Kyocera FS-6025, FS-6030MFP Service Bulletin 2K3 0027 B446

Q’

Com

bi

p

ati-

Service Bulletin Ref. No.

2K3-0027 (B446)

<Date> December 21, 2011

Subject Measures against the J9000 Jam (No Original Feed Jam)

(Page.1/2)

Model

FS-C8020MFP, FS-C8025MFP, FS-6025FP, FS-6025MFP/B,

FS-6030MFP

Phenomenon

The DP feed roller does not descend and the J9000 (No original feed jam) may appear.

Cause

If high stack of originals is forcibly pushed in, the stopper holding the leading edge of the originals hits the seal on

the top cover rib and sticks to it. If feeding from the DP is started in this state, the DP feed roller does not descend

enough, which causes J9000 (No original feed jam).

Corrective Measures

The seal affixed to the top cover rib on the machine rear side was removed in order to limit the adherence between

the stopper and the top cover rib.

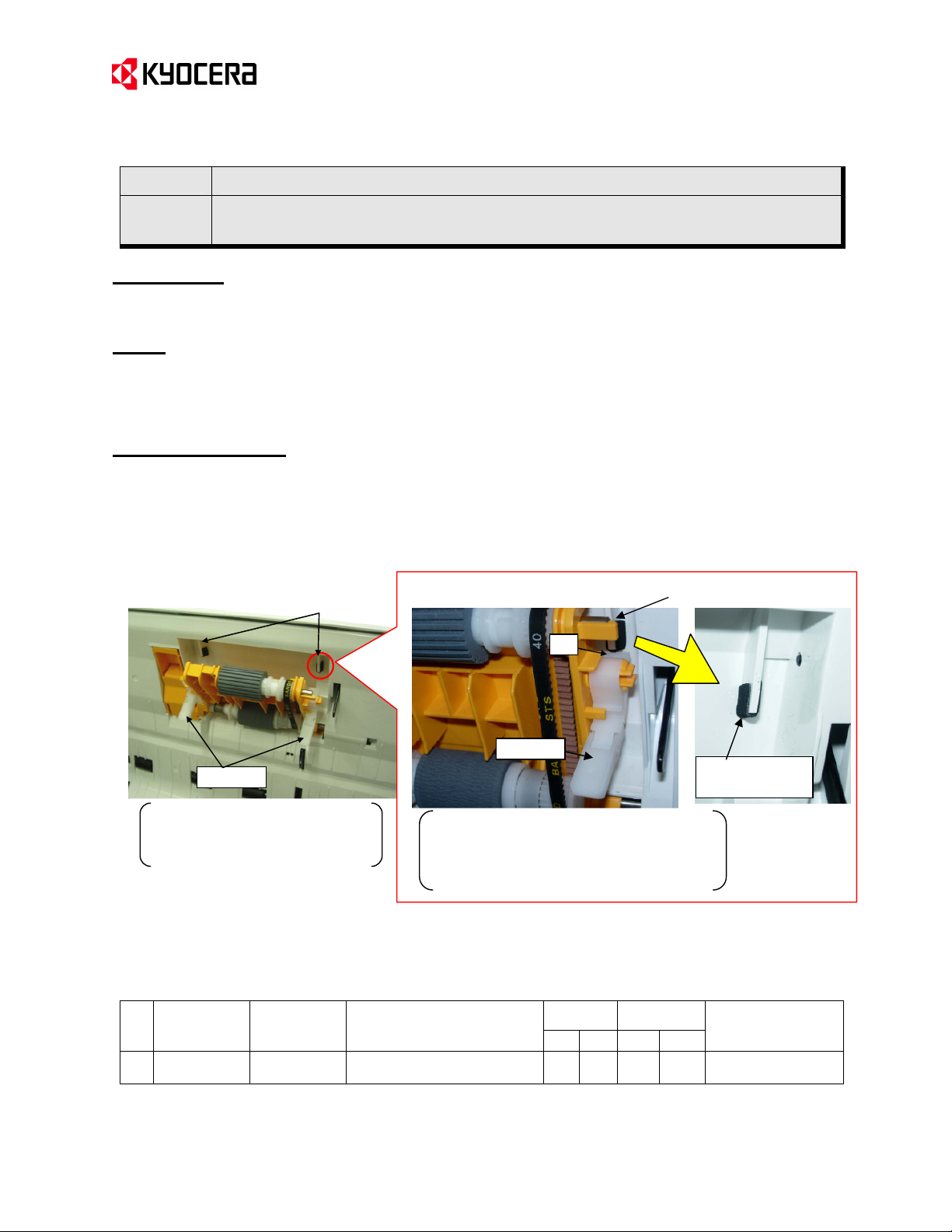

<DP feed roller section>

[When originals are inserted]

The DP feed roller descends and

the stopper is separated from the

top cover rib.

No.

1

*Please use the new part for the new models.

Stopper

Old Part

No.

303M894050

3M894050

Top cover rib

New Part

No.

303M894051

3M894051

*For more details on the mechanism, please refer to the next page.

PARTS COVER PF ASSY SP 1 1

X

Stopper

[Before originals are inserted]

The DP feed roller is lifted up and the stopper

descends while the point marked X on the

stopper contacts the top cover rib.

Description

ty

Old New Old New

Top cover rib

lity

X O

Seal removed

(Machine rear)

Remarks

European Service & Development Center (ESDC)

KYOCERA MITA Europe B.V.

Service Bulletin Ref. No.

KMC’s Classification Entire Stock Rework In-Field modification at next visit

Field Measure:

Please remove the seals affixed to the top cover rib at the machine rear side only if the phenomenon

described above appears.

(In order to maintain the stopper function, do not remove the seal on the machine front side which is same as

the one on the rear side.)

Serial Nos. of the Affected Machines: Planned from the November 2011* production

(Page.2/2)

2K3-0027 (B446)

<Date> December 21, 2011

In-Field modification by case No modification necessary

*The above is the plan at the present moment. Please note that this information is subject to change.

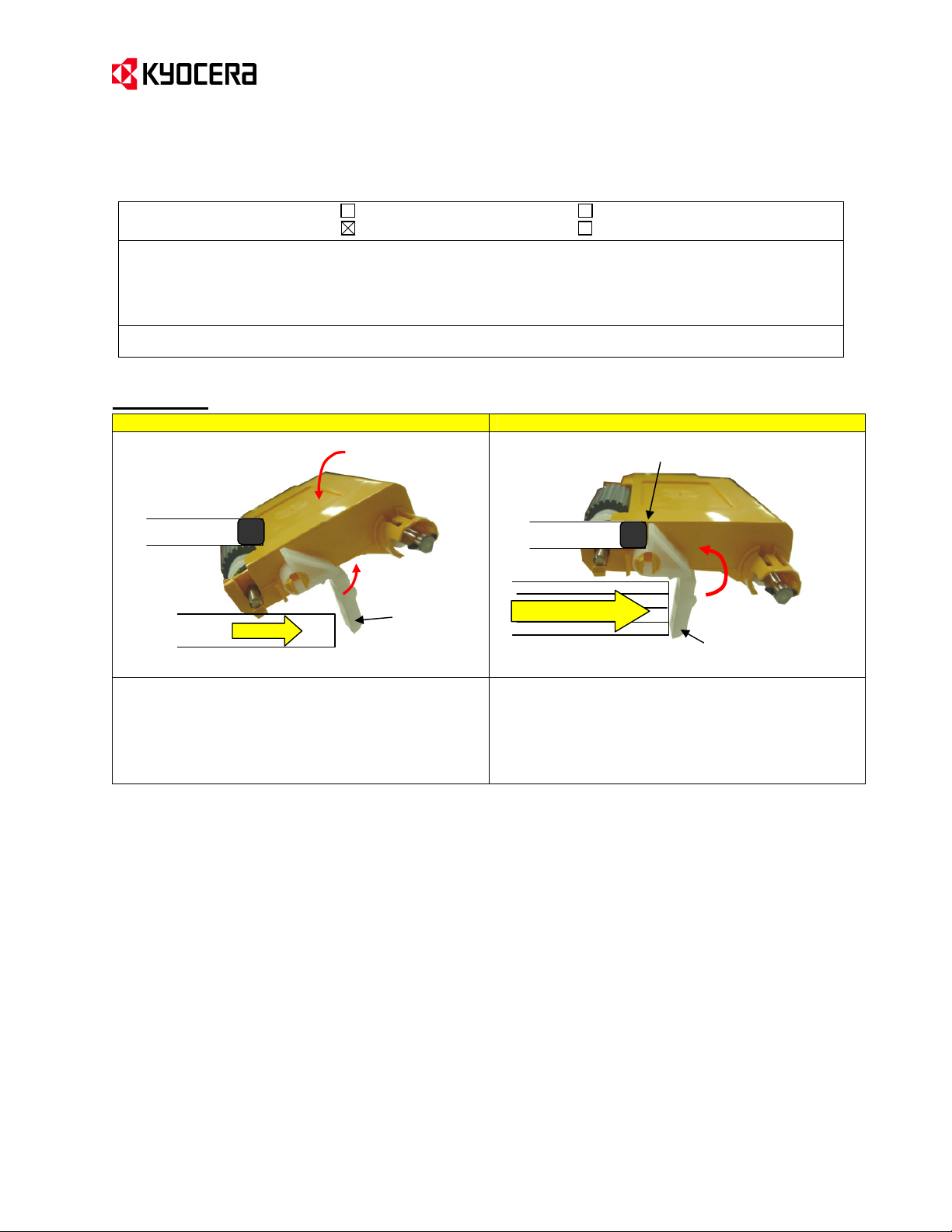

Mechanism

Normal Operation When high stack of originals are forcibly set

High adherence between the rib seal

and the stopper

Top cover rib

Stopper

Original

1) Original is set.

2) Drive starts and the DP feed roller descends.

3) The stopper position is lowered with the motion

above and separated from the top cover rib.

Then, the stopper can rotate.

4) The original is fed.

Top cover rib

Original forcibly set

Stopper

1) High stack of originals is forcibly set.

2) The stopper sticks to the seal affixed to the top cover

rib due to the impact and the stopper is not separated

from the rib when the DP feed roller descends.

3) The DP feed roller does not descend and No original

feed jam occurs.

European Service & Development Center (ESDC)

KYOCERA MITA Europe B.V.

Loading...

Loading...