Page 1

ECOSYS FS-4300DN

ECOSYS FS-4200DN

ECOSYS FS-4100DN

ECOSYS FS-2100DN

ECOSYS FS-2100D

SERVICE

MANUAL

Published in August 2012

842LV110

2LVSM060

First Edition

Page 2

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE

OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

It may be illegal to dispose of this battery into the municipal waste stream. Check with your

local solid waste officials for details in your area for proper disposal.

ATTENTION

IL Y A UN RISQUE D’EXPLOSION SI LA BATTERIE EST REMPLACEE PAR UN MODELE

DE TYPE INCORRECT. METTRE AU REBUT LES BATTERIES UTILISEES SELON LES

INSTRUCTIONS DONNEES.

Il peut être illégal de jeter les batteries dans des eaux d’égout municipales. Vérifiez avec les

fonctionnaires municipaux de votre région pour les détails concernant des déchets solides

et une mise au rebut appropriée.

Notation of products in the manual

For the purpose of this service manual, products are identified by print speed at A4.

ECOSYS FS-4300DN : 60 ppm model

ECOSYS FS-4200DN : 50 ppm model

ECOSYS FS-4100DN : 45 ppm model

ECOSYS FS-2100DN : 40 ppm model (with Network)

ECOSYS FS-2100D : 40 ppm model (without Network)

Page 3

Revision history

Revision Date pages Revised contents

Page 4

This page is intentionally left blank.

Page 5

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 6

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect com-

pliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point of attention is

shown inside the symbol.

General warning. Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action. Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required. Remove the power plug from the wall outlet.

Always ground the copier.

Page 7

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check that

it is adequate for the rated current. .....................................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes, lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the proper

authorities. ..........................................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .........

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. .................

• Do not install the copier near a radiator, heater, other heat source or near flammable material. This

may cause fire. ...................................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ............

• Always handle the machine by the correct locations when moving it. .................................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may cause

the copier to move unexpectedly or topple, leading to injury. ..............................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally

ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately.

If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical atten-

tion. .....................................................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. .........................................................................................................................

Page 8

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ................

• Always follow the procedures for maintenance described in the service manual and other related

brochures. ..........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety mechanisms

and protective circuits. ........................................................................................................................

• Always use parts having the correct specifications. ............................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related brochure

when replacing them. Using a piece of wire, for example, could lead to fire or other serious acci-

dent. ...................................................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ..................................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ...............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it

is dirty, clean it to remove the risk of fire or electric shock. .................................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ...............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause electric

shock if handled improperly. ...............................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are safely

secured so they will not be caught in rotating sections. ......................................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. ..........

• Handle the fixing section with care to avoid burns as it can be extremely hot. ..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. ...........................................................................................................

Page 9

• Do not remove the ozone filter, if any, from the copier except for routine replacement. ......................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ........................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ................................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ..........

• Remove toner completely from electronic components. .....................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ......................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten connector,

trapped wire and missing screws. .......................................................................................................

• Check that all the caution labels that should be present on the machine according to the instruction

handbook are clean and not peeling. Replace with new ones if necessary. .......................................

• Handle greases and solvents with care by following the instructions below: ......................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the power

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. ...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet immedi-

ately. ...................................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the

specified refiner; it may generate toxic gas. ........................................................................................

• Keep the machine away from flammable liquids, gases, and aerosols. A fire or an electric shock

might occur. ........................................................................................................................................

Page 10

This page is intentionally left blank.

Page 11

2LV/2L1/2L2/2MS/2MT

CONTENTS

1-1 Specifications

1-1-1 Specifications ........................................................................................................................ 1-1-1

1-1-2 Parts names .......................................................................................................................... 1-1-4

(1) Machine (front side)..........................................................................................................1-1-4

(2) Machine (rear side)........................................................................................................... 1-1-6

(3) Operation section ............................................................................................................. 1-1-7

1-1-3 Machine cross section ........................................................................................................... 1-1-8

(1) 60/50/45 ppm model......................................................................................................... 1-1-8

(2) 40 ppm model................................................................................................................... 1-1-9

1-2 Installation

1-2-1 Installation environment......................................................................................................... 1-2-1

1-2-2 Unpacking and installation..................................................................................................... 1-2-2

1-2-3 Install the expansion memory (option)................................................................................. 1-2-12

1-2-4 Install the memory card (SD card) (option).......................................................................... 1-2-13

1-2-5 Option composition.............................................................................................................. 1-2-14

1-3 Maintenance Mode

1-3-1 Service mode......................................................................................................................... 1-3-1

(1) Executing a service mode ................................................................................................ 1-3-1

(2) Description of service mode ............................................................................................. 1-3-2

(3) Printing an event log....................................................................................................... 1-3-15

1-4 Troubleshooting

1-4-1 Paper misfeed detection ........................................................................................................ 1-4-1

(1) Paper misfeed indication .................................................................................................. 1-4-1

(2) Paper misfeed detection condition ................................................................................... 1-4-1

(2-1) PF-320 (500 sheets Paper feeder)......................................................................... 1-4-1

(2-2) PF-315+ (Bulk Paper Feeder) ................................................................................ 1-4-2

1-4-2 Self-diagnostic function ......................................................................................................... 1-4-8

(1) Self-diagnostic function .................................................................................................... 1-4-8

(2) Self diagnostic codes........................................................................................................ 1-4-8

1-4-3 Image formation problems ................................................................................................... 1-4-24

(1) No image appears (entirely white).................................................................................. 1-4-25

(2) No image appears (entirely black).................................................................................. 1-4-25

(3) Image is too light. ........................................................................................................... 1-4-26

(4) The background is colored. ............................................................................................ 1-4-27

(5) White streaks are printed vertically................................................................................. 1-4-27

(6) Black streaks are printed vertically. ................................................................................ 1-4-28

(7) Streaks are printed horizontally. ..................................................................................... 1-4-28

(8) Spots are printed. ........................................................................................................... 1-4-28

(9) Image is blurred.............................................................................................................. 1-4-29

(10) Paper is wrinkled. ........................................................................................................... 1-4-29

(11) Offset occurs. ................................................................................................................. 1-4-29

(12) Part of image is missing. ................................................................................................ 1-4-29

(13) Fusing is loose................................................................................................................ 1-4-30

(14) Image is out of focus. ..................................................................................................... 1-4-30

1-4-4 Electric problems ................................................................................................................. 1-4-31

1-4-5 Mechanical problems........................................................................................................... 1-4-35

Page 12

2LV/2L1/2L2/2MS/2MT

1-5 Assembly and disassembly

1-5-1 Precautions for assembly and disassembly........................................................................... 1-5-1

(1) Precautions....................................................................................................................... 1-5-1

(2) Drum unit .......................................................................................................................... 1-5-1

(3) Toner ................................................................................................................................ 1-5-1

(4) How to tell a genuine Kyocera toner container................................................................. 1-5-2

1-5-2 Outer covers .......................................................................................................................... 1-5-3

(1) Detaching and refitting the top cover................................................................................ 1-5-3

(2) Detaching and refitting the inlet cover and slot cover....................................................... 1-5-3

(3) Detaching and refitting the right upper cover.................................................................... 1-5-4

(4) Detaching and refitting the right lower cover .................................................................... 1-5-4

(5) Detaching and refitting the rear left cover......................................................................... 1-5-5

(6) Detaching and refitting the left upper cover...................................................................... 1-5-5

(7) Detaching and refitting the left lower cover ...................................................................... 1-5-6

(8) Detaching and refitting the rear cover .............................................................................. 1-5-6

1-5-3 Paper feed section................................................................................................................. 1-5-8

(1) Detaching and refitting the paper feed roller .................................................................... 1-5-8

(2) Detaching and refitting the retard roller ............................................................................ 1-5-8

(3) Detaching and refitting the MP paper feed pulley............................................................. 1-5-9

1-5-4 Developer section ................................................................................................................ 1-5-13

(1) Detaching and refitting the developer unit ...................................................................... 1-5-13

1-5-5 Drum section ....................................................................................................................... 1-5-15

(1) Detaching and refitting the drum unit.............................................................................. 1-5-15

(2) Detaching and refitting the chager roller unit.................................................................. 1-5-15

1-5-6 Transfer/separation section ................................................................................................. 1-5-16

(1) Detaching and refitting the transfer roller assembly ....................................................... 1-5-16

(2) Detaching and refitting the separation needle unit ......................................................... 1-5-17

1-5-7 Optical section ..................................................................................................................... 1-5-18

(1) Detaching and refitting the laser scanner unit ................................................................ 1-5-18

1-5-8 Fuser section ....................................................................................................................... 1-5-19

(1) Detaching and refitting the fuser unit.............................................................................. 1-5-19

1-5-9 ejection section .................................................................................................................... 1-5-21

(1) Detaching and refitting the ejection unit ......................................................................... 1-5-21

1-5-10 PWBs................................................................................................................................... 1-5-22

(1) Detaching and refitting the main PWB............................................................................ 1-5-22

(2) Detaching and refitting the engine PWB......................................................................... 1-5-22

(3) Detaching and refitting the relay-L PWB ........................................................................ 1-5-24

(4) Detaching and refitting the power source PWB.............................................................. 1-5-25

(5) Detaching and refitting the high voltage PWB ................................................................ 1-5-26

(6) Detaching and refitting the operation PWB .................................................................... 1-5-28

1-5-11 Others .................................................................................................................................. 1-5-29

(1) Detaching and refitting the main driving motor unit ........................................................ 1-5-29

(2) Detaching and refitting the paper feed driving motor unit............................................... 1-5-30

(3) Detaching and refitting the power source fan motor....................................................... 1-5-30

(4) Direction of installing the principal fan motors ................................................................ 1-5-31

1-6 Requirements on PWB Replacement

1-6-1 Upgrading the firmware ......................................................................................................... 1-6-1

1-6-2 Remarks on PWB replacement ............................................................................................. 1-6-2

(1) Engine PWB ..................................................................................................................... 1-6-2

Page 13

2LV/2L1/2L2/2MS/2MT

2-1 Mechanical Construction

2-1-1 Paper feed/conveying section ............................................................................................... 2-1-1

(1) Cassette paper feed section............................................................................................. 2-1-1

(2) MP tray paper feed section............................................................................................... 2-1-2

(3) Conveying section ............................................................................................................ 2-1-3

2-1-2 Drum section ......................................................................................................................... 2-1-4

(1) Charger roller unit............................................................................................................. 2-1-4

(2) Cleaning unit..................................................................................................................... 2-1-5

2-1-3 Developer section .................................................................................................................. 2-1-6

2-1-4 Optical section ....................................................................................................................... 2-1-7

(1) Laser scanner section ...................................................................................................... 2-1-7

2-1-5 Transfer/Separation section .................................................................................................. 2-1-8

2-1-6 Fuser section ......................................................................................................................... 2-1-9

2-1-7 Eject/Feedshift section ........................................................................................................ 2-1-11

2-1-8 Duplex conveying section....................................................................................................2-1-13

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout ............................................................................................................ 2-2-1

(1) PWBs................................................................................................................................ 2-2-1

(2) Switches and sensors....................................................................................................... 2-2-3

(3) Motors............................................................................................................................... 2-2-5

(4) Clutches and others.......................................................................................................... 2-2-7

2-3 Operation of the PWBs

2-3-1 Main PWB (MPWB) ............................................................................................................... 2-3-1

2-3-2 Engine PWB (EPWB) ............................................................................................................ 2-3-6

2-3-3 Power source PWB (PSPWB) ............................................................................................. 2-3-13

2-3-4 Relay-L PWB (R-LPWB)...................................................................................................... 2-3-15

2-3-5 High voltage PWB (HVPWB)............................................................................................... 2-3-18

2-4 Appendixes

2-4-1 Appendixes ............................................................................................................................ 2-4-1

(1) Maintenance kits............................................................................................................... 2-4-1

(2) Repetitive defects gauge .................................................................................................. 2-4-2

(3) Firmware environment commands ................................................................................... 2-4-3

(4) Wiring diagram (60/50/45 ppm model) ........................................................................... 2-4-11

(5) Wiring diagram (40ppm model) ...................................................................................... 2-4-13

Installation Guide

500 sheets paper feeder

2000 sheets bulk paper feeder

Expanded HDD (SSD)

IEEE1284 Interface

Network interface

Wireless LAN interface

Page 14

2LV/2L1/2L2/2MS/2MT

This page is intentionally left blank.

Page 15

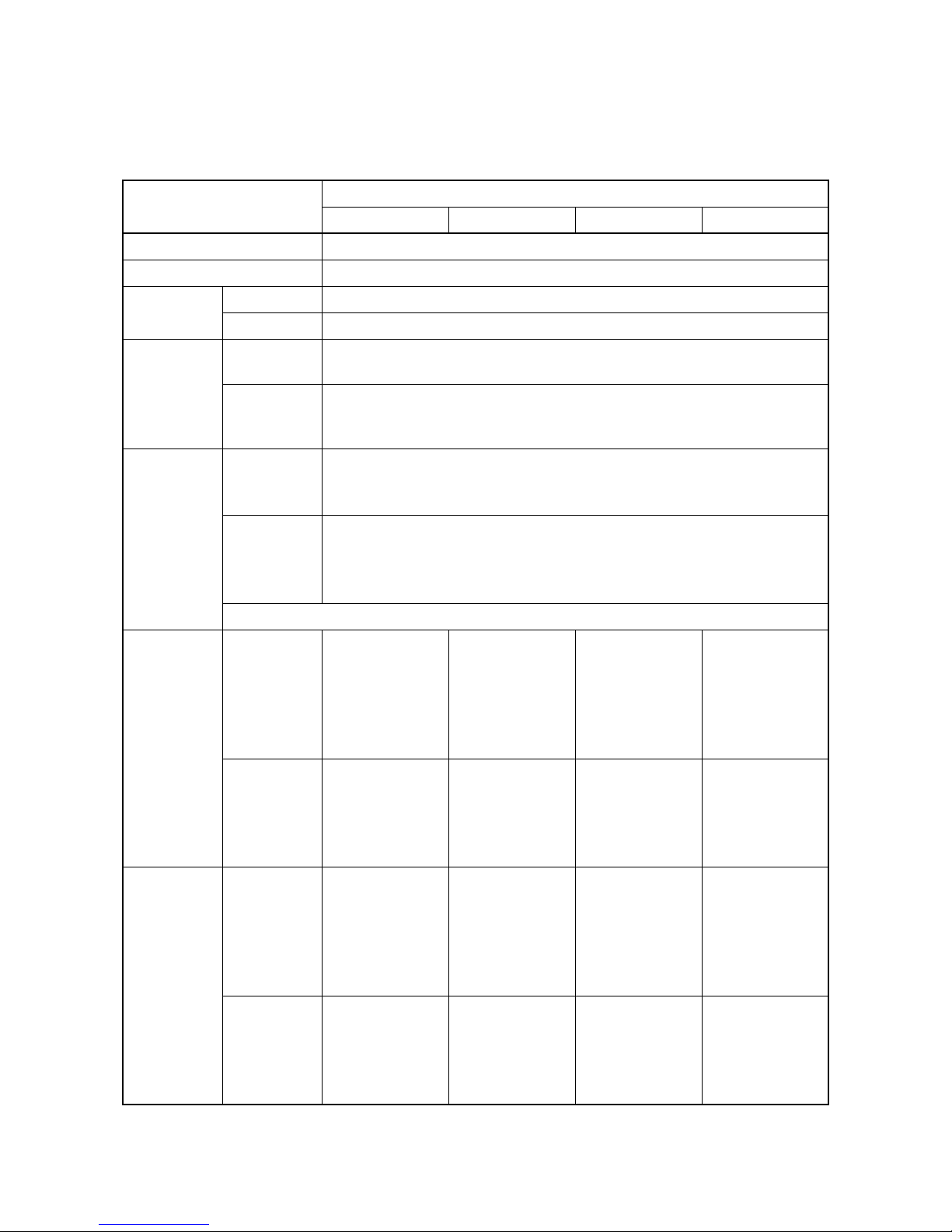

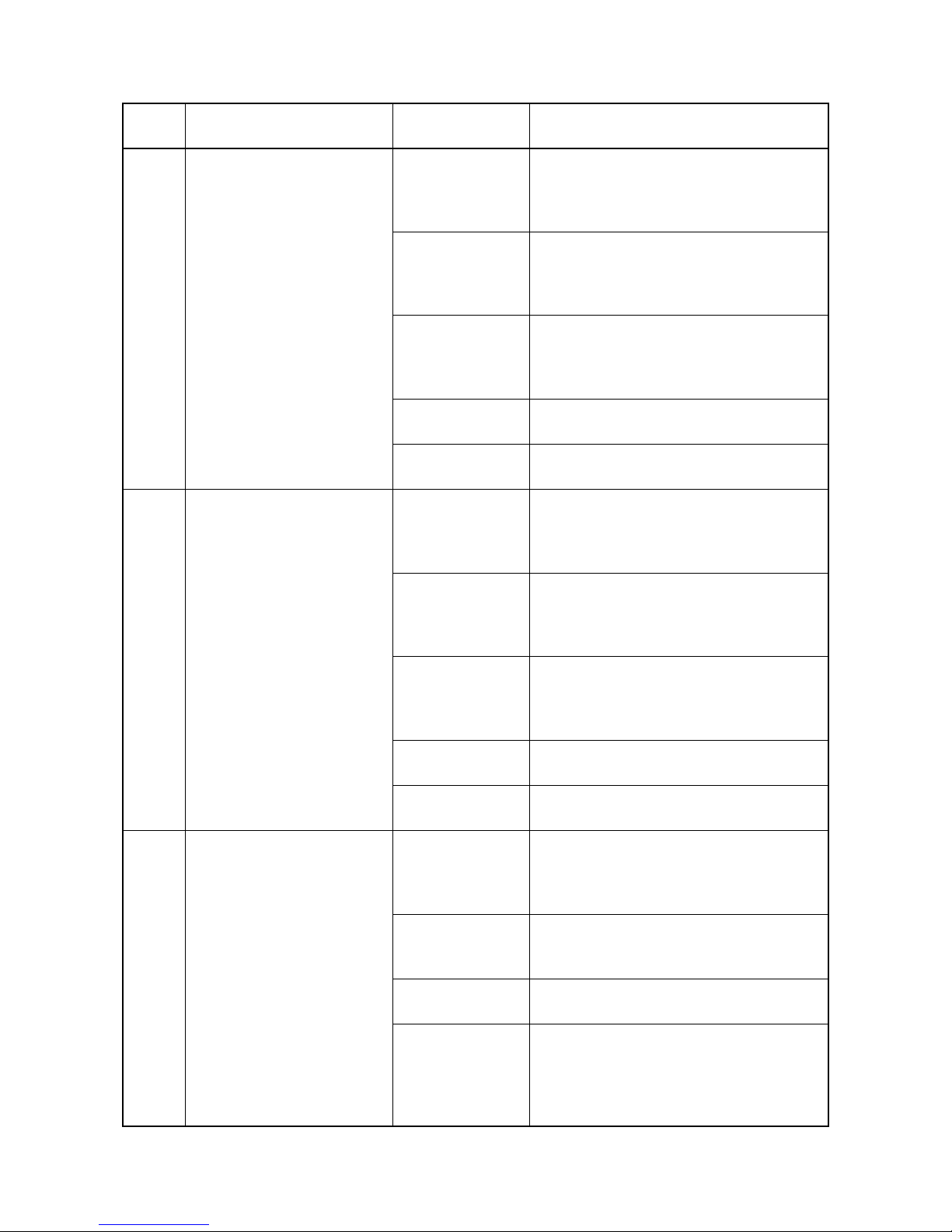

1-1 Specifications

1-1-1 Specifications

2LV/2L1/2L2/2MS/2MT

Item

Specifications

60 ppm 50 ppm 45 ppm 40 ppm

Typ e Desktop

Printing method Electrophotography by semiconductor laser

Paper

weight

Cassette 60 to 120 g/m

MP tray 60 to 220 g/m

Cassette

Plain, Recycled, Bond, Color (Colour), Preprinted, Letterhead,

Prepunched, Rough, High quality, Custom 1 to 8

2

2

, 230 g/m

2

(Postcard)

Paper

type

MP tray

Plain, Recycled, Bond, Color (Colour), Preprinted, Letterhead,

Prepunched, Rough, High quality, Label, Transparency, Postcard, Vellum,

Thick, Envelope, Custom 1 to 8

Legal, Oficio II, Mexican Oficio, Letter, Executive, Statement, Folio, A4,

Cassette

B5(JIS), A5, B6 *1, A6 *1, Return postcard *1, B5(ISO), C5, DL *1, 16K,

Custom

Paper

size

MP tray

Legal, Oficio II, Mexican Oficio, Letter, Executive, Statement, Folio, A4,

B5(JIS), A5, B6, A6, Return postcard, Postcard, B5(ISO), C5, Commercial

#10, DL, Commercial #9, Monarch, Commercial #6-3/4, Youkei4, Youkei2,

16K, Custom

*1: 60/50/45 ppm model only

[Simplex]

50/52

- /42

40

27

27

Printing

speed

A4/Letter

-/Legal

B5R

A5R

A6R

60/62

- /50

48

32

32

(ppm)

Full speed

[Duplex]

A4/Letter

-/Legal

B5R

A5R

43/44

- /25

34

23

36/37

- /21

28

19

45/47

- /38

36

23

23

32/33

- /16

25

16

40/42

- /33

33

22

22

20/21

- /16.5

16.5

11

[Simplex]

A4/Letter

-/Legal

B5R

Printing

speed

A5R

A6R

(ppm)

Half speed

[Duplex]

A4/Letter

-/Legal

B5R

A5R

30/31

- /25

24

16

16

21.5/22

- /12.5

17

11.5

1-1-1

25/26

- /21

20

13.5

13.5

18/18.5

- /10.5

14

9.5

22.5/23.5

- /19

18

11.5

11.5

16/16.5

- /8

12.5

8

20/21

- /17

16.5

11

11

10/10.5

- /8

8

5.5

Page 16

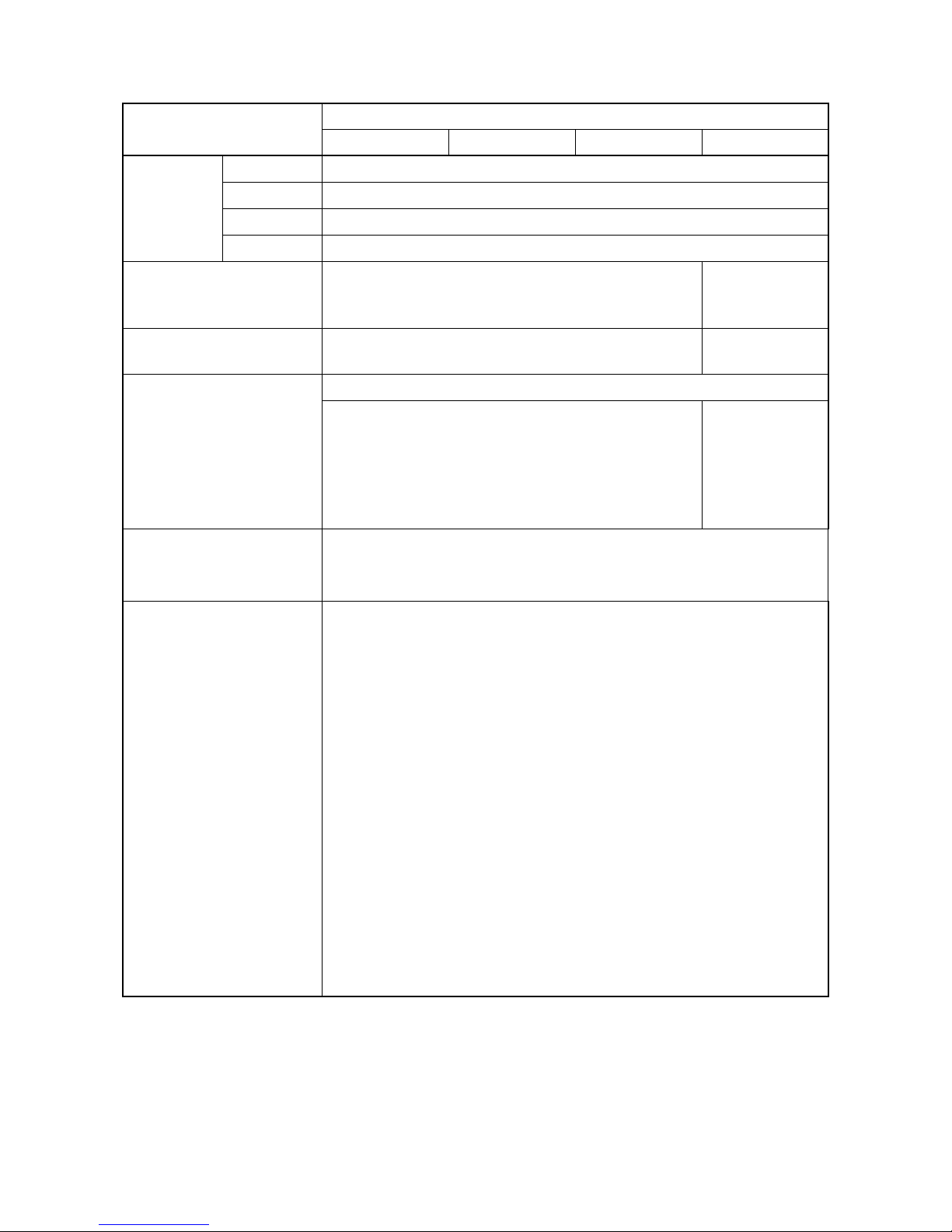

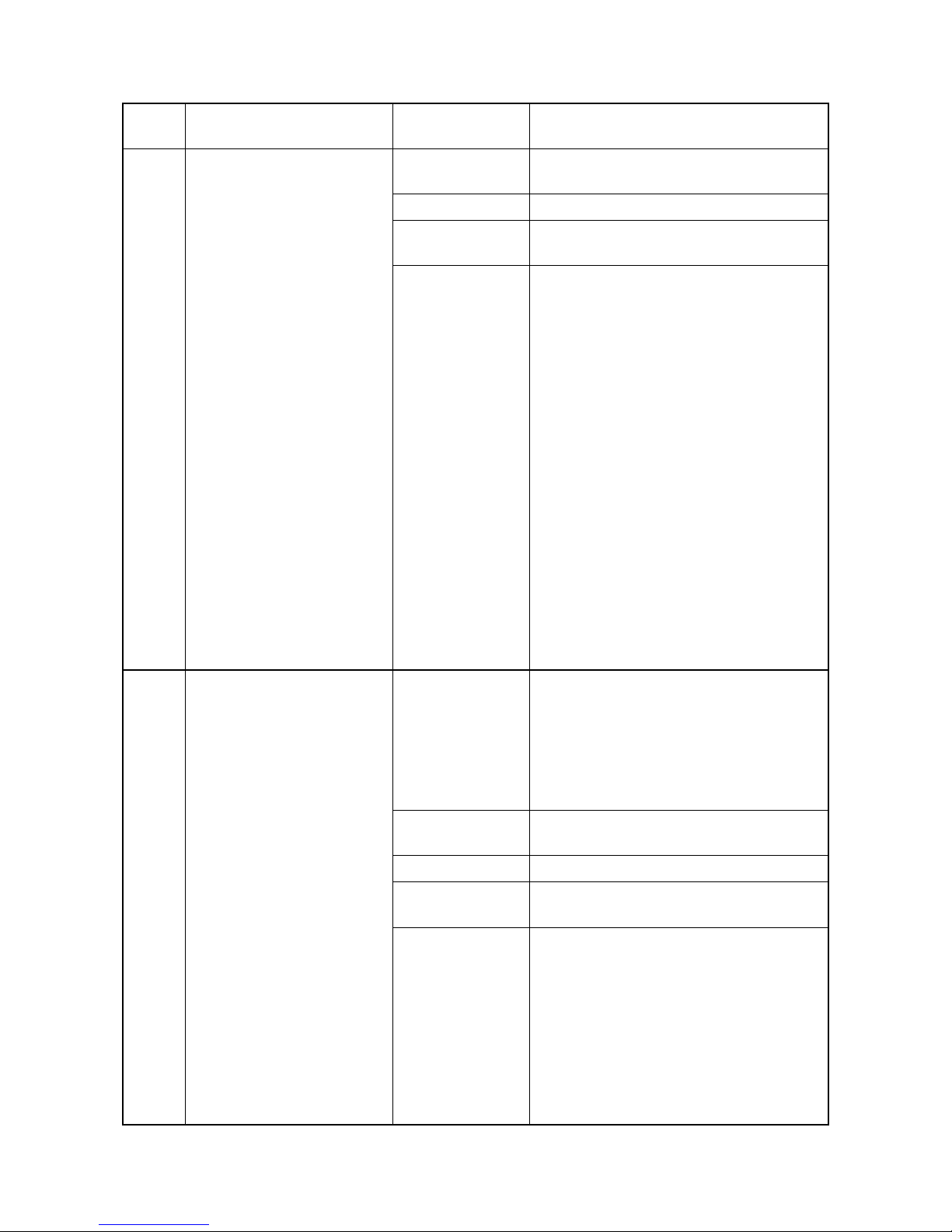

2LV/2L1/2L2/2MS/2MT

Item

Specifications

60 ppm 50 ppm 45 ppm 40 ppm

Resolution

First print time

Fine1200, Fast1200(KIR), 600dpi(KIR) , 300dpi

9.0 s or less

(A4, feed from cassette)

Warm-up

time

(22 °C/

71.6 °F,

60% RH)

Paper

capacity

Output tray

capacity

Power on/

Off mode/

25 s or less

Sleep mode

Low power

mode

-

Cassette 500 sheets (80g/m

MP tray 100 sheets (80 g/m

Facedown

500 sheets (67g/m

Faceup 100 sheets (67g/m

20 s or less 15 s or less 15 s or less

2

)

2

)

2

)

2

)

Photoconductor a-Si drum (diameter 30 mm)

Image write system Semiconductor laser

Charging system Contact charger roller method

Developer system

Mono component dry developing method

Toner replenishing: Automatic from the toner container

Transfer system Transfer roller method

Separation system Small diameter separation, dischager needle (DC bias)

Cleaning system Counter blade cleaning + cleaning roller

Charge erasing system Exposure by cleaning lamp (LED)

250 sheets

2

(67g/m

)

-

Heat and pressure fusing with the heat roller and the press roller

Fusing system

Heat source: halogen heater

Abnormally high temperature protection devices: thermostat

CPU PowerPC465, ARM7/ARM9 PowerPC465 *1

Main memory 256 MB / 1280 MB (Standard / Max) *2

Windows XP, Windows XP Professional,

Windows Server 2003, Windows Server 2003 x64 Edition,

Operating system

Windows Vista x86 Edition, Windows Vista x64 Edition,

Windows 7 x86 Edition, Windows 7 x64 Edition,

Windows Server 2008, Windows Server 2008 x64 Edition,

Apple Macintosh OS X

USB device interface connector: 1 (USB 2.0)

Interface

Standard

Option

USB host interface connector: 2 (USB 2.0)

Network interface connector: 1 (10BASE-T/100BASE-TX/1000BASE-T) *3

eKUIO slot: 1

Page description language PRESCRIBE

Emulation PCL6, KPDL3, XPS, Line printer, IBM Proprinter X24E, EPSON LQ-850

1-1-2

Page 17

2LV/2L1/2L2/2MS/2MT

Item

Tem p e r a t u r e 10 to 32.5 °C/50 to 90.5 °F

Operating

environment

Humidity 15 to 80% RH

Altitude 2,500 m/8,202 ft or less

Brightness 1,500 lux or less

Dimensions (W × D × H)

Weight

(with toner container)

Space required (W × D)

Power source

120 V AC, 60 Hz

220 - 240 V AC, 50/60 Hz

Options

Specifications

60 ppm 50 ppm 45 ppm 40 ppm

380 × 416 × 320 mm / 14 15/16” × 16 3/8 “× 12 1/4”

380 × 416 × 285

14 15/16” × 16 3/

8 “× 11 1/4”

14.6 kg / 32.2 lb

13.5kg/29.8lb

380 × 593 mm / 14 15/16” × 23 3/8” (using MP tray)

380 × 1138 mm / 14 15/16” × 44 13/16”

(using 2000 sheets paper feeder + Faceup tray)

380 × 799 mm /

14 15/16” × 31 7/

16”

(using 2000

sheets paper

feeder)

more than 10.0 A

more than 6.0 A

500 sheets paper feeder, 2000 sheets bulk paper feeder, Faceup tray *4,

Expanded HDD (SSD), IEEE1284 Interface, Network interface,

Wireless LAN interface, Expanded memory, SD card,

Card Authentication Kit, IC card reader, Data Security Kit(E), USB keyboard,

UG-33(Thin print)

*1: 40 ppm (without Network) model ;

*2: 40 ppm (without Network) model ; 128 MB / 1152 MB (Standard / Max)

*3: 40 ppm (without Network) model ; Network interface connector : 0

*4: 60/50/45 ppm model only

NOTE: These specifications are subject to change without notice.

1-1-3

Page 18

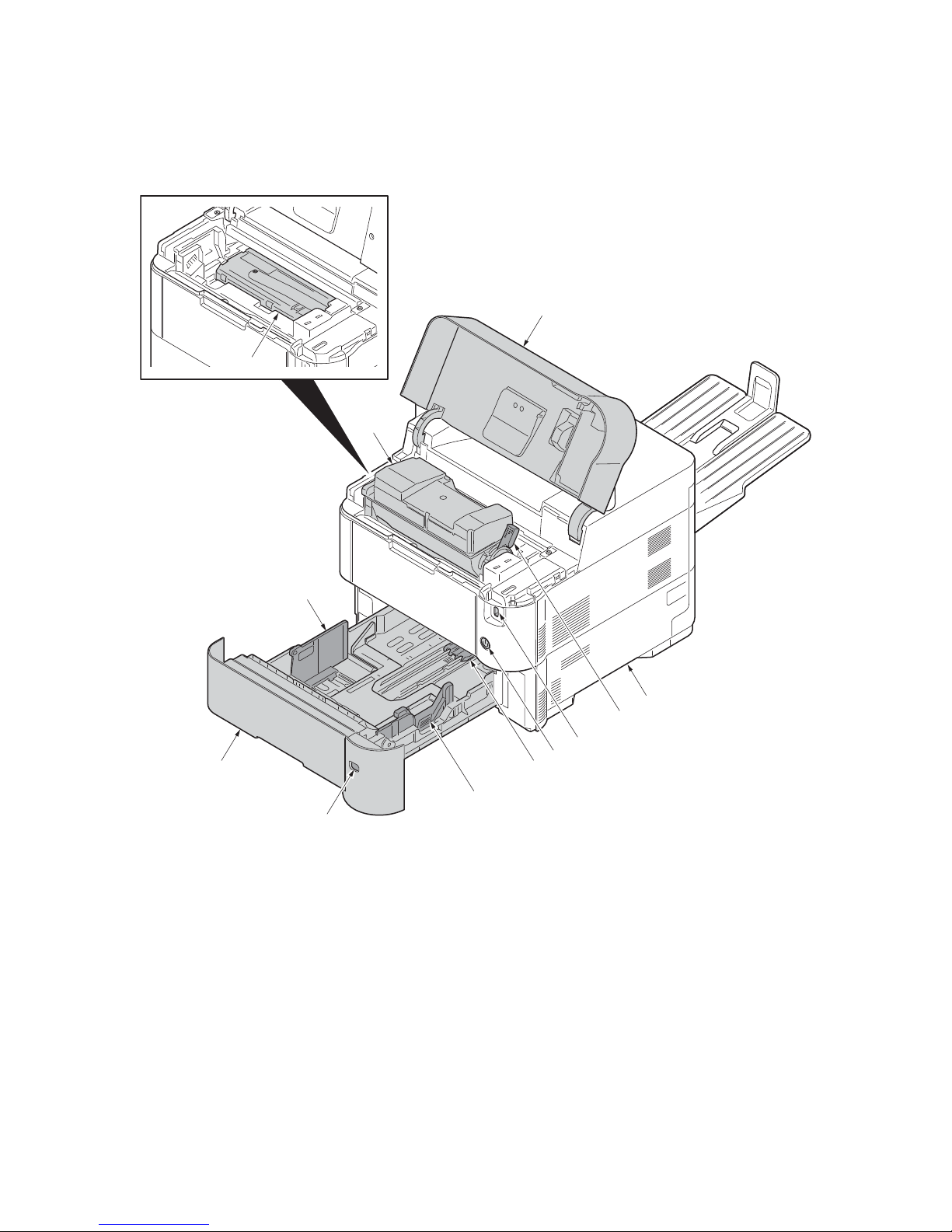

1-1-2 Parts names

1. Machine

2. Power switch

3. Cassette

4. Paper size label

5. Paper width guides

6. Paper length guide

7. USB memory slot

8. Top cover

9. Toner container

10. Lock lever (Toner container)

11. Developer unit

(1) Machine (front side)

11

2LV/2L1/2L2/2MS/2MT

8

9

3

5

1

10

7

2

6

5

4

Figure 1-1-1

1-1-4

Page 19

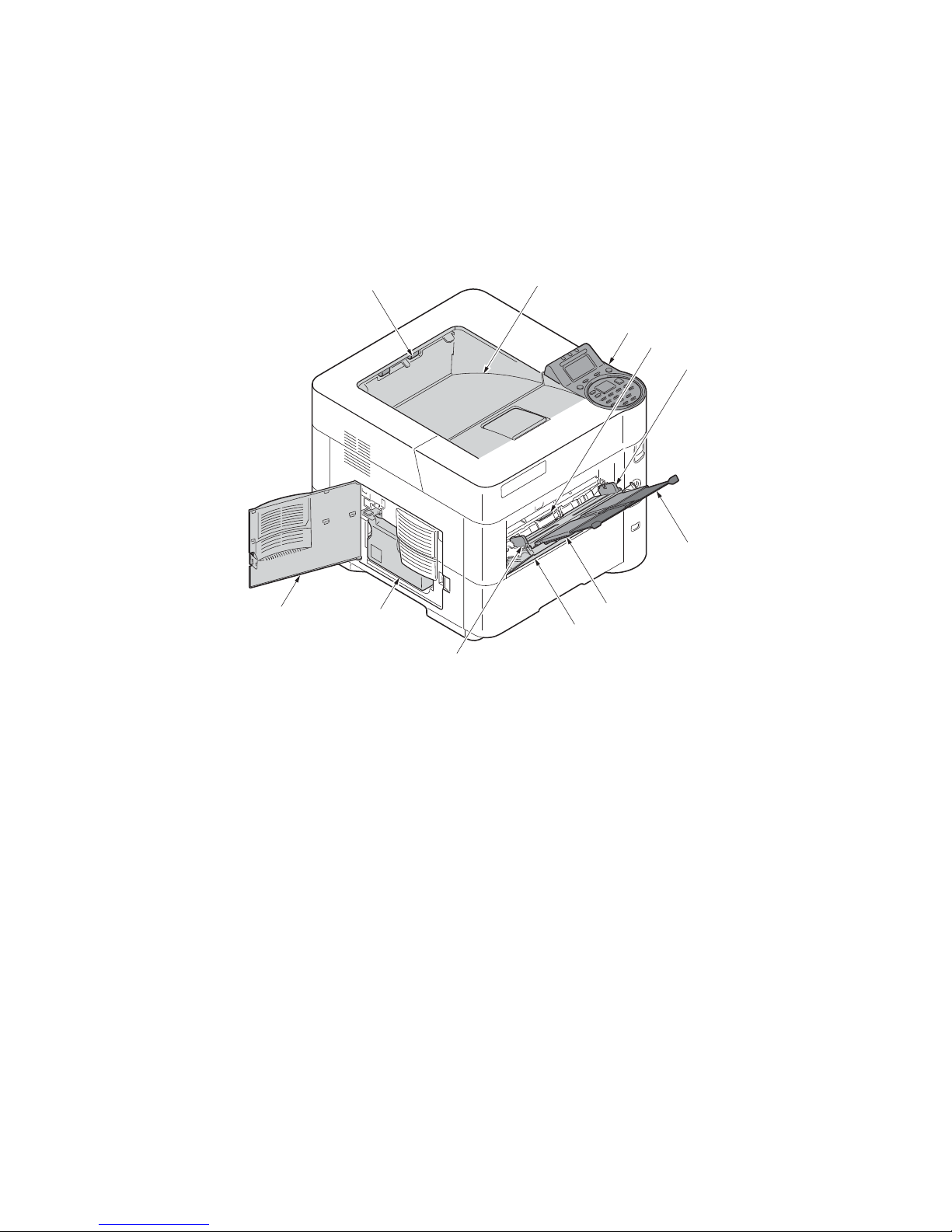

2LV/2L1/2L2/2MS/2MT

12. Operation panel

13. MP (multi purpose) tray

14. MP middle tray

15. MP top tray

16. MP Paper width guides

17. MP paper feed roller

18. Left cover

19. Waste toner box

20. Top tray (facedown)

21. Eject roller

18

21

19

20

12

17

16

15

14

13

16

Figure 1-1-2

1-1-5

Page 20

(2) Machine (rear side)

22. Rear cover

23. Faceup roller *1

24. Tray attachment plate *2

25. Faceup tray *2

26. Paper stopper *2

27. Network interface connector *3

28. USB interface connector

29. USB port

30. Power cord connector

*1: 60/50/45 ppm model only

*2: 60/50/45 ppm model only (Option)

*3: Except 40 ppm model

(without Network)

27

28

29

30

2LV/2L1/2L2/2MS/2MT

23

26

24

25

Figure 1-1-3

1-1-6

22

Page 21

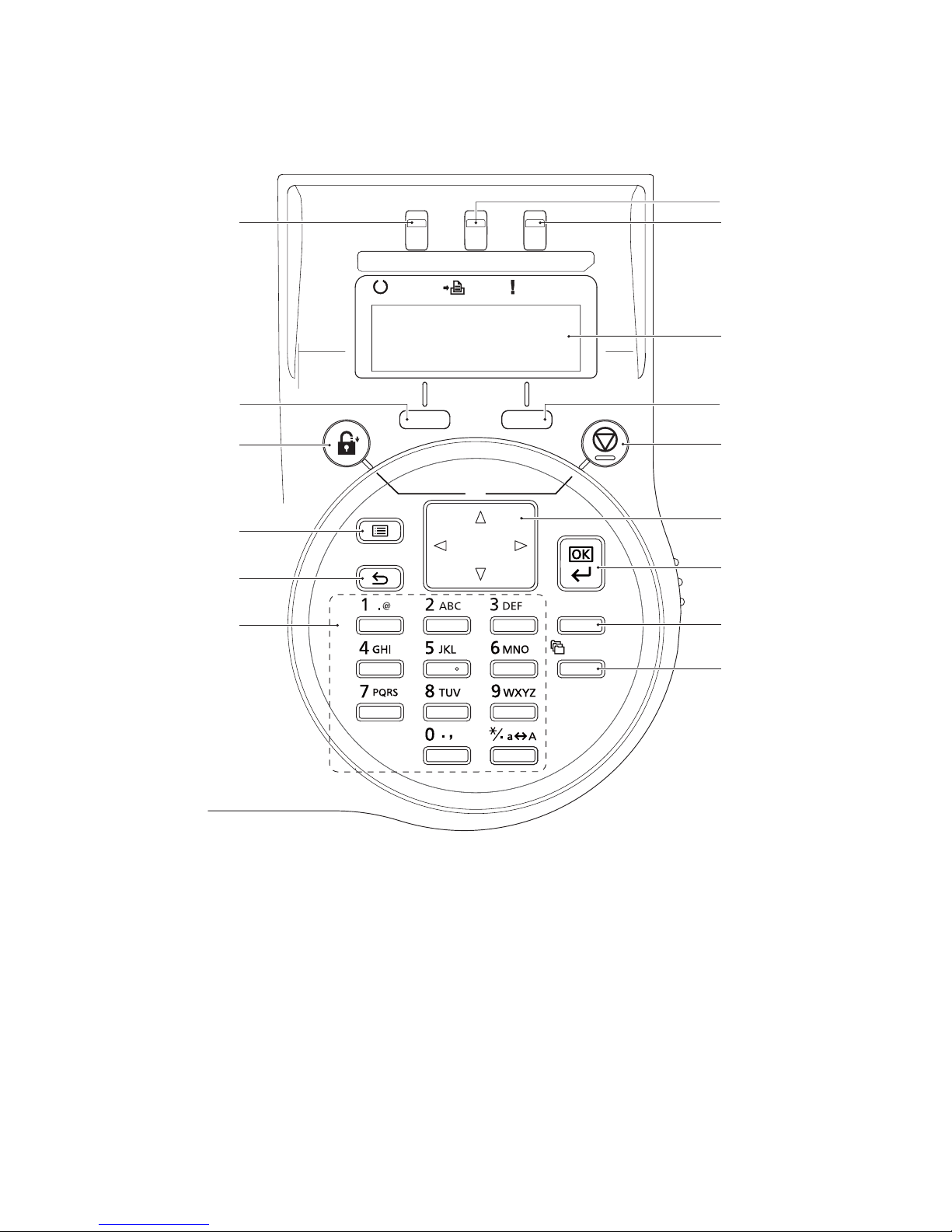

(3) Operation section

RReadyeady DataData

AttentioAttention

Logout

Cancel

BackBack

ClearClear

Documement Box

Menuenu

39

37

31

35

40

43

42

38

34

33

36

32

44

45

41

31. Ready indicator

32. Data indicator

33. Attention indicator

34. Message display

35. Left select key

36. Right select key

37. Logout key

38. Cancel key

39. Menu key

40. Back key

41. Numeric keys

42. Cursor keys

43. OK key

44. Clear key

45. Document box key

2LV/2L1/2L2/2MS/2MT

Figure 1-1-4

1-1-7

Page 22

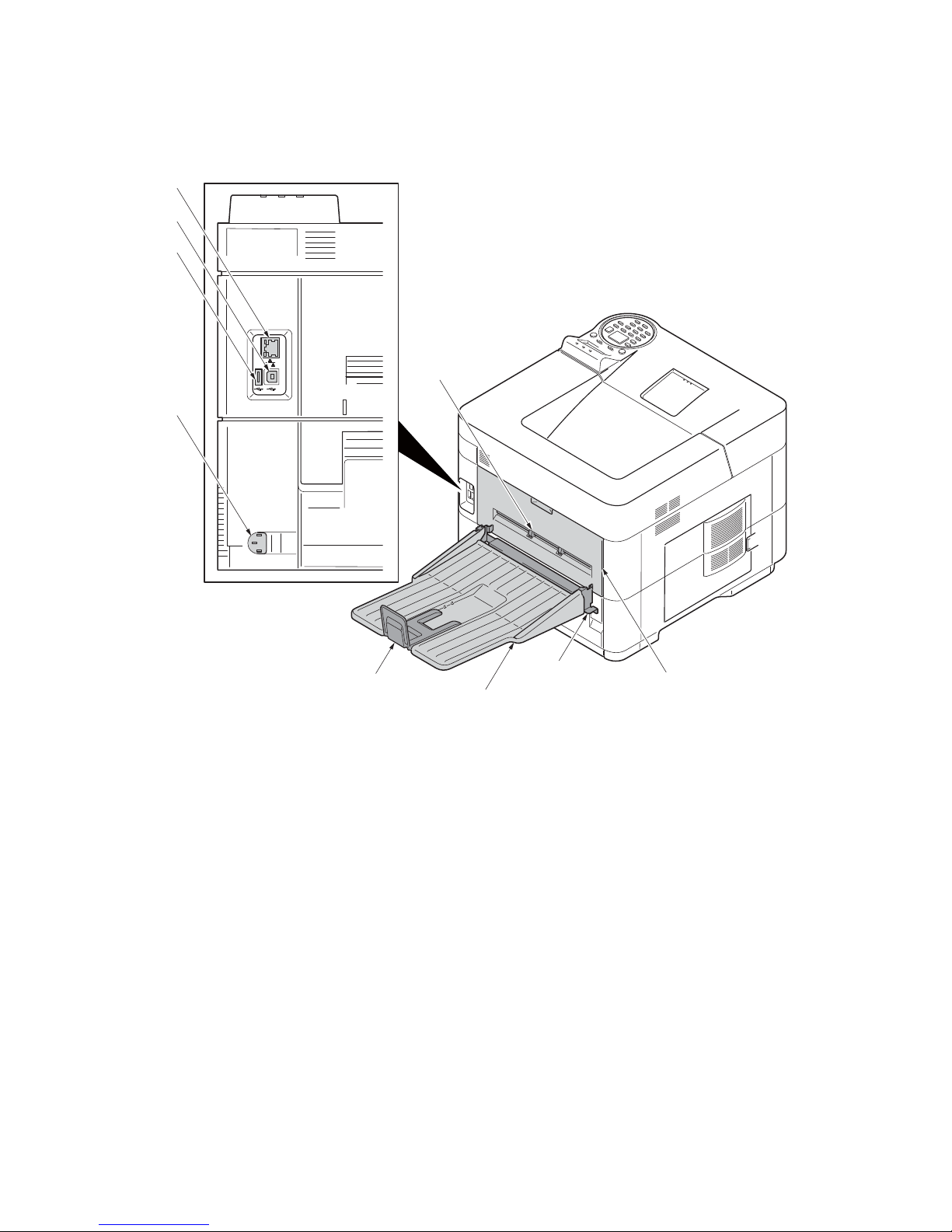

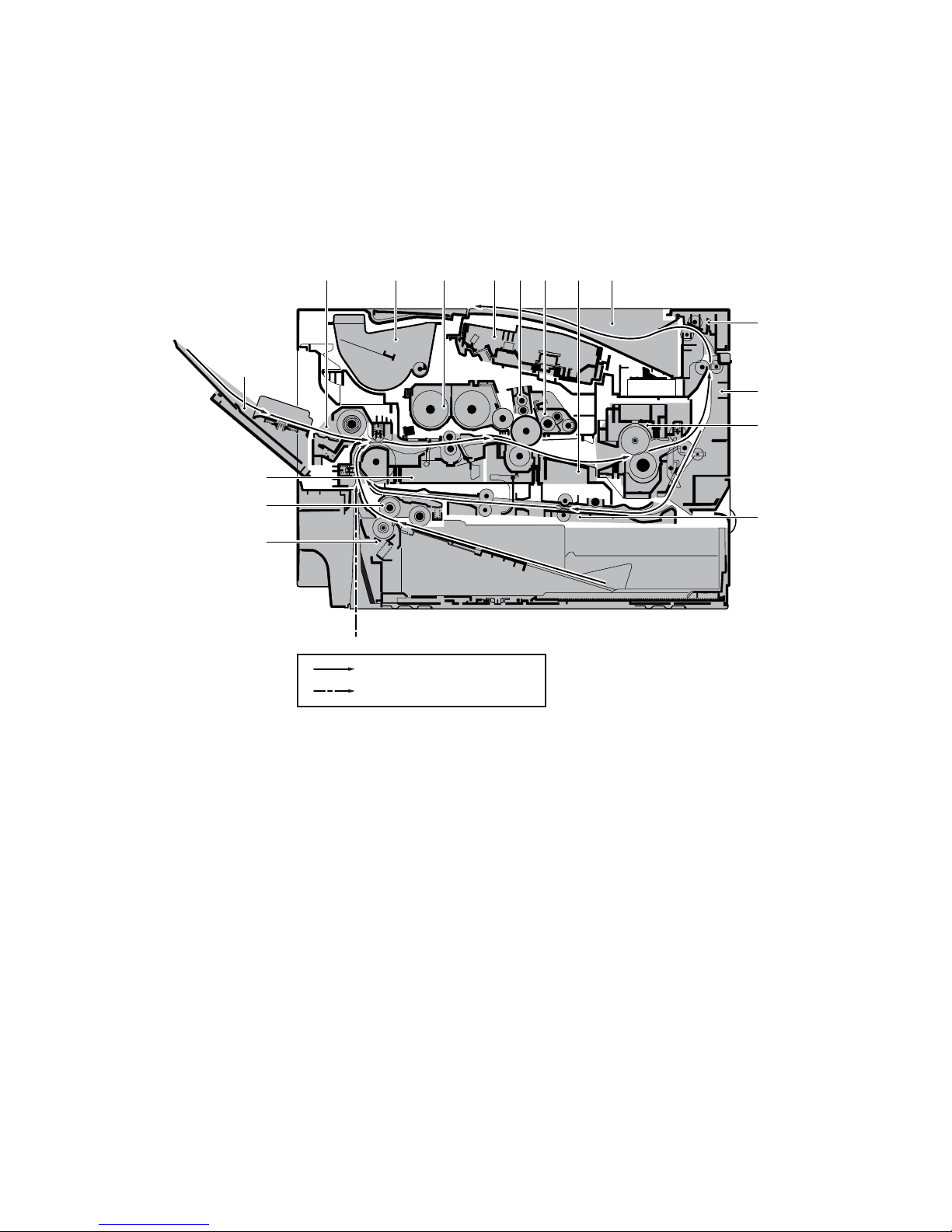

1-1-3 Machine cross section

1. Cassette

2. Cassette paper feed section

3. Paper feed conveying section

4. MP tray

5. MP tray paper feed section

6. Toner container

7. Developer unit

8. Laser scanner unit (LSU)

9. Charger roller unit

10. Drum unit

11. Transfer/Separation section

12. Eject tray (facedown)

13. Eject section

14. Eject conveying section

15. Fuser unit

16. Duplex conveyning section

17. Faceup tray (option)

(1) 60/50/45 ppm model

5

7

96 128

2LV/2L1/2L2/2MS/2MT

10 11

13

4

14

15

3

2

1

Paper path

Paper path (Option)

Figure 1-1-5

16

17

1-1-8

Page 23

(2) 40 ppm model

1. Cassette

2. Cassette paper feed section

3. Paper feed conveying section

4. MP tray

5. MP tray paper feed section

6. Toner container

7. Developer unit

8. Laser scanner unit (LSU)

9. Charger roller unit

10. Drum unit

11. Transfer/Separation section

12. Eject tray (facedown)

13. Eject section

14. Eject conveying section

15. Fuser unit

16. Duplex conveyning section

2LV/2L1/2L2/2MS/2MT

5

7

10 1196 128

13

4

14

15

3

2

16

1

Paper path

Paper path (Option)

Figure 1-1-6

1-1-9

Page 24

2LV/2L1/2L2/2MS/2MT

This page is intentionally left blank.

1-1-10

Page 25

2LV/2L1/2L2/2MS/2MT

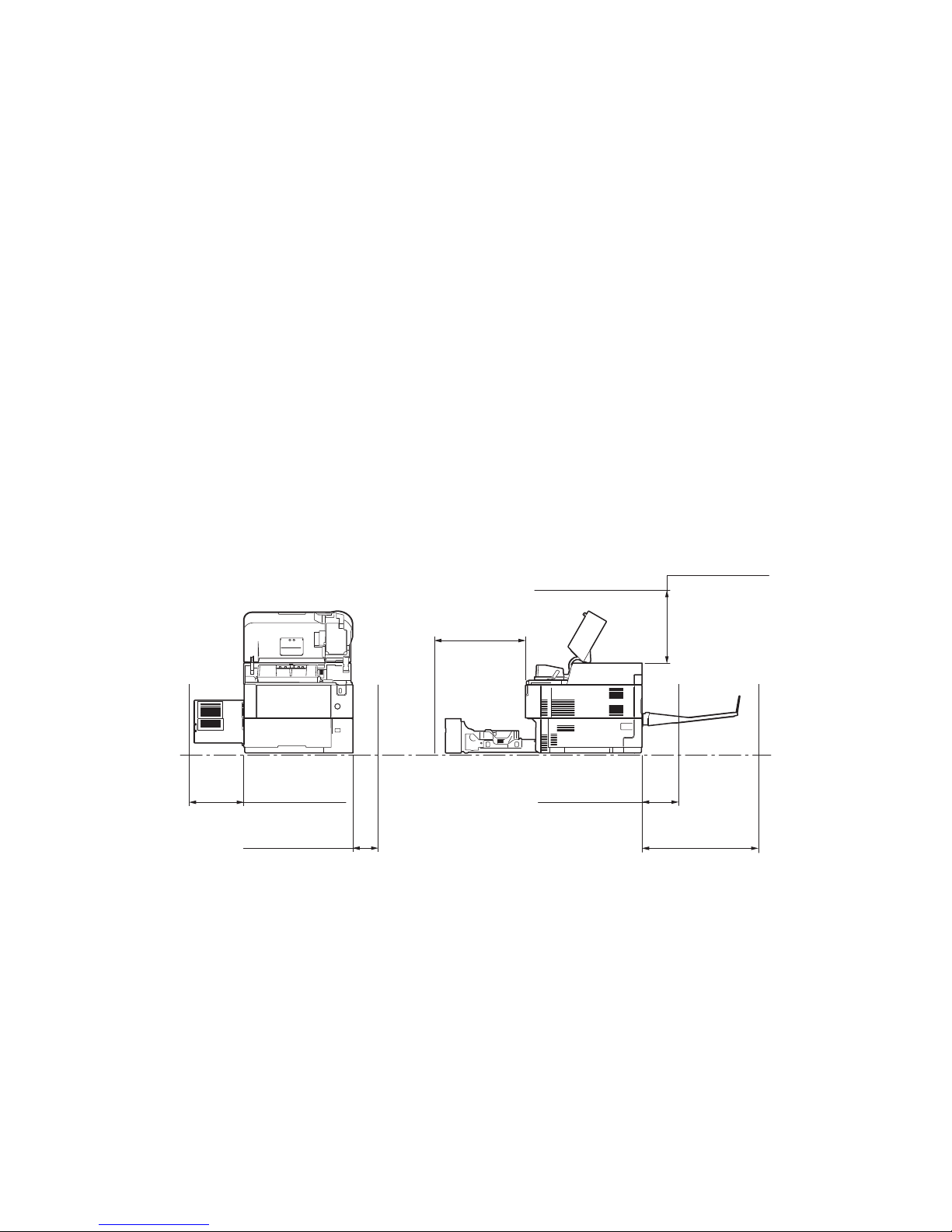

1-2 Installation

1-2-1 Installation environment

1. Temperature: 10 to 32.5°C/50 to 90.5°F

2. Humidity: 15 to 80% RH

3. Power supply: 120 V AC, 12.0 A

220 - 240 V AC, 6.5 A

4. Power supply frequency: 50 Hz ±2%/60 Hz ±2%

5. Installation location

Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or other strong light when removing paper jams.

Avoid locations subject to high temperature and high humidity or low temperature and low humidity; an

abrupt change in the environmental temperature; and cool or hot, direct air.

Avoid places subject to dust and vibrations.

Choose a surface capable of supporting the weight of the machine.

Place the machine on a level surface (maximum allowance inclination: 1°).

Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such

as mercury, acidic of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

Select a well-ventilated location.

6. Allow sufficient access for proper operation and maintenance of the machine.

300mm or more

11

13/16”

or more

100mm or more

15/16”

3

or more

500mm or more

19

11/16”

or more

*1: Without the faceup tray

*2: With the faceup tray (60/50/45 ppm model)

Figure 1-2-1

200mm or more

7

7/8”

or more *1

400mm or more

3/4”

or more

15

400mm or more

15

3/4”

or more *2

1-2-1

Page 26

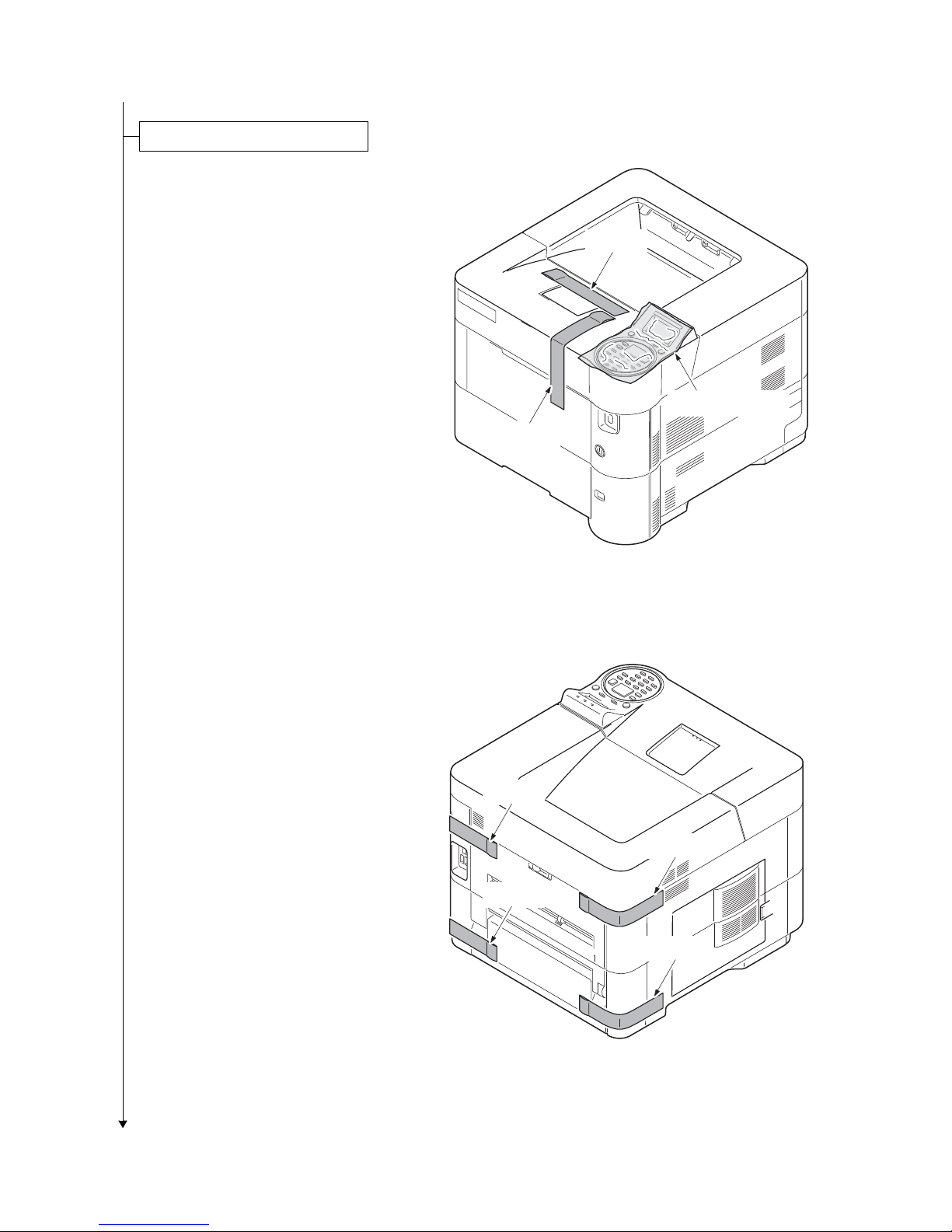

1-2-2 Unpacking and installation

Unpacking

1. Outer case

2. Inner case

3. Bottom pad R

4. Bottom pad L

5. Machine cover (740 × 700)

6. Machine

7. Upper pad R

8. Upper pad L

9. Operation guide

10. Operation sheets Assy *1

11. Waste toner bottle

12. Power cord

*1: Except 240V model

2LV/2L1/2L2/2MS/2MT

6

11

12

10

5

4

3

9

8

7

2

Caution: Place the machine on a level surface.

1

Figure 1-2-2

1-2-2

Page 27

Removing the tapes and pads

1. Remove two tapes.

2. Remove the protection sheet.

2LV/2L1/2L2/2MS/2MT

Ta pe

Protection sheet

Ta pe

3. Remove four tapes.

Figure 1-2-3

Tape

Tape

Tape

Tape

Figure 1-2-4

1-2-3

Page 28

(60/50/45 ppm model only)

Tape

Top cover

Spacer

Installing the toner container

4. Open the top cover.

5. Remove the tape and the spacer.

2LV/2L1/2L2/2MS/2MT

1. Remove the container label by

removing the tape.

Caution: Check the contents of the

container label and remove a container.

Figure 1-2-5

Container label

Tape

Figure 1-2-6

1-2-4

Page 29

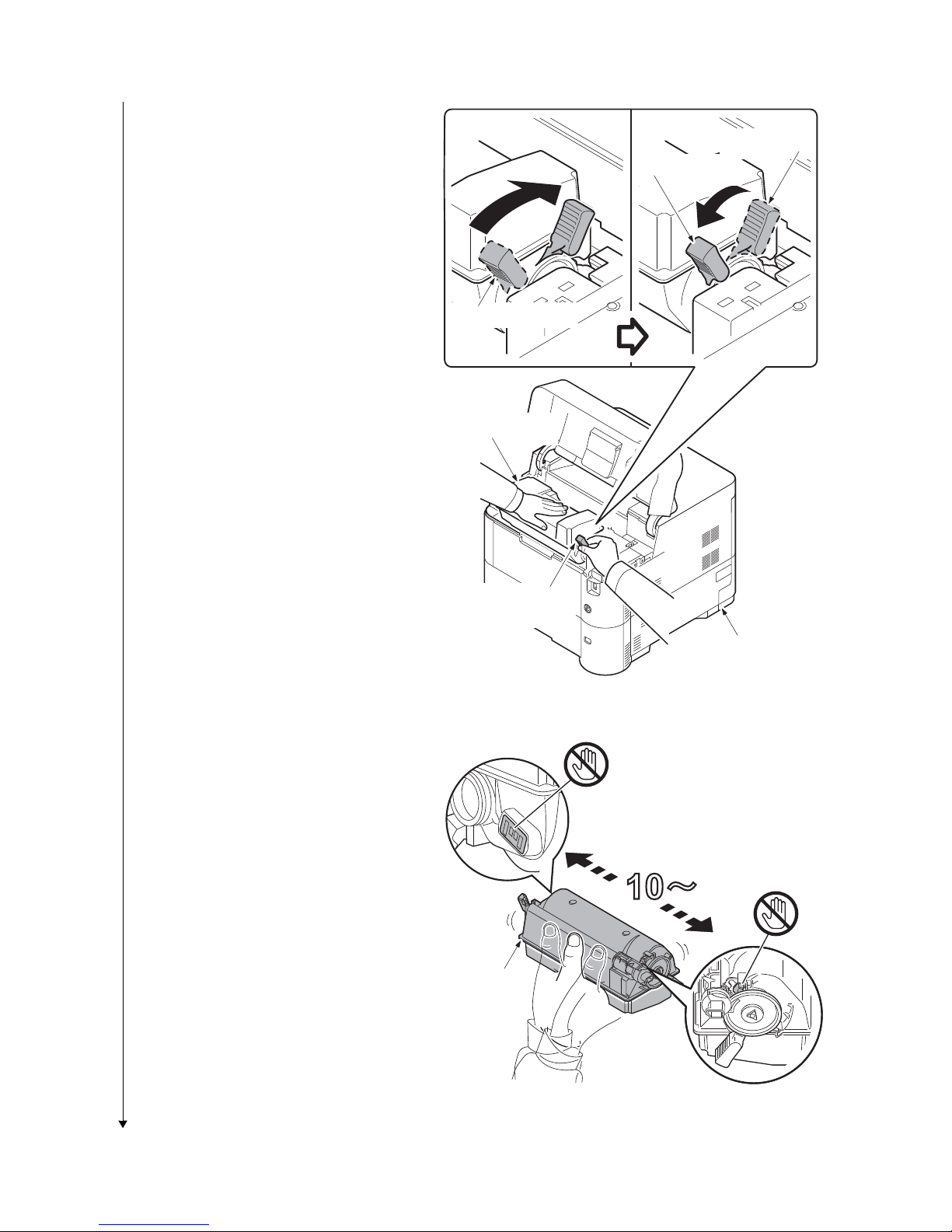

2LV/2L1/2L2/2MS/2MT

2. Rotate the toner container lock lever to

the lock position and then remove the

toner container from the printer by

returning it to the unlock position.

Lock position

Unlock position

Shipment position

Toner container

3. Shake the turned toner container 10

times or more as shown in the figure in

order to distribute the toner evenly

inside the container.

Caution:Do not press too firmly on the

center of the toner container or touch

the toner feed slot or the terminal parts.

4. Set the toner container to the printer

and then turn the toner container lock

lever to the lock position.

5. Close the top cover.

Toner container

lock lever

Printer

Figure 1-2-7

Terminal parts

Toner feed slot

To ne r

container

Figure 1-2-8

1-2-5

Page 30

1. Openthe left cover.

Installing the waste toner box

Waste toner box

Cap

Left cover

Setting of the fuser pressure release lever (40 ppm model only)

2. Open the cap of the waste toner box.

3. Install the waste toner box.

4. Close the left cover.

2LV/2L1/2L2/2MS/2MT

1. Open the rear cover.

2. Push the release lever down for

changing the lever position to a normal

position from a shipment position.

3. Close the rear cover.

Figure 1-2-9

Release lever

(Shipment position)

Release lever

(Normal position)

Rear cover

Figure 1-2-10

1-2-6

Page 31

1. Pull the cassette from the printer out.

Loading paper

(40 ppm model only)

Botom plate

Cassette

Cassette size dial

Cassette size window

Paper width guide

Paper width guide

Lock lever

(40 ppm model only)

2. Push the bottom plate down.

(Common)

3. Turn the cassette size dial so that the

size of the paper you are going to use

appears in the cassette size window.

2LV/2L1/2L2/2MS/2MT

Figure 1-2-11

4. Push the lock lever on the left side

guide and slide to the desired paper

size.

Figure 1-2-12

Figure 1-2-13

1-2-7

Page 32

5. Push the lock lever and slide the paper

(Legal/Folio)

Paper length guide

Extension cassette

Lock button

Paper

Muximum

line

length guide to the desired paper size.

If you are going to set paper that is longer than A4, pull out the extension cassettes pushing the lock lbutton one by

one and adjust them to the desired

paper size.

2LV/2L1/2L2/2MS/2MT

6. Fan the media (paper/transparencies),

then tap it on a level surface to avoid

media jams or skewed printing.

7. Slide the paper into the paper cassette.

8. Insert the cassette into the slot in the

printer. Push it straight in as far as it will

go.

Figure 1-2-14

Figure 1-2-15

1-2-8

Page 33

1. Rotate the operation panel ring in the

Replace the operation panel sheet (except 240V AC model)

Operation panel

sheet

Operation panel

cover

Operation panel

ring

counterclockwise direction.

2. Remove the operation panel cover.

3. Replace it to the operation panel sheet

of the corresponding language.

4. Refit all the removed parts.

2LV/2L1/2L2/2MS/2MT

5. Stick the language sheet of the corresponding language.

Figure 1-2-16

Language sheet

Figure 1-2-17

1-2-9

Page 34

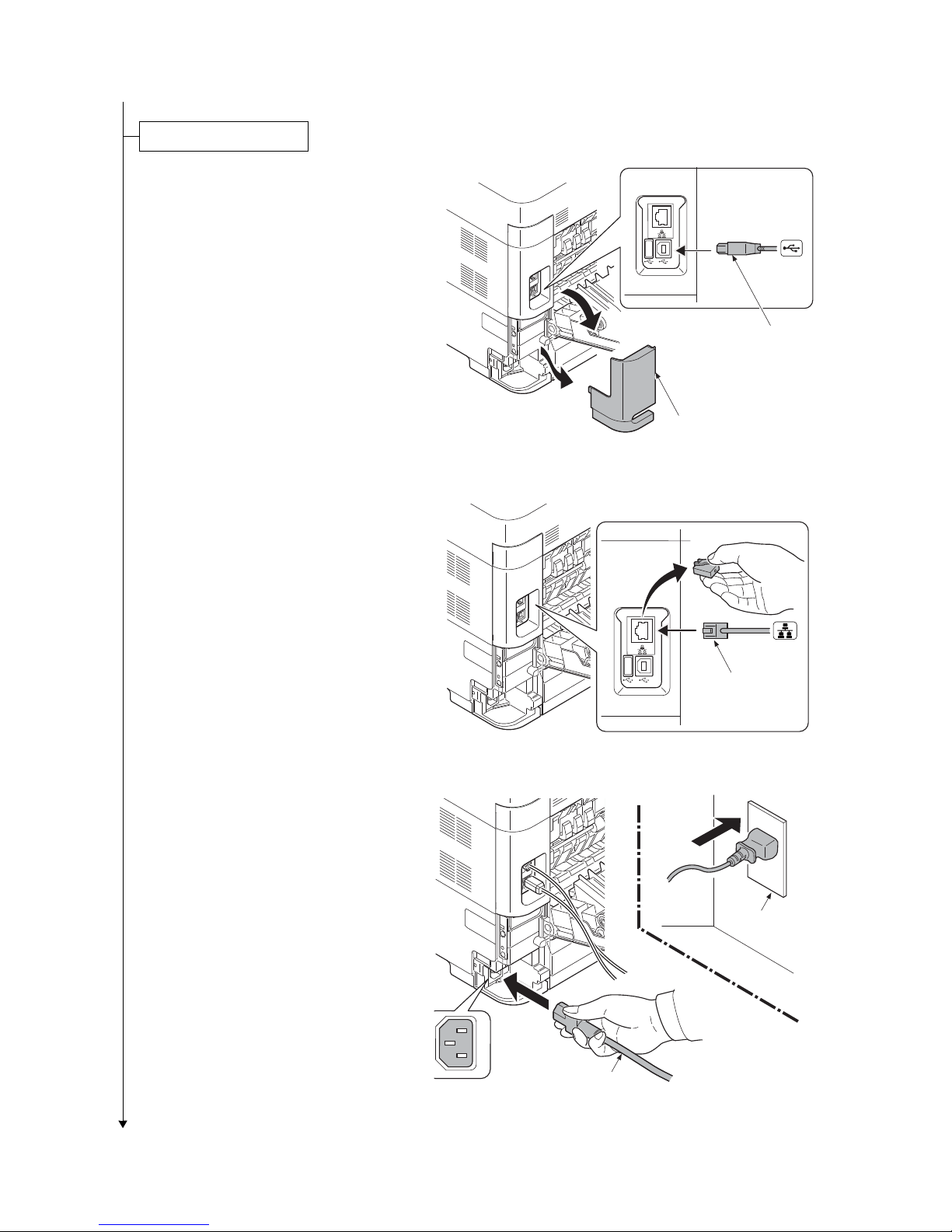

1. Remove the inlet cover.

Connecting the cable

Network

interface cable

Power cord

Wall outlet

2. Open the rear cover.

3. Connect the USB interface cable to the

printer and PC.

2LV/2L1/2L2/2MS/2MT

USB interface cable

Inlet cover

Figure 1-2-18

4. Connect the network interface cable to

the printerand network.

5. Connect the power cord to the printer

and the wall outlet.

6. Refit the inlet cover.

7. Close the rear cover.

Figure 1-2-19

Figure 1-2-20

1-2-10

Page 35

2LV/2L1/2L2/2MS/2MT

Power on

Setting the language

Printout the status page

Completion of the machine installation

8. Press the power switch and then check

the lighting up of ready indicator.

9. Installing the printer driver (refer to

operation guide).

Power switch

1. Press the menu key.

2. Select [Device Common] using the cursor up/down keys.

3. Press the OK key.

4. Select [Language] using the cursor up/down keys.

5. Press the OK key.

6. Select the language to set using the cursor up/down keys.

7. Press the OK key.

ON

Ready indicator

ON

Figure 1-2-21

1. Press the menu key.

2. Select [Report Print] using the cursor up/down keys.

3. Press the OK key.

4. Select [Status Page] using the cursor up/down keys.

5. Press the OK key.

6. Select the [YES] using the left select key.

7. [Accepted] is displayed and the page will be printed.

8. Press the menu key.

1-2-11

Page 36

1-2-3 Install the expansion memory (option)

Procedure

1. Remove the inlet cover.

2. Remove the slot cover.

3. Unplug the power cable.

Caution: Do not insert or remove main

PWB assembly while machine power is

on.

Doing so may cause damage to the

machine and the main PWB.

2LV/2L1/2L2/2MS/2MT

Slot cover

Inlet cover

4. Remove five screws and then remove

the main PWB assembly.

5. Aligning the cutouts of the memory

module with the matching keys of the

socket, carefully plug the memory module into the memory socket until it clicks

in place.

6. Then, push down the memory module

to secure.

7. Refit the main PWB assembly and the

screws.

8. Refit the covers.

9. Plug the printer into a power outlet.

10. Print a status page to check the memory expansion. (See page 1-3-2)

If memory expansion has been properly

performed, information on the installed

memory is printed with the total memory

capacity has been increased.

Standard memory capacity 256 MB. *1

Figure 1-2-22

Expansion

memory

Main PWB

Assembly

Memory socket

Screw

Screw

Screw

Screw

*1: 40 ppm (without Metwork); 128MB

Figure 1-2-23

1-2-12

Page 37

1-2-4 Install the memory card (SD card) (option)

Procedure

1. Remove the main PWB assembly from

the machine. (SeePage 1-2-12)

2. SD card is inserted in a SD card slot.

Maximum memory capacity 32 GB.

3. Remove the main PWB assmbly and

the covers.

Main PWB assembly

SD card slot

2LV/2L1/2L2/2MS/2MT

Figure 1-2-24

SD card

1-2-13

Page 38

1-2-5 Option composition

2LV/2L1/2L2/2MS/2MT

USB Flash Memory

Faceup Output Tray PT-320

(60/50/45 ppm model only)

Expansion Memory

(DIMM 256 MB/

512 MB/1 GB)

Gigabit Ethernet Board

IB-50

SD Memory Card

SDHC Memory Card

SSD HD-6

Attchment PB-325

Bulk Paper Feeder PF-315+

Paper Feeder PF-320

IC card reader

Thin Print Kit UG-33

1-2-14

Wireless LAN

interface card

IB-51

Parallel

Interface Card

IB-32

USB KeyboardData security kit (E) Card Authentication Kit (B)

Page 39

2LV/2L1/2L2/2MS/2MT

1-3 Maintenance Mode

1-3-1 Service mode

The machine is equipped with a maintenance function which can be used to maintain and service the

machine.

(1) Executing a service mode

Start

Press the Menu key.

Select [Adjust/Maint.] using the cursor

up/down keys and press the OK key.

Select [Service Setting] using the cursor

up/down keys and press the OK key.

The selected service mode is run.

Press the Menu key.

End

The Mode Selection Menu appears.

The Adjust/Maintenance menu appears.

The Service Setting menu appears.

1-3-1

Page 40

(2) Description of service mode

Service items Description

Service Status Printing a status page for service purpose

Description

Prints a status page for service purpose. The status page includes various settings and

service cumulative.

Purpose

To acquire the current printing environmental parameters and cumulative information.

Method

1. Enter the Service Setting menu.

2. Select [Status Page] using the cursor up/down keys.

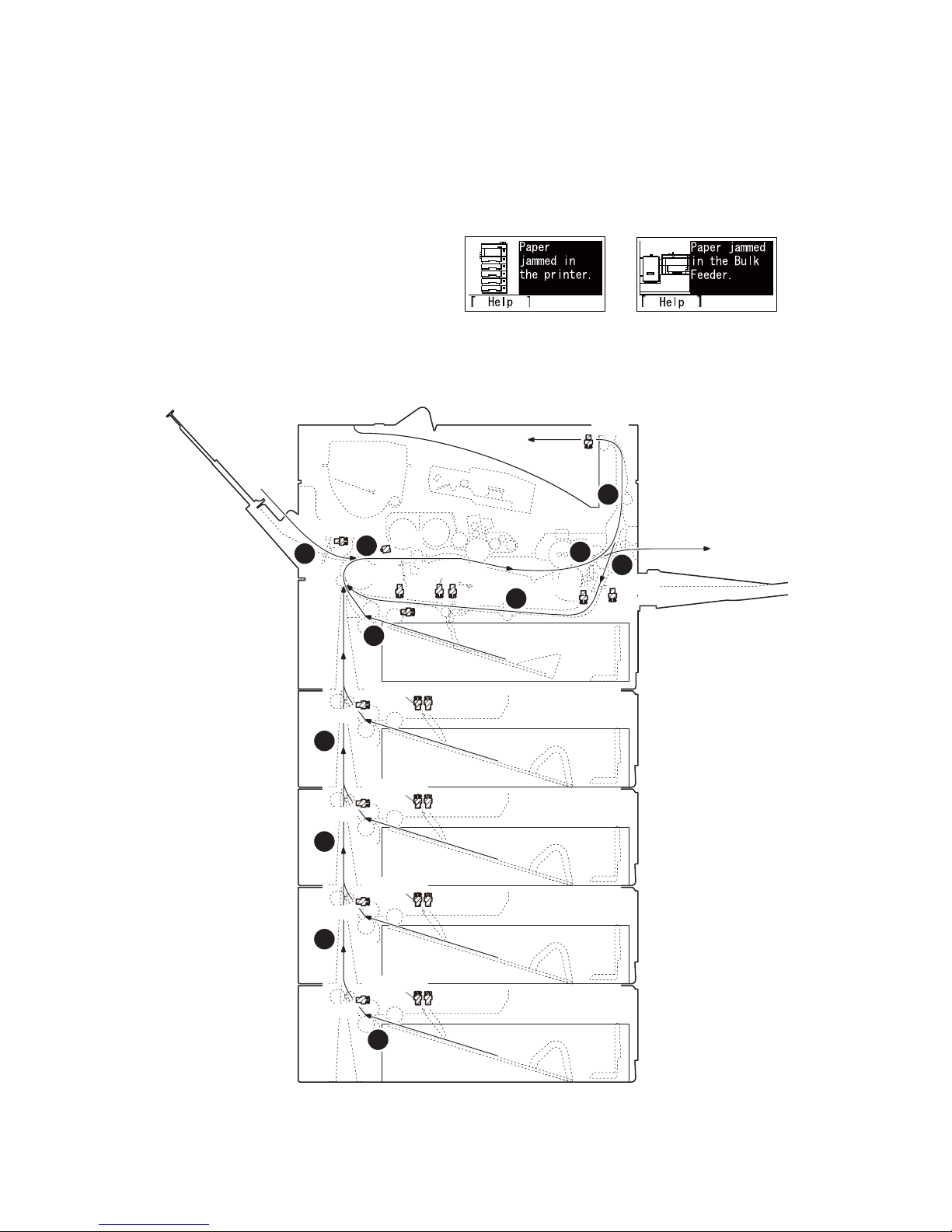

3. Press the OK key.

4. Select the [YES] using the left select key.

[Accepted] is displayed and two pages will be printed.

2LV/2L1/2L2/2MS/2MT

1-3-2

Page 41

Service items Description

Service status page (1)

2LV/2L1/2L2/2MS/2MT

Service Status Page

Printer

(1)

Firmware version 2LV_2000.000.000 2012.04.19

Controller Information

Memory status

(7)

Standard Size

(8)

Option Slot

(9)

Total Size

Time

(10)

Local Time Zone

(11)

Date and Time

(12)

Time Server

Installed Options

(13)

Paper feeder2

(14)

Paper feeder3

Paper feeder4

(15)

Paper feeder5 Not Installed

(16)

Bulk Feeder

(17)

Memory card Installed

(18)

SSD Installed

(19)

Card Authentication Kit (B) Installed

(20)

Security Kit(E)

(21)

Data Security Kit (E)

UG-33 Installed

(22)

USB Keyboard Connected

(23)

USB Keyboard Type US-English

(24)

(25)

Print Coverage

(26)

Average(%)

K: 1.10

(27)

Last Page (%)

128.0 KB

128.0 KB

256.0 KB

+01:00 Tokio

19/06/2010 16:39

10.183.53.13

Installed

Installed

Not Installed

Not Installed

Installed

/ Usage Page(A4/Letter Conversion)

/ 1111111.11

1.00

(2)

2012/04/19 16:39

(3) (4) (5)

[XXXXXXXX] [XXXXXXXX] [XXXXXXXX]

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

PDF mode

Y5 00

(28) (29)

FRPO Status

User Top Margin

User Left Margin

A1+A2/100

A3+A4/100

.

.

.

.

0.00

0.00

1

Figure 1-3-1

1-3-3

RP Code

1234 5678 9012

5678 9012 3456

9012 3456 7890

3456 7890 1234

(6)

[XXXXXXXXXXXXXXXX]

Page 42

Service items Description

Service status page (2)

Service Status Page

Printer

2LV/2L1/2L2/2MS/2MT

2012/04/19 16:39

Firmware version 2LV_2000.000.000 2012.04.19

Engine Information

(30)

NVRAM Version

(31)

MAC Address

1/2

(34) (35)

(36)

100/100

(37)

0/0/0/0/0/0/0/

0/0/0/0/0/0/0/

(38)

0/0/0/0/

(39)

0000000/0000000/0000000/0000000/0000000/0000000/0000000/0000000/

(40)

0000000/0000000/0000000/0000000/

F00/U00/0/0/0/30/30/70/70/00/00/00/abcde/1/0/1/

_1F31225_1F31225

00:C0:EE:D0:01:0D

[XXXXXXXX] [XXXXXXXX] [XXXXXXXX]

Send Information

(32)

(33)

Date and Time

Address

10/06/19 16:39

(41)(42)(43)(44)(45)(46)(47)(48)(49)(50)(51)(52)(53)(54)(55)(56)

0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/

(57)

0000/0000/0000/0000/0000/0000/0000/0000/0000/0000/

12345678/11223344/00001234abcd567800001234abcd5678/01234567890123456789012345678901/0008/00/07

(58)

t/

(59)

00/

(60)

00000000000000000000000000000000/00000000000000000000000000000000/

0000000000000000000000000000000000000000000000000000000000000000/

(63)

00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

(64)

00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/00000000/

[ ] [ ] [ ] [ ] [ ]

(65)

[2LV_81BR.001.010]

0/3/

(69)

(77)

(78)

(79)

(80)

(81)

(67)(68)

1/1/0 2010 /12/15 12:34:56

1/5/

(70)(71)

20/100/1/1/5

1/2/3/4/5/6/7/8/9/10/11/12/13/14/15/16

0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/

0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/

0.00/

0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/0.00/

0/

(82)

ABCD/ABCDEFGHIJ/

(66)

(72)(73)(74)(75)(76)

(83)(84)

(61)(62)

1-3-4

2

Figure 1-3-2

[XXXXXXXXXXXXXXXX]

Page 43

Service items Description

No. Description Supplement

(1) Firmware version -

(2) System date -

(3) Engine soft version -

(4) Engine boot version -

(5) Operation panel mask version -

(6) Machine serial number -

(7) Standard memory size -

(8) Optional memory size -

(9) Total memory size -

(10) Local time zone -

(11) Report output date Day/Month/Year hour:minute

(12) NTP server name -

(13) Presence or absence of the

optional paper feeder 1

Installed/Not Installed

(14) Presence or absence of the

optional paper feeder 2

Installed/Not Installed

(15) Presence or absence of the

optional paper feeder 3

Installed/Not Installed

(16) Presence or absence of the

optional paper feeder 4

Installed/Not Installed

(17) Presence or absence of the

optional bulk feeder

Installed/Not Installed

(18) Presence or absence of the

optional memory card

Installed/Not Installed

(19) Presence or absence of the

optional SSD

Installed/Not Installed

(20) Presence or absence of the

optional Card Authentication

Kit(B)

Installed/Not Installed/Trial

(21) Presence or absence of the

optional Security Kit(E)

Installed/Not Installed

(22) Presence or absence of the

optional UG-33

Installed/Not Installed

(23) The connection state of an

optional USB Keyboard

Connected/Not Connected

(24) Displays setting of optional USB

Keyboard

US English/US English with Euro/German/French

Detail of service status page

1-3-5

2LV/2L1/2L2/2MS/2MT

Page 44

Service items Description

No. Description Supplement

(25) Page of relation to the A4/Letter -

(26) Average coverage for printer Black

(27) Coverage on the final output

page

-

(28) FRPO setting -

(29) RP Code Code the engine software version and the date of

update.

Code the main software version and the date of

update.

Code the engine software version and the date of the

previous update.

Code the main software version and the date of the

previous update.

(30) NV RAM version _ 1F3 1225 _ 1F3 1225

(a) (b) (c) (d) (e) (f)

(a) Consistency of the present software version and

the database

_ (underscore): OK

* (Asterisk): NG

(b) Database version

(c) The oldest time stamp of database version

(d) Consistency of the present software version and

the ME firmware version

_ (underscore): OK

* (Asterisk): NG

(e) ME firmware version

(f) The oldest time stamp of the ME database version

Normal if (a) and (d) are underscored, and (b) and (e)

are identical with (c) and (f).

(31) Mac address -

(32) The last sent date and time -

(33) Transmission address -

(34) Destination information -

(35) Area information -

(36) Margin settings Top margin/Left margin

(37) Top offset for each paper source MP tray/Paper feeder 1/Paper feeder 2/

Paper feeder 3/Paper feeder 4/Duplex/Page rotation

(38) Left offset for each paper source MP tray/Paper feeder 1/Paper feeder 2/

Paper feeder 3/Paper feeder 4/Duplex/Page rotation

(39) Margin/Page length/Page width

settings

Top margin integer part/Top margin decimal part/

Left margin integer part/Left margin decimal part/

Page length integer part/Page length decimal part/

Page width integer part/Page width decimal part

Detail of service status page

1-3-6

2LV/2L1/2L2/2MS/2MT

Page 45

Service items Description

No. Description Supplement

(40) Life counter (The first line) Machine life/MP tray/Cassette/Paper feeder 1/

Paper feeder 2/Paper feeder 3/Paper feeder 4/Duplex

Life counter (The second line) Bulk Feeder counter/Drum counter K/

Developer counter K/Maintenance kit counter

(41)

Panel lock information F00: OFF

F01: Partial Lock 1

F02: Partial Lock 2

F03: Partial Lock 3

F04: Full Lock

(42) USB information U00: Not installed/U01: Full speed/U02: Hi speed

(43)

Paper handling information 0: Paper source unit select/1: Paper source unit

(44) Black and white printing double

count mode

0: All single counts

3: Folio, Single count, Less than 330 mm (length)

(45) Billing counting timing -

(46) Temperature (machine inside) -

(47) Temperature (machine outside) -

(48) Relative temperature

(machine outside)

-

(49) Absolute temperature

(machine outside)

-

(50) XLI calibration information -

(51) Beam A/BD synchronous fine-

tuning value

-

(52) Beam B/BD synchronous fine-

tuning value

-

(53) Fixed assets number -

(54) Job end judgment time-out time -

(55) Job end detection mode -

(56) PRESCRIBE environmental

reset

-

(57) Media type attributes

1 to 28 (Not used: 18, 19, 20)

Weight settings Fuser settings

0: Light 0: High

1: Normal 1 1: Middle

2: Normal 2 2: Low

3: Normal 3 3: Vellum

4: Heavy 1 Duplex settings

5: Heavy 2 0: Disable

6: Heavy 3 1: Enable

7: Extra Heavy

2LV/2L1/2L2/2MS/2MT

1-3-7

Page 46

Service items Description

No. Description Supplement

(58) RFID information Product (OEM/maker) / destination code / a toner

name / lot number / toner capacity / toner empty information / number of times of toner refilling

(59) Toner install mode information 0:OFF

t:ON

(60) Drum status -

(61) Drum surface potential -

(62) Drum density -

(63) LSU light volume distribution -

(64) DRT parameter coefficient -

(65) Soft version of the optional

paper feeder

Paper feeder 1/Paper feeder 2/Paper feeder 3

Paper feeder 4

(66) Version of the optional message -

(67) Altitude 0: Standard

1: High altitude 1

2: High altitude 2

(68) Charger roller correction 1 to 5

(69) Data Sanitization details result -

(70) Toner Low setting 0:Invalid

1: Effective

(71) Toner Low detection level 0 to 100(%)

(72) Number of page that swept out

at any time (SP1)

1 to 65535

(73) Number of page that swept out

at instancy (SP2)

1 to 65535

(74) The practice standard printing

rate of development TC (SGE)

0 to 15

(75) The practice standard printing

rate according to area TC

(SDR)

0 to15

(76) The number of times of enforce-

ment of the development TC

-

(77) The number of times of enforce-

ment according to area

-

2LV/2L1/2L2/2MS/2MT

1-3-8

Page 47

Service items Description

No. Description Supplement

(78) The last page printing rate of

each area

0.00 to 100.00(%)

(79) The average printing rate of

each area

0.00 to 100.00(%)

(80) The average printing rate for the

1000 past

0.00 to 100.00(%)

(81) The average printing rate for the

1000 past of each area

0.00 to 100.00(%)

(82) ErP application 0: ErP Un-Applying mode

1: ErP Application mode

(83) Drum ID -

(84) Drum serial number -

Code conversion

ABCDEFGH I J

0123456789

2LV/2L1/2L2/2MS/2MT

1-3-9

Page 48

Service items Description

LS-4300DN SN:SPL8307597 Counter:1135

Network Status Printing a status page for network

Description

Prints a status page for network.

Execution is possible only the model with network.

Purpose

To acquire the detailed network setting information.

Method

1. Enter the Service Setting menu.

2. Select [Network Status Page] using the cursor up/down keys.

3. Press the OK key.

4. Select the [YES] using the left select key.

[Accepted] is displayed and Network status page will be printed.

Test Page Printing a test page

Description

The test page is printed with halftones.

Purpose

To check the activation of the developer and drum units.

2LV/2L1/2L2/2MS/2MT

Method

1. Enter the Service Setting menu.

2. Select [Test Page] using the cursor up/down keys.

3. Press the OK key.

4. Select the [YES] using the left select key.

[Accepted] is displayed and Test page will be printed.

Figure 1-3-3

1-3-10

Page 49

Service items Description

Maintenance Counter reset for the maintenance kit

Description

The "Install MK" message means that maintenance kit should be replaced at fixed pages

of printing. The interval counter must be manually reset using this service item.

Maintenance kit MK-3102 (for 120 V ) (40 ppm) :300,000 images

Maintenance kit MK-3132 (for 120 V ) (60/50/45 ppm) :500,000 images

Maintenance kit MK-3100 (for 230 V ) (40 ppm) :300,000 images

Maintenance kit MK-3130 (for 230 V ) (60/50/45 ppm) :500,000 images

Maintenance kit includes the following units:

Drum unit

Developer unit

Transfer roller assembly

Fuser unit

Paper feed roller assembly

Retard roller assembly

Purpose

To reset the life counter for maintenance kit.

2LV/2L1/2L2/2MS/2MT

Method

Drum unit (see page 1-5-15)

Developer unit (see page 1-5-13)

Transfer roller assembly (see page 1-5-16)

Fuser unit (see page 1-5-19)

Paper feed roller assembly (see page 1-5-8)

Retard roller assembly (see page 1-5-8)

Method

1. Enter the Service Setting menu.

2. Select [Maintenance] using the cursor up/down keys.

3. Press the OK key.

4. Select the [YES] using the left select key.

[Completed] is displayed.

The counter for each component is reset immediately.

Note:

Occurrences of resetting the maintenance kits are recorded on the service status page

or event log in number of pages at which the maintenance kit was replaced (see page 13-2, page 1-3-17 ). This may be used to determine the possibility that the counter was

errorneously or unintentionally reset.

1-3-11

Page 50

Service items Description

New Developer

Initializing the developing unit (toner install mode)

Description

The new developing unit is shipped from the factory with no toner contained. The developing unit can be automatically replete with toner when a toner container is installed onto

it and the printer is turned on. However, because the toner reservoir in the developing

unit has a large capacity, it requires a lengthy period of time until a substantial amount of

toner has been fed to get the printer ready. (A new developing unit needs approximately

200 g for triggering the sensor inside.)

Purpose

To execute when the developing unit has been replaced.

Method

1. Enter the Service Setting menu.

2. Select [New Developer] using the cursor up/down keys.

3. Press the OK key.

4. Select the [YES] using the left select key.

[Accepted] is displayed.

The toner installation is performed when power is turned on and off.

NOTE: Toner supply is stopped when toner installation mode is performing.

2LV/2L1/2L2/2MS/2MT

Auto Drum

Refresh

Automatic drum surface refreshing

Description

The drum surface refreshing operation is normally performed when the power is turned

on to the printer or during warm-up when the printer is recovering from the Sleep mode,

but even then only at those times that the temperature/humidity sensor detects the drum

surface to be in a state of dew condensation. By using this mode, it is possible to force

the drum surface refreshing operation to be performed automatically at a predetermined

period of time, regardless of the status detected by the temperature/humidity sensor.

Purpose

To prevent bleeding of the output image when the printer's operating environment is one

of high humidity.

Method

1. Enter the Service Setting menu.

2. Select [Auto Drum Refresh] using the cursor up/down keys.

3. Press the OK key.

4. Select the desire mode (Off/Short/Standard/Long) using the cursor up/down keys.

5. Press the OK key. The new value is set.

1-3-12

Page 51

Service items Description

Drum Drum surface refreshing

Description

Rotates the drum approximately 3 minutes with toner lightly on the overall drum using

the high-voltage output control. The cleaning blade in the drum unit scrapes toner off the

drum surface to clean it.

Purpose

To clean the drum surface when image failure occurs due to the drum. This mode is

effective when dew condensation on the drum occurs.

Method

1. Enter the Service Setting menu.

2. Select [Drum] using the cursor up/down keys.

3. Press the OK key.

4. Select the [YES] using the left select key.

Drum surface refreshing will start.

2LV/2L1/2L2/2MS/2MT

Write Data

Write data (USB memory data write)

Description

To write data into a USB memory.

Execution is possible only when a USB memory is detected.

Method

Install the USB memory before attempting to write data.

1. Enter the Service Setting menu.

2. Select [Write Data] using the cursor up/down keys.

3. Press the OK key.

4. Select the [YES] using the left select key.

5. [Data waiting] is displayed and the printer waits for data to be written.

6. When the data is sent, [Processing] appears and the data is written to USB memory.

When data writing ends, the display returns to [Ready].

1-3-13

Page 52

Service items Description

Altitude adj. Setting altitude adjustment

Description

Sets the altitude adjustment mode.

Purpose

Used when print quality deteriorates in an installation at the altitude of 1,500 meters or

higher.

Method

1. Enter the Service Setting menu.

2. Select [Altitude Adj.] using the cursor up/down keys.

3. Press the OK key.

4. Select [Normal], [High 1] or [High 2] using the cursor up/down keys.

5. Press the OK key. The setting is set.

MC Setting main charger output

Description

Sets the main charger output.

Execution is possible only when the altitude adjustment mode is set to [Normal].

Purpose

Execute when the image density declines, dirt of a background or an offset has

occurred.

2LV/2L1/2L2/2MS/2MT

Method

1. Enter the Service Setting menu.

2. Select [MC] using the cursor up/down keys.

3. Press the OK key.

4. Select [1] to [5] using the cursor up/down keys.

5. Press the OK key. The setting is set.

1-3-14

Page 53

(3) Printing an event log

Service items Description

Printing an

event log

Printing an event log (EVENT LOG)

Description

Prints a history list of occurrences of paper jam, self-diagnostics, toner replacements,

etc.

Purpose

To allow machine malfunction analysis based on the frequency of paper misfeeds, self

diagnostic errors and replacements.

Method

1. Connect the USB or network cable between machine and PC (network).

2. Remove the inlet cover and connect the power cord.

Network cable

2LV/2L1/2L2/2MS/2MT

USB cable

Inlet cover

Power cord

Figure 1-3-4

3. Refit the inlet cover.

4. Turn the main power switch on. Make sure the machine is ready.

5. Send the following PRESCRIBE command sequence from the PC to the machine.

!R!KCFG"ELOG";EXIT;

6. A sheet of event log will be printed.

Completion

1-3-15

Page 54

Service items Description

Printing an

Remarks: Details of configurations (See above 5.)

event log

Notes on Connecting to USB

(1)Save the PRESCRIBE commands above as a text file in the PC.

(2)Select the Sharing tab of the printer properties and share the printer.

(3)Select a USB port in the Port tab. (Specify the printer name for sharing.)

(4)From the DOS Prompt, execute the following command line:

copy file-name\\computer-name\shared-printe

File-name should be the name of the file that was saved in step 1.

Notes on connecting via network (using FTP protocol)

(1)Save the PRESCRIBE commands above as a text file in the PC.

(2)From the DOS Prompt, execute the following command line:

ftp printer-IP-address

Do not specify user name and password.

(3)From the DOS Prompt, execute the following command:

put file-name

File-name should be the name of the file that was saved in step 1.

2LV/2L1/2L2/2MS/2MT

1-3-16

Page 55

Service items Description

No. Items Description

(1) System version

(2) System date

(3) Engine soft version

(4) Engine boot version

(5) Operation panel mask version

(6) Machine serial number

Event log

Event Log

Printer

(1)

Firmware version 2LV_2000.000.000 2010.06.19

(7)

Paper Jam Log

#

Count.

16

1876543

15

166554

14

4988

13

4988

12

4988

11

4988

10

1103

9

1103

8

1103

7

1103

6

1027

5

1027

4

1027

3

1027

2

406

1

36

(8)

Service Call Log

#

Count.

5

5295

4

2099

3

1054

2

809

1

30

Maintenance Log

(9)

#

Count.

3

3454

2

417

1

34

Unknown toner Log

(10)

#

Count.

3

3454

2

406

1

32

Event Descriprions

0501.01.08.01.01

4020.01.08.01.01

0501.01.08.01.01

4020.01.08.01.01

0501.01.08.01.01

4020.01.08.01.01

0501.01.08.01.01

4020.01.08.01.01

0501.01.08.01.01

4020.01.08.01.01

0501.01.08.01.01

4020.01.08.01.01

0501.01.08.01.01

4020.01.08.01.01

0501.01.08.01.01

4020.01.08.01.01

0501.01.08.01.01

(a) (b) (c) (d) (e)

Service Code

01.6000

01.2100

01.4000

01.6000

01.2100

Item

01.01

01.01

01.01

Item

01.00

01.00

01.00

(e)

(11)

Counter Log

J0100:

(f)

J0105:

J0106:

J0110:

J0111:

J0512:

J0513:

J0518:

J0519:

J1020:

.

.

.

.

.

.

.

.

.

.

.

.

0

0

0

0

0

0

0

0

0

0

2LV/2L1/2L2/2MS/2MT

(2)

19/June/2010 08:40

(3) (4) (5)

[XXXXXXXX] [XXXXXXXX] [XXXXXXXX]

1

J4201:

J4202:

J4203:

J4208:

J4209:

.

.

.

.

.

.

C0030:

(g)

0

C0070:

0

C0100:

0

C0120:

0

C0130:

0

C2100:

C2200:

C2300:

C2330:

C2340:

.

.

.

.

.

.

.

.

.

.

.

.

T00:

1

(h)

1

1

1

1

1

1

1

1

1

T01:

1

Detail of event log

1-3-17

Figure 1-3-5

(6)

[XXXXXXXXXXXXXXXX]

Page 56

Service items Description

No. Items Description

(7) Paper Jam

Log

# Count. Event

Remembers 1 to 16 of

occurrence. If the

occurrence of the previous paper jam is less

than 16, all of the paper

jams are logged. When

the occurrence

excesseds 16, the oldest occurrence is

removed.

The total page count at

the time of the paper

jam.

Log code (hexadecimal, 5 categories)

(a) Cause of a paper

jam

(b) Paper source

(c) Paper size

(d) Paper type

(e) Paper eject

(a) Cause of paper jam (Hexadecimal)

Refer to page 1-4-1 for paper jam location

0000: Initial jam

0100: Secondary paper feed request time out

0101: Waiting for process package to be ready

0104: Waiting for conveying package to be ready

0106: Paper feeding request for duplex printing time out

0107: Waiting for fuser package to be ready

0120: Receiving a duplex paper feeding request while paper is empty

0121: Exceeding number of duplex pages circulated

0501: No paper feed of jam (cassette 1)

0502: No paper feed of jam (cassette 2)

0503: No paper feed of jam (cassette 3)

0504: No paper feed of jam (cassette 4)

0505: No paper feed of jam (cassette 5)

0508: No paper feed of jam (duplex section)

0509: No paper feed of jam (MP tray)

0511: Multiple sheets of jam (cassette 1)

0512: Multiple sheets of jam (cassette 2)

0513: Multiple sheets of jam (cassette 3)

0514: Multiple sheets of jam (cassette 4)

0515: Multiple sheets of jam (cassette 5)

0518: Multiple sheets of jam (duplex section)

0519: Multiple sheets of jam (MP tray)

0529: No paper feed of jam (bulk feeder)

0539: Multiple sheets of jam (bulk feeder)

1403: PF feed sensor 1 non arrival jam (cassette 3)

1404: PF feed sensor 1 non arrival jam (cassette 4)

1405: PF feed sensor 1 non arrival jam (cassette 5)

1413: PF feed sensor 1 stay jam (cassette 3)

1414: PF feed sensor 1 stay jam (cassette 4)

1415: PF feed sensor 1 stay jam (cassette 5)