Page 1

FS-C8600DN

FS-C8650DN

SERVICE

MANUAL

Published in June 2012

842MN111

2MNSM061

Rev. 1

Page 2

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE

OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

It may be illegal to dispose of this battery into the municipal waste stream. Check with your

local solid waste officials for details in your area for proper disposal.

ATTENTION

IL Y A UN RISQUE D’EXPLOSION SI LA BATTERIE EST REMPLACEE PAR UN MODELE

DE TYPE INCORRECT. METTRE AU REBUT LES BATTERIES UTILISEES SELON LES

INSTRUCTIONS DONNEES.

Il peut être illégal de jeter les batteries dans des eaux d’égout municipales. Vérifiez avec les

fonctionnaires municipaux de votre région pour les détails concernant des déchets solides

et une mise au rebut appropriée.

Notation of products in the manual

For the purpose of this service manual, products are identified by print speed at A4 and

black and white modes.

FS-C8600DN: 45 ppm model

FS-C8650DN: 55 ppm model

Page 3

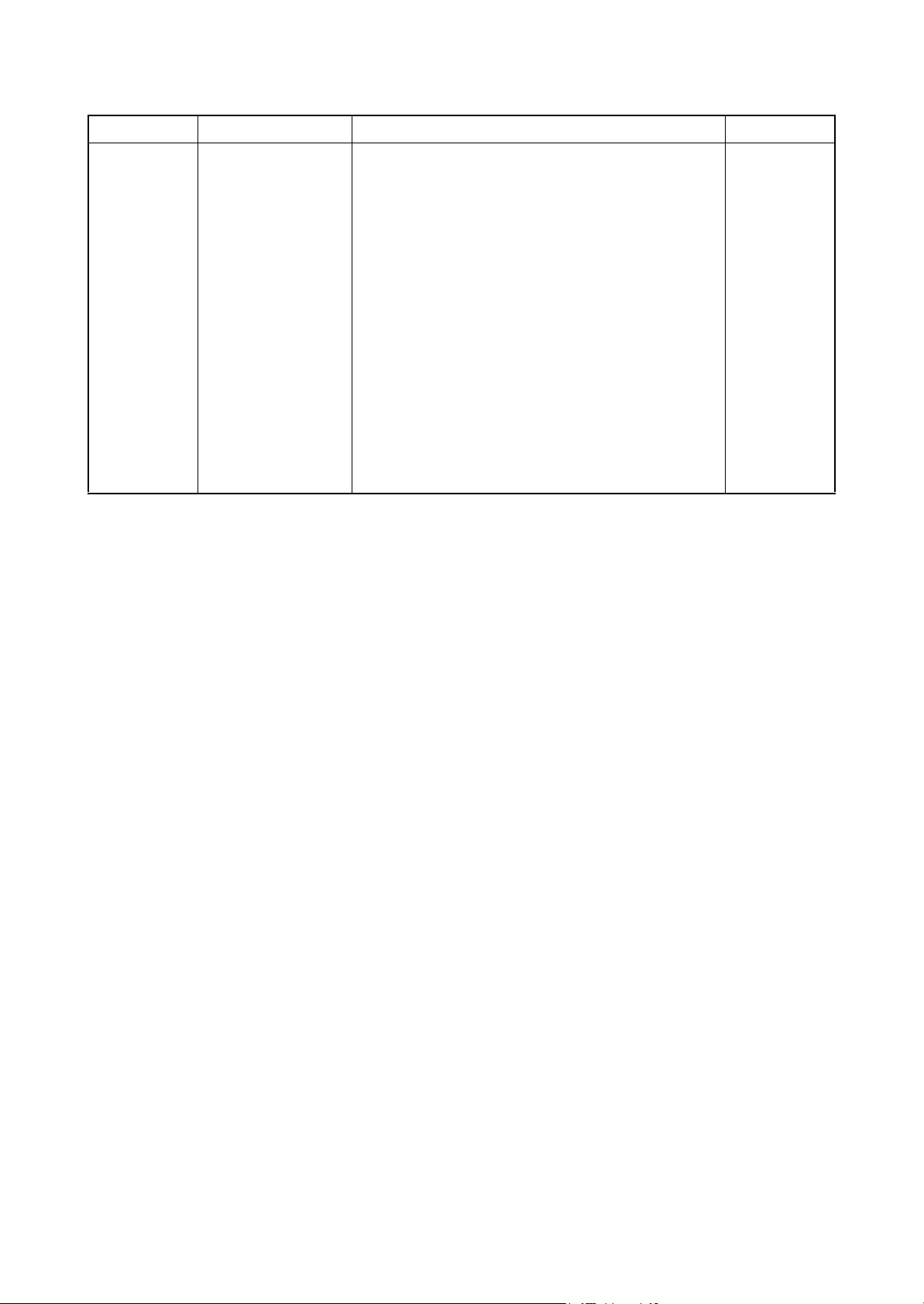

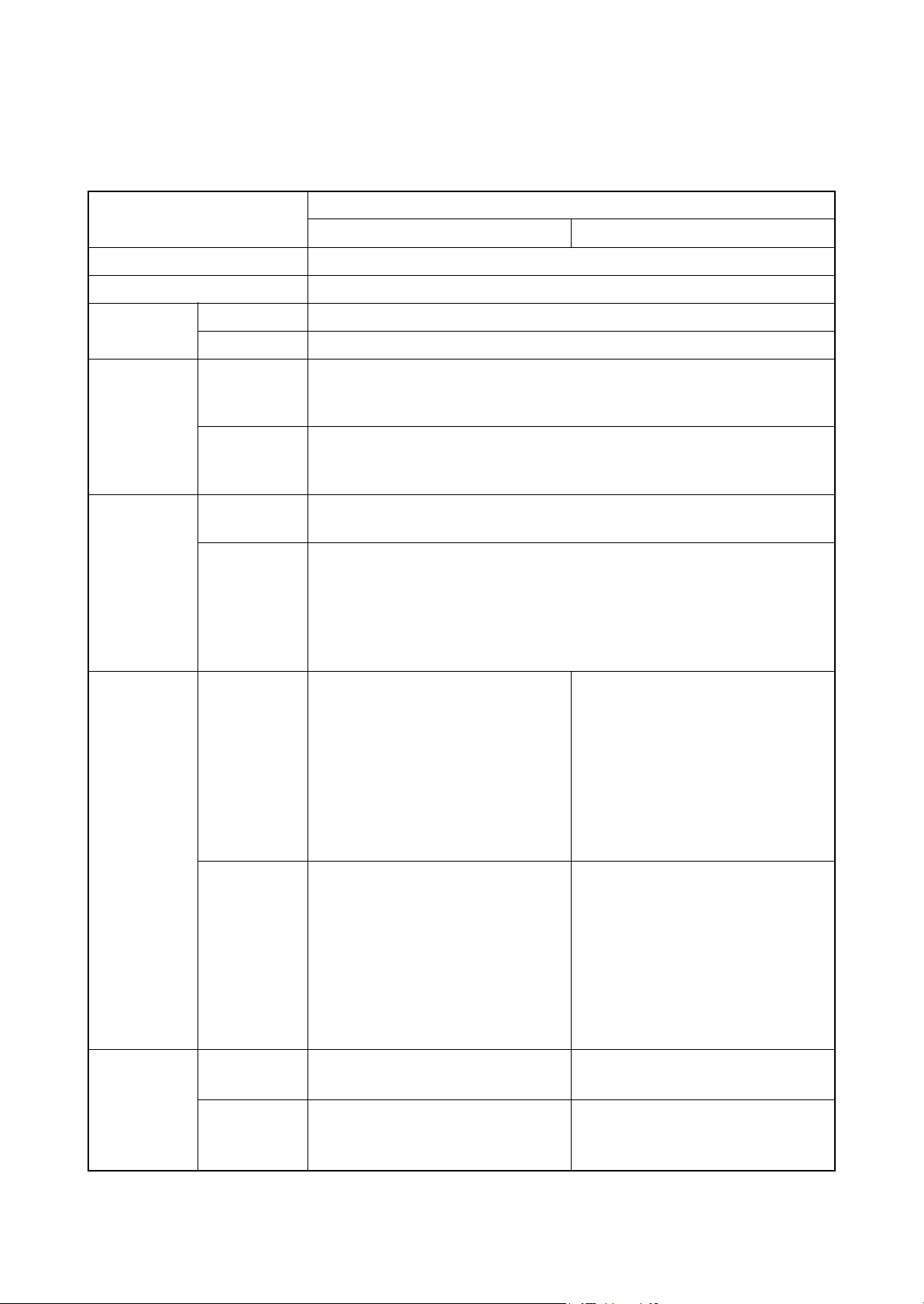

Revision history

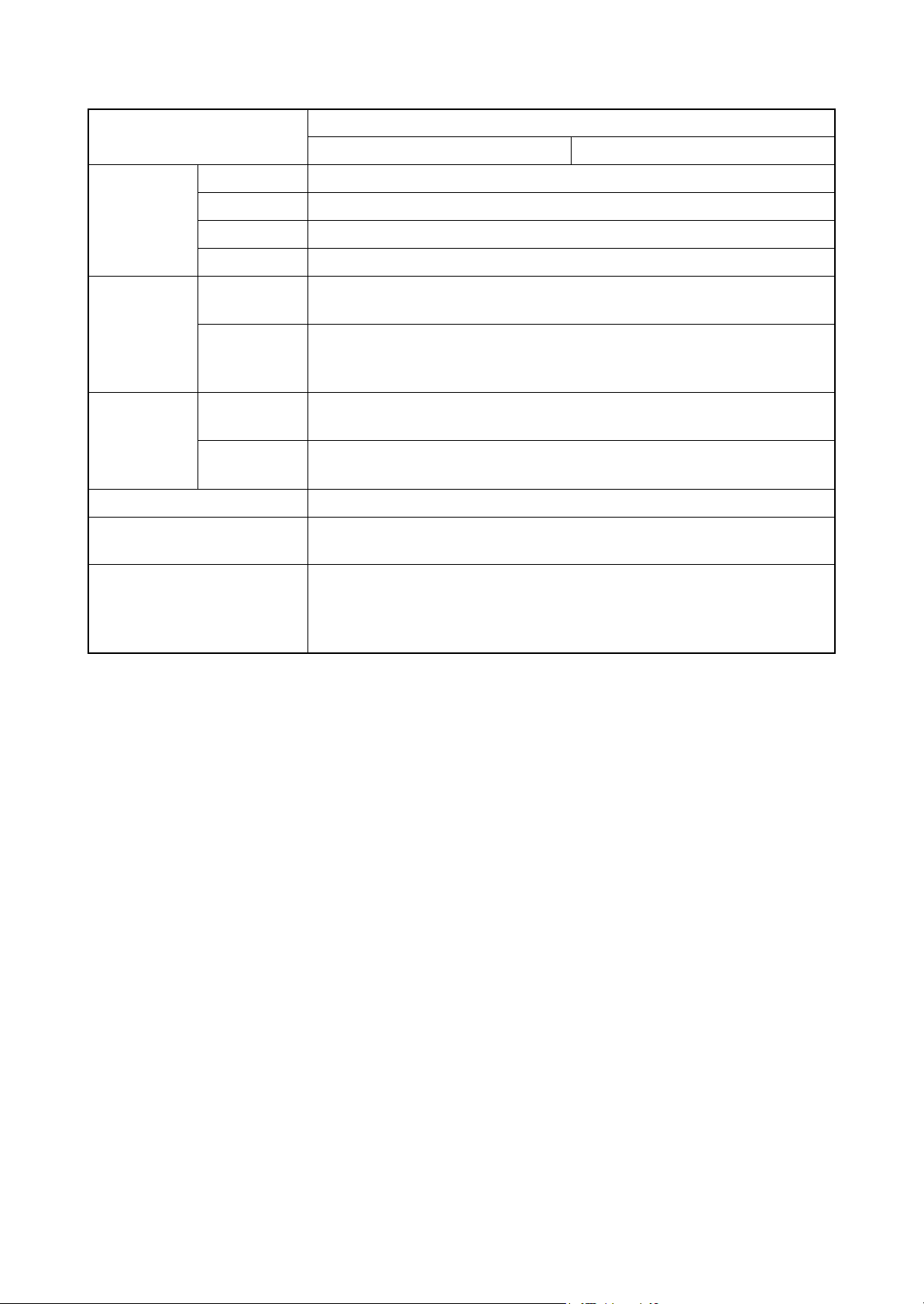

Revision Date Replaced pages Remarks

1 June 18, 2012 Contents, 1-1-1 to 1-1-3,1-1-6,1-2-2,1-2-8,1-2-9,

1-2-19,1-2-20,1-2-22,1-2-26,1-2-28,1-3-32,1-2-33,

1-2-38,1-2-43,1-3-6 to 1-3-8,1-3-10,1-3-16,1-3-17,

1-3-21 to 1-3-23,1-3-26 to 1-3-29,1-3-31 to 1-3-34,

1-3-37,1-3-38,1-3-48,1-3-49,1-3-53,1-3-54,1-3-59,

1-3-60,1-3-62,1-3-65,1-3-72,1-3-76,1-3-77,1-3-79,

1-3-84,1-3-85,1-3-87 to 1-3-91,1-3-93 to 1-3-96,

1-3-99,1-3-106,1-3-108,1-3-112 to 1-3-116,1-3-126,

1-3-130 to 1-3-133,1-3-135,1-3-137,1-3-139,

1-3-141,1-3-147 to1-3-150,1-4-2,1-4-26 to 1-4-28,

1-4-35 to 1-4-39,1-4-42,1-4-55,1-4-58 to 1-4-60,

1-4-71,1-4-88,1-4-90,1-4-91,1-5-1,1-5-4,1-5-8,

1-5-11,1-5-17,1-5-18,1-5-24,1-5-26,1-5-32,1-5-44 to

1-5-46,1-5-48,1-5-49,1-5-54,1-5-79 to 1-5-81,1-6-1,

1-6-2,2-2-1,2-2-3,2-3-1,2-3-8,2-3-28,2-3-32,2-3-36,

2-3-46,2-3-56,2-3-62,2-3-68,2-3-72,2-4-3,2-4-7,

2-4-8,2-4-13,2-4-22,2-4-23

Page 4

This page is intentionally left blank.

Page 5

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 6

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect com-

pliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point of attention is

shown inside the symbol.

General warning. Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action. Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required. Remove the power plug from the wall outlet.

Always ground the machine.

Page 7

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check that

it is adequate for the rated current. .....................................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the machine may cause fire

or electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes, lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the proper

authorities. ..........................................................................................................................................

CAUTION:

• Do not place the machine on an infirm or angled surface: the machine may tip over, causing injury. .

• Do not install the machine in a humid or dusty place. This may cause fire or electric shock. ..............

• Do not install the machine near a radiator, heater, other heat source or near flammable material.

This may cause fire............................................................................................................................

• Allow sufficient space around the machine to allow the ventilation grills to keep the machine as

cool as possible. Insufficient ventilation may cause heat buildup and poor printing performance. .....

• Always handle the machine by the correct locations when moving it. .................................................

• Always use anti-toppling and locking devices on machines so equipped. Failure to do this may

cause the machine to move unexpectedly or topple, leading to injury. ...............................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally

ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately.

If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical atten-

tion. .....................................................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the

machine’s instruction handbook. .......................................................................................................

Page 8

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ................

• Always follow the procedures for maintenance described in the service manual and other related

brochures. ..........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety mechanisms

and protective circuits. ........................................................................................................................

• Always use parts having the correct specifications. ............................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related brochure

when replacing them. Using a piece of wire, for example, could lead to fire or other serious acci-

dent. ...................................................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ..................................................................

• Always check that the machine is correctly connected to an outlet with a ground connection. ...........

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it

is dirty, clean it to remove the risk of fire or electric shock. .................................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ...............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause electric

shock if handled improperly. ...............................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are safely

secured so they will not be caught in rotating sections. ......................................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. ..........

• Handle the fixing section with care to avoid burns as it can be extremely hot. ..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. ...........................................................................................................

Page 9

• Do not remove the ozone filter, if any, from the machine except for routine replacement. .................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ........................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ................................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ..........

• Remove toner completely from electronic components. .....................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ......................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten connector,

trapped wire and missing screws. .......................................................................................................

• Check that all the caution labels that should be present on the machine according to the instruction

handbook are clean and not peeling. Replace with new ones if necessary. .......................................

• Handle greases and solvents with care by following the instructions below: ......................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the power

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. ...........................................................................................................................

• Should smoke be seen coming from the machine, remove the power plug from the wall outlet

immediately. .......................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the

specified refiner; it may generate toxic gas. ........................................................................................

• Keep the machine away from flammable liquids, gases, and aerosols. A fire or an electric shock

might occur. ........................................................................................................................................

Page 10

This page is intentionally left blank.

Page 11

CONTENTS

1-1 Specifications

1-1-1 Specifications ........................................................................................................................ 1-1-1

1-1-2 Parts names .......................................................................................................................... 1-1-4

(1) Machine ............................................................................................................................ 1-1-4

(2) Option ............................................................................................................................... 1-1-6

(3) Operation panel ................................................................................................................ 1-1-7

1-1-3 Machine cross section ........................................................................................................... 1-1-8

1-2 Installation

1-2-1 Installation environment......................................................................................................... 1-2-1

1-2-2 Unpacking and installation..................................................................................................... 1-2-2

(1) Installation procedure .......................................................................................................1-2-2

(2) Shut-down ......................................................................................................................1-2-19

(3) Setting initial print modes ............................................................................................... 1-2-20

1-2-3 Installing the cassette heater (option).................................................................................. 1-2-21

1-2-4 Installing the gigabit ethernet board (option) ....................................................................... 1-2-26

1-2-5 Installing the IC card reader holder (option) ........................................................................ 1-2-28

1-2-6 Installing the duct unit (option)............................................................................................. 1-2-43

2MN/2N1-1

1-3 Maintenance Mode

1-3-1 Maintenance mode ................................................................................................................ 1-3-1

(1) Executing a maintenance item ......................................................................................... 1-3-1

(2) Maintenance modes item list ............................................................................................ 1-3-2

1-4 Troubleshooting

1-4-1 Paper misfeed detection ........................................................................................................ 1-4-1

(1) Paper misfeed indication .................................................................................................. 1-4-1

(2) Paper misfeed detection condition ................................................................................... 1-4-2

1-4-2 Self-diagnostic function ....................................................................................................... 1-4-26

(1) Self-diagnostic function .................................................................................................. 1-4-26

(2) Self diagnostic codes...................................................................................................... 1-4-27

1-4-3 Image formation problems ................................................................................................... 1-4-86

(1) No image appears (entirely white).................................................................................. 1-4-87

(2) No image appears (entirely black).................................................................................. 1-4-87

(3) Image is too light. ........................................................................................................... 1-4-88

(4) The background is colored. ............................................................................................ 1-4-88

(5) White streaks are printed vertically................................................................................. 1-4-89

(6) Black streaks are printed vertically. ................................................................................ 1-4-89

(7) Streaks are printed horizontally. ..................................................................................... 1-4-89

(8) Spots are printed. ...........................................................................................................1-4-90

(9) Image is blurred.............................................................................................................. 1-4-90

(10) The leading edge of the image is consistently misaligned with the original. ..................1-4-90

(11) The leading edge of the image is sporadically misaligned with the original. ..................1-4-90

(12) Paper is wrinkled. ...........................................................................................................1-4-91

(13) Offset occurs. .................................................................................................................1-4-91

(14) Part of image is missing. ................................................................................................ 1-4-91

(15) Fusing is loose................................................................................................................ 1-4-92

(16) Image is out of focus. ..................................................................................................... 1-4-92

(17) Image center does not align with the original center. ..................................................... 1-4-92

Page 12

(18) Unevenly repeating horizontal streaks in the printed objects.

Colored spots in the printed objects. .............................................................................. 1-4-92

1-4-4 Electric problems ................................................................................................................. 1-4-93

1-4-5 Mechanical problems........................................................................................................... 1-4-98

1-5 Assembly and disassembly

1-5-1 Precautions for assembly and disassembly........................................................................... 1-5-1

(1) Precautions....................................................................................................................... 1-5-1

(2) Drum................................................................................................................................. 1-5-1

(3) Toner ................................................................................................................................ 1-5-1

(4) How to tell a genuine Kyocera toner container................................................................. 1-5-2

1-5-2 Paper feed section................................................................................................................. 1-5-3

(1) Detaching and refitting the primary paper feed unit.......................................................... 1-5-3

(2) Detaching and refitting the forwarding pulley, paper feed pulley and separation pulley... 1-5-7

(3) Detaching and refitting the MP tray paper feed unit ......................................................... 1-5-8

(4) Detaching and refitting the MP forwarding pulley,

MP paper feed pulley and MP separation pulley ............................................................ 1-5-12

1-5-3 Optical section ..................................................................................................................... 1-5-17

(1) Detaching and refitting the LSU...................................................................................... 1-5-17

(2) Color registration adjustment.......................................................................................... 1-5-24

1-5-4 Image formation section ...................................................................................................... 1-5-27

(1) Detaching and refitting the inner unit.............................................................................. 1-5-27

(2) Detaching and refitting the developer unit and drum unit ............................................... 1-5-29

(3) Detaching and refitting the charger roller unit................................................................. 1-5-31

1-5-5 Transfer section ................................................................................................................... 1-5-32

(1) Detaching and refitting the paper conveying unit ........................................................... 1-5-32

(2) Detaching and refitting the transfer belt unit................................................................... 1-5-34

(3) Detaching and refitting the cleaning pre brush ............................................................... 1-5-36

(4) Detaching and refitting the transfer roller ....................................................................... 1-5-38

1-5-6 Fuser section ....................................................................................................................... 1-5-40

(1) Detaching and refitting the fuser unit.............................................................................. 1-5-40

(2) Detaching and refitting fuser IH unit ............................................................................... 1-5-42

1-5-7 PWBs................................................................................................................................... 1-5-44

(1) Detaching and refitting the main PWB............................................................................ 1-5-44

(2) Detaching and refitting the engine PWB......................................................................... 1-5-49

(3) Detaching and refitting the power source PWB.............................................................. 1-5-51

(4) Detaching and refitting the high voltage PWB 1 ............................................................. 1-5-54

(5) Detaching and refitting the high voltage PWB 2 ............................................................. 1-5-55

(6) Detaching and refitting the fuser IH PWB....................................................................... 1-5-56

1-5-8 Drive section........................................................................................................................ 1-5-61

(1) Detaching and refitting the drum drive unit K and the drum drive unit MCY................... 1-5-61

(2) Detaching and refitting the main drive unit ..................................................................... 1-5-64

(3) Detaching and refitting the fuser drive unit, transfer drive unit and feed drive unit.........1-5-65

(4) Detaching and refitting the lift motor 1 and 2.................................................................. 1-5-71

1-5-9 Others .................................................................................................................................. 1-5-72

(1) Detaching the eject filter ................................................................................................. 1-5-72

(2) Detaching and refitting the toner filter............................................................................. 1-5-73

(3) Detaching and refitting the fan filter................................................................................ 1-5-74

(4) Detaching and refitting the transfer belt filter.................................................................. 1-5-75

(5) Detaching and refitting the left filter ................................................................................ 1-5-76

(6) Detaching and refitting the developer filter ..................................................................... 1-5-77

(7) Detaching and refitting the hard disk unit ....................................................................... 1-5-78

(8) Detaching and refitting the eject unit .............................................................................. 1-5-80

2MN/2N1-1

Page 13

(9) Direction of installing the principal fan motors ................................................................ 1-5-81

1-6 Requirements on PWB Replacement

1-6-1 Upgrading the firmware ......................................................................................................... 1-6-1

1-6-2 Remarks on main PWB replacement..................................................................................... 1-6-2

1-6-3 Remarks on engine PWB replacement ................................................................................. 1-6-4

2-1 Mechanical Construction

2-1-1 Paper feed/conveying section ............................................................................................... 2-1-1

(1) Cassette paper feed section............................................................................................. 2-1-1

(2) MP tray paper feed section............................................................................................... 2-1-3

(3) Paper conveying section .................................................................................................. 2-1-5

2-1-2 Drum section ......................................................................................................................... 2-1-7

2-1-3 Developer section .................................................................................................................. 2-1-9

2-1-4 Laser scanner section ......................................................................................................... 2-1-11

2-1-5 Transfer/Separation section ................................................................................................2-1-13

(1) Intermediate transfer unit section ................................................................................... 2-1-13

(2) Secondary transfer roller section.................................................................................... 2-1-15

2-1-6 Fuser section ....................................................................................................................... 2-1-17

2-1-7 Eject/Feedshift section ........................................................................................................ 2-1-19

2-1-8 Duplex conveying section.................................................................................................... 2-1-21

2MN/2N1

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ............................................................................................................ 2-2-1

(1) PWBs................................................................................................................................ 2-2-1

(2) Switches and sensors....................................................................................................... 2-2-4

(3) Motors............................................................................................................................... 2-2-6

(4) Fan motors ....................................................................................................................... 2-2-8

(5) Others............................................................................................................................. 2-2-10

2-3 Operation of the PWBs

2-3-1 Main PWB.............................................................................................................................. 2-3-1

2-3-2 Engine PWB .......................................................................................................................... 2-3-8

2-3-3 Power source PWB ............................................................................................................. 2-3-32

2-3-4 Front PWB ........................................................................................................................... 2-3-36

2-3-5 Feed PWB 1 ........................................................................................................................ 2-3-46

2-3-6 Feed PWB 2 ........................................................................................................................ 2-3-56

2-3-7 Relay PWB .......................................................................................................................... 2-3-62

2-3-8 Motor control PWB .............................................................................................................. 2-3-68

2-3-9 LSU relay PWB.................................................................................................................... 2-3-72

2-4 Appendixes

2-4-1 Appendixes ............................................................................................................................ 2-4-1

(1) List of maintenance parts ................................................................................................. 2-4-1

(2) Maintenance kits............................................................................................................... 2-4-2

(3) Periodic maintenance procedures .................................................................................... 2-4-3

(4) Repetitive defects gauge .................................................................................................. 2-4-7

(5) Firmware environment commands ................................................................................... 2-4-8

(6) Wiring diagram ............................................................................................................... 2-4-15

Page 14

2MN/2N1

This page is intentionally left blank.

Page 15

1-1 Specifications

1-1-1 Specifications

Machine

2MN/2N1-1

Item

Specifications

45 ppm 55 ppm

Type Desktop

Printing method Electrophotography by semiconductor laser, tandem drum system

Paper weight

Cassette 60 to 256 g/m

MP tray 60 to 300 g/m

2

2

Plain, Rough, Vellum, Recycled, Preprinted, Bond, Color (Colour),

Cassette

Prepunched, Letterhead, Thick, High Quality, Custom 1 to 8

(Duplex: Same as simplex)

Paper type

Plain, Transparency (OHP film), Rough, Vellum, Labels, Recycled,

MP tray

Preprinted, Bond, Cardstock, Color (Colour), Prepunched, Letterhead,

Thick, Coated, Envelope, High Quality, Custom 1 to 8

Cassette

A3, B4, A4, A4R, B5, B5R, A5R, Ledger, Legal, Letter, LetterR,

StatementR, Oficio II, 12 × 18", Folio, 8K, 16K, 16KR

A3, B4, A4, A4R, B5, ISO B5, B5R, A5R, B6R, A6R, Return postcard,

Paper size

MP tray

Postcards, Envelope DL, Envelope C5, Envelope C4, Envelope #10

(Commercial #10), Envelope #9 (Commercial #9), Envelope #6

(Commercial #6 3/4), Envelope Monarch, Youkei 2, Youkei 4, Ledger,

Legal, Letter, LetterR, Executive, StatementR, Oficio II, 12 × 18", Folio,

8K, 16K, 16KR, Custom (98× 148mm × 304.9 × 1219.2mm)

Printing

speed

First print

time

(A4, feed from

cassette)

B/W

Color

B/W

Color

A4 : 45 ppm

Letter : 45 ppm

A4R : 24 ppm

LetterR : 24 ppm

A3 : 22 ppm

Ledger : 22 ppm

B4 : 27 ppm

Legal : 21 ppm

B5 : 45 ppm

A4 : 45 ppm

Letter : 45 ppm

A4R : 24 ppm

LetterR : 24 ppm

A3 : 22 ppm

Ledger : 22 ppm

B4 : 27 ppm

Legal : 21 ppm

B5 : 45 ppm

5.4 s or less

6.6 s or less

A4 : 55 ppm

Letter : 55 ppm

A4R : 24 ppm

LetterR : 24 ppm

A3 : 27 ppm

Ledger : 27 ppm

B4 : 33 ppm

Legal : 21 ppm

B5 : 55 ppm

A4 : 50 ppm

Letter : 50 ppm

A4R : 24 ppm

LetterR : 24 ppm

A3 : 25 ppm

Ledger : 25 ppm

B4 : 30 ppm

Legal : 21 ppm

B5 : 50 ppm

4.9 s or less

6.2 s or less

1-1-1

Page 16

2MN/2N1-1

Item

45 ppm 55 ppm

Warm-up

time

(22 °C/71.6

°F, 60% RH)

Paper

capacity

Power on 41 s or less

Low Power 25 s or less

Sleep

Cassette

41 s or less

550 sheets (64 g/m

500 sheets (80 g/m

A4/Letter or less

MP tray

165 sheets (64 g/m

More than A4/Letter

55 sheets (64 g/m

Main tray 500 sheets (80 g/m

Output tray

capacity

Job separa-

tor tray

250 sheets (80 g/m

(When the Documents Finisher is installed, 100 sheets.)

Photoconductor a-Si (drum diameter 30 mm)

Image write system Semiconductor laser

Charging system Charger roller

Touch down developing system

Developing system

Developer: 2-component

Toner replenishing: Automatic from the toner container

Specifications

2

)

2

)

2

) 150 sheets (80 g/m2)

2

) 50 sheets (80 g/m2)

2

)

2

)

45 s or less

25 s or less

45 s or less

Transfer system

Primary: Roller transfer system (Intermediate transfer belt)

Secondary:Roller transfer system

Separation system Small diameter separation, Separation electrode

Cleaning system

Drum: Counter blade, Cleaning roller

Transfer belt: Fur brush

Charge erasing system Exposure by cleaning lamp (LED)

Belt fusing

Fusing system

Heat source: IH

Abnormally high temperature protection devices: thermostat

CPU PowerPC 750GL/750 MHz

Main

memory

Standard 1024 MB (1024 MB DIMMx 1)

Maximum 2048 MB(1024 MB DIMMx 2)

Hard Disk 160 GB (160 GB x 1) (standard)

USB Interface Connector: 1 (Hi-Speed USB)

Interface

Standard

Option

USB Port: 2 (Hi-Speed USB)

Network interface: 1 (10 BASE-T/100 BASE-TX/1000 BASE-T)

Network interface: 1 (10 BASE-T/100 BASE-TX/1000 BASE-T)

Resolution 600 × 600 dpi

Operating system

Windows XP, Windows Server 2003, Windows Vista, Windows 7, Windows

Server 2008, Apple Macintosh OS 10.x

Page description language PRESCRIBE

1-1-2

Page 17

2MN/2N1-1

Operating

environment

Dimensions

(W × D × H)

Space

required (W

× D)

Weight 111 kg / 244.7 lb

Power source

Item

Temperature 10 to 32.5 °C/50 to 90.5 °F

Humidity 15 to 80% RH

Altitude 2,500 m/8,202 ft or less

Brightness 1,500 lux or less

machine

only

machine

with Paper

feeder

Using

MP tray

FUll system

672 × 787 × 744 mm

26 29/64 × 30 63/64 × 29 13/32”

672 × 787 ×1053 mm

26 29/64 × 30 63/64 × 41 19/64”

1001 × 787 mm

39 13/32 × 30 63/64

1937 × 787 mm (machine + 4000-sheet finisher + Side deck)

76 17/64 × 30 63/64”

120 V AC, 60 Hz, more than 12.0 A

220 - 240 V AC, 50/60 Hz, more than 7.2 A

45 ppm 55 ppm

Specifications

Paper feeder, Large capacity feeder, Side deck, Side multi tray, Side paper

Options

NOTE: These specifications are subject to change without notice.

feeder, Side large capacity feeder, 1000-sheet finisher, 4000-sheet finisher,

Center-folding unit, Mailbox, Punch unit, Data security kit,Emulation option

kit, Gigabit ethernet board, IC card reader holder and Duct unit

1-1-3

Page 18

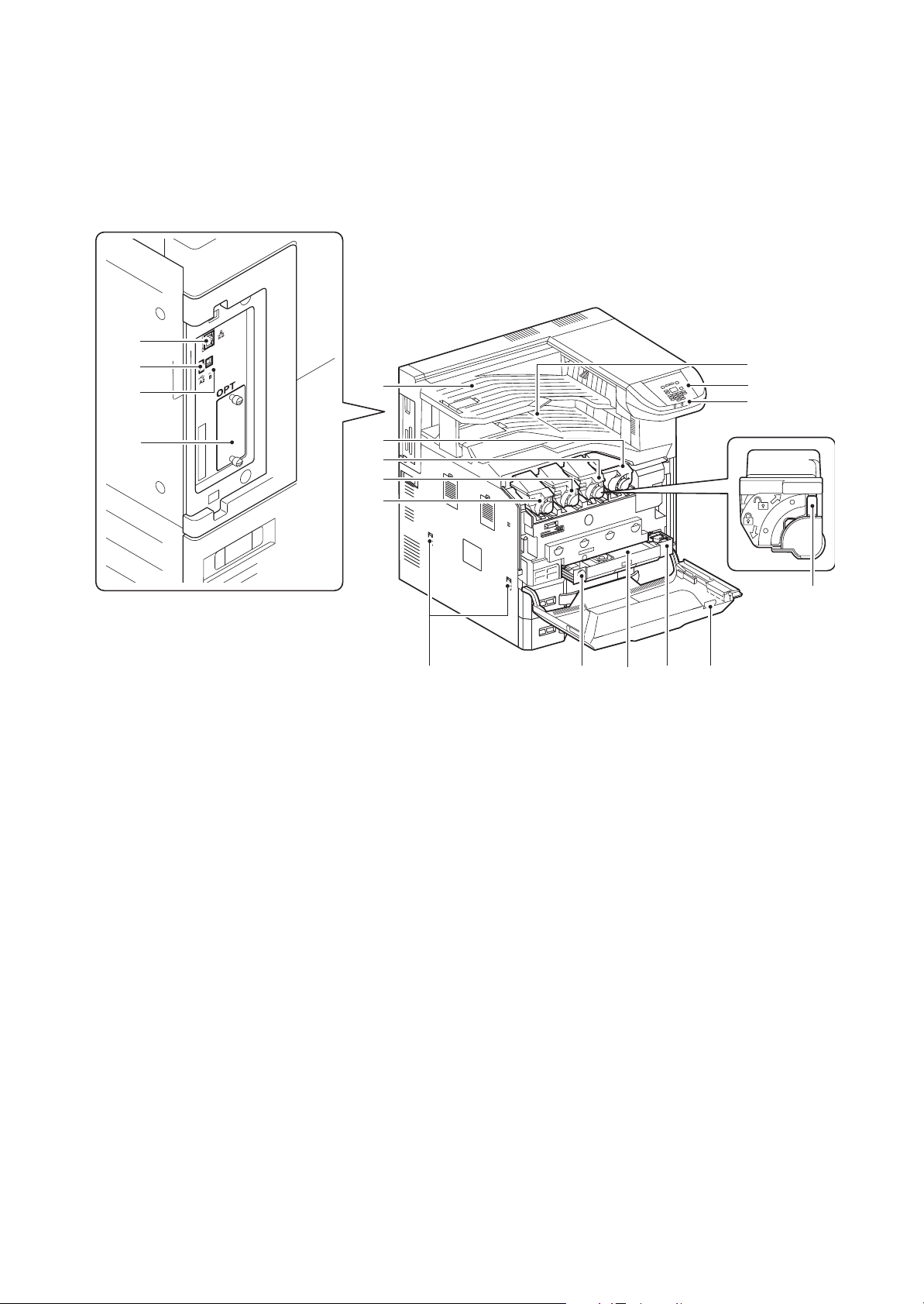

1-1-2 Parts names

7

8

18

13 10 11

3

4

5

6

1

2

15

16

17

14

12

9

1. Operation panel

2. Indicators

3. Main tray

4. Job separator tray

5. Toner container K

6. Toner container M

7. Toner container C

8. Toner container Y

9. Release button

10. Waste toner box

11. Waste toner tray

12. Front cover

13. Handles

14. Network interface connector

15. USB port

16. USB interface connector

17. Option interface

18. Toner container release lever

(1) Machine

2MN/2N1

Figure 1-1-1

1-1-4

Page 19

2MN/2N1

36

25

22 23

26

33

35

19

30

32

34

27

29

24 24

20 21

31

28

19. USB port

20. Cassettes 1

21. Cassettes 2

22. Paper length guide

23. Guide lock lever

24. Paper width guide

25. Paper width adjusting tab

26. Paper conveying unit

27. Paper conveying unit lever

28. Duplex cover lever

29. Duplex cover

30. MP paper width guide

31. Main power switch

32. MP support Tray

33. MP (Multi-Purpose) tray

34. Paper conveying cover lever

35. Paper conveying cover

36. Handle

Figure 1-1-2

1-1-5

Page 20

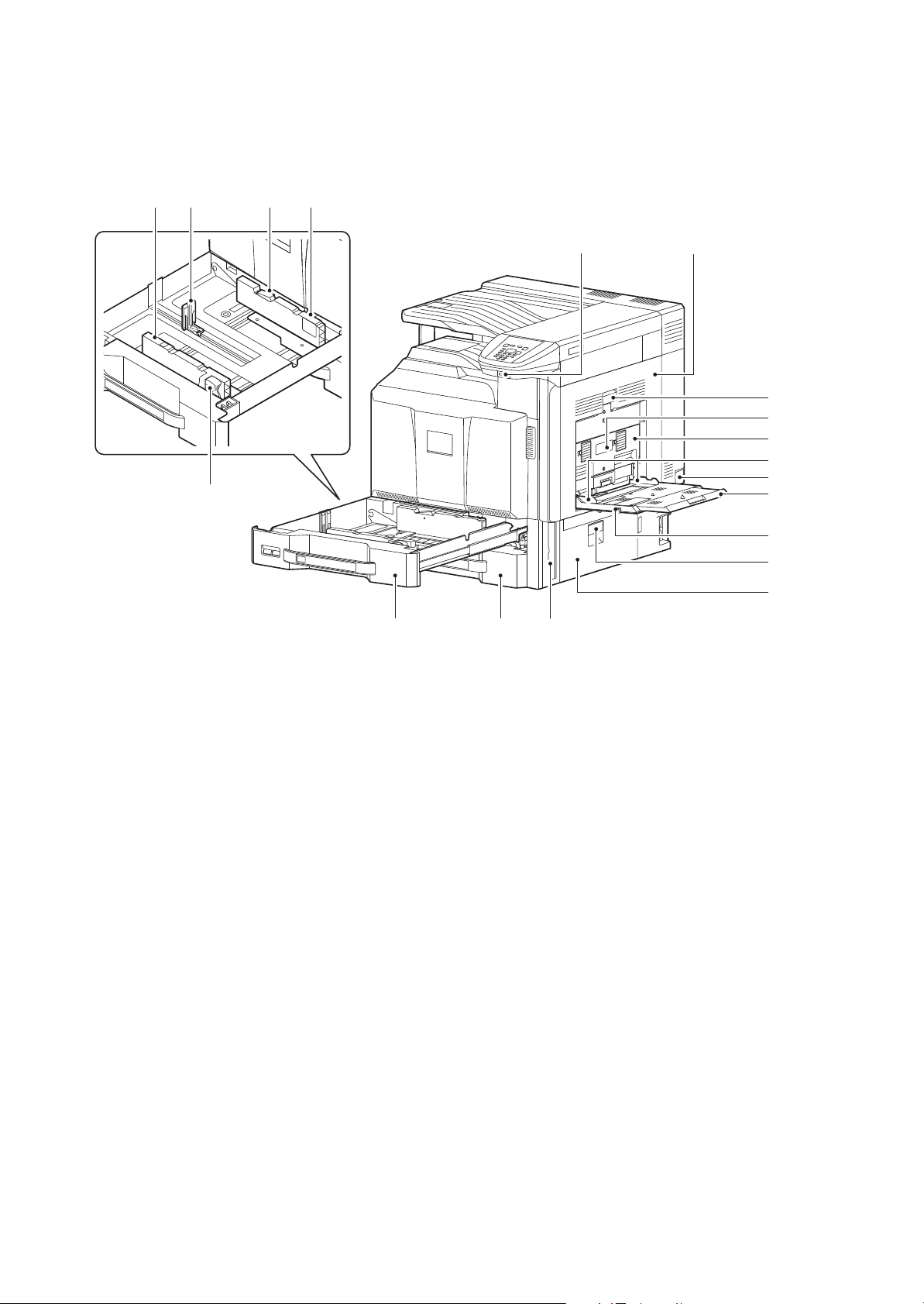

(2) Option

1. Machine

2. Paper feeder

3. Large capacity feeder

4. Side deck

5. Side multi tray

6. Side paper feeder

7. Side large capacity feeder

8. 1000-sheet finisher

9. 4000-sheet finisher

10. Center-folding unit

11. Mailbox

8

2MN/2N1-1

11

11

4

9

10

1

5

6

2

3, 7

Figure 1-1-3

* : The mailbox can be installed either the main unit or the 4000-sheet finisher.(Not installable at the same

time)

1-1-6

Page 21

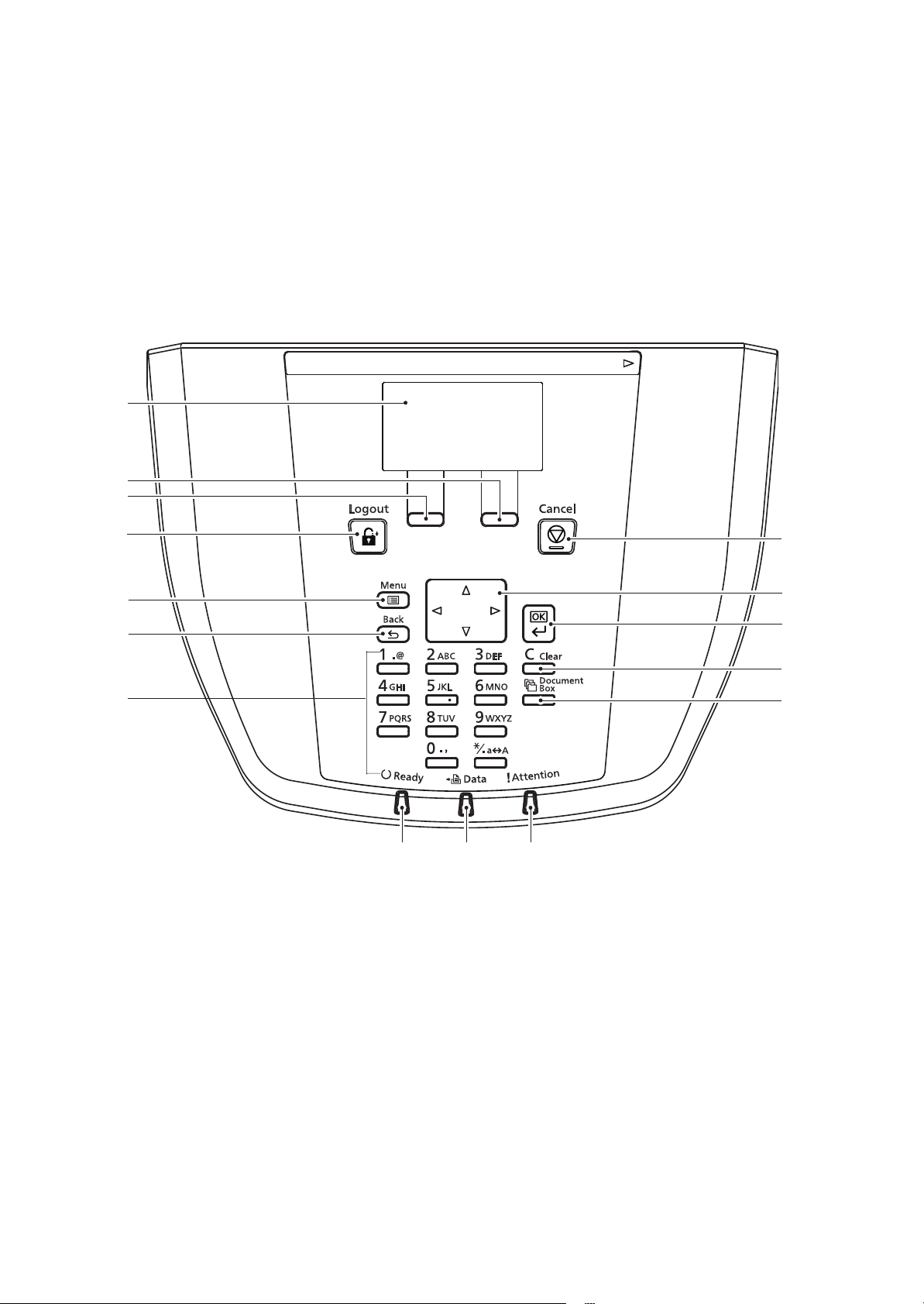

(3) Operation panel

1. Message display

2. Right select key

3. Left select key

4. Logout key

5. Menu key

6. Back key

7. Numeric keys

8. Cancel key

9. Cursor key

10. OK key

11. Clear key

12. Print Box key

13. Ready indicator

14. Data indicator

15. Attention indicator

2MN/2N1

Figure 1-1-4

1-1-7

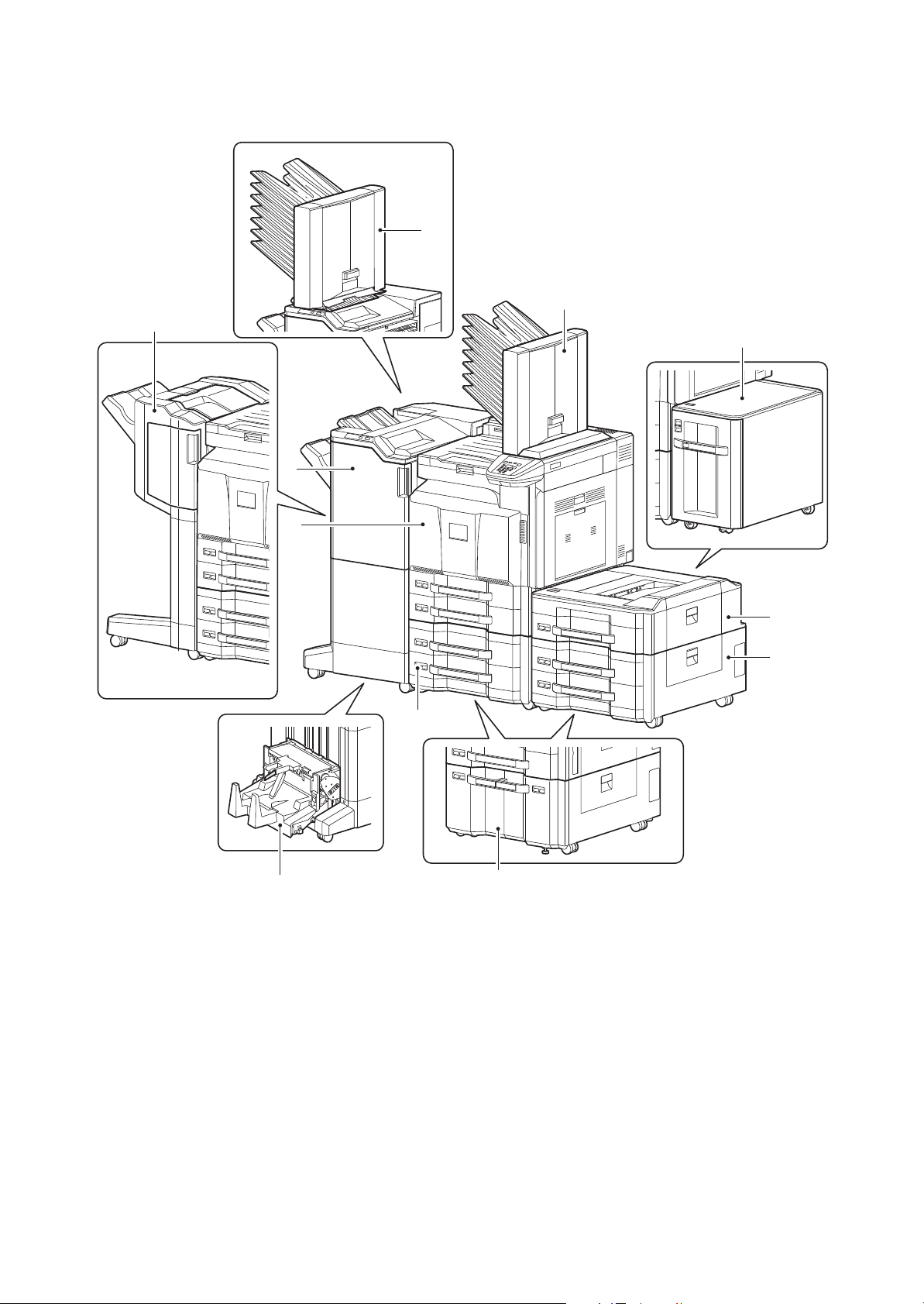

Page 22

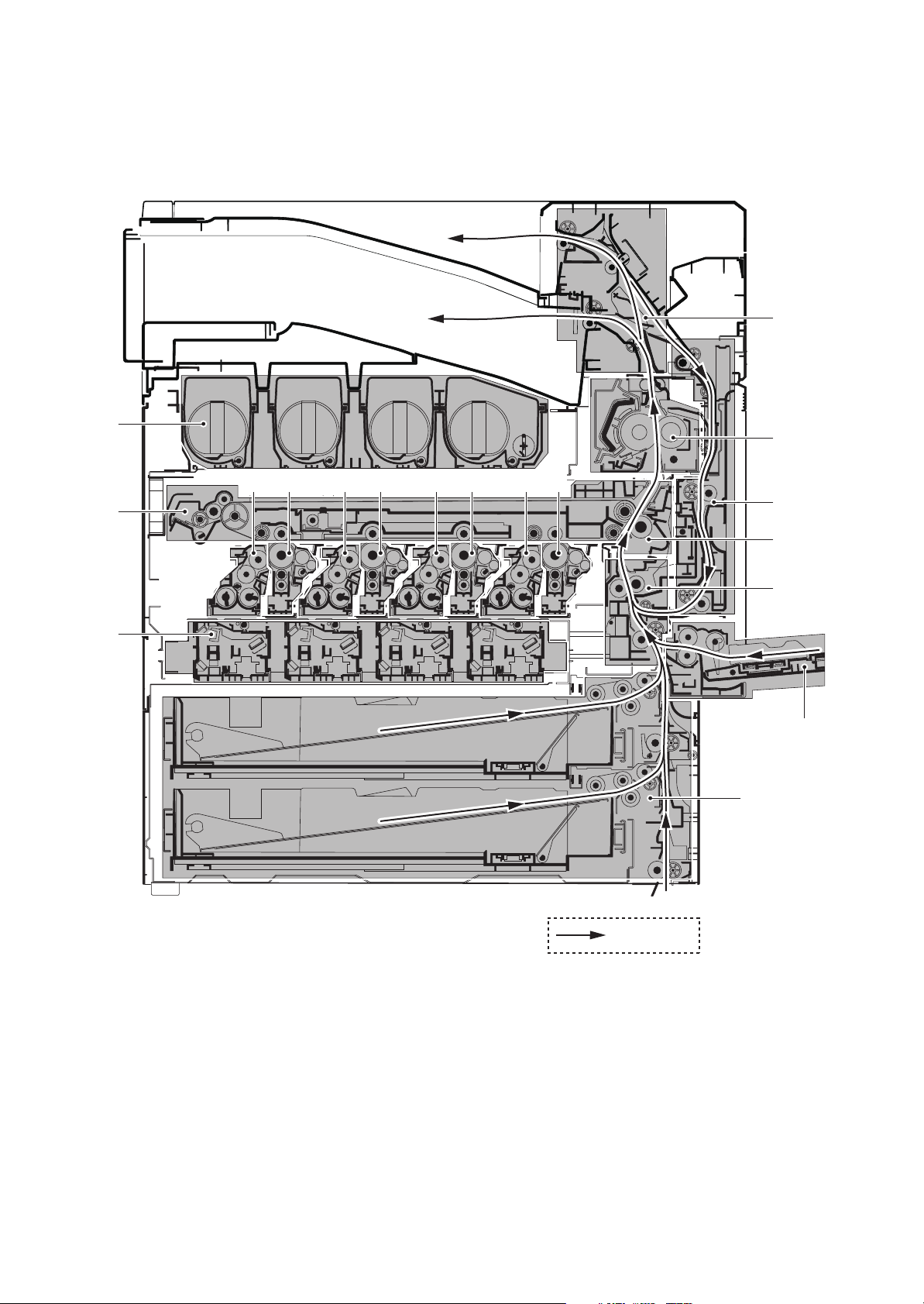

1-1-3 Machine cross section

1. Cassette paper feed section

2. MP tray paper feed section

3. Paper conveying section

4. Laser scanner unit

5. Drum unit K

6. Drum unit M

7. Drum unit C

8. Drum unit Y

9. Developer unit K

10. Developer unit M

11. Developer unit C

12. Developer unit Y

13. Toner container section

14. Primary transfer section

15. Secondary transfer/Separation sections

16. Fuser section

17. Eject/Feed shift sections

18. Duplex section

2MN/2N1

17

13

14

16

12 8 11 7 10 6 9 5

18

15

3

4

2

1

Figure 1-1-5

1-1-8

Paper Path

Page 23

1-2 Installation

1-2-1 Installation environment

1. Temperature: 10 to 32.5°C/50 to 90.5°F

2. Humidity: 15 to 80% RH

3. Power supply: 120 V AC, 12.0 A

220 - 240 V AC, 7.2 A

4. Power source frequency: 50 Hz ± 2%/60 Hz ± 2%

5. Installation location

Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or other strong light when removing paper jams.

Avoid locations subject to high temperature and high humidity or low temperature and low humidity; an

abrupt change in the environmental temperature; and cool or hot, direct air.

Avoid places subject to dust and vibrations.

Choose a surface capable of supporting the weight of the machine.

Place the machine on a level surface (maximum allowance inclination: 1°).

Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such

as mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

Select a well-ventilated location.

6. Allow sufficient access for proper operation and maintenance of the machine.

Machine front : 100 cm/ 40"

Machine rear : 10 cm/ 4"

Machine right : 35 cm/ 14"

Machine left : 30 cm/ 12"

Machine top : 40 cm/ 15"

2MN/2N1

35 cm (14")30 cm (12") 100 cm (40") 10 cm (4")

Figure 1-2-1

1-2-1

Page 24

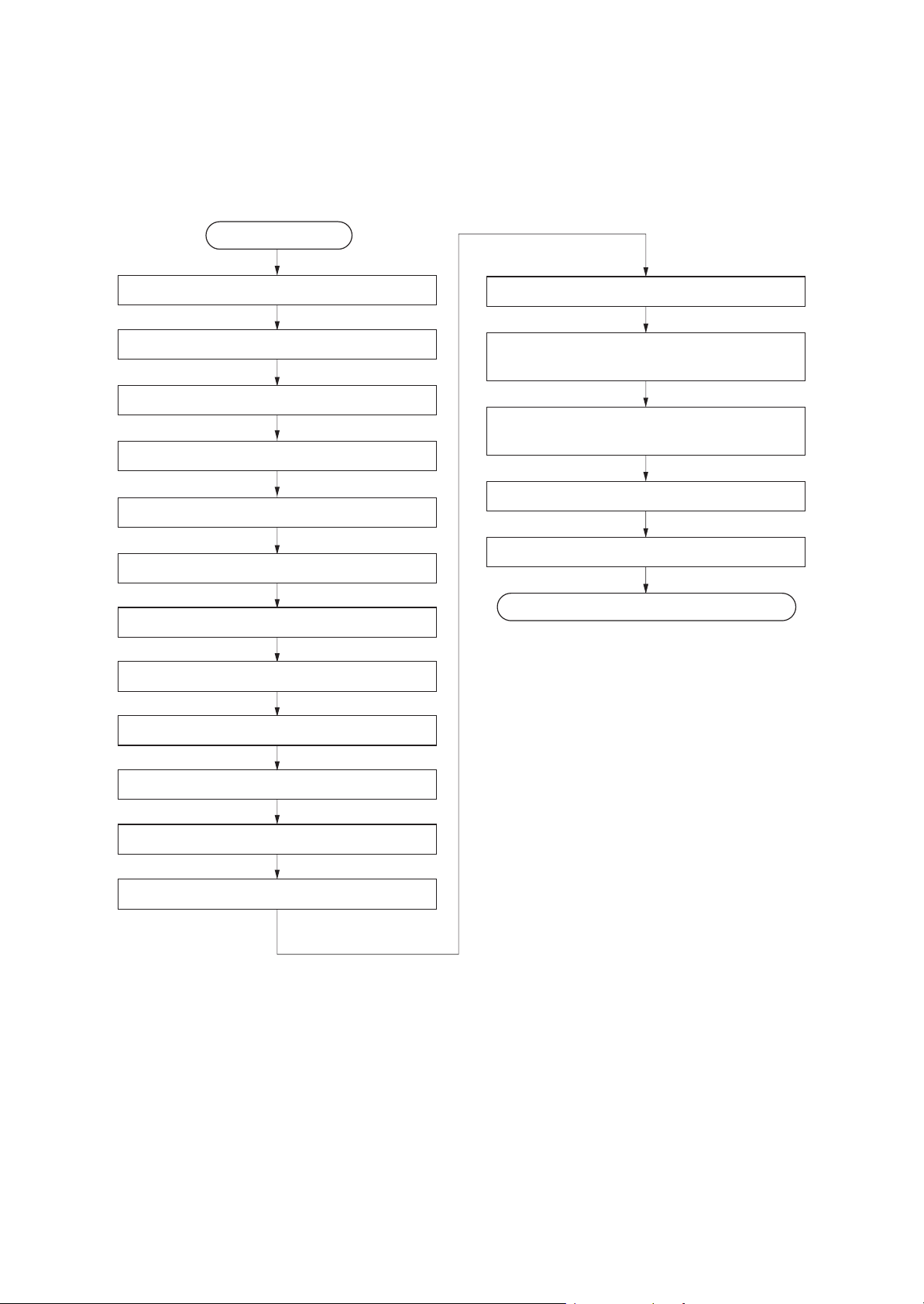

1-2-2 Unpacking and installation

(1) Installation procedure

Start

2MN/2N1-1

Unpacking

Removing the tapes and spacers

Installing the main tray and jobseparator tray

Release of lift plate stopper

Loading paper

Installing the toner containers

Unlocking the developer waste exit

Installing the waste toner box

Installing optional devices

Adjusting the image

Setting the delivery date

(maintenance item U278)

*

Output an own-status report

(maintenance item U000)

Exit maintenance mode

Print out the user setting list

Completion of the machine installation.

Installing the cassette heater (option)

Replacing operation panel sheet

Connect the power cord

*: *:When the finisher has been installed, the job separator tray and the main tray are not needed.

1-2-2

Page 25

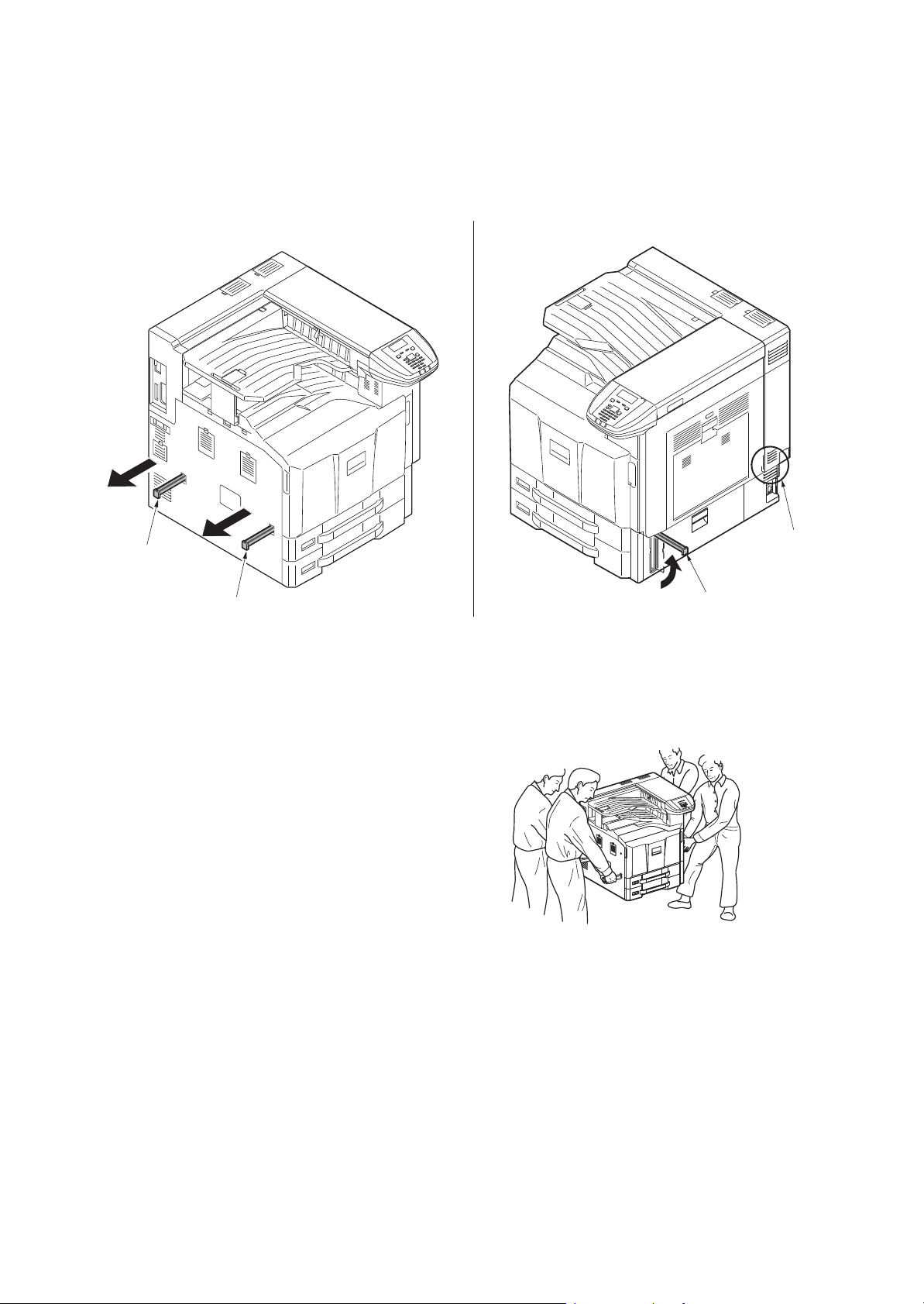

2MN/2N1

Moving the machine

When moving the machine, pull out three carrying handles, and move with carrying handles and the handhold.

Carrying

handle

Carrying

handle

*: Moving this machine is a job for four peo-

ple.

Handhold

Carrying

handle

Figure 1-2-2

1-2-3

Figure 1-2-3

Page 26

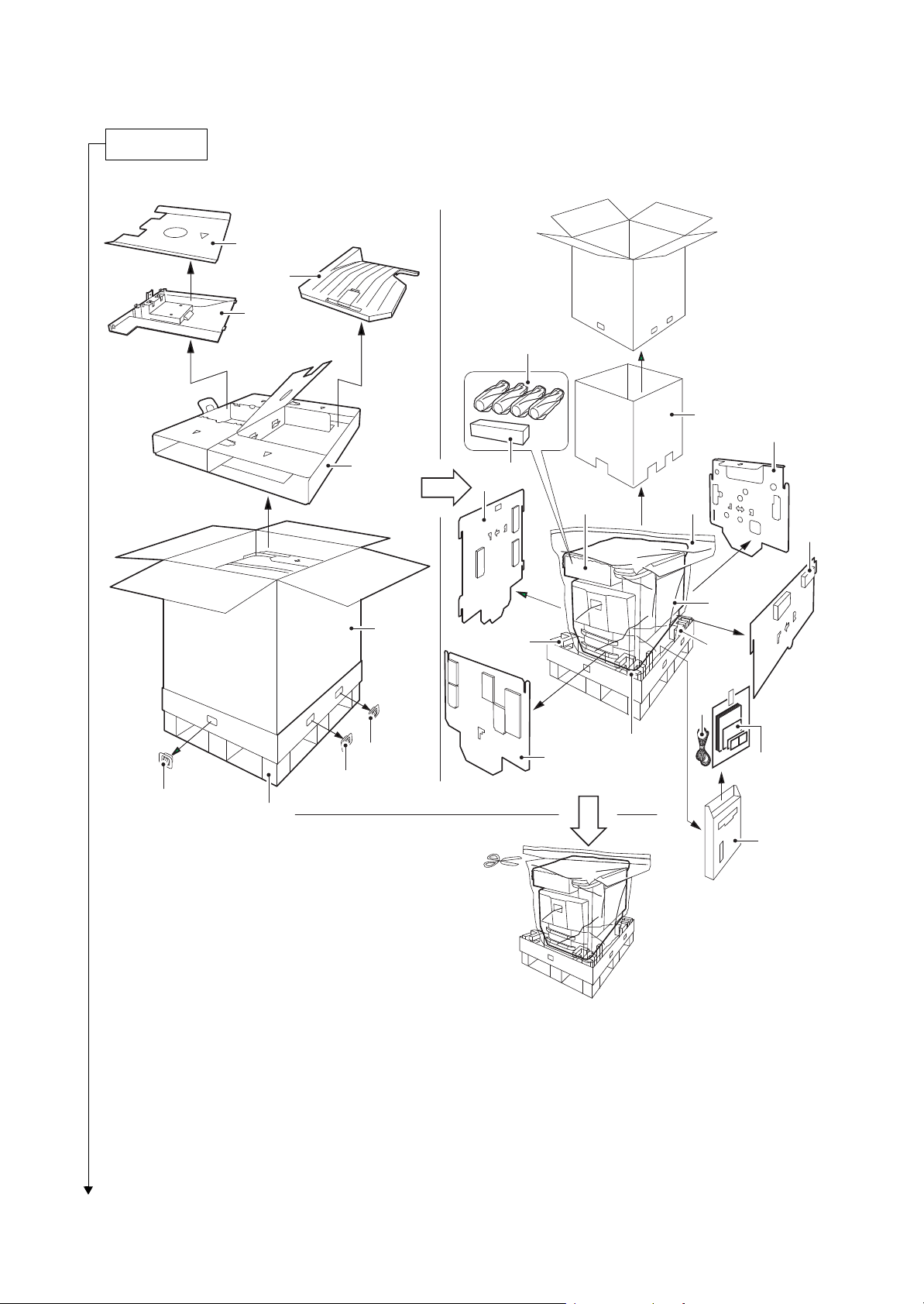

120V model

Unpacking

2MN/2N1

17

18

16

13

3

11

4

14

9

12

13

10

1

2

7

7

20

6

8

6

6

7

21,22,

23,24,25

5

19

Figure 1-2-4

1-2-4

Page 27

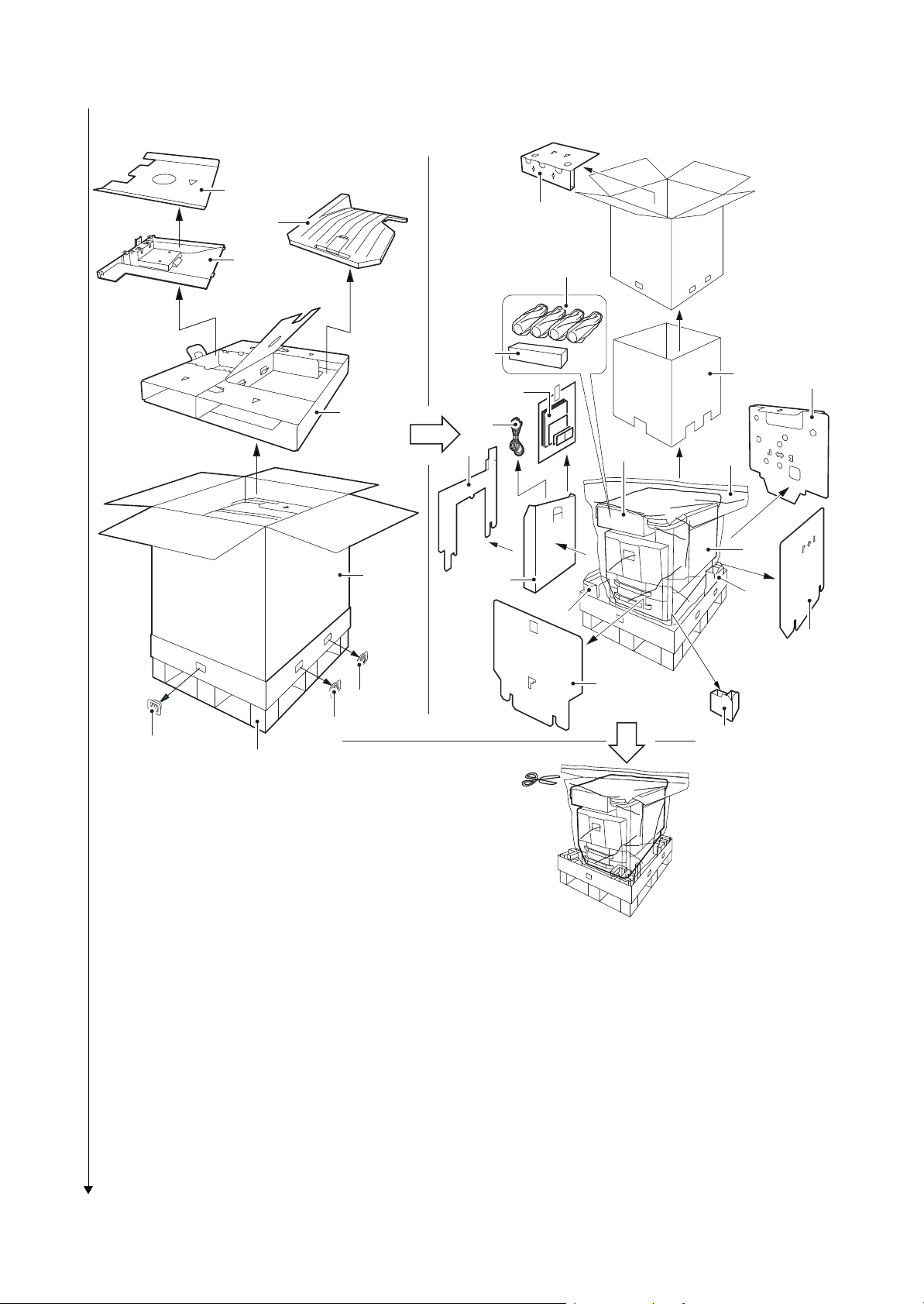

220-240V model

1. Machine

2. Outer case

3. Inner case

4. Spacer A

5. Skid

6. Hinge joints

7. Bottom pad

8. Front pad

9. Left pad

10. Right pad

11. Re a r p a d

12. Top spacer

13. Machine cover

14. Toner container (Y,M,C,K)

15. Waste toner box

16. Main tray

17. Spacer B

18. Job separetor tray

19. Document tray

20. Power cord

21. Plastic bag

22. Paper size plates

23. Paper media plates

24. Pin

25. Operation guide etc.

26. Top pad

2MN/2N1

17

26

18

16

13

14

21,22,

4

23,24,25

3

11

20

9

12

13

1

2

19

7

7

10

8

6

Place the machine on a level surface.

6

6

7

5

Figure 1-2-5

1-2-5

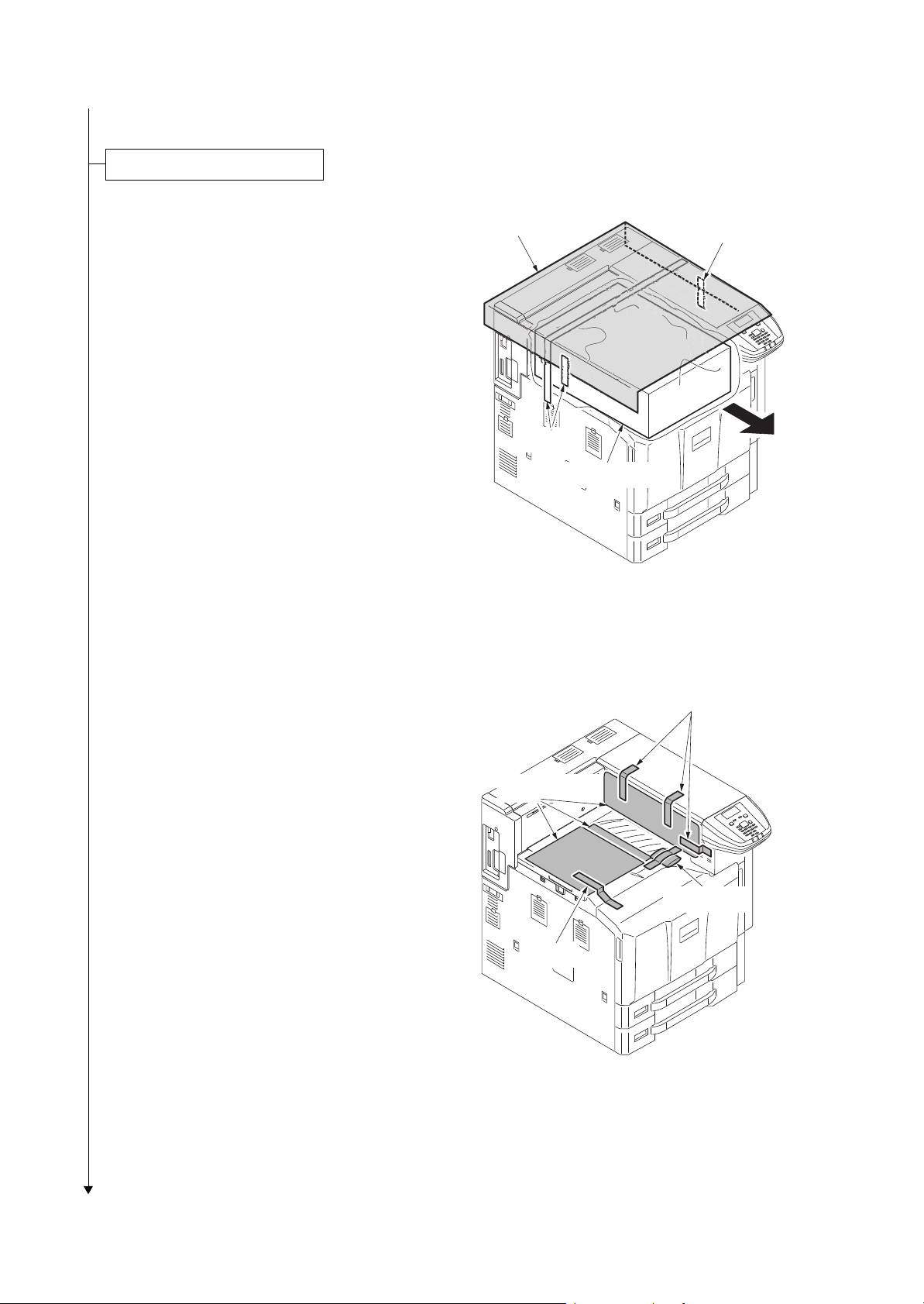

Page 28

2MN/2N1

Removing the tapes

1. Remove two tapes and the protect

sheet.

2. Remove tape and the top spacer.

Protect sheet

Ta pe s

Top spacer

Ta pe

Figure 1-2-6

3. Remove tape and then two protect

sheets.

4. Remove three tapes and then protect

sheet.

5. Remove tape and then silica gel.

Ta pe

Protect sheets

Silica gel

Ta pe

Figure 1-2-7

1-2-6

Page 29

6. Open the front cover and then remove

Ta pe

Ta pe

Ta pe s

Ta pe

Protect sheet

tape.

2MN/2N1

Ta pe

Figure 1-2-8

1. Remove three tapes and then remove

three protect sheet.

2. Remove two tapes.

Figure 1-2-9

1-2-7

Page 30

3. Remove tape.

Installing the main tray and job separator tray

2MN/2N1-1

Ta pe

Figure 1-2-10

*: When the finisher has been installed, the job separator tray and the main tray are not needed.

1. Install the main tray included by latching

in two hooks and securing by one

screw.

Main tray

Hooks

Pin

Figure 1-2-11

1-2-8

Page 31

2MN/2N1-1

Release of lift plate stopper

2. Raise the tray fixing plate.

3. Latch the three hooks to the job separator tray.

4. Load the tray on the tray fixing board

and slide it to secure.

*: Make sure that the two clicks have been

properly locked.

Hook

Jobseparator tray

Hook

Hooks

Hook

Tray fixture plate

Figure 1-2-12

1. Pull cassette 1 and 2 out.

2. Remove the lift plate stopper from each

cassette and attach it to the storage

location.

When moving the machine, attach the

lift plate in original position.

Lift plate

stopper

Cassette

Figure 1-2-13

1-2-9

Page 32

2MN/2N1

Loading paper

1. Squeeze the ends of the bottom of the

paper length guide and move the guide

to fit the length of the paper.

2. Press the guide lock lever to release

the lock.

3. Grasp the paper width adjusting tab and

move the paper width guides to fit the

paper.

Paper length guide

Figure 1-2-14

Guide lock lever

Paper width

adjusting tab

paper width guides

Figure 1-2-15

1-2-10

Page 33

2MN/2N1

4. Align the paper flush against the right

side of the cassette.

*: Before loading the paper, be sure that it is

not curled or folded.

*: Ensure that the loaded paper does not

exceed the level indicated.

*: Make sure that the paper length guide

and the paper width guides are correctly

abut with the paper. Be sure to remove

spaces between the guides and the

paper.

Paper

Figure 1-2-16

1-2-11

Page 34

5. Press the guide lock lever to lock.

2MN/2N1

Guide lock lever

Figure 1-2-17

6. Insert the paper size plate and the

paper media plate.

7. Gently push the cassette back in.

Paper media plate

Paper size plate

Figure 1-2-18

1-2-12

Page 35

1. Open the front cover.

Installing the toner containers

Toner container

Toner container

2. Hold the toner container vertically and

hit the upper part about 3 times. Invert

the toner container so that the other end

is up, and hit in the same way.

3. Hold the toner container horizontally

and shake from side to side about 3

times.

2MN/2N1

4. Install four color toner containers.

5. Turn down the toner container release

levers to lock the four color toner containers.

Figure 1-2-19

K

M

C

Y

Toner container

Toner container

Release lever

Figure 1-2-20

1-2-13

Page 36

2MN/2N1

Unlocking the developer waste exit

Caution

To ease setup, the device was shipped

with the developer unit already replenished

with developer. Therefore, to prevent

developer from spilling during shipping, a

developer shutter is equipped with the

developer unit.

To disengage the shutter, use the following

procedure: Note that if the shutter is not

completely disengaged and retained in

place, the developer in the developer unit

may clog at the outlet causing a damage to

the developer unit.

1. Remove the tape and then remove the

set up leaflet.

*: The setup leaflet must be affixed in posi-

tion before dispatching the machine.

2. Press the fixing pin in four positions and

rotate.

*: Fully insert the fixing pin keeping the line

vertical and rotate by 90 degrees clockwise. Make sure that the central line is

horizontal.

Ta pe

Set up leaflet

[Locked] [Released]

1

2

Fixing pin

Fixing pin

Figure 1-2-21

1-2-14

Page 37

3. Remove a screw and slide the lever

Installing the waste toner box

right wards.

4. Fix the lever using the screw previously

removed at the right screw hole and

unlock the developer waste exit.

*: When the device is shipped again or

removed, use the reverse procedure to

lock in the developer waste exit. Failure

to observe this caution could result in

deteriorated print quality and/or C calls.

2MN/2N1

[Locked] [Released]

3

2

1

Screw

Caution

Before installing the waste toner box,

unlock the developer waste exit (see page

1-2-14).

1. Push the release button and pull out the

waste toner tray.

2. Open the lid and install the waste toner

box.

3. Push the waste toner tray back in.

4. Close the front cover.

Lever

Screw

Figure 1-2-22

Waste toner tray

Release button

Lever

2

1

Lid

Waste toner box

Figure 1-2-23

1-2-15

Page 38

1. Install the optional devices (job separa-

Installing optional devices

Installing the cassette heater (option)

Connect the power cord

Adjusting the image

tor, document finisher and/or fax kit

etc.) as necessary.

1. Install the optional cassette heater as

necessary (see page 1-2-21).

2MN/2N1

1. Connect the power cord to the power

cord connector on rear lower of the

machine.

2. Connect the power plug to the wall outlet.

1. Turn the main power switch on.

2. Check the messages on the operation panel

After completion of warming up, in case to display "Warning for high temperature. Adjust the room temperature." on the operation panel, follow the step 3. (Performing Drum Refresh)

In case to display “Warning for low temperature. Adjust the room temperature.” on the operation panel,

install the machine in the other location this message won’t be shown.

Installing the machine in a low temperature environment could cause image quality problems.

In case to have no display, follow the step 4 (Performing LSU cleaning).

*: Perform the high altitude settings when a leakage is developed on images in a high altitude installation,

such as in Mexico City.

U140 - AC Calb - High Altitude - Mode 2

3. Performing drum refresh (see the operation guide)

Press the Menu key.

In the Adjust/Maint. menu screen, press cursor key to select Service Setting.

Press the OK key.

In the Service Setting. menu screen, press cursor key to select [Durm].

Press [OK]. A confirmation screen appears.

Press [Yes] ([Left select key]).

1-2-16

Page 39

2MN/2N1

Setting the delivery date (maintenance item U278)

4. Performing LSU cleaning (see the operation guide)

In the Adjust/Maint. menu screen, press cursor key to select Service Setting.

Press the OK key.

In the Service Setting. menu screen, press cursor key to select [LSU].

Press the OK key. A confirmation screen appears.

Press [Yes] ([Left select key]).

5. Performing calibration

(see the operation guide,U464 Setting the ID correction operation - performing calibration)

In the Adjust/Maint. menu screen, press cursor key to select ColorCalibration.

Press the OK key. A confirmation screen appears.

Press [Yes] ([Left select key]).

*: Performing color registration (see the operation guide,U469 Adjusting the color registration)

Print Chart (Printing the color registration correction chart)

In the Adjust/Maint. menu screen, press cursor key to select Color Regist.

Press the OK key.

In the Color Regist menu screen, press cursor key to select Detail.

Press the OK key.

In the Detail menu screen, press cursor key to select [Print Chart].

Press the OK key. A confirmation screen appears.

Press [Yes] ([Left select key]).

Adjust Magenta

In the Adjust/Maint. menu screen, press cursor key to select Color Regist.

Press the OK key.

In the Color Regist menu screen, press cursor key to select Detail.

Press the OK key.

In the Detail menu screen, press cursor key to select [Adjust Magenta].

Press the OK key.The Adjust Magenta screen appears.

In the H and V charts for magenta printed in Print Chart above, note the values

where the lines are closest to forming a single straight line.

*:

Values corrected are H-1, H-2, H-3, H-4, H-5, H-6, H-7, V-3.

Highlight the read value using the cursor up or down key and fill the other entries using the left and right

cursor keys.

When you have completed all the values, press the OK key.

The setting is saved and you are returned to the Color Regist. Detail menu screen.

Adjust Cyan and Adjust Yellow

In the Detail menu screen, press cursor key to select [Adjust Cyan] or [Adjust Yellow].

Press the OK key.The Adjust Cyan or Adjust Yellow screen appears.

Using the same procedure as for magenta above, identify the cyan and yellow values

in the color registration correction chart and set them in the printer.

6. Make test prints.

If image quality is unsatisfactory after test printing, execute calibration,

then retry U410-Adjusting the halftone automatically.

1. Press the menu key while pressing and holding the OK and down cursor keys simultaneously.

1-2-17

Page 40

2MN/2N1

Output an own-status report (maintenance item U000)

Exit maintenance mode

Print out the user setting list

Completion of the machine installation

2. Enter the maintenance mode by entering 10871087 using the numeric keys. (see page P.1-3-1)

3. Enter 278 using the numeric keys and press the Ok key.

4. Select [Today].

5. Press the Ok key. The delivery date is set.

6. Press the Back key to exit.

1. Enter 000 using the numeric keys and press the Ok key.

2. Select [Maintenance] and press the Ok key. A status report is output.

3. Press the back key to exit.

1. Enter 001 using the numeric keys and press the Ok key. The machine exits the maintenance mode.

1. Select [Report Print] to output the user various setting reports.

1-2-18

Page 41

(2) Shut-down

To turn main power off, be sure to perform the following before turning the main power switch off.

*: Before proceeding, make sure that the

data lamp is turned off.

*: The hard disk may be operating when the

Data indicator is lit or blinking. Turning off

the main power switch while the hard disk

is operating may cause damage.

Figure 1-2-24

2MN/2N1-1

1. Press menu key.

2. Press the cursor key to select Shut

down.

3. Press OK key. A confirmation screen

appears.

4. Press [Yes] (Left Select key).

5. Follow the instructions on the display to

turn the main power switch off.

Shut down.

Are you sure?

[ Yes ] [ No ]

Completed.

Turn the main power

switch off.

Figure 1-2-25

1-2-19

Page 42

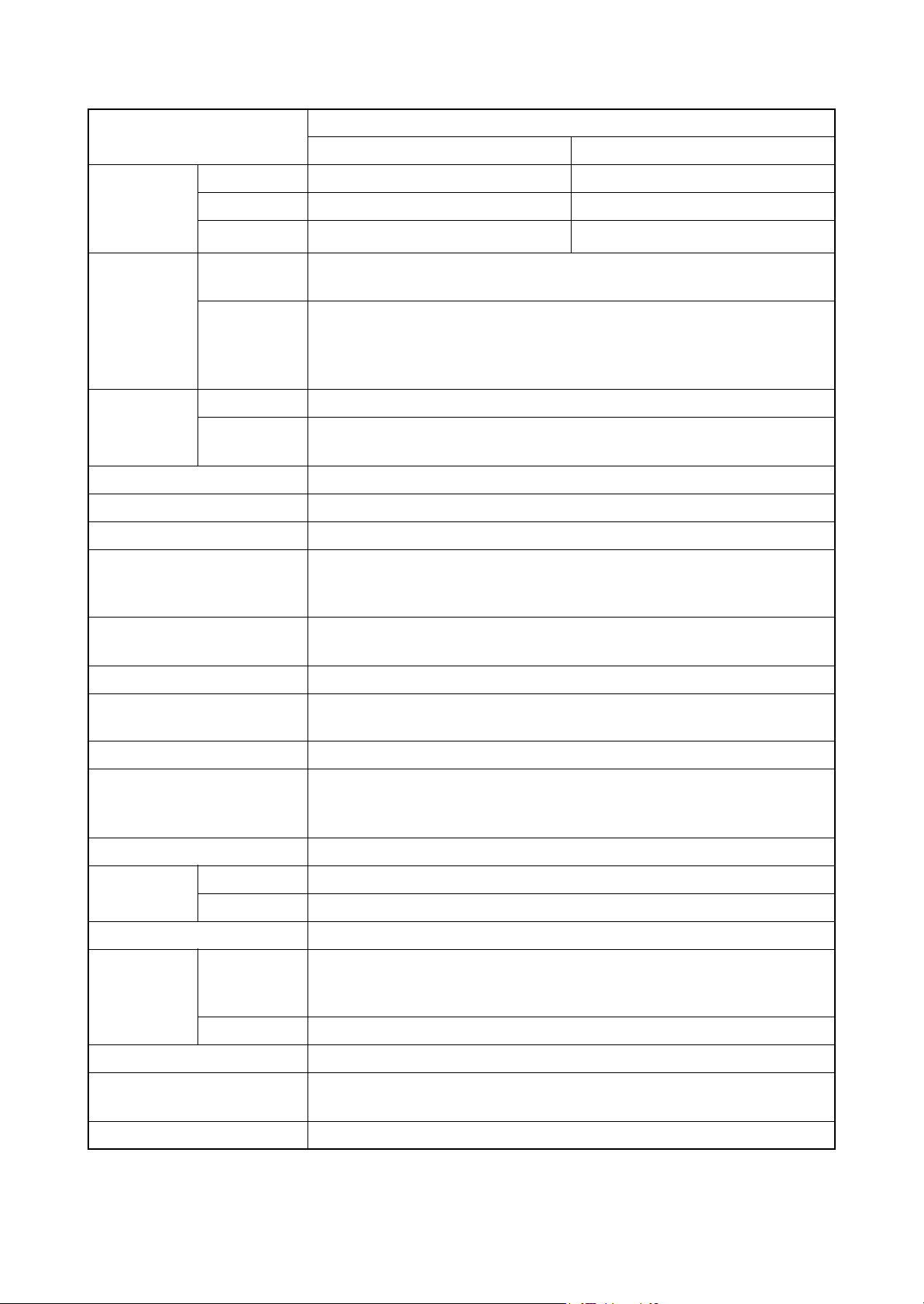

(3) Setting initial print modes

Factory settings are as follows:

2MN/2N1-1

Maintenance

item No.

U253 Switching between double and single counts DBL(A3/Ledger)

U260 Selecting the timing for print counting Eject

U285 Setting service status page On

U323 Setting abnormal temperature and humidity warning On

U325 Setting the paper interval Off/1

U327 Setting the cassette heater control Off

Contents Factory setting

1-2-20

Page 43

1-2-3 Installing the cassette heater (option)

Cassette heater installation requires the following parts:

Parts Quantity Part.No.

Cassette heater set (120V) 1 302K994930

Cassette heater set (240V) 1 302K994940

Supplied parts of cassette heater set (302K994930):

Parts Quantity Part.No.

Cassette heater (120V) 1 302H794620

Wire saddle 3 7YZM610001++H0

Label 1 302KP34220

Connector cover 1 303NF04140

M3 x 8 tap-tight S screw 2 7BB700308H

2MN/2N1

M4 x 8 tap-tight S screw 1 7BB700408H

Supplied parts of cassette heater set (302K994940):

Parts Quantity Part.No.

Cassette heater (240V) 1 302H794610

Wire saddle 3 7YZM610001++H0

Label 1 302KP34220

Connector cover 1 303NF04140

M3 x 8 tap-tight S screw 2 7BB700308H

M4 x 8 tap-tight S screw 1 7BB700408H

1-2-21

Page 44

Procedure

Cassette slider 1

Cassette 1

Cassette slider 2

Release lever

1. After confirming the data lamp is turned

off, perform shut-down on the operation

panel, turn power off, and unplug the

power receptacle(see page P.1-2-19).

2. Pull the cassette 1 forward.

3. Draw out Cassette 1 by releasing the

release lever.

2MN/2N1-1

Figure 1-2-26

4. Pull the cassette 2 forward.

5. Draw out Cassette 2 by releasing the

release lever.

Cassette slider 1

Cassette 2

Release lever

Cassette slider 2

Figure 1-2-27

1-2-22

Page 45

6. Fit three wire saddles on the bottom

Cassette heater

Wire saddles

Wire saddle

Screw

Screw

frame of the machine.

7. Fit the cassette heater using two M3 x 8

screws.

2MN/2N1

Figure 1-2-28

1-2-23

Page 46

8. Connect the connector of the cassette

Cassette heater

Label

Connector cover

Screw

heater to the connector in the rear

frame of the machine.

9. Pass the wire of the cassette heater

through three wire saddles and then

fasten the wire.

2MN/2N1

Wire saddle

Wire saddle

Cassette heater

Connector

10. After installing the cassette heater,

install the connector cover using the M4

× 8 screw.

11. Clean the label with alcohol and then

affix the label.

Figure 1-2-29

Figure 1-2-30

1-2-24

Page 47

12. To install Cassette 1 and Cassette 2,

align the cassette slider 2 and cassette

slider 1 with each other.

13. Push the cassette in fully.

2MN/2N1

Cassette 1, 2

Cassette slider 2

Cassette slider 1

Figure 1-2-31

1-2-25

Page 48

1-2-4 Installing the gigabit ethernet board (option)

Gigabit ethernet board installation requires the following parts:

Parts Quantity Part.No.

Gigabit ethernet board 1 1505JV0UN0 (option)

Procedure

1. After confirming the data lamp is turned

off, perform shut-down on the operation

panel, turn power off, and unplug the

power receptacle (see page P.1-2-19).

2. Open the controller lid.

3. Remove two pins and then remove the

slot cover.

2MN/2N1-1

Slot cover

Figure 1-2-32

Pin

Pin

1-2-26

Page 49

4. Insert the gigabit ethernet board along

the groove in OPT2 and secure the

board with two pins that have been

removed in step 3.

*: Do not directly touch the gigabit ethernet

board terminal.

Hold the top and bottom of the gigabit

ethernet board, or the projection of the

board to insert the gigabit ethernet board.

2MN/2N1

Gigabit

ethernet board

Pin

Pin

5. Plug the modular connector cable into

the line terminal,

6. Close the controller lid.

Groove

Figure 1-2-33

Network cable

1-2-27

Figure 1-2-34

Page 50

1-2-5 Installing the IC card reader holder (option)

IC card reader holder installation requires the following parts:

Parts Quantity Part.No.

IC card reader holder 1 1709AD0UN0 (option)

Relaying USB wire

*1: For internal wirings only

Supplied parts of IC card reader holder (1709AD0UN0):

Card reader case 1 -

Card reader base 1 -

Card reader mount 1 -

Card reader tray 1 -

USB Wire (For extension) 1 -

*

Parts Quantity Part.No.

1 302MN46210

2MN/2N1-1

Pin 3 303NS24410

Clamp 6 7YZM690002++H01

The card reader base, card reader mount, and the pin are packaged as an assembled kit.

For internal wirings

Procedure

1. After confirming the data lamp is turned

off, perform shut-down on the operation

panel, turn power off, and unplug the

power receptacle(see page P.1-2-19).

2. Pull the paper conveying unit out.

3. Remove two screws and then remove

the upper right cover.

Upper right

cover

Screw

Screw

1-2-28

Paper conveying

unit

Figure 1-2-35

Page 51

2MN/2N1

4. Remove two screws.

5. Unhook three hooks and then remove

the Left upper cover.

Screws

Hooks

Hook

Left upper cover

6. Remove screw and then remove the

rear tray cover.

Left upper cover

Figure 1-2-36

Rear tray cover

Screw

1-2-29

Figure 1-2-37

Page 52

7. Remove seven screws and then

Top cover

Screw

Screw

Screw

Screw

Screw

remove the rear upper cover.

2MN/2N1

Screws

Screws

Screws

Screw

8. Remove five screws and then remove

the Top cover.

Figure 1-2-38

Figure 1-2-39

1-2-30

Page 53

9. Cut out the aperture plate on the upper

right cover using nippers.

2MN/2N1

Upper right cover

Aperture

10. Fit two clamps.

Figure 1-2-40

Clamps

1-2-31

Figure 1-2-41

Page 54

11. Fit four clamps.

2MN/2N1-1

Clamps

Clamp

Figure 1-2-42

12. Release ten wire saddles.

13. Remove two wire holders.

Wire holders

Clamps

Clamps

Clamps

Clamps

Clamps

Figure 1-2-43

1-2-32

Page 55

14. Connect the relaying USB wire to the

USB wire of the IC card reader.

15. Insert the connector of the relaying USB

wire to the main PWB.

16. Fix the USB wire of the IC card reader

using ten wire saddles and two wire

holders.

2MN/2N1-1

17. Pass the USB wire of the IC card reader

through two clamps and then fasten the

wire.

Figure 1-2-44

Clamps

IC card reader

1-2-33

Figure 1-2-45

Page 56

18. .Fix the wirings of extra portion using

two clamps so that the distance of the

USB power line from the clamp to the

IC card reader is approximately

160mm.

2MN/2N1

Clamps

160 mm

IC card reader

Figure 1-2-46

19. Route the IC card reader through the

opening in the upper right cover and fix

the upper right cover using the two

screws.

Upper right

cover

Screw

IC card reader

Screw

Figure 1-2-47

1-2-34

Page 57

20. Remove the pin of the card reader base

r

and then remove the card reader

mount.

2MN/2N1

Card reade

base

Card reader

mount

Pin

21. Fit the card reader mount to the

machine using two pins.

Figure 1-2-48

Right upper

cover

Pins

Card reader

mount

Figure 1-2-49

1-2-35

Page 58

22. Refit the card reader base to card

reader mount using the pin removed in

step 20.

2MN/2N1

Card reader

mount

Card reader

base

Pin

Figure 1-2-50

23. Fit the card reader tray to the card

reader base.

Choose the direction of mounting the IC

card reader according to the depth of

the reader.

10mm to 22mm: Face the mark A

upwards.

Less than 10mm: Face the mark B

upwards.

A

B

A

B

Card reader

tray

Card reader

base

Card reader

tray

1-2-36

Card reader

base

Figure 1-2-51

Page 59

24. Mount the IC card reader on the card

A

A

A

reader base.

2MN/2N1

IC card reader

Figure 1-2-52

25. Hook the two hooks of the card reader

case to fit the card reader case to the

card reader base.

Press its top until it clicks in.

Card reader

case

Hooks

26. Replace the cover which was removed.

Figure 1-2-53

1-2-37

Page 60

For external wirings

r

Procedure

1. After confirming the data lamp is turned

off, perform shut-down on the operation

panel, turn power off, and unplug the

power receptacle(see page P.1-2-19).

2. Remove the pin of the card reader base

and then remove the card reader

mount.

2MN/2N1-1

Card reade

base

Card reader

mount

3. Remove the upper right cover

(see page P.1-2-28).

4. Cut out the aperture plate on the upper

right cover using nippers

(see page P.1-2-31).

5. Replace the cover which was removed.

6. Fit the card reader mount to the

machine using two pins.

Pin

Figure 1-2-54

Right upper

cover

1-2-38

Pins

Card reader

mount

Page 61

7. Refit the card reader base to card

A

A

B

B

Card reader

tray

Card reader

tray

Card reader

Card reader

base

reader mount using the pin removed in

step 2.

2MN/2N1

Figure 1-2-55

Card reader

mount

Card reader

base

Pin

Figure 1-2-56

8. Fit the card reader tray to the card

reader base.

Choose the direction of mounting the IC

card reader according to the depth of

the reader.

10mm to 22mm: Face the mark A

upwards.

Less than 10mm: Face the mark B

upwards.

Figure 1-2-57

1-2-39

Page 62

9. Route the USB wire of the IC card

A

Aperture

USB wire

IC card reader

A

A

reader through the aperture of the card

reader base and mount the IC card

reader on the card reader base.

2MN/2N1

10. Hook the two hooks of the card reader

case to fit the card reader case to the

card reader base.

Press its top until it clicks in.

Figure 1-2-58

Card reader

case

Hooks

Figure 1-2-59

1-2-40

Page 63

2MN/2N1

11. Fit six clamps.

Right side: three

Rear side: three

Clamps

Clamps

12. Pass the USB wire of the IC card reader

through six clamps and then fasten the

wire.

13. Connect the USB wire to the machine.

If the length does not suffice, use the

USB wire supplied.

Figure 1-2-60

Clamps

USB wire

Clamps

1-2-41

Figure 1-2-61

Page 64

2MN/2N1

Enabling IC Card Authentication

Precautions

To install the optional function, you need the License Key. Please access the designated web site of your

dealer or service representative, and register “Machine No.” indicated on your machine and “Product ID” indicated on the License Certificate supplied with the product to issue the License Key.

1. Turn the main power switch on.

2. Press [Menu].

3. Select Op Function. Press OK key.

4. The Login screen appears.

5. With the Login User Name entry field selected, press OK key.The Login User Name entry screen is dis-

played.

6. Enter the Login User Name using the numeric keys then press OK key.

7. Select the Login Password entry field. press OK key.

8. Enter the Login Password with the numeric keys then press OK key.

9. Pressing [Login] ([Right Select]).

10. The Op Functions menu appears.

11. Select the IC Card, then press OK key.

12. Select the License On. then press OK key.

13. Select the Official. then press OK key.

14. To use the application as a trial, select Trial and press OK key.

15. Enter the License key using the numeric keys.

16. When the confirmation screen appears, press [Yes] ([Left Select]).

To use a SSFC card, run maintenance mode U222 and set SSFC.

1-2-42

Page 65

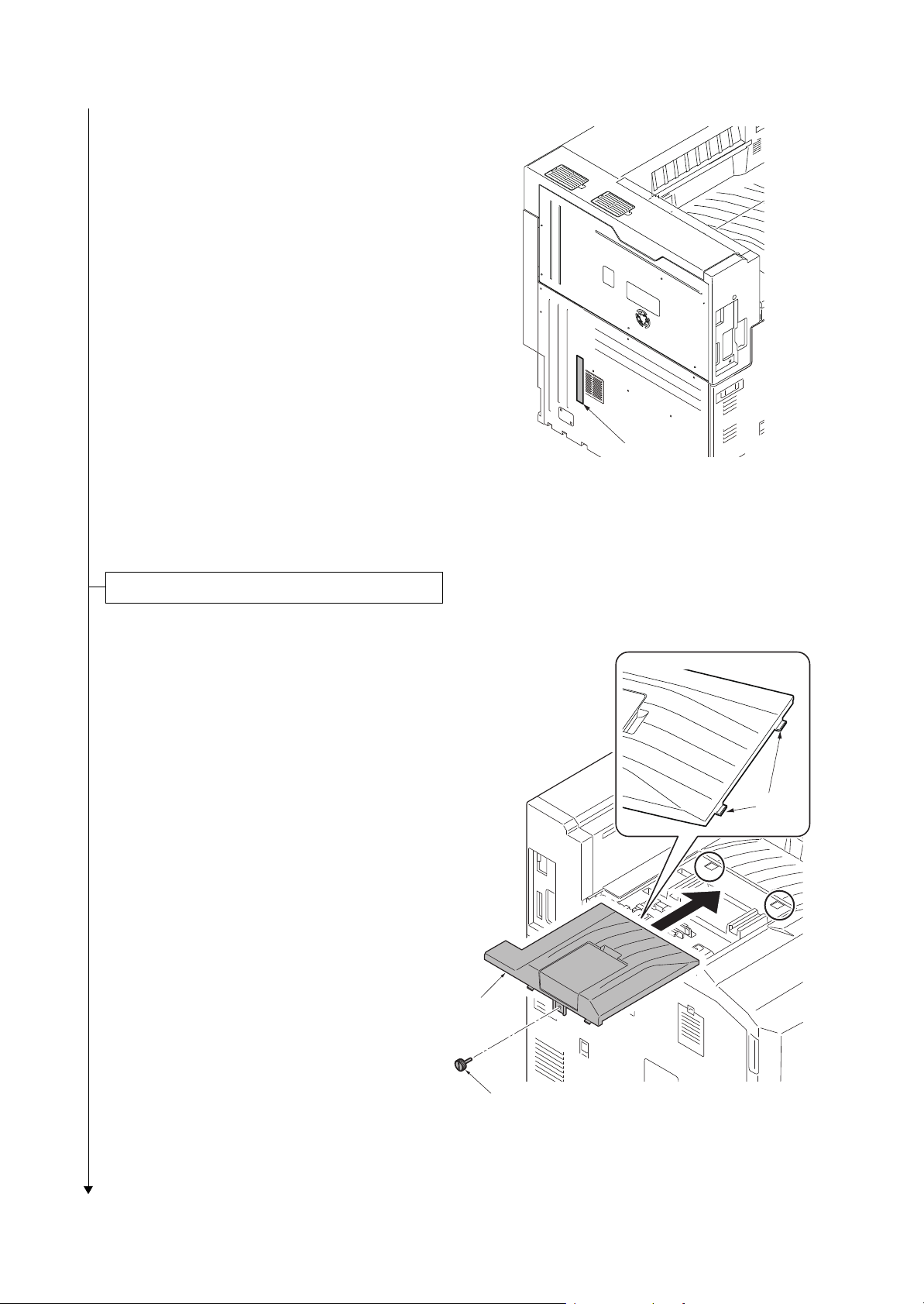

1-2-6 Installing the duct unit (option)

Duct unit installation requires the following parts:

Parts Quantity Part.No.

Duct unit 1 302LC94530

Supplied parts of duct unit (302LC94530):

Parts Quantity Part.No.

Duct A 1 -

Duct B 1 -

Filter 2 -

M3 x 8 tap-tight P screw 2 7BB200308H

2MN/2N1-1

M3 x 8 tap-tight P screw (black)

M3 x 8 tap-tight S screw (black) 2 7BB782308H

*: This option unit cannot be installed together with the finisher.

Procedure

1. After confirming the data lamp is turned

off, perform shut-down on the operation

panel, turn power off, and unplug the

power receptacle(see page P.1-2-19).

2. Fit duct B to duct A using two M3 x 8

tap-tight P screws.

1 7BB282308H

Duct A

Duct B

M3 x 8

tap-tight

P screw

1-2-43

M3 x 8

tap-tight

P screw

Figure 1-2-62

Page 66

2MN/2N1

3. Fit two filters to duct A.

Duct A

Filters

4. Remove the screw A from the rear

lower cover.

Rear lower

cover

1-2-44

Figure 1-2-63

Screw A

Figure 1-2-64

Page 67

5. Fit the duct unit to the machine using

the removed screw A, M3 x 8 tap-tight P

screw (black) and two M3 x 8 tap-tight S

screws (black).

2MN/2N1

M3 x 8 tap-tight

S screws (black)

M3 x 8 tap-tight

P screw (black)

Screw A

Figure 1-2-65

1-2-45

Page 68

2MN/2N1

This page is intentionally left blank.

1-2-46

Page 69

2MN/2N1

1-3 Maintenance Mode

1-3-1 Maintenance mode

The machine is equipped with a maintenance function which can be used to maintain and service the

machine.

(1) Executing a maintenance item

Perform this operation when the panel displays

Ready to print or that the cover is open.

Start

Press the menu key while pressing and

holding the OK and down cursor keys

simultaneously.

Enter “10871087” using

the numeric keys.

( 0 -16digit)

Press the Right Select key for [Enter].

Yes

Yes

Enter the maintenance item

number using the numeric keys.

Press the OK key.

The selected maintenance item is run.

Press the Back key.

Repeat the same

maintenance item?

No

Run another maintenance

item?

No

Enter 001 using the numeric keys

and press the OK key.

End

Maintenance mode is exited.

1-3-1

Page 70

(2) Maintenance modes item list

2MN/2N1

Section

General U000 Outputting an own-status report -

Initialization

Drive,

paper

feed and

paper

conveying system

Item

No.

U001 Exiting the maintenance mode -

U002 Setting the factory default data -

U004 Setting the machine number -

U019 Displaying the ROM version -

U021 Memory initializing -

U024 HDD formatting -

U030 Checking the operation of the motors -

U031 Checking switches and sensors for

U032 Checking the operation of the clutches -

U033 Checking the operation of the solenoids -

U034 Adjusting the print start timing -

Content of maintenance item

45ppm 55ppm

paper conveying

LSU Out Top 0/0/0/0/0/0/0/0/0/0/0/0

LSU Out Left 0/0/0/0/0/0/0/0/0

Initial setting

-

LSU Out Top B/W - 0/0/0/0/0/0

LSU Out Top 3/4 0/0/0/0/0/0

U037 Checking the operation of the fan motors -

U051 Adjusting the deflection in the paper

Paper Loop Amount -5/0/-5/0/

-5/0/-5/0

-6/-1/-5/0

Paper Loop Amount B/W - -8/-8/-8/

Paper Loop Amount 3/4 -2/-2/-2/-2/-3/-2

U052 Setting the fuser motor control

Set Loop Sensor -

Loop Sensor Control On/On/On/On

Set Loop Sensor Valid On

U053 Setting the adjustment of the motor

speed

Motor1

Motor2

12 11

0/0/0/17/0

-7/-1/-7/-1/

-7/-1/-7/-1/

-8/-2/-7/-1

-8/-9/-8

0/0/0/15/0

1-3-2

Page 71

2MN/2N1

Section

Drive,

paper

feed and

paper

conveying system

Item

No.

U053 Motor3 27/0/-30/

Content of maintenance item

45ppm 55ppm

-30/82/0/18/-30/-30/

0/0/0/0

Motor4 -/28 25/22

Motor5 - 0/0/14/0

Motor6 - -16/0/-25/

Motor1 Half 0

Motor2 Half 0/0/0/34/0 0/0/0/30/0

Motor3 Half 54/0/-43/

-43/164/0/

36/-60/-60

Motor1 3/4 0

Motor2 3/4 0/0/0/22/0

Motor3 3/4 35/0/-39/-39/106/0/

23/

-39/-39

Initial setting

-18/0/-27/

-27/73/0/

16/-27/-27/

0/0/0/0

-25/66/0/

15/-24/-24

-36/0/-38/

-38/147/0/

32/-54/-54

-26/0/-39/-39/106/0/

23/

-39/-39

High

voltage

U059 Setting fan mode

Fan Mode Mode1

Cooling Mode 0

U089 Outputting a MIP-PG pattern

U100 Adjusting main high voltage

Adj AC Bias -

Set AC Auto Adj On

Set DC Bias -

Adj DC Bias 0/0/0/0/0/0/0/0 0/0/0/0/0/0/0/0/0

Set Low Temp 1

Set Charger Freq 8807/

Chk Current -

Set AC Gain Auto

U101 Setting the voltage for the primary trans-

fer

-/

10690/

8857

11022/10690/10690

8857

Normal Full 126 131

Normal Half 108 110

Normal 3/4 118 118

1-3-3

Page 72

2MN/2N1

Section

High

voltage

Item

No.

U101 Normal B/W - 135

U106 Setting the voltage for the secondary

Content of maintenance item

Add Color 2/2/5

Add Color 2nd -3/-3/-2/-14

Surround Correct Off

transfer

Light/Normal 1st

Normal2/3 1st

Light/Normal 2nd

Normal2/3 2nd

Light/Normal 1st 3/4(Gloss)

Normal2/3 1st 3/4(Gloss)

Light/Normal 2nd 3/4(Gloss)

Normal2/3 2nd 3/4(Gloss)

Light/Normal 1st B/W

Normal2/3 1st B/W

45ppm 55ppm

143/134/120 150/139/128

207/155/124 220/163/128

Initial setting

131/123/120

180/140/120

- 150/144/128/

Light/Normal 2nd B/W

Normal2/3 2nd B/W

Heavy1 1st 3/4 133/129/124

Heavy1 2nd 3/4 155/150/124

Heavy4/5 1st Half 126/123/119 130/127/122

Heavy4/5 2nd Half 144/140/119 151/146/122

OHP 134/129/124 139/133/128

Bias 1/1/1/-/138/126/133 1/1/1/1/143/130/133

U107 Setting the transfer cleaning voltage -

Belt(A) 202/180/192/- 207/182/192/212

Belt(B) 150/110/130/- 160/110/130/160

U108 Setting separation shift bias -

Output 55/55/55/55/0/0

Output 3/4 55/55/55/55

Output B/W 20/20/20/20

Timing -

Subtraction Value -35

- 183/171/128

U110 Checking the drum count -

U111 Checking the drum drive time -

U117 Checking the drum number -

U118 Displaying the drum history -

U119 Setting the drum -

1-3-4

Page 73

2MN/2N1

Section

High

voltage

Developer U130 Initial setting for the developer -

Item

No.

U122 Checking the transfer belt unit number -

U123 Displaying the transfer belt unit history -

U127 Checking/clearing the transfer count -

U128 Setting transfer high-voltage timing -5/0/13 -5/0/10

U131 Adjusting the toner sensor control volt-

U132 Replenishing toner forcibly

U135 Checking toner motor operation -

U136 Setting toner near end detection 3/3

U139 Displaying the temperature and humidity

Content of maintenance item

45ppm 55ppm

age

Manual 150/150/150/150

Mode Auto

outside the machine

Initial setting

-

-

U140 Displaying developer bias

Sleeve DC 84/84/84/70/-

Sleeve AC 155/155/155/155/-

Mag DC 155/155/155/155/-

Mag AC 160/200/200/200/- 160/200/200/200/160

Sleeve Freq 5345/

Sleeve Duty 68/-

Mag Duty 43/- 43/43

AC Calib 15/15/15/12

U147 Setting for toner applying operation

Mode Mode1

Upper Limit 2.0

Minimum 10

Interval Number 250/100/50

84/84/84/70/70

155/155/155/155/155

155/155/155/155/155

5511/5345/5345/5345

-/

5345/

5345

68/68

Mode1