Page 1

KMR 1550 B

1.948-204

1.948-224

www.karcher.com

5.956-700 A2005741 (05/03)

Page 2

Deutsch

Bedienungsanleitung Seite 1

Ersatzteilliste Seite 242

English

Français

Italiano

Nederlands

Español

ЕллзнйкЬ

Norsk

Operating Instructions Page 23

Spare Parts List Page 242

Notice d’instructions Page 45

Liste des pièces de rechange Page 242

Istruzioni per l’uso Pagina 67

Elenco pezzi di ricambio Pagina 242

Gebruiksaanwijzing Pagina 89

Lijst met vervangingsonderdelen Pagina 242

Instrucciones de servicio Página 111

Lista de repuestos Página 242

ПдзгЯет чейсйумпэ УелЯдб 133

КбфЬлпгпт бнфбллбкфйкюн УелЯдб 242

Bruksanvisning side 155

Reservedelsliste side 242

Svenska

Suomi

Hrvatski

Bruksanvisning sid 177

Reservdelslista sid 242

Käyttöohje Sivu 199

Varaosaluettelo Sivu 242

Uputstvo za upotrebu Strana 221

Popis rezervnih dijelova Strana 242

Page 3

KMR 1550 B

Operating instructions for users

English

Contents

For your safety ................................................................. 24

On behalf of the environment ......................................... 25

Intended applications ...................................................... 25

Unit functions ................................................................... 25

Main features ...............................................................................................

Prior to initial start-up ..................................................... 26

Unloading procedure ...................................................................................

Moving the sweeper.....................................................................................

Operating the sweeper .................................................... 27

Operating controls .......................................................................................

Dashboard ...................................................................................................

Preparing the sweeper for use ....................................... 28

Adjusting the driver’s seat ...........................................................................

Filling the fuel tank .......................................................................................

Opening the fuel tap ....................................................................................

Starting the sweeper........................................................ 29

Driving the sweeper for the first time ...........................................................

Moving off ....................................................................................................

Braking .........................................................................................................

Bringing the sweeper to a halt and stopping the engine .............................

Cleaning the filter............................................................. 30

Automatic cleaning ......................................................................................

Manual cleaning...........................................................................................

Emptying the waste container ........................................ 30

Typical applications ......................................................... 31

Sweeping a dry floor surface .......................................................................

Sweeping a damp or wet floor surface ........................................................

Picking up large items (sticks, cans, etc.)....................................................

Overcoming obstacles .................................................................................

Long-term storage ........................................................... 32

Transporting the sweeper ............................................... 32

Cleaning and care ............................................................ 33

Maintenance ..................................................................... 33

First engine oil change.................................................................................

Initial inspection after 8 operating hours......................................................

Daily maintenance .......................................................................................

Maintenance intervals..................................................................................

Safety information applicable to maintenance tasks ...................................

Maintenance tasks ........................................................... 34

Tipping the seat forwards/backwards ..........................................................

Disconnecting the battery ............................................................................

Opening/closing the bonnet .........................................................................

Tool compartment and on-board tool kit ......................................................

Checking the tyre pressure..........................................................................

Checking the engine oil level .......................................................................

Topping up with engine oil ...........................................................................

Replacing the engine oil ..............................................................................

Replacing the engine oil filter ......................................................................

Cleaning the air filter....................................................................................

Replacing the fuel filter ................................................................................

Checking the hydraulic fluid level ................................................................

Checking the level of electrolyte in the battery ............................................

Charging the battery ....................................................................................

Replacing the sealing strips.........................................................................

Replacing the side brush .............................................................................

Replacing the brush roller............................................................................

Replacing fuses ...........................................................................................

Replacing the dust filter ...............................................................................

Adjusting the sweeping pattern ...................................................................

Troubleshooting ............................................................... 43

Technical specifications.................................................. 44

23

Page 4

English

Operating instructions for users

KMR 1550 B

For your safety

Before you use this machine for the first time, please read the following:

– these operating instructions

– the enclosed leaflet Safety Information No. 5.956-250.

Make sure that all information contained therein is complied with.

Explosion hazard while refuelling!

n Do not fill up with fuel

– in an enclosed space

– while the engine is running.

n Do not smoke while refuelling the vehicle.

n Fuel expands as it becomes warmer.

Do not fill the tank right up to the top. Leave a gap of at least 1 cm under

the bottom edge of the filler neck.

n Wipe up any fuel they may have been spilt and ensure that the cap is

replaced firmly on the tank.

Fire hazard while sweeper is operating!

n Keep highly inflammable materials away from the engine and the exhaust

while the sweeper is operating.

Danger of toppling over on steep slopes!

The sweeper could topple over while it is being driven across or turning

round on a sleep slope.

n The maximum gradient up or down which the sweeper can be driven is

18%.

n Do not drive at right angles to a slope with a gradient steeper than 10%.

Danger of toppling over if bends are negotiated at high speed!

n The sweeper could topple over if it is driven round a bend at high speed.

Drive slowly round bends.

Caution when carrying out maintenance or repairs!

In order to prevent the engine from being started unintentionally, proceed as

follows:

n Remove the ignition key.

n Disconnect the battery at the negative terminal.

Caution while handling the battery!

Observe the safety information provided by the battery manufacturer.

Always use batteries and chargers recommended by KÄRCHER, otherwise

your warranty could be rendered invalid.

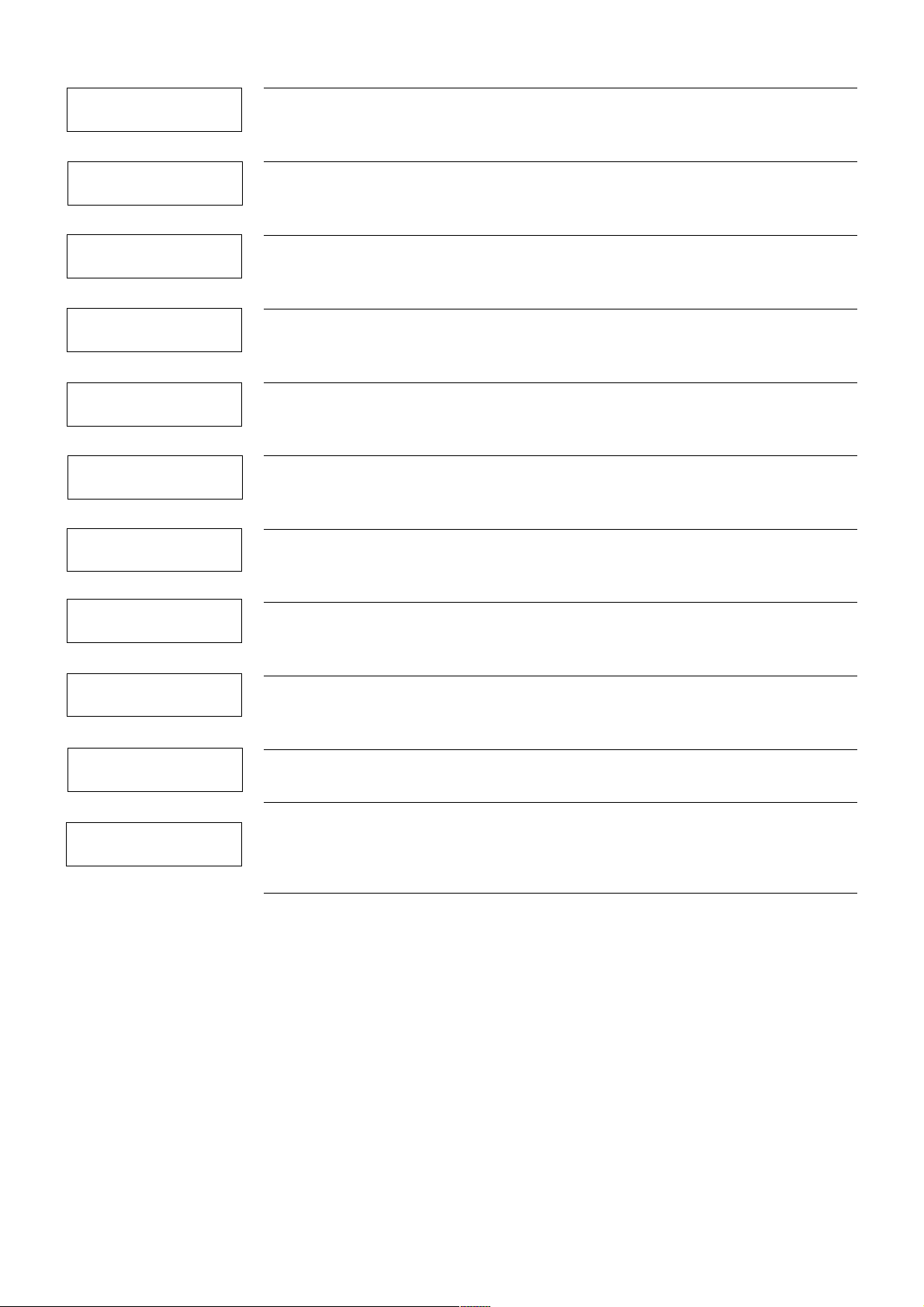

Caution while transporting the sweeper!

Make sure that the sweeper is secured properly if you are going to transport

it to a different location.

Do not use a forklift truck for loading purposes as it could damage the

sweeper.

n Apply the parking brake.

n Secure the sweeper as shown in the illustration, using

– web belts

or

– ropes

or

– chains.

24

Page 5

KMR 1550 B

Operating instructions for users

English

On behalf of the

environment

Intended

applications

Caution, environmental hazard due to exhausted batteries!

Exhausted batteries should not be treated as domestic refuse. Make sure

that are disposed of in an environmentally appropriate manner.

Caution, environmental hazard due to engine oil or hydraulic

fluid!

After you have changed the engine oil or hydraulic fluid, take the waste

product to a recognised collection point or to a waste disposal company.

This sweeper

– has been designed for cleaning outdoor areas

– corresponds to Usage Category “U” for dust particles that do not constitu-

te a danger to health

– should not be used in enclosed spaces

– may not be used on public roads or paths unless it has first been inspec-

ted by an official testing authority (MOT).

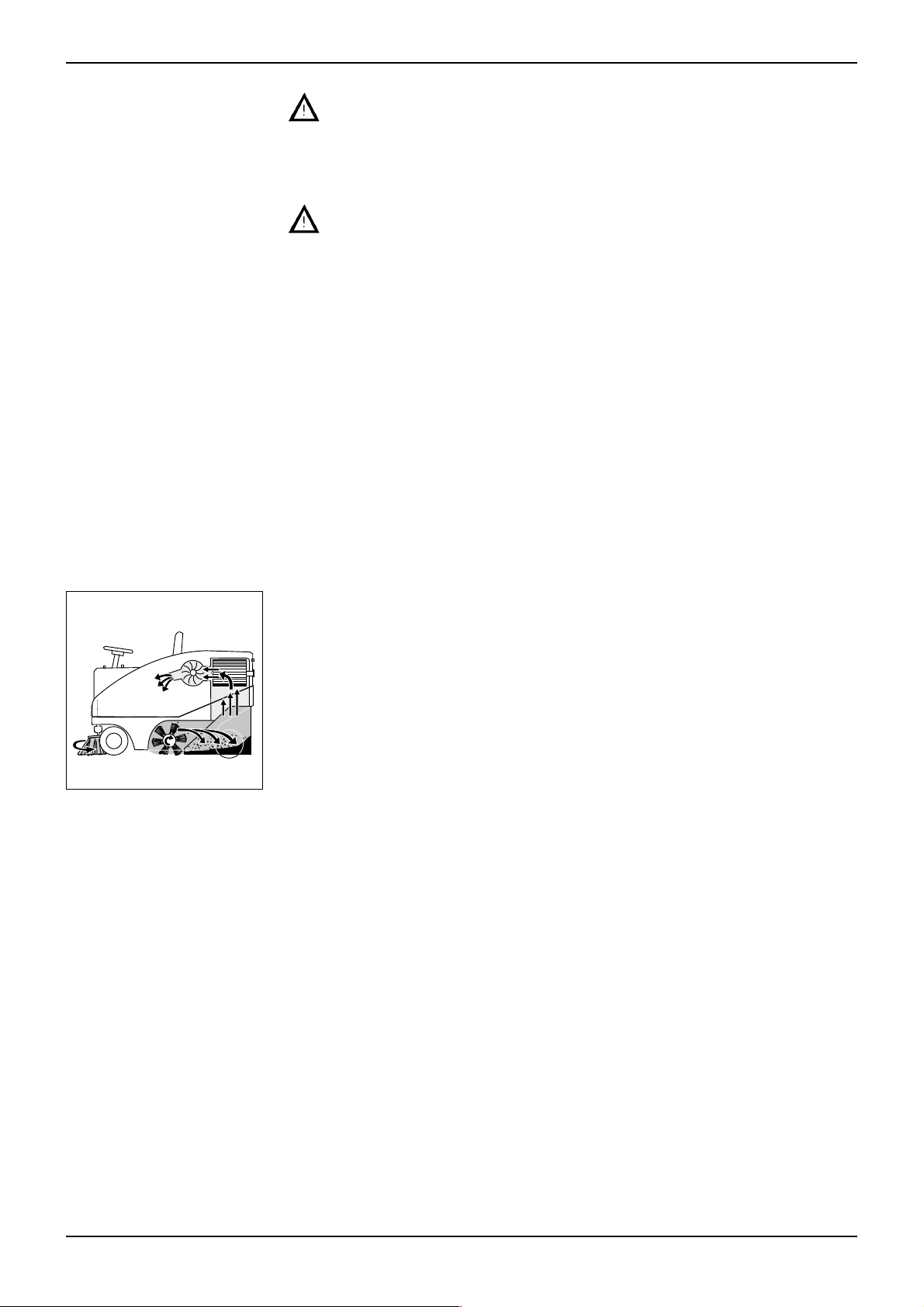

Unit functions

Main components

Drive

– 2-cylinder petrol engine (11.8 kW according to DIN 70 020)

– continuously-variable hydraulic drive system acting on front wheel

– brush roller and side brush driven by hydraulic motor

– hydraulic system for emptying dirt container

– high-performance generator.

Sweeping unit

– brush roller with back-over-the-top action for particularly effective filling

of waste container

– floating brush roller arrangement automatically adjusts to uneven floor

surfaces

– Resettable to stationary main brush to significantly reduce wear of main

brush for dealing with only slight dirt accumulation

– rapid replacement mechanism for brush roller and side brush

– adjustable side brush can be raised, swings out automatically

– bulk waste flap for picking up larger objects (e.g. cigarette packets

or drinks cans).

Filter system

– integrated vacuum unit with radial turbine acting on the brush roller

– two-part filter with 2 x 6 m2 filter area

– preliminary dust filter

– electrical filter shaker with automatic control.

25

Page 6

English

Operating instructions for users

KMR 1550 B

Prior to initial

start-up

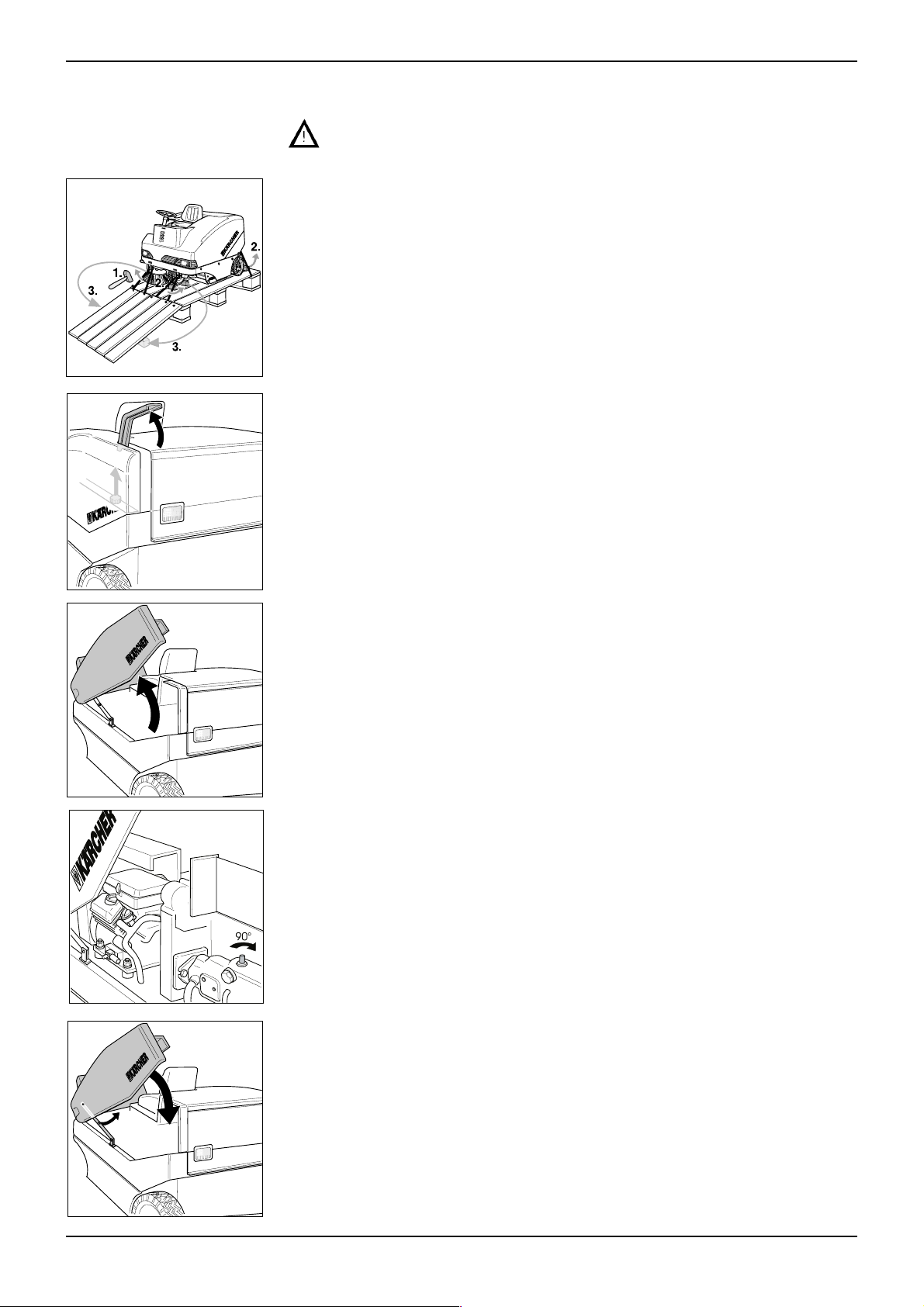

Unloading procedure

Do not use a forklift truck for unloading as it could cause damage to the sweeper.

The sweeper has been lashed onto a pallet to ensure that it can be transported safely. The procedure for unpacking the sweeper is as follows:

1. Remove the wooden boards from the pallet and nail them onto the end of

the pallet (in front of the sweeper).

2. Detach the wires holding the sweeper in place at the ends of the pallet.

3. Knock away the blocks used for locking the wheels and use them for the

support of the wooden planks on the left and right.

4. Drive the sweeper off the pallet and down the ramp made from the boards.

5. The side brush has been tied to the chassis for transport. Undo the cord

holding it in place.

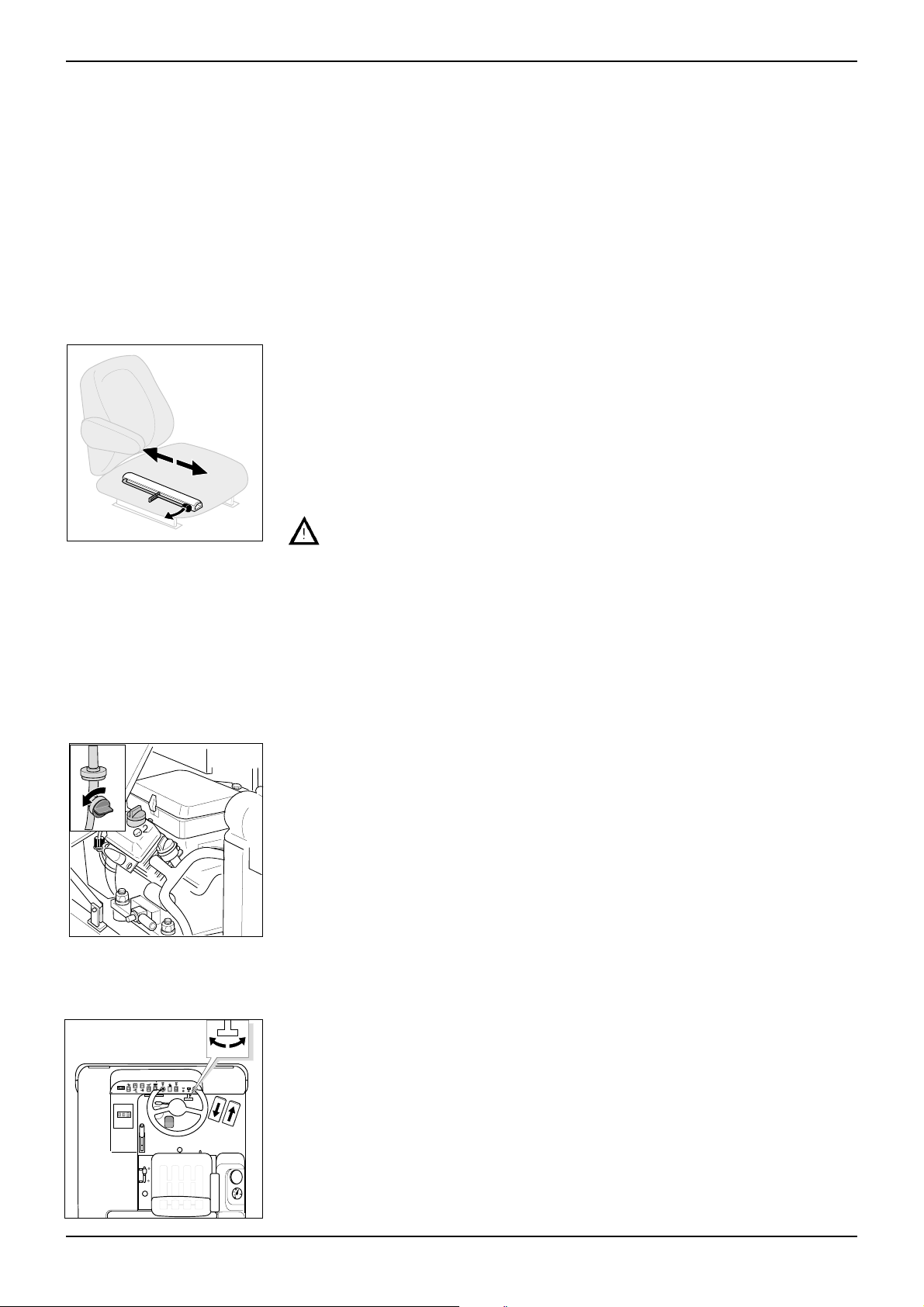

Moving the sweeper

If you want to move the sweeper without starting the engine,

n Pull the section of panelling upwards and unscrew the knob on the inside

of the bonnet.

n Raise the bonnet towards the front until it automatically locks in position.

n Take the open-jawed spanner (7 mm A/F) out of the tool kit.

n Turn the free-wheel arm (bypass) on the hydraulic pump either to the right

or left by 90°, using the open-jawed spanner (7 mm A/F).

Note:

Do not move the sweeper over long distances or at a speed faster than

10 km/h with the switched off (e.g. when it is being towed), as this will result

in damage to the hydraulic system.

After moving the sweeper without the engine running

n Turn the free-wheel arm back through 90°, otherwise it will not be possible

to drive the sweeper normally.

26

n Lift the rod up slightly and close the bonnet.

n Tighten the knob on the inside of the bonnet.

Page 7

KMR 1550 B

Operating the sweeper

Operating instructions for users

Operating controls

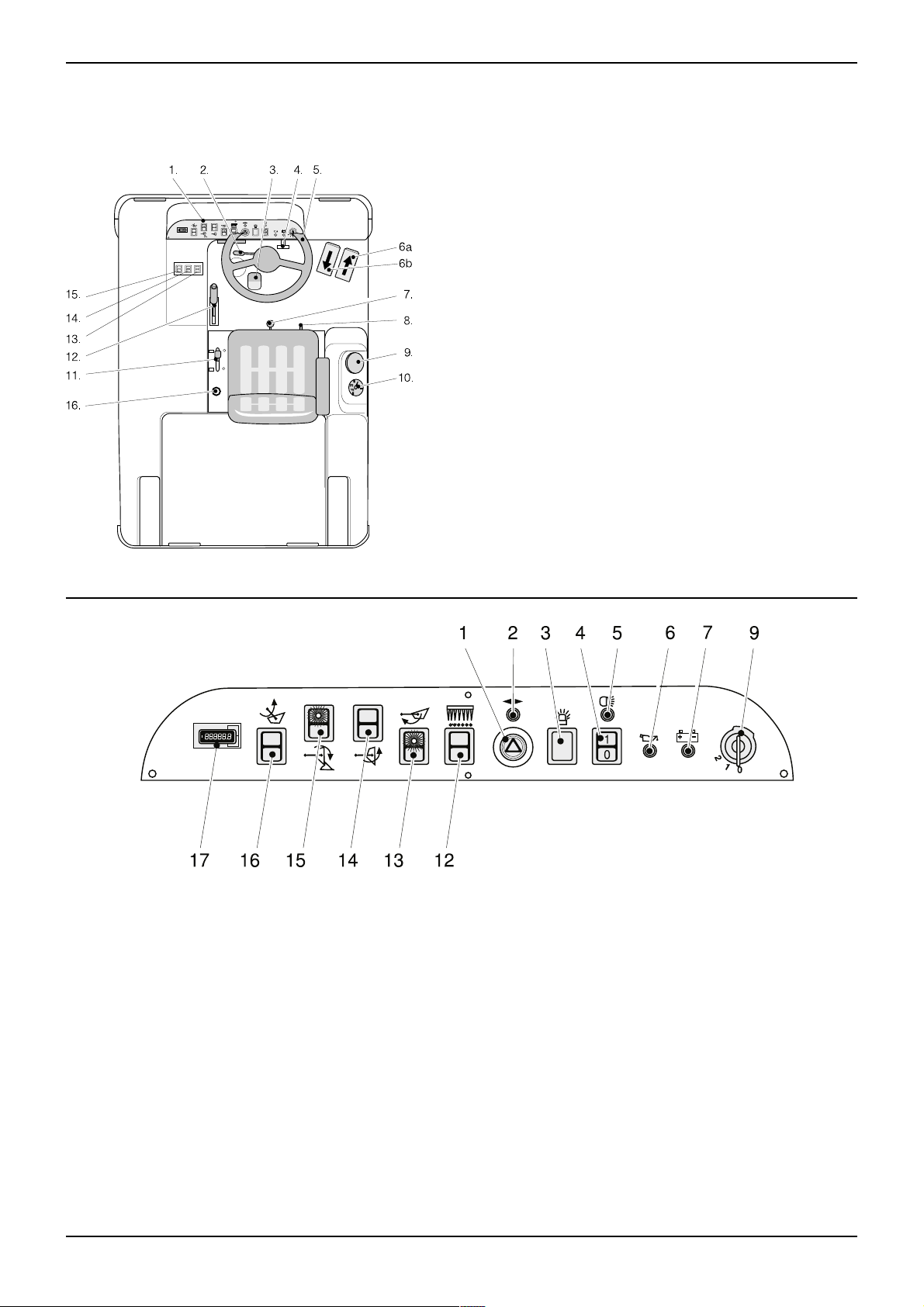

1. Dashboard

(see next page for description of operating controls)

2. Lever on steering column (indicators, light, horn,

main beam flasher)

3. Bulk waste flap

4. Adjusting r.p.m. of side brush

5. Steering wheel

6a. Forward drive pedal

6b. Reverse drive pedal

7. Vacuum unit

8. Adjusting mechanism, driver’s seat

9. Fuel cap

10. Level indicator, fuel tank

11. Throttle lever

12. Parking brake

13. Raise/lower RH side brush

14. Raise/lower brush roller

15. Raise/lower LH side brush (optional)

16. Cold-start lever (choke)

English

Dashboard

1. Hazard warning lights

2. Indicator light (green), direction indicators

3. Rotating warning lamp (optional accessory)

4. Sidelights

5. Indicator light (green) for sidelights

6. Indicator light (red), oil pressure, diesel

engine

(extinguishes as soon as the engine oil pump

has built up sufficient pressure. If it lights up

while the sweeper is operating, check the oil

level or call Customer Service. See Chapter:

“Maintenance”).

7. Indicator light (red), battery charge state

(extinguishes as soon as the dynamo starts

up. If it lights up while the sweeper is operating, call Customer Service).

8. Indicator light, preheating engine

9. Ignition lock

10. Indicator light (clear), engine air-intake filter

(when illuminated, clean or replace air filter on

diesel engine. See Chapter: “Maintenance”).

11. Indicator light (red), coolant

(if light illuminates while the sweeper is operating, check amount of water in radiator. See

Chapter: “Maintenance”).

12. Button for filter shaker

13. Switch, lower waste container

14. Switch, tip waste container inwards

15. Switch, tip waste container outwards

16. Switch, raise waste container

17. Operating hours recorder

27

Page 8

English

Operating instructions for users

KMR 1550 B

Preparing the

sweeper for use

All directions given (left/right, front/rear) are as seen from the driver’s seat.

n Check the oil level in the engine (see Chapter: “Maintenance”).

n Check the level of coolant in the radiator (see Chapter: “Maintenance”).

n Check the amount of fuel in the tank and fill up, if required (see below).

n Check the level of hydraulic fluid and top up, if required (see Chapter:

“Maintenance”).

n Check the air pressure in the tyres (see Chapter: “Maintenance”).

n Inspect the brush roller and remove any string, rope, etc., that may be

caught up in the brushes.

n Check the dust filter. If it is very dirty, operate the shaker to clean it off .

n Empty the waste container.

Adjusting the driver’s seat

The driver’s seat can be adjusted to fit people of different sizes.

n Pull the lever outwards.

n Adjust the seat position and release the lever.

n Move the seat back and forth to ensure that it has locked in position.

Filling the fuel tank

Explosion hazard while refuelling!

n Do not fill up with fuel

– in an enclosed space

– while the engine is running.

n Do not smoke while refuelling the vehicle.

n Fuel expands as it becomes warmer.

Do not fill the tank right up to the top. Leave a gap of at least 1 cm under

the bottom edge of the filler neck.

n Wipe up any fuel they may have been spilt and ensure that the cap is

replaced firmly on the tank.

Opening the fuel tap

n Open up the bonnet and make sure it locks in position.

n Open the fuel tap.

OPEN = Knob turned so that it is parallel to fuel pipe

n Close the bonnet.

Adjusting r.p.m. of side brush

n A clockwise turn reduces the r.p.m. of the side brush.

+-

n A counterclockwise turn increases the r.p.m. of the side brush.

28

Page 9

KMR 1550 B

Operating instructions for users

English

Starting the

sweeper

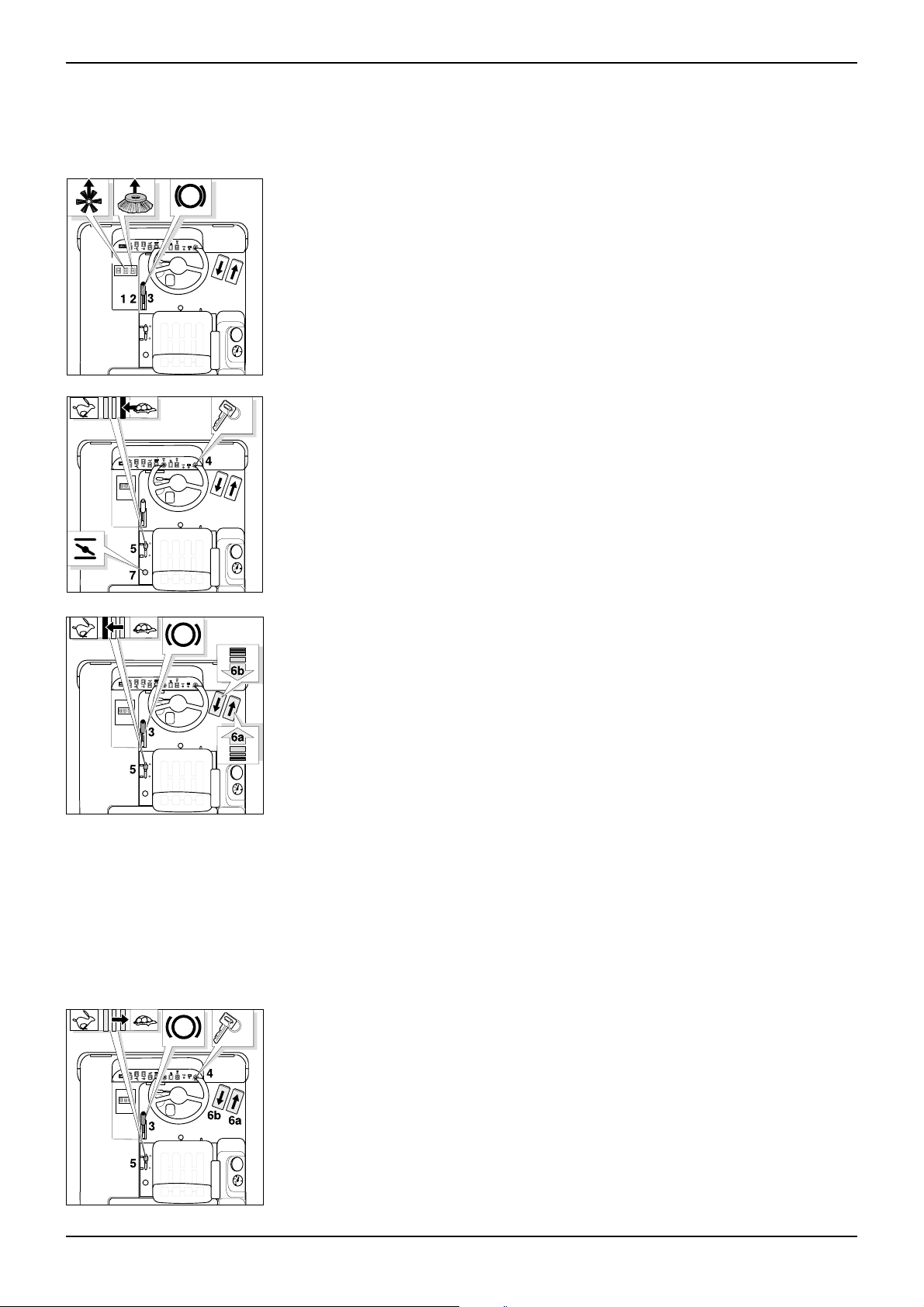

Driving the sweeper for the first time

Select a location with plenty of space to drive the sweeper initially, until you

become familiar with the individual operating controls and their functions.

All directions given (left/right, front/rear) are as seen from the driver’s seat.

n Sit down on the driver’s seat.

The engine cannot be started unless the driver is sitting on the seat

(seat contact switch).

As soon as the driver gets up from the seat, the engine cuts out

(safety shutdown).

n Raise the brush roller 1.

– Press button

n Raise the side brush 2.

– Press button

n Apply the parking brake 3.

n If engine is cold

– pull cold-start lever 7 (choke).

n Set throttle lever 5 to approx. 1/3 max. speed.

n Start engine

– turn ignition key 4 clockwise until engine starts.

n When engine is running smoothly, push cold-start lever 7 back in.

Setting off

Note:

If the sweeper has not been used for longer than 2 months, run the engine for

a few minutes with the unit in neutral before commencing work.

n Set the throttle lever 5 to operating speed (maximum revs., lever pushed

towards the rear.)

n Release the parking brake 3.

– Press the release button and push the lever downwards.

n Depress drive pedal slowly

– 6a Machine drives forward

– 6b Machine reverses

The speed at which the sweeper travels forwards or backwards is infinitely

variable and is controlled by applying pressure to the drive pedal.

Avoid pressing the drive pedal with a jerky movement, otherwise the hydraulic

system could be damaged as a result.

Negotiate slopes with engine at full speed but sweeper travelling slowly (drive

pedal pressed only ½ way down).

Braking

n Lift your foot off the drive pedal 6a/6b and the sweeper brakes automatical-

ly.

Avoid braking the sweeper abruptly by pressing the pedal against the

direction of travel, as this could cause damage to the hydraulic system.

Bringing the sweeper to a halt and stopping the engine

n Lift your foot off the drive pedal 6a/6b. The sweeper brakes automatically

and comes to a halt.

n Set the throttle lever 5 to minimum revs. (push lever forwards).

n Apply the parking brake 3.

n It is very important that you raise the brush roller and side brush so that

the bristles do not become damaged.

n Stop the engine.

– Turn the ignition key 4 anticlockwise to position 0 and pull it out.

After the engine has been switched off, the filter is automatically cleaned for approx. 10 seconds.

29

Page 10

English

Operating instructions for users

KMR 1550 B

Cleaning the filter

Emptying the

waste container

Automatic cleaning

n Stop the sweeper and switch off the engine.

After the engine has been switched off, the filter is automatically cleaned

for approx. 10 seconds.

Manual cleaning

During the time that the sweeper is actually operating, the filter should be

cleaned approx. every 15–30 minutes (depending on the amount of dust).

n Stop the sweeper.

n Raise the brush roller and side brush.

n Switch off the vacuum unit 1.

n Push the button 2 on the dashboard for approx. 10 seconds.

n Switch the vacuum unit on again.

After the filter has been cleaned, you can empty the waste container.

Some important points in advance

Injury hazard!

Make sure that there are no persons or animals standing at the back of the

sweeper, in the immediate vicinity of the waste container, while it is being

emptied.

Danger of hands become trapped!

Keep hands well away from all parts of the emptying mechanism.

Danger of toppling over!

If the sweeper is standing on a slope with an incline greater than 5%, it

could topple over while it is being emptied.

Do not empty the waste container while the sweeper is standing on a slope

unless the incline is less than 5%, as seen in the direction of travel.

n Stop the sweeper.

n Raise the brush roller.

(The waste container cannot be emptied while the brush roller is lowered.)

n Swivel the waste container upwards.

When the waste container has reached the required height:

n Tip out the contents.

Note:

The waste container must have been raised to a certain height before it can

be tipped. It is ready for tipping when the green indicator light in the button

on the dashboard is illuminated.

n Tip the waste container back inwards.

30

Page 11

KMR 1550 B

T ypical applications

Operating instructions for users

n Swivel the waste container downwards.

Note:

The waste container cannot be fully retracted until it has been tipped all the

way back into its original position.

Caution while sweeping!

Do not sweep up any packing bands, wire or similar objects, as these could

cause damage to the sweeping mechanism.

Sweeping Dry Floors

Two different main brush settings are possible:

a) Stationary main brush – sweeping pattern is rigidly fixed, see “Setting

Sweeping Pattern” (in chapter on maintenance),

b) Floating main brush – with its deadweight the main brush rests on the

floor and adapts to floor irregularities

Resetting to “Floating Main Brush”

n Raise main brush

n Open and stay cover

n Reset adjusting screw from position 2 into position 1

English

For slight and normal dirt accumulation:

n For large-floor cleaning –

Lower main brush 1

– Press button

n To switch on dust pick-up

– Move up lever 2

Additionally

n For cleaning up to edge –

Lower side brush 3

– Press button

Note:

The side brush only works when the main brush roller has been lowered.

At regular intervals:

n Clean the filter (see earlier description).

n Empty the waste container (see earlier description).

Notes:

In order to achieve the best cleaning results, the maximum travelling speed is

automatically reduced from 15 km/h to 8 km/h when the brush roller is lowered.

If you are sweeping up very fine dust particles, use the side brush as little as

possible. Even more dust will be created otherwise, as the vacuum unit is not

effective round the side brush.

If the side brush hits an obstacle, it automatically retracts into the side of the

sweeper.

During the time that the sweeper is operating, the filter should be cleaned

approx. every 15–30 minutes (depending on the amount of dust).

Sweeping a damp or wet floor surface

Follow the same basic procedure as for sweeping dry surfaces. To protect the

filter from moisture:

n Switch off the vacuum unit.

– Push the lever downwards.

At regular intervals:

n Empty the waste container (see earlier description).

31

Page 12

English

Operating instructions for users

Picking up large items (sticks, cans, etc.)

Caution!

When the bulk waste flap is open, the brush roller can throw out stones or grit

towards the front of the sweeper. Make sure when you open the flap that no

person, animal or equipment will be endangered.

n Press the pedal and the bulk waste flap will open.

n Drive over the large items at slow speed with the bulk waste flap open.

Note:

In order to prevent dust being created unnecessarily, close the bulk waste flap

again as soon as possible.

Overcoming obstacles

Obstacles up to 5 cm in height

– You can drive over these without any problems. Open the bulk waste flap

beforehand.

Obstacles up to a maximum of 10 cm in height (e.g. kerbs)

– You can slowly drive backwards over these at an angle of 45°. Raise the

brush roller and open the bulk waste flap beforehand.

KMR 1550 B

Long-term storage

Transporting the

sweeper

Obstacles more than 10 cm in height

– You can only drive over these by using a suitable ramp.

If you do not intend to use the sweeper for a longer period of time

(e.g. during the winter months), proceed as follows:

n Drain the fuel tank.

n Close the fuel tap.

n Make sure the side brush and main brush roller are raised in order to

avoid damage to the bristles.

n Clean the inside and outside of the sweeper.

n Change the engine oil (see chapter on “Maintenance”).

n Park the sweeper where it is protected from the elements and secure it

against rolling away.

n Pull out the ignition key.

n Charge the battery with a suitable charging device at intervals of approx. 2

months (see chapter on “Maintenance”).

If the sweeper is going to be transported on the back of a vehicle, it must be

properly secured so that it cannot move unintentionally.

n Apply the parking brake.

n Secure the sweeper in the manner shown in the illustration only, using

– web belts

or

– ropes

or

– chains.

32

Page 13

KMR 1550 B

Operating instructions for users

English

Cleaning and care

Maintenance

Before you carry out any cleaning or general maintenance tasks,

n Park the sweeper and switch off the engine.

Cleaning the inside of the sweeper:

You can clean out the inner parts of the sweeper by blowing them through

with compressed air.

Cleaning the outside of the sweeper:

The outside of the sweeper can be wiped off with a damp cloth. Do not use

any aggressive cleaning agents which might cause damage to the plastic

components.

First engine oil change

Caution!

When an engine is new, it is subject to increased abrasion. In order that the

engine does not suffer any damage, we recommend that you change the

engine oil and the oil filter after the first 8 operating hours.

Initial inspection after 8 operating hours

Caution!

In order to ensure that your sweeper functions safely and reliably, it should

undergo an initial inspection after approx. 8 operating hours. The inspection

should be carried out by an authorised service agent.

n Inspect all Bowden cables and adjust them if necessary.

n Replace the hydraulic fluid filter.

n Change the engine oil.

n Check that no hydraulic components are leaking and that they all function

correctly.

n Check that the handbrake functions correctly.

n Check the tyre pressure (specified value: 8 bar)

Daily maintenance

n Check the engine oil level.

n Check the hydraulic fluid level and top up if required.

n Check the tyre pressure (specified value: 8 bar).

n Inspect the brush roller for string, rope, etc. which may have been caught

up and remove it if necessary.

n Inspect the dust filter and if it is very dirty, shake it clean.

n Empty the dirt container.

Maintenance intervals

Keep to the service intervals set out in the maintenance booklet so that your

sweeper functions reliably and you retain the full benefit of the warranty.

The maintenance booklet 5.950-047 can be found in the tool compartment on

the sweeper (under the bonnet).

The necessary maintenance tasks should be carried out by an authorised

service agent.

Safety information applicable to maintenance tasks

Caution!

Before you begin any maintenance tasks, please read the enclosed leaflet

Safety Information No. 5.956-250.

33

Page 14

English

Operating instructions for users

Caution! Make sure engine cannot be started unintentionally.

In order to prevent the engine from being started unintentionally, proceed as

follows after you have parked the sweeper.

n Pull out the ignition key.

n Disconnect the battery at the negative terminal.

The necessary maintenance tasks or daily inspections can be carried out with

the bonnet raised or the seat tipped forward.

Injury hazard!

Do not open the bonnet until the motor has been switched off.

Burns hazard!

Take care not to touch the exhaust when you open the bonnet.

Injury hazard!

If you need to work under the waste container while it is in the raised position, you must first of all secure the container to prevent it from dropping down

unintentionally:

n Secure the waste container at both sides.

– Undo the hand screw in the side cover.

– Insert the hand screw into the locking bolt and pull it out.

KMR 1550 B

Maintenance tasks

n Release the bolt before using the sweeper again.

– Push the bolt inwards as far as it will go.

– Undo the hand screw and replace it in the side cover.

Tilting the seat forwards/backwards

n Pull the lever and slide the seat forwards.

n Undo the catch with the square spanner (with ignition key).

n Tip the seat forwards until it locks in position.

n To close the compartment, release the mechanism holding the seat in the

raised position and fold the seat down.

34

Page 15

KMR 1550 B

Operating instructions for users

Disconnecting the battery

n Slide the seat forwards and tilt it towards the front.

n Use an open-jawed spanner (size 10 mm) to first of all loosen the clamp

on the negative terminal ( – ) and then pull it off. Repeat the procedure for

the positive terminal ( + ).

n Reconnect the battery by first of all attaching the clamp on the positive

terminal ( + ) and then the clamp on the negative terminal ( – ).

Opening/closing the bonnet

n Pull the section of panelling upwards and unscrew the knob on the inside

of the bonnet.

n Raise the bonnet towards the front until it automatically locks in position.

English

n Lift the rod up slightly and close the bonnet.

n Screw the knurled knob back into the inside of the bonnet.

Tool compartment and sweeper tool kit

n There is a tool compartment under the bonnet. This compartment contains

the tools required to carry out routine maintenance tasks.

Checking tyre pressure

n Park the sweeper on a level surface.

n Check the tyre pressure and make any necessary corrections.

Air pressure for front and rear wheels = 8 bar.

35

Page 16

English

1

Operating instructions for users

Checking the engine oil level

Caution,

Risk of burns from hot exhaust pipe!

n Park the sweeper on a level surface.

n Unscrew the dipstick.

n Wipe the dipstick clean and screw it back in.

n Unscrew the dipstick once again.

The oil level should be between the “Min” and the “Max” marks.

If the oil level is below “Min” – top up with engine oil.

If the oil level is above “Max” – drain off excess engine oil.

n Screw the dipstick back in again.

Topping up with engine oil

n Pour engine oil into the engine through the filler hole in the cylinder head.

Engine oil SAE 30 or SAE10W-30.

The engine oil must correspond to the following classification:

SF, SE, SD or SC and should be a primary raffinate.

The engine oil should contain no additives.

If the outside temperature is below –5 °C, 5W-30 or 5W-20 can also be

used.

KMR 1550 B

Replacing the engine oil

Caution,

Environmental hazard caused by engine oil!

Deposit the waste oil resulting from an oil change at a waste oil collection

point or take it to a waste disposal company.

Caution,

Danger of burns from hot exhaust pipe or scalding by hot

engine oil!

n Run the engine until it reaches operating temperature.

n Park the sweeper on a level surface.

n Open the bonnet.

n Place a suitable receptacle under the sweeper to collect the waste oil.

n Unscrew valve and drain out oil through a hose.

n Pour fresh engine oil into the filler hole.

Capacity: 1.65 litres

n Make sure that the oil filler hole is properly sealed.

n Wipe off any oil that may have been spilt and dispose of the waste oil

properly.

36

Page 17

KMR 1550 B

Operating instructions for users

Replacing the engine oil filter

n Drain off the engine oil.

n Open the service flap

– Unscrew knob and lift off service flap.

n Unscrew the engine oil filter.

n Rub engine oil into the seal on the new oil filter.

n Attach the new engine oil filter by hand and screw it down until the seal

just touches the casing.

n Tighten the engine oil filter by giving it another half turn.

n Pour in new engine oil and check the level.

n Start the engine and check that there are no leaks.

English

Cleaning the air filter

n Remove the cover on the air filter.

n Take out the filter cartridge.

n Separate the paper and plastic inserts.

n Renew the paper insert (this insert cannot be cleaned).

n Clean the plastic insert

– Wash the plastic insert in soapy water (e.g. water with a little washing

up liquid added) and rinse it thoroughly in clean water.

– Allow the insert to dry and then spray it lightly with engine oil.

– Squeeze out any excess oil.

n Refit all parts of the filter and secure the cover in place.

Replacing the fuel filter

n Close the fuel tap.

n Undo both hose clamps on the fuel filter.

n Pull hoses off the filter.

n Fit new filter by reversing procedure above.

37

Page 18

English

Operating instructions for users

Checking the hydraulic fluid level

n Park the sweeper on a level surface.

n Clean the area surrounding the dipstick.

n Pull out the dipstick.

n Wipe the dipstick clean and re-insert it.

n Pull out the dipstick once again and read off the oil level.

The fluid should be level with the rough section on the dipstick. If the fluid

level is too low, this is a sign that there is a leak in the hydraulic system.

Do not start the sweeper. Call Customer Service.

n Insert the dipstick.

KMR 1550 B

38

Page 19

KMR 1550 B

Operating instructions for users

Safety information

English

which must be observed when handling batteries.

Comply with the user instructions and ensure that these are displayed

at the charging station. Before the operator carries out any work on

batteries, he/she must have received proper instruction from a suitably

qualified person.

Wear safety goggles and protective clothing when working on batteries. Observe accident prevention regulations, as well as DIN VDE

0510, VDE 0105 Part 1.

Smoking is forbidden!

Make sure that there are no naked flames, other source of heat or

sparks in the proximity of the battery, otherwise there is a danger of

explosion or fire.

If electrolyte comes into contact with skin or eyes, rinse the affected

area with plenty of clean water. The metal parts of battery cells are

permanently live. Therefore do not place any tools or other objects on

top of the battery.

Explosion and fire hazard! Avoid short-circuits.

Warning! The metal parts of battery cells are permanently live. Therefore do not place any tools or other objects on top of the battery.

Electrolyte is highly corrosive. Under normal operating conditions it is

not possible for anything to come into contact with the electrolyte. If

the battery housing is destroyed, the bound electrolyte that leaks out

is just as corrosive as liquid electrolyte.

Return to manufacturer!

Exhausted batteries bearing this symbol are a re-usable resource

which should be recycled accordingly. Exhausted batteries that are not

intended to be recycled must be disposed of as hazardous waste in

compliance with all relevant regulations.

Checking the electrolyte in the battery

Check the acid concentration in electrolyte-filled batteries at regular intervals.

Make sure the battery is fully charged before it is tested.

If required:

n Top up with distilled water until the level of fluid is approx. 1 cm above the

lead plates.

Charging the battery

Note:

Only use a regulated charger that is suitable for use with starter batteries and

is capable of delivering a charging current of 4–6 A.

n Stop the sweeper and remove the ignition key.

n Tilt the seat forwards.

n Connect the positive terminal (red clamp) to the charger.

n Connect the negative terminal (black clamp) to the charger.

n Connect the charger to the mains and switch it on. The charging time is

specified by the manufacturer of the charger.

39

Page 20

English

Direction of travel

Operating instructions for users

Replacing sealing strips

The sealing strips fulfil an important function. They maintain the partial vacuum in the area surrounding the brushes that is necessary for the sweeper to

perform properly. In so doing, they ensure that no dust is expelled while the

machine is sweeping.

Damaged or worn out sealing strips should be replaced immediately.

n Stop the sweeper and turn off the engine.

n Remove the hex screws and pull off the sealing strips.

n Insert new sealing strips and align them as follows.

Adjust the side strips so that they clear the ground by 3–5 mm.

Adjust the strip at the front so that when the sweeper is travelling forwards, it bends backwards by 20–40 mm and the strip at the rear so that it

bends backwards by 0–20 mm.

n Tighten the hex screws.

Replacing the side brush

n Stop the sweeper and turn off the engine.

n Raise the side brush.

n Undo the three nuts by hand.

n Remove the side brush.

n Attach the new side brush.

n Screw on the three nuts by hand and tighten securely.

KMR 1550 B

Replacing the brush roller

n Stop the sweeper and turn off the engine.

Burns hazard!

Take care not to touch the hot exhaust.

n Remove the 3 screws (Torx) and lift off the side cover.

n Remove the hand screws in the oscillating linkage.

40

Page 21

KMR 1550 B

Operating instructions for users

n Remove the next three hand screws and lift off the roller cover.

n Pull out the brush roller at the side.

English

Brush roller viewed

from above

Direction of travel

Note: Raise the brush roller unit before inserting a new roller.

n Insert a new brush roller, paying attention to correct alignment (see illu-

stration). The projections on the driver must slot into the recesses in the

brush roller.

n Continue with assembly in reverse order of removal.

Replacing fuses

n Stop the sweeper and switch off the engine.

n Open the bonnet.

n Remove the cover.

n Replace any blown fuse with one with the same rating. There are spare

fuses in the fuse box.

Note:

If the same fuse blows several times, this is a sign that there is a fault in the

electric circuitry. Locate and repair the fault (see section on Troubleshooting).

Replacing the dust filter

Dust filters should be inspected for signs of damage every 50 operating

hours. A damaged filter allows dust to be blown into the engine compartment

and surrounding area. A significant build-up of dust at the air exit from the

fan is an indication that the filter is not properly seated or is defective.

n Raise the waste container to its max. height.

n Secure the waste container at both sides.

– Undo the screw in the side cover.

– Insert the hand screw into the locking bolt and pull it out.

n Remove the two hand screws in the preliminary filter and lift out the filter

from below.

n Loosen 2 screws on the thrust bearing and turn the thrust bearing anti-

clockwise up to the stop (1). Draw out the thrust bearing towards the rear

(2).

n Draw the filter element towards the rear and take it out to the rear (3).

41

Page 22

English

Operating instructions for users

n Centre the new filter on the driver (1). Push in the thrust bearing (2). Turn

the thrust bearing clockwise until the stop and fasten with the screws (3).

n Insert the preliminary filter and secure it with the two hand screws.

Setting the Sweeping Pattern

Note:

The main brush can be reset to:

– Floating 1: With its deadweight the main brush rests on the floor.

– Stationary 2: The sweeping pattern is adjustable at the main brush.

In order to adjust the sweeping pattern reset the main brush to “Stationary”.

n Open and stay cover

n Reset main brush to “Stationary 2”

KMR 1550 B

n The sweeping pattern can be altered by turning the adjusting screw.

To increase coverage – turn screw outwards

or

To reduce coverage – turn screw inwards

n Close the bonnet.

Check the sweeping pattern after making any adjustments.

n Drive the sweeper onto a dusty surface.

n Lower the brush roller and let it sweep for several seconds.

n Raise the brush roller and drive the sweeper backwards a short distance

with the bulk waste flap opened.

n The width of the contact area should be 60 - 80 mm.

Note:

If the sweeping pattern is irregular in shape, arrange for Customer Service to

make the necessary corrections.

42

Page 23

KMR 1550 B

Operating instructions for users

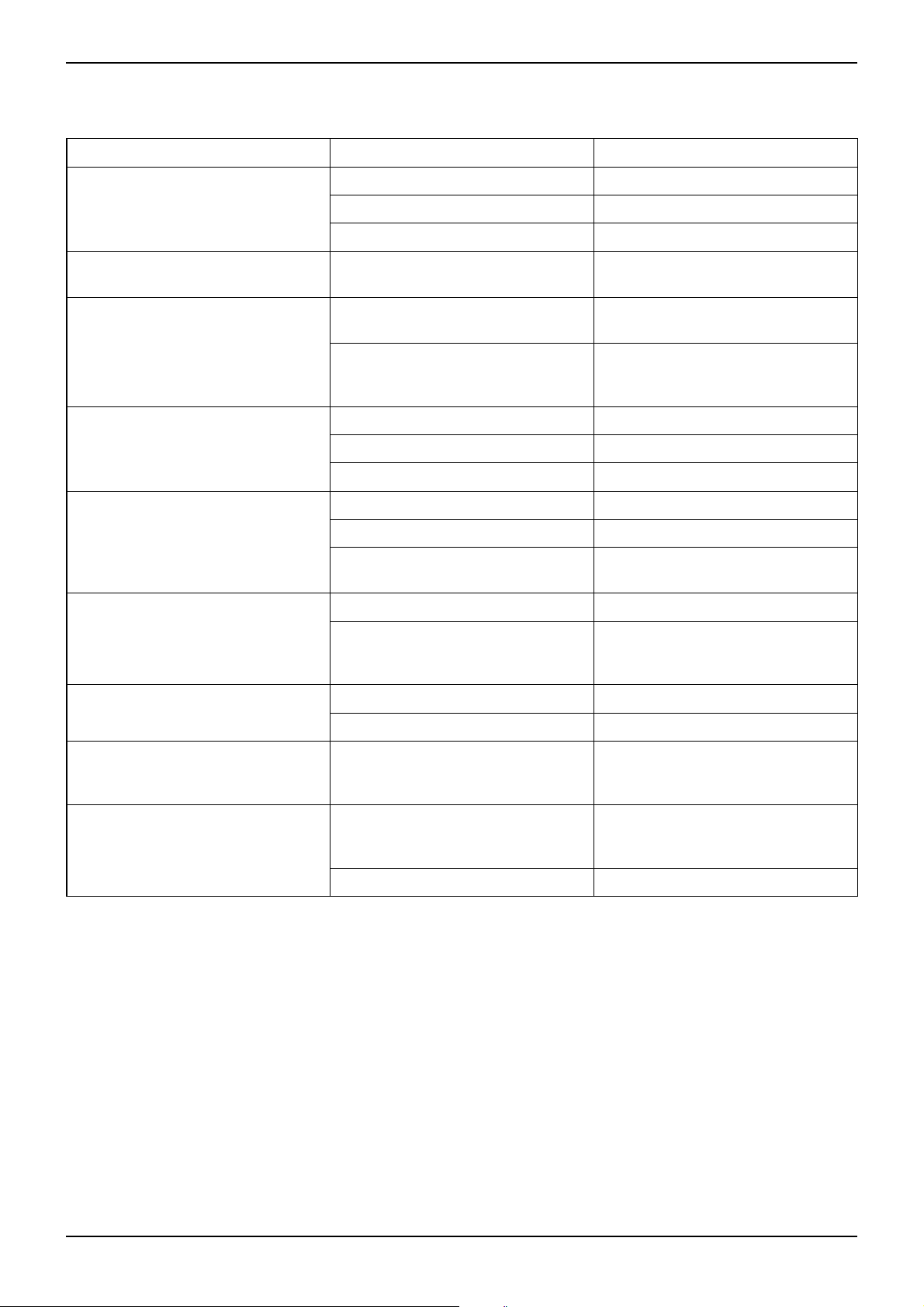

Troubleshooting

Problem Possible cause Remedy

English

Engine does not start

Sweeper does not move

Brushes do not rotate

No vacuuming function

Poor sweeping results

Dust is blown out during

sweeping

Battery is flat Recharge or replace battery

No fuel in tank Refill tank and bleed fuel system

Fuel tap is closed Open fuel tap

Free-wheel arm on hydraulic pump

(bypass valve) is in open position

Switch on brush roller lever is

stuck

Brush roller or side brush have

been jammed by bands, string,

wire, etc.

Vacuum unit is switched off Switch on vacuum unit

Blower is not rotating Check tension of V-belt

Filter is clogged up Clean or replace filter

Brushes are worn out Replace brushes

Waste container is full Empty waste container

Sweeping pattern is set up

incorrectly

Vacuum unit is switched off Switch on vacuum unit

Seals on the sweeper are worn

down. Filter is not fitted correctly or

is defective.

Close valve by turning arm through

90º

Call Customer Service

Remove obstruction

Set up sweeping pattern correctly

Replace seals. Fit filter correctly or

replace it.

Waste container cannot be

raised for emptying

Sweeper travels

forwards/backwards although

drive pedal is not pressed

Indicator light (red) oil pressure

and acoustic signal

Brush roller is still lowered Switch off brush roller

Defective switch Call Customer Service

Zero position is not set up correctly Call Customer Service

Engine oil level is too low Check engine oil level and top up if

required (see Chapter:

Maintenance)

Fault on engine Call Customer Service

43

Page 24

English

Technical specifications

Operating instructions for users

KMR 1550 B

Dimensions and weights

Length 1.805 mm

Width 1.290 mm

Height 1.410 mm

Unladen weight (ready for operation) 700 kg

(with 2 side brushes) 72 0 kg

Max. permissible overall weight 1.080 kg

Driving and sweeping performance

Max. travelling speed 1 6 km/h

Max. climbing ability/gradient 1 8 %

Effective sweeping width

without side brush 95 0 mm

Effective sweeping width

with 1 side brush 1.250 mm

Effective sweeping width

with 2 side brushes 1.600 mm

Area rating (theoretical)

without side brush 7.600 m²/h

with 1 side brush 10.000 m²/h

with 2 side brushes 12.800 m²/h

Waste container

Theoretical capacity 17 5 l

Max. usable capacity 160 l

Lifting height 1.450 mm

Filter surface area 1 2 m ²

Sweeping unit

Drive system

Variable volume hydraulic pump 0–20 cm³

Constant volume hydraulic motor 25 0 cm³

Hydraulic fluid

Filling amount 2 5 l

Class * DIN HVLP 51524/3 100 c St / 40 °C

* recommended hydraulic fluid: BP BARTRAN

HV100.

Protection class splashproof

Ambient conditions

temperature -5 to + 4 0 ° C

air humidity, not wet with dew 0 - 90 %

Operating cycle

Under favourable conditions, the sweeper has an

operating cycle of 10 hours with a full fuel tank at

the start. The actual time is dependent upon several

factors:

– surface structure of the ground and how level it is

– how well the sweeper has been maintained

– type of brush roller and its degree of wear.

Noise emission

Sound level (EN 60704-1) 79 dB(A)

Guaranteed noise level

(2000/14/EC) 103 dB(A)

Machine vibration

Rated vibration value

(ISO 5349) < 2,5 m/s²

Brush roller with V-shaped rows of bristles

Diameter of brush roller 37 5 mm

Diameter of side brush 52 0 m m

Vehicle tyres 4.00-8 6PR

Air pressure, front 8 bar

Air pressure, rear 8 b a

Engine

Model Vangard

Type 4-stroke

Cylinders 2

Capacity 480 cm³

Output (at 3600 r.p.m.) 11.8 kW

Fuel (min. 85 octane rating)regular grade unleaded

petrol

Engine oil

(see section “Replacing the engine oil”) 1,65 l

Battery 12 Volt

32 Ah

Starter electric

Ignition electromagnetic

Spark plug Champion RC 12 YC

44

Page 25

KMR 1550 B

1.948-204.0

1.948-224.0

7.348-242.0

6.961-480.0

6.303-135.0

7.312-003.0

6.961-481.0

6.414-526.0

5.047-430.0

6.491-287.0

6.491-288.0

6.491-250.0

6.961-485.0

7.312-261.0

7.304-395.0

6.310-066.0

6.906-083.0

4.020-003.0

6.961-103.0

6.905-623.0

6.277-429.0

6.961-118.0

6.491-220.0

6.310-066.0

6.491-285.0

6.961-199.0

5.047-429.0

4.620-004.0

6.961-118.0

6.961-538.0

6.961-103.0

4.020-003.0

6.277-429.0

17.02.2003 - 1/2

Page 26

KMR 1550 B

1.948-204.0

1.948-224.0

6.491-583.0

6.961-023.0

7.651-006.0

7.651-014.0

6.651-371.0

6.491-584.0

6.961-268.0

6.961-412.0

7.651-020.0

7.651-004.0

6.961-521.0

7.651-014.0

7.651-006.0

6.651-372.0

6.633-406.0

7.644-007.0

7.644-018.0

7.644-040.0

4.515-034.0

6.961-016.0

6.961-008.0

6.961-008.0

4.515-034.0

7.311-012.0

6.961-536.0

7.651-014.0

>>MICROMP<< LADETECHNIK

24V 30A Wa

6.435-296.0

6.654-116.0

17.02.2003 - 2/2

Page 27

DICHIARAZIONE DI CONFORMITÀ CE

Dichiariamo con la presente, che la macchina qui di seguito indicata, in

DÉCLARATION DE CONFORMITÉ EUROPÉENNE

Par la présente, nous déclarons que la machine ci-après répond, de par

base alla sua concezione e al tipo di costruzione, e nella versione da

noi introdotta sul mercato, è conforme ai relativi requisiti fondamentali di

sa conception et sa construction ainsi que de par le modèle que nous

avons mis sur le marché, aux exigences de sécurité et d’hygiène en

sicurezza e di sanità delle direttive della CE.

In caso di modifica apportate alla macchina senza il nostro accordo,

questa dichiarazione perde la sua validità.

Prodotto: Spazzatrice / macchina applicata

Tipo: 1.948-xxx

Direttive CE pertinenti:

Direttiva macchine (98/37/EG)

modificata dalle 91/263/EWG, 92/31/EWG, 93/68/EWG

Direttive CE sulle emissioni acustiche (2000/14/UE)

vigueur de la directive européenne.

En cas de modification de la machine effectuée sans notre accord, cette

déclaration sera caduque.

Produit: Balayeuse / machine autoporteuse

Type: 1.948-xxx

Directives européennes en vigueur:

Directive européenne sur les machines (98/37/EG)

Directive européenne sur la compatibilité électromagnétique

(89/336/EWG) modifiée par 91/263/EWG, 92/31/EWG, 93/68/EWG

Directive CE relative aux émissions sonores (2000/14/UE)

Norme armonizzate applicate:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Norme nazionali applicate:

CISPR 12

Metodo di valutazione conformità utilizzato

Allegato V

Livello potenza sonora misurato:

101 dB(A)

Livello potenza sonora garantito:

103 dB(A)

Mediante accorgimenti interni, è stato assicurato che gli apparecchi di

serie siano sempre conformi ai requisiti delle attuali direttive CE e alle

norme applicate.

I firmatari agiscono su incarico e con i poteri dell’Amministrazione.

Normes harmonisées appliquées:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Normes nationales appliquées:

CISPR 12

Procédure d’analyse de conformité utilisée

Annexe V

Niveau de puissance sonore mesuré:

101 dB(A)

Niveau de puissance sonore garanti:

103 dB(A)

La conformité permanente des appareils de série avec les exigences

consignées dans les directives actuelles de la CE et avec les normes

appliquées est garantie par des mesures internes.

Les soussignés agissent par ordre et avec les pleins pouvoirs de la

Direction commerciale.

EU DECLARATION OF CONFORMITY

We hereby declare that the equipment described below conforms to the

relevant fundamental safety and health requirements of the appropriate

EU Directives, both in its basic design and construction as well as in the

version marketed by us.

This declaration will cease to be valid if any modifications are made to

the machine without our express approval.

Product: Sweeper / Ride-on unit

Model: 1.948-xxx

Relevant EU Directives:

EU Machinery Directive (98/37/EG)

EG - KONFORMITÄTSERKLÄRUNG

Hiermit erklären wir, daß die nachfolgend bezeichnete Maschine

aufgrund ihrer Konzipierung und Bauart sowie in der von uns in Verkehr

gebrachten Ausführung den einschlägigen grundlegenden Sicherheits-

und Gesundheitsanforderungen den unten aufgeführten EG-Richtlinien

entspricht. Bei einer nicht mit uns abgestimmten Änderung der

Maschine verliert diese Erklärung ihre Gültigkeit.

Produkt:Kehrsaugmaschine / Aufsitzmaschine

Typ: 1.948-xxx

Einschlägige EG-Richtlinien

EG-Maschinenrichtlinie (98/37/EG)

EU Directive on Electromagnetic Compatibility (89/336/EWG)

amended by 91/263/EWG, 92/31/EWG, 93/68/EWG

EU guideline on noise emissions (2000/14/EU)

Harmonised standards applied:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Relevant EU Directives:

CISPR 12

EG-Richtlinie Elektromagnetische Verträglichkeit (89/336/EWG)

geändert durch 91/263/EWG, 92/31/EWG, 93/68/EWG

EG-Richtlinie über Geräuschemissionen (2000/14/EU)

Angewandte harmonisierte Normen:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Angewandte nationale Normen:

CISPR 12

Applied conformity valuation method

Appendix V

Measured noise level:

101 dB(A)

Guaranteed noise level:

103 dB(A)

Appropriate internal measures have been taken to ensure that series-

production units conform at all times to the requirements of current EU

Directives and relevant standards.

Angewandtes Konformitäts- Bewertungsverfahren

Anhang V

Gemessener Schallleistungspegel:

101 dB(A)

Garantierter Schallleistungspegel:

103 dB(A)

Prüfgrundsätze des Hauptverbandes der gewerblichen

Berufsgenossenschaft Kehrsaugmaschinen

Es ist durch interne Maßnahmen sichergestellt, daß die Seriengeräte

The signatories are empowered to represent and act on behalf of the

company management.

immer den Anforderungen der aktuellen EG-Richtlinien und den

angewandten Normen entsprechen.

Die Unterzeichnenden handeln im Auftrag und mit Vollmacht der

Geschäftsführung.

Page 28

EU-KONFORMITETSERKLÆRING

Vi erklærer herved at maskinen som er beskrevet nedenfor, i

konstruksjon og utførelse tilsvarer markedsførte modell og er i

overensstemmelse med de gjeldende og grunnleggende sikkerhets- og

helsekrav i EU-direktivet.

Denne erklæring mister sin gyldighet dersom maskinen endres uten

etter avtale med oss.

Produkt: Feiemaskin / Rider

Type: 1.948-xxx

Дюлщуз рйуфьфзфбò åê

ЕмеЯт, дзлюнпхме ìå ôçí рбспэуб, üôé ôï мзчЬнзмб ðïõ

чбсбкфзсЯжефбé рбсбкЬфщ, ëüãù ôïõ óчедйбумпэ êáé ôïõ

фсьрпх кбфбукехЮт, üðùò êáé ëüãù ôçò рбсбллбгЮт ðïõ

äéáôЯиефбй áðü ìáò óôçí бгпсЬ, бнфбрпксЯнефбé óôéò ó÷åôéêÝò

âбуйкЭт брбйфЮуейт буцблеЯбт êáé хгеЯбт ôùí Пдзгйюн ÅÊ. Óå

ресЯрфщуз бллбгюн óôï мзчЬнзмб чщсЯт рспзгпэменç

ухнненьзуз ìáæß ìáò, рбэей íá йучэей ç рбспэуб дЮлщуз.

Рспъьí: МзчбнéêÞ óêïýðá/ МзчбнЮ кбибсйумпэ ìå èÝóç ãéá ôïí

ïäçãü

Ôýðïò: 1.948-xxx

Gjeldende EU-direktiv:

EU-direktiv for maskiner (98/37/EG)

EU-direktiv for elektromagnetisk toleranse (89/336/EWG)

endret ved 91/263/EWG, 92/31/EWG, 93/68/EWG

EU-direktiv om støyemisjoner (2000/14/EU)

Anvendte overensstemmende normer:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Anvendte nasjonale normer:

CISPR 12

Anvendt metode for vurdering av samsvar

Tillegg V

Målt lydeffektnivå:

101 dB(A)

Garantert lydeffektnivå:

103 dB(A)

Gjennom interne tiltak er det sikret at serieproduserte maskiner alltid er i

Ó÷åôéêýò ПдзгЯет ÅÊ:

ПдзгЯб ÅÊ учефйкЬ ìå ôéò мзчбнЭт (98/37/EG)

ПдзгЯб ÅÊ ðåñß злекфспмбгнзфйкЮт óõìâбфьфзфпт (89/336/EWG)

ðïõ фспрпрпйЮизке ìå ôçí ПдзгЯб 91/263/EWG, 92/31/EWG,

93/68/EWG

ПдзгЯб ÅÊ ðåñß ЕкрпмрÝò ипсэвùí (2000/14/EÅ)

ЕнбсмпнйумЭнб ðñüôõðá ðïõ Эчпхн åöáсмпуиåß:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

ЕинйкЬ рсьфхрб ðïõ Эчпхн ецбсмпуиеЯ:

CISPR 12

ЕцбсмпуиеЯуб мЭипдпт áîéпльгзузт óõìмьсцщузт

РбсЬсфзмб V

Мефсзиåßóá уфЬимз бкпхуфйкЮт рЯеузт:

101 dB(A)

ДйбуцблйумЭнз уфЬимз бкпхуфйкЮт рЯеузт:

103 dB(A)

Ìå лзциЭнфб еущфесйкЬ мЭфсб Ý÷åé еобуцблйуиеЯ, üôé ïé

ухукехЭт уейсЬт кбфбукехЮт бнфбрпксЯнпнфбé рЬнфб óôéò

overensstemmelse med kravene i de aktuelle EU-direktiver og anvendte

normer.

Undertegnede handler etter oppdrag og med fullmakt fra ledelsen.

брбйфЮуейт ôùí ерйкбЯсщн пдзгйюн ÅÊ êáé óôá ецбсмпуиЭнфб

рсьфхрб. Ïé хрпгсЬцпнфет енесгпэн ìå енфплЮ êáé кбфьрйí

еопхуйпдьфзузт ôçò ГенйкЮт Дйеэихнузт.

DECLARACIÓN DE CONFORMIDAD DE LA UNIÓN EUROPEA

Por la presente declaramos los abajo firmantes que la máquina

designada a continuación cumple, tanto por su concepción y clase de

EU-CONFORMITEITSVERKLARING

Hiermee verklaren wij dat de hierna vermelde machine op grond van

construcción como por la ejecución que hemos puesto en circulación,

haar concipiëring en constructie en in de door ons in omloop gebrachte

las normas fundamentales de seguridad y protección de la salud

uitvoering beantwoordt aan de desbetreffende veiligheids- en

formuladas en las directivas comunitarias correspondientes.

gezondheidsvoorschriften van de EG-richtlijnen.

La presente declaración pierde su validez en caso de alteraciones en la

máquina efectuadas sin nuestro consentimiento explícito.

Producto: Barredora de suelos

Modelo: 1.948-xxx

Directivas comunitarias aplicables:

Directiva comunitaria sobre máquinas (98/37/EG)

Directiva sobre compatibilidad electromagnética (89/336/EWG)

modificada mediante 91/263/EWG, 92/31/EWG, 93/68/EWG

Normativa UE sobre emisiones de ruidos (2000/14/EU)

Na een wijziging aan de machine die niet in overleg met ons wordt

uitgevoerd, verliest deze verklaring haar gel

Produkt: veegmachine / machine met stoel

Type: 1.948-xxx

Desbetreffende EG-richtlijn:

EG-machinerichtlijn (98/37/EG)

EG-richtlijn elektromagnetische verenigbaarheid (89/336/EWG)

gewijzigd door 91/263/EWG, 92/31/EWG, 93/68/EWG

EG-richtlijn t.a.v. geluidsemissies (2000/14/EU)

Toegepaste geharmoniseerde normen:

Normas armonizadas aplicadas:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Normas nacionales aplicadas:

CISPR 12

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Toegepaste nationale normen:

CISPR 12

Toegepaste conformiteits-beoordelingsprocedure

Proceso de valoración de conformidad utilizado

Anexo V

Bijlage V

Gemeten geluidsniveau:

Nivel de potencia acústica medido:

101 dB(A)

Nivel de potencia acústica garantizado:

101 dB(A)

Gegarandeerd geluidsniveau:

103 dB(A)

103 dB(A)

Mediante una serie de medidas internas, queda asegurado que los

Door interne maatregelen is er voor gezorgd dat de standaard-

apparaten altijd beantwoorden aan de eisen van de actuele richtlijnen

aparatos y equipos de serie cumplan siempre las exigencias formuladas

en las directivas comunitarias actuales y en las normas

correspondientes a aplicar.

Los firmantes actúan autorizados y con poder otorgado por la dirección

en de toegepaste normen.

De ondergetekenden handelen in opdracht en op volmacht van de

bedrijfsleiding.

de la empresa

Page 29

IZJAVA O SUGLASNOSTI

Ovime izjavljujemo, da stroj opisan u nastavku na temelju njegove

koncepcije i konstrukcije kao i izvedbe, koju smo stavili u prodaju,

odgovara dotičnim osnovnim sigurnosnim i zdravstvenim zahtjevima

nadalje navedenih EZ-odredaba. U slučaju promjena na stroju, koje nisu

dogovorene s nama, ova izjava gubi na svojoj važnosti.

Proizvod: Stroj za smeće / stroj s vozačkim sjedalom

5.957-165 (01/02)

Alfred Kärcher Kommanditgesellschaft.

Sitz Winnenden. Registergericht: Waiblingen, HRA 169.

Persönlich haftende Gesellschafterin. Kärcher Reinigungstechnik

GmbH. Sitz Winnenden, 2404 Registergericht Waiblingen, HRB

Geschäftsführer:

Dr. Bernhard Graf, Hartmut Jenner, Georg Metz

Alfred Kärcher GmbH & Co.KG

Cleaning Systems

Alfred-Kärcher-Straße 28-40

P.O.Box 160

D-71349 Winnenden

Tel.:++49 7195 14-0

Fax :++49 7195 14-2212

Tip: 1.948-xxx

Relevantne EU-smjernice

EU-smjernica za strojeve (98/37/EG);

EU-smjernica za elektromagnetsku podnošljivost (89/336/EWG)

izmijenjena od strane 91/263/EWG, 92/31/EWG, 93/68/EWG

Sprovedene harmonizirane norme:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Navedene nacionalne norme:

CISPR12

Primijenjeni postupak procjene konformnosti:

Dodatak V

Izmjerena razina buke:

101dB(A)

Zajamčena razina buke:

103 dB(A)

Ispitna načela Glavne udruge gospodarskog strukovnog udruženja za

zbrinjavanje otpada usisavačima za smeće

Unutarnjim mjerama je osigurano da serijski uređaji uvijek odgovaraju

zahtjevima aktuelnih EU-smjernica i sprovedenih normi. Potpisnici

djeluju u ime i s punomoćju rukovodstva.

EU-VAATIMUSTENMUKAISUUSVAKUUTUS

Me vakuutamme, että alla mainittu tuote vastaa suunnittelultaan ja

rakenteeltaan sekä valmistustavaltaan EU-direktiivien asianomaisia

FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

Härmed försäkrar vi att den enligt nedan angivna maskinen till

konstruktion, byggnadssätt och i av oss levererat utförande motsvarar

turvallisuus- ja terveysvaatimuksia.

Jos koneeseen tehdään muutoksia, joista ei ole sovittu kanssamme,

tämä vakuutus ei ole enää voimassa.

tillämpliga baskrav beträffande säkerhet och hälsa enligt EU-direktiven.

Vid ändringar på maskinen som icke avtalats med oss upphör denna

försäkran att gälla.

Tuote: Lakaisukone / päältä ajettava

Tyyppi: 1.948-xxx

Produkt: Sopmaskin / Sopåkmaskin

Typ: 1.948-xxx

Asianomaiset EU-direktiivit:

EU-konedirektiivi (98/37/EG)

EU-direktiivi sähkömagneettinen yhteensopivuus (89/336/EWG)

muutettu 91/263/EWG, 92/31/EWG, 93/68/EWG

EU-melupäästödirektiivi (2000/14/EU)

Sovelletut harmonisoidut normit:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Sovelletut kansalliset normit:

CISPR 12

Tillämpliga EU-direktiv:

EG maskindirektiv (98/37/EG)

EG direktiv för elöverkänslighet (89/336/EWG)

ändrat genom 91/263/EWG, 92/31/EWG, 93/68/EWG

EG-direktiv över ljudemissioner (2000/14/EU)

Tillämpade harmoniserade normer:

DIN EN 60335-1, DIN EN 60335-2-72, DIN EN 50 082-1:1993

Tillämpade nationella normer:

CISPR 12

Sovellettu vaatimuksenmukaisuuden arviointimenetelmä

Liite V

Mitattu äänitehotaso:

101 dB(A)

Använt förfarande för utvärdering av överensstämmelse

Bilaga V

Uppmätt ljudeffektsnivå:

101 dB(A)

Taattu äänitehotaso:

103 dB(A)

Garanterad ljudeffektsnivå:

103 dB(A)

Sisäisin toimenpitein varmistetaan, että sarjatuotantolaitteet vastaavat

aina voimassaolevien EU-direktiivien vaatimuksia ja sovellettuja

normeja.

Allekirjoittaneet toimivat yrityksen johdon toimeksiannosta ja

valtuuttamina.

Vi har genom interna åtgärder säkerställt, att serietillverkade maskiner

alltid motsvarar aktuella EU-direktiv och tillämpade normer.

De undertecknade agerar på uppdrag av och med fullmakt av

företagsledningen.

Loading...

Loading...