Page 1

EP

Operating & Software Manual - V1.0

Page 2

Strada EP

Table of Contents

Strada EP - Operating Manual

Table of Contents ...........................................................................................................................................................................1

General Warnings and Safety Speci cations........................................................................................................................ 2

De nition of Model .......................................................................................................................................................................4

Installation........................................................................................................................................................................................ 6

Operating the Espresso Machine and Preparing Co ee.................................................................................................. 7

Preparing Other Hot Drinks.........................................................................................................................................................9

Preventative Maintenance and Weekly Cleaning...............................................................................................................10

De-Commissioning and Demolition......................................................................................................................................11

NOTE: The Software Programming Manual follows the Operating Manual

www.lamarzocco.com V1.0

Page 3

1. General Warnings and Safety Specifi cations

1) This operating manual is an integral and essential part of

the product and must be supplied to users. Users are asked

to read the enclosed warnings and cautions carefully, as

they provide valuable information concerning safety during

installation, operation and maintenance. This manual must

be kept in a safe place and be available for consultation to

new and experienced users alike.

2) Ensure product integrity by inspecting the packaging, making

sure it presents no signs of damage which might have affected

the enclosed machine.

3) Check the machine’s integrity after having carefully removed

the packaging.

4) Packaging (boxes, plastic bags, foam parts and whatever

else) must not be left around within easy reach of children,

due to the potential danger it represents, nor be discarded in

the environment.

5) Check to see that data on the rating plate corresponds to

those of the main electrical supply which the machine will be

hooked up to.

6) Installation must be performed according to local electrical

and plumbing codes and regulations. Installation must also

comply to manufacturer instructions, and must be performed

by qualifi ed and authorized personnel.

12) Using any electrical device requires that certain fundamental

rules be observed. In particular:

- do not touch the device with wet or humid hands and feet;

- do not use the device while having no shoes on your feet;

- do not use extension cords in bath or shower rooms;

- do not unplug the device from the power outlet by pulling

on the power supply cable;

- do not expose the device to atmospheric agents (rain, sun,

etc.);

- do not allow children or untrained personnel to use this

device.

13) Before carrying out any maintenance and/or cleaning

operation, turn the main switch, which is located on the front

left of the machine, to the “0” or OFF position, and disconnect

the machine from the electrical network by unplugging the

cord or by switching off the relative circuit breaker. For any

cleaning operation, follow the instructions contained in this

manual only.

14) In case the machine is operating in a faulty manner or breaks

down, disconnect it from the electrical network (as described

in the preceding point) and close the water supply valve. Do

not attempt to repair it. Contact a qualifi ed and authorized

professional to perform any repair. Any repairs must be

performed exclusively by the manufacturer or by an authorized

centre using only original parts. Non compliance with the

above could compromise the safe operation of the machine.

7) Incorrect installation may cause injury/damage to people,

animals or objects, for which the manufacturer shall not be

held responsible.

8) Safe electrical operation of this device will be achieved

only when the connection to the power outlet has been

completed correctly and in observance of all local, national,

and international electrical codes and safety regulations,

and particularly by grounding the unit. Make sure grounding

has been done properly as it represents a fundamental

safety requirement. Ensure qualifi ed personnel check such

connection.

9) Furthermore, you must ensure that the capacity of the

available electrical system is suitable for the maximum power

consumption indicated on the espresso machine.

10) We do not recommend using adapters, multiple plugs and/

or extension cords. If you cannot avoid using them, make

sure that they are exclusively of the kind which conforms to

local, national, and international electrical codes and safety

regulations, being careful not to exceed the power and current

ratings indicated on such adapters and extension cords.

11) This device must be used exclusively for the functions it

has been designed and built for. Any other application is

inappropriate and dangerous.

15) You should plan to make use of a specifi c connector during

installation, as required by local, national, and international

electrical codes and regulations.

16) In order to avoid dangerous overheating problems, it is

recommended that the power supply cable be fully unfurled.

17) Do not obstruct air intake and exhaust grilles and, in particular,

do not cover the cup warmer tray with cloths or other items.

18) The machine’s power supply cable must not be replaced by

users. In case the power supply cable becomes damaged,

shut off the machine and disconnect the machine from the

electctrical network by switching off the relative circuit breaker

and close off the water supply; to replace the power supply

cord, contact qualifi ed professionals only.

Note:

In case of doubt, do not go on any further and contact your dealer

or retailer immediately. They will send out specialized personnel

authorized to perform service on the espresso machine.

The manufacturer shall not be held responsible for any damages

caused by improper and/or irrational use.

WARNING

THIS EQUIPMENT MUST BE INSTALLED TO COMPLY WITH THE

APPLICABLE FEDERAL, STATE, OR LOCAL PLUMBING CODES

2

La Marzocco, S.r.l. Scarperia, Firenze, ItaliaV1.0

Page 4

Strada EP

This operating manual refers exclusively to the below model, of our own manufacture:

1) Common Dimensions, Weights, and Features

2. Defi nition of Model

Strada 3 group Electronic Paddle: 3EP

1000 675

450

14

••Weight: Kg. 90

9

9

15

Legend

1) Group Display

2) Main Switch

3) Steam Wand Lever

4) Electronic Brew Paddle Lever

5) Hot Water Wand

6) Hot Water Mix Valve

7) Hot Water Switch

8) Programming Display

9) Steam Wand Protection

10) Steam Wand

www.lamarzocco.com V1.0

11) Removable Drain Tray

12) Waste Water Hose Holder

13) Programming Jog Wheel14

14) Drain Tray Grate

15) USB Key Connection

For additional information on electronics, and software

programming, please see the section entitled Software

Programming.

3

Page 5

2. Defi nition of Models

1) General Description

The machine is built in a 3 group version and consist essentially

of 2 differnt type of boilers and is essentially composed of the

following parts:

1) Steam Boiler (produces steam and hot water)

2) 3 Coffee (“saturation”) boilers

3) Brewing groups

4) Exterior Cover

5) Water pump/s

2) Description of the various parts

• Steam Boiler

The Steam Boiler consists of a cylindrical tank made of AISI

300 series stainless steel. Each unit is subject to a hydraulic

test, at a pressure of 6 bar, and has an operating pressure

of 1.3-1.5 bar. The following is a list of effective volumes and

power ratings according to the number of groups installed:

3 groups 11 liters 4000 Watts

Covers are installed at either end of the cylindrical tank and

on one of them there is housing for the water heating element,

which allows the steam boiler to reach operating pressure within

approximately 25 minutes. Operating pressure is maintained

by temperature probe. The steam boiler has various fi ttings

used for safety devices, for supplying hot water and steam,

and for the heating element.

Composed of AISI 300 series stainless steel tube. Heating

is accomplished through an immersion-type plated heating

element.

- Operating pressure of 1.3-1.5 bar, controlled automatically

through a pressure switch or a temperature probe, adjusted to

open the heating element supply circuit at 1.5 bar and close

it at 1.3 bar.

- The pressure is displayed by means of a pressure gauge with

a scale of 0 to 2 bar.

- Safety device, based on an expansion type mechanical valve,

with counter-acting spring adjusted to 1.8 bar.

- Testing: hydraulic test at 4.5 bar performed on ready-to-use

small boilers, at our factory;

- Operating temperature 95°C (adjustable), controlled

automatically by an electronic temperature controller with an

accuracy of 0.2 °C. Operating pressure of 9 bar, developed

mechanically by a special positive-displacement pump which

is activated automatically every time coffee is brewed.

-Pressure is displayed through a pressure gauge with a scale

from 0 to 15 bar.

-Safety device, based on an expansion type mechanical valve,

with counteracting spring adjusted to 13.5 bar.

-Testing: Hydraulic test at 18 bar performed on ready-to-use

small boilers, at our factory;

• Brewing Groups

They consist of precision casting made of stainless steel. The

brewing group accepts the portafi lter used to hold the ground

coffee; the water fl ows through the brewing group, through the

portafi lter basket, through the portafi lter spout, and into the

cup(s) after brewing has been activated.

• Exterior Cover

It consists of a stainless sheet steel body. The structure has

been the object of specifi c studies to provide good aesthetics,

lower ergonometric costs for the operator and reduce the

chance of damage to a minimum.

• Sound Pressure

The weighted sound pressure level of the machine is lower

than 70dBA.

• Water Pump

There are two type of pump workink on this model of Strada:

• Rotary vane positive displacement pump set-up to operate

anytime an electric level gauge whenever the steam boiler

needs to be replenished.

• Coffee Boiler

The Coffee Boiler consists of a cylindrical tank made of AISI

300 series stainless steel.

for brewing coffee).

Each unit is subject to a hydraulic test, at a pressure of 18 bar,

and has an operating pressure of 9 bar. The following is a list

of effective volume and power ratings according to the number

of groups installed:

3 groups - 3 x 1,3 liters 3 x 800 Watts

Covers are installed at either end of the cylindrical tank

and on one of them there is housing for the water heating

elements. The temperature of the coffee boiler is maintained

by an electronic temperature controller (PID capable) with an

accuracy of 0.2°C. The brewing groups are installed on the

boiler.

Composed of an AISI 300 series stainless steel tube. Heating

is accomplished through an immersion-type plated heating

element.

One each group (hot water generator

4

• Magnetic drive gear pump to operate whenever brewing

coffee following manual or preset pressure profi le from

0 to 12 bar.

La Marzocco, S.r.l. Scarperia, Firenze, ItaliaV1.0

Page 6

Strada EP

3. Installation

WARNING

This equipment must not be used by children, mentally

or physically challenged individuals or anyone lacking

necessary know-how unless supervised

by specialized personnel.

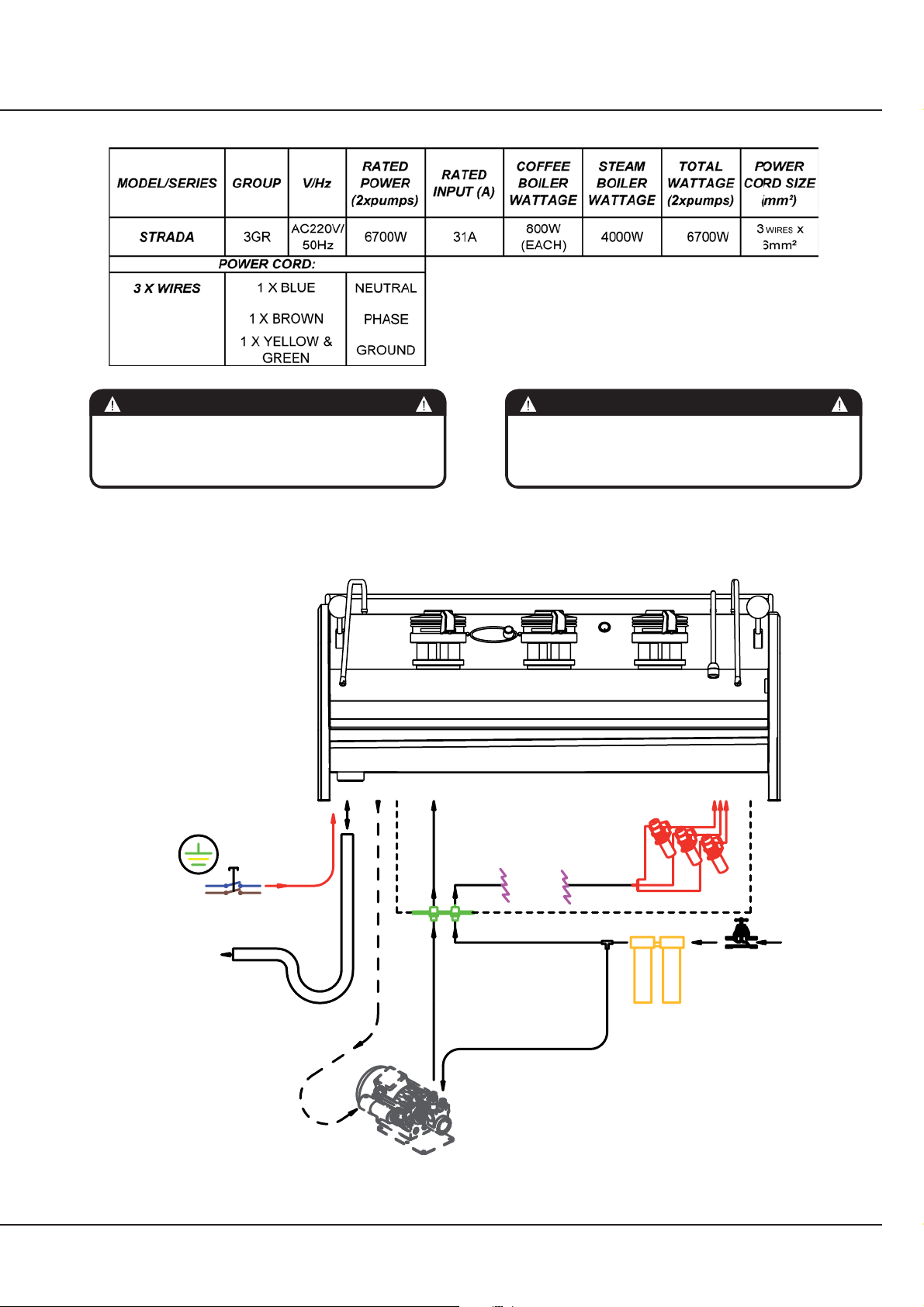

POWER SUPPLY

CORD

WARNING

The Coffee Boiler and Steam Boiler contain water at elevated

temperature. Water temperature over 125° F / 52° C can

instantly cause severe burns or death from scalding.

(Coffee Boiler 200° F / 93.3° C - Steam Boiler 260° F / 127° C)

MAGNETIC DRIVE

GEAR PUMP FOR

COFFEE BOILERS

MAIN SWITCH

AND ELECTRICAL

SUPPLY

CONNECTION

WASTE/DRAIN

MOTOR POWER

OPTIONAL

WATER PUMP

CORD

BRAIDED HOSE

A.2.023A.2.023

OPTIONAL

WATER PUMP

AND MOTOR FOR

STEAM BOILER

www.lamarzocco.com V1.0

INSIDE

THE

MACHINE

WATER

CONNECTIONS

WATER

FILTRATION/

SOFTNER

MAIN WATER

SUPPLY VALVE

5

Page 7

3. Installation

1) Accessories

WARNING

WARNING

At each installation, the machine should be equipped with a new set

Check the package to make sure that the following accessories

are included:

• 1 x SINGLE and 3 x DOUBLE portafi lters

• 2 x SINGLE and 4 x DOUBLE fi lters

• 1 x tamper

• 1 x blind fi lter

• 1 x cleaning detergent

• 3 x stainless steel braided hose for water connections

• 1 x 1,5 mt of reinforced plastic tubing for drainage

• 1 x hose clamp

• 1 x TEE Fitting

In order to proceed with installation, it is necessary that the

following are available:

a) Pipes carrying drinking water with a 3/8”G (BSP) end

connection.

b) Electrical Supply according to the specifi cation of the

espresso machine purchased: 200/220/380/VAC - 50/60Hz

electrical connection with ground, protected socket and

approved circuit breaker.

c) Indirect waste water drain system.

of tubes for plumbing and related gaskets.

NOTE: The differential pressure water pump is a volumetric

pump and has been designed to be used exclusively with

cold water. Make sure that water is always present while

the pump is operating, otherwise air can be introduced

into the brew boiler causing an undesirable condition.

CAUTION

BEFORE MAKING ANY ELECTRICAL CONNECTIONS MAKE

SURE THAT THE 2 STRAIN RELIEF CONNECTORS ARE FIRMLY

SECURED TO THE BODY OF THE MACHINE IN ORDER TO

PREVENT INADVERTENT STRESS ON THE POWER CABLES.

3) Electrical Connections

a) Power Supply Cord

This is the main power supply cable that provides power to the

entire espresso machine. There are different types of cable

based upon the electrical requirements of the espresso machine

purchased.

b) Water Pump Motor Power Cord

This is the power supply for the water pump motor. The internal

electronics will switch the pump motor on when needed.

3-core cable with 1.5 mm2 cross section (CE) or 3-core AWG 16

(for UL version) secured to espresso machine via a strain relief

connector.

NOTE:

• The drinking water stopcock and the terminal switches

for the electrical system need to be located in the most

convenient position for the operator to access them easily

and quickly.

• The machine should be placed on a fl at counter and must

be placed in settings with the following temperatures:

Minimum room temperature: 5°C

Maximum room temperature: 32°C

• If the machine has been temporarily housed in settings with

a room temperature of less that 0°C, the machine must

be placed in a warmer environment in order to gradually

defrost the hydraulic system prior to use.

• Water pressure supply must be between 4 and 8 bar.

2) Water Supply Connection

Connect the inlet of the water fi lter/softener to the drinking water

supply using one of the supplied stainless steel braided hoses.

Before connecting the espresso machine to the fi lter/softener,

fl ush the water supply line and the fi ltration system in order to

eliminate any residual particles which could otherwise get stuck

in taps or valves thus preventing them from working properly.

Connect the water supply connections of the espresso

machine; the coffee boiler inlet direct to the water filter

T-fi tting and the Steam Boiler to the water pump outlet using

one of the supplied stainless steel braided hoses. Then

connect the water pump inlet to the water fi lter/softener outlet.

WARNING

4) Waste Water Drain Connection

The espresso machine drain is to be connected by means of

the included reinforced plastic tubing. Connect one end of the

reinforced plastic tubing to the drain hose connection on the left

side of the espresso machine. Secure with included hose clamp.

WARNING

THE MOTOR PUMP MUST BE SITUATED

CLOSE TO THE MACHINE IN AN ACCESIBLE

PLACE FOR MAINTENANCE BUT NOT FOR

ACCIDENTAL INTERFERENCE AND WHERE

THERE IS AN OPTIMAL AIR CIRCULATION

Connect the other end to a suitable waste water collection system.

In case such a system is not available, drained liquids may be

collected in a suitable bucket and any necessary drain pipe

extensions should be made using steel-lined PVC tubing and

suitable hose clamps.

WARNING

HAZARDOUS VOLTAGE! DISCONNECT FROM

POWER SUPPLY BEFORE SERVICING

WARNING

THE MANUFACTURER DECLINES ANY RESPONSIBILITY FOR ANY

EVENT LEADING TO LIABILITY SUITS WHENEVER GROUNDING HAS

NOT BEEN COMPLETED ACCORDING TO CURRENT LOCAL, NATIONAL

AND INTERNATIONAL REGULATIONS AND ELECTRICAL CODES,

AND/OR IN LACK OF PROPERLY CONNECTED ELECTRICAL PARTS.

WATER PRESSURE SUPPLY MUST BE BETWEEN 4 AND 8 BAR

IF SUFFICIENT PRESSURE IS NOT AVAILABLE WE SUGGEST

THAT AN ADDITIONAL WATER SUPPLY SYSTEM IS USED

6

WARNING

U.S.A. AND CANADA ONLY

DO NOT CONNECT TO A CIRCUIT OPERATING AT

MORE THAN 150 V TO GROUND

La Marzocco, S.r.l. Scarperia, Firenze, ItaliaV1.0

Page 8

Strada EP

GR1

GR2

GR3

4. Operating the Espresso Machine and Preparing Coffee

1) Starting the Espresso Machine

Filling the Boilers with Water:

Once the installation procedures have been completed, it is

necessary to fi ll the boiler tanks with water. Complete the

following procedure to properly fi ll the boiler tanks:

a) Coffee Boiler

The water fl ows inside the coffee boilers directly, as soon as the

water system and water fi lter/softener valves are opened.

Since the infl ow of water will compress the air in the boiler, it

will be necessary to remove or “bleed” the air from the coffee

boilers. All air must be removed in order to completely “saturate”

the coffee boiler/group assemblies.

To remove the air from the boiler, or “bleed the groups”, it will be

necessary to remove the plastic cap and the handle from the top

of the group.

should be heating to operating temperatures.

2) Waiting for the Espresso Machine to Heat to

Operating Temperature

During this time, it may happen that the pointer of the coffee

boiler pressure reaches as high as 14-15 bar. This may happen

anytime that the heating element is in the “on” condition. In

this case, it is necessary to adjust the expansion valve (see the

picture below about the three coffee boiler expasion valves) in

such a way that the pressure never exceeds 13.5bar.

In normal operating conditions, the coffee boiler pressure

transducer, while brewing, can read anywhere from 0-12 bar

when brewing.

GR3

GR2

GR1

Loosen the bleed screws one at a time to allow air to escape until

water fl ows from below the screw head. Tighten the screw to stop

the water from fl owing. Over tightening can cause damage to the

sealing washer and the group cover. Repeat this procedure on

all groups.

b) Steam Boiler

Turn the main switch to position “1” or ON, then push the encoder

knob for three seconds and the automatic steam boiler level

function will be switched on, activating the auto-fi ll solenoid

valve and the motor pump. This will fi ll the steam boiler to a

predetermined level and will shut off when full.

Note: Air inside the steam boiler may build up pressure (which

may be detected through the pressure gauge).

Once the pump stops, check the display, the message “Coffee

Boiler Filled?” should be displayed. Push the Encoder Knob to

confi rm that the preceding procedures are complete.

The installation is now complete and the espresso machine

The steam boiler pressure is visible through a pressure gauge

placed inside the machine, behind the control and the 1st group.

When the steam boiler reaches operating temperature, the light

on the Tea dispense button will switch on.

3) Installing the Portafi lters

Install the portafi lter(s) by inserting them into the group and rotate

the handle from left to right. When the portafi lters are inserted

properly, you can press any of the brew buttons to start the fl ow

of water through the portafi lter. ou should allow hot water to

pass through the portafi lter(s) for a few seconds each time, in

order to pre-heat the portafi lter.

Note: It is important to leave the portafi lters installed in the

espresso machine when not in use. The portafi lter must remain

heated for the brew process to function correctly.

Filter

Basket

Basket

Spring

Portafilter

O-ring

Double

Spout

www.lamarzocco.com V1.0

7

Page 9

4. Operating the Espresso Machine and Preparing Coffee

4) Brewing Coffee

It is now possible to remove one of the portafi lters to make an

espresso beverage through the manipulation of the pressure to

your taste.

The Strada Electronic Paddle is an formidable appliance for making

espresso beverage that could develop extraction water pressure

from 0 to 12 bar as you go.

Press down on the ground coffee with the supplied tamper and

install the fi lter holder to the bottom of the group.

Move the paddle to begin the brewing process. As soon as you

start to turn the lever placed on top of the group the magnetic drive

gear pump will pushing water into the portafi lter.

By turning the lever of the Electronic Paddle it is possible to vary

the speed of the gear pump, as much it will be turned as faster

the pump will go.

It is possible to pre-infused allows you to bring out different fl avor

components which affect the balance and body of the shot, and

produce rounder, softer espresso that highlights brightness,

sweetness and delicates note.

Do not remove the portafi lter when its realtive group is brewing hot

liquids. The Coffee Boiler contains water at elevated temperature.

Water temperature over 125° F / 52° C can instantly cause severe

WARNING

burns or death from scalding.

Note:Some baristas suggest fl ushing the group with water to

remove remaining coffee oil or particles. Some fl ush after every

shot. Experimentation and practice is suggested to establish the

best possible procedure for brewing coffee.

5) General Notes for Coffee Preparation

The potafi lters must remain heated since they are partially isolated

from the group due to the rubber gasket between them. This can be

accomplished by leaving the portafi lters installed on the machine

when not in use. The portafi lters may also be actively heated.

This procedure may be carried out by activating one of the brew

buttons to fl ush hot water through the portafi lter then turning off

the water fl ow.

Other than the type of coffee blend being used, naturally, the size

of the coffee granules is extremely important in the preparation of

a good cup of coffee. Ideal grinding can be determined by making

various coffees using the amount of ground coffee that you would

normally use for each cup (we recommend at least 6g). The most

suitable grinding allows coffee to fl ow gradually from the fi lter

holder spout - neither too slowly, nor too quickly. A general rule is

that a double dose should dispense approximately 2 fl uid oz. of

espresso in approximately 25 seconds.

IMPORTANT

To improve fl avor, the temperature of water in the coffee boiler,

which has a direct impact on the groups, may eventually be

increased or reduced via the digital display (please consult the

Software Programming Manual for detailed instructions).

8

La Marzocco, S.r.l. Scarperia, Firenze, ItaliaV1.0

Page 10

Strada EP

1) Steaming Milk or Other Liquids

Dip one of the 2 steam wands (part 8, page 3) which are connected

to the steam valve, into the liquid to be heated. Turn the steam

lever on gradually until steam is released at the end of the wand.

The steam will heat the liquid and raise its temperature.

To avoid severe burns, do not allow any liquid to overfl ow.

In order to successfully foam milk , please follow these steps:

• Place the pitcher that is partially fi lled with milk under the steam

wand. Open the steam valve and bring the temperature of the milk

to nearly 149/158° F 65/70° C.

• Lower the pitcher so that the wand tip is just below the surface

of the milk; at this point, move the container up and down just

enough to dip the nozzle end in and out of the milk until you get

the right amount of foam. Gradually pour the foamed milk over

warm espresso for a fresh cup of cappuccino.

In order to prevent heated liquid from being sucked back

into the steam boiler, it is recommended that the steam

valve and steam wand be purged by opening the valve for

a few seconds to allow steam to escape from the end of

the steam wand. Failure to do so can cause heated liquid

to be transferred from the pitcher to the steam boiler (due

to a vacuum created by cooling parts). This condition is

undesirable and can contaminate the steam boiler.

5. Preparing Other Hot Drinks

2) Preparing Tea and Other hot Drinks.

You may dispense hot water by using the fi xed nozzle (part 10,

page 3). To dispense hot water, press the tea water button.

This button commands hot water delivery.

The temperature of the water may be adjusted by adjusting the

mixing valve.

www.lamarzocco.com V1.0

9

Page 11

6. Preventative Maintenance and Weekly Cleaning

WARNING

THE MACHINE MUST BE INSTALLED SO THAT QUALIFIED

TECHNICAL PERSONNEL CAN EASILY ACCESS IT FOR EVENTUAL

MAINTENANCE.

CAUTION

THE MACHINE MUST NOT BE DIPPED IN, NOR SPLASHED

WITH WATER WHILE CLEANING. FOR CLEANING

OPERATIONS, PLEASE FOLLOW THE INSTRUCTIONS

LISTED BELOW VERY CAREFULLY.

1) Cleaning groups and drain wells

- Put a tablespoon of detergent powder for coffee machines into

the blind fi lter, supplied with the machine, and attach it on the

group to be cleaned.

WARNING

DO NOT REMOVE THE PORTAFILTER WHEN ITS REALTIVE GROUP IS

BREWING HOT LIQUIDS. THE COFFEE BOILER CONTAINS WATER AT

ELEVATED TEMPERATURE. WATER TEMPERATURE OVER 125° F / 52° C

CAN INSTANTLY CAUSE SEVERE BURNS OR DEATH FROM SCALDING.

- Turn the Paddle Valve on and off approximately 10 times (10

seconds intervals) on each group.

- Rinse the group using a normal fi lter by running hot water through

it several times.

2) Cleaning fi lters and fi lter holders

- Put 2 or 3 teaspoons of detergent powder for coffee machines

in about 1/2 a litre of VERY HOT water.

- Dip fi lters and fi lter holders in the heated solution and leave them

fully submerged for about 10 minutes.

- Rinse thoroughly with clean water and run hot water through one

group several times with the fi lters in place.

- Make one cup of coffee and discard in order to remove any

unpleasant fl avor.

cleaned periodically with a damp cloth.

6) Cleaning the Diffuser Screen

Due to portafi lter discharge operations (subsequent to coffee

brewing), a certain amount of coffee grounds may slowly build-up

GROUP

ASSEMBLY

DIFFUSER

SCREEN

DIFFUSER

SCREW

and even partially obstruct the diffuser screen.

To clean it, fi rst unscrew the diffuser screw, then remove the

diffuser screen.

Put 2 or 3 teaspoons of cleaning detergent for coffee machines in

about 1/2 a litre of water inside a heat-resistant container and heat.

Place the diffuser screen(s) and diffuser screw(s) in the solution

and leave them fully submerged for about 10 minutes.

Rinse thoroughly with clean water. Install and run hot water

through each group several times with the screen installed.

7) Water Pump

When brewing coffee, and you can adjust pump pressure by turning

the by-pass screw clockwise to increase and counter-clockwise to

reduce pressure. Adjust pressure only when one or more groups

are brewing coffee.

8) Water Filter/Softener

Please see the documentation accompanying the water fi lter/

softener for proper operating and cleaning instructions.

3) Cleaning the drain collector

Remove the drain tray daily and clean.

Inspect the drain well also, and wash away any leftover grounds.

4) Cleaning the body

Wipe the stainless steel surfaces with a soft, non abrasive cloth.

Do not use any alcohol or solvents whatsoever on painted or

decorative parts to avoid damage.

5) Cleaning the hot water and steam nozzles

Steam nozzles must be cleaned immediately after use with a

damp cloth and by producing a short burst of steam to prevent

the formation of deposits inside the nozzles, which may alter the

fl avor of other drinks to be heated. Hot water nozzles must be

10

La Marzocco, S.r.l. Scarperia, Firenze, ItaliaV1.0

Page 12

Strada EP

1) De-Commissioning and Demolition

Start by setting the main switch to the “0” or OFF position.

Disconnecting from the power outlet

Disconnect the espresso machine from the electrical network by

switching off the associated circuit breaker or circuit protection

device. Remove the power supply cord from the power connection.

Remove the Pump Motor Power Cord from the water pump motor.

Disconnecting from the water system

Shut off the water supply by closing the specifi c valve located

upstream of the water fi lter/softener inlet. Disconnect the water

pipe at the water fi lter/softener inlet. Remove the hose connecting

the espresso machine to the water pump. Remove the reinforced

plastic tubing on the drain connection.

At this point, the machine may be removed from the bar, being

very careful not to drop it or crush your fi ngers.

The machine is made out of various materials and therefore, if

not intended for further service, should be delivered to a recycling

center which will select materials to be recycled or discarded.

7. De-Commissioning and Demolition

Current regulations make it illegal to discard the machine by leaving

it on public grounds or on any private property.

Recycling notice:

Warning for the protection of the environment.

Old electrical equipment is made of valuable materials, it is not

normal domestic waste! We kindly

ask that our clients contribute to the

protection of the environment and

natural resources by delivering this

equipment to a recycling center, if such

centers are present in any one specifi c

territory.

www.lamarzocco.com V1.0

11

Page 13

Strada EP

Strada EP - Software Programming and Pressure Profile Manual

Table of Contents ............................................................................................................................................................................1

Strada Programming Introduction .......................................................................................................................................... 2

Accessing Programming Mode ................................................................................................................................................ 3

Description of the Programming Levels ............................................................................................................................... 4

Start Up Procedure ....................................................................................................................................................................... 6

www.lamarzocco.com V1.0

Page 14

Strada Programming Introduction

Description

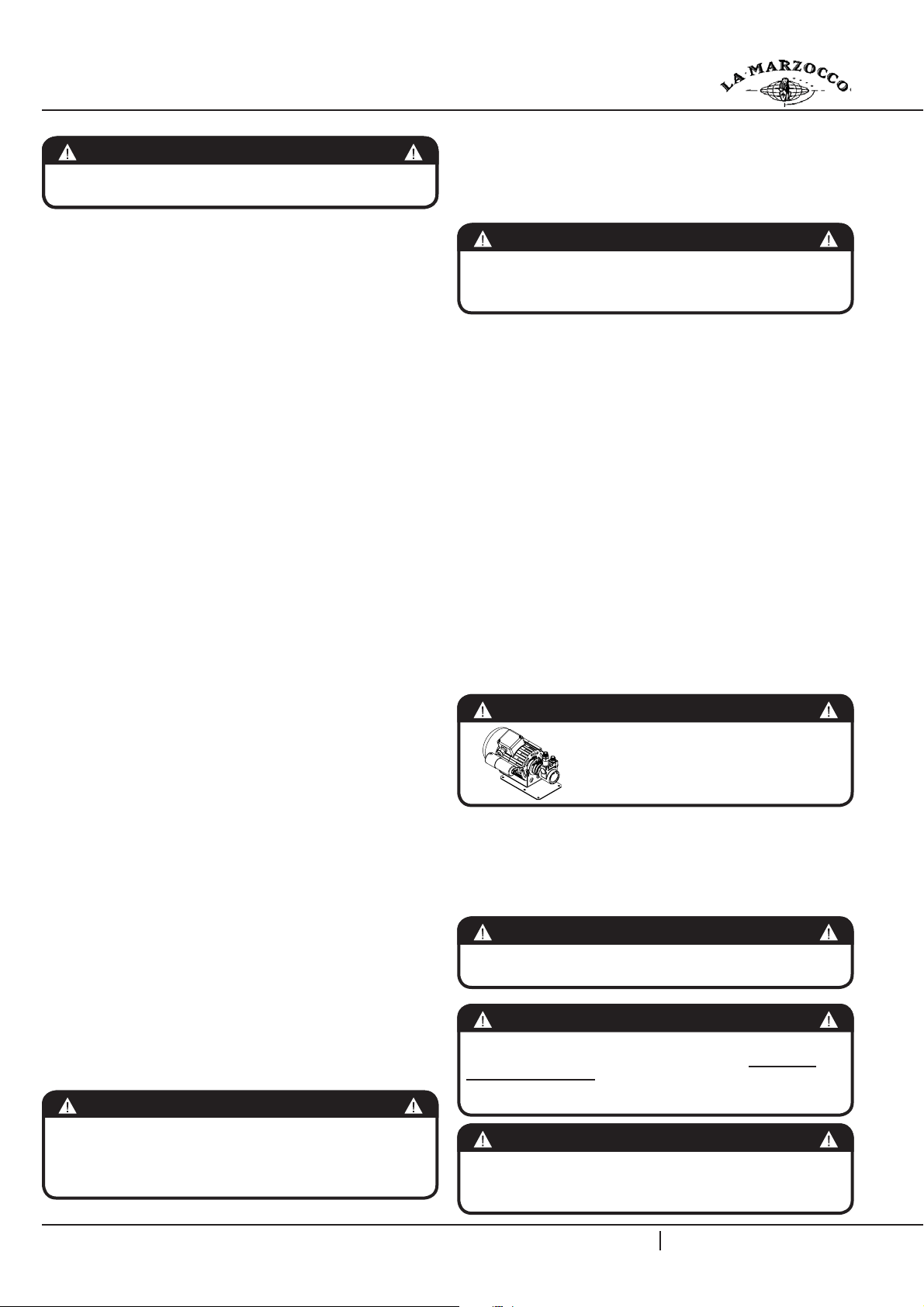

• The Strada espresso machine has a very functional CPU

with many programmable settings.

• The following is a brief introduction to the controls and

display and how they interact with the operator.

Digital Display and Jog Wheel

The digital display is a backlit screen capable of displaying 2 lines with 16 characters each. The display enables the

operator to interact with the espresso machine to change parameter values. The display also provides valuable information to the operator. There are several warnings that can be displayed to alert the operator of an unusual condition

or fault. Additionally, simple messages are displayed alerting the operator that an action has been started or that a

process needs to begin.

The jog wheel is always located on the left of group one. By turning it to the right it is possible to increase the value.

By turning it left, it is possible to decrease the value and by pushing it down, it is possible to scroll through the software

menu, enter functions or conrm rst installation.

It is possible to turn on/off the Strada coffee machine by pushing and holding the Jog wheel for 3 seconds.

2

La Marzocco, S.r.l. Firenze, Scarperia, ItaliaV1.0

Page 15

Strada

Description

Accessing Programming Mode

Programming Mode

• To change any congurable parameter the operator must rst

enter the programming mode.

• There are three levels of the programming mode that allow

modification to specific parameters, depending on the

sequence that is followed

The three programming levels are as follows:

• Barista Level - No Password Necessary. Limited parameters

are available.

• Technical Level - Barista level parameters plus additional

parameters are available.

• Factory Level - Factory password needed. Barista Level

and Technician level parameters plus additional parameters

are available.

www.lamarzocco.com V1.0

3

Page 16

Description of the Levels

Programming sequence

Barista Menu

Operating Procedure: with the coffee machine on, press and

hold the jog wheel for 5 seconds and the Barista Level

menu will appear.

Programming Sequence

Operating Procedure: First hold the knob for 3 seconds to

achieve the OFF status, then realease it and press and

hold it again for an additional 5 seconds. The Technician

Level menu will appear.

• Coffee Boiler 1 Switching on/off

• Coffee Boiler 2 Switching on/off

• Coffee Boiler 3 Switching on/off

• Coffee Boiler 1 Temperature

• Coffee Boiler 2 Temperature

• Coffee Boiler 3 Temperature

• Steam Boiler Temperature

• Clock Adjust

Technical Menu

• Language

• Temperature Measurement Units (°F - °C)

• User name

• Coffee Boiler 1 Temperature

• Coffee Boiler 2 Temperature

• Coffee Boiler 3 Temperature

• Steam Boiler Temperature

• Clock Adjust

• Auto On/Off

• Cup Heating

• Pumps Setting for Automatic Fill

• Steam Boiler Automatic Fill

• Pump Setting for Tea Water

• Coffee Boiler 1 Temperature Offset

• Coffee Boiler 2 Temperature Offset

• Coffee Boiler 3 Temperature Offset

• Total Doses

• Filter Alarm

4

La Marzocco, S.r.l. Firenze, Scarperia, ItaliaV1.0

Page 17

Strada EP

Programming Sequence

Description of the Levels

Factory Menu

Operating Procedure: First hold the knob for 3 seconds to

achieve the OFF status, then realease it and press and

hold it again for 15 additional seconds. The Factory Level

menu will appear.

• Machine Group Number

• Open Valves

• Coffee Boilers Proportional, Integral, derivative (PID) Setting

• Coffee Boilers PID Start

• Coffee Boiler 1 Heating Timeout

• Coffee Boiler 2 Heating Timeout

• Coffee Boiler 3 Heating Timeout

• Steam Boiler Heating Timeout

• Steam Boilers Proportional, Integral, derivative (PID) Setting

• Steam Boiler PID Start

• Steam Boiler Level Probe Sensitivity

• Steam Boiler Level Probe Delay

• Steam Boiler Level Timeout

• Language

• Temperature Measurement Units (°F - °C)

• User Name

• Coffee Boiler 1 Temperature

• Coffee Boiler 2 Temperature

• Coffee Boiler 3 Temperature

• Steam Boiler Temperature

• Clock Adjust

• Auto On/Off

• Cup Heating

• Pumps Setting

• Steam Boiler Automatic Fill

• Pump setting for Tea Water

• Coffee Boiler 1 Temperature Offset

• Coffee Boiler 2 Temperature Offset

WARNING

TO EMPTY THE BOILERS IT IS

NECESSARY TO USE THE FUCTION

“OPEN VALVES” IN THE FACTORY MENU

www.lamarzocco.com V1.0

5

Page 18

Start Up Procedures

Description

• The following is the procedure for turning on the espresso

machine.

• Please follow the procedures carefully to avoid any damage.

Turning the Espresso Machine On!

Display Operating Procedure

Turn the Main Switch to the On position. (ON=1, Off=Ø)

1

The message at left will be displayed briey. This message indicates the revision level of the

software installed in this espresso machine.

The espresso machine is now ON and information concerning the boiler and heating elements

will appear..

! !

WARNING

HAZARDOUS VOLTAGE! DISCONNECT FROM

POWER SUPPLY BEFORE SERVICING

6

La Marzocco, S.r.l. Firenze, Scarperia, ItaliaV1.0

Page 19

Strada

Description

• The following is the procedure for turning off the espresso

machine.

• Please follow the procedure carefully to avoid any damage.

• This machine has two off settings. One setting turns off all

components of the espresso machine and the other turns

off power to the entire espresso machine.

Start Up Procedures

Turning the Espresso Machine Off

Display Operating Procedure

The following is the procedure for safely turn off the espresso machine.

1

Press and hold the Jog wheel for 3 seconds. The display changes to the following:

2

This is the OFF setting used in normal operating conditions.

3

The main switch should be turned to the OFF position during servicing or other conditions

4

requiring the OFF position.

! !

WARNING

HAZARDOUS VOLTAGE DISCONNECT FROM

POWER SUPPLY BEFORE SERVICING

www.lamarzocco.com V1.0

7

Page 20

Pressure Prole Editor Application

pressure

time

Description

This Prole Editor is used to create multiple pressure prole les that are stored on a USB Flash drive. The drive is then reconnected

to a machine that uses them to reproduce one of the pressure proles for each group.

During the runs, the machine records actual pressure and pump data on the USB Flash drive which can be transferred back to this

application for display and plotting.

The actual pressure data can be compared to the associated design prole data to determine the accuracy of the generated pressure

curve.

A USB Key with the software which you may install on your PC is included as accessory.

Launching the application

Launch the Prole application by double clicking the Prole Editor

Icon. The application will open with a default prole for Group# 1

called File# 1.

Setting Preferences

The number of Intervals and the overall End Time for a particular

curve can be changed using the up/down boxes in the control panel at the top of the screen. Note, the curve default Intervals and

the End Time along with the Maximum Pressure can be changed for future default curves by clicking the Settings menu and

then clicking Pressure Preferences. Changing these after editing

a curve will not change the values for that curve. They will only

change the defaults for new curves. The preference values will be

recalled each time the application is launched.

Editing a Curve

Using the Left Mouse button, drag each of the square markers on

the curve to the desired locations. Note, you cannot drag a point

left or right beyond the previous or next point. Once a curve has

had at least one point edited, its color changes from red to blue and the number of edited curves for this group shown in the status

box below the plot is incremented. When you are satised with the curve you can click the CURVE# up box to increment to the next

curve for this group. Only four curves can be added to a group. The curve numbers range from 0 to 3. You can go back to a lower

curve number and reedit it if like. The check box labeled VALID should be checked for each valid curve (default is Valid).

Saving a Group

When all of the curves are edited, they can be saved to a USB

Flash drive. Plug in the Flash drive and wait until it has mounted.

Click the File menu and then click Find Removable drive. Then

from the File menu click on Save Group# x where x is the group

number you are saving which corresponds to the present value

in the GROUP# up/down box. A le save menu will open with

the correct lename already set. You can navigate to another

location if necessary, otherwise just click Save. You can cancel

if you change your mind. Note, if the le already exists on the

Flash Drive a warning will inform you that you are overwriting an

existing le. After you have saved a group le, the GROUP# will

be incremented and a new default le will be displayed and you

can start editing the four les for the next group.

Note: the last location used to save les will be the default location each time the application is launched. If you quit before

saving any group, a warning message will be displayed stating

that your edited data will be lost.

8

La Marzocco, S.r.l. Firenze, Scarperia, ItaliaV1.0

Page 21

Strada EP

Loading the Log

Click on File and then Log File then Load Log. A le open dialog will be displayed using the same directory as the one used for

saving the prole group les. The dialog will display all les with a .log extension. Select the le to load, click Open and the log

le will be read in. Note, at the same time, the prole group les that are located in the same directory will also be read in to be

plotted with the associated log le.

Displaying the Log

The log le may be displayed in three different forms. Clicking File, Log File, View Log will display the converted data in spreadsheet format. The data has been converted to BAR for pressure and Volts for the pump motor. The associated prole le number is

also displayed for each group.

Clicking File, Log File, View Raw Log displays the raw (unconverted data) in spreadsheet format. In both cases a new

column has been added to each group to display the number

of design prole that was used by the machine.

Clicking File, Log File, Plot Log will display a plot of the log

data along the design prole that was used. Since the log

contains all groups and multiple runs in each group you have

to specify which to plot using the up/down boxes in the control

box at the top of the plot. Also displayed in the control box is

the number of design prole that was used.

Manual Programming of the Pressure Prole

Press and hold the button on the group where you wish to record the pressure prole, then on the display the sentence PROFILE N° will ashing.

Now the machine is ready to be programmed, at the end press again the button and the machine is ready to repeat the prole.

All proles programmed on the 1st group will repeated on the others.

Programming the Pressure Prole with USB

Draw the desired pressure prole with the Prole editor installed on your PC and upload it in to the USB Key. Insert the USB Key on

the Coffee Machine port and follow the display instructions.

Wait until the display will let you unplug the USB Key from the Coffee Machine Port, then you can star to use the pressure proles

drawn.

Uploading the Pressure Proles from the Coffee Machine to the USB Key

Insert the USB Key in to the Coffee Machine Port and follows the instructions displayed. It is possible recording directly the pressure

prole in to the USB Key, just let go off the rst sentence that is appearing when you plug the USB Key and program the pressure

prole as same procedure as in the manual, then is possible to read the proles with the Prole Editor.

www.lamarzocco.com V1.0

9

Page 22

LA MARZOCCO SRL

Via La Torre, 14/H

Località La Torre

50038 Scarperia

(Florence) - ITALY

T. +39 055 849 191

F. +39 055 849 1990

info@lamarzocco.com

www.lamarzocco.com

Loading...

Loading...