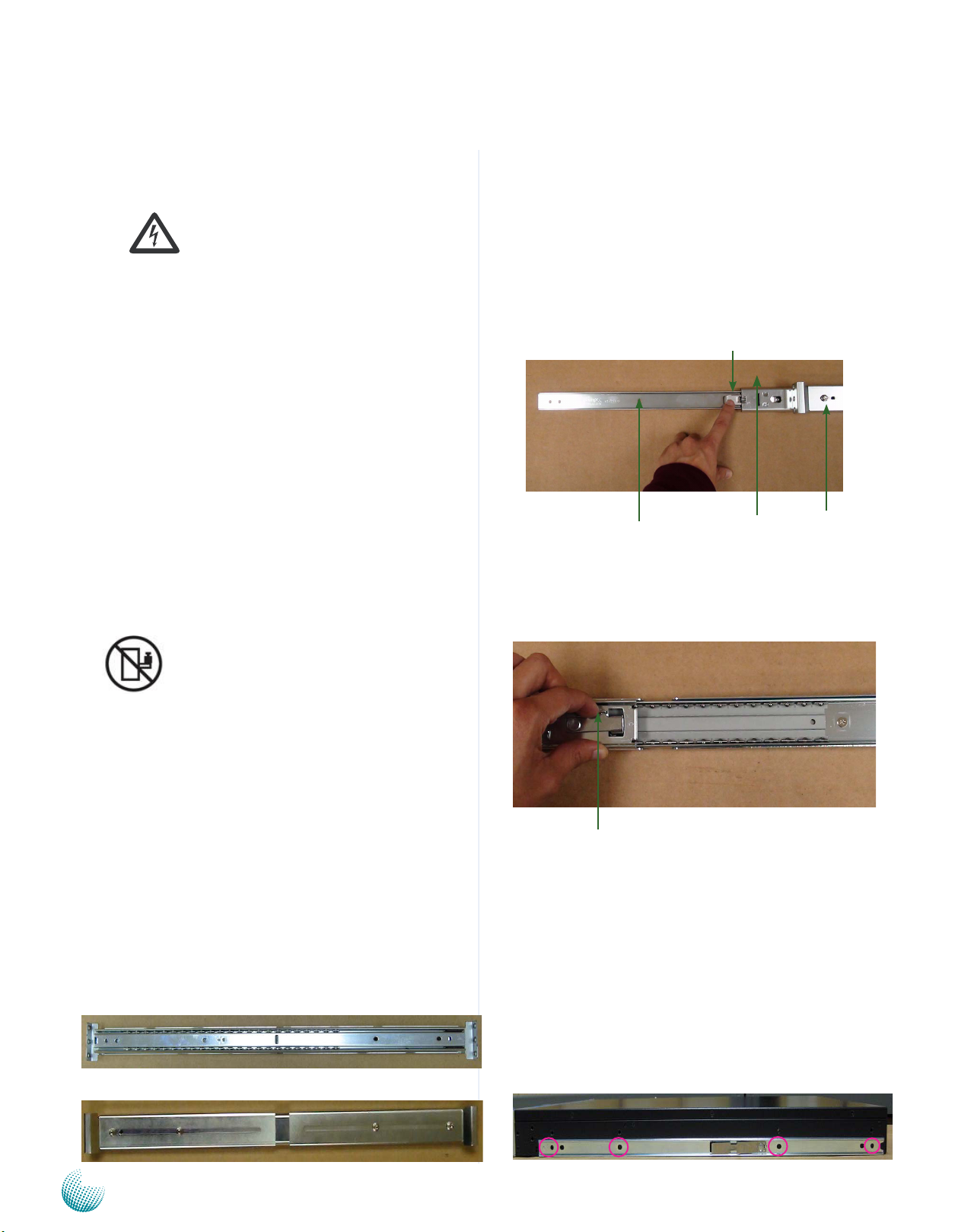

Inner Rail Installation

To install the inner rail, separate it from the middle rail first.

Follow the following procedures:

Place the rails as shown below. The finger tab of 1.

extension safety lock should reveal.

Press the finger tab and pull the inner rail from the 2.

middle rail until they completely separate.

Finger tab

Inner rail

Turn it inside up, and then hold down the middle 3.

extension rail safety lock to stretch the middle rail.

Note that the middle rail cannot be separated.

Outer rail

Middle rail

CAUTION :

Slide/rail mounted equipment is not to be used as a shelf or

a work space.

Required Tools

Philips (cross head) screwdriver (#1 bit and #2 bit)1.

Hex nut driver2.

Anti-static wrist strap and conductive foam pad 3.

(recommended)

Din-Rail mounting kit contains the following items:

2 adjustable outer rail•

2 inner rail with safety stop•

* Both outer and inner rail are attached when shipped

8 crosshead threaded screws•

Middle rail extension safety lock

Attaching Din-rails to the chassis

Position the inner rail alongside the side of the system’s 1.

chassis with the finger tab facing outward and at the

rear of the chassis with two notches.

Align the screw holes of the rail and the mounting 2.

holes of the chassis and then fix the inner rail to the

system with crosshead threaded screws.

Likewise, attach the other side of the inner rail to the 3.

system’s chassis.

Network Application Platforms

8

Page 14

Chapter 2

Introduction

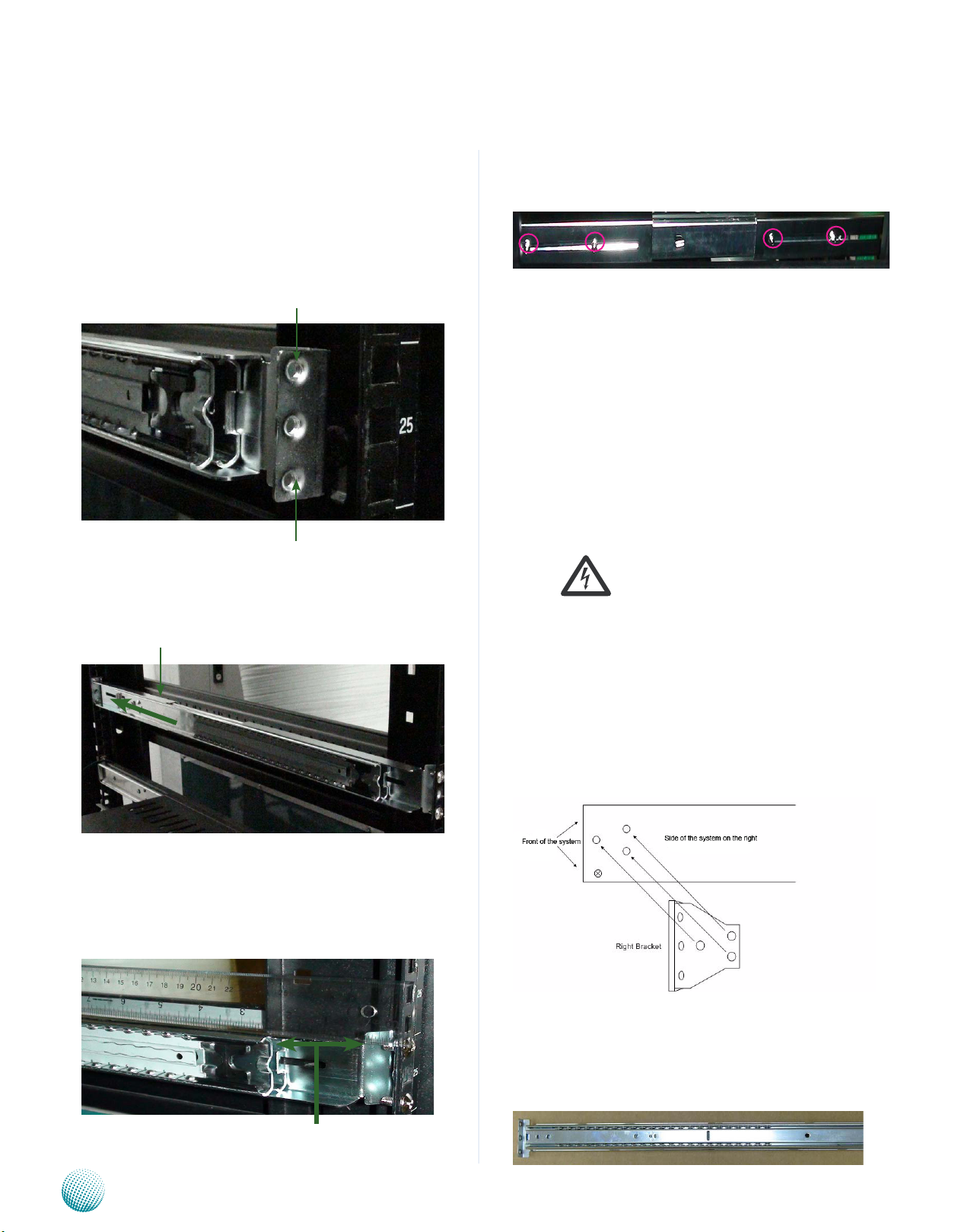

Outer Rail Installation

Use the following procedures to install the outer rail

Attach the rail bracket to the posts of the rack by using 1.

two screws (Rail bracket screws are not included, use

the original manufacture’s rack bracket screws.) Do

not completely tighten the screws; leave them loose

to allow for adjustment so that the middle rail can

slide.

Tighten the rail bracket to the rack's post with

screws

Extend the outer back rail to the back of the rack and 2.

firmly tighten it with rack bracket screws.

Outer back rail

Firmly tighten the Hex nut (4 on each side) on the 1.

outer rail after adjusting the middle rail to its proper

place..

Installing the system to the rack

Fully extend the left and right rails until they are locked 1.

by the extension locks firmly.

Holding the system with its front facing you, lift the 2.

chassis and carefully insert the system with the inner

rail attached to the middle rail.

Push the chassis all the way toward the back until you 3.

hear a click when the rail locks. Hold down the finger

tabs to unlock the middle extension safety locks while

sliding the system.

Ear Bracket Rack Mounting

Installation and handling precaution:

Installation must be performed only by a trained 1.

electrician or by a person who understands all the

installation and device specifications, including

electrical specifications, which are to be applied.

Caution: Do not use the power supply handles to 2.

carry the system.”

Repeat step 1 and 2 above to install other brackets (2 3.

in the Front and 2 in the Back).

Adjusting the middle rail

Adjust the middle rail to about 2.5 inches from the 1.

front rack post.

Network Application Platforms

Attach the mounting brackets to the two sides of 1.

the system by fastening them with the black screws

included in the bracket mounting kit.

Align the holes of the ear bracket and mounting holes 2.

of the rack.

While holding the chassis in place, use appropriate 3.

screws to secure it to the rack.

2.5"

9

Page 15

Chapter 3

Onboard 512 MB/1GB

DDR2 667 SDRAM

(Optional)

X4 DMI

Intel

82583V

Intel

82583V

Intel

82583V

Intel

82583V

6 x GbE RJ-45 LAN Ports

With 2 Pairs Bypass ( A, B, E only)

Intel

82541PI

Intel

82541PI

1x DDR2

667/800Mhz SO-DIMM

CH 0

6x PCI-E

x1

VGA

2 x SATA II

USB 2.0

Winbond

83627THG

RJ45 Console

Port

KB/Mouse

LPC

1x 3.5"or 2.5"

HDD Bay

Console Pin

header

410 / 510

Processor

CFII socket

2x USB 2.0

2x USB 2.0

Pin Header

Mini PCI-E Socket

2 x 6 Pin Header

Intel

82574L

Intel

82583V

2 x PCI

LCM Module

2 x GbE RJ-45 Ports

( B & D only)

Chapter 3: Motherboard Information

Block Diagram

The block diagram depicts the relationships among the

interfaces or modules on the motherboard. Please refer

to the following figure for your motherboard’s layout

design.

Motherboard Information

Additional

Network Application Platforms

10

Page 16

Chapter 3

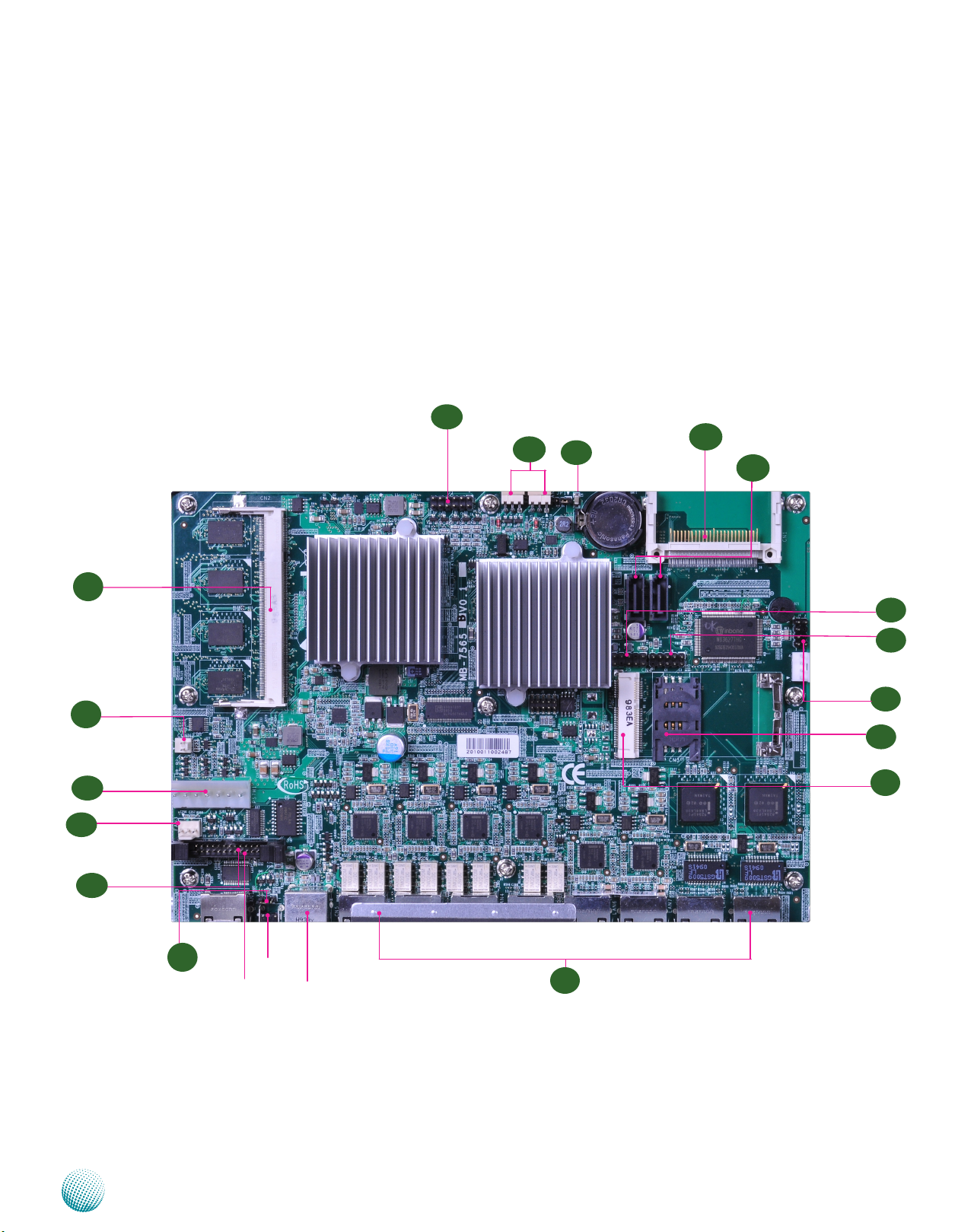

Motherboard Layout

The motherboard layout shows the connectors and

jumpers on the board. Refer to the following picture

as a reference of the pin assignments and the internal

connectors.

Motherboard Information

M8

M1

M2

M3

ATX Power

Connector

SO-DIMM

Socket

Power Switch Connector

Fan3

Connector

VGA Interface

M7

Fan1 and Fan2 Connector

Clear CMOS

M4

M9

Compact Flash Connector

M10

M11

Serial Port

Connector

USB 3 and 4

Connectors

Serial Port Connector

Keyboard and

Mouse Connectors

SIM Card

connector

Mini PCI-E

Connector

M12

M13

M14

M15

M16

M5

M6

Hardware and Software

Reset jumper

Network Application Platforms

Reset Switch

USB2.0 Ports

M17

Ethernet Ports

11

Page 17

Chapter 3

Motherboard Information

Jumper Settings

M1

SO-DIMM Socket : It is for connecting the DDR2 667

memory (200 pin). Besides the 512MB/1G on-board

DDR2 667 SDRAM, the system can support up to a

total of 3GB.

M8

Power Switch Connector(CONN2): This connector

is for the system power button. Pressing the power

button turns the system on or puts the system in sleep

or soft-off mode depending on the BIOS settings.

Pin No. Pin name

1

2

M3

ATX Power Connector(PS1): The 8-pin connector is for

connecting ATX power supply plugs. Find the proper

orientation when inserting the plugs, for the supply

plugs are designed to fit these connectors in only one

orientation.

Function PSON 5VSB GND +3.3V +12V GND GND +5V

PIN NO. 8 7 6 5 4 3 2 1

1 PANSW

2 GND

GPIO GND K3 K1 LCD LPD7 Function

23 21 19 17 15 13 PIN No.

LPD5 LPD3 LPD1 LAFD- LSTIN- VCC Function

11 9 7 5 3 1 PIN No.

23 21 19 17 15 13 11 9 7 5 3 1

24 22 20 18 16 14 12 10 8 6 4 2

12 10 8 6 4 2 PIN No.

LPD4 LPD2 LPD0 LINIT- VEE IOGND FUNCTION

24 22 20 18 16 14

VCC3 VCC3 K4 K2 VCC LPD6

M6

Hardware or Software Reset Jumper(JP2): The jumper

can be adjusted to be in either hardware or software

reset mode when the reset switch is pressed. The

hardware reset will reboot the system without turning

off the power. The software reset can be programmed

to reset a software to its default setting.

1

Pin No. Function

2

1-2 (Default) Software Reset

3

2-3 Hardware Reset

8 7 6 5 4 3 2 1

M4

Fan Connectors(FAN1/FAN2): The 3-pin header is for

connecting the system and CPU fan. The BIOS will

list the CPU and system fans’ monitored temperature

and speed under the menu of Hardware Health

Configuration. You could also configure the target

temperature to adjust the fan speed automatically.

Function Ground +12V Fan Status

PIN NO. 1 2 3

3 2 1

M5

Front LCD Module Connector(J9): The 24-pin

connector is for connecting the front system panel.

M7

VGA Interface (J1): It is for connecting the VGA

interface cable.

Function CRT ON GND GND GND GND DD_CLK

PIN No. 2 4 6 8 10 12

2 4 6 8 10 12

1 3 5 7 9 11

PIN No. 1 3 5 7 9 11

Function Red Green Blue HSYNC VSYNC DD_DATA

M8

Auxiliary Fan Connector (FAN3): This connector is for

connecting any additional cooling fans.

Function Ground +12V Fan Status

PIN NO. 1 2 3

1 2 3

Network Application Platforms

12

Page 18

Chapter 3

Motherboard Information

M9

Clear CMOS jumper (JP1): It is for clearing the CMOS

memory and system setup parameters by erasing

the data stored in the CMOS RAM such as the system

passwords.

1

2

3

M10

CompactFlash Connector (CN1): It is for connecting

Pin No. Function

1-2 (Default) Normal

2-3 Clear CMOS

a Compact Flash card to be served as your system's

storage. The socket is CF type II and can fit into both

bype I and type II cards.

M11

SATA 1 and 2 Connectors(J2, J3): It is for connecting a

2.5’’ or 3.5” SATA harddisk to be served as your system’s

storage. The ICH8M provides hardware support for

Advanced Host Controller Interface (AHCI) which is

a programming interface for SATA host controllers.

AHCI provides advanced performance and usability

enhancements with SATA such as Hot-Plug, no

master/savle designation for SATA devices and native

command queuing.

M12

USB 3 and 4 Connectors(J5) : It is for connecting USB

module cables. Two external USB ports and two onboard USB pin headers are provided by the ICH8M’s

integrated USB host controller which complies to

both Universal Host Controller Interface (UHCI) and

Enhanced Host Controller Interface (EHCI) standards

The later standard enables USB2.0 and support up to

480 Mbps connection speed.

Function GND USBD0+ USBD0- KEY USB_VCC

PIN NO. 9 7 5 3 1

9 7 5 3 1

10 8 6 4 2

PIN NO. 10 8 6 4 2

Function USB_VCC Key USBD1- USBD1+ GND

M13

Serial Interface Connectors(J6): It is for connecting

the RS-232 serial port module cable. The RS-232

communication port is provided by the Winbond

83627THG which is an LPC-interfaced super I/O

device.

Pin No. Function

1

2

3

4

5

6

7

1 Ground

2 Ground

3 TX+

4 TX5 Ground

6 RX7 RX+

Note: To configure your Hard disk using the

integrated RAID functionality, the Intel® Matrix

Storage Manager software has to be installed on

your Operating System. Visit the Intel support

page at

http://www.intel.com/design/chipsets/

matrixstorage_sb.htm#benefit for more

information and download links.

The Intel controller hubs are also supported by

Linux.Beginning with Linux kernel version 2.6.27,

the mdadm utility 3.0 supports RAID 0, RAID 1,

RAID 10, and RAID 5.

To use the RAID features in dmraid and mdadm,

you will need to set up the RAID volume using the

Intel® Matrix Storage Manager option ROM (click

CTRL + I when prompted during boot to enter the

option ROM user interface).

Network Application Platforms

Function GND Data Termi-

PIN NO. 9 7 5 3 1

PIN NO. 10 8 6 4 2

Function Key Ring

M14

Keyboard and Mouse Connector (J4): It is for

nal Ready

9 7 5 3 1

10 8 6 4 2

Indicator

Transmitted Data

Clear to

Send

Received

Data

Request to

Send

Data Carrier Detect

connectiNg the PS/2 keyboard and mouse interface

cable.

Pin No. Function

VCC 1

MSDATA 3

KBDATA 5

GND 7

M15

SIM Card Tray(CN3): It is for connecting SIM card for

1

3

5

7

Pin No. Function

2

2 MSCLK

4

4 KEY

6

6 KEY

8

8 KBCLK

mobile Internet connection.

M16

Mini-PCIe Socket(CN4): It is for connecting WiFi

module to serve Wireless LAN connections or

connecting Wireless 3G module for mobile Internet

connections.

Data

Set

Ready

13

Page 19

Chapter 3

M17

The system’s LAN ports are provided by Intel Ethernet

controllers which include Intel 82574L (1 port as the

optional management port), 82583V (5 Ethernet LAN

ports) and 82541PI (the additional 2 Ethernet LAN

ports through the PCI interfaces).

The following chart gives a comparison of these

controllers:

Motherboard Information

Controller P h y s i c a l

Description

82583V Single Port GbE Controller 9x9 mm PCI-e 1.1 (2.5Ghz) TCP segmentation ofoad, TCP, UDP,

82574L Single Port GbE Controller 9x9 mm PCI-e 1.1 (2.5 Ghz) TCP segmentation ofoad, TCP, UDP,

82541PI Single Port GbE Controller 15x15mm PCI 2.3 (33/66 MHz) TCP segmentation ofoad, TCP, UDP,

Host Interface Performance Features Management Features Power

IPv4 checksum ofoad

IPv4 checksum ofoad, interrupt

moderation, VLAN support, jumbo

frames, RSS, MSI, MSI-X

IPv4 checksum ofoad

PXE remote boot 700 mW

IPMI pass-through via SMBus or

NC-SI, WoL, PXE remote boot,

ISCSI boot, VLAN ltering

IPMI pass-through via SMBus,

WoL, PXE remote boot, ASF 2.0

700 mW

1.0W

Network Application Platforms

14

Page 20

Chapter 4

Chapter 4: BIOS Settings

Updating the BIOS

The Basic Input/Output System (BIOS) can be updated

using the designated Flash Utility. To obtain the utility,

please contact us either through the sales rep or technical

support.

Note:

For the update version of the BIOS image, please

visit Lanner’s support page at

http://assist.lannerinc.com. Then select support

center from the Main Menu and look under the

folder for the desired product category. The

resources for each product including the BIOS

image will be contained within a folder named by

the product model.

Bios Settings

Network Application Platforms

15

Page 21

Chapter 4

Accessing the BIOS menu

You will need to enter the BIOS Setup program to configure

the system when you are installing a motherboard or

when the system prompts “Run Setup” during start-up.

This section explains how to configure your system using

this program.

Even if you have never enter the BIOS Setup program

when you are installing a motherboard, you can change

the configuration of your computer in the future with

the BIOS Setup program. For example, you may want to

enable the security password feature or change the power

management settings. This requires you to configure

your system using the BIOS Setup program so that the

computer can recognize these changes and record them

in the CMOS RAM .

Bios Settings

When you start up the computer, the system provides you

with the opportunity to run this program. Press <Delete>

during the Power-On-Self-Test (POST) to enter the Setup

utility (There are a few cases that other keys are used, such

as <F1>, <F2>, and so forth.); otherwise, POST continues

with its test routines.

The Setup program is designed to make it as easy to use as

possible. Being a menu-driven program, it lets you scroll

through the various sub-menus and make your selections

from the available options using the navigation keys.

Note: This manual describes the standard look of

the setup screen. There may be some instances in which

the motherboard features can vary from one to another

due to customization. This means that some of the options

described in this manual mays not match that of your

motherboard’s AMIBIOS.

Navigating the BIOS menu

The BIOS setup utility uses a key-based navigation system

called hot keys. Most of the BIOS setup utility hot keys can

be used at any time during the setup navigation process.

Keys Description

-><- Left/Right The Left and Right <Arrow> keys

allow you to select an setup screen.

For example: Main screen, Advanced

->

Up/Down The Up and Down <Arrow> keys

->

+- Plus/Minuss The Plus and Minus <Arrow> keys

Tab The <Tab> key allows you to select

Note: The <F8> key on your keyboard is the FailSafe key. It is not displayed on the key legend by default.

To set the Fail-Safe settings of the BIOS, press the <F8>

key on your keyboard. It is located on the upper row of

a standard 101 keyboard. The Fail-Safe settings allow

the motherboard to boot up with the least amount of

options set. This can lessen the probability of conflicting

settings.

screen, Boot screen, and so on.

allow you to select an setup item or

sub-screen.

allow you to change the field value

of a particular setup item. For

example: Date and Time.

setup fields.

These keys include <F1>, <F10>, <Enter>, <ESC>, <Arrow>

keys, and so on.

Network Application Platforms

16

Page 22

Chapter 4

The Main Menu

The main BIOS setup menu is the first screen that you can

navigate. Each main BIOS setup menu option is described

in this chapter.

The Main BIOS setup menu screen has two main frames. The

left frame displays all the options that can be configured.

“Grayed-out” options are configured parameters and

cannot be modified. On the other hand, Options in blue

can be modified.

The right frame displays the key legend. Above the key

legend is an area reserved for a text message. When an

option is selected in the left frame, it is highlighted in

white. Often a text message will accompany it.

Bios Settings

System Time/System Date

Use this option to change the system time and date.

Highlight System Time or System Date using the <Arrow>

keys. Enter new values through the keyboard. Press the

<Tab> key or the <Arrow> keys to move between fields.

The date must be entered in MM/DD/YY format. The time

is entered in HH:MM:SS format.

Network Application Platforms

17

Page 23

Chapter 4

Advanced Settings

Select the Advanced tab from the setup screen to enter

the Advanced BIOS Setup screen. You can select any of

the items in the left frame of the screen, such as SuperIO

Configuration, to go to the sub menu for that item. You

can display an Advanced BIOS

Setup option by highlighting it using the <Arrow> keys.

All Advanced BIOS Setup options are described in this

section. The Advanced BIOS Setup screen is shown at

the right. The sub menus are described on the following

pages.

Bios Settings

CPU Configuration

This setting allows the users to view and configurae the

settings of the CPU installed on the system.

Option Description

Manufacturer This shows the CPU brand name.

CPU Frequency/

FSB Speed

Cache L1, Cache L2This specifies the size of the Level 1 and Level

Ratio Actual

Value

MAX CPUID

Value Limit

Execute-Disable

Bit Capability

This shows the CPU frequency and Front Side

Bus frequency in Megahertz.

2 caches in Kilobytes.

This shows the actual CPU ratio.

The CPUID tells the OS/BIOS what the

maximum capabilities are for the processor.

When enabled, the processor will limit the

maximum CPUID input value to 03h when

it is queried by the operating system, even if

the processor supports a higher CPUID input

value.

When disabled, the processor will return the

actual maximum CPUID input value of the

processor when it is queried by the operating

system. It is recommended that you leave it

at the default setting of Disabled. You should

only enable it if you intend to use the Intel

Pentium 4 processor with Hyper-Threading

Technology with an operating system that

does not support it.

Execute Disable Bit is an Intel hardware-based

security feature that can reduce exposure to

viruses and malicious-code attacks. To use

Execute Disable Bit, you must also install a

supporting operating system.

Network Application Platforms

18

Page 24

Chapter 4

Option Description

Hyper Threading

Technology

IDE Configuration Settings

You can use this screen to select options for the IDE

Configuration Settings. Use the up and down <Arrow>

keys to select an item. Use the <Plus> and <Minus> keys to

change the value of the selected option. A description of

the selected item appears on the right side of the screen.

The settings are described on the following pages. An

example of the IDE Configuration screen is at the right.

This option allows the user to enable or

disable the HyperThreading™ support of the

Intel® Pentium® 4 HT processor. By default

this setting is enabled. This setting should

be disabled in Microsoft™ Windows 2000 or

older systems.

Bios Settings

Primary IDE Master, Primary IDE Slave, Secondary IDE Master,

Secondary IDE Slave:

Select one of the hard disk drives to configure it. Press

<Enter> to access its the sub menu. The options on the

sub menu are described as in the following..

Network Application Platforms

19

Page 25

Chapter 4

Primary /Secondary IDE Master and Slave Sub Menu

From the IDE Configuration screen, press <Enter> to

access the sub menu for the primary/secondary IDE

master and slave drives. Use this screen to select options

for the Primary and Secondary IDE drives. Use the up and

down <Arrow> keys to select an item. Use the <Plus> and

<Minus> keys to change the value of the selected option.

The settings are described on the following pages. The

screen for the Primary IDE Master is shown at the right.

Type

This option sets the type of device that the AMIBIOS

attempts to boot from after the Power-On-Self-Test (POST)

has completed.

Option Description

Not Installed Set this value to prevent the BIOS from

searching for an IDE disk drive on the specified

channel.

Auto Set this value to allow the BIOS to automatically

detect the IDE disk drive type attached to the

specified channel. This setting should be used

if an IDE hard disk drive is attached to the

specified channel. This is the default setting.

CDROM This option specifies that an IDE CD-ROM drive

is attached to the specified IDE channel. The

BIOS will not attempt to search for other types

of IDE disk drives on the specified channe.

ARMD This option specifies an ATAPI Removable

Media Device.

Bios Settings

This includes, but is not limited to:

•ZIP

•LS-120

LBA/Large Mode

LBA (Logical Block Addressing) is a method of addressing

data on a disk drive.

Option Description

Disabled Set this value to prevent the BIOS from using

Large Block Addressing mode control on the

specified channel.

Auto Set this value to allow the BIOS to automatically

detect the Large Block Addressing mode control

on the specified channel. This is the default

setting.

Block (Multi-Sector Transfer)

This option sets the block mode multi sector transfers

option.

Network Application Platforms

20

Page 26

Chapter 4

Option Description

Disabled Set this value to prevent the BIOS from using

Multi-Sector Transfer on the specified channel.

The data to and from the device will occur one

sector at a time.

Auto Set this value to allow the BIOS to automatically

detect device support for Multi-Sector Transfers

on the specified channel. If supported, Set this

value to allow the BIOS to automatically detect

the number of sectors per block for transfer

from the hard disk drive to the memory. The

data transfer to and from the device will occur

multiple sectors at a time. This is the default

setting.

PIO Mode

IDE PIO (Programmable I/O) mode programs timing

cycles between the IDE drive and the programmable

IDE controller. As the PIO mode increases, the cycle time

decreases.

Bios Settings

Option Description

Auto Set this value to allow the BIOS to auto detect

the PIO mode. Use this value if the IDE disk

drive support cannot be determined. This is the

default setting.

0 Set this value to allow the BIOS to use PIO mode

0. It has a data transfer rate of 3.3 MBs.

1 Set this value to allow the BIOS to use PIO mode

0. It has a data transfer rate of 5.2 MBs.

2 Set this value to allow the BIOS to use PIO mode

0. It has a data transfer rate of 8.3 MBs.

3 Set this value to allow the BIOS to use PIO mode

0. It has a data transfer rate of 11.1MBs.

4 Set this value to allow the BIOS to use PIO

mode 4. It has a data transfer rate of 16.6 MBs.

This setting generally works with all hard disk

drives manufactured after 1999. For other disk

drive, such as IDE CD-ROM drives, check the

specifications of the drive.

DMA Mode

This setting allows you to adjust the DMA (Direct memory

access) mode options.

Option Description

Auto Set this value to allow the BIOS to automatically

detect the DMA mode. Use this value if the IDE

disk drive support cannot be determined. This is

the default setting.

SWDMA0 Set this value to allow the BIOS to use Single

Word DMA mode 0. It has a data transfer rate of

2.1 MBs.

Network Application Platforms

21

Page 27

Chapter 4

Option Description

SWDMA1 Set this value to allow the BIOS to use Single

Word DMA mode 1. It has a data transfer rate of

4.2 MBs.

SWDMA2 Set this value to allow the BIOS to use Single

Word DMA mode 2. It has a data transfer rate of

8.3 MBs.

MWDMA0 Set this value to allow the BIOS to use Multi Word

DMA mode 0. It has a data transfer rate of 4.2

MBs.

MWDMA1 Set this value to allow the BIOS to use Multi Word

DMA mode 1. It has a data transfer rate of 13.3

MBs.

MWDMA2 Set this value to allow the BIOS to use Multi Word

DMA mode 2. It has a data transfer rate of 16.6

MBs.

UDMA0 Set this value to allow the BIOS to use Ultra DMA

mode 0. It has a data transfer rate of 16.6 MBs.

It has the same transfer rate as PIO mode 4 and

Multi Word DMA mode 2.

UDMA1 Set this value to allow the BIOS to use Ultra DMA

mode 1. It has a data transfer rate of 25 MBs.

UDMA2 Set this value to allow the BIOS to use Ultra DMA

mode 2. It has a data transfer rate of 33.3 MBs.

UDMA3 Set this value to allow the BIOS to use Ultra DMA

mode 3. It has a data transfer rate of 44.4 MBs. To

use this mode, it is required that an 80-conductor

ATA cable is used.

UDMA4 Set this value to allow the BIOS to use Ultra DMA

mode 4. It has a data transfer rate of 66.6 MBs. To

use this mode, it is required that an 80-conductor

ATA cable is used.

UDMA5 Set this value to allow the BIOS to use Ultra DMA

mode 5. It has a data transfer rate of 99.9 To use

this mode, it is required that an 80-conductor

ATA cable is used.

UDMA6 Set this value to allow the BIOS to use Ultra DMA

mode 6. It has a data transfer rate of 133.2 MBs. To

use this mode, it is required that an 80-conductor

ATA cable is used.

Bios Settings

S.M.A.R.T. for Hard disk drives

Self-Monitoring Analysis and Reporting Technology

(SMART) feature can help predict impending drive

failures.

Option Description

Auto Set this value to allow the BIOS to automatically

detect hard disk drive support. Use this setting if

the IDE disk drive support cannot be determined.

This is the default setting.

Disabled Set this value to prevent the BIOS from using the

SMART feature.

Enabled Set this value to allow the BIOS to use the SMART

feature on support hard disk drives.

32Bit Data Transfer

Network Application Platforms

22

Page 28

Chapter 4

This option sets the 32-bit data transfer option.

Option Description

Disabled Set this value to prevent the BIOS from

using 32-bit data transfers.

Enabled Set this value to allow the BIOS to use 32-bit

data transfers on support hard disk drives.

This is the default setting.

Hard disk drive Write Protect

Set this option to protect the hard disk drive from being

overwritten.

Bios Settings

Option Description

Disabled Set this value to allow the hard disk drive to be

used normally. Read, write, and erase functions

can be performed to the hard disk drive. This is

the default setting.

Enabled Set this value to prevent the hard disk drive from

being erased.

IDE Detect Time Out (Seconds)

Set this option to stop the AMIBIOS from searching for

IDE devices within the specified number of seconds.

Basically, this allows you to fine-tune the settings to allow

for faster boot times. Keep adjusting this setting until a

suitable timing in which all all IDE disk drives attached.

are detected is found.

Option Description

0 This value is the best setting to use if the onboard

IDE controllers are set to a specific IDE disk drive

in the AMIBIOS.

5 Set this value to stop the AMIBIOS from searching

the IDE bus for IDE disk drives in 5 seconds. A

large majority of ultra ATA hard disk drives can be

detected well within five seconds.

10 Set this value to stop the AMIBIOS from searching

the IDE bus for IDE disk drives in 10 seconds.

15 Set this value to stop the AMIBIOS from searching

the IDE bus for IDE disk drives in 15 seconds.

Network Application Platforms

23

Page 29

Chapter 4

Option Description

20 Set this value to stop the AMIBIOS from searching

the IDE bus for IDE disk drives in 20 seconds.

25 Set this value to stop the AMIBIOS from searching

the IDE bus for IDE disk drives in 25 seconds.

30 Set this value to stop the AMIBIOS from searching

the IDE bus for IDE disk drives in30 seconds.

35 Set this value to stop the AMIBIOS from searching

the IDE bus for IDE disk drives in 35 seconds.

ATA(PI) 80 Pin Cable Detection

Set this option to specify the Ultra ATA80 cable detection method.

Bios Settings

Option Description

Host Choose this value to use the IDE controller of the

Motherboard to detect the attached IDE cable

type (either 80 or 40 pins).

Device Choose this value to use the IDE hard disk to

detect the attached IDE cable type (either 80 or

40 pins).

Host &

Device

Choose this value to use both the IDE hard disk

and the IDE controller to detect the attached IDE

cable type (either 80 or 40 pins). This is the default

setting.

SuperIO Configuration

In this screen, you will be able to modify the IRQ address

of the serial and parallel ports which are provided by the

Winbond 83627THG chip.

Configure Win627THF Super IO ChipSet

Network Application Platforms

24

Page 30

Chapter 4

You can use this screen to select options for the Super I/O

settings. Use the up and down <Arrow> keys to select an

item. Use the <Plus> and <Minus> keys to change the

value of the selected option. The settings are described

on the following pages. The screen is shown at right.

Serial Port1 Address

This option specifies the base I/O port address and Interrupt

Request address of serial port 1. The Optimal setting is

3F8/IRQ4. The Fail-Safe default setting is Disabled.

Option Description

Disabled Set this value to prevent the serial port from

accessing any system resources. When this

option is set to Disabled, the serial port physically

becomes unavailable.

3F8/IRQ4 Set this value to allow the serial port to use 3F8

as its I/O port address and IRQ 4 for the interrupt

address. This is the default setting. The majority of

serial port 1 or COM1 ports on computer systems

use IRQ4 and I/O Port 3F8 as the standard setting.

The most common serial device connected to this

port is a mouse. If the system will not use a serial

device, it is best to set this port to Disabled.

2F8/IRQ3 Set this value to allow the serial port to use 2F8

as its I/O port address and IRQ 3 for the interrupt

address. If the system will not use a serial device,

it is best to set this port to Disabled.

3E8/IRQ4 Set this value to allow the serial port to use 3E8

as its I/O port address and IRQ 4 for the interrupt

address. If the system will not use a serial device,

it is best to set this port to Disabled.

2E8/IRQ3 Set this value to allow the serial port to use 2E8

as its I/O port address and IRQ 3 for the interrupt

address. If the system will not use a serial device,

it is best to set this port to Disabled.

Bios Settings

Serial Port2 Address

This option specifies the base I/O port address and

Interrupt Request address of serial port 2. The Optimal

setting is 2F8/IRQ3. The Fail-Safe setting is Disabled.

Network Application Platforms

25

Page 31

Chapter 4

Option Description

Disabled Set this value to prevent the serial port from

accessing any system resources. When this

option is set to Disabled, the serial port physically

becomes unavailable.

3F8/IRQ4 Set this value to allow the serial port to use 3F8

as its I/O port address and IRQ 4 for the interrupt

address. This is the default setting. The majority of

serial port 1 or COM1 ports on computer systems

use IRQ4 and I/O Port 3F8 as the standard setting.

The most common serial device connected to this

port is a mouse. If the system will not use a serial

device, it is best to set this port to Disabled.

2F8/IRQ3 Set this value to allow the serial port to use 2F8

as its I/O port address and IRQ 3 for the interrupt

address. If the system will not use a serial device,

it is best to set this port to Disabled.

3E8/IRQ4 Set this value to allow the serial port to use 3E8

as its I/O port address and IRQ 4 for the interrupt

address. If the system will not use a serial device,

it is best to set this port to Disabled.

2E8/IRQ3 Set this value to allow the serial port to use 2E8

as its I/O port address and IRQ 3 for the interrupt

address. If the system will not use a serial device,

it is best to set this port to Disabled.

Bios Settings

Parallel Port Address

This option specifies the I/O address used by the parallel

port. The Optimal setting is 378. The Fail-Safe setting is

Disabled.

Option Description

Disabled Set this value to prevent the parallel port from

accessing any system resources. When the value

of this option is set to Disabled, the printer port

becomes unavailable.

378 Set this value to allow the parallel port to use 378

as its I/O port address. This is the default setting.

The majority of parallel ports on computer

systems use IRQ7 and I/O Port 378H as the

standard setting.

278 Set this value to allow the parallel port to use 278

as its I/O port address.

3BC Set this value to allow the parallel port to use 3BC

as its I/O port address.

Network Application Platforms

26

Page 32

Chapter 4

Parallel Port IRQ

This option specifies the IRQ used by the parallel port.

Option Description

5 Set this value to allow the serial port to use

Interrupt 5.

7 Set this value to allow the serial port to use

Interrupt 7. This is the default setting. The

majority of parallel ports on computer systems

use IRQ7 and I/O Port 378H as the standard

setting.

Bios Settings

Network Application Platforms

27

Page 33

Chapter 4

Hardware Health Configuration

This menu shows the hardware monitor configuration

settings. Select an item then press <Enter> to display the

configuration options.

Fan1/Fan2 Smart Fan Function

It allows you to configure the smart fan feature. You can

manually turn on the system fan or set the target system

temperature at which the system fan will start running

if the fan is not yet turned on. And the system fan can

also be turned off automatically if the temperature for

the system is at or below the specified value. Refer to

Motherboard Layout on Chapter 3 Block Diagram for

system fan connectors.

Bios Settings

USB drive can boot the system even when there is no USB

drivers loaded on the system. Set this value to allow the

system to select the Emulation type for a USB drive.

Option Description

Auto Set this value to allow the system to automatically

detect a USB drive emulation type.

Floppy Set this value to allow the system to select floppy

emulation type.

Hard Disk

Drive

Set this value to allow the system to select hard

disk drive emulation type.

AHCI Configuration

If you have configured and enabled your SATA disc

with an AHCI (Advanced Host Controller Interface)

functionality, use this menu to verify whether the system

has detected your SATA disc as an AHCI-capable hard disk.

Instead of relying on the legacy IDE detection, the AHCI

provides advanced features and support for SATA disc

management.

Network Application Platforms

28

Page 34

Chapter 4

Remote Access Settings

You can use this screen to select options for the Remote

Access Configuration. Use the up and down <Arrow> keys

to select an item. Use the <Plus> and <Minus> keys to

change the value of the selected option. The settings are

described on the following pages. The screen is shown at

right.

Remote Access

You can disable or enable the BIOS remote access feature

here.

Option Description

Disabled Set this value to prevent the BIOS from using

Remote Access.

Serial Set the value for this option to Serial to allow

the system to use the remote access feature.

The remote access feature requires a dedicated

serial port connection.

Bios Settings

Network Application Platforms

29

Page 35

Chapter 4

Serial Port Number

Select the serial port you want to use for console

redirection. You can set the value for this option to either

COM1 or COM2.

Option Description

115200 8,n,1 Set this value to allow you to select 115200 as

the baud rate (transmitted bits per second) of

the serial port.

57600 8,n,1 Set this value to allow you to select 57600 as the

baud rate (transmitted bits per second) of the

serial port.

19200 8,n,1 Set this value to allow you to select 19200 as the

baud rate (transmitted bits per second) of the

serial port

Bios Settings

Redirection After BIOS POST

A terminal emulation program, such as HyperTerminal,

running on the other computer can be used to establish

the connection and communicate with the system. There

are three possible configurations for console redirection:

Option Description

Disabled

Always

Boot Loader

The console is never active, and the serial

port is available to the operating system.

The console is always active and is not

available to the operating system.

The console is enabled only during BIOS

self-test during power-up; after the OS

begins to load the console will be disabled

and the serial port will be made available to

the operating system.

USB Configuration

Network Application Platforms

30

Page 36

Chapter 4

In this screen, you will be able to configure the USB

controller.

You can use this screen to select options for the USB

Configuration. Use the up and down <Arrow> keys to

select an item. Use the <Plus> and <Minus> keys to

change the value of the selected option. The settings are

described on the following pages.

Note: The device listed under the USB Devices

Enabled indicates the auto-detected values. If no

device is detected, the item shows None.

Bios Settings

Legacy USB Support

This option enable or disable the support ofr USB devices

on legacy operating systems (OS), e.g., Windows ME/98/

NT, and MS-DOS.Normally if this option is not enabled, any

attached USB mouse or USB keyboard will not become

available until a USB compatible operating system is fully

booted with all USB drivers loaded. When this option is

enabled, any attached USB mouse or USB keyboard can

be used on the system even when there is no USB drivers

loaded on it.

Option Description

Auto Allow the system to detect the presence of USB

devices at startup. If detected, the USB controller

legacy mode is enabled If it is not detected, the

USB control er legacy mode is disabled.

Enabled Enable the support for USB devices on legacy

operating system

Disabled Disable this function.

USB 2.0 Controller Mode

This option set the USB 2.0 controller to operate in

HiSpeed(480 Mbps) or Full Speed (12Mbps).

Network Application Platforms

31

Page 37

Chapter 4

BIOS EHCI Hand-off

This option enable or disable the support for the operating

systems which does not have an EHCI Hand-Off feature.

Option Description

Enabled Enable the support for the OS without EHCI

Hand-Off feature.

Disabled Disable the support for the OS without EHCI

Hand-Off feature.

USB Mass Storage Device Configuration

In this screen, you can configure the attached USB drive to

be used as the system’s hard drive.

Bios Settings

USB Mass Storage Reset Delay

This option sets the reset timing for the USB Mass Storage

to be initialized.

Option Description

10 Sec When set to 10 Sec, the BIOS will wait for up to 10

seconds for the USB flash drive to initialize.

20 Sec When set to 10 Sec, the BIOS will wait for up to 20

seconds for the USB flash drive to initialize.

30 Sec When set to 10 Sec, the BIOS will wait for up to 30

seconds for the USB flash drive to initialize.

40 Sec When set to 10 Sec, the BIOS will wait for up to 40

seconds for the USB flash drive to initialize.

Emulation Type

USB Emulation refers the system being able to boot to

a USB drive. Normally if this option is not enabled, any

attached USB drive will not become available until a USB

compatible operating system is fully booted with all USB

drivers loaded. When this option is enabled, any attached

USB drive can boot the system even when there is no USB

Network Application Platforms

32

Page 38

Chapter 4

drivers loaded on the system. Set this value to allow the

system to select the Emulation type for a USB drive.

Option Description

Auto Set this value to allow the system to automatically

detect a USB drive emulation type.

Floppy Set this value to allow the system to select floppy

emulation type.

Hard Disk

Drive

Lan Bypass Control

In this screen, you can configure the Lan Bypass

functionality.

Set this value to allow the system to select hard

disk drive emulation type.

Bios Settings

Lan Bypass for Port 1 and Port 2 (or Port3 and Port 4)

You can activate or deactivate the Lan Bypass ports. For

the description of the physical ports that are capable of

the LAN Bypass function, refer to the Front Panel Feature in

Chapter 1 Introduction.

Lan Bypass for Port1 and Port 2 when power off

You can enable or disable the automatic activation of

Network Application Platforms

33

Page 39

Chapter 4

hardware Lan Bypass function in the event of a power

failure. Hardware Bypass can automatically activate to

allow network traffic to continue.

Bios Settings

Network Application Platforms

34

Page 40

Chapter 4

Boot Setup

Select the Boot tab from the setup screen to enter the Boot

BIOS Setup screen. You can select any of the items in the

left frame of the screen, such as Boot Device Priority, to

go to the sub menu for that item. You can display an Boot

BIOS Setup option by highlighting it using the <Arrow>

keys. All Boot Setup options are described in this section.

Select an item on the Boot Setup screen to access the sub

menu for:

Boot Settings Configuration •

Boot Device Priority •

USB Drives •

Bios Settings

Boot Settings Configuration

In this screen, you will be able to configure the boot

procedures and the related elements.

Quick Boot

Enabling this item allows the BIOS to skip some poweron self-tests (POST) while booting to decrease the time

needed to boot the system. When set to [Disabled], BIOS

performs the complete series of tests. Select Enabled or

Disabled to enable or disable the quick boot

Quiet Boot

Enabling this item allows the BIOS to suppress the

messages displayed during the POST.

AddOn ROM Display Mode

This option controls the display of ROM messages form

the BIOS of add-on devices such as the graphics card or

the SATA controller during the start-up sequence.

Option Description

Force BIOS When setting to Force BIOS,

third-party ROM messages will

be forced to display during the

start-up sequence.

Keep Current When setting to Keep Current,

third-party ROM messages will

only be displayed if the device’s

manufacturer has set the addon device to do so.

Bootup Num-Lock

This option lets you to enable or disable the function of

the NumLock key.

Network Application Platforms

35

Page 41

Chapter 4

PS/2 Mouse Support

It lets you enable or disable support for PS/2 mouse.

Wait for ‘F1’ if error

It determines whether the message, “Press F1 to continue”

should be displayed when error occurs during start-up.

Option Description

Enabled When setting to enabled, the system dis-

plays the message, “Press F1 to continue”

and waits for the input. when error occurs

during start-up.

Disabled When setting to Disabled, the system will

not halt the start-up sequence even when

an error is detected.

Hit ‘DEL’ Message Display

When this item is set to Enabled, the system displays the

message , “Press DEL to run Setup” during the start-up

sequence.

Interrupt 19 Capture

Bios Settings

Set this value to allow option ROMs such as network

controllers to trap BIOS interrupt 19.

Option Description

Disabled The BIOS prevents option ROMS from trap-

ping interrupt 19.

Enabled The BIOS allows option ROMs to trap inter-

rupt 19.

Boot Device Priority

Use this screen to specify the order in which the system

checks for the device to boot from. To access this screen,

select Boot Device Priority on the Boot Setup screen and

press <Enter>. The following screen is displayed at right:

Network Application Platforms

36

Page 42

Chapter 4

Security Settings

Select Security Setup from the Setup main BIOS setup

menu. All Security Setup options, such as password

protection and virus protection, are described in this

section. To access the sub menu for the following items,

select the item and press <Enter>:

Supervisor Password

It indicates whether a supervisor password has been set. If

the password has been installed, it displays, “Installed “. If

not, it displays, “Not Installed”.

Bios Settings

The system provides both a Supervisor and a User

password. If you use both passwords, the Supervisor

password must be set first.

The system can be configured so that all users must enter

a password every time the system boots or when Setup

is executed, using either the Supervisor password or

User password. If you select password support, you are

prompted to enter a password with one to six characters.

Type the password on the keyboard. The password does

not appear on the screen when typed. Make sure you

write it down. If you forget it, you must clear the CMOS

ram and reconfigure it.

User Password

It indicates whether a user password has been set. If the

password has been installed, it displays, “Installed “. If not,

it displays, “Not Installed”.

Network Application Platforms

37

Page 43

Chapter 4

Change Supervisor Password

Select this option and press <Enter> to access the sub

menu. You can use the sub menu to change the supervisor

password.

Change User Password

Select this option and press <Enter> to access the sub

menu. You can use the sub menu to change the user

password.

Bios Settings

Clear User Password

Select this option and press <Enter> to access the

sub menu. You can use the sub menu to clear the user

password.

Network Application Platforms

38

Page 44

Chapter 4

Exit Menu

Select the Exit tab from the setup screen to enter the Exit

BIOS Setup screen. You can display an Exit BIOS Setup

option by highlighting it using the <Arrow> keys. All Exit

BIOS Setup options are described in this section. The Exit

BIOS Setup screen is at right.

Saving Changes and Exit

When you have completed the system configuration

changes, select this option to leave Setup and reboot the

computer so the new system configuration parameters

can take effect. .

Bios Settings

Discard Changes and exit

Select this option to discard changes and exit.

Discard Changes and Exit Setup Now?

Select this option to quit Setup without making any

permanent changes to the system configuration. Select

this option and press <Enter>.

Load Optimal Defaults

It automatically loads a complete set of default settings to

all Setup options when you Select this option. The Optimal

settings are designed for maximum system performance,

but may not work best for all computer applications. In

particular, do not use the Optimal Setup options if your

computer is experiencing system configuration problems.

Select Load Optimal Defaults from the Exit menu and

press <Enter>.

Network Application Platforms

39

Page 45

Appendix A

Appendix A: Programming Watchdog Timer

A watchdog timer is a piece of hardware that can be

used to automatically detect system anomalies and reset

the processor in case there are any problems. Generally

speaking, a watchdog timer is based on a counter that

counts down from an initial value to zero. The software

selects the counter’s initial value and periodically restarts

it. Should the counter reach zero before the software

restarts it, the software is presumed to be malfunctioning

and the processor’s reset signal is asserted. Thus, the

processor will be restarted as if a human operator had

cycled the power.

For sample watchdog code, see watchdog folder on the

Driver and Manual CD

Programming Watchdog Timer

To program the watchdog timer, you must write a program

which writes I/ O port address 443 (hex). The output data is

a value of time interval. The value range is from 01 (hex) to

3E (hex), and the related time interval is 1 sec. to 62 sec.

Data Time Interval

01 1 sec.

02 2 sec.

03 3 sec.

04 4 sec.

..

..

..

3E 62 sec.

After data entry, your program must refresh the

watchdog timer by rewriting the I/O port 443 (hex) while

simultaneously setting it. When you want to disable the

watchdog timer, your program should read I/O port 443

(hex).

For sample watchdog code, see watchdog folder on the

Driver and Manual CD

Network Application Platforms

40

Page 46

Appendix B

Appendix B: Setting up Console Redirections

Console redirection lets you monitor and configure a

system from a remote terminal computer by re-directing

keyboard input and text output through the serial port.

This following steps illustrate how to use this feature.

Connect one end of the console cable to console port 1.

of the system and the other end to serial port of the

Remote Client System.

Configure the following settings in the BIOS Setup 2.

menu for the device: Please refer to the Remote Access

Settings on Chapter 4 BIOS Settings.

BIOS > Advanced > Remote Access Configuration >

Serial Port Mode > [115200, 8 , n ,1 ]

Setting up Console Redirection

Configure Console Redirection on the client system. 3.

The following illustration is an example on Windows

platform:

A. Click the start button, point to Programs > a.

Accessories > Communications and select Hyper

Terminal.

B. Enter any name for the new connection and b.

select any icon.

Click OK.c.

From the “Connect to”. Pull-down menu, select the d.

appropriate Com port on the client system and

click OK.

Select 115200 for the Baud Rate, None. for Flow e.

contorl, 8 for the Data Bit, None for Parity Check,

and 1 for the Stop Bit.