Landoll 5531 User Manual

Model 5531

Grain Drill

Operator’ s Manual

LANDOLL CORPORATION

1900 North Street

Marysville, Kansas 66508

(785) 562-5381

800-428-5655 ~ WWW.LANDOLL.COM

F-716-1213 12/2013

1-2 f-716-1213 Edition

1 Introduction

Understanding Safety Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 Standard Specifications

3 Assembly Instructions

Press Wheel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Small Seed Attachment Installation (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4 Operation and Maintenance

Tractor Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Grain Drill Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table of Contents

Attaching Grain Drill To The Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Transport Locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Folding/Unfolding the Grain Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Leveling the Hitch Clevis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Leveling the Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Transporting the Grain Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Compressor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Air System Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Openers – Hydraulic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Hydraulic Lift System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Loup II Drill Monitor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Seed Meter Gate Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Seed Rate Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Meter/Seed Rate Handle Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Seed Rate Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Dry Fertilizer Combination Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Fertilizer Box – Clean Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Fertilizer – Rate Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Fertilizer – Rate Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Small Seed Rate Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

F-716-1213 Edition i

Small Seed Meter Assembly/Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Air Spring Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Opener Blade Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Opener – Press Wheel Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Opener Scraper Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Opener Soil Strip Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Drive Shaft – Coupler Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Walkboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Ladder Use and Transport Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Hydraulic Row Markers (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Hydraulic Row Marker Disc Adjustment (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

5531 Point Row Clutch (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Wheel Bearing Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Hydraulic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Hose Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Lubrication Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

5 Troubleshooting Guide

ii F-716-1213 Edition

Chapter 1

Introduction

The Landoll Model 5531 Grain Drill is a quality product designed to give years of trouble free performance. By

following each section of this manual, your system will perform as designed for you and your operation

CHAPTER 1 gives basic instructions on the use of this manual.

CHAPTER 2 gives product specifications. These specifications supply lengths and measures for your

equipment. A S tandard Bolt Torque Table is provided to give guidelines for bolt to rques to

be used when servicing this product.

CHAPTER 3 contains assembly instructions for your Model 5531 Grain Drill. When these procedures

are correctly followed, your equipment should provide you years of trouble-free operation

and service.

CHAPTER 4 instructs how to operate your equipment before using it, and describes adjustments

needed. It also gives practical advice for the care and maintenance of your Landoll

equipment. Drawings in this section locate adjustment points on the equipment.

NOTE: IF THE EQUIPMENT IS IMPROPERLY ASSEMBLED OR MAINTAINED, THE

WARRANTY IS VOID. IF YOU HAVE ANY QUESTIONS CONTACT:

LANDOLL CORPORATION

1900 NORTH STREET

MARYSVILLE, KANSAS 66508

or phone:

(785) 562-5381 or

(800) 428-5655

or FAX:

(888) 527-3909

CHAPTER 5 is a troubleshooting guide to aid in diagnosing and solving problems with the equipment.

PARTS LIST is a separate manual showing the various assemblies, subassemblies, and systems.

Refer to that manual when ordering Landoll replacement parts. Order parts from your

Landoll dealer.

WARRANTY The Warranty Registration form is included with the product documents. Fill it out and

mail it within 15 days of purchase

NOTE: IMPROPER ASSEMBLY, MODIFICATION, OR MAINTENANCE OF YOUR

LANDOLL MACHINE CAN VOID YOUR WARRANTY.

COMMENTS Address comments or questions regarding this publication to:

LANDOLL CORPORATION

1900 NORTH STREET

MARYSVILLE, KANSAS 66508

ATTENTION: PUBLICATIONS -DEPT. 55

1-1

INTRODUCTION

DANGER

WARNING

CAUTION

NOTE

NOTE

Understanding Safety Statements

You will find various types of safety information on the

following pages and on the machine signs (decals)

attached to the vehicle. This section explains their

meaning.

The Safety Alert Symbol means ATTENTION! YOUR

SAFETY IS INVOLVED!

Danger means a life-threatenin g sit ua ti on ex is ts.

Death can occur if safety measures or

instructions on this label are not properly

followed.

Warning means serious injury or death can occur

if safety measures or instructions on this label

are not properly followed.

Caution means serious equipment or other

property damage can occur if instruction s on this

label are not properly followed.

Means that failure to follow these instructions could

cause damage to the equipment or cause it to operate

improperly.

Make sure you read and understand the informatio n

contained in this manual and on the machine signs

(decals) before you attempt to operate or maintain this

vehicle.

The safety statements contai ned in this manual relate to

the operation of the Model 5531 Grain Drill.

1-2 F-716-1213 Edition

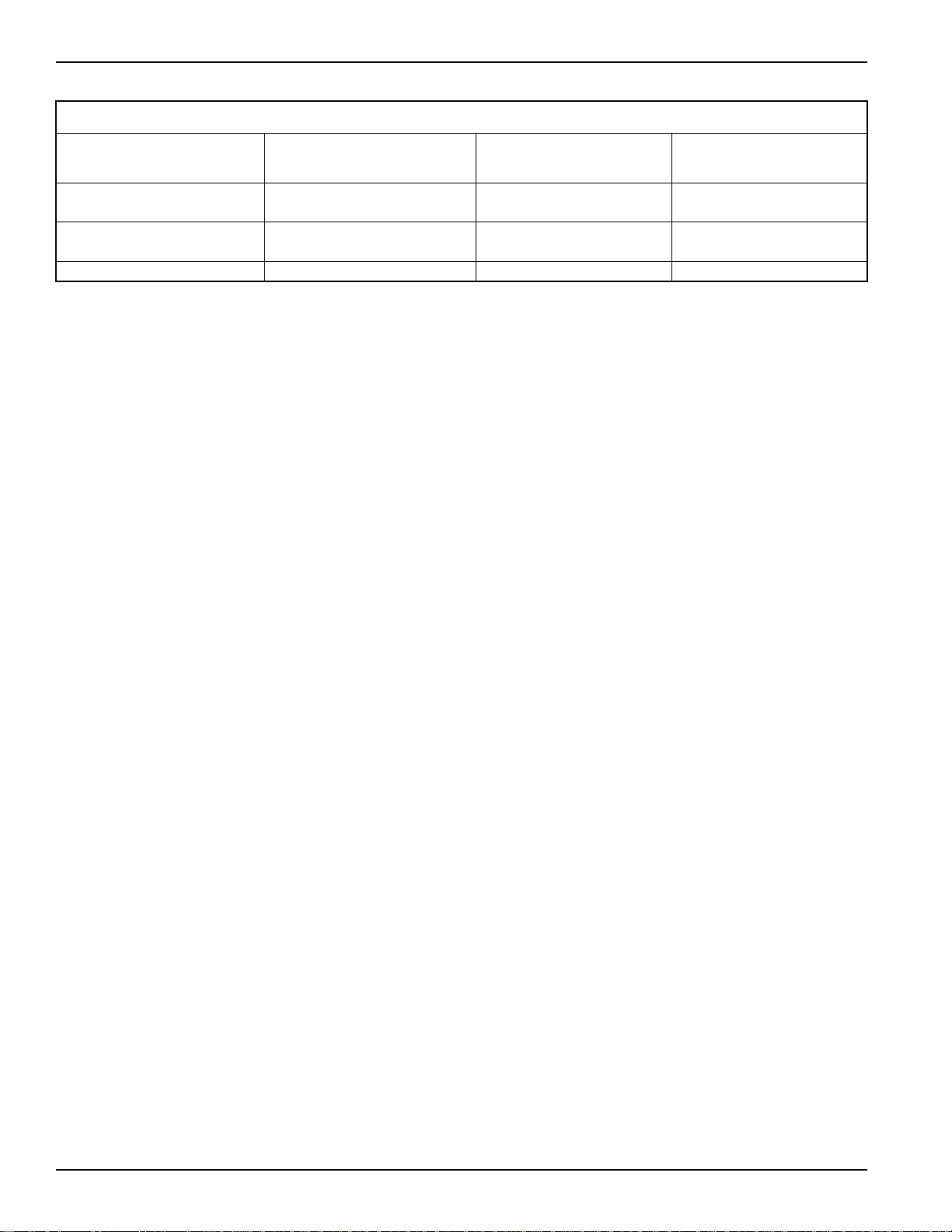

Standard Specifications

5531 SERIES GRAIN DRILL

Chapter 2

MODEL

NUMBER

5531-30X7.5

5531-30X10

5531-40X7.5

5531-40X10

Specifications are subject to change withou t prior notification.

MODEL

NUMBER

5531-30X7.5

5531-30X10

5531-40X7.5

5531-40X10

Specifications are subject to change withou t prior notification.

WORKING

WIDTH

30’-0” 7-1/2” 48 14’-6” (4) 380/55R 16.5

30’-0” 10” 36 14’-6” 17,010

40’-0” 7-1/2” 64 14’-6” 24,560

40’-0” 10” 48 14’-6” 22,640

WORKING

WIDTH

30’-0” 7-1/2” 48 14’-6” (4) 380/55R 16.5

30’-0” 10” 36 14’-6” 17,500

40’-0” 7-1/2” 64 14’-6” 24,560

40’-0” 10” 48 14’-6” 22,560

ROW

SPACING

5531 SERIES GRAIN DRILL W/ FERTILIZER

ROW

SPACING

NO. OF

OPENERS

NO. OF

OPENERS

TRANSPORT

TRANSPORT

WIDTH

WIDTH

TIRE AND

WHEELS

(frame)

(4) 11L -15,

12 ply - 6 bolt (wing)

TIRE AND

WHEELS

(frame)

(4) 11L -15,

12 ply - 6 bolt (wing)

ESTIMATED

WEIGHT (LBS.)

18,450

ESTIMATED

WEIGHT (LBS.)

18,990

5531 SERIES GRAIN DRILL W/ SMALL GRASS SEED

MODEL

NUMBER

5531-30X7.5

5531-40X7.5

Specifications are subject to change withou t prior notification.

WORKING

WIDTH

30’-0” 7-1/2” 48 15 ’-6 ” (4) 380/55R 16.5

40’-0” 7-1/2” 64 15’-6” 24,560

ROW

SPACING

NO. OF

OPENERS

TRANSPORT

WIDTH

TIRE AND

WHEELS

(frame)

(4) 11L -15,

12 ply - 6 bolt (wing)

ESTIMATED

WEIGHT (LBS.)

18,990

2-1

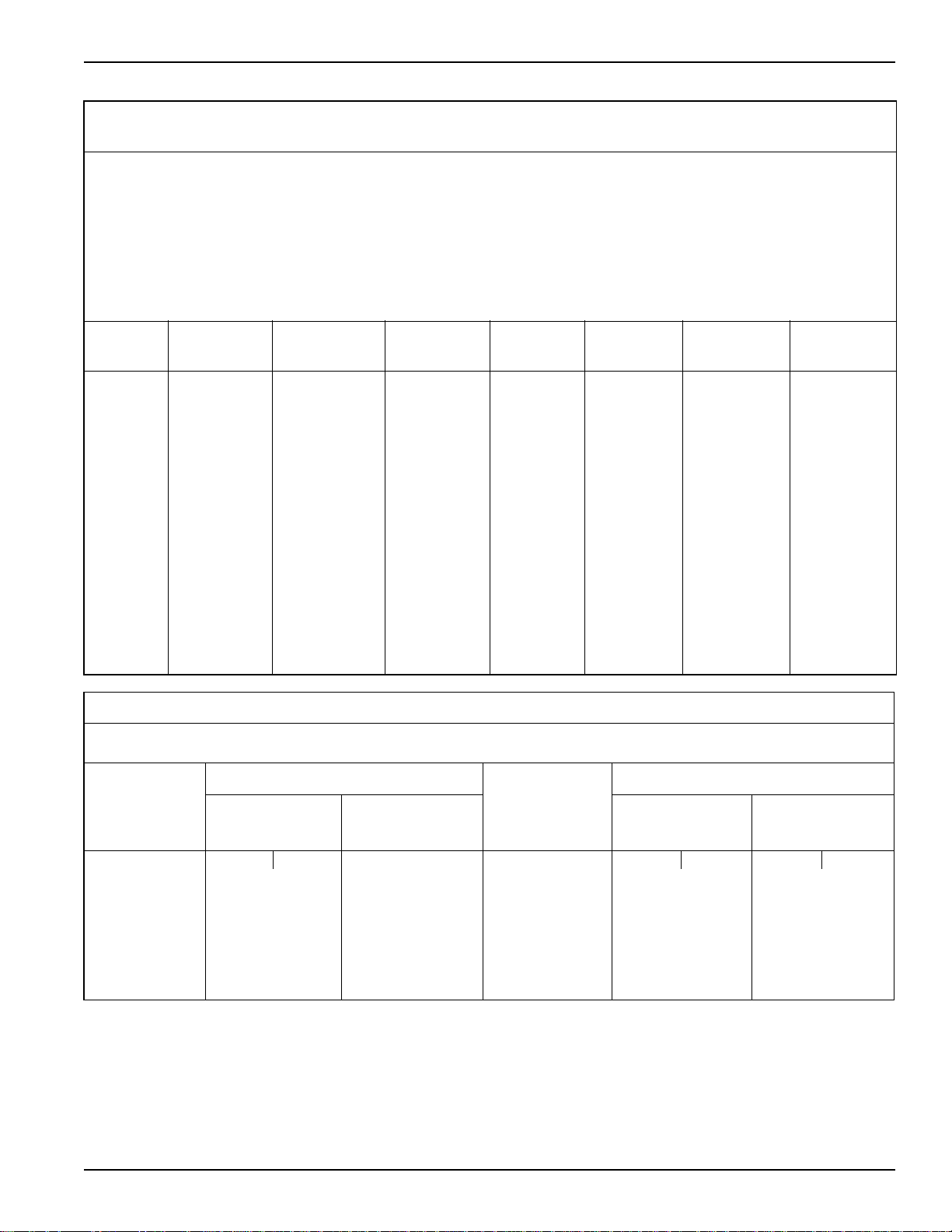

STANDARD SPECIFICATIONS

TIRE INFLATION

TIRE

SIZE

380/55R 16.5 Goodyear 150A8/B 7400 lbs. @30

380/60R 16.5 Goodyear 150A8/B 7400 lbs. @30

11L x 15 Goodyear 12 Ply/3860 lbs 52 psi

MANUFACTURER

TIRE

mph

mph

PLY/LOAD

RATING

INFLATION PRESSURE

74 psi

73 psi

(psi) (max.)

2-2 F-716-1213 Edition

STANDARD SPECIFICATIONS

LANDOLL CORPORATION

GENERAL TORQUE SPECIFICATIONS (REV. 4/97)

THIS CHART PROVIDES TIGHTENING TORQUES FOR GENERAL PURPOSE APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED ON PROCESS

OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED NUTS AND CAPSCREWS ASSEMBLED WITHOUT SUPPLEMENTAL LUBRICATIO N (AS RECEIVED CONDITION).

THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE LUBRICANTS ARE USED.

WHEN FASTENERS ARE DRY (SOLVENT CLEANED), ADD 33% TO AS RECEIVED CONDITION TORQUE.

BOLT HEAD IDENTIFICATION MARKS INDICATE GRADE AND MAY VAR Y FROM MANUFACTURER TO MANUFACTURER.

THICK NUTS MUST BE USED ON GRADE 8 CAPSCREWS.

USE VALUE IN [ ] IF USING PREVAILING TORQUE NUTS.

TORQUE IS SPECIFIED IN FOOT POUNDS

UNC

Size

SAE Grade2SAE Grade5SAE Grade

8

UNF

Size

SAE Grade 2SAE Grade5SAE Grade

8

1/4-20 4 [5] 6 [7] 9 [11] 1/4-28 5 [6] 7 [9] 10 [12]

5/16-18 8 [10] 13 [16] 18 [22] 5/16-24 9 [11] 14 [17] 20 [25]

3/8-16 15 [19] 23 [29] 35 [43] 3/8-24 17 [21] 25 [31] 35 [44]

7/16-14 24 [30] 35 [43] 55 [62] 7/16-20 27 [34] 40 [50] 60 [75]

1/2-13 35 [43] 55 [62] 80 [100] 1/2-20 40 [50] 65 [81] 90 [112]

9/16-12 55 [62] 80 [100] 1 1 0 [137] 9/16-18 60 [75] 90 [112] 130 [162]

5/8-11 75 [94] 110 [137] 170 [212] 5/8-18 85 [106] 130 [162] 180 [225]

3/4-10 130 [162] 200 [250] 280 [350] 3/4-16 150 [188] 220 [275] 320 [400]

7/8-9 125 [156] 320 [400] 460 [575] 7/8-14 140 [175] 360 [450] 500 [625]

1-8 190 [237] 408 [506] 680 [850] 1-14 210 [263] 540 [675] 760 [950]

1-1/8-7 270 [337] 600 [750] 960 [1200] 1-1/8-12 300 [375] 660 [825] 1080 [1350]

1-1/4-7 380 [475] 840 [1050] 1426 [1782] 1-1/4-12 420 [525] 920 [1150] 1500 [1875]

1-3/8-6 490 [612] 110 [1375] 1780 [2225] 1-3/8-12 560 [700] 1260 [1575] 2010 [2512]

1-1/2-6 650 [812] 1460 [1825] 2360 [2950] 1-1/2-12 730 [912] 1640 [2050] 2660 [3325]

1-3/4-5 736 [920] 1651 [2063] 2678 [3347] 1-3/4-12 920 [1150] 2063 [2579] 3347 [4183]

METRIC

COARSE THREAD METRIC CLASS 10.9 FASTENERS AND CLASS 10.0 NUTS AND THROUGH HARDENED FLAT WASHERS, PHOSPHATE COATED, ROCKWELL

“C” 38-45.

USE VALUE IN [ ] IF USING PREVAILING TORQUE NUTS.

Nominal

Thread

Diameter

mm

Standard Torque Nominal

Newton-

Meters

Foot-

Pounds

Thread

Diameter

mm

Standard Torque

Newton-

Meters

Foot-

Pounds

6 10 [14] 7 [10] 20 385 [450] 290 [335]

7 16 [22] 12 [16] 24 670 [775] 500 [625]

8 23 [32] 17 [24] 27 980 [1105] 730 [825]

10 46 [60] 34 [47] 30 1330 [1470] 990 [1090]

12 80 [101] 60 [75] 33 1790 [1950] 1340 [1450]

14 125 [155] 90 [115] 36 2325 [2515] 1730 [1870]

16 200 [240] 150 [180] 39 3010 [3210] 2240 [2380]

18 275 [330] 205 [245]

Table 2-1: General Torque Specifications

2-3

STANDARD SPECIFICATIONS

LANDOLL CORPORATION

HYDRAULIC FITTING TORQUE SPECIFICATIONS

THIS CHART PROVIDES TIGHTENING TORQUES FOR HYDRAULIC FITTING APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED ON PROCESS

OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED CARBON STEEL AND STAINLESS STEEL FITTINGS ASSEMBLED WITHOUT SUPPLEMENTAL LUBRICATION (AS

RECEIVED CONDITION). THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE LUBRICANTS ARE USED.

BRASS FITTINGS AND ADAPTERS - 65% OF THE TORQUE VALUE FOR STEEL. STAINLESS STEEL, ALUMINUM AND MONEL - THREADS ARE TO BE

LUBRICATED

.

TORQUE IS SPECIFIED IN FOOT POUNDS

Dash Size 37 Degree JIC O-Ring (ORS) O-Ring Boss (ORB)

-4 11-13 15-17 13-15

-5 14-16 — 21-23

-6 20-22 34-36 25-29

-8 43-47 58-62 40-44

-10 55-65 100-110 57.5-62.5

-12 80-90 134-146 75-85

-16 115-125 202-218 109-121

-20 160-180 248-272 213-237

-24 185-215 303-327 238-262

-32 250-290 — 310-340

o

37

JIC, ORS, & ORB (REV. 10/97)

PARKER BRAND FITTINGS

GATES BRAND FITTINGS

Dash Size 37 Degree JIC O-Ring (ORS) O-Ring Boss (ORB)

-4 10-11 10-12 14-16

-5 13-15 — —

-6 17-19 18-20 24-26

-8 34-38 32-40 37-44

-10 50-56 46-56 50-60

-12 70-78 65-80 75-83

-14 — 65-80 —

-16 94-104 92-105 111-125

-20 124-138 125-140 133-152

-24 156-173 150-180 156-184

-32 219-243 — —

AEROQUIP BRAND FITTINGS

Dash Size 37 Degree JIC O-Ring (ORS) O-Ring Boss (ORB)

-4 11-12 10-12 14-16

-5 15-16 — 18-20

-6 18-20 18-20 24-26

-8 38-42 32-35 50-60

-10 57-62 46-50 72-80

-12 79-87 65-70 125-135

-14 — — 160-180

-16 108-113 92-100 200-220

-20 127-133 125-140 210-280

-24 158-167 150-165 270-360

-32 245-258 — —

Table 2-2: Hydraulic Fitting Torque Specifications

2-4 F-716-1213 Edition

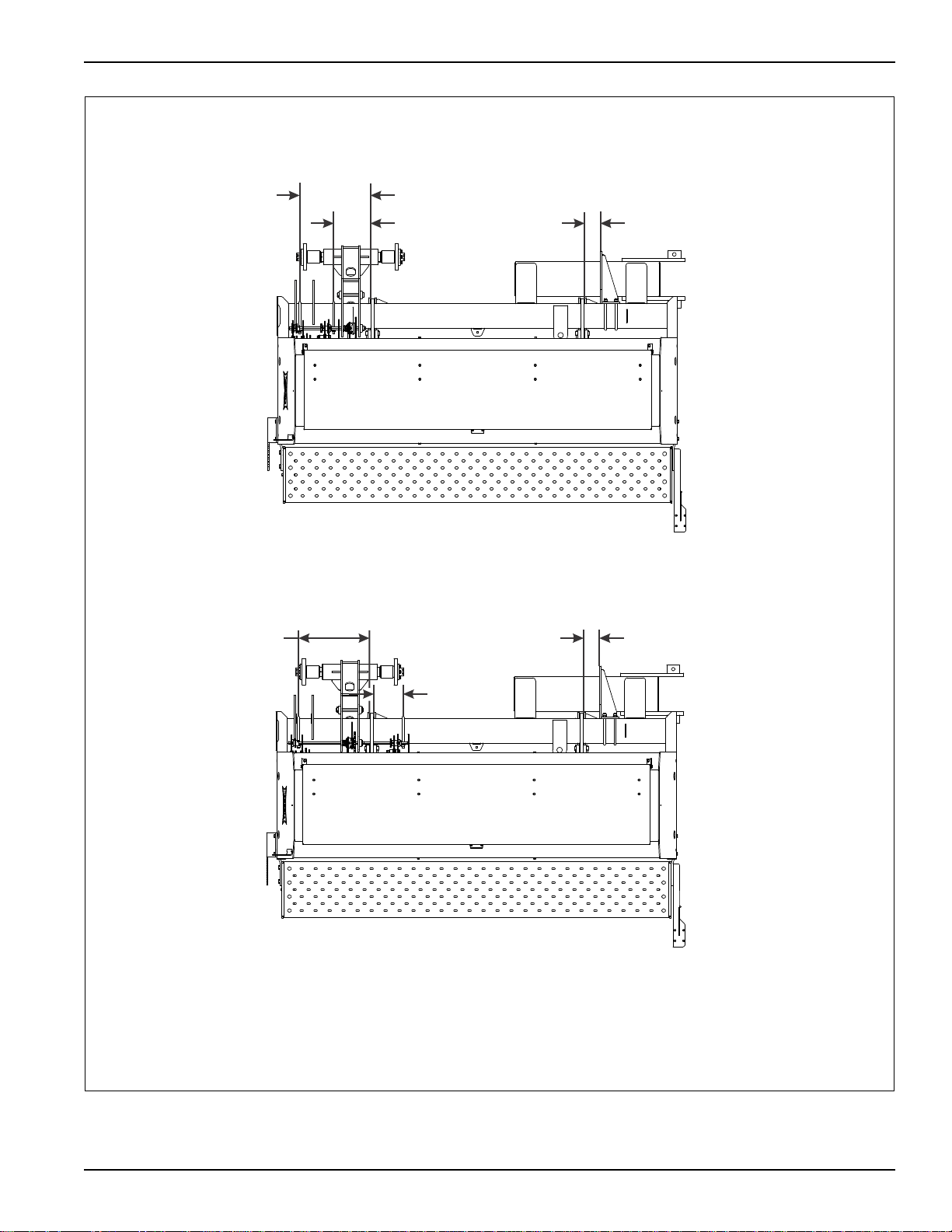

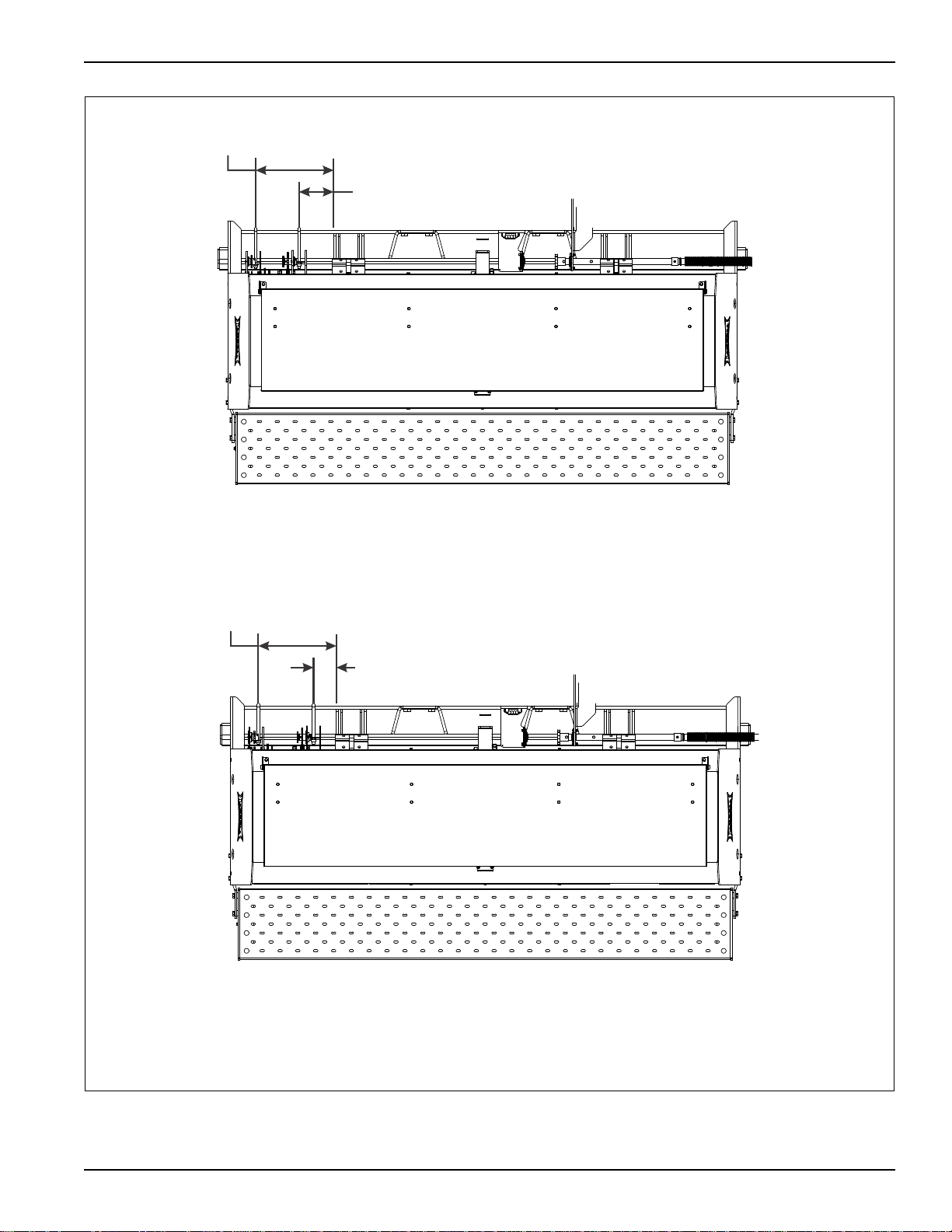

5531-30’

SEED BOX

7-1/2” SPACING

LEFT WING

5531-30’

LEFT WING SEED BOX

10” SPACING

20-3/8

10-5/8

4-5/8

20-3/8

26-1/8

4-5/8

5531-30 left wing

STANDARD SPECIFICATIONS

Figure 2-1: 5531-30 Left Wing Placement

2-5

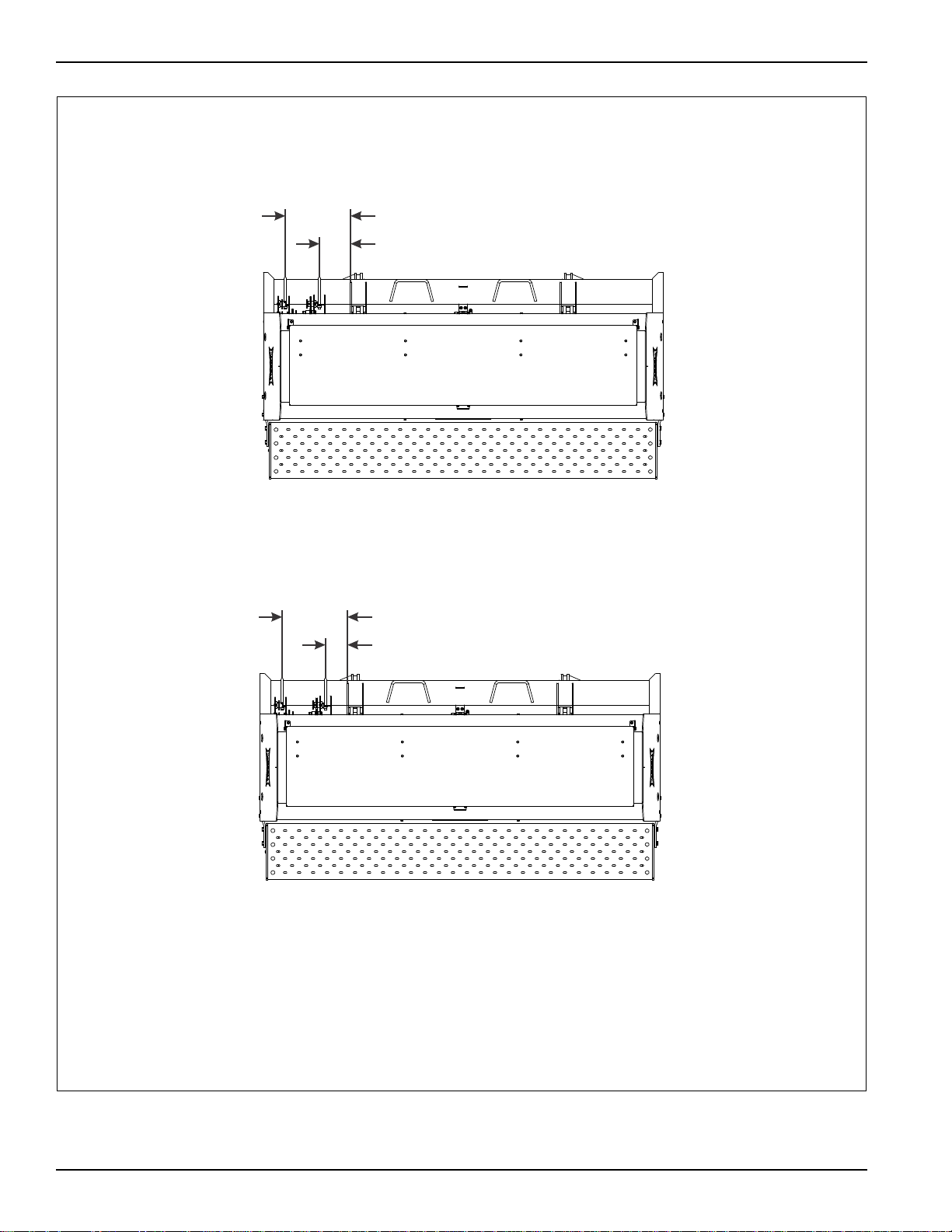

STANDARD SPECIFICATIONS

18-1/2

8-5/8

5531-30’

CENTER SEED BOX

7-1/2” SPACING

5531-30’

CENTER SEED BOX

10” SPACING

18-1/2

5-1/16

5531-30 center

Figure 2-2: 5531-30 Center Placement

2-6 F-716-1213 Edition

STANDARD SPECIFICATIONS

5531-30’

SEED BOX

7-1/2” SPACING

RIGHT WING

5531-30’

RIGHT WING SEED BOX

10” SPACING

21-15/16

4-5/8

10-9/16

18-1/4 22 20-3/8

21-15/16

4-5/8

17-3/4

18-1/4

22

20-3/8

5531-30 right wing

Figure 2-3: 5531-30 Right Wing Placement

2-7

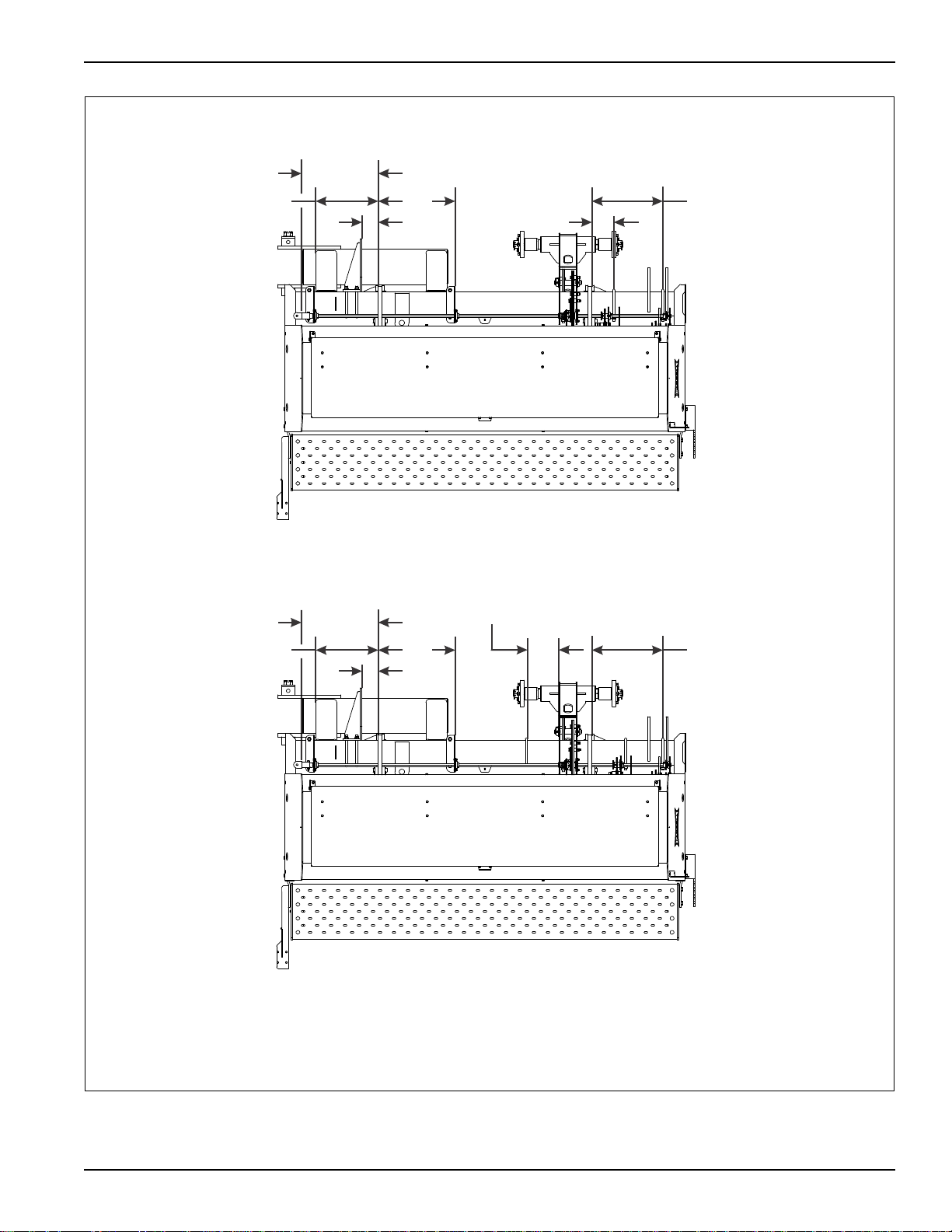

STANDARD SPECIFICATIONS

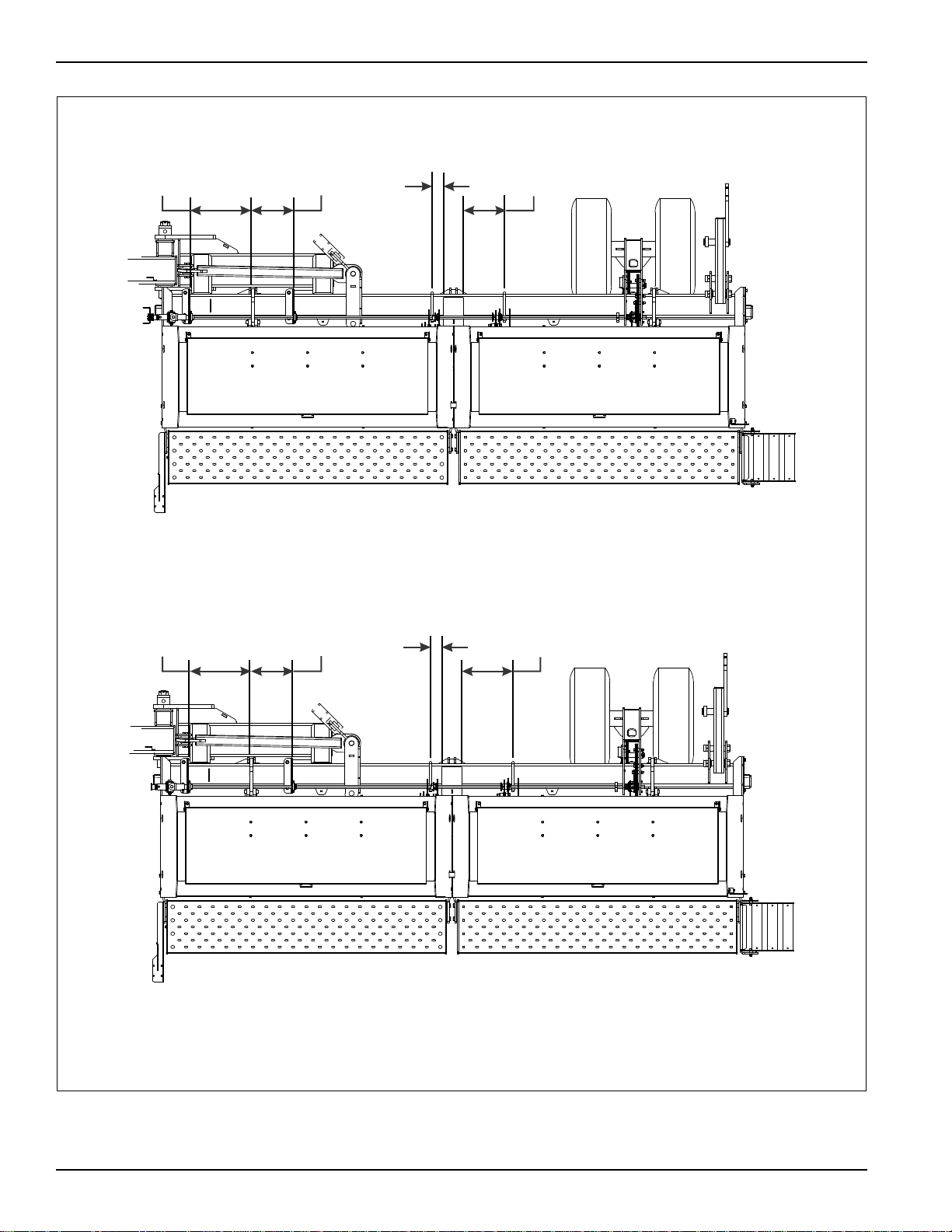

18-1/4

LEFT OUTER

WING SEED BOX

LEFT INNER

WING SEED BOX

5531-40

LEFT WING SEED BOXES

7-1/2” SPACING

21

LEFT OUTER

WING BOXSEED

LEFT INNER

WING BOXSEED

5531-40

LEFT WING SEED BOXES

10” SPACING

5531-40 left wing placement

3-3/8

3-3/8

2-8 F-716-1213 Edition

Figure 2-4: 5531-40 Left Wing Placement

18-1/2

5531-40

CENTER SEED BOX

7-1/2” SPACING

5531-40 center placement

8-5/8

5531-40

CENTER SEED BOX

10” SPACING

18-1/2

5-1/16

STANDARD SPECIFICATIONS

Figure 2-5: 5531-40 Center Placement

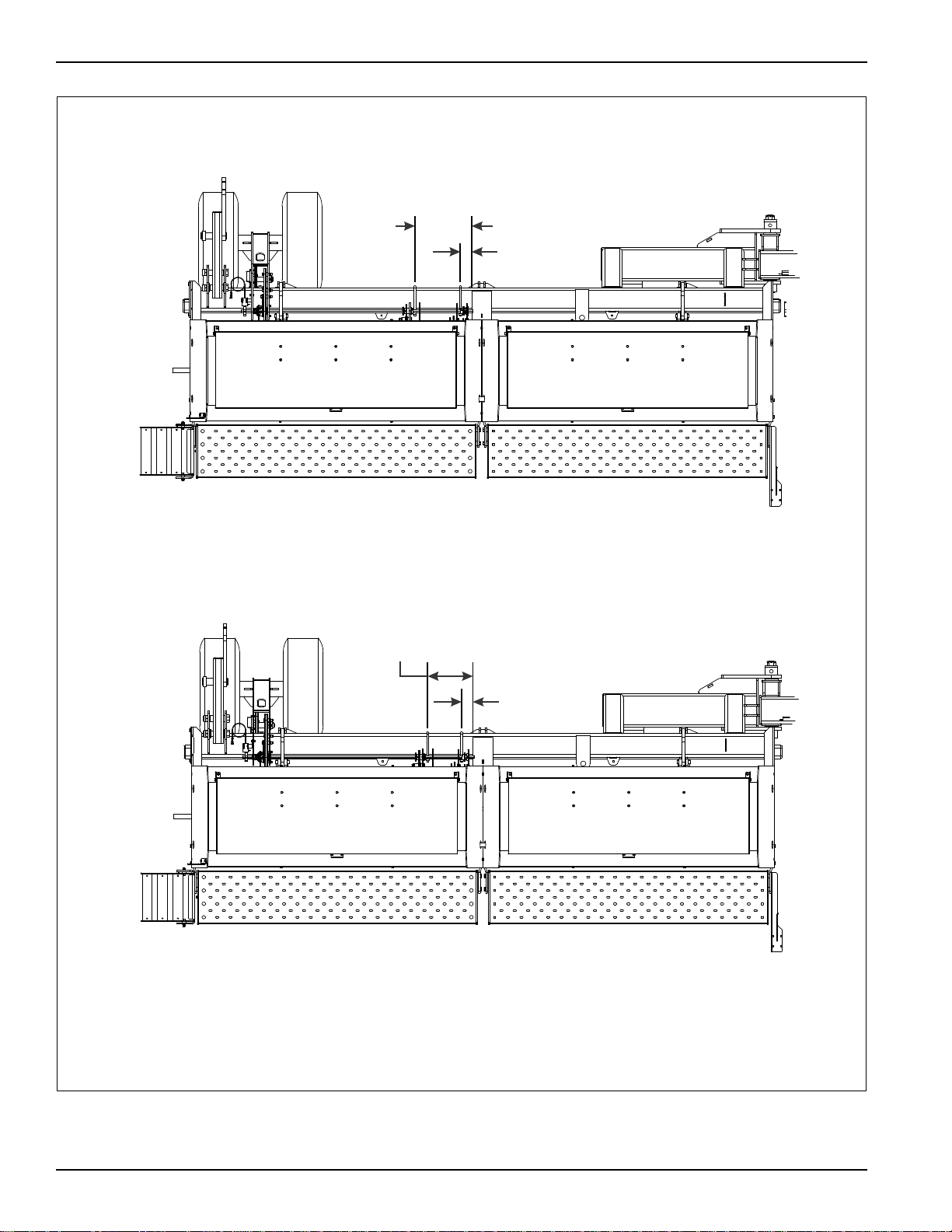

2-9

STANDARD SPECIFICATIONS

18-1/4

12-3/4

3-3/8

13-1/4

RIGHT INNER

WING BOXSEED

RIGHT OUTER

WING BOXSEED

5531-40

RIGHT WING BOXES

7-1/2” SPACING

SEED

18-1/4 12-3/4 3-3/8 16

RIGHT INNER

WING BOXSEED

RIGHT OUTER

WING BOXSEED

5531-40

RIGHT WING BOXES

10” SPACING

SEED

5531-40 right wing placement

2-10 F-716-1213 Edition

Figure 2-6: 5531-40 Right Wing Placement

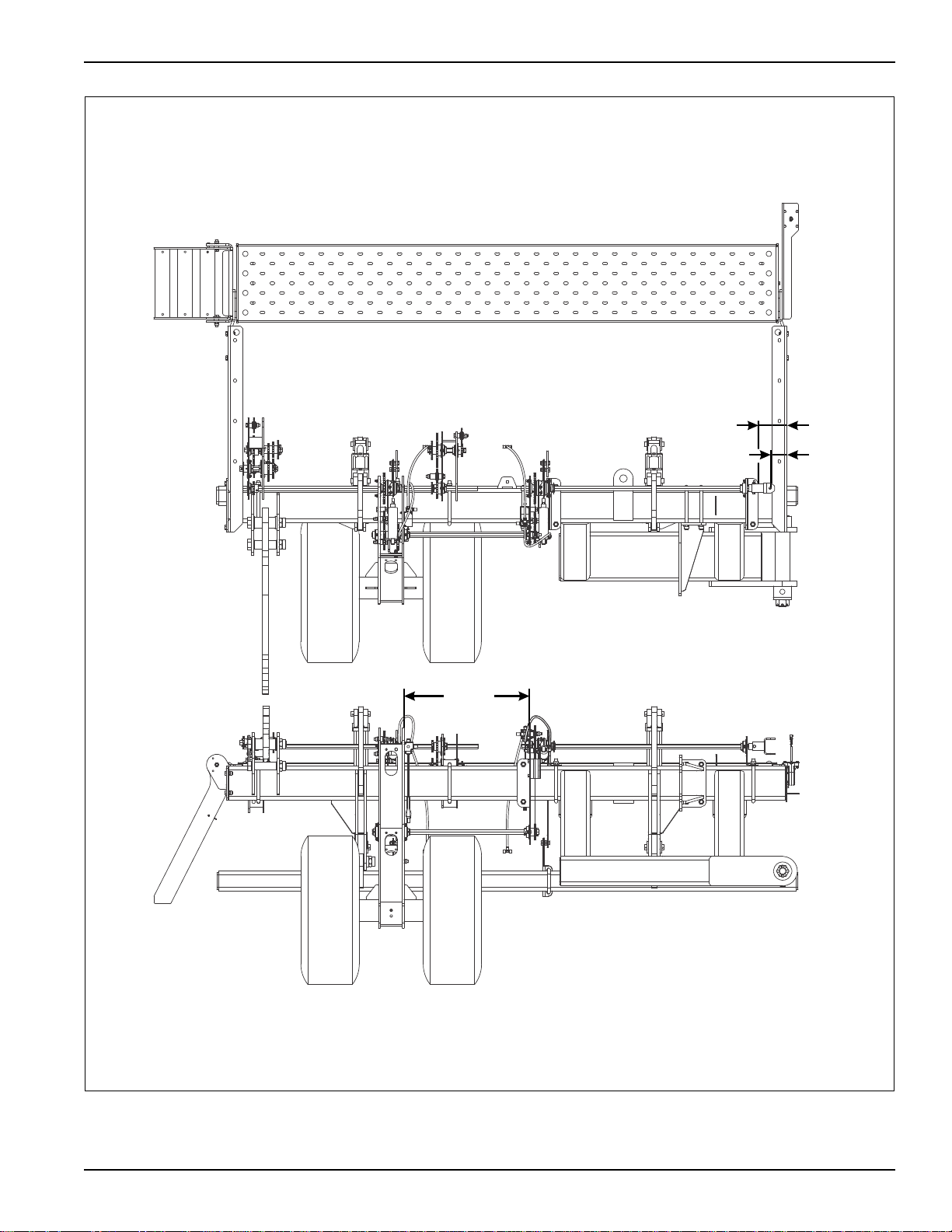

STANDARD SPECIFICATIONS

5-29/32

3-13/32

25-5/8

5531-30 point row clutch placement

Figure 2-7: 5531-30 Point Row Clutch Placement

2-11

STANDARD SPECIFICATIONS

5-29/32

3-13/32

68-13/16

20-7/16

5531-40 point row clutch placement

2-12 F-716-1213 Edition

Figure 2-8: 5531-40 Point Row Clutch Placement

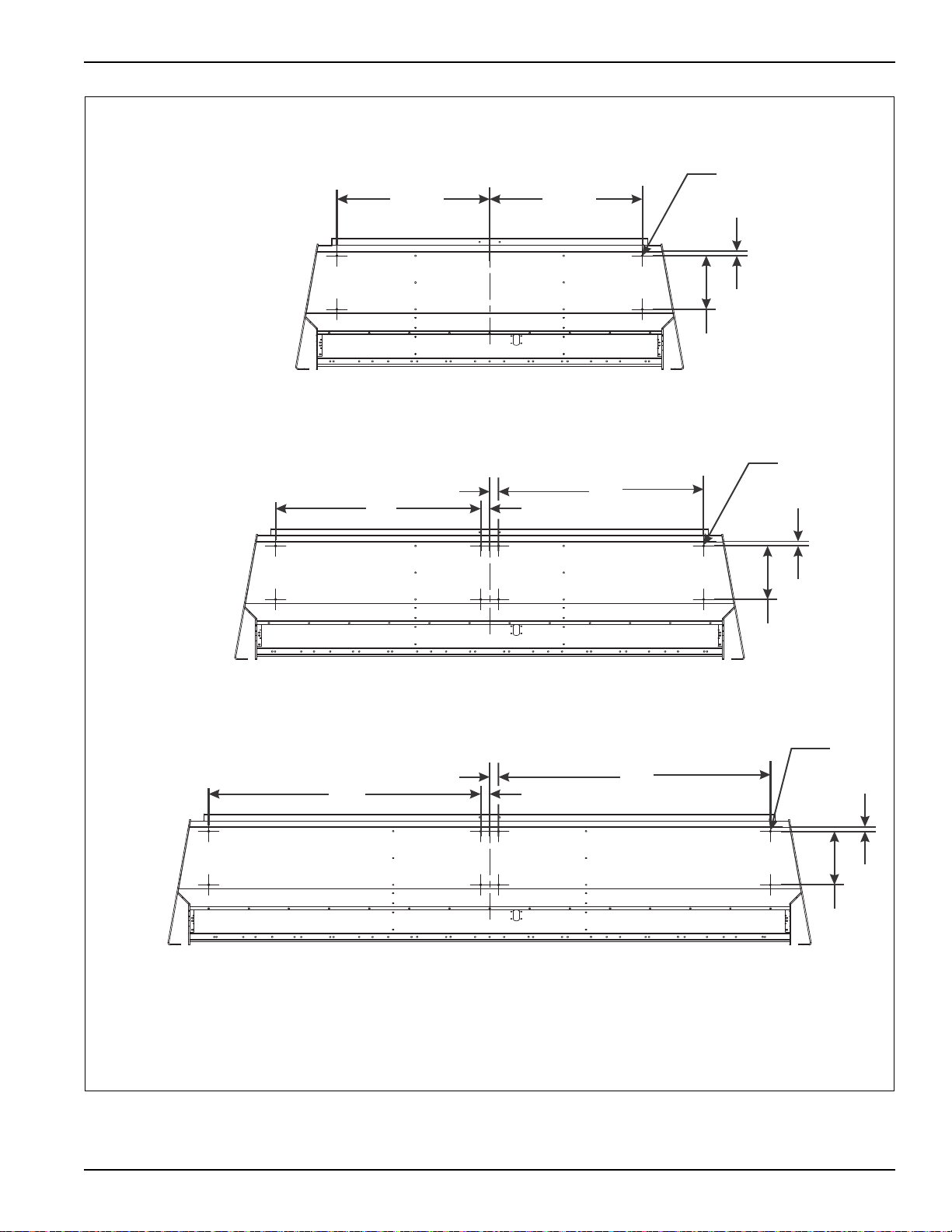

STANDARD SPECIFICATIONS

1

12

34-1/434-1/4

small seed attachment drilling placement

11246

46

2

2

Ø .406

Ø .406

11261

61

2

2

Ø .406

7-1/2’ SEED BOX (P/N 154842)

10’ SEED BOX (P/N 143932)

12-1/2’ SEED BOX (P/N 159102)

Figure 2-9: Small Seed Attachment Drilling Placement

2-13

STANDARD SPECIFICATIONS

Page Intentionally Blank

2-14 F-716-1213 Edition

Your new 5531 Grain Drill comes nearly completely

DANGER

WARNING

DANGER

CAUTION

assembled from the factory and ready to go to the field.

This section includes press wheel and option assembly

procedures.

To insure alignment of assemblies, leave the nuts loose

until completion of final assembly. Use lock washers or

flat washers as specified. Spread all cotter pins.

After completion of final assemb ly, tighten all nuts

evenly to prevent misalignment, distortion or binding.

Tighten all screws and nuts to the recommended torques

(See Table 2-1 on page 2-3.)

Opener blades are extremely sharp. Exercise

extreme care when working on or near opener

blades. Do not allow opener blades to roll over or

fall onto any body part. Do not allow wrenches to

slip when working near blades. Never push

wrenches toward opener blades. Do not climb

over machine above opener blades. Failure to

stay clear of opener blade edges can cause

serious personal injury or death.

Chapter 3

Assembly Instructions

Do not attempt to lift heavy parts (such as the

frame, wheel lift, and pull hitch) manually. Use a

hoist or a forklift to move these parts into

position.

To prevent accidental lowering:

• All hydraulically elevated equipment must be

locked out using the cylinder lockouts.

• Lower equipment to the ground while

servicing or when it is idle.

• Failure to take measures to prevent

accidental lowering may result in serious

personal injury or death.

Be sure to bleed the hydraulic system of all air in

lines after inst allation. Failure to bleed the system

of all air can result in improper machine

operation.

3-1

ASSEMBLY INSTRUCTIONS

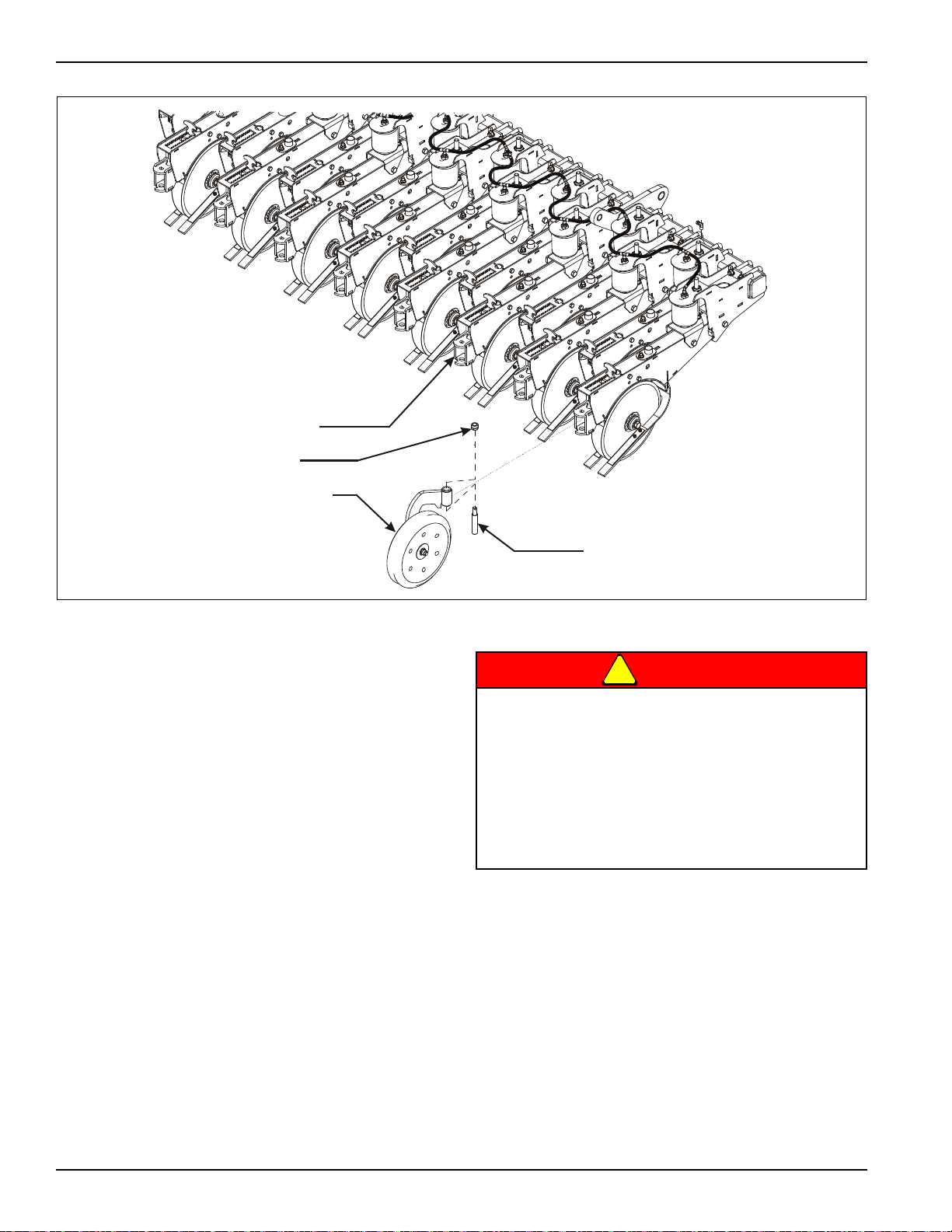

DANGER

press wheel assembly

AIR OPENER ASSEMBLY

3/4-10 HEX LOCK NUT

PRESS WHEEL ASSEMBLY

PRESS WHEEL ARM

PIN

Figure 3-1: Press Wheel Assembly

Press Wheel Assembly

1. Attach each press wheel assembly to each air

opener assembly on the Grain Drill using press

wheel arm pin and 3/4-10 hex lock nut (See

Figure 3-1.)

Opener blades are extremely sharp. Exercise

extreme care when working on or near opener

blades. Do not allow opener blades to roll o ver or

fall onto any body part. Do not allow wrenche s to

slip when working near blades. Never push

wrenches toward opener blades. Do not climb

over machine above opener blades. Failure to

stay clear of opener blade edges can cause

serious personal injury or death.

3-2 F-716-1213 Edition

5531 small seed attach

EXISTING MAIN SEED

BOX ASSEMBL Y

EXISTING SMV SIGN

SMALL SEED BOX ASSEMBLY

RELOCATED SMV

SIGN

SMALL SEED

SHIELD

BEARING ASSEMBLY

CHAIN ADJUSTMENT

BRACKET

BEARING ASSEMBLY

AND MOUNT

ASSEMBLY INSTRUCTIONS

Figure 3-2: Small Seed Assembly Overview

3-3

ASSEMBLY INSTRUCTIONS

SEED BOX BRACKET

1/2-13 X 1-1/4 HEX

HEAD CAP SCREW

seed box bracket screw removal

Small Seed Attachment Installation (Option)

Refer to 3-2 for small seed attachment overview.

Use these instructions to install the optional small seed

attachment to the rear main seed box of 5531 Grain Drill.

1. Attach the drill to the tractor and lower the unit to the

ground. Leave the drill attached to the tractor while

assembling the small seed attachment. This will

prevent tipping of the drill while support stands are

removed.

2. Remove the SMV sign from the rear of the existing

seed box. Reinstall the mounting screws in the seed

box to plug the holes.

3. Determine whether the existing drill boxes have

mounting holes for the small seed attachment. See

Figure 2-9 for hole locations. If the mounting holes

do not exist, these holes must be drilled in existing

boxes before installing the attachment.

a. First locate and mark the center of the existing

seed box along the top rear box edge. Base all

dimensions from this mark.

b. Mark and center punch hole placement per

drawing.

c. Using a 13/32” diameter drill bit, drill the

mounting holes.

4. Remove the 3/8” hex lock nuts and 2-hole mounting

plates from the front of the small seed box assembly.

5. Carefully raise the small seed attachment and insert

the mounting screws through the holes drilled in the

rear of the main seed box. Inst all the 2-hole mounting

plates and 3/8” hex lock nuts on the inside of the

main drill box to secure the small seed attachment.

6. Remove the three outer locking nuts on the seed

shaft bearing assembly. Slide the bearing assembly

over the small seed square meter shaft. Insert the

bearing assembly mounting screws into the small

seed drive mount located on the end of the small

seed box assembly. Loosely install the three locking

nuts to hold the bearing assembly in place.

7. Just in front of the small seed bearing assembly,

remove the rear 1/2-13 x 1-1/4 hex head cap screw

from the existing seed box bracket (See Figure 3-3.)

3-4 F-716-1213 Edition

Figure 3-3: Removal of Rear Screw from Existing

Seed Box Bracket

Loading...

Loading...