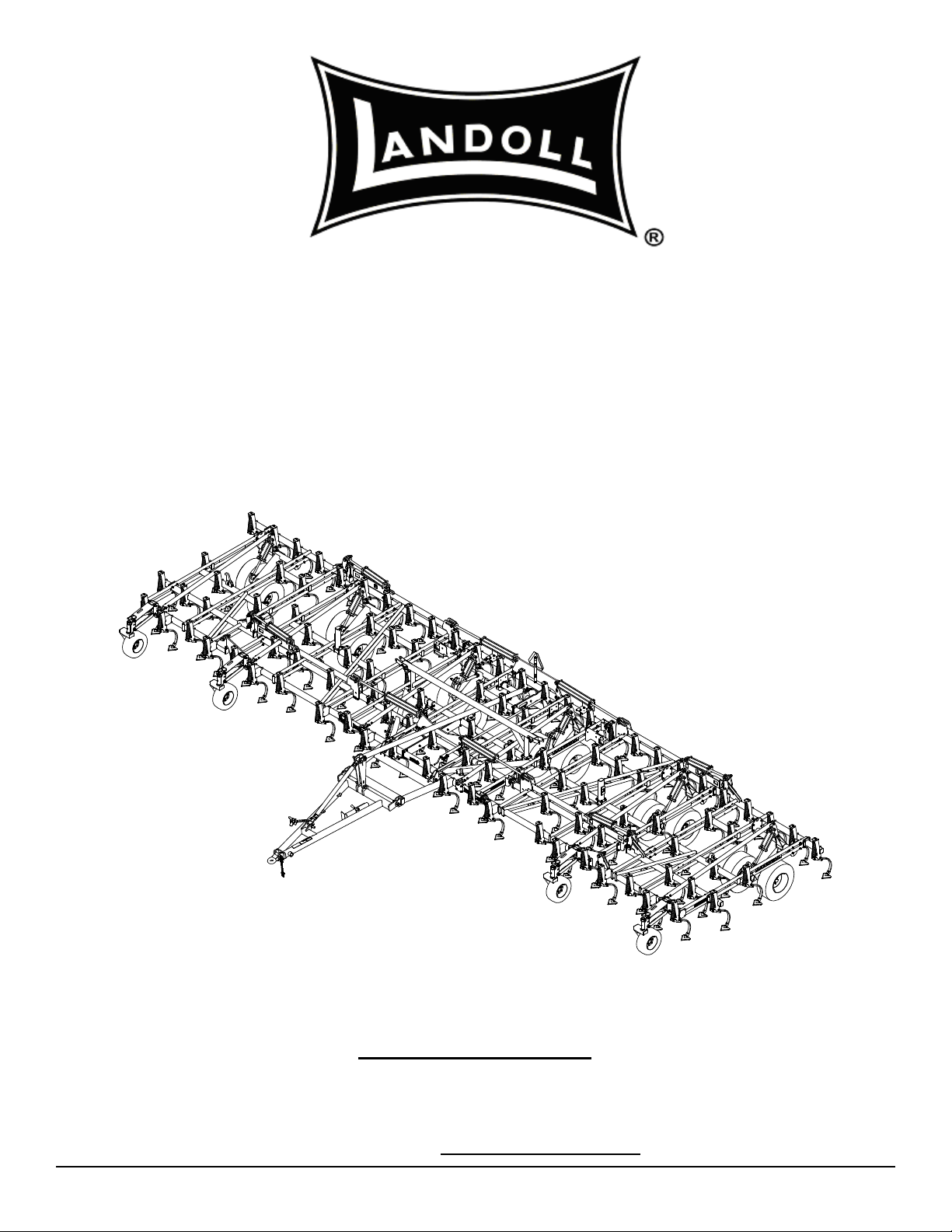

Landoll 9650 User Manual

Model 9650

Field Cultivator

Operator’ s Manual

LANDOLL CORPORATION

1900 North Street

Marysville, Kansas 66508

(785) 562-5381

800-428-5655 ~ WWW.LANDOLL.COM

F-605-0313 03/2013

1 Introduction

Understanding Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 Standard Specifications

3 Assembly Instructions

Frame and Hitch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Center Frame Tire Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Leveling Linkage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Inner Wing Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Outer Wing Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Wing Lift Tire Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Front Gauge Wheel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Table of Contents

Lighting and SMV Bracket Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Hydraulic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Shank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

4 Row Coil Tine Harrow Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

5 Row Spike Harrow Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3 Row Spike and Reel Harrow Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Rear Tow Hitch (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

4 Operation and Maintenance

Hydraulic Lift System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Hydraulic Fold System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Tractor Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Prior to Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Leveling (Front-to-Rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Leveling (Side to Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Gauge Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Depth Stop Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

F-605-0313 Edition i

Spring Shank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Sweeps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Wheel Bearing Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4 Row Coil Tine Harrow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

5 Row Spike Harrows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

3 Row Spike and Reel Harrow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

5 Troubleshooting Guide

ii F-605-0313 Edition

Chapter 1

Introduction

The Landoll Model 9650 Field Cultivator is a quality product designed to give years of trouble free performance. By

following each section of this manual, your system will perform as designed for you and your operation

CHAPTER 1 gives basic instructions on the use of this manual.

CHAPTER 2 gives product specifications. These specifications supply lengths and measures for your

equipment. A S tandard Bolt Torque Table is provided to give guidelines for bolt to rques to

be used when servicing this product.

CHAPTER 3 contains assembly instructions for your Model 9650 Field Cultivator. When these

procedures are correctly followed, your equipment should provide you years of

trouble-free operation and service.

CHAPTER 4 instructs how to operate your equipment before using it, and describes adjustments

needed. It also gives practical advice for the care and maintenance of your Landoll

equipment. Drawings in this section locate adjustment points on the equipment.

NOTE: IF THE EQUIPMENT IS IMPROPERLY ASSEMBLED OR MAINTAINED, THE

WARRANTY IS VOID. IF YOU HAVE ANY QUESTIONS CONTACT:

LANDOLL CORPORATION

1900 NORTH STREET

MARYSVILLE, KANSAS 66508

or phone:

(785) 562-5381 or

(800) 428-5655

or FAX:

(888) 527-3909

CHAPTER 5 is a troubleshooting guide to aid in diagnosing and solving problems with the equipment.

PARTS LIST is a separate manual showing the various assemblies, subassemblies, and systems.

Refer to that manual when ordering Landoll replacement parts. Order parts from your

Landoll dealer.

WARRANTY The Warranty Registration form is included with the product documents. Fill it out and

mail it within 15 days of purchase.

NOTE: IMPROPER ASSEMBLY, MODIFICATION, OR MAINTENANCE OF YOUR

LANDOLL MACHINE CAN VOID YOUR WARRANTY.

COMMENTS Address comments or questions regarding this publication to:

LANDOLL CORPORATION

1900 NORTH STREET

MARYSVILLE, KANSAS 66508

ATTENTION: PUBLICATIONS -DEPT. 55

1-1

INTRODUCTION

DANGER

WARNING

CAUTION

NOTE

NOTE

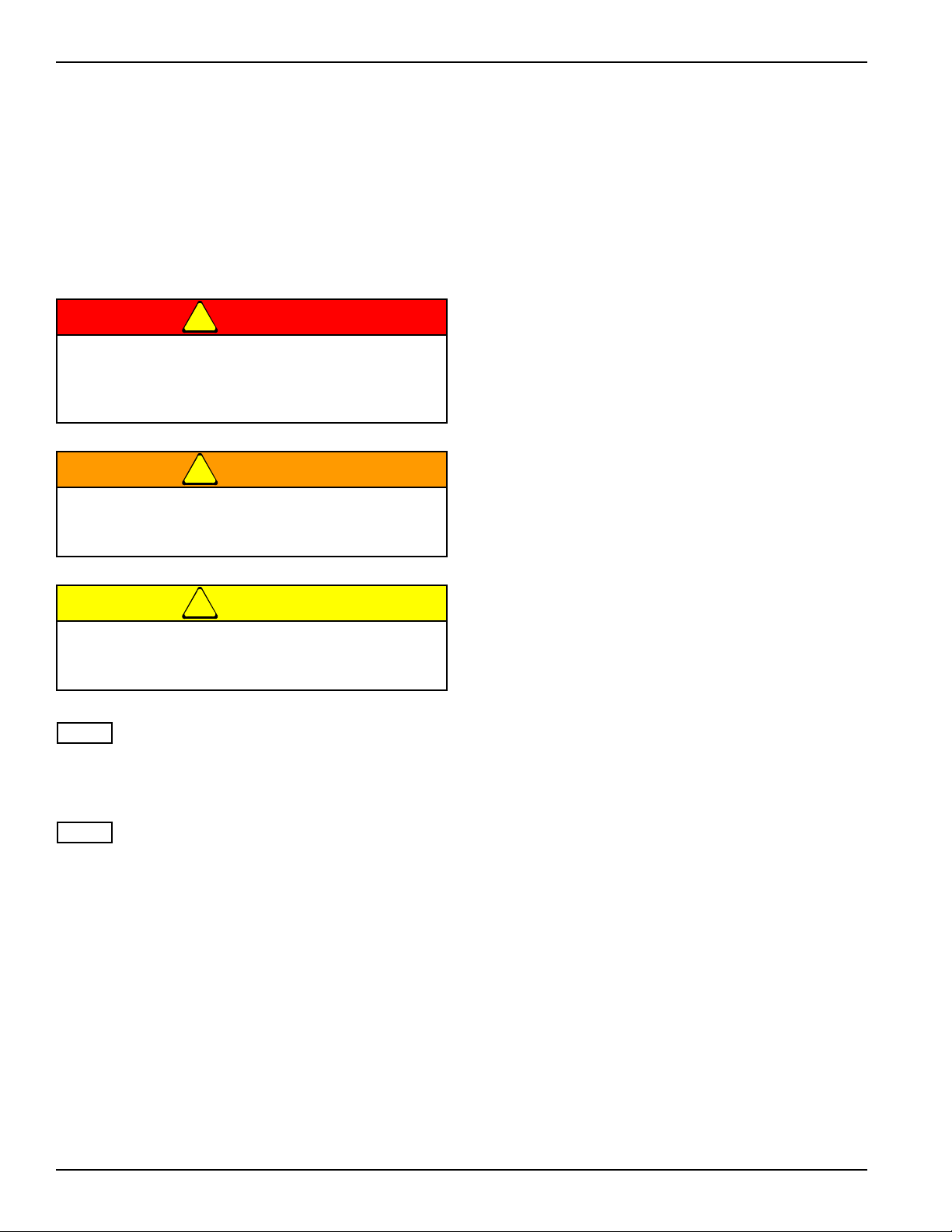

Understanding Safety Statements

You will find various types of safety information on the

following pages and on the machine signs (decals)

attached to the vehicle. This section explains their

meaning.

The Safety Alert Symbol means ATTENTION! YOUR

SAFETY IS INVOLVED!

Danger means a life-threatenin g sit ua ti on ex is ts.

Death can occur if safety measures or

instructions on this label are not properly

followed.

Warning means serious injury or death can occur

if safety measures or instructions on this label

are not properly followed.

Caution means serious equipment or other

property damage can occur if instruction s on this

label are not properly followed.

Means that failure to follow these instructions could

cause damage to the equipment or cause it to operate

improperly.

Make sure you read and understand the informatio n

contained in this manual and on the machine signs

(decals) before you attempt to operate or maintain this

vehicle.

The safety statements contai ned in this manual relate to

the operation of the Model 9650 Field Cultivator.

1-2 F-605-0313 Edition

Chapter 2

Standard Specifications

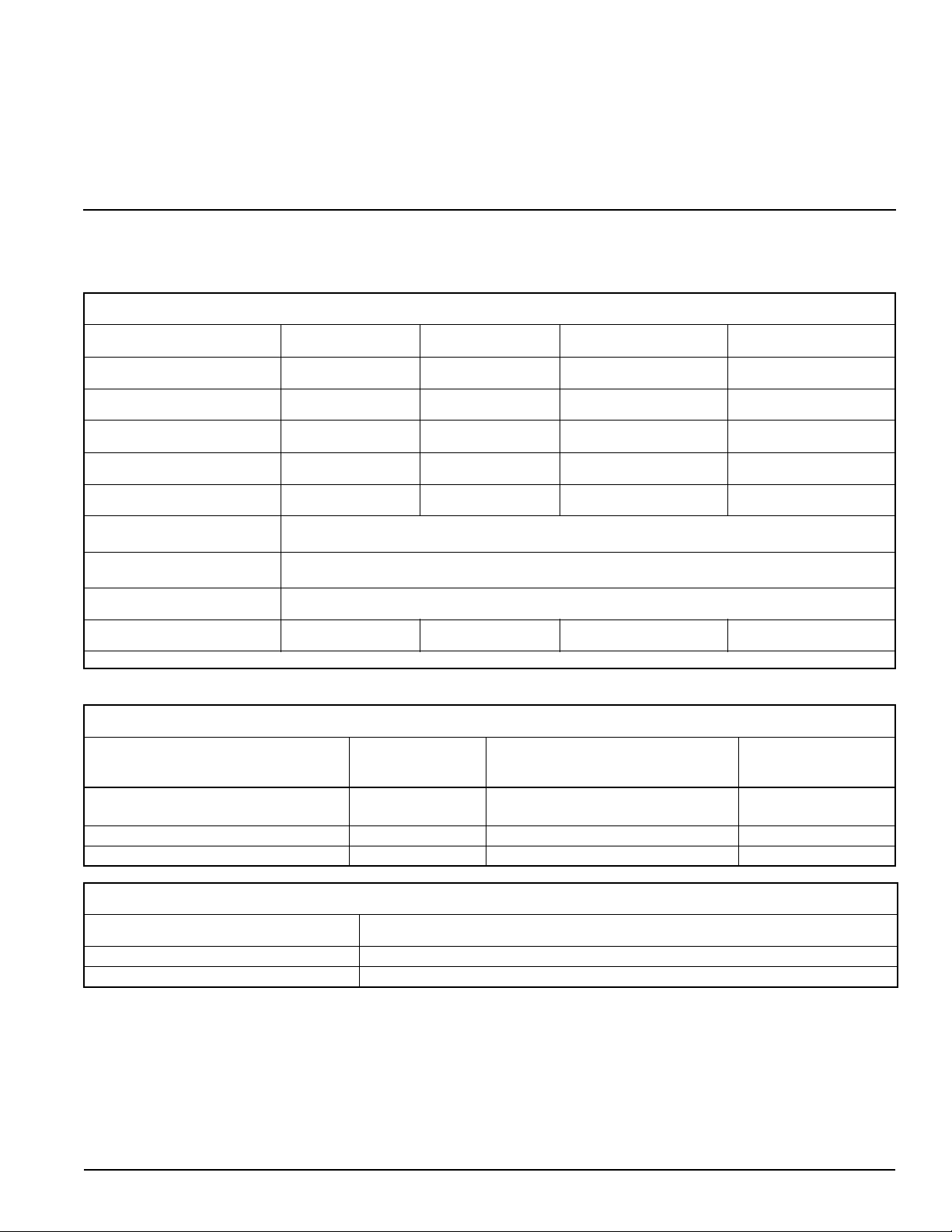

9650 Field Cultivator

Model No. 9650-38 9650-42 9650-46 9650-50

Working Width

Tran sport Width

Tran sport Height

No. Of Shanks

Shanks per Section

Tire Size And Ply

Spindle Size

Wheel Bolt Pattern

Estimated Weight

Specifications Are Subject To Change Without Prior Notification.

38’-6” 42’-6” 46’-6” 50’-6”

17’-4” 17’-4” 17’-4” 17’-4”

11’-11” 11’-11” 13’-11” 13’-11”

77 85 93 101

10-15-27-15-10 14-15-27-15-14 14-19-27-19-14 18-19-27-19-18

(4) 12.5L x 15, Load F Tires (Center Frame Section)

(8) 11L x 15, 12 ply Tires (Inner and Outer Wings)

3” Spindle on Center Frame

2-1/4” Spindle on Wings

8 Bolt Wheels (Frame Center) and 6 Bolt Wheels (Inner and Outer Wings)

16,440 17,640 18,400 18,950

Tire Inflation

Inflation Pressure

Tire Size Tire Manufacturer Ply/Load Rating

12.5L x 15 Load Range F

FI Farm Highway Service

11L x 15, 12 ply Carlisle 12 Ply/ 3,200 lbs. 52 psi

20.5 x 8.0-10 Load Range D/ 1,320 lb. 70 psi

Recommended Torque Specification for Lug Bolts and Nuts

Bolt Size Torque (Ft. Lbs.)

9/16-18 (Heavy Duty Disc) 80 - 90 ft. lbs

5/8-18 (Heavy Duty Disc) 85 - 100 ft. lbs

Carlisle F Load 5,620 lbs. @ 30 mph 90 psi

(Psi) (Max.)

2-1

STANDARD SPECIFICATIONS

LANDOLL CORPORATION

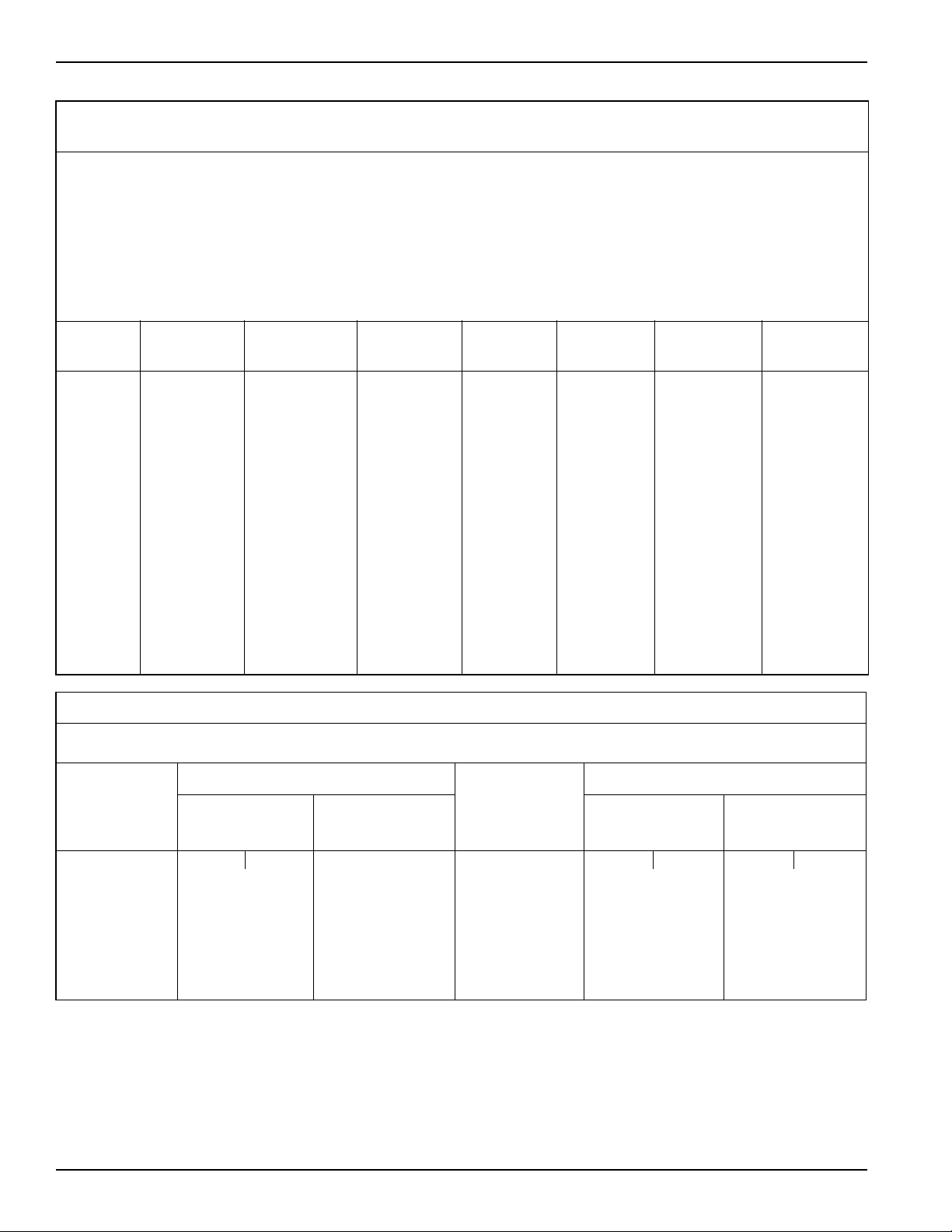

GENERAL TORQUE SPECIFICATIONS (REV. 4/97)

THIS CHART PROVIDES TIGHTENING TORQUES FOR GENERAL PURPOSE APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED ON PROCESS

OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED NUTS AND CAPSCREWS ASSEMBLED WITHOUT SUPPLEMENTAL LUBRICATIO N (AS RECEIVED CONDITION).

THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE LUBRICANTS ARE USED.

WHEN FASTENERS ARE DRY (SOLVENT CLEANED), ADD 33% TO AS RECEIVED CONDITION TORQUE.

BOLT HEAD IDENTIFICATION MARKS INDICATE GRADE AND MAY VARY FROM MANUFACTURER TO MANUFACTURER.

THICK NUTS MUST BE USED ON GRADE 8 CAPSCREWS.

USE VALUE IN [ ] IF USING PREVAILING TORQUE NUTS.

TORQUE IS SPECIFIED IN FOOT POUNDS

UNC

Size

1/4-20 4 [5] 6 [7] 9 [11] 1/4-28 5 [6] 7 [9] 10 [12]

5/16-18 8 [10] 13 [16] 18 [22] 5/16-24 9 [11]

SAE Grade2SAE Grade5SAE Grade

8

UNF

Size

SAE Grade 2SAE Grade5SAE Grade

8

14

[17] 20 [25]

3/8-16 15 [19] 23 [29] 35 [43] 3/8-24 17 [21] 25 [31] 35 [44]

7/16-14 24 [30] 35 [43] 55 [62] 7/16-20 27 [34] 40 [50] 60 [75]

1/2-13 35 [43] 55 [62] 80 [100] 1/2-20 40 [50] 65 [81] 90 [112]

9/16-12 55 [62] 80 [100] 110 [137] 9/16-18 60 [75] 90 [112] 130 [162]

5/8-11 75 [94] 110 [137] 170 [212] 5/8-18 85 [106] 130 [162] 180 [225]

3/4-10 130 [162] 200 [250] 280 [350] 3/4-16 150 [188] 220 [275] 320 [400]

7/8-9 125 [156] 320 [400] 460 [575] 7/8-14 140 [175] 360 [450] 500 [625]

1-8 190 [237] 408 [506] 680 [850] 1-14 210 [263] 540 [675] 760 [950]

1-1/8-7 270 [337] 600 [750] 960 [1200] 1-1/8-12 300 [375] 660 [825] 1080 [1350]

1-1/4-7 380 [475] 840 [1050] 1426 [1782] 1-1/4-12 420 [525] 920 [1150] 1500 [1875]

1-3/8-6 490 [612] 110 [1375] 1780 [2225] 1-3/8-12 560 [700] 1260 [1575] 2010 [2512]

1-1/2-6 650 [812] 1460 [1825] 2360 [2950] 1/1-2-12 730 [912] 1640 [2050] 2660 [3325]

1-3/4-5 736 [920] 1651 [2063] 2678 [3347] 1-3/4-12 920 [1150] 2063 [2579] 3347 [4183]

METRIC

COARSE THREAD METRIC CLASS 10.9 FASTENERS AND CLASS 10.0 NUTS AND THROUGH HARDENED FLAT WASHERS, PHOSPHATE COATED, ROCKWELL

“C” 38-45.

USE VALUE IN [ ] IF USING PREVAILING TORQUE NUTS.

Nominal

Thread

Diameter

mm

Standard Torque Nominal

Newton-

Meters

Foot-

Pounds

Thread

Diameter

mm

Standard Torque

Newton-

Meters

Foot-

Pounds

6 10 [14] 7 [10] 20 385 [450] 290 [335]

7 16 [22] 12 [16] 24 670 [775] 500 [ 625]

8 23 [32] 17 [24] 27 980 [1105] 730 [825]

10 46 [60] 34 [47] 30 1330 [1470] 990 [1090]

12 80 [101] 60 [75] 33 1790 [1950] 1340 [1450]

14 125 [155] 90 [115] 36 2325 [2515] 1730 [1870]

16 200 [240] 150 [180] 39 3010 [3210] 2240 [2380]

18 275 [330] 205 [245]

Table 2-1: General Torque Specifications

2-2 F-605-0313 Edition

STANDARD SPECIFICATIONS

LANDOLL CORPORATION

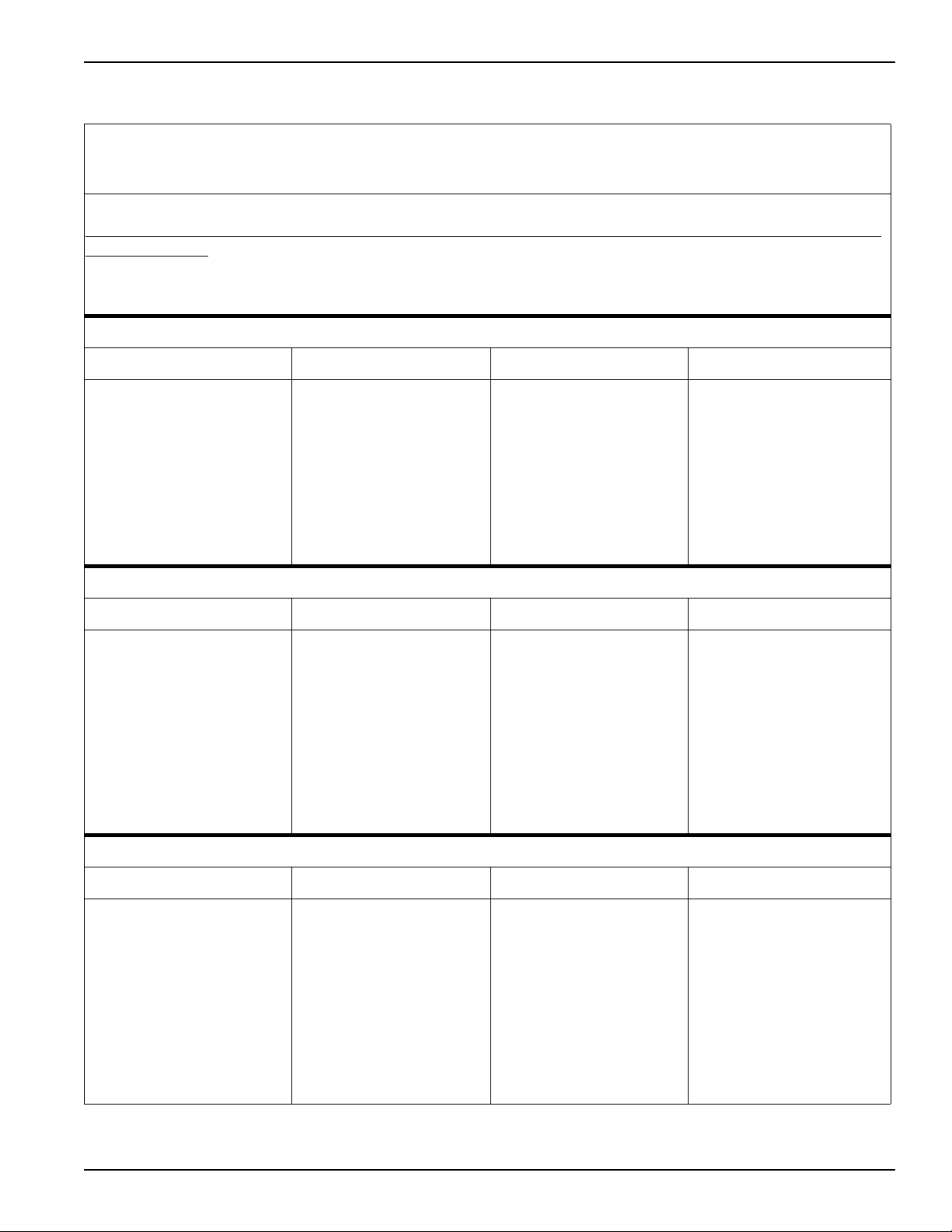

HYDRAULIC FITTING TORQUE SPECIFICATIONS

THIS CHART PROVIDES TIGHTENING TORQUES FOR HYDRAULIC FITTING APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED ON PROCESS

OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED CARBON STEEL AND STAINLESS STEEL FITTINGS ASSEMBLED WITHOUT SUPPLEMENTAL LUBRICATION (AS

RECEIVED CONDITION). THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE LUBRICANTS ARE USED.

BRASS FITTINGS AND ADAPTERS - 65% OF THE TORQUE VALUE FOR STEEL. STAINLESS STEEL, ALUMINUM AND MONEL - THREADS ARE TO BE

LUBRICATED

.

TORQUE IS SPECIFIED IN FOOT POUNDS

Dash Size 37 Degree JIC O-Ring (ORS) O-Ring Boss (ORB)

-4 11-13 15-17 13-15

-5 14-16 — 21-23

-6 20-22 34-36 25-29

-8 43-47 58-62 40-44

-10 55-65 100-110 57.5-62.5

-12 80-90 134-146 75-85

-16 115-125 202-218 109-121

-20 160-180 248-272 213-237

-24 185-215 303-327 238-262

-32 250-290 — 310-340

o

37

JIC, ORS, & ORB (REV. 10/97)

PARKER BRAND FITTINGS

GATES BRAND FITTINGS

Dash Size 37 Degree JIC O-Ring (ORS) O-Ring Boss (ORB)

-4 10-11 10-12 14-16

-5 13-15 — —

-6 17-19 18-20 24-26

-8 34-38 32-40 37-44

-10 50-56 46-56 50-60

-12 70-78 65-80 75-83

-14 — 65-80 —

-16 94-104 92-105 111-125

-20 124-138 125-140 133-152

-24 156-173 150-180 156-184

-32 219-243 — —

AEROQUIP BRAND FITTINGS

Dash Size 37 Degree JIC O-Ring (ORS) O-Ring Boss (ORB)

-4 11-12 10-12 14-16

-5 15-16 — 18-20

-6 18-20 18-20 24-26

-8 38-42 32-35 50-60

-10 57-62 46-50 72-80

-12 79-87 65-70 125-135

-14 — — 160-180

-16 108-113 92-100 200-220

-20 127-133 125-140 210-280

-24 158-167 150-165 270-360

-32 245-258 — —

Table 2-2: Hydraulic Fitting Torque Specifications

2-3

STANDARD SPECIFICATIONS

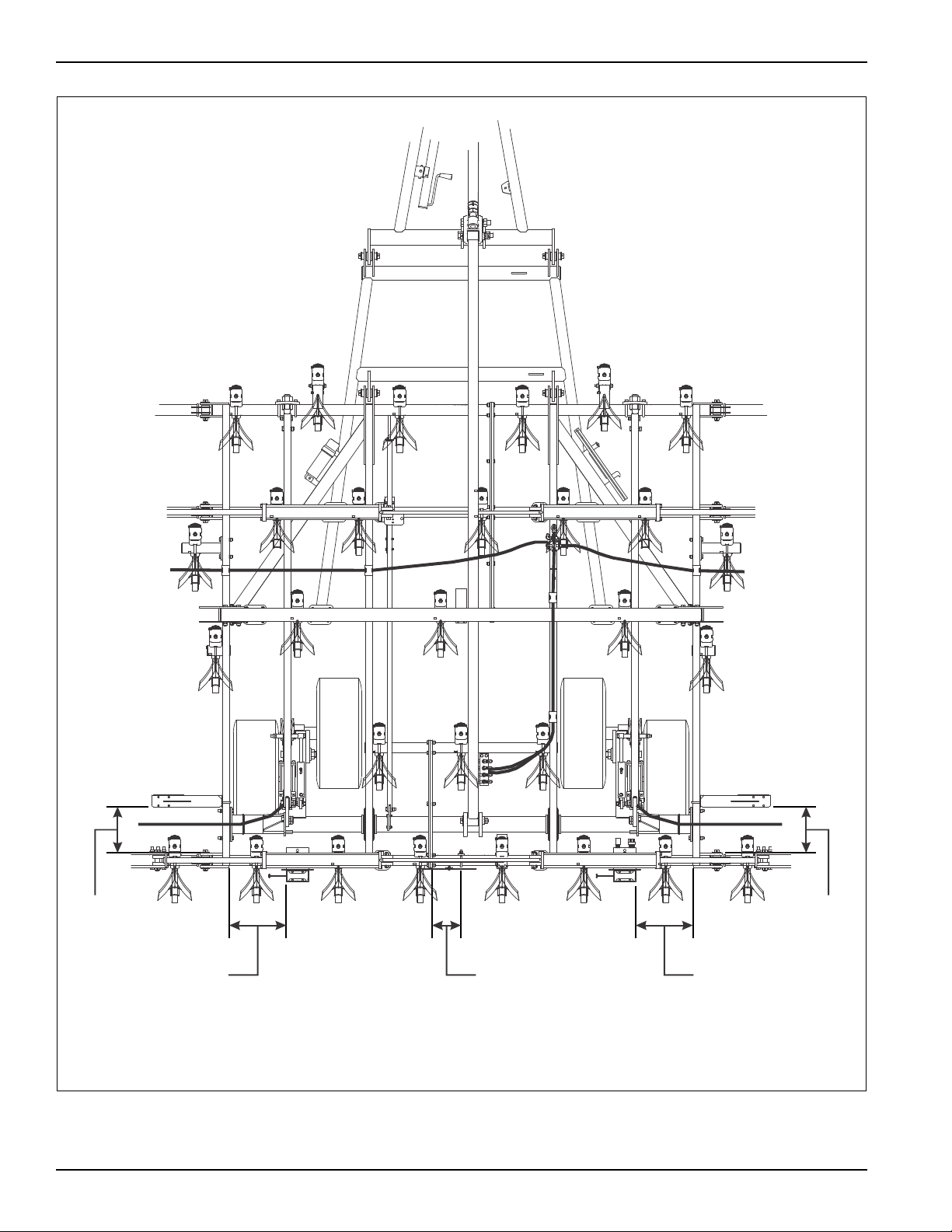

13-1/2

13-1/2

16-3/4

16-3/4

8-1/2

9650-placement

Figure 2-1: Light and SMV Bracket Placement (All Models)

2-4 F-605-0313 Edition

10-1/2 10-1/2

9650-front-gauge-wheel-placement

NOTE: RIGHT SIDE SHOWN - LEFT SIDE FRONT GAUGE

WHEEL PLACEMENT USES SAME DIMENSIONS.

15

9

9

STANDARD SPECIFICATIONS

Figure 2-2: Front Gauge Wheel Placement

2-5

STANDARD SPECIFICATIONS

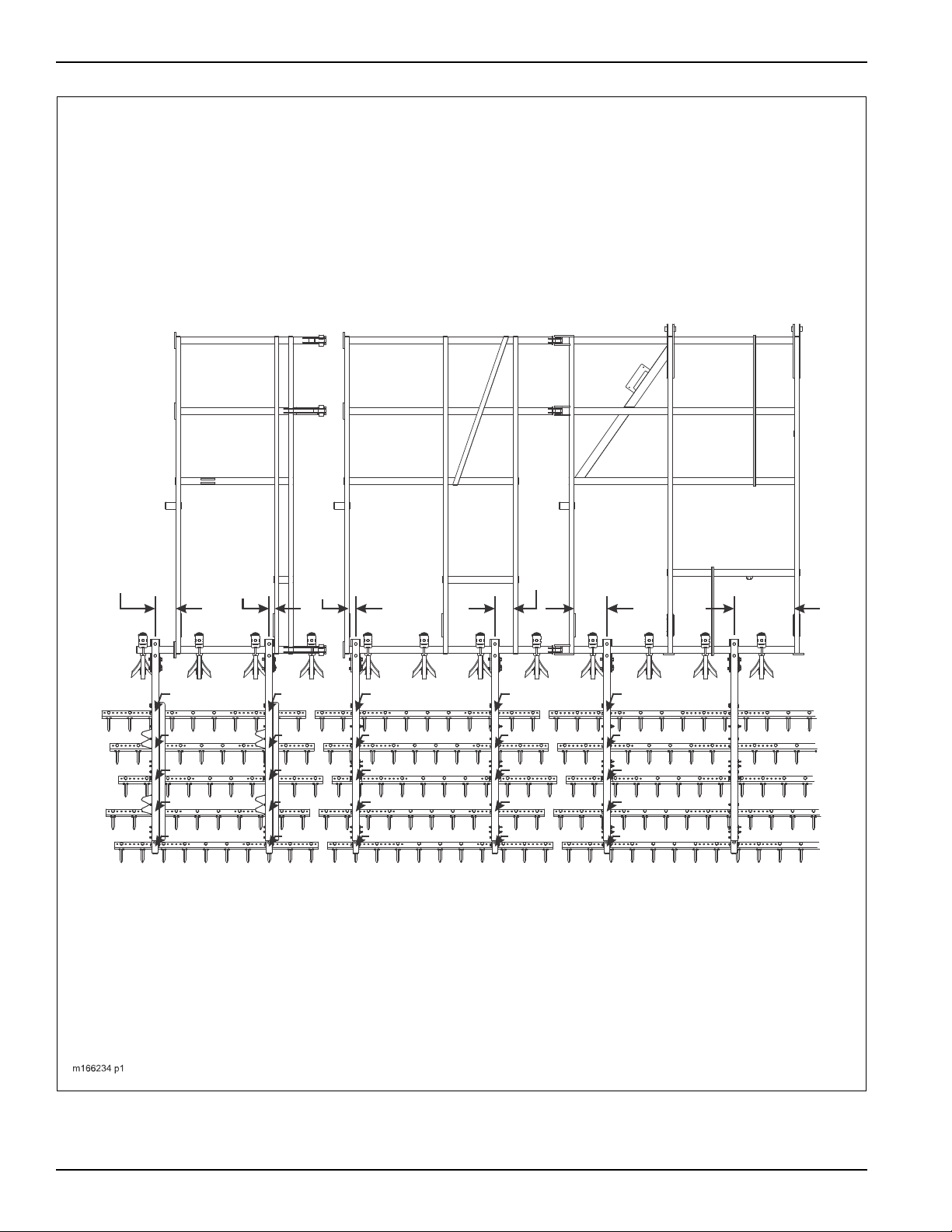

14

2

8

26

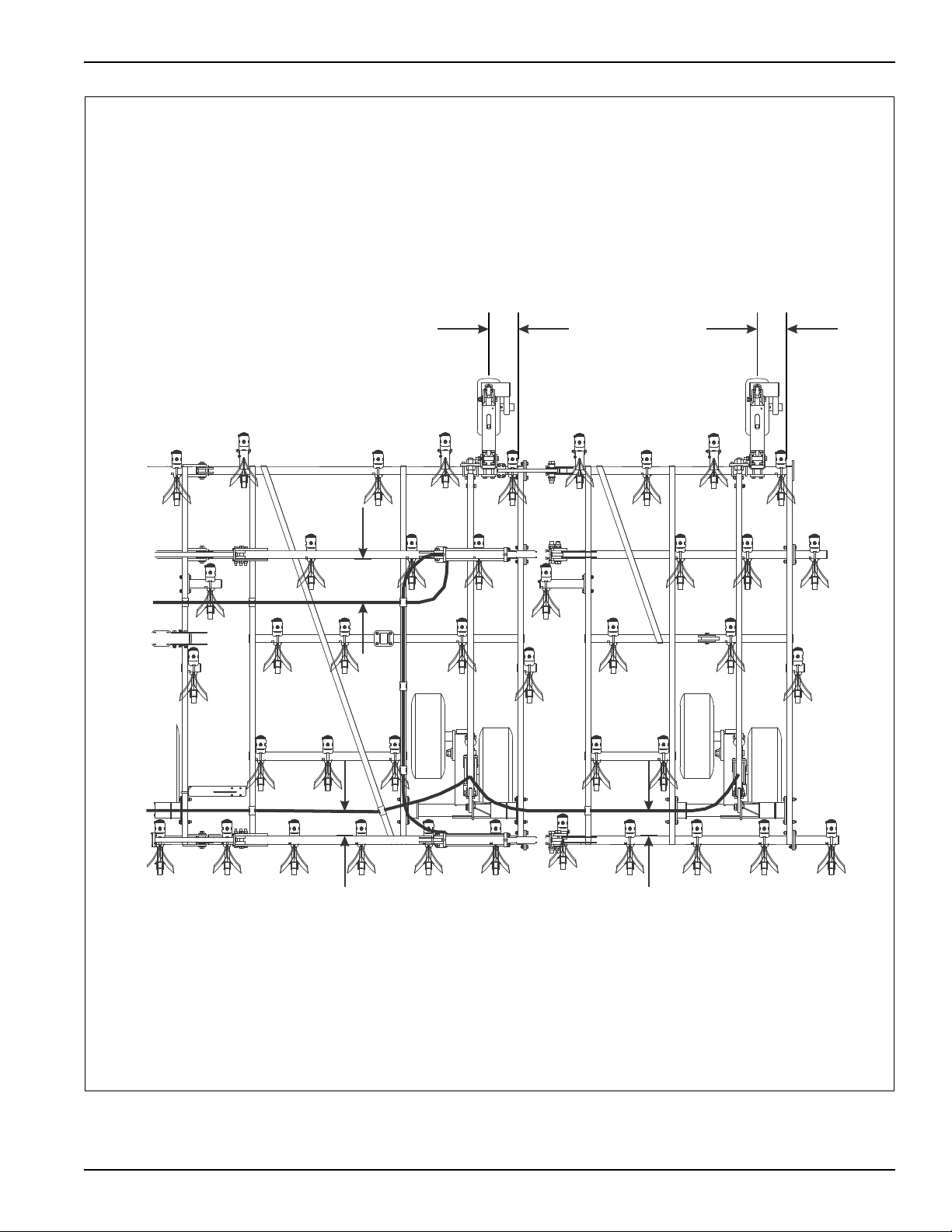

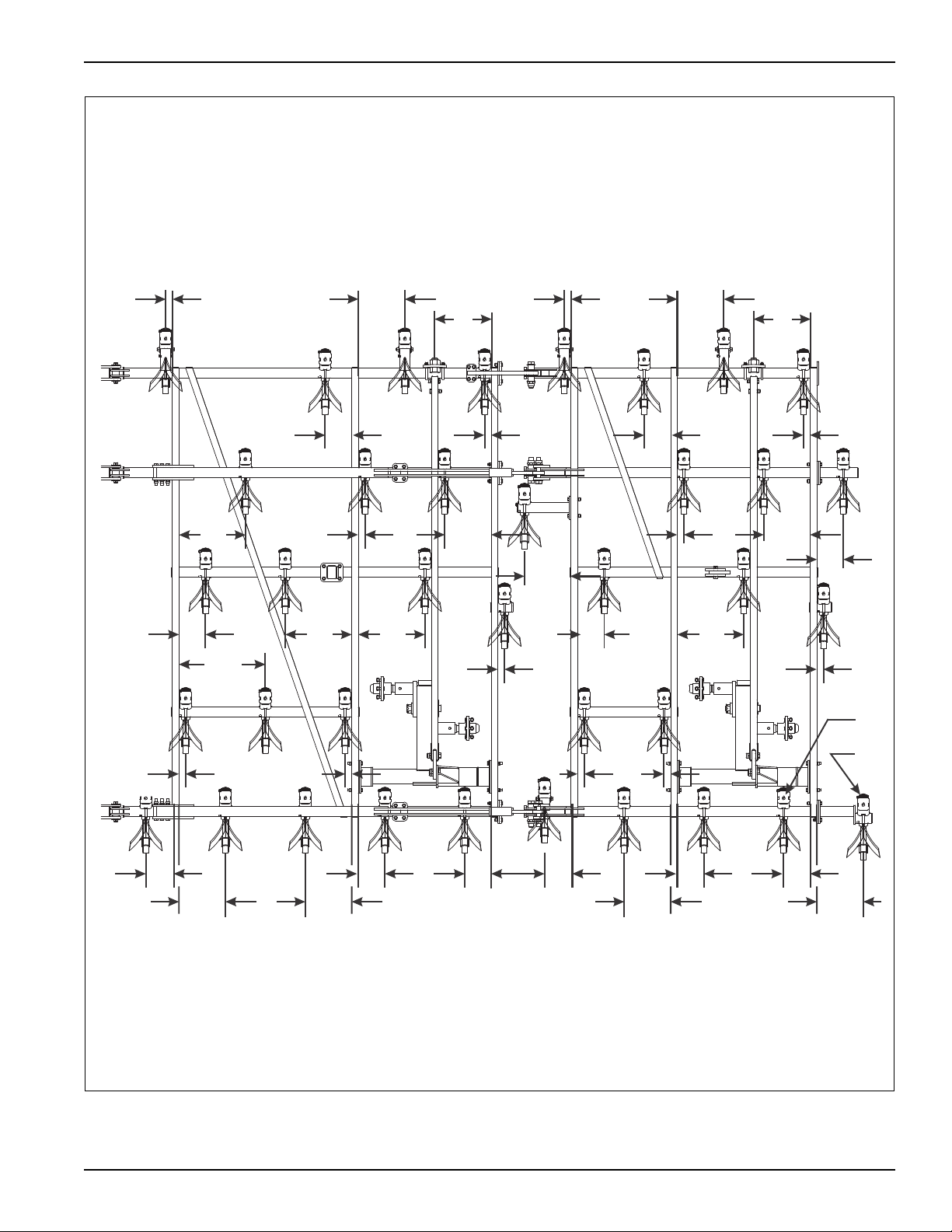

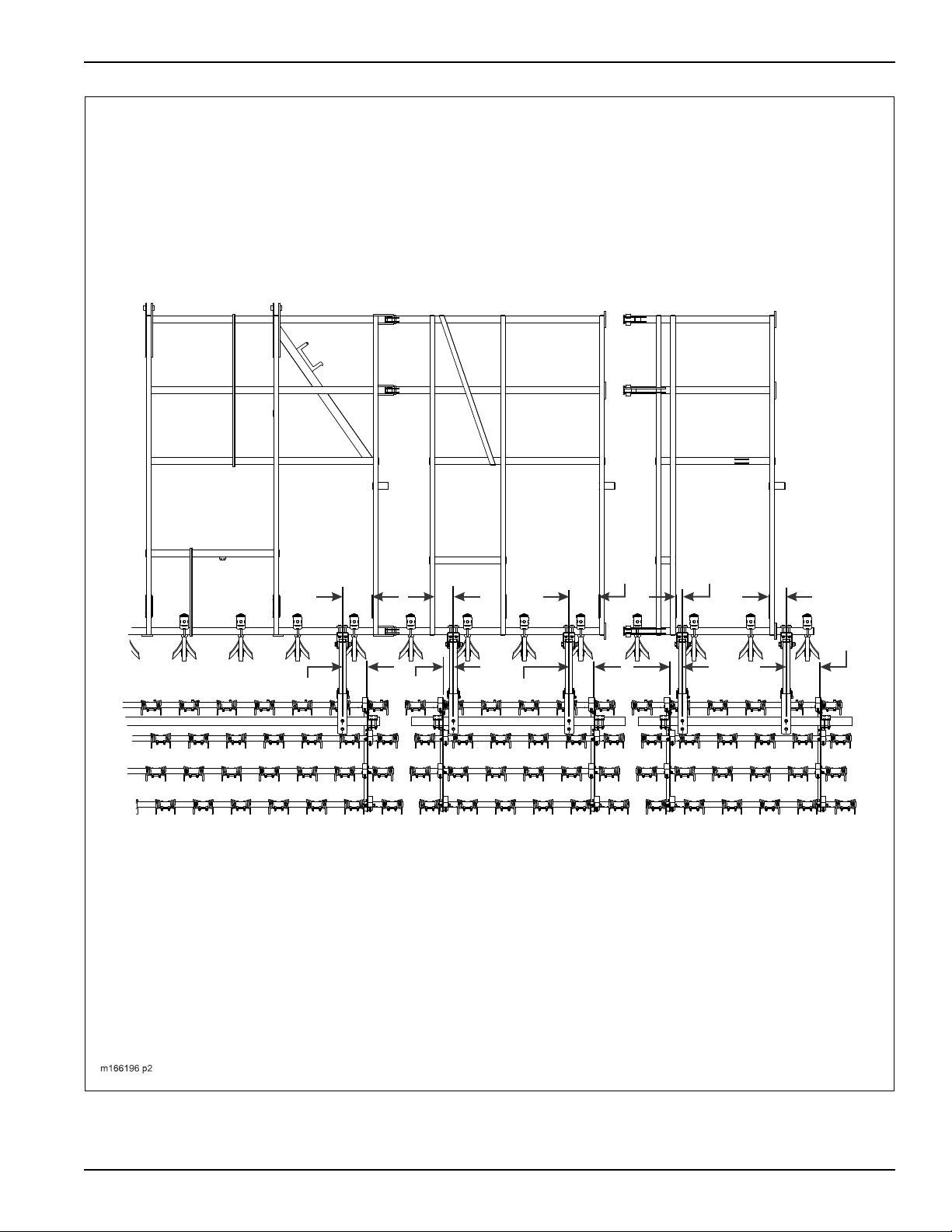

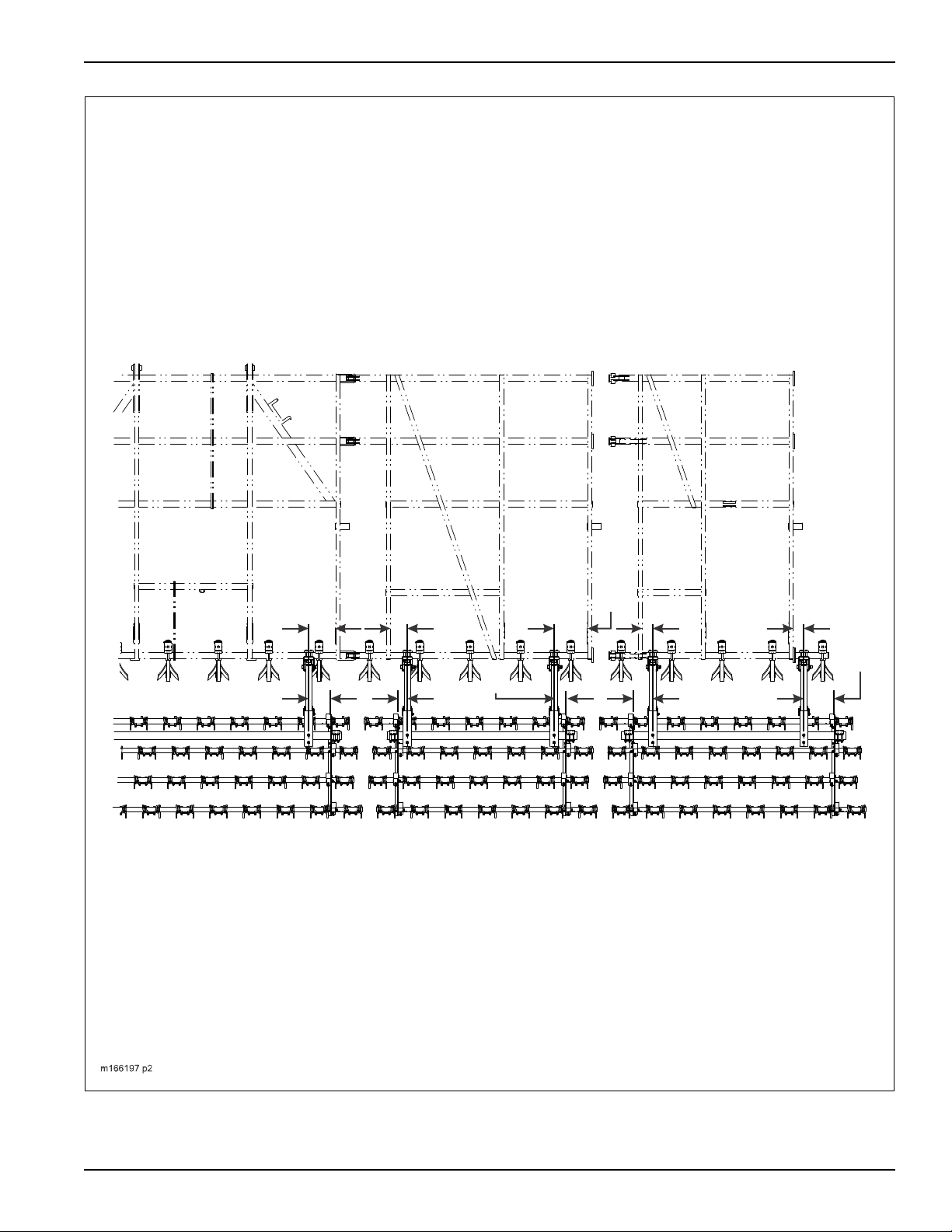

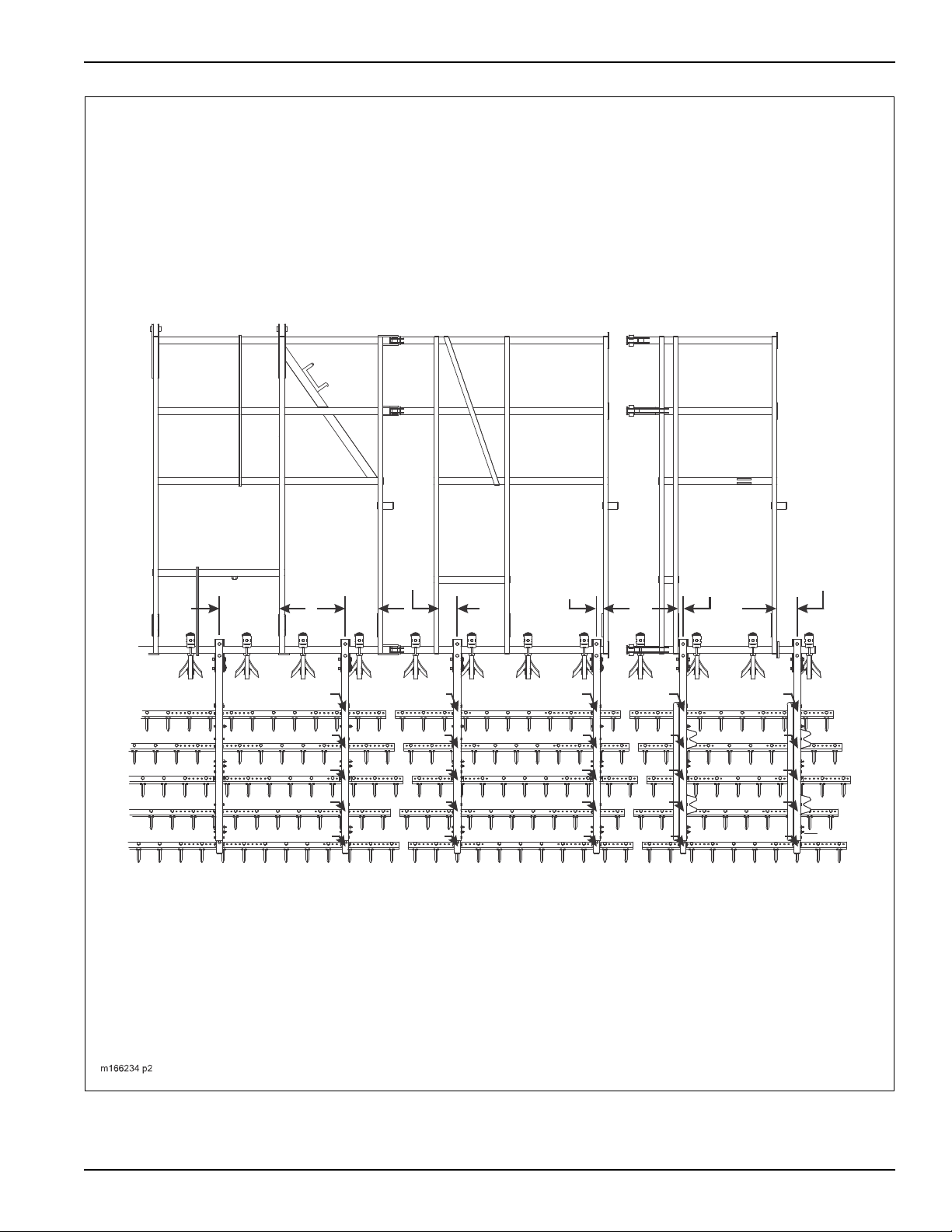

9650-38-42 main frame shank placement

8

148882

2

2

20

2020

2

14

8

20

214828

2

17

8

2

17

14 14

2-6 F-605-0313 Edition

Figure 2-3: Shank Placement (38’ and 42 ' M ode ls )

(Main Frame)

14

8 8 8

8

83214

38’

42’

2 2

2

8

2

2

2

22020

81414142

8

2

26

2 14

2

2

17 17

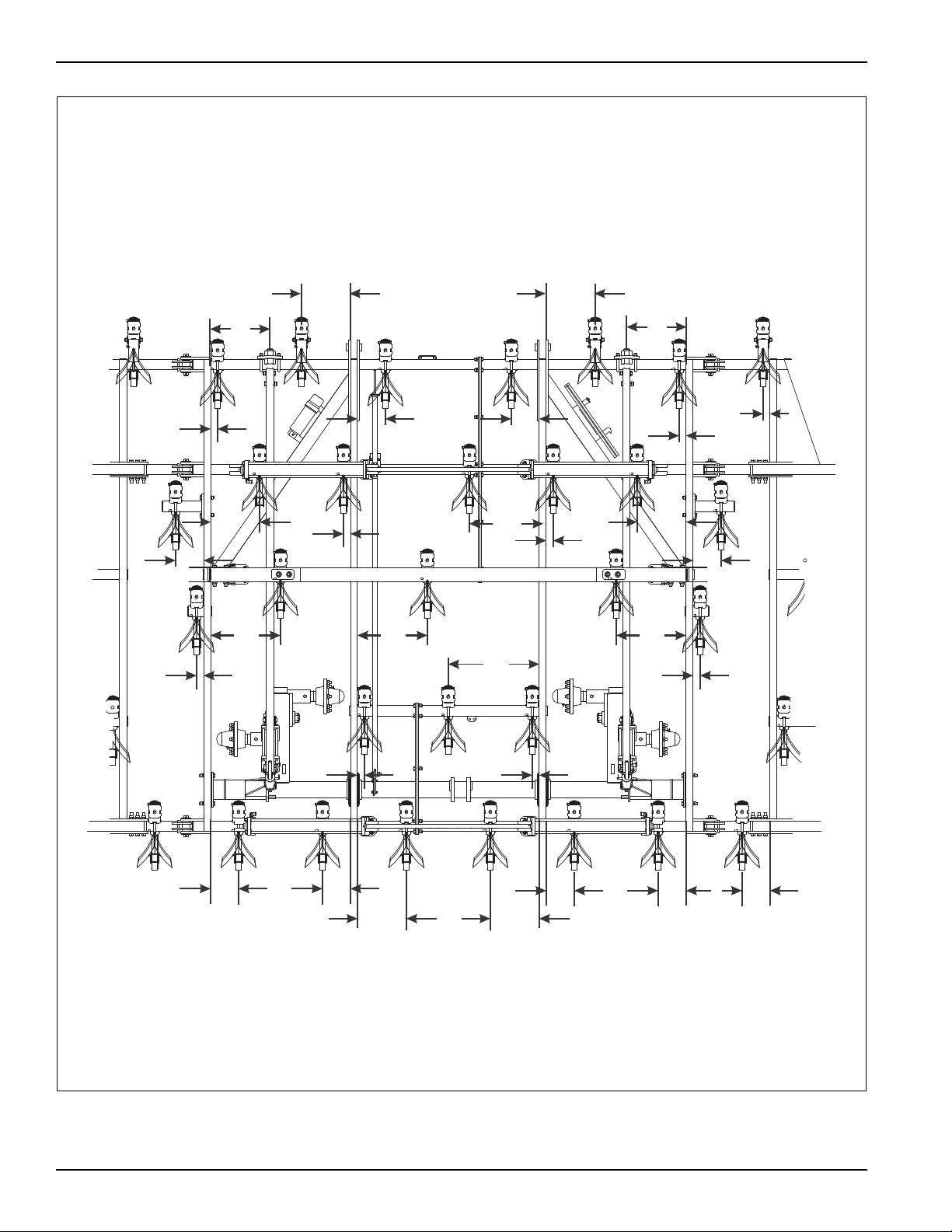

9650-38-42 right wings shank placement

NOTE: RIGHT SIDE WINGS SHOWN - LEFT SIDE WINGS SHANK

PLACEMENT USES SAME DIMENSIONS.

STANDARD SPECIFICATIONS

Figure 2-4: Shank Placement (38’ and 42 ' M ode ls )

(Right Wings Shown)

2-7

STANDARD SPECIFICATIONS

14

2

8

2681488

8

2

2

2

20

2020

2

14

8

20

214828

2

17

8

2

17

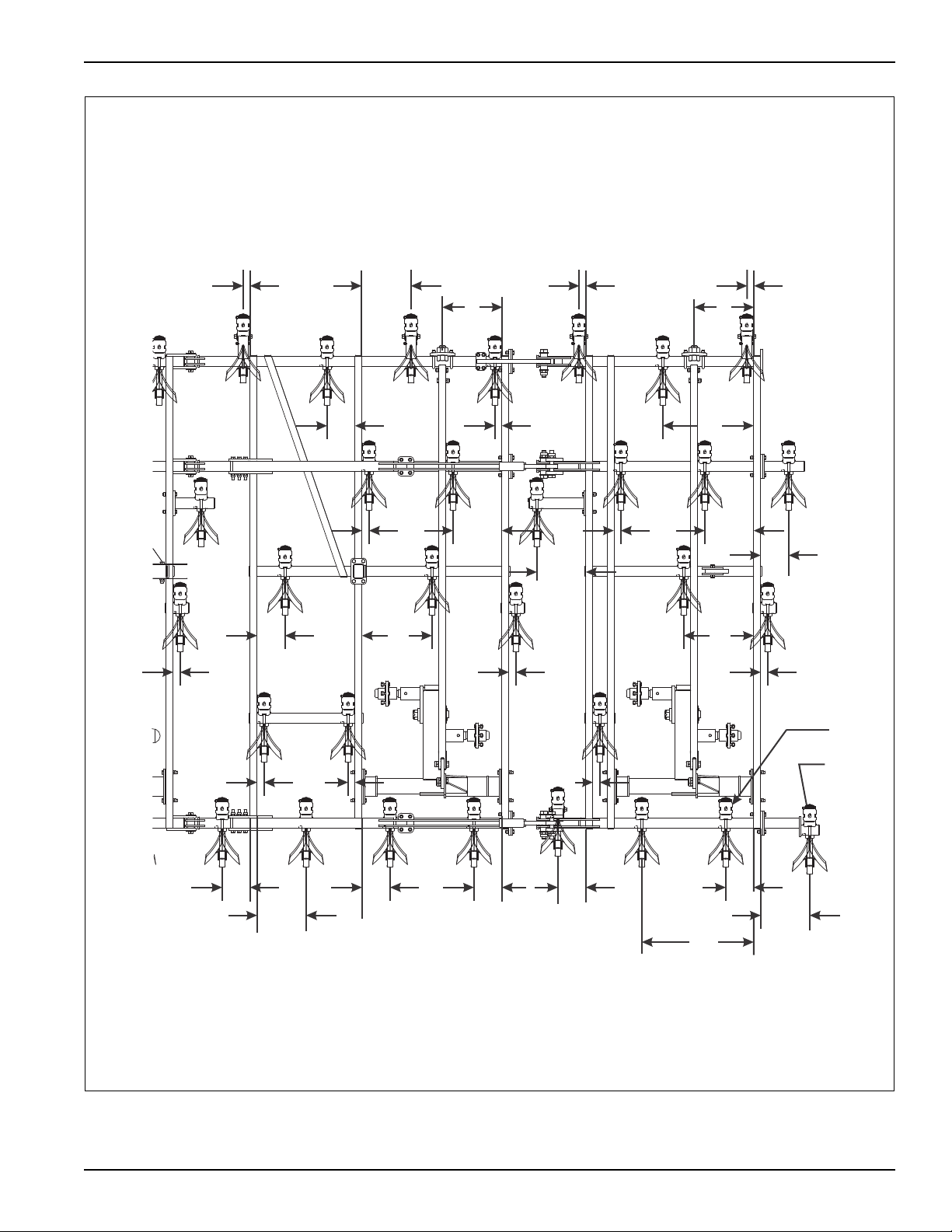

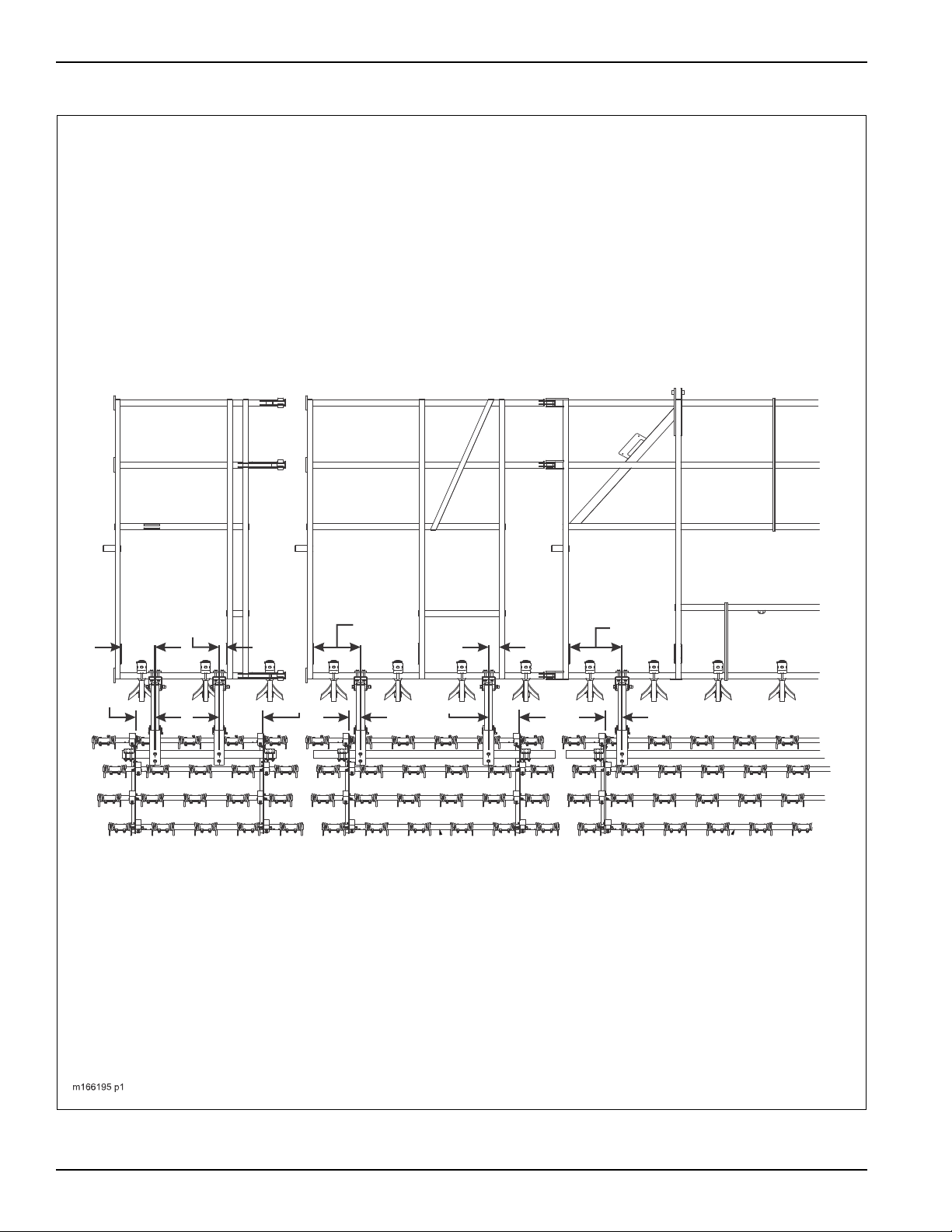

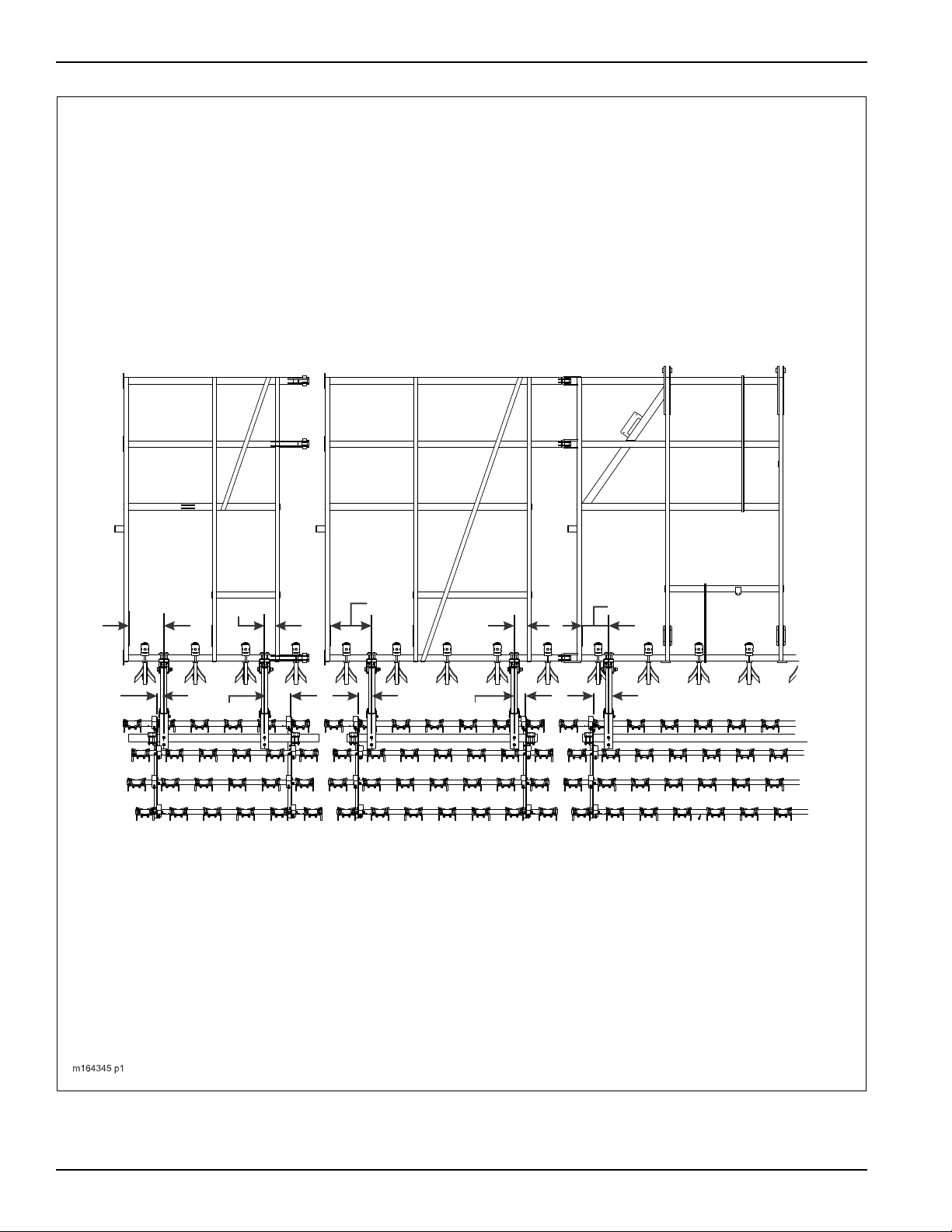

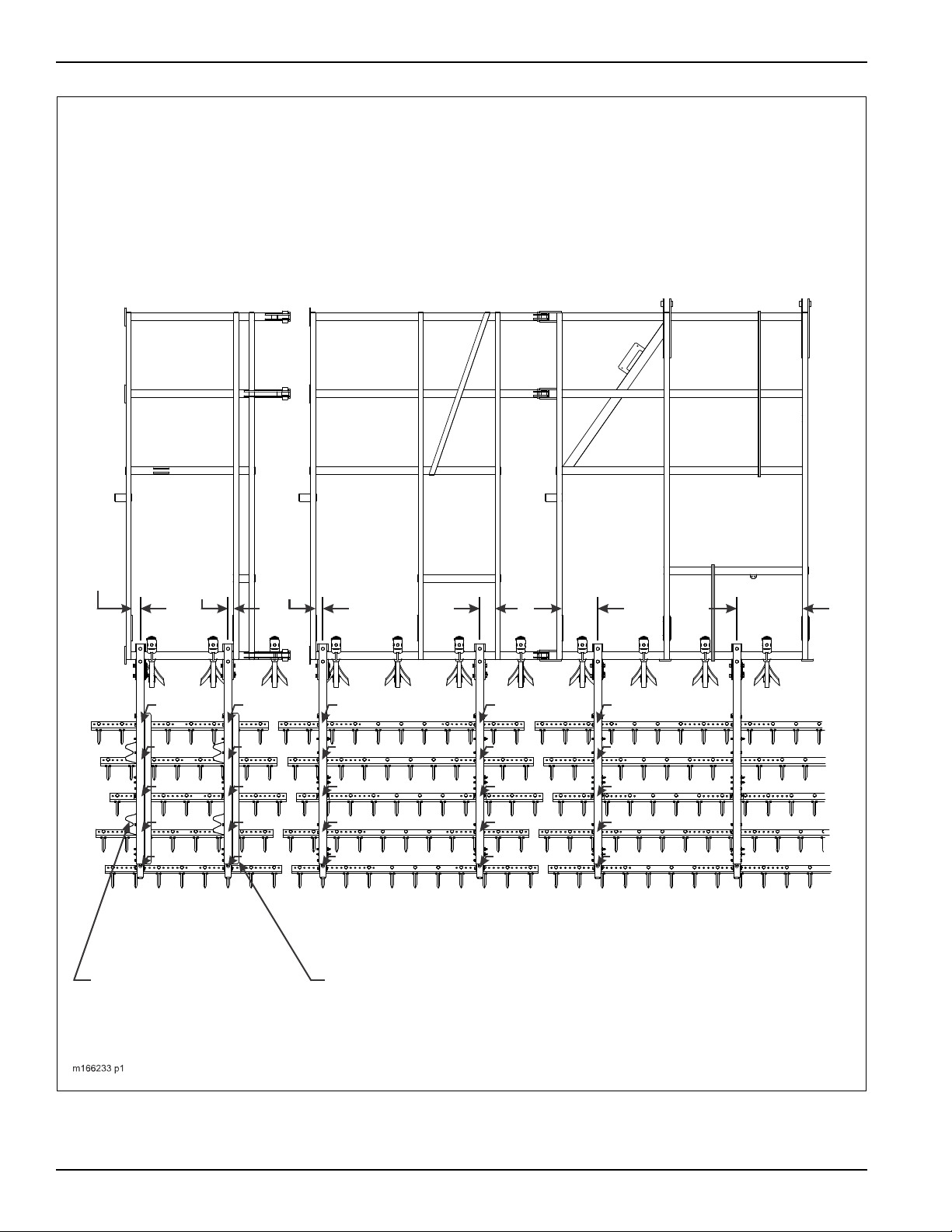

9650-46-50 main frame sh ank placement

2-8 F-605-0313 Edition

Figure 2-5: Shank Placement (46' and 50’ Models)

(Main Frame)

14

8 8

46’

50’

2 2

2

8

2

2

22620

81414142821417

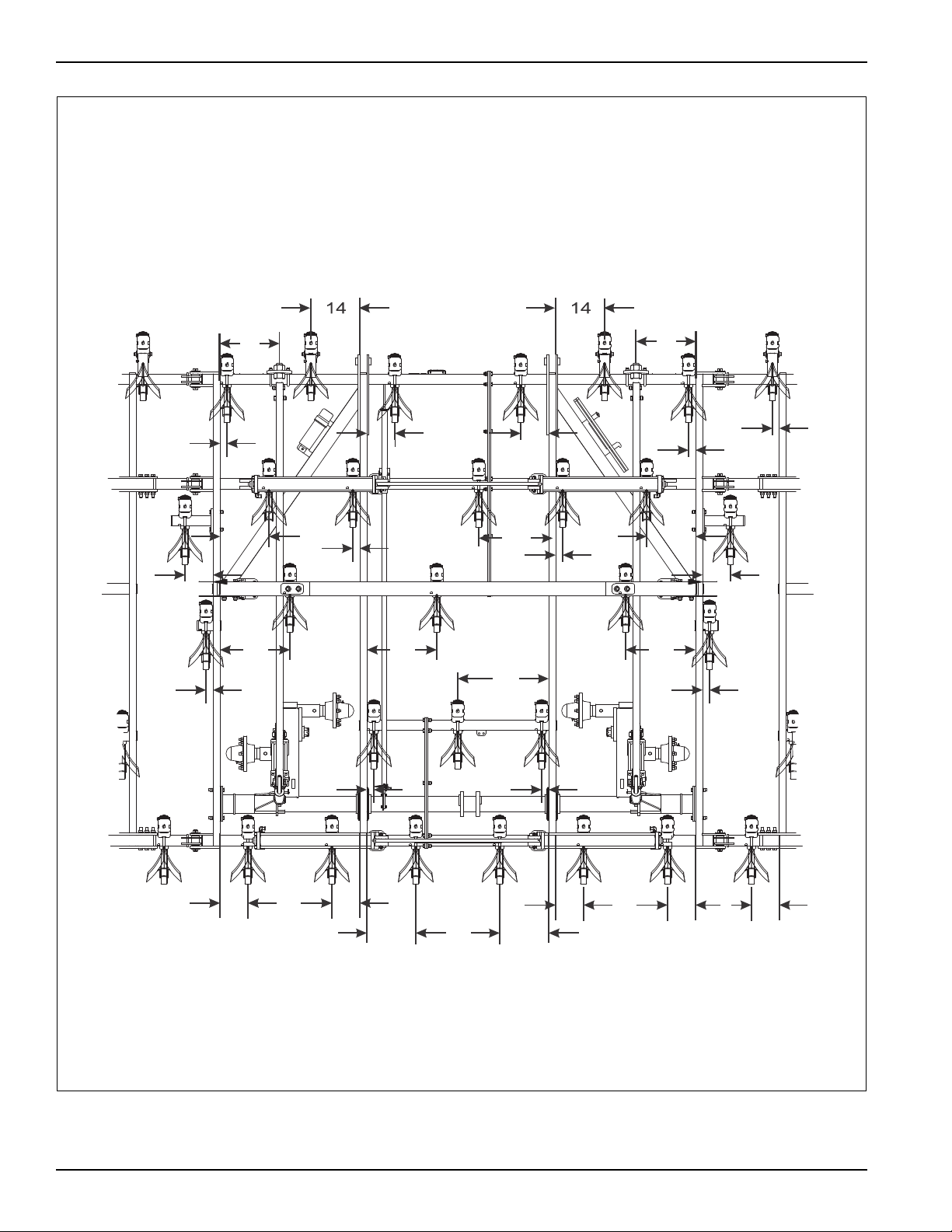

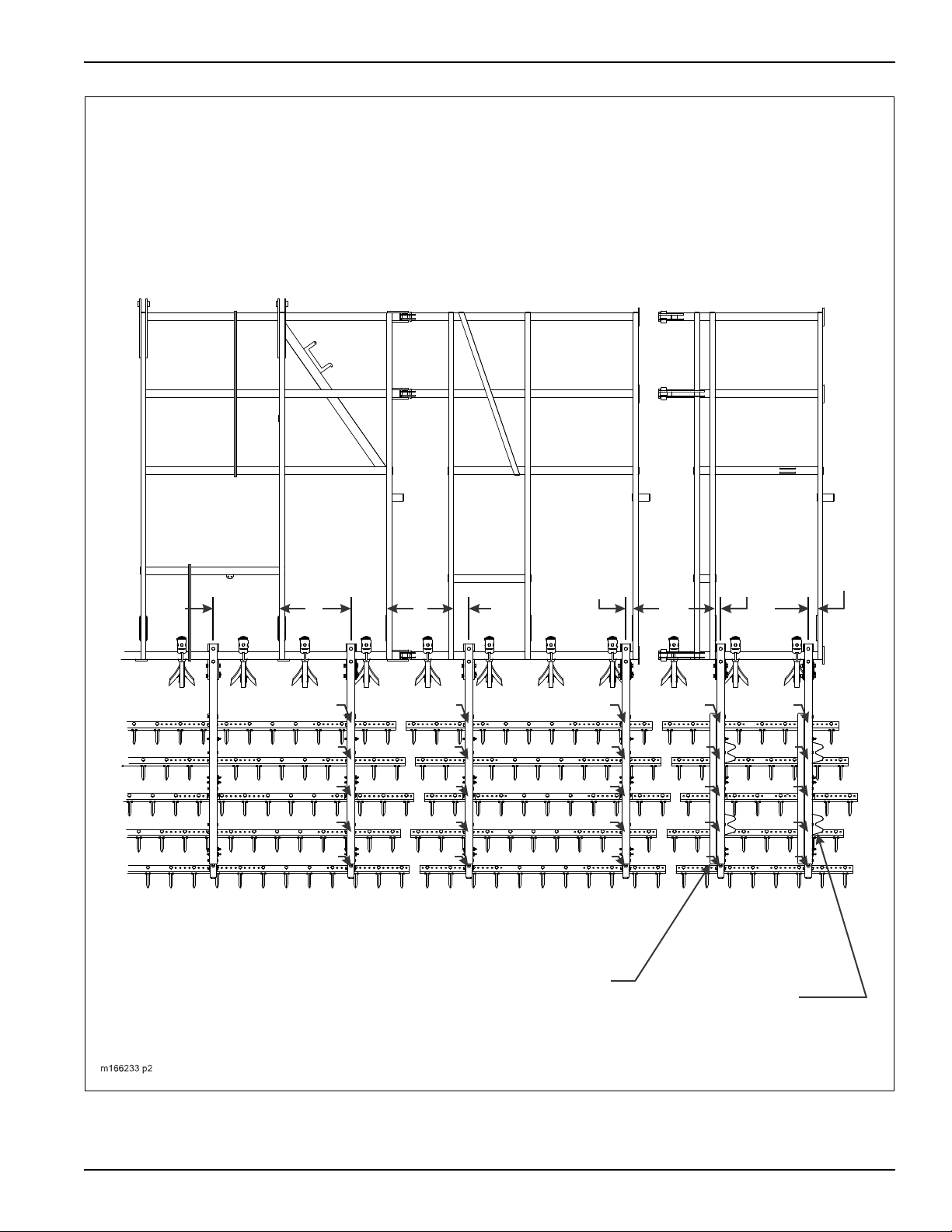

9650-46-50 right wings shank placement

1481481488

2

8

2020

20

2

17

2 14

8

2

NOTE: RIGHT SIDE WINGS SHOWN - LEFT SIDE WINGS SHANK

PLACEMENT USES SAME DIMENSIONS.

STANDARD SPECIFICATIONS

Figure 2-6: Shank Placement (46’ and 50 ' M ode ls )

(Right Wings Shown)

2-9

STANDARD SPECIFICATIONS

13

7-1/4

3

16-7/16

18

4-1/4

4

11-7/16

20

6-1/4

5 TINE 8 IN

HARROW ASSEMBLY

6 TINE 8 IN

HARROW ASSEMBLY

9 TINE 8 IN

HARROW ASSEMBLY

2-10 F-605-0313 Edition

Figure 2-7: 4 Row Coil Tine Harrow Placement (38' Model)

(Left Half)

STANDARD SPECIFICATIONS

13

10-7/16

5 TINE 8 IN

HARROW ASSEMBLY

9 TINE 8 IN

HARROW ASSEMBLY

6 TINE 8 IN

HARROW ASSEMBLY

3

13-1/4

5-7/16

3

7-1/4

20

9-7/16

16

Figure 2-8: 4 Row Coil Tine Harrow Placement (38’ Model)

(Right Half)

2-11

STANDARD SPECIFICATIONS

5

11-1/4

3

8-7/16

13

7-1/4

8

7-7/16

13

7-1/4

6 TINE 8 IN

HARROW ASSEMBLY

6 TINE 8 IN

HARROW ASSEMBLY

10 TINE 8 IN

HARROW ASSEMBLY

Figure 2-9: 4 Row Coil Tine Harrow Placement (42' Model)

(Left Half)

2-12 F-605-0313 Edition

STANDARD SPECIFICATIONS

5

14-7/16

6 TINE 8 IN

HARROW ASSEMBLY

10 TINE 8 IN

HARROW ASSEMBLY

6 TINE 8 IN

HARROW ASSEMBLY

3

5-1/4

10-7/16

8

4-1/4

13

10-7/16

13

Figure 2-10: 4 Row Coil Tine Harrow Placement (42’ Model)

(Right Half)

2-13

STANDARD SPECIFICATIONS

17

3-1/4

5

12-7/16

20

6-1/4

6

5-7/16

13

7-1/4

6 TINE 8 IN

HARROW ASSEMBLY

7 TINE 8 IN

HARROW ASSEMBLY

10 TINE 8 IN

HARROW ASSEMBLY

2-14 F-605-0313 Edition

Figure 2-11: 4 Row Coil Tine Harrow Placement (46' Model)

(Left Half)

STANDARD SPECIFICATIONS

17

6-7/16

13

10-7/16

8

4-1/4

16

5-7/16

5

9-1/4

10 TINE 8 IN

HARROW ASSEMBLY

7 TINE 8 IN

HARROW ASSEMBLY

6 TINE 8 IN

HARROW ASSEMBLY

Figure 2-12: 4 Row Coil Tine Harrow Placement (46’ Model)

(Right Half)

2-15

STANDARD SPECIFICATIONS

5

11-1/4

5

12-7/16

20

6-1/4

6

5-7/16

13

7-1/4

8 TINE 8 IN

HARROW ASSEMBLY

7 TINE 8 IN

HARROW ASSEMBLY

10 TINE 8 IN

HARROW ASSEMBLY

2-16 F-605-0313 Edition

Figure 2-13: 4 Row Coil Tine Harrow Placement (50' Model)

(Left Half)

STANDARD SPECIFICATIONS

5

14-7/16

8 TINE 8 IN

HARROW ASSEMBLY

10 TINE 8 IN

HARROW ASSEMBLY

7 TINE 8 IN

HARROW ASSEMBLY

5

9-1/4

16

5-7/16

8

4-1/4

13

10-7/16

Figure 2-14: 4 Row Coil Tine Harrow Placement (50’ Model)

(Right Half)

2-17

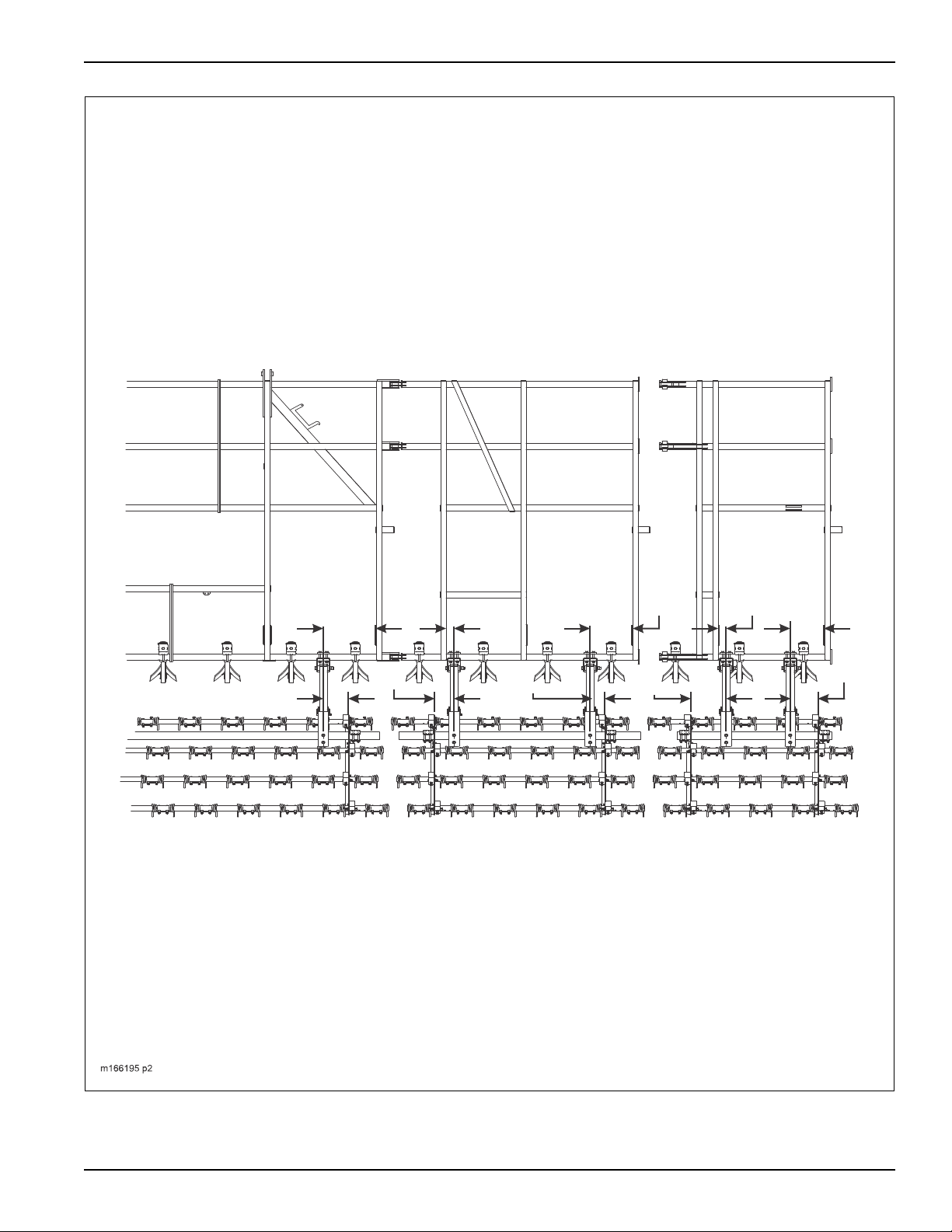

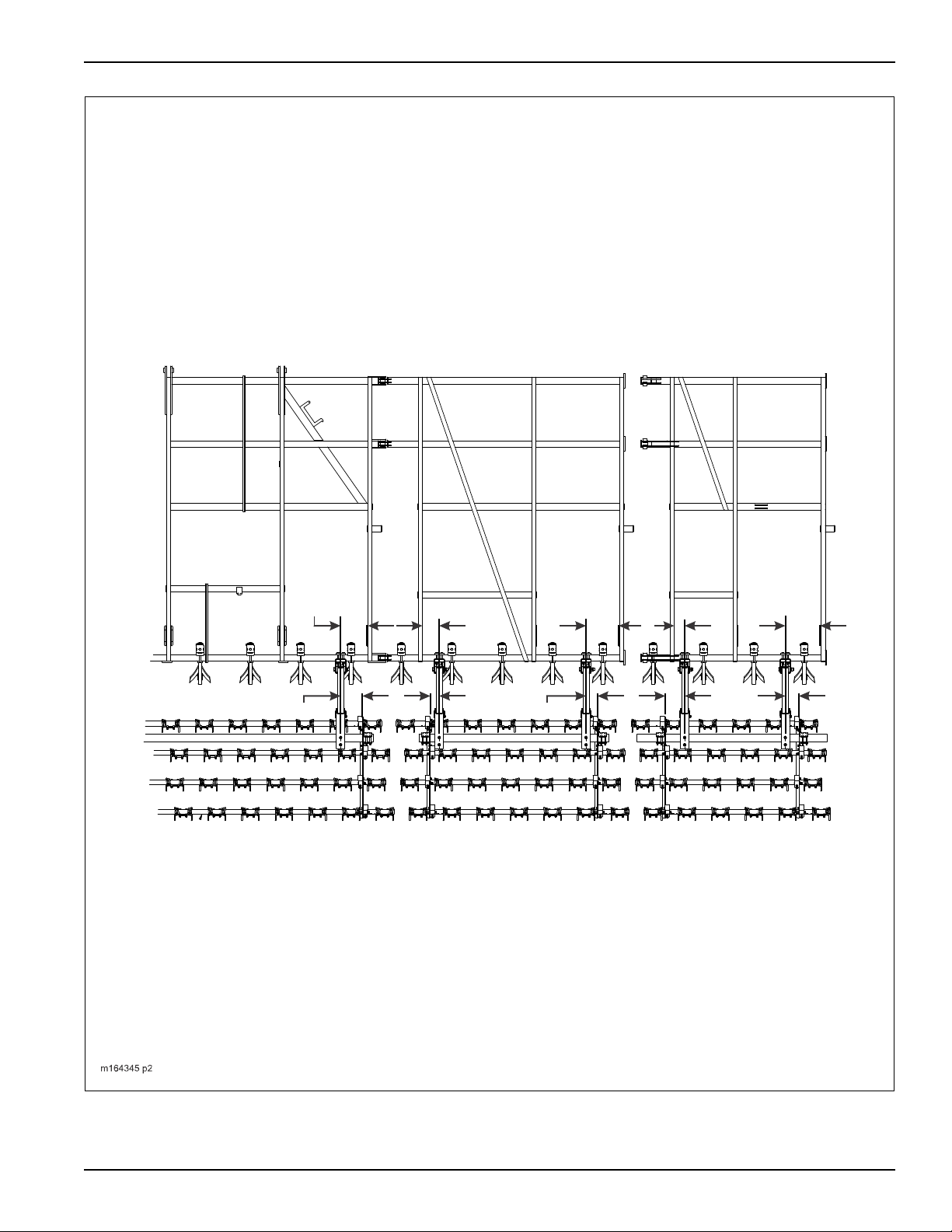

STANDARD SPECIFICATIONS

3-5/8

2-1/4

6

14

8 TOOTH SPIKE

HARROW ASSEMBLY

1 1 TOOTH SPIKE

HARROW ASSEMBLY

17 TOOTH SPIKE

HARROW ASSEMBLY

2-3/4

25-3/4

11TH HOLE

9TH HOLE

7TH HOLE*

10TH HOLE

8TH HOLE

9TH HOLE

11TH HOLE

13TH HOLE

10TH HOLE

12TH HOLE*

10TH HOLE

8TH HOLE

6TH HOLE

9TH HOLE

7TH HOLE*

10TH HOLE

12TH HOLE*

14TH HOLE

11TH HOLE

13TH HOLE

14TH HOLE

12TH HOLE*

10TH HOLE

13TH HOLE

11TH HOLE

* DENOTES USE OF BAR CLAMP W/ TABS

(P/N 166152)

CA TCH TRAY

HOOK

CA TCH TRAY

NOTE: FOR PROPER SPIKE HARROW PLACEMENT,

BE SURE TO COUNT BOTH ROUND AND SQUARE

(SPIKE) HOLES.

Figure 2-15: 5 Row Spike Harrow Placement (38' Model)

2-18 F-605-0313 Edition

(Left Half)

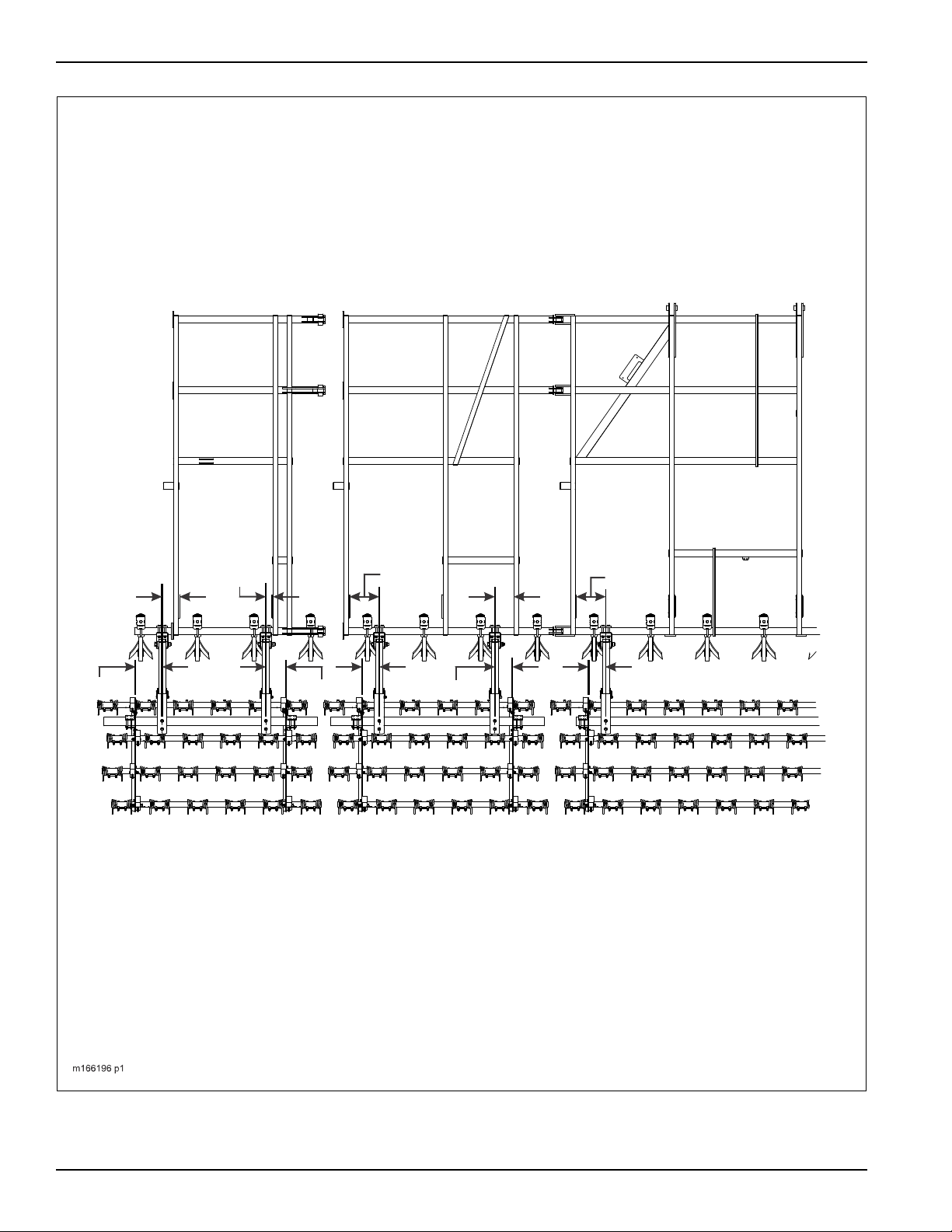

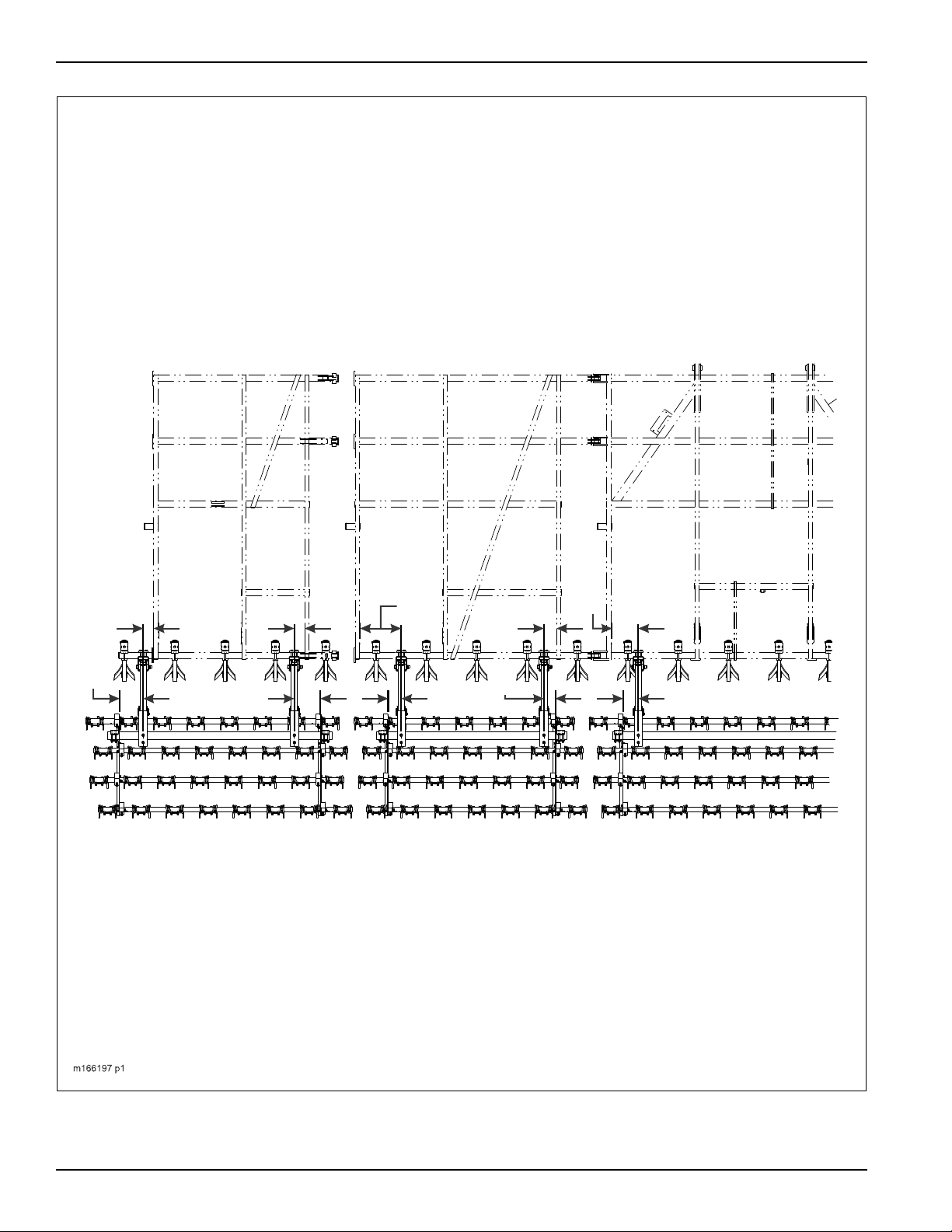

STANDARD SPECIFICATIONS

3-5/8

2-1/4

6

14

8 TOOTH SPIKE

HARROW ASSEMBLY

1 1 T OOTH SPIKE

HARROW ASSEMBLY

17 TOOTH SPIKE

HARROW ASSEMBLY

2-3/4

25-3/4

10TH HOLE

12TH HOLE*

14TH HOLE

11TH HOLE

13TH HOLE

14TH HOLE

12TH HOLE*

10TH HOLE

13TH HOLE

11TH HOLE

6TH HOLE

8TH HOLE

10TH HOLE

7TH HOLE*

9TH HOLE

13TH HOLE

11TH HOLE

9TH HOLE

12TH HOLE*

10TH HOLE

7TH HOLE*

9TH HOLE

11TH HOLE

8TH HOLE

10TH HOLE

* DENOTES USE OF BAR CLAMP W/ TABS

(P/N 166152)

CA TCH TRAY

HOOK

CA TCH TRAY

NOTE: FOR PROPER SPIKE HARROW PLACEMENT,

BE SURE TO COUNT BOTH ROUND AND SQUARE

(SPIKE) HOLES.

Figure 2-16: 5 Row Spike Harrow Placement (38’ Model)

(Right Half)

2-19

STANDARD SPECIFICATIONS

8-3/4

2-1/4

7-3/4

14

17 TOOTH SPIKE

HARROW ASSEMBL Y

11 TOOTH SPIKE

HARROW ASSEMBLY

10 TOOTH SPIKE

HARROW ASSEMBLY

2-3/4

25-3/4

13TH HOLE

11TH HOLE

9TH HOLE

12TH HOLE*

10TH HOLE

9TH HOLE

11TH HOLE

13TH HOLE

10TH HOLE

12TH HOLE*

10TH HOLE

8TH HOLE

6TH HOLE

9TH HOLE

7TH HOLE*

11TH HOLE

13TH HOLE

15TH HOLE

12TH HOLE*

14TH HOLE

14TH HOLE

12TH HOLE*

10TH HOLE

13TH HOLE

11TH HOLE

* DENOTES USE OF BAR CLAMP W/ TABS

(P/N 166152)

NOTE: FOR PROPER SPIKE HARROW PLACEMENT,

BE SURE TO COUNT BOTH ROUND AND SQUARE

(SPIKE) HOLES.

Figure 2-17: 5 Row Spike Harrow Placement (42' Model)

2-20 F-605-0313 Edition

(Left Half)

STANDARD SPECIFICATIONS

8-3/4

2-1/4

7-3/4

14

10 TOOTH SPIKE

HARROW ASSEMBLY

1 1 T OOTH SPIKE

HARROW ASSEMBL Y

17 TOOTH SPIKE

HARROW ASSEMBLY

2-3/4

25-3/4

10TH HOLE

12TH HOLE*

14TH HOLE

11TH HOLE

13TH HOLE

15TH HOLE

13TH HOLE

11TH HOLE

14TH HOLE

12TH HOLE*

6TH HOLE

8TH HOLE

10TH HOLE

7TH HOLE*

9TH HOLE

13TH HOLE

11TH HOLE

9TH HOLE

12TH HOLE*

10TH HOLE

9TH HOLE

11TH HOLE

13TH HOLE

10TH HOLE

12TH HOLE*

* DENOTES USE OF BAR CLAMP W/ TABS

(P/N 166152)

NOTE: FOR PROPER SPIKE HARROW PLACEMENT,

BE SURE TO COUNT BOTH ROUND AND SQUARE

(SPIKE) HOLES.

Figure 2-18: 5 Row Spike Harrow Placement (42’ Model)

(Right Half)

2-21

Loading...

Loading...