Page 1

(Page.1/3)

Subject

Improvement of the Assembly Work (Disuse of the Parts)

Model l:

TASKalfa 7550ci, TASKalfa 6550ci, TASKalfa 5550ci,

TASKalfa 4550ci, TASKalfa 3550ci, TASKalfa 3050ci,

TASKalfa 8000i, TASKalfa 6500i, TASKalfa 5500i,

TASKalfa 4500i, TASKalfa 3500i, FS-C8650DN, FS-C8600DN,

DP-770, DP-771, PF-780, AK-730, BF-730

DP-770/771

TASKalfa 5550ci/4550ci/3550ci/3050ci, TASKalfa 5500i/4500i/3500i

PF-780

TASKalfa 7550ci/6550ci, TASKalfa 5550ci/4550ci, TASKalfa 8000i/6500i, FS-C8650DN, FS-C8600DN

AK-730

TASKalfa 5550ci/4550ci/3550ci/3050ci, TASKalfa 5500i/4500i/3500i

BF-730

DF-790/DF-790(B) (Main unit: TASKalfa 7550ci/6550ci, TASKalfa 5550ci/4550ci/3550ci/3050ci,

TASKalfa 8000i/6500i,TASKalfa 5500i/4500i/3500i, FS-C8650DN, FS-C8600DN)

KMC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measure: No particular problem is expected.

Serial Nos. of the Affected Machines:

After using up the old stock. (The serial number information will not be available.)

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

patility

Remarks

Old

New

Old

New

Affected models: DP-770

1

303LL04110

3LL04110

-----------

COVER BOTTOM REAR

1

- O -

*1

Affected models: DP-771, TASKalfa 7550ci/6550ci, TASKalfa 8000i/6500i

2

303M407520

3M407520

-----------

COVER PF REAR

1

- O -

*1

3

303M404090

3M404090

-----------

FILM LED

1

- O -

*2

4

303M406140

3M406140

-----------

SPONGE LIFT

2

- O -

*3

Affected models: PF-780, TASKalfa 7550ci/6550ci, TASKalfa 5550ci/4550ci/3550ci/3050ci,

TASKalfa 8000i/6500i, TASKalfa 5500i/4500i/3500i, FS-C8650DN, FS-C8600DN

5

302LC06170

2LC06170

------------

SPRING GUIDE F

(*4)

-

O

-

*5

Affected models: TASKalfa 7550ci/6550ci, TASKalfa 8000i/6500i

6

302F924380

2F924380

------------

SPRING RELEASE FUSER R

1

-

O

-

*6

7

302LF28390

2LF28390

------------

DUCT RELAY

1

-

O

-

*7

Affected models: AK-730, TASKalfa 5550ci*, TASKalfa 4550ci*, TASKalfa 5500i*, TASKalfa 4500i*

--- * AK standard model (120V)

8

302F924380

2F924380

------------

SPRING RELEASE FUSER R

1

-

O

-

*6

Affected models: BF-730

9

303ND04060

3ND04060

------------

COVER FRONT SUB

1

-

O

-

*1

Service Bulletin Ref. No. 2LC-0099 (C275)

[Parts Change Information] <Date> October 17, 2012

Affected models:

Topic

The following parts (No.1 to No.9) were abolished in order to improve the assembly work.

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Page 2

(Page.2/3)

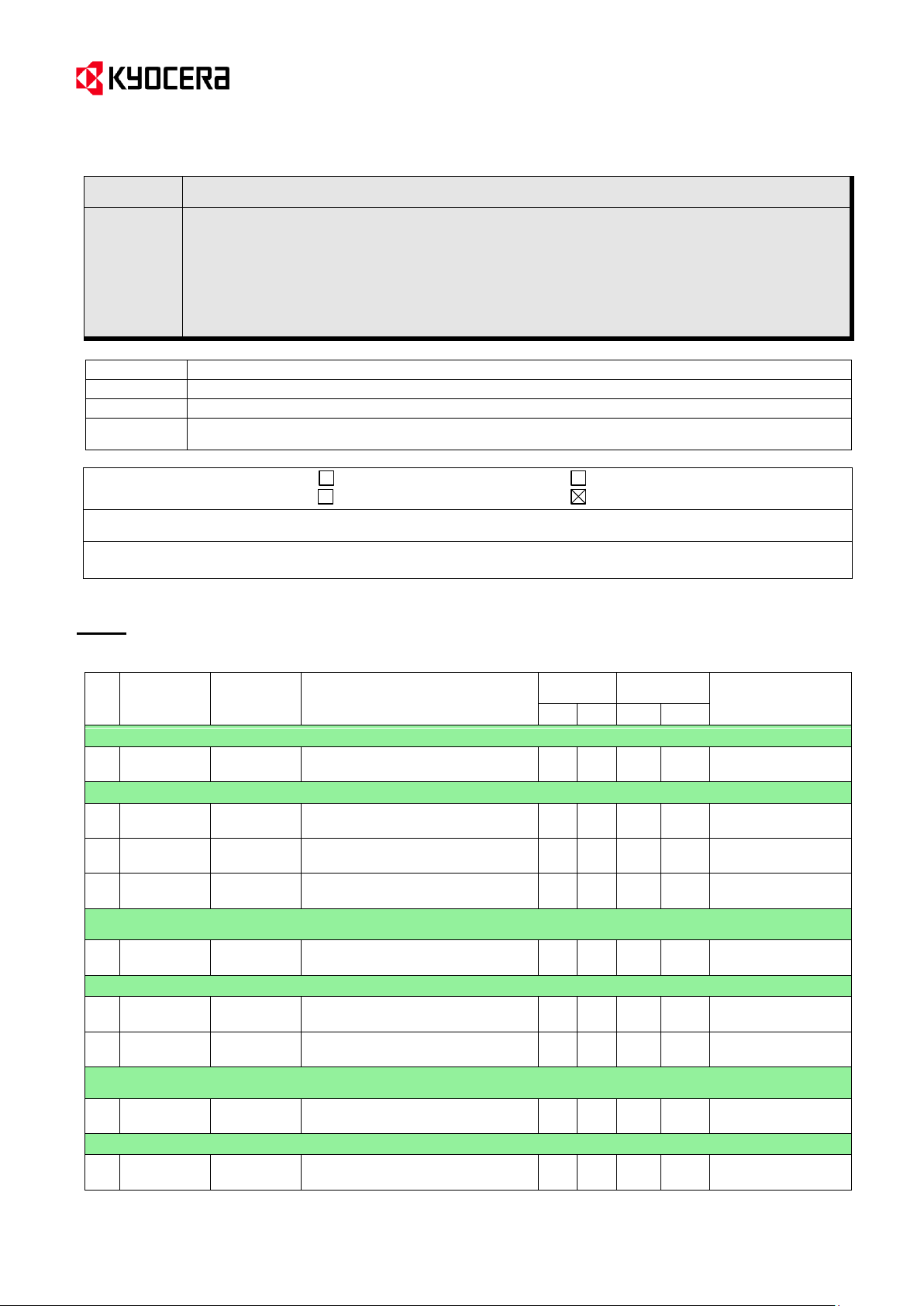

(Machine rear side)

(Machine front side)

(Without the lift levers)

(DP original tray section)

No.1

No.3

No.2

No.4

No.5

Service Bulletin Ref. No. 2LC-0099 (C275)

[Parts Change Information] <Date> October 17, 2012

*1: No.1, 2 and 9 had been applied as screen. They are now disused after it was confirmed that there is no problem in

functionality.

*2: No.3 had been applied to prevent the direct contact with the LED. However, it is now disused since the LED is hardly

contacted.

*3: No.4 had been applied for preventing the noise when lowering the DP lift plate. However, it is now disused since it did not

function due to direct contact with the resin parts.

*4: One pc. per paper feeding unit for the cassette will be used. (PF-780: 1 pc; main unit: 2 pcs.)

*5: No.5 had been fitted at the fulcrum section of the vertical paper conveying guide in order to easily see the jammed paper.

However, it is now disused since the guide is opened by the jammed paper’s stiffness even if this spring (No.5) is not fitted.

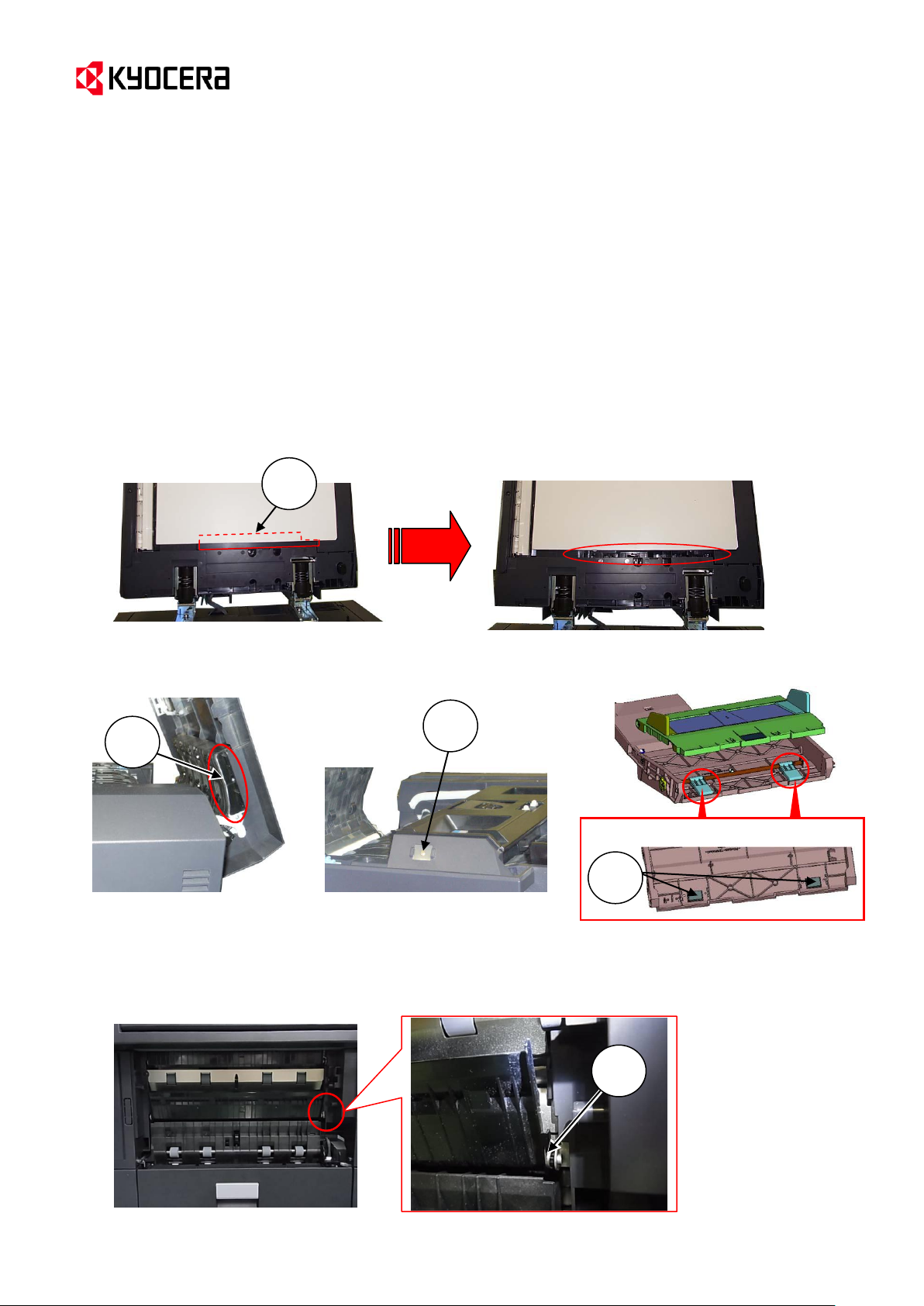

*6: Two springs (No.6, No.8) had been applied to operate the handle of the BR paper conveying unit. However, they are now

disused after it was confirmed that there is no problem in functionality even if only one spring (302LF2858_) is fixed.

*7: No.7 had been applied as cooling duct. However, it is now disused since it did not function due to change of the air flow

since the first mass production.

[DP-770]

(Old) (New)

[DP-771, TASKalfa 7550ci/6550ci and TASKalfa 8000i/6500i]

[PF-780, TASKalfa 7550ci/6550ci, TASKalfa 5550ci/4550ci/3550ci/3050ci,TASKalfa 8000i/6500i, TASKalfa

5500i/4500i/3500i, FS-C8650DN and FS-C8600DN]

(The photo below shows the machine right side when the paper conveying cov er is open.)

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Page 3

(Page.3/3)

Machine

front side

Handle spring

(No.6, No.8: They are fixed inside of the bridge unit at the

part circled in red.)

Machine front right side

No.7

No.9

Service Bulletin Ref. No. 2LC-0099 (C275)

[Parts Change Information] <Date> October 17, 2012

[TASKalfa 7550ci/6550ci, TASKalfa 8000i/6500i (Bridge section) and AK-730]

(The photo below shows the bridge section without the upper guide.)

[BF-730] (The photo below shows the view from the machine front side.)

(Old) (New)

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Loading...

Loading...