Kyocera FS-C8020MFP, FS-8025MFP SERVICEBULLETINS 2KZ 0007 B201 2

Q’

Com

bi

pati-

Component of No.1

*3

Service Bulletin Ref. No.

Subject

(Revised Issue 2)

(Page.1/4)

2KZ-0007 (B201)

<Date> March 16, 2012

Measures against the Fuser Pressure Release Motion Noise

(Rattling Noise)

Model

This time, the description with (-->) was revised from the previous information.

<Number of changes: 2> The serial numbers of the affected machiens were added.

FS-C8020MFP, FS-C8025MFP

Topic

The following change was made in order to reduce the motion noise generated when the axis distance between the

fuser roller and press roller was automatically increased after printing to reduce the fuser pressure in the stand-by

mode.

Content of Changes

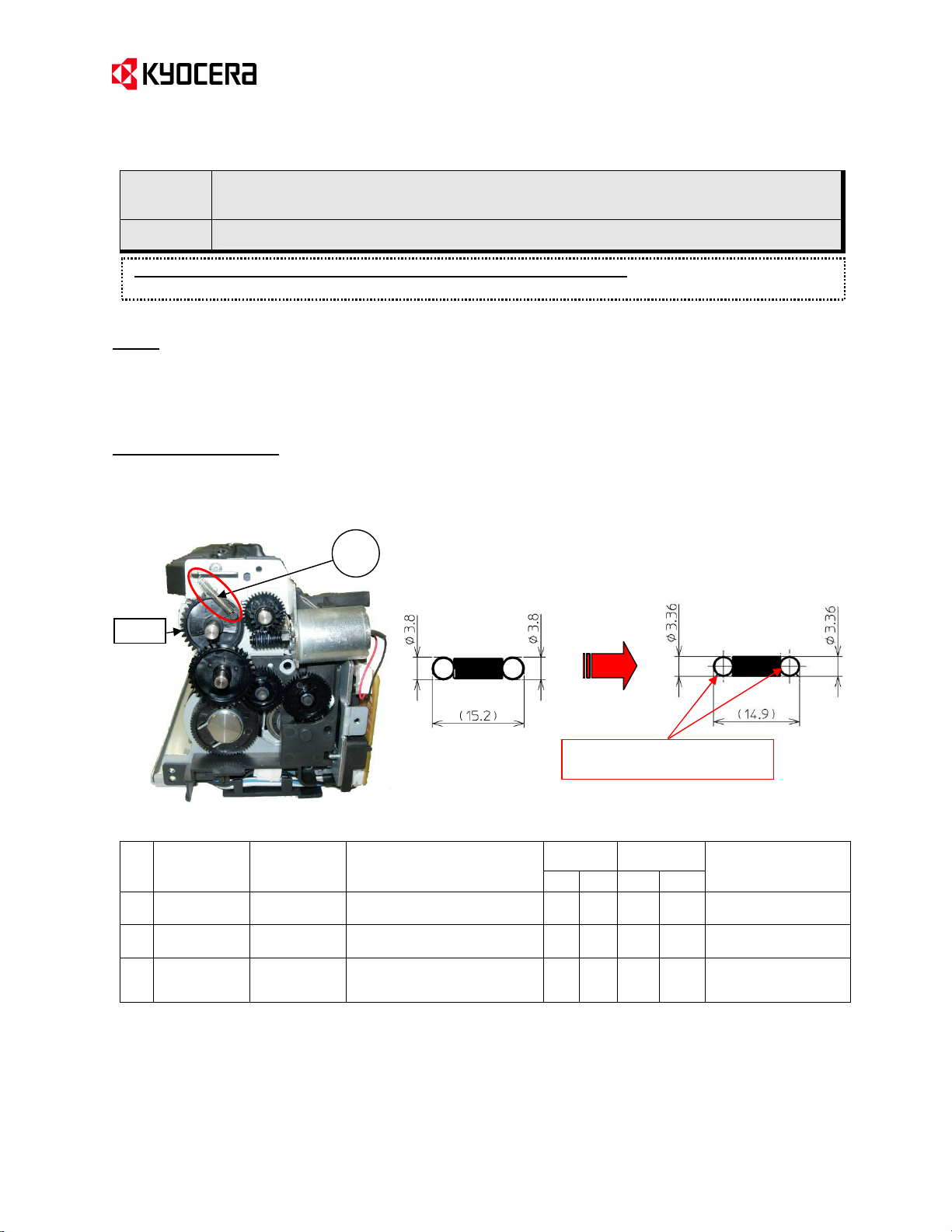

1) The tension of the spring (No.3) was reduced in order to reduce the motion noise (rattling noise) generated

when the gear is pulled to increase the axis distance between the fuser roller and press roller.

No.1

(Old) Spring tension 0.17 N (New) Spring tension 0.062 N

Gear

No.

*3: Newly registered as service part

“+” at the head of part name indicates that it is a component part.

Old Part

No.

302K093090

1

2K093090

302K09K090

2

2K09K090

3 - - - -

New Part

No.

302K093091

2K093091

302K09K091

2K09K091

302K025751

2K025751

European Service & Development Center (ESDC)

<Change of the spring tension>

The hook is with two turns for

distinction.

Description

FK-895 1 1

FK-895(KR) 1 1

+SPRING DRIVE PRESS - 1

KYOCERA MITA Europe B.V.

ty

Old New Old New

lity

X O

X O

- O

Remarks

Except KMKR

For KMKR

and 2

(Revised Issue 2)

Service Bulletin Ref. No.

2KZ-0007 (B201)

(Page.2/4)

<Date> March 16, 2012

KMC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measure:

Please replace the spring with the new one (No.3) in case that the motion noise described above was pointed

by a customer.

(Please refer to the next pages for the procedures to replace the spring (No.3).)

Serial Nos. of the Affected Machines: (-->) Please refer to the tables on Page 4.

<Procedures to replace the spring (No.3)>

No. Procedures Details

Set the fuser pressure to the reduced side before

replacing the spring (No.3). Take out the fuser

unit to securely set it to the reduced side by

following the procedures below.

1

1) Set the machine to the state of “Ready to copy”

2) Open the right cover while the machine is powered ON.

3) Wait for six seconds while the right cover is open.

The fuser pressure is controlled so that it can be

automatically switched to the reduced pressure side even if

the pressure setting is at the increased side.

4) Take out the fuser unit from the machine after six seconds.

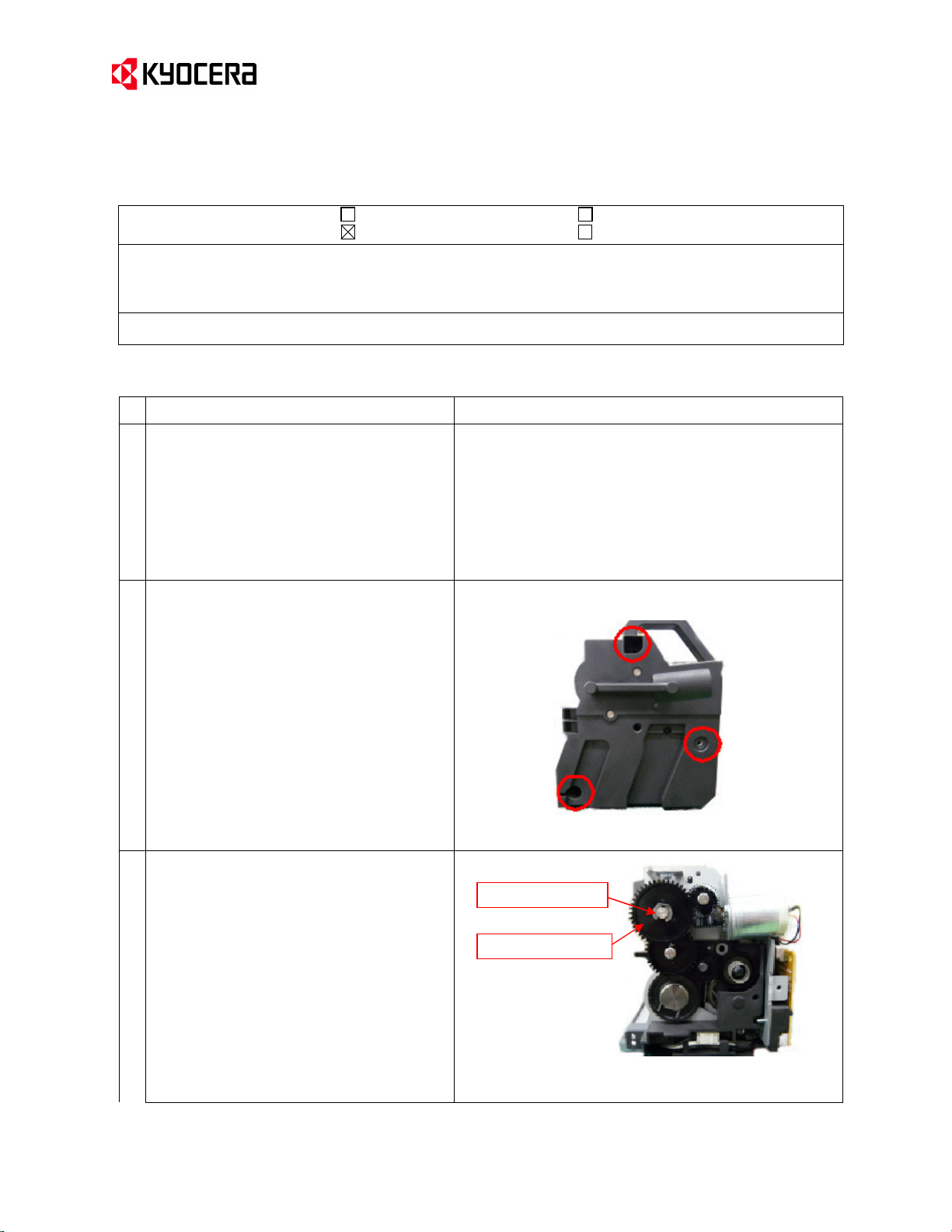

Remove the screw (x3) and take out the front

cover (COVER FUSER FRONT) of the fuser unit.

2

Remove the metal stop ring and take out the gear

(GEAR Z18S-Z43S).

3

Metal stop ring

GEAR Z18S-Z43S

European Service & Development Center (ESDC)

KYOCERA MITA Europe B.V.

Loading...

Loading...