Kyocera TASKalfa 2550ci, FS-C8020MFP, FS-C8520, FS-8025MFP, FS-8525MFP SERVICEBULLETINS 2MV 0011 C326

(Page.1/2)

Subject

Measures against the JAM421x (Exit Sensor Stay Jam)

Model l:

FS-C8025MFP, FS-C8020MFP, FS-C8525MFP, FS-C8520MFP,

TASKalfa 2550ci

KDC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measures:

When the paper jam J421x frequently occurs, it might be caused by the factor described below. In this case,

please replace the spring in the fuser unit with the new spring (No.7) by following the attached procedures

(Excel file).

Serial Nos. of the Affected Machines: Planned from the available timing in the Dec. 2012* production

* The above is the plan at the present moment. Please note that this information is subject to change.

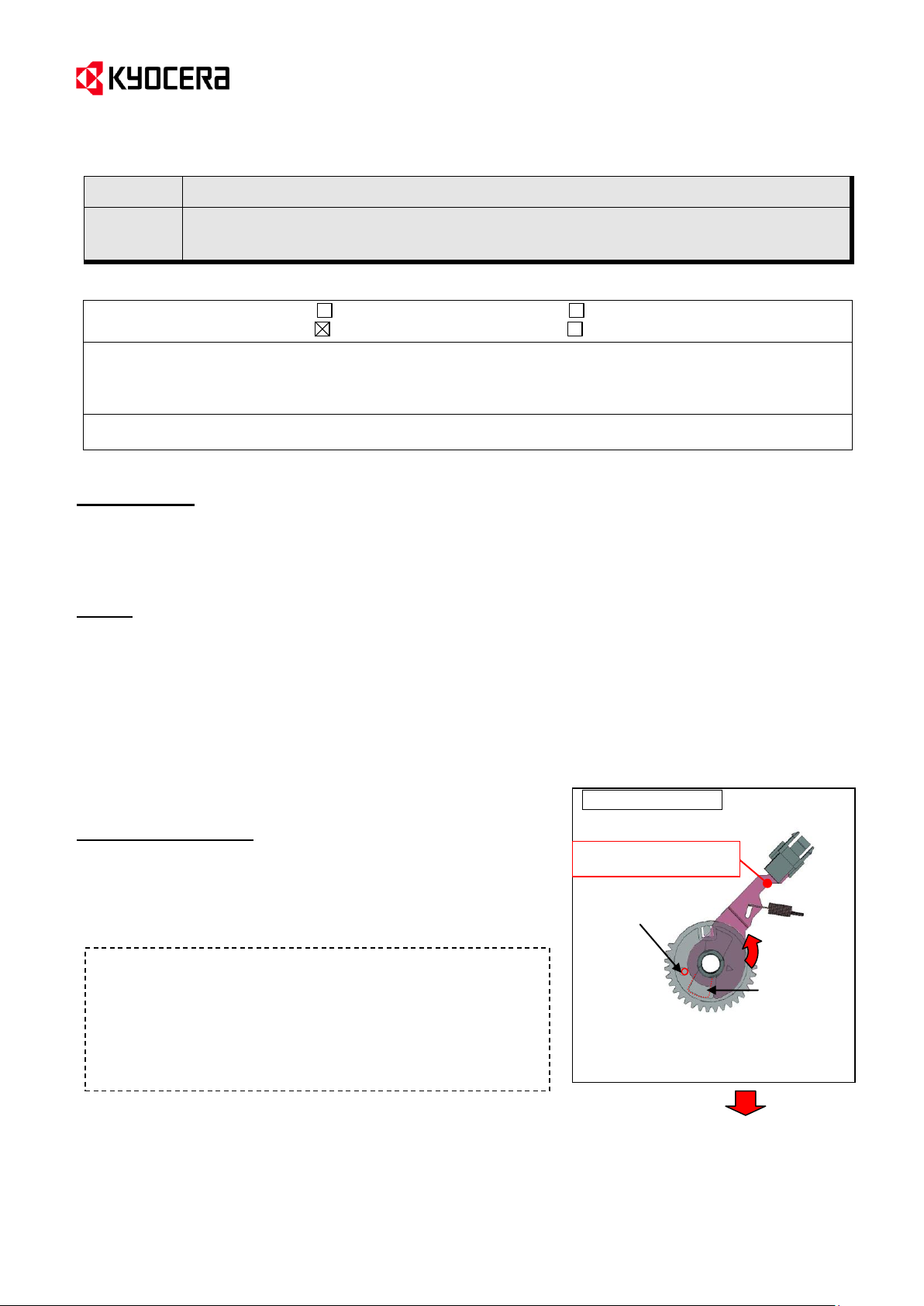

<Operation of the following parts when pressurizing the fuser>

The cams to switch the fuser pressure rotate counterclockwise when

feeding paper except in the envelope mode and the paper is

pressurized by being pinched by the heat and the press rollers.

The metal actuator is lifted up to turn OFF the PI sensor by the gear

fitted at the same shaft as the cams when the pressure is sufficiently

applied, and then the cams stop.

(If the pressure is released, the parts are rotated in reverse.)

Fig. X (Wrong state)

Normally, the protrusion of the gear lifts up

the metal actuator. However, the metal

actuator is lifted up by the fan-shaped rib

may prematurely turn OFF the PI sensor.

PI sensor is

prematurely turned

Protrusion of

the gear

Fanshaped rib

Service Bulletin Ref. No. 2MV-0011 (C326)

<Date> December 17, 2012

(Notice) This phenomenon does not occur in the envelope mode, which does not require fuser pressure operation.

Phenomenon

In a very rare case, when paper is ejected from the fuser unit while the cams are switching the fuser pressure

stop on the way of their rotation, the OFF timing of the eject sensor might be delayed due to contact of the cam

with the actuator to switch the exit sensor and it may cause the paper jam J421x*.

* The last digit of the jam code indicates the paper source.

Cause

Depending on the neighboring gear's thermal expansion or structural variation, etc, the metal actuator (A) has no

gap margin to the thrust direction. In this state, the actuator (A) may prematurely turn OFF the PI sensor (Refer

to X in the following figure) by rotating together with the gear, and the cams may stop on the way of their rotation.

Then, the OFF timing of the eject sensor may be delayed due to contact of the actuator to switch the eject sensor

with the rear side cam immediately after trailing edge is exited from the fuser unit (Refer to Y), which may cause

paper jam detection.

Metal actuator (A): Regulates the rotation of the cams to switch the fuser pressure to prevent excessive rotation

in the pressure direction.

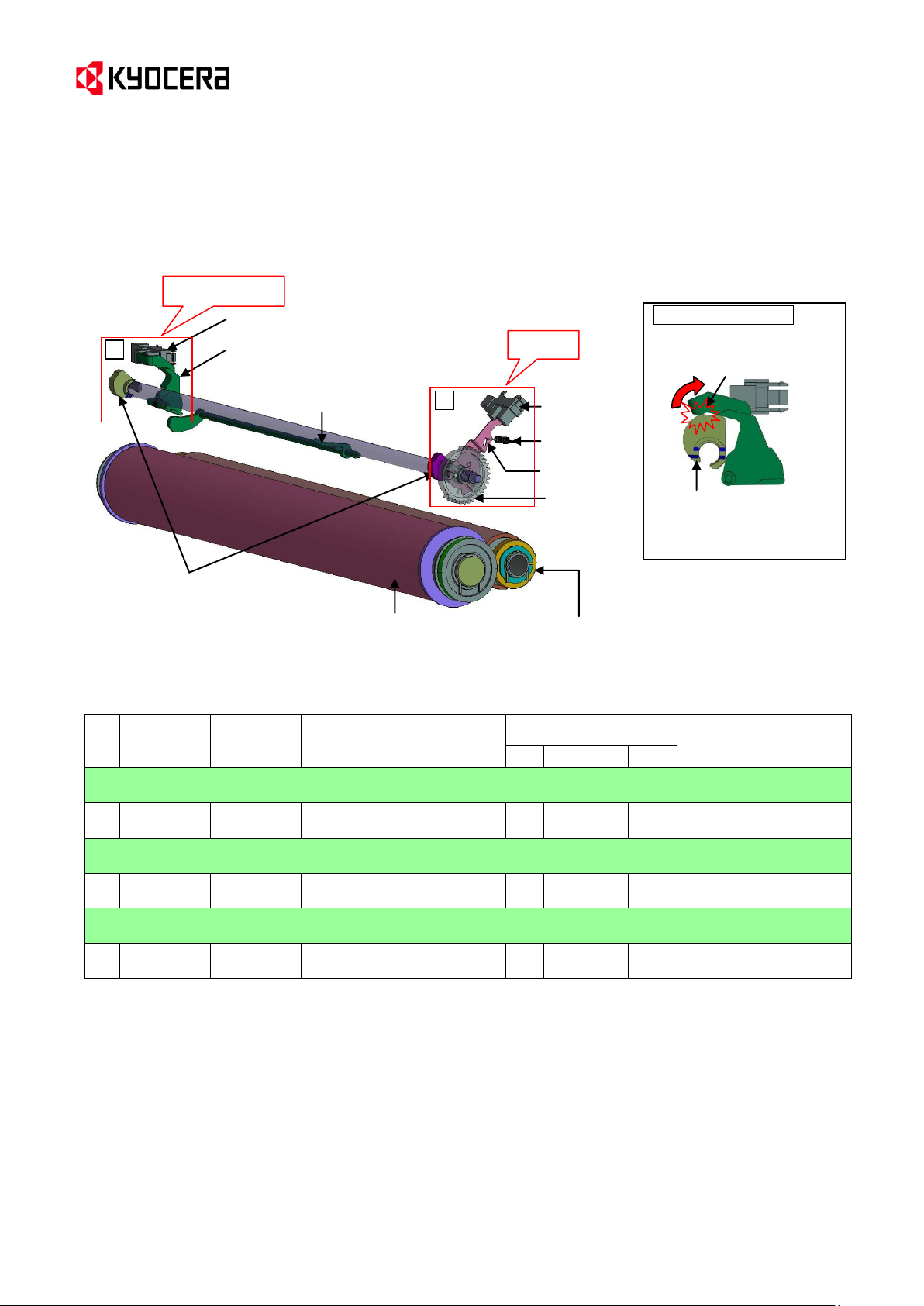

Content of Changes

The tension of the spring (No.7) to release the metal actuator was

increased so that the metal plate will not rotated at the premature

timing by the gear loads applied from the thrust direction.

[Positions of the parts --- Related parts only]

(The illustration below shows the normal fuser pressure state.)

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

(Page.2/2)

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

patility

Remarks

Old

New

Old

New

TASKalfa255c/FS-C8025MFP, TASKalfa205c/FS-C8020MFP,

TASKalfa 256ci/FS-C8525MFP, TASKalfa 206ci/FS-C8520MFP

1

302MY93081

2MY93081

302MY93082

2MY93082

FK-896

1

1

X

O

Except KDCN and KDKR

TASKalfa 2550ci

2

302MV93091

2MV93091

302MV93092

2MV93092

FK-8315

1

1

X

O

Except KDCN and KDKR

Common component parts of No.1 to No.6

3

------------

302K025941

2K025941

+SPRING PRESS

ACTUATOR

-

1

-

O

Service part for field

measures (*1)

(Machine

rear side)

(Machine

front side)

Heat roller

Press roller

Spring (No.7)

Eject sensor (in ON mode)

Actuator 1 to switch the eject sensor

(It is linked with the actuator 1 which actually

contacts paper.)

Cams to switch the fuser pressure

(The cams above fully rotate in the

pressure direction.)

Gear

PI sensor

Metal actuator

Cause

Phenomenon

Y

X

Actuator 2 switching the

eject sensor

Fig. Y (Wrong state)

Rear cam: It stops on the way

of its rotation as the PI sensor

is turned OFF when applying

pressure.

Rotation of the actuator 1 to

turn ON the eject sensor may

be delayed by this contact.

Service Bulletin Ref. No. 2MV-0011 (C326)

<Date> December 17, 2012

"+" mark at the beginning of the part name indicates that it is a component part.

*1: The old spring is not individually supplied.

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Loading...

Loading...