Page 1

DOWNTOWN 125i

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

All rights reserved. Any reproduction or

permission of KWANG YANG Motor Co., Ltd.

By KWANG YANG Motor Co., Ltd.

1st Edition, April 2009

unauthorized use without the written

is expressly prohibited.

T100-LFA7-A2

Page 2

PREFACE

C

C

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

DOWNTOWN 125i

TABLE OF CONTENTS

This Service Manual describes the

technical features and servicing

procedures for the KYMCO

Downtown 125i.

Section 1 contains the precautions for

all operations stated in this manual.

Read them carefully before any

operation is started.

Section 2 is the removal/installation

procedures for the frame covers which

are subject to removal/installation

frequency during maintenance and

servicing operations.

Section 3 describes the inspection/

adjustment procedures, safety rules

and service information for each part,

starting from periodic maintenance.

Sections 5 to 11 give instructions for

disassembly, assembly and

adjustment of engine parts. Section

13-14 is the AFI system. Section 15 to

16 is the removal/ installation of

chassis. Section 17 to 20 states the

testing and measuring methods of

electrical equipment.

Most sections start with an assembly

or system illustration and

troubleshooting for the section. The

subsequent pages give detailed

procedures for the section.

The information and contents

included in this manual may be

different from the motorcycle in case

specifications are changed.

KWANG YANG MOTOR CO., LTD.

QUALITY TECHNOLOGY DEPT.

EDUCATION SECTION

GENERAL INFORMATION

EXHAUST MUFFLER/FRAME

COVERS

INSPECTION/ADJUSTMENT

LUBRICATION SYSTEM

ENGINE REMOVAL/INSTALLATION

CYLINDER HEAD/VALVES

ENGINE

CYLINDER/PISTON

DRIVE AND DRIVEN PULLEYS

FINAL REDUCTION

A.C. GENERATOR/STARTER

CLUTCH

CRANKCASE/CRANKSHAFT

COOLING SYSTEM

Fi DIAGNOSTIC TOOL OPERATION

FUEL INJECTION SYSTEM

CHASSIS

HANDLEBAR/FRONT

WHEEL/FRONT BRAKE/FRONT

SHOCK ABSORBER/STEERING

STEM

REAR BRAKE/REAR FORK/REAR

WHEEL/REAR SHOCK ABSORBER`

ELE

EQUIPMENT

BATTERY/CHARGING SYSTEM

TRI

IGNITION SYSTEM

AL

STARTING SYSTEM

LIGHTS/METERS/SWITCHES

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Page 3

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

DOWNTOWN 125i

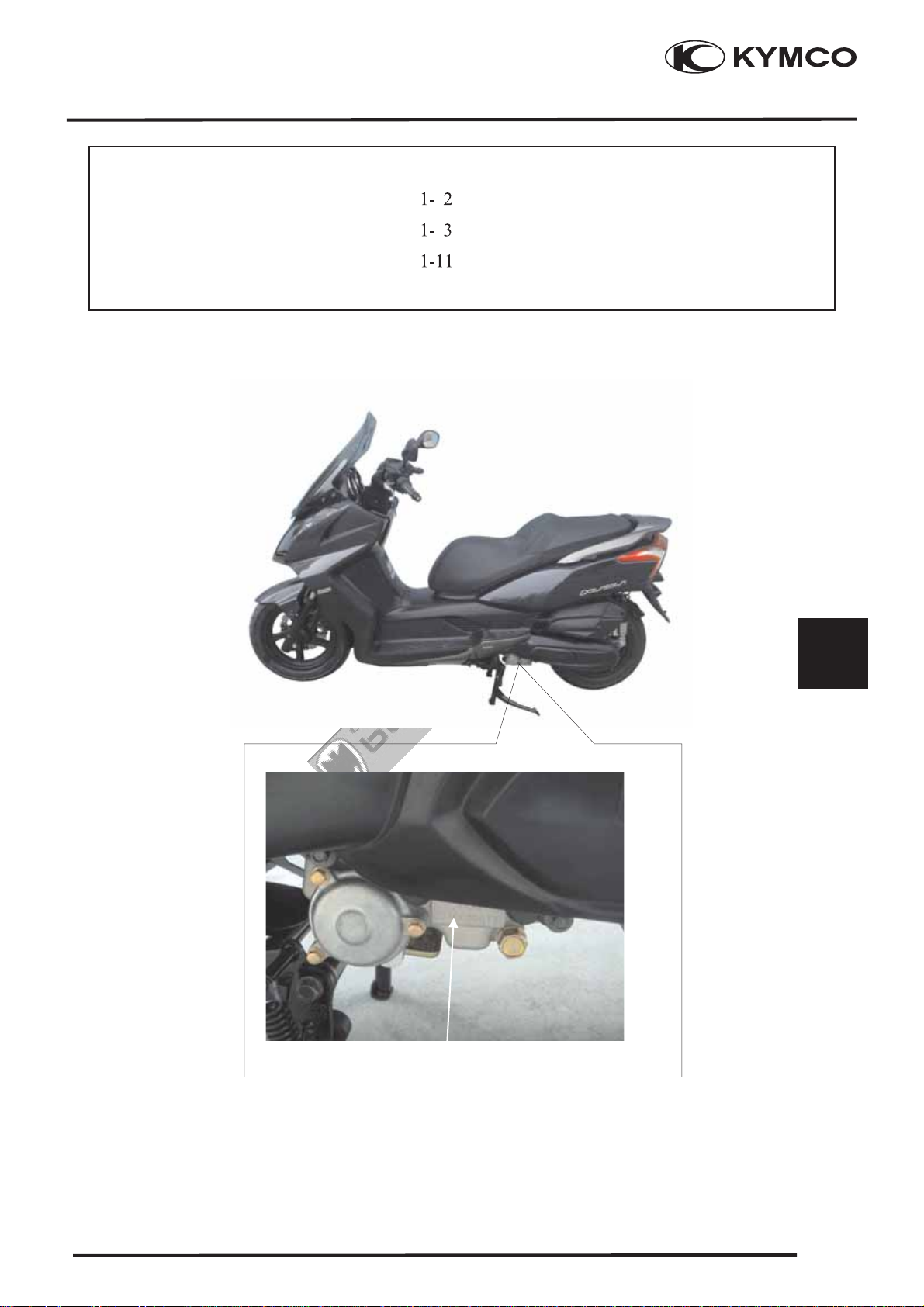

ENGINE SERIAL NUMBER

SPECIFICATIONS

SERVICE PRECAUTIONS

TORQUE VALUES

SPECIAL TOOLS....................................

ENGINE SERIAL NUMBER

...................................

..................................

................... 1- 1

.....................

LUBRICATION POINTS..........................1-14

1-12

Location of Engine Serial Number

1

-1-

1-1

Page 4

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

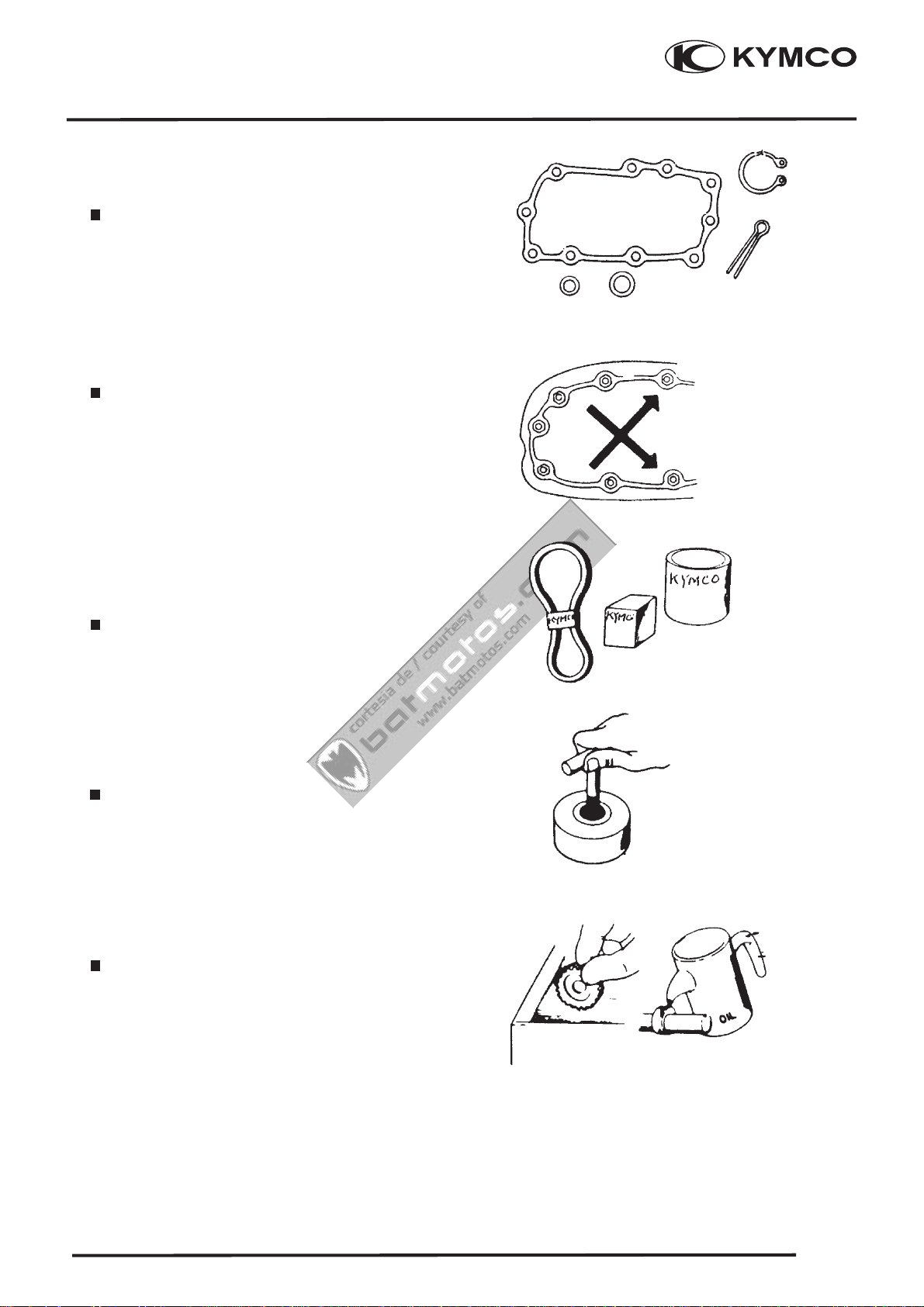

SPECIFICATIONS

Name DOWNTOWN125i

Model No. SK25AA

Overall length 2200mm

Overall width 800 mm

Overall height 1410 mm

Wheel base 1542 mm

Engine type

Displacement 124.8cc

Fuel Used 92# nonleaded gasoline

Front wheel 68

Net weight (kg) Rear wheel 96

Total 164

Front wheel 70

Gross weight(kg) Rear wheel 104

Total 178

Tires

RR Ground clearance 140 mm

Perform- Braking distance (m)

ance

Engine

Min. turning radius 2600mm

Starting system

Type

Cylinder arrangement Single cylinder

Combustion chamber type Semi-sphere

Valve arrangement O.H.C.4V

Bore x stroke (mm) 54 x 54.5

Compression ratio 11.7:1

Compression pressure

(kg/cm²)

Max .horsepower (ps/rpm) 15/8750~9000

Max. torque (kg m/rpm) 1.17/8500~8750

Port

timing

Valve Intake 0.10 mm

Front wheel 120/80-14

Rear wheel 150/70-13

Intake

(1mm)

Exhaust

(1mm)

Open 8 °BTDC

Close 31° BTDC

Open 32° BTDC

Close 6 °BTDC

O.H.C.

7.9m/30km/h

Starting motor

liquid cooled 4 stroke

15

DOWNTOWN 125i

Air cleaner type & No Paper element, wet

Fuel System

Fuel capacity 12.5 L

Throttle type

Ignition System

Electrical Equip.

Battery Capacity 12V10AH

Power Drive System

Clutch Type Dry multi-disc clutch

Transmis-

sion Gear

Reduction

Gear

Front Caster angle 28°

Moving Device

Axle

Tire pressure

(kg/cm²)1

person

Turning Left 40?

angle

Brake system

type

Damping

Device

Suspension

type

Frame type PIPE UNDER BONE

Type

Spark plug

Sparkpluggap 0.6~0.7mm

Type Non-stage transmission

Operation

Type Two-stage reduction

Reduction 1st

ratio

Trail length 140mm

2nd

Front 2.0

Rear 2.25

Right 40?

Front Disk brake

Rear

Front Telescope

Rear DOUBLE SWING

Butterfly type

ECU

NGK CR7E

Automatic centrifugal

type

0.83~2.2

10.41

Disk brake

clearance Exhaust 0.10 mm

Idle speed (rpm) 1850rpm

Lubrication

System

Lubrication type

Oil pump type Inner/outer rotor type

Oil filter type Full-flow filtration

Oil capacity 1.2 L

Exchanging capacity 1.0 L

Cooling Type Liquid cooling

Forced pressure &

Wet sump

-2-

Page 5

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

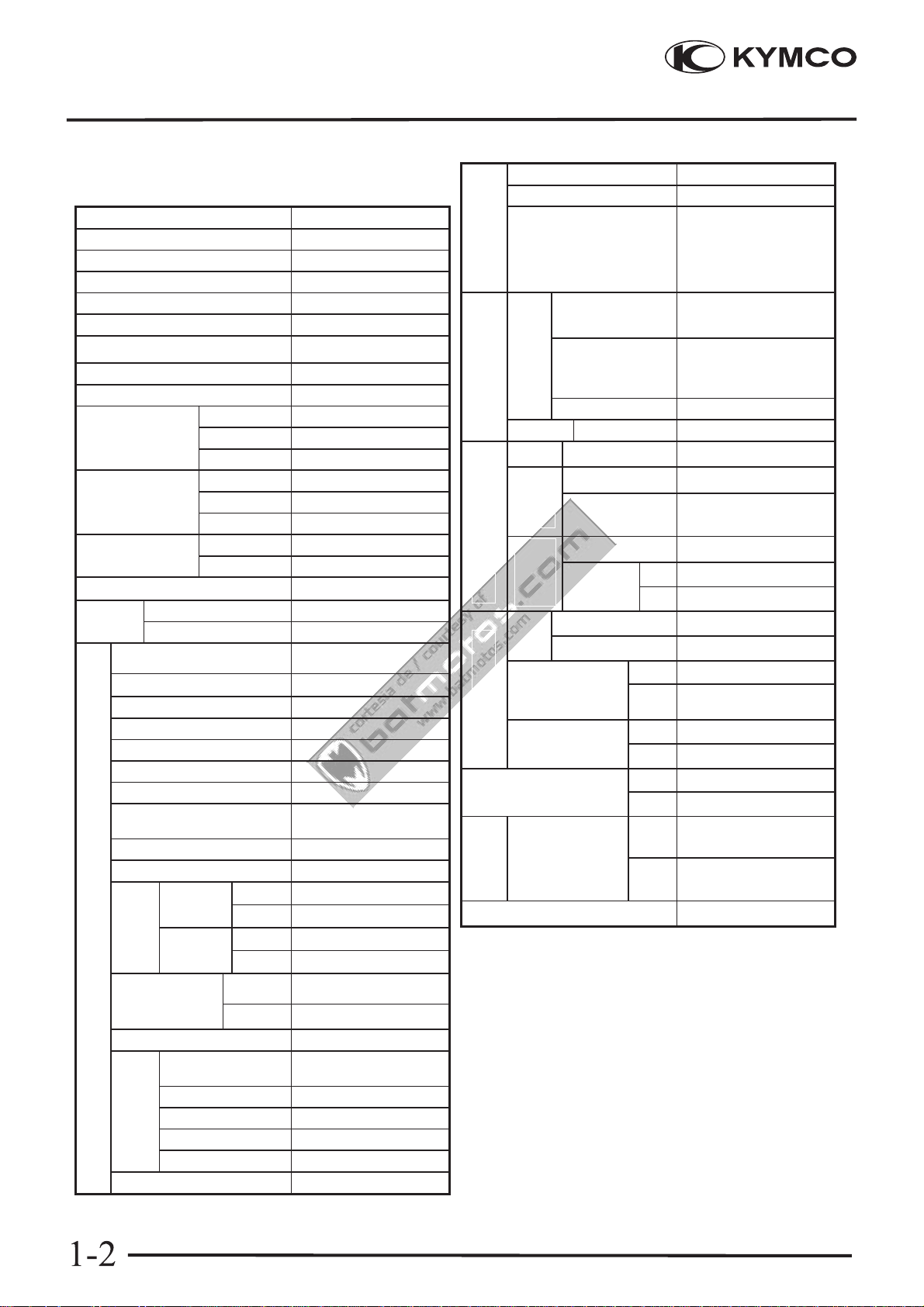

SERVICE PRECAUTIONS

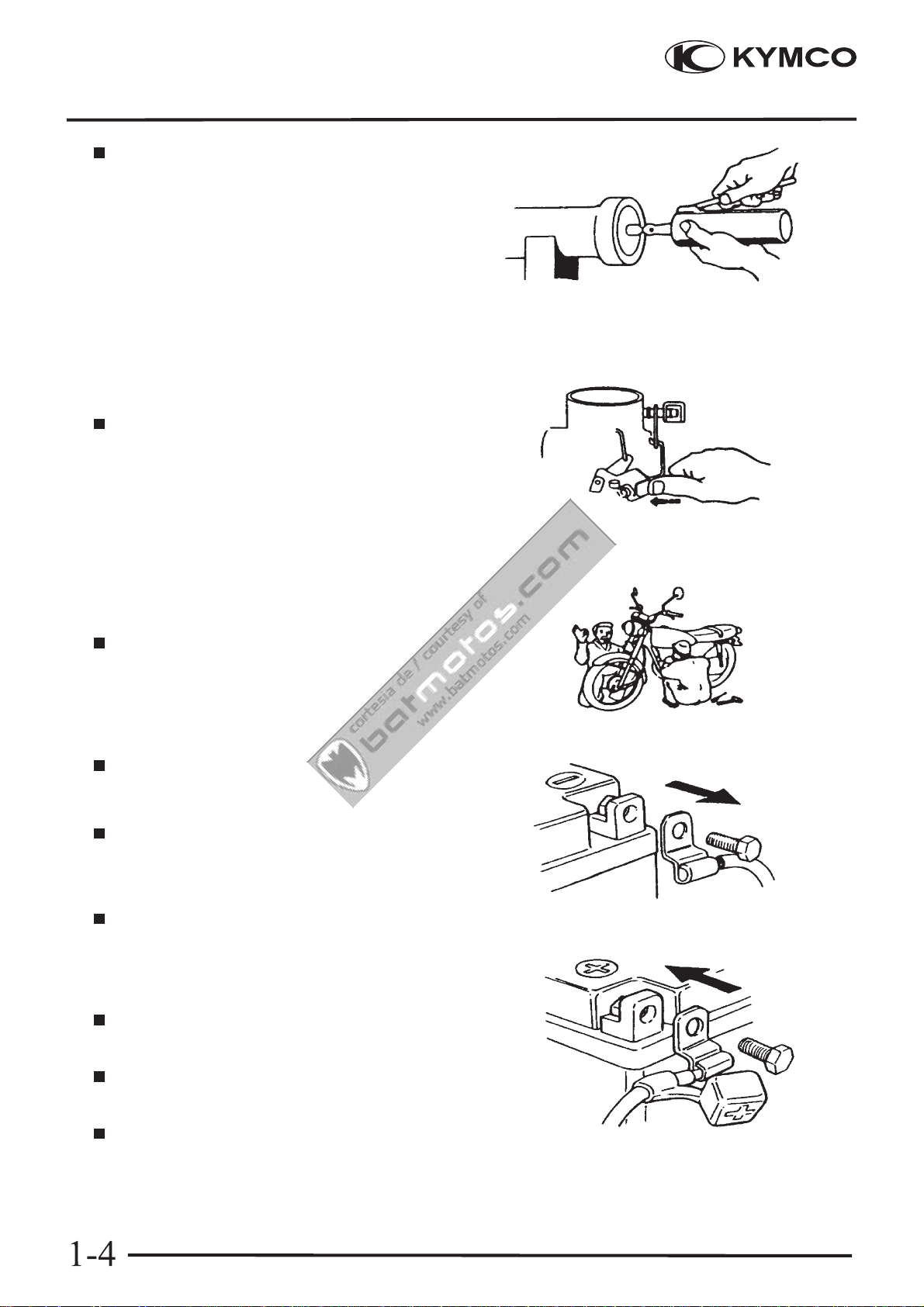

Make sure to install new gasket, O-rings, circlips,

cotter pins, etc. When reassembling.

.

When tightening bolts or nuts, begin with

larger-diameter to smaller ones at several

times, and tighten to specified torque

diagonally.

DOWNTOWN 125i

-

Use genuine parts and lubricants.

When servicing the motorcycle, be sure to

use special tools for removal and installation.

After diassembly, clean removed parts.

Lubricate sliding surfaces with engine oil

before reassembly.

-3-

1-3

Page 6

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

Apply or add designated greases and

lubricants to the specified lubrication points.

After reassembly, check all parts for proper

tightening and operation.

DOWNTOWN 125i

When two person work together, pay attention

to the mutual working safety.

Disconnect the battery negative (-) terminal

before operation.

When using a spanner or other tools, make

sure not to damage the motorcycle surface.

After operation, check all connecting points,

fasteners, and lines for proper connection

and installation.

When connecting the battery, the positive

(+) terminal must be connected first.

After connection, apply grease to

the battery terminals.

Terminal caps shall be installed securely.

-4-

Page 7

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

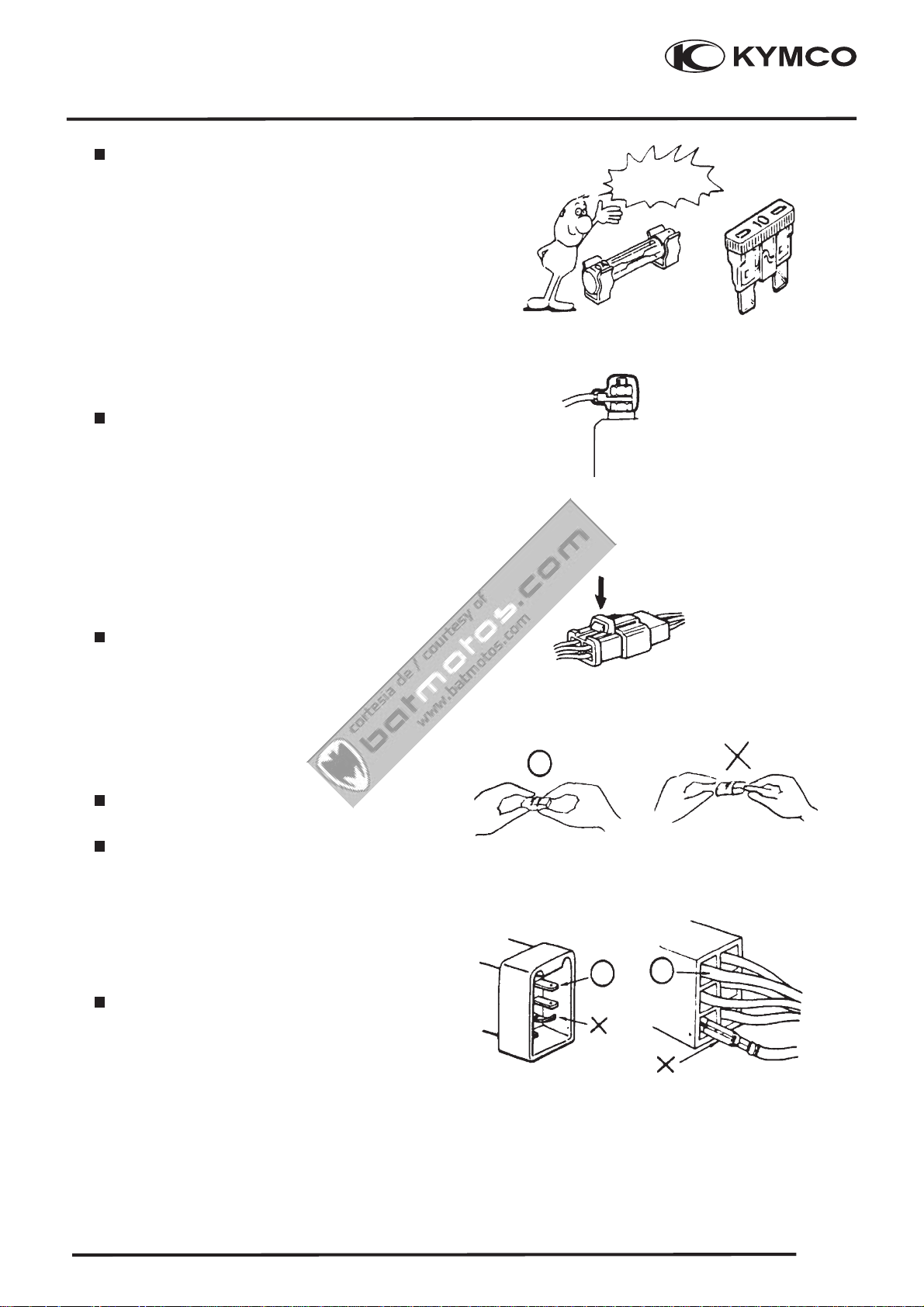

If the fuse is burned out, find the cause

and repair it. Replace it with a new one

according to the specified capacity.

After operation, terminal caps shall be

installed securely.

DOWNTOWN 125i

Confirm

Capacity

When taking out the connector, the lock

on the connector shall be released before

operation.

Hold the connector body when connecting

or disconnecting it.

Do not pull the connector wire.

Check if any connector terminal is bending,

protruding or loose.

-5-

1-5

Page 8

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

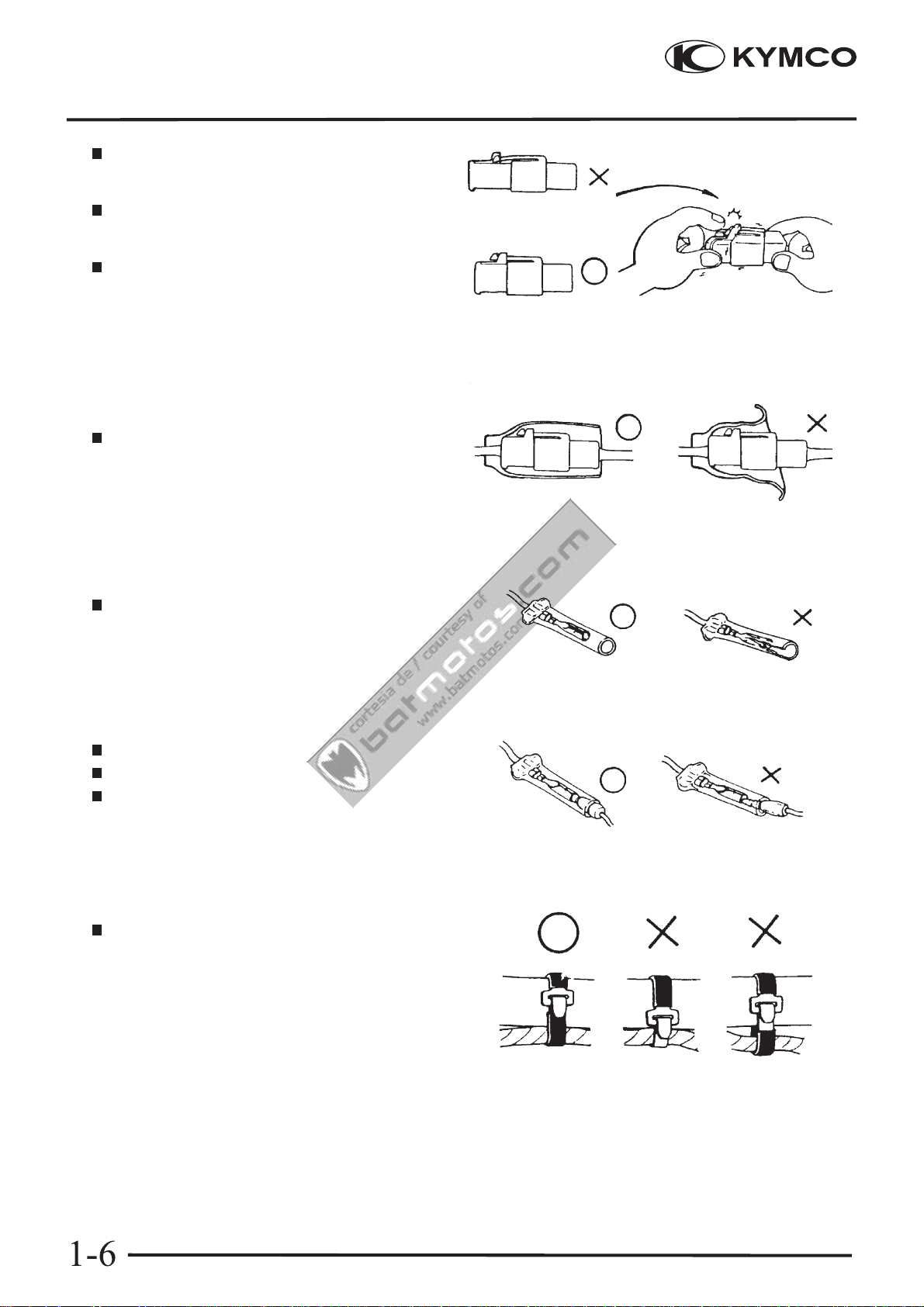

The connector shall be inserted completely.

DOWNTOWN 125i

If the double connector has a lock, lock it

at the correct position.

Check if there is any loose wire.

Before connecting a terminal, check for

damaged terminal cover or loose negative

terminal.

Check the double connector cover for

proper coverage and installation.

click

Insert the terminal completely.

Check the terminal cover for proper coverage.

Do not make the terminal cover opening

face up.

Secure wire harnesses to the frame with

their respective wire bands at the designated

locations.

Tighten the bands so that only the insulated

surfaces contactthe wireharnesses.

-6-

Page 9

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

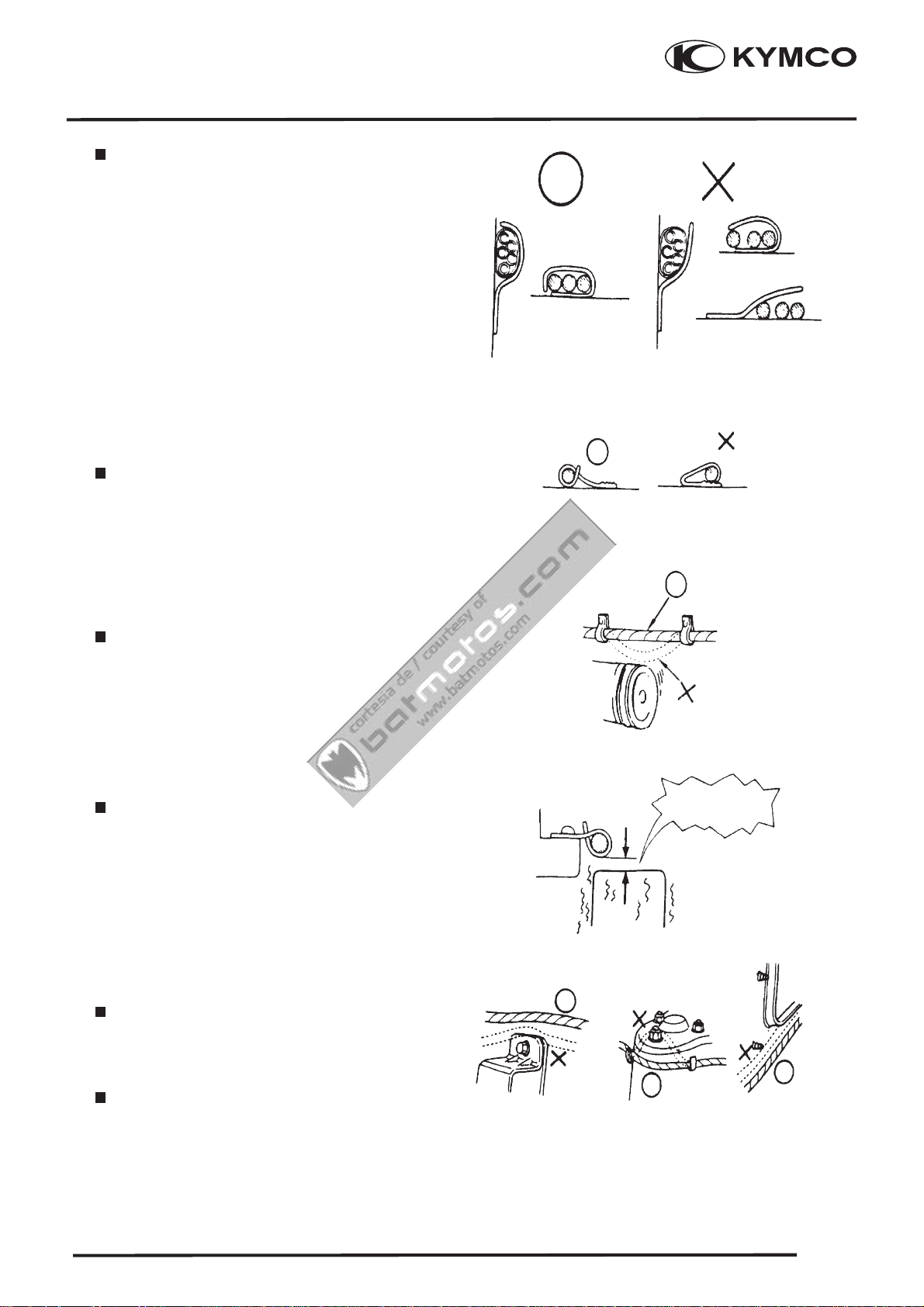

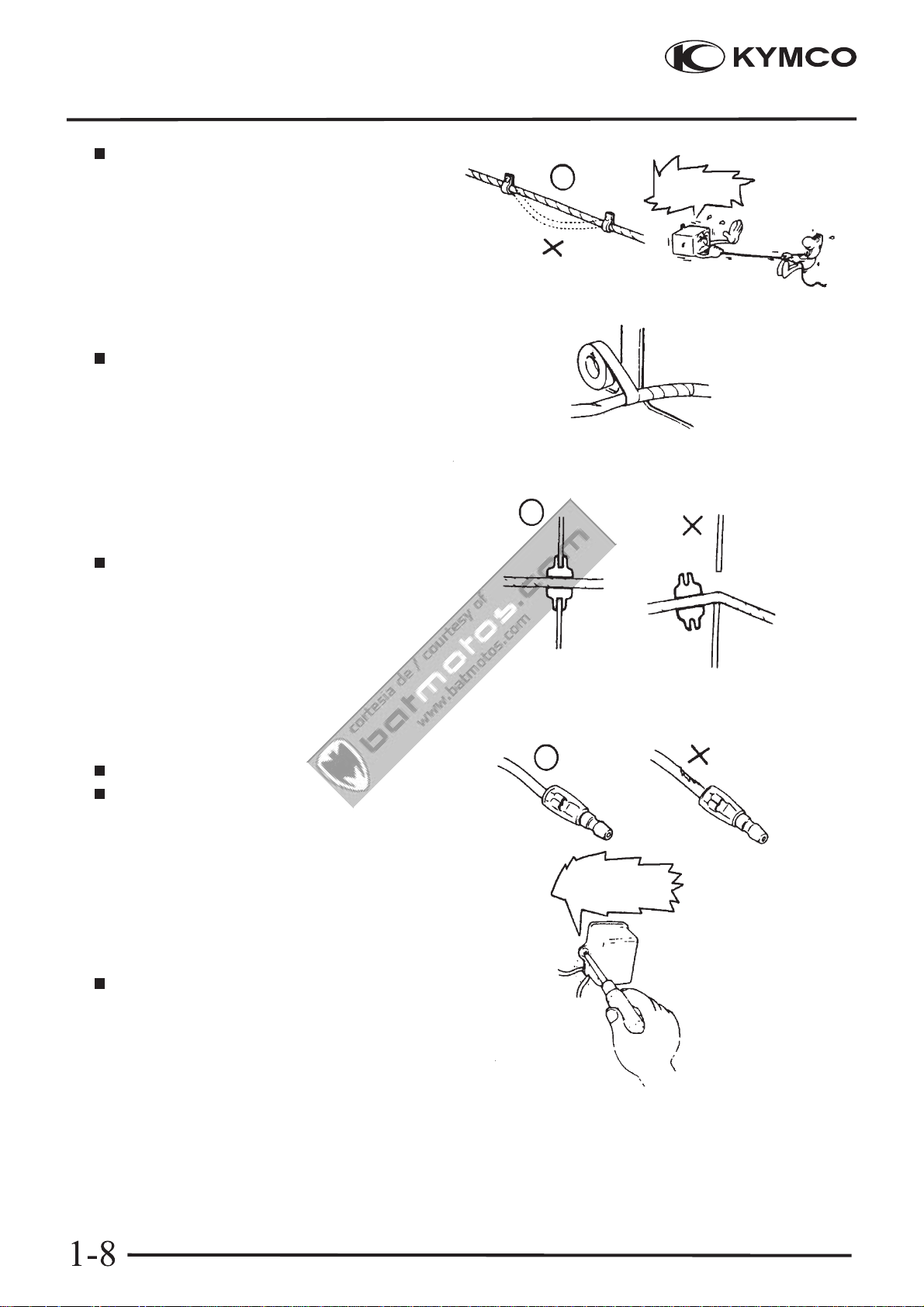

After clamping, check each wire to make

sure it is secure.

Do not squeeze wires against the weld or

its clamp

DOWNTOWN 125i

After clamping, check each harness to make

sure that it is not interfering with any moving

or sliding parts.

When fixing the wire harnesses, do not make

it contact the parts which will generate high

heat.

Route wire harnesses to avoid sharp edges

or corners. Avoid the projected ends of bolts

and screws.

No contact !

Route wire harnesses passing through the side

of bolts and screws. Avoid the projected ends

of bolts and screws.

-7-

1-7

Page 10

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

Route harnesses so they are neither pulled

tight nor have excessive slack.

Protect wires and harnesses with electrical

tape or tube if they contact a sharp edge or

corner.

DOWNTOWN 125i

Do not pull

too tight!

When rubber protecting cover is used to

protect the wire harnesses, it shall be

installed securely.

Do not break the sheath of wire.

If a wire or harness is with a broken sheath,

repair by wrapping it with protective tape

or replace it.

When installing other parts, do not press

or squeeze the wires.

Do not press or

squeeze the wire.

-8-

Page 11

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

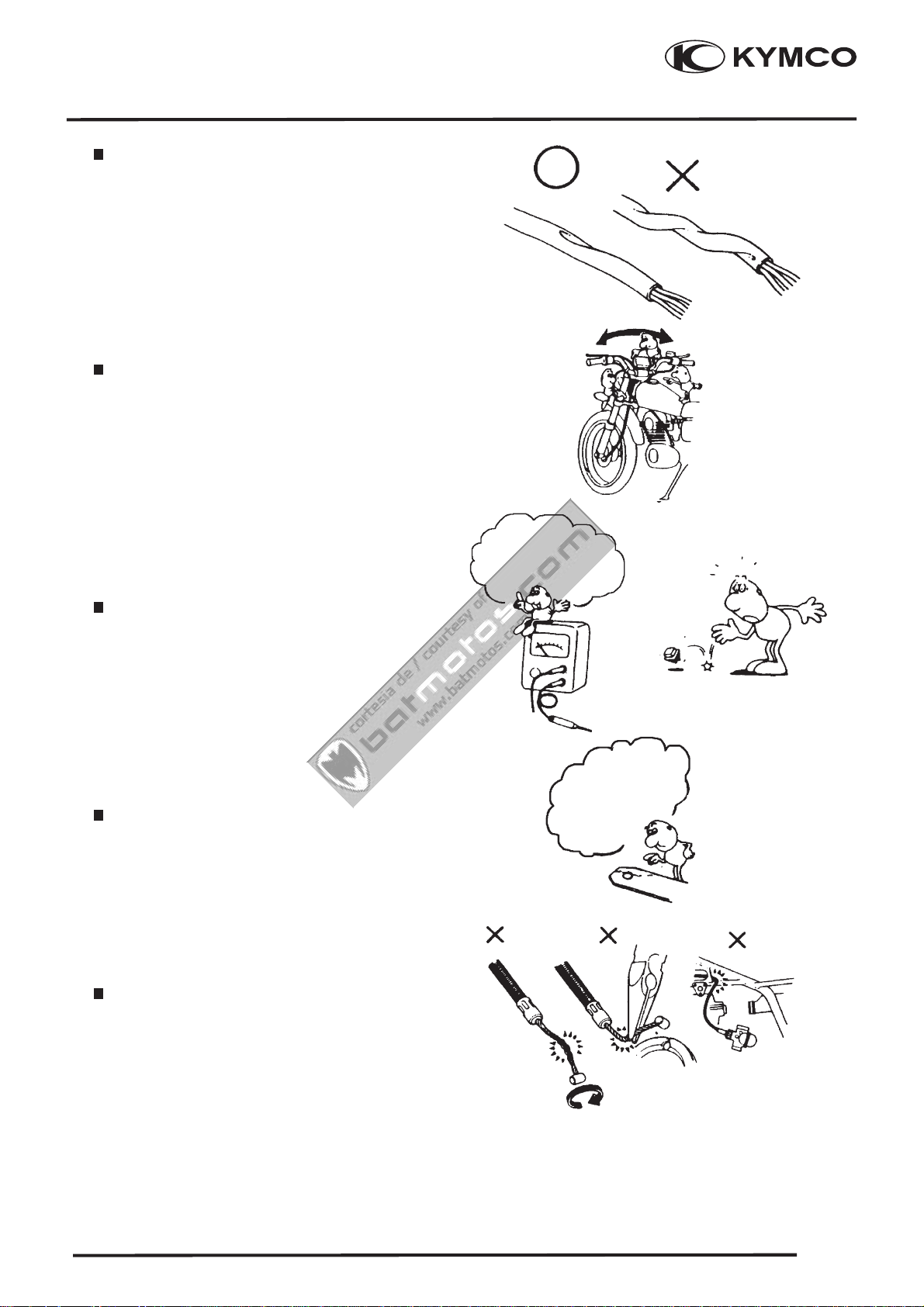

After routing, check that the wire harnesses

are not twisted or kinked.

Wire harnesses routed along with handlebar

should not be pulled tight, have excessive

slack or interfere with adjacent or surrounding

parts in all steering positions.

DOWNTOWN 125i

Do you understand the

instrument?

Is the instrument

set correctly?

When a testing device is used, make sure to

understand the operating methods

thoroughly and operate according

to the operating instructions.

Be careful not to drop any parts.

When rust is found on a terminal, remove

the rust with sand paper or equivalent before

connecting.

Remove Rust !

-9-

1-9

Page 12

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

Symbols :

The following symbols represent the servicing methods and cautions included in

this service manual.

DOWNTOWN 125i

Engine Oil

Grease

Gear Oil

Special

:Apply engine oil to the specified points.

(Use designated engine oil for lubrication).

:Apply grease for lubrication.

:Transmission Gear Oil (90#)

:Use special tool.

:Caution

:Warning

.

-10-

Page 13

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

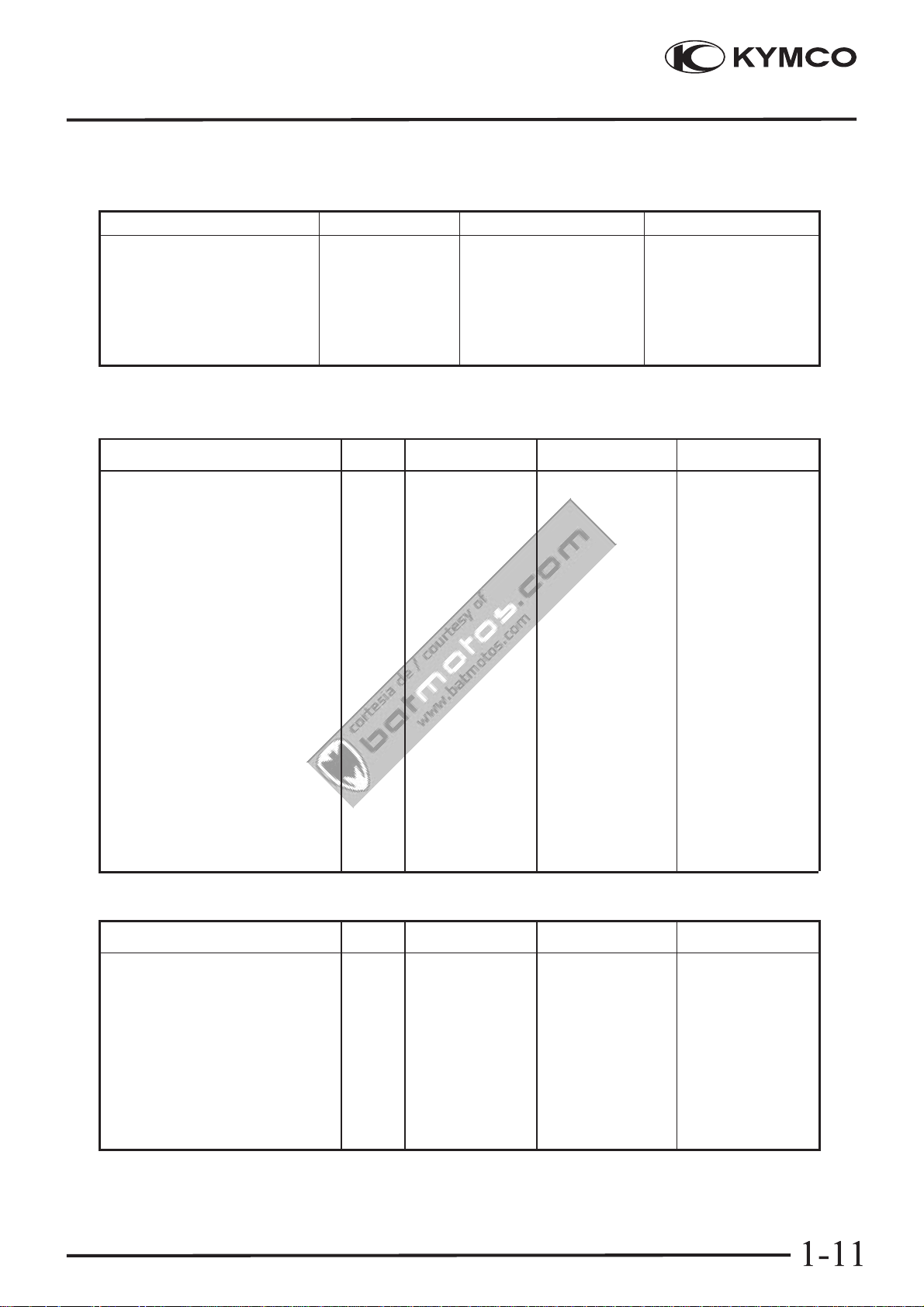

TORQUE VALUES

STANDAR TORQUE VALUES

Item Torque (kg -f m) Item Tor (kg -que f m)

DOWNTOWN 125i

5mm bolt, nut

6mm bolt, nut

8mm bolt, nut

10mm bolt, nut

12mm bolt, nut

Torque specifications listed below are for important fasteners.

ENGINE

Item Qty Thread dia.(mm) Torque (kgf-m) Remarks

Cylinder head bolt A

Cylinder head bolt B

Oil filter screen cap

O2 sensor

Cylinder head cover

Tappet adjusting hole cap

Cam chain set plate

Engine oil drain bolt

Clutch outer nut

Clutch drive plate nut

Starter motor mounting bolt

Oil pump bolt

Drive face nut

Spark plug

A.C. Generator flywheel

Cam chain tensioner pivot

0.45~0.6

0.8~1.2

1.8~2.5

3.0~4.0

5.0~6.0

5mm screw

6mm screw, SH bolt

6mm flange bolt, nut

8mm flange bolt, nut

10mm flange bolt, nut

6

6

30

12

6

30

6

12

12

28

6

6

12

10

12

6

0.45~0.6

0.7~1.1

1.0~1.4

2.4~3.0

3.0~4.5

0.7~1.1

0.7~1.1

2.0~3.0

0.7~1.1

0.8~0.9

1.0~2.0

1.0~1.4

2.0~3.0

5.0~6.0

5.0~6.0

0.8~1.2

0.7~1.1

5.5~6.5

1.0~1.4

5.0~6.0

0.8~1.2

FRAME

Item Qty Thread dia.(mm) Torque (kgf-m) Remarks

Steering stem lock nut

Front axle

Rear axle nut

Rear shock absorber upper bolt

Rear shock absorber lower bolt

Muffler exh. Pipe

-11-

Bc1

14

16

10

10

8

6.0~6.5

1.5~2.5

11~13

3.5~4.5

3.5~4.5

1.8~2.0

U - nut

U - nut

Page 14

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

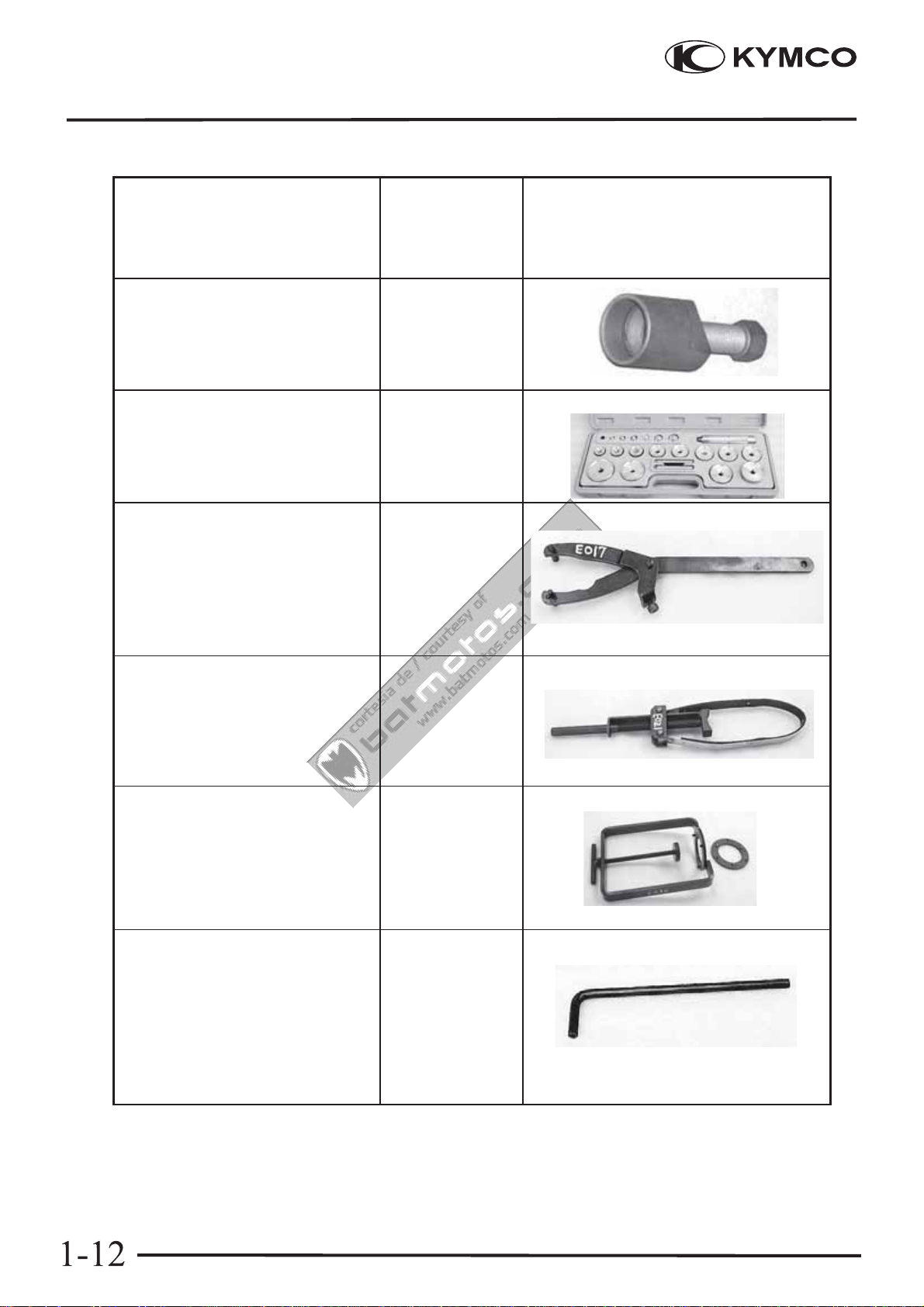

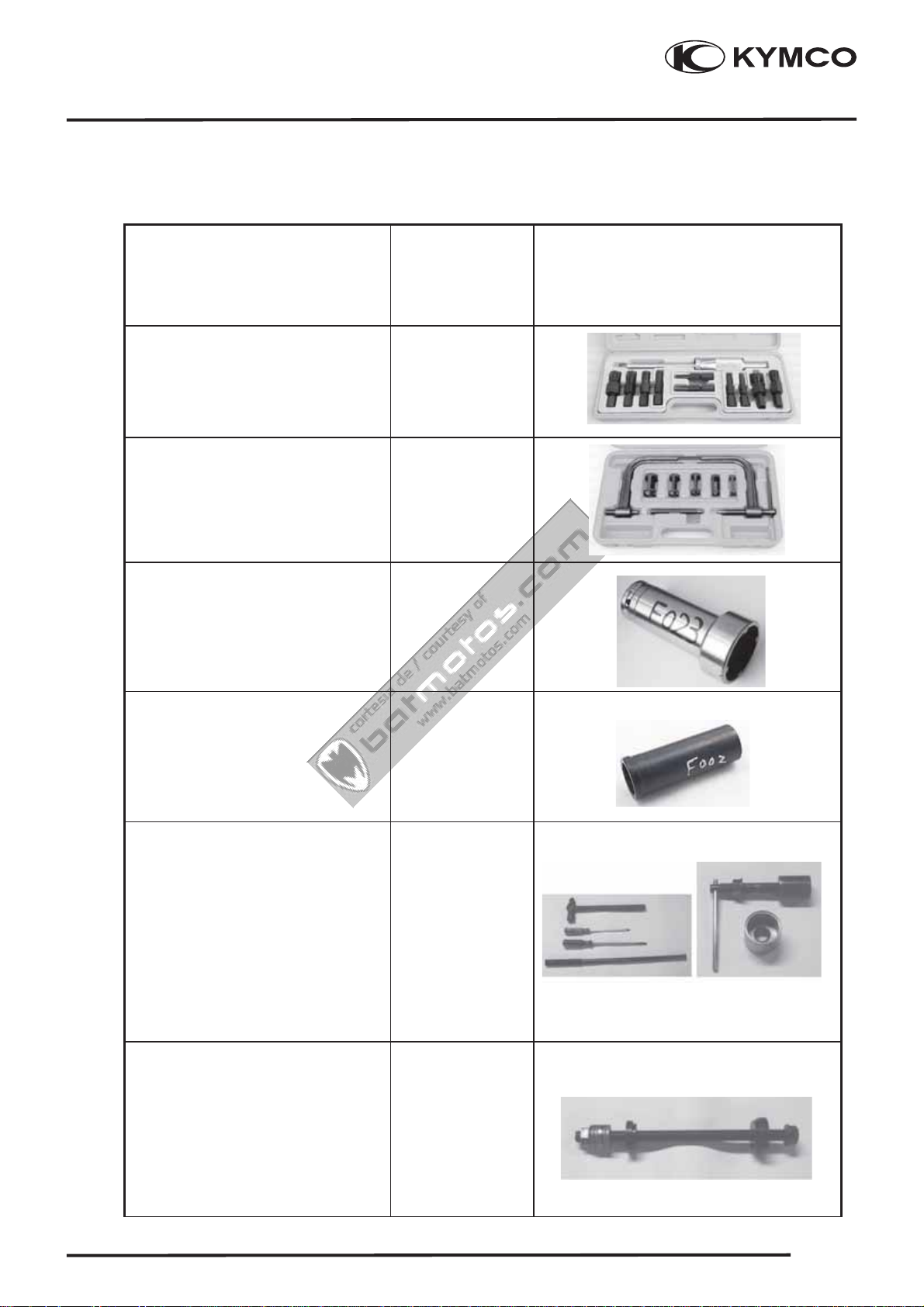

SPECIAL TOOLS

Tool Name Tool No.

Flywheel puller

DOWNTOWN 125i

Illustration

(Note: the special tools may differ

slightly from those shown in the

figure of this manual.)

(Refer to the “STARTER

CLUTCH” section in the chapter

10.)

Oilsealandbearing

installer

Universal holder

(Refer to the “DRIVE PULLEY,

DRIVE BELT AND DRIVEN

PULLEY” section in the chapter

8.)

Flywheel holder

(Refer to the “STARTER

CLUTCH” section in the chapter

10.)

A120E00003

A120E00014

A120E00017

A120E00021

Clutch spring compressor

(Refer to the “DRIVE PULLEY,

DRIVE BELT AND DRIVEN

PULLEY” section in the chapter

8.)

Valve adjuster

(Refer to the “VA LV E

CLEARANCE”sectioninthe

chapter 3.)

A120E00034

A120E00036

(Cont’d)

-12-

Page 15

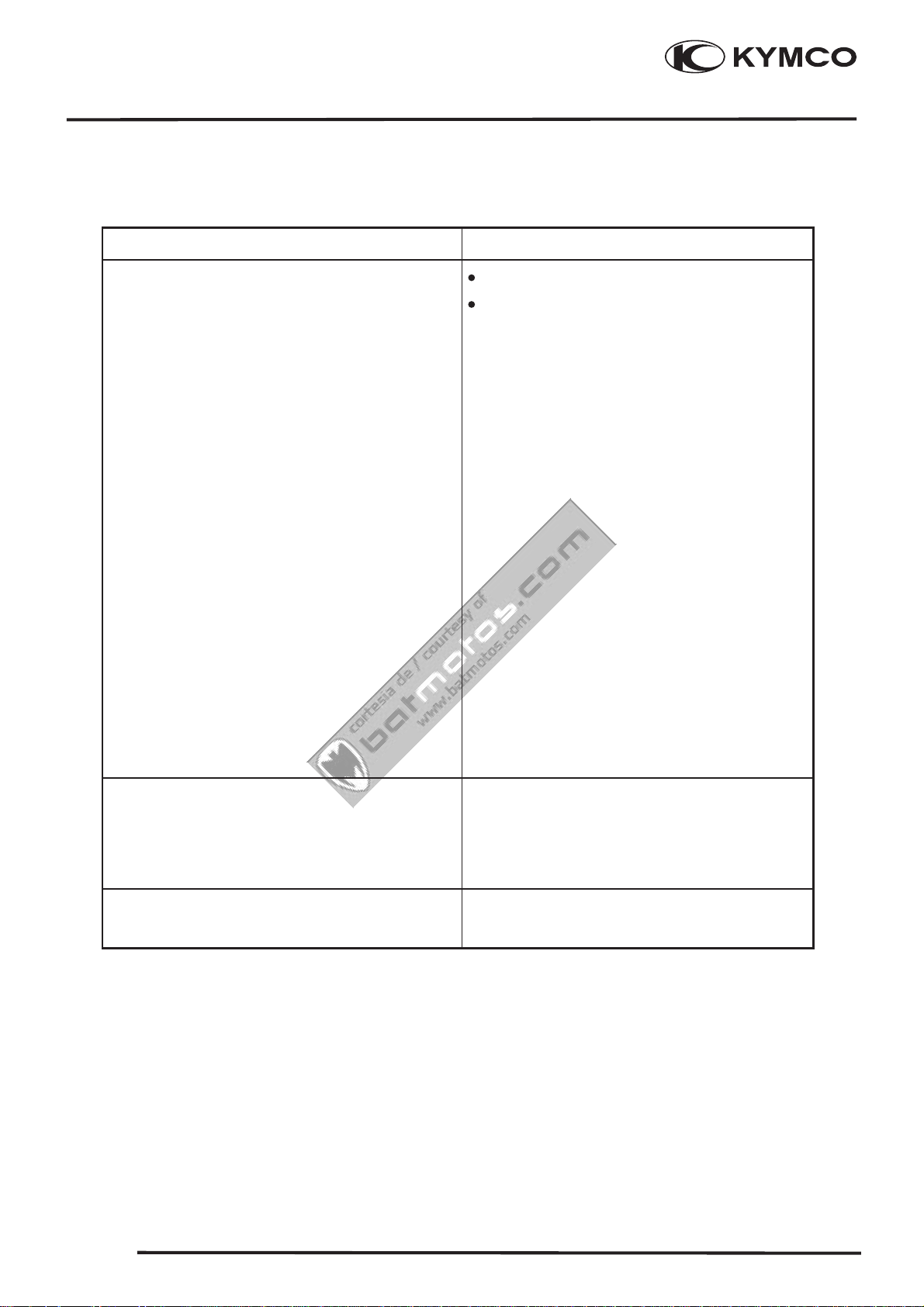

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

SPECIAL TOOLS

Tool Name Tool No.

Bearing puller A120E00037

Valve spring compressor

DOWNTOWN 125i

Illustration

(Note: the special tools may differ

slightly from those shown in the

figure of this manual.)

(Refer to the “CYLINDER

HEAD” section in the chapter 6.)

Lock nut wrench

(Refer to the “STEERING

STEM” section in the chapter 15.)

Lock nut wrench

(Refer to the “STEERING

STEM” section in the chapter 15.)

Bottom Ball Race

Remove

Cone Race Remove

(Refer to the “STEERING

STEM” section in the chapter 15.)

special tool/ Top Ball

special tool

A120E00040

A120F00023

A120F00002

A120F00009

Bottom Ball Race

Install

Top Ball Cone Race

Install

(Refer to the “STEERING

STEM” section in the chapter 15.)

-13-

special tool

special tool

A120F00019

1-13

Page 16

1. GENERAL INFORMATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

LUBRICATION POINTS

ENGINE

Lubrication Points Lubricant

DOWNTOWN 125i

Valve guide/valve stem movable part

Cam lobes

Valve rocker arm friction surface

Cam chain

Cylinder lock bolt and nut

Piston surroundings and piston ring grooves

Piston pin surroundings

Cylinder inside wall

Connecting rod/piston pin hole

Connecting rod big end

Crankshaft R/L side oil seal

Starter reduction gear engaging part

Countershaft gear engaging part

Final gear engaging part

Bearing movable part

O-ring face

Oil seal lip

Genuine KYMCO Engine Oil (SAE15W-40)

API , SJ Engine Oil

Starter idle gear

Friction spring movable part/shaft movable part

Shaft movable grooved part

A.C. generator connector

Transmission case breather tube

High-temperature resistant grease

Adhesive

1-14

-14-

Page 17

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

DOWNTOWN 125i

2

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

2

EXHAUST MUFFLER/FRAME COVERS

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 2- 1

TROUBLESHOOTING----------------------------------------------------- 2- 1

FASTENER REMOVAL AND REINSTALLATION------------------ 2- 2

FRAME COVERS REMOVAL/INSTALLATION--------------------- 2- 3

EXHAUST MUFFLER ----------------------------------------------------- 2-14

2-0

Page 18

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

DOWNTOWN 125i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• When removing frame covers, use care not to pull them by force because the cover joint claws

may be damaged.

• Make sure to route cables and harnesses according to the Cable & Harness Routing.

TORQUE VALUES

Exhaust muffler pipe nuts 1.8~2.2 kgf-m

Exhaust muffler brake /RR Frok 3.2~3.8 kgf-m

RR/Engine case 3.0~4.0 kgf-m

TROUBLESHOOTING

Noisy exhaust muffler

• Damaged exhaust muffler

• Exhaust muffler joint air leaks

Lack of power

• Caved exhaust muffler

• Clogged exhaust muffler

• Exhaust muffler air leaks

2-1

Page 19

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

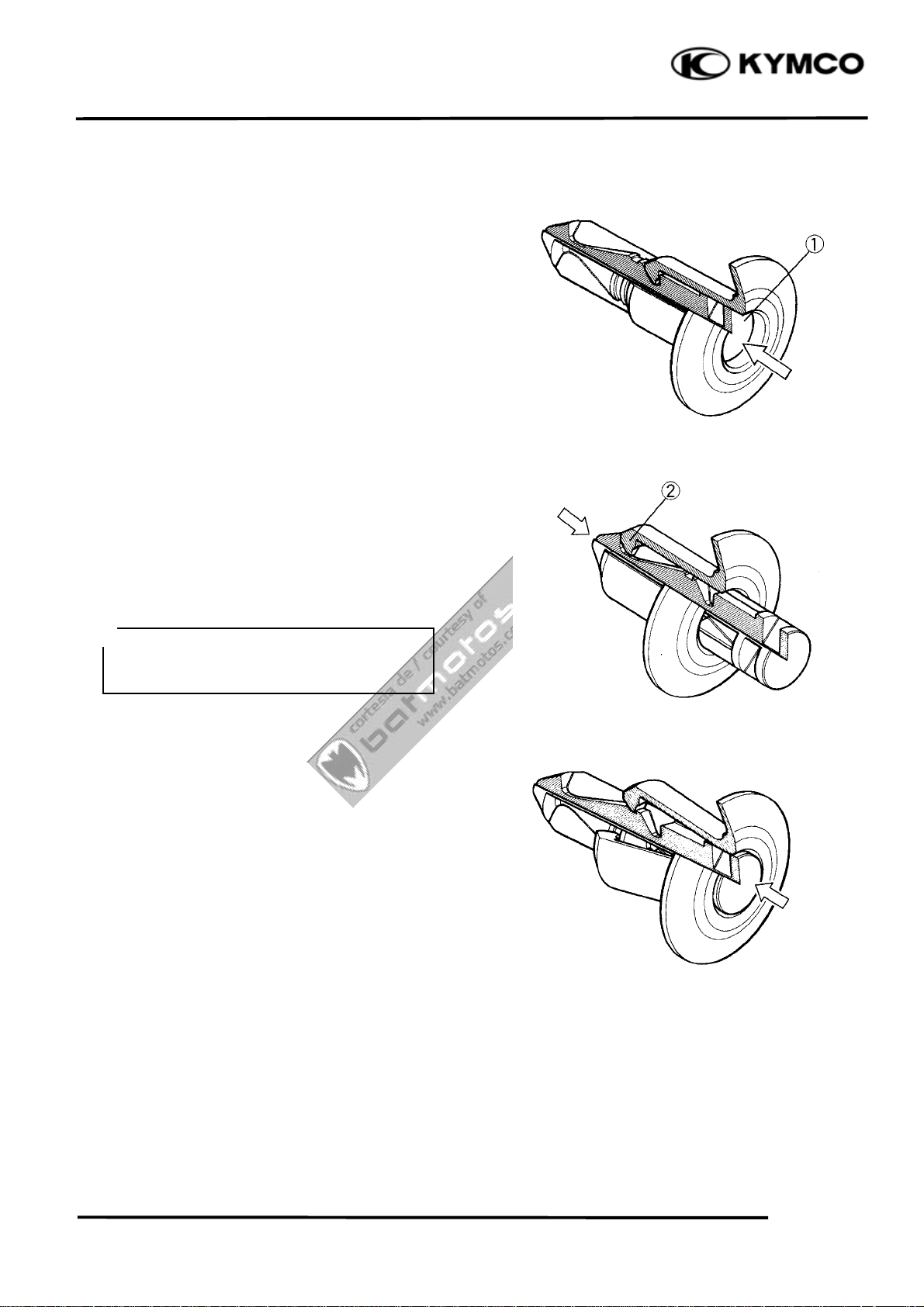

FASTENER REMOVAL AND

REINSTALLATION

REMOVAL

Depress the head of fastener center piece {.

Pull out the fastener.

INSTALLATION

Let the center piece stick out toward the head

so that the pawls | close.

Insert the fastener into the installation hole.

DOWNTOWN 125i

*

To prevent the pawl | from damage,

insert the fastener all the way into the

installation hole

Push in the head of center piece until it

becomes flush with the fastener outside face.

2-2

Page 20

2

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

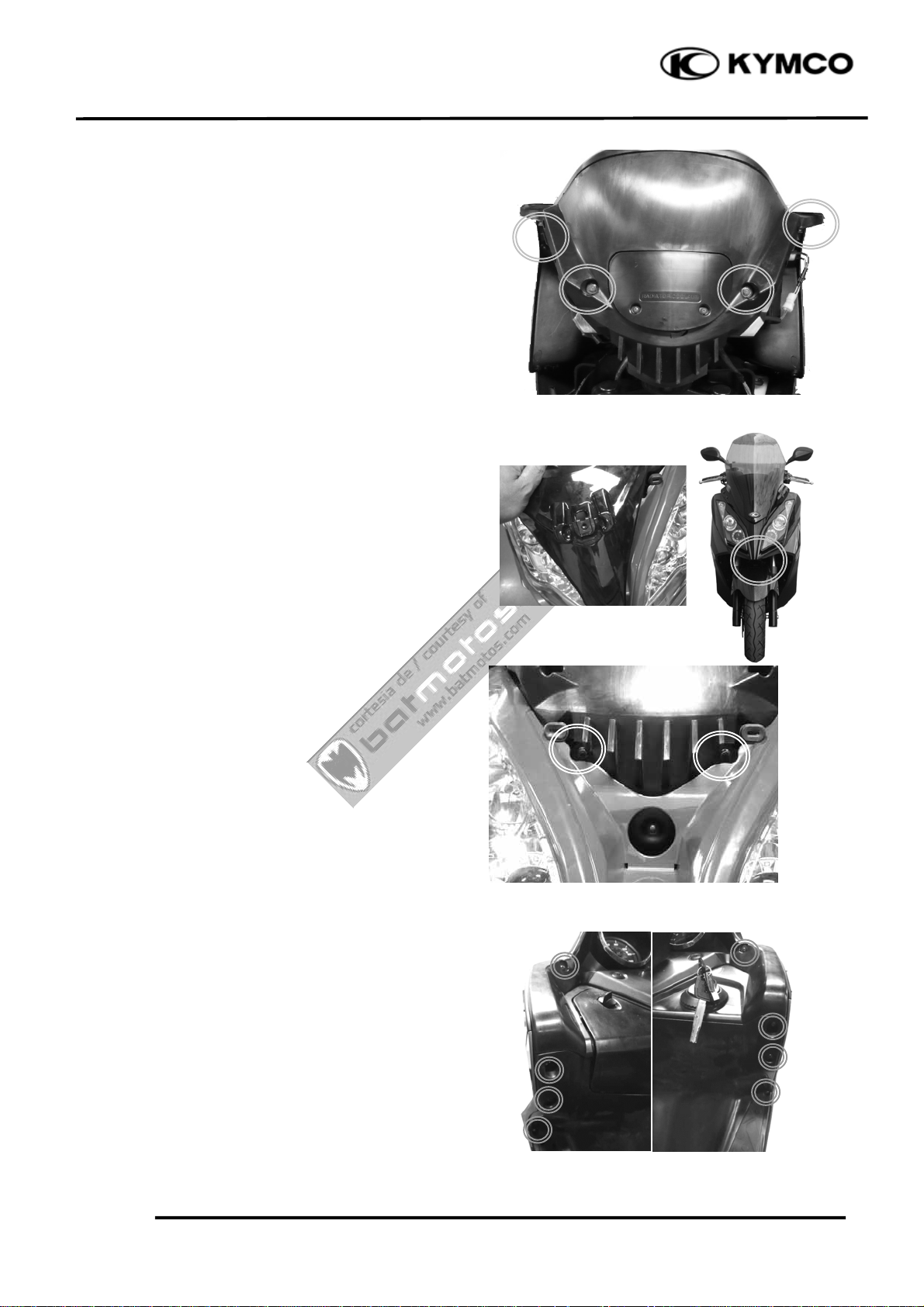

FRAME COVERS REMOVAL/

INSTALLATION

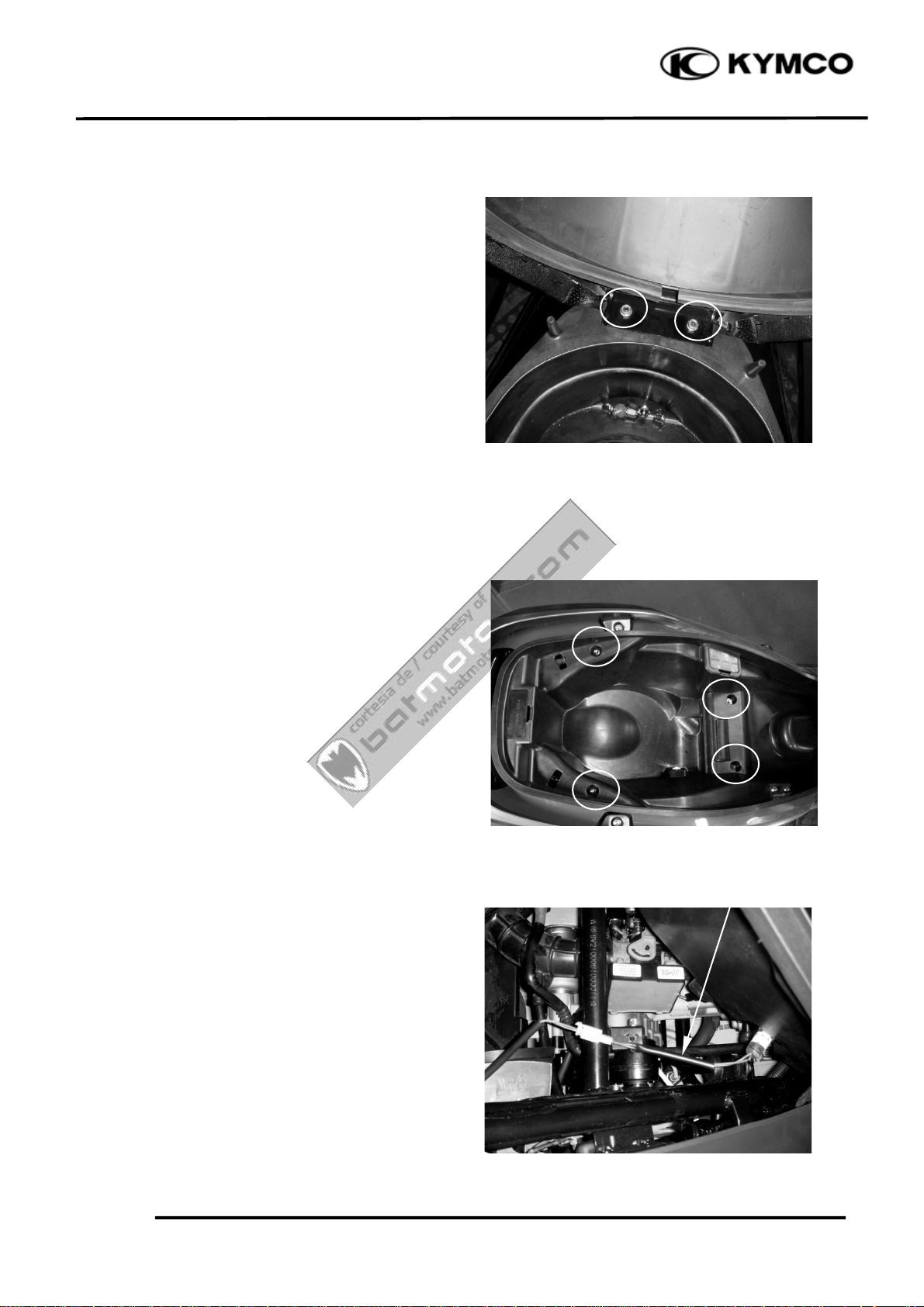

SEAT

Unlock the seat with the ignition key.

Open the seat.

Remove the two nuts and the seat.

Installation is in the reverse order of removal.

DOWNTOWN 125i

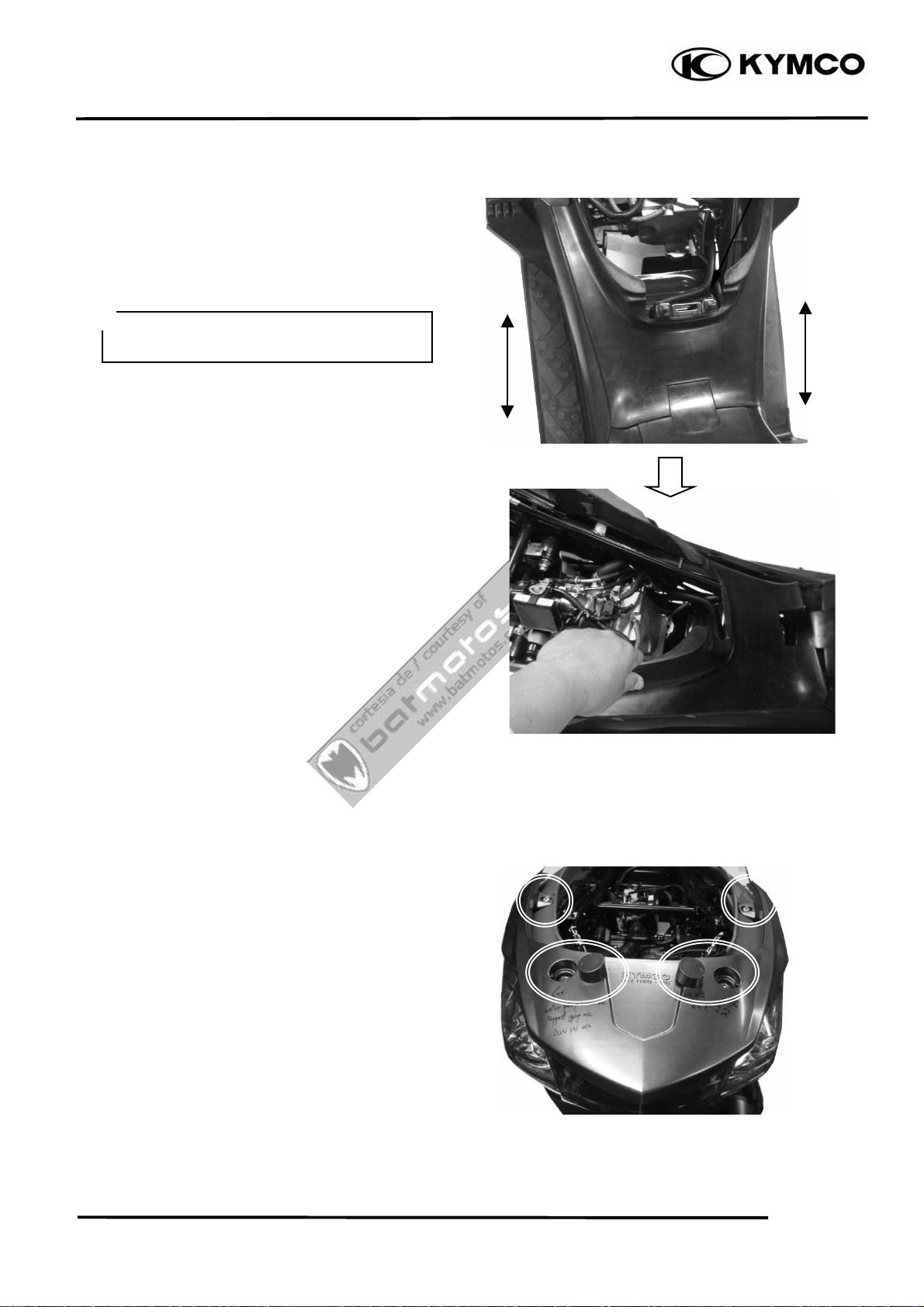

LUGGAGE BOX

Unlock the seat with the ignition key.

Open the seat.

Remove four bolts, and the fastener on the

right side of luggage box, then lift luggage

box.

Disconnect the luggage box light connector,

then remove the luggage box.

Installation is in the reverse order of removal.

Luggage Box Light Connecto

2-3

Page 21

2

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

DOWNTOWN 125i

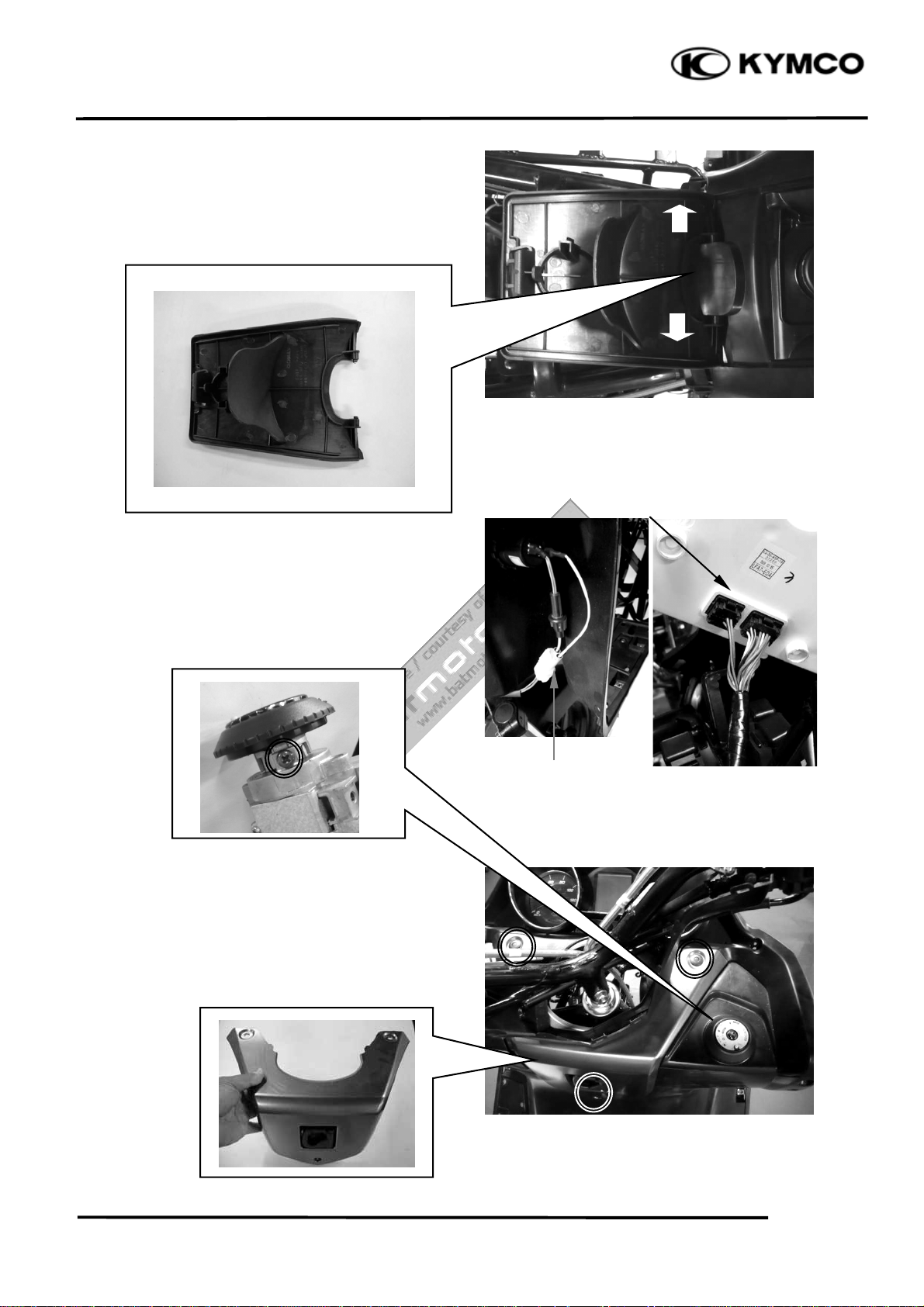

CENTER COVER

Remove the luggage box.

Remove the center cover.

*

During removal, do not pull the joint

claws forcedly to avoid damage.

Installation is in the reverse order of removal.

Center Cove

Remove four bolts and , then remove the rear

carrier.

2-4

Page 22

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

Installation is in the reverse order of removal.

DOWNTOWN 125i

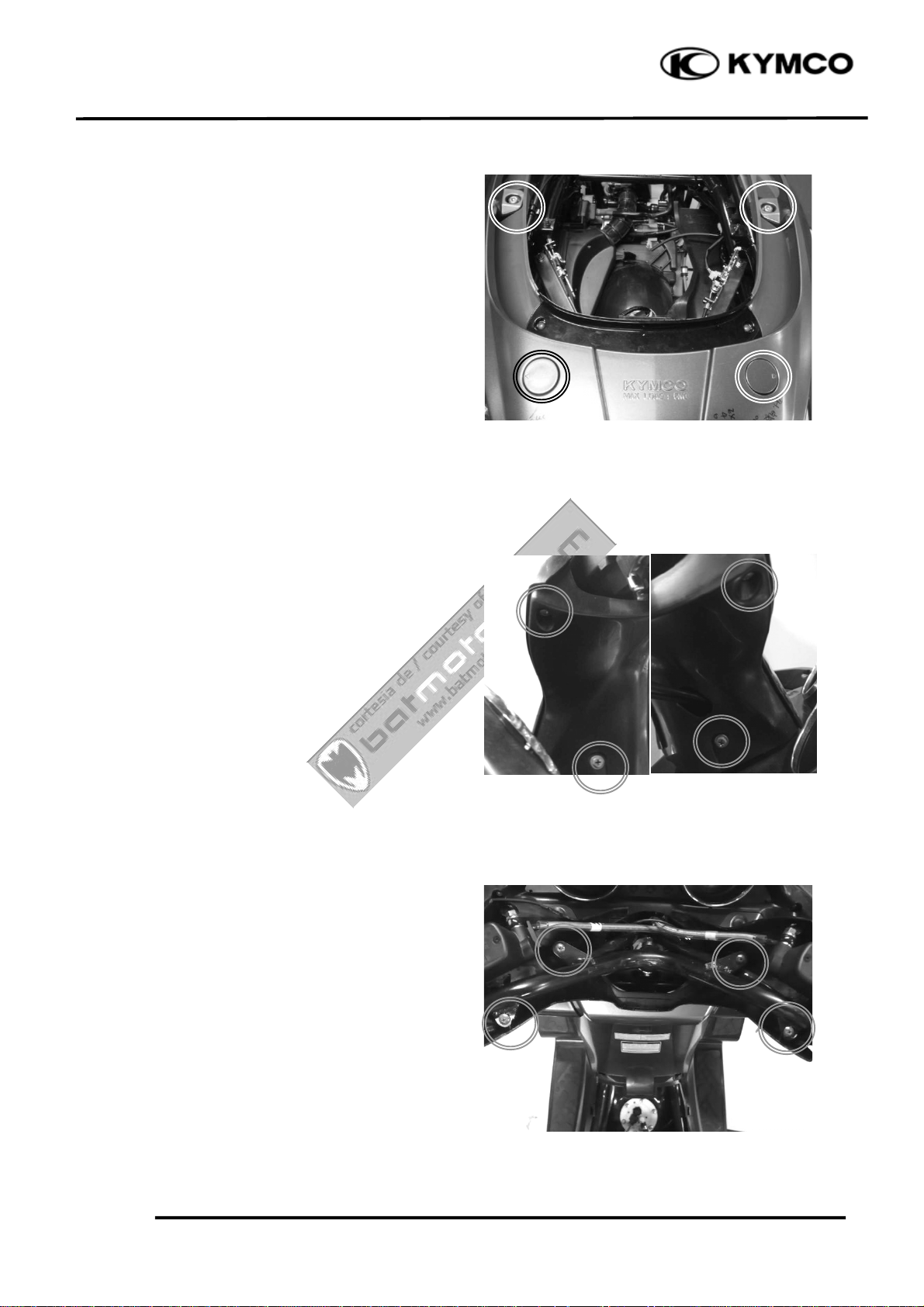

UPPER/LOWER HANDLEBAR COVER

Remove the four screws. then remove upper

handlebar cover.

Remove the four screws, then remove the

bottom handlebar cover.

Disconnect the throttle cable refer to the

“THROTTLE BODY /TPS” section , then

pull the throttle cable out from the lower

cover. Remove the lower cover.

Installation is in the reverse order of removal.

2-5

Page 23

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

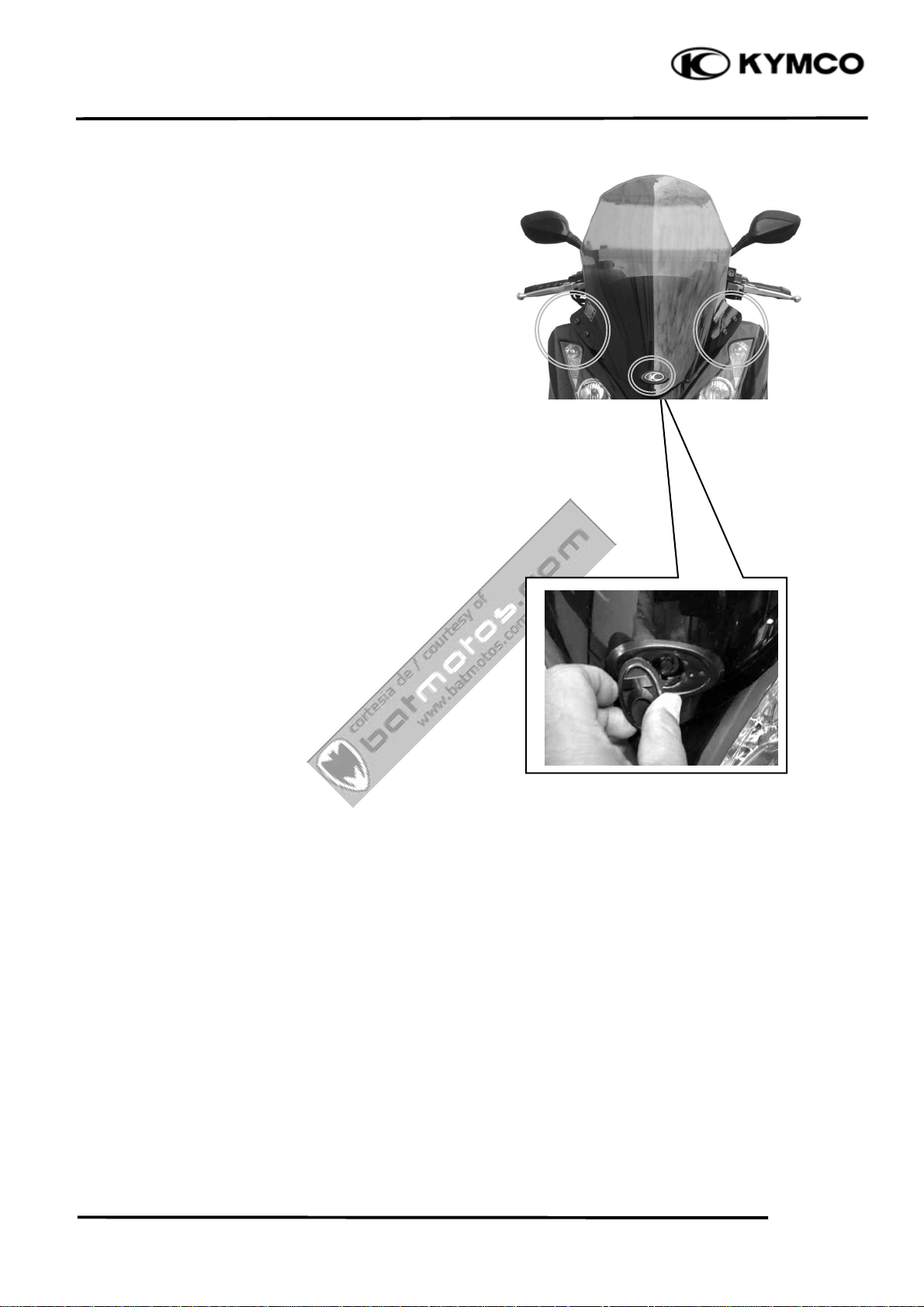

WINDSHIELD/WINDSHIELD GARNISH

Remove five bolts and windshield garnish.

DOWNTOWN 125i

2-6

Page 24

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

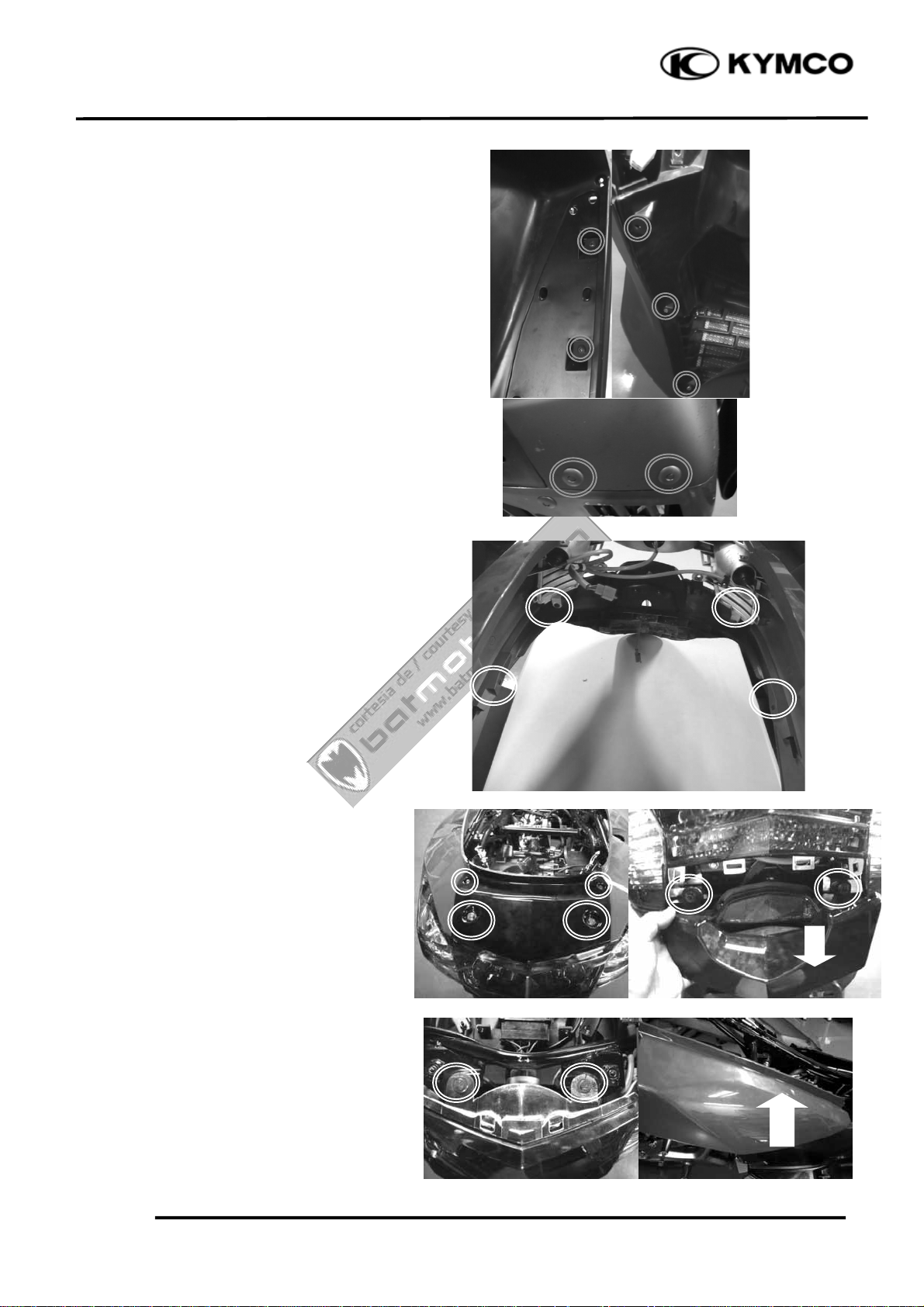

FRONT CENTER COVER

Remove the windshield

Remove four screws, then remove the front

center cover.

Remove the front cover.

Installation is in the reverse order of removal.

FRONT COVER

Remove the small front cover(black) screw

DOWNTOWN 125i

Remove the small front cover(black)

Remove two nuts.

Remove eight screws from the inner cover.

Remove the front cover

2-7

Page 25

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

Disconnect the headlight/position light

connect and right/left turn signal light

connectors.

Installation is in the reverse order of removal.

FRONT FENDER

DOWNTOWN 125i

Remove four screws.

screws and front fender.

Installation is in the reverse order of removal.

RIGHT/LEFT FOOT SKIRT

Remove the six screws attaching to the right

or left skirt.

*

During removal, do not pull the joint

claws forcedly to avoid damage.

Installation is in the reverse order of removal.

2-8

Page 26

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

DOWNTOWN 125i

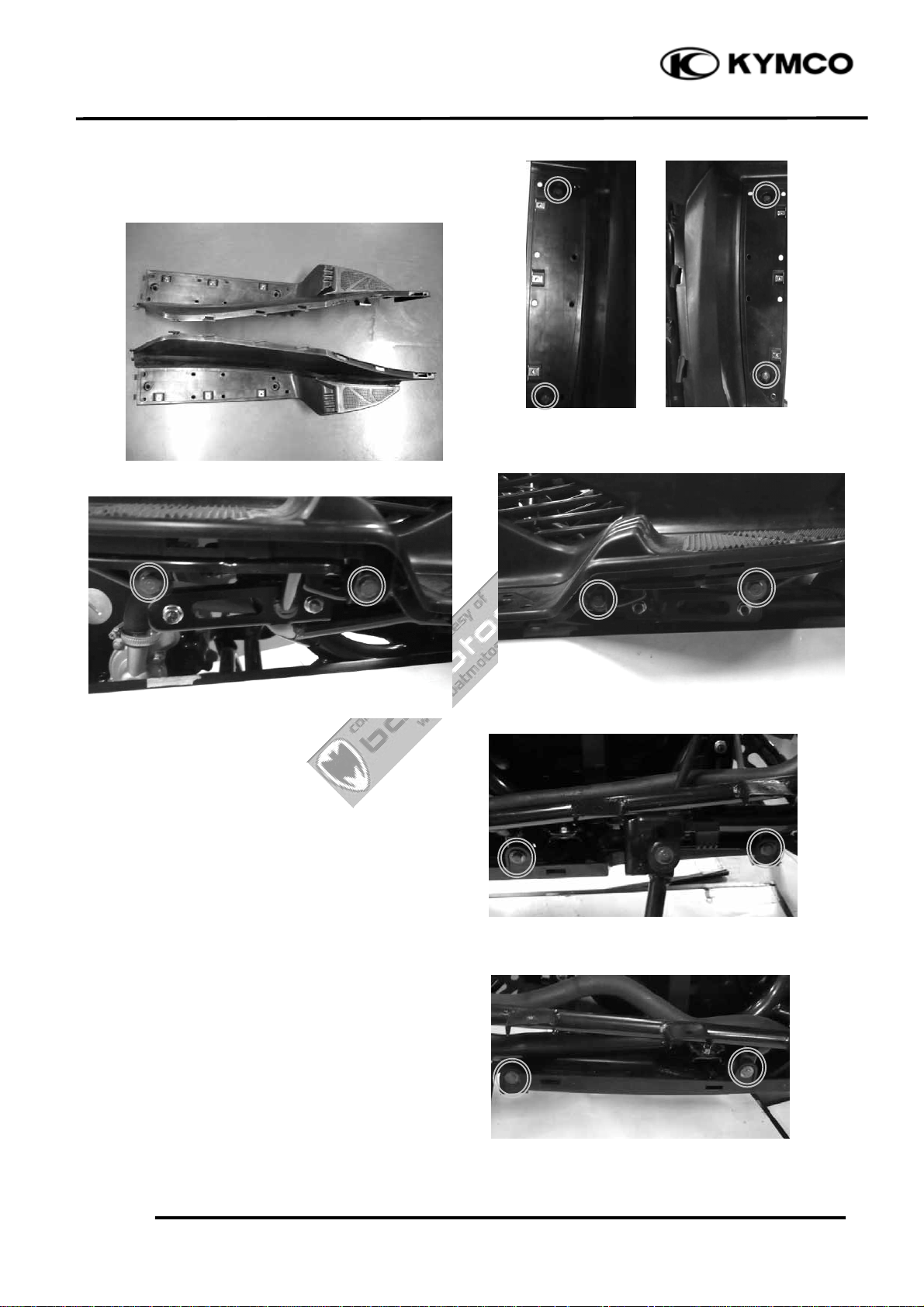

FRONT LOWER COVER

Remove the front cover

Remove the foot skirt

Remove seven screws and front lower cover.

Installation is in the reverse order of removal.

REAR FENDER

Remove the body cover and then the rear

fender .

Installation is in the reverse order of removal.

BODY COVER

Remove the rear center cover.

Remove the right and left foot skirts

Remove the rear carrier.

Remove six screws and two nuts then

remove the body cover.

2-9

Page 27

2

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

DOWNTOWN 125i

Disconnect the taillight connector.

Installation is in the reverse order of removal.

TIRE FENDER

Remove the body cover .

Remove four bolts attaching to the tire fender

Taillight Connecto

Installation is in the reverse order of removal.

FLOORBOARD

Remove the body cover

Remove the right /left skirt

Remove two screws.

2-10

Page 28

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

Remove eight bolts, then remove the

floorboard.

DOWNTOWN 125i

UNDER COVER

Remove four bolts

Remove the under cover.

2-11

Page 29

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

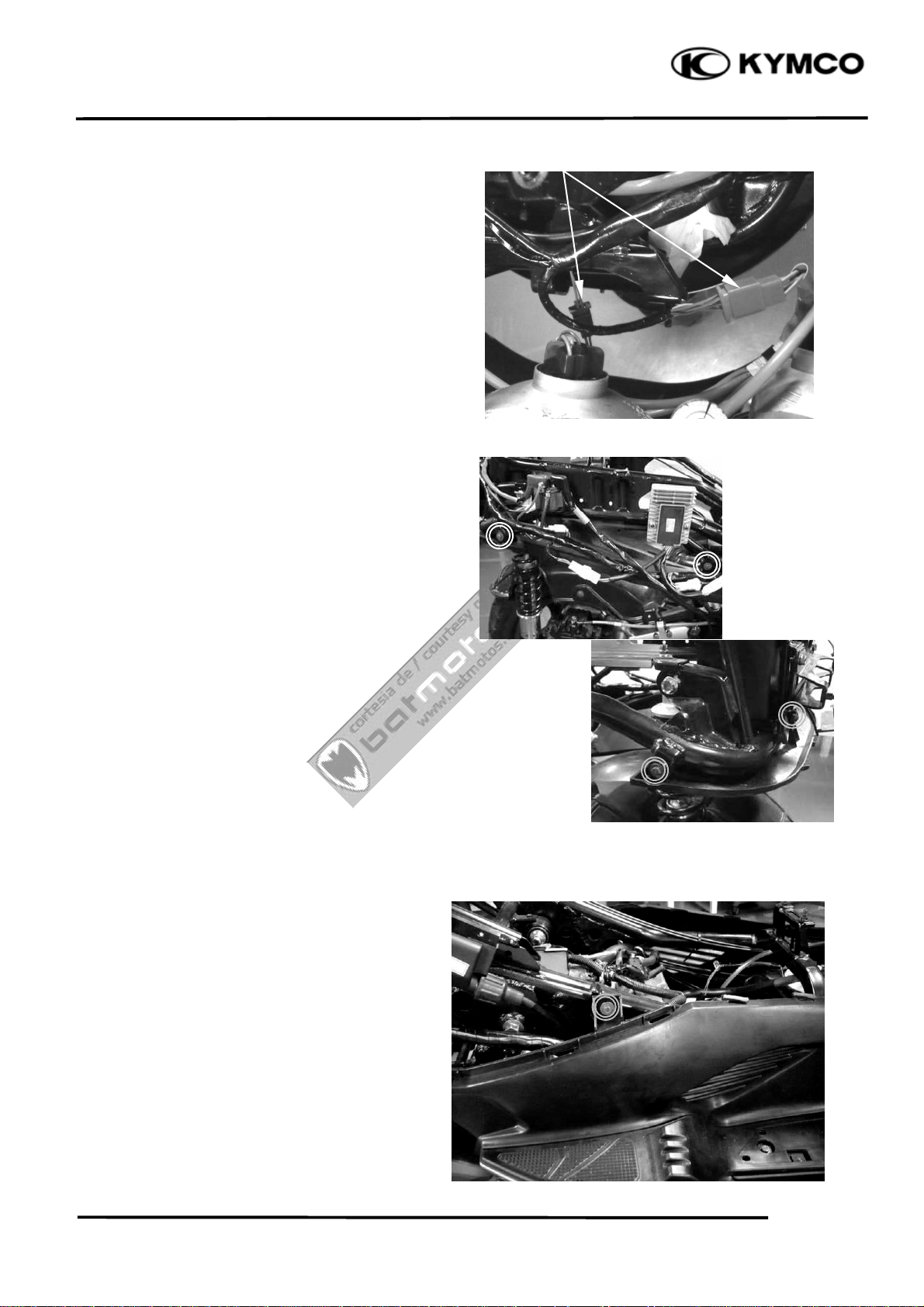

Remove the fuel tank cap cover.

Installation is in the reverse order of removal.

Speedometer Wires

METER PANEL

DOWNTOWN 125i

Disconnect the speedometer wires.

Disconnect the DC power connectors.

Remove one screws

Remove the ignition key garnish

Remove three screws from the inner cover,

then remove the handler panel.

Installation is in the reverse order of removal.

DC power Connectors

2-12

Page 30

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

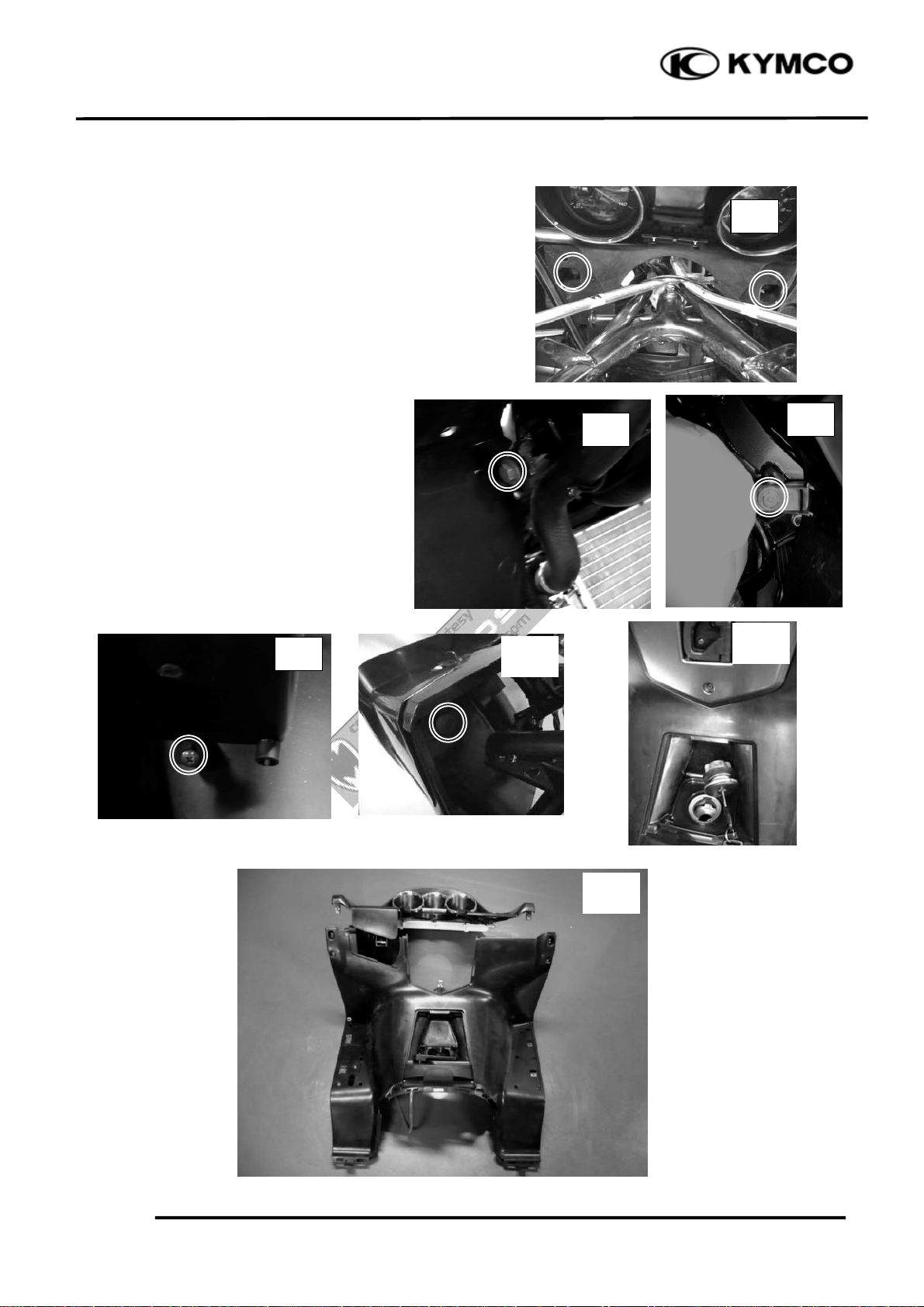

INNER COVER

Remove the front cover .

Remove the front lower cover .

Remove the floorboard

Remove four bolts and front glove box one

screw.

DOWNTOWN 125i

(1)

Remove two fastener bolts then remove

the fuel tank fill cap.

Remove the inner cover

(3)

(4)

(2)

(2)

(5)

2-13

(6)

Page 31

2

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

EXHAUST MUFFLER

REMOVAL

Disconnect the O2 heater/O2 sensor

connector .

Remove the two exhaust pipe joint nuts

DOWNTOWN 125i

Remove three muffler mount bolts and

muffler and gasket.

2-14

Page 32

2

t

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. EXHAUST MUFFLER/FRAME COVERS

INSTALLATION

Replace the gasket with a new one.

Install the exhaust muffler and three

mounting bolt.

Install and tighten the two exhaust pipe joint

nuts to the specified torque

Torque: 20 N•m (2 kgf•m,)

Tighten the three mounting bolts

DOWNTOWN 125i

Torque: 35 N•m (3.5 kgf•m,)

Remove the coolant tank cover.

Gaske

2-15

Page 33

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

DOWNTOWN 125i

3

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

INSPECTION/ADJUSTMENT

3

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 3- 1

MAINTENANCE SCHEDULE-------------------------------------------- 3- 2

FUEL LINE------------------------------------------------------------------- 3- 4

THROTTLE OPERATION------------------------------------------------- 3- 4

ENGINE OIL ----------------------------------------------------------------- 3- 5

TRANSMISSION OIL ------------------------------------------------------ 3-11

AIR CLEANER -------------------------------------------------------------- 3-12

SPARK PLUG---------------------------------------------------------------- 3-13

VALVE CLEARANCE ----------------------------------------------------- 3-14

IDLE SPEED ----------------------------------------------------------------- 3-15

CYLINDER COMPRESSION --------------------------------------------- 3-16

DRIVE BELT ---------------------------------------------------------------- 3-16

CLUTCH SHOE WEAR---------------------------------------------------- 3-17

HEADLIGHT AIM ---------------------------------------------------------- 3-17

COOLANT ------------------------------------------------------------------- 3-18

BRAKE FLUID -------------------------------------------------------------- 3-19

BRAKE PAD WEAR ------------------------------------------------------- 3-19

NUTS/BOLTS/FASTENERS ---------------------------------------------- 3-20

WHEELS/TIRES ------------------------------------------------------------ 3-20

SUSPENSION---------------------------------------------------------------- 3-21

SIDE STAND ---------------------------------------------------------------- 3-22

3-0

Page 34

3

g

y

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

DOWNTOWN 125i

SERVICE INFORMATION

GENERAL

! WARNING

•Before running the engine, make sure that the working area is well-ventilated.

Never run the en

ine in a closed area. The exhaust contains poisonous carbon

monoxide gas which may cause death to people.

•Gasoline is extremel

flammable and is explosive under some conditions. The

working area must be well-ventilated and do not smoke or allow flames or

sparks near the working area or fuel storage area.

SPECIFICATIONS

Throttle grip free play : 2~6 mm

Spark plug : DINK 125: NGK: DPR7EA9

: DOWNTOWN125 i: NGK CR7E

Spark plug gap : 0.6~0.7 mm

Valve clearance : IN: 0.1 mm EX: 0.1 mm

Idle speed : 1850 rpm

Cylinder compression : 15 kg/cm²

Engine oil capacity:

At disassembly : 1.2L

At change : 1.0L

Gear oil capacity :

At disassembly : 0.13L

At change : 0.12L

Coolant capacity :

Reserve tank capacity: 0.49 liter

Radiator capacity : 0.87 liter

Ignition timing : ECU control

TIRE

1 Rider (75 kg) 2 Riders (150 kg)

Front 2.0 kgf/cm² 2.00 kgf/cm²

Rear 2.25 kgf/cm² 2.25 kgf/cm²

TIRE SPECIFICATION:

Front :120/80-14

Rear : 150/70-13

3-1

Page 35

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

TORQUE VALUES

Front axle : 2.0 kgf-m

Rear axle nut : 12 kgf-m

DOWNTOWN 125i

MAINTENANCE SCHEDULE

Perform the pre-ride inspection at each scheduled maintenance period.

This interval should be judged by odometer reading or months, whichever comes first.

I: INSPECT AND CLEAN, ADJUST, LUBRICATE OR REPLACE IF NECESSARY

C: CLEAN R: REPLACE A: ADJUST L: LUBRICATE

The following maintenance schedule specifies all maintenance required to keep your scooter in

peak operating condition. Maintenance work should be performed in accordance with standards

and specifications of KYMCO by properly trained and equipped technicians. Your KYMCO dealer

meets all of these requirements.

*Should be serviced by your KYMCO dealer, unless the owner has the proper tools and service

data and is mechanically qualified.

**In the interest of safety, we recommend these items be serviced only by your KYMCO dealer.

KYMCO recommends that your KYMCO dealer should road test your scooter after each

periodic maintenance is carried out.

3-2

Page 36

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

MAINTENANCE SCHEDULE

DOWNTOWN 125i

FREQUENCY

ITEM MONTH

AIR CLEANER

THROTTLE OPERATION

VALVE CLEARANCE

FUEL LINE

CRANKCASE BREATHER

ENGINE OIL

ENGINE OIL FILTER

ENGINE IDLE SPEED

TRANSMISSION OIL

DRIVE BELT

OIL STRAINER SCREEN

WHICHEVER

COMES

FIRST

X 1000 km

X 1000 mi

ODOMET E R READING

5

1

0.6

1

C

RRRR

10 15 20 25 30

36

I

I

I

I

RRR

RRR

I

912

126

R

I

I

IIII

AAA

I

CCCCCC

CC

RRR

III

I

I

R

R

II

I

15 18

302418

36

RR

RRR

RRRSPARK PLUGS

RI

I

RRRR

I

II

REFER

TO

PAGE

FREQUENCY

ITEM

CLUTCH SHOE WEAR

BRAKE FLUID

BRAKE PAD WEAR

BRAKE SYS T EM

BRAKE LIG HT SW ITCH

STEERING BEARINGS

HEADLIGHT AIM

NUTS, BOLTS, FASTENERS

WHEELS/TIRES

WHICHEVER

COMES

FIRST

X 1000 km

X 1000 mi

NOTE MONTH

ODOMETER READING [NOTE (1)]

5

1

0.6 3 6 9 12 15 18

1

10 15 20 25 30

126

I

I

III

I

R

IIII

II

IIIIII

IIIIII

IIIIII

IIIIII

III

302418

36

II

R

I

R

II

I

III

REFER

TO

PAGE

3-3

Page 37

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

FUEL LINE

Check the fuel lines and replace any parts which

show signs of deterioration, damage or leakage.

THROTTLE OPERATION

DOWNTOWN 125i

Check the throttle grip for smooth movement.

Measure the throttle grip free play.

Free Play: 2~6 mm

Major adjustment of the throttle grip free play is

made with the adjusting nut at the throttle body

side. Adjust by loosening the lock nut and

turning the adjusting nut.

3-4

Page 38

3

S

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

Minor adjustment is made with the adjusting

nut at the throttle grip side.

Slide the rubber cover (1) out and adjust by

loosening the lock nut (3) and turning the

adjusting nut (2).

(Chart)

ENGINE OIL VIS C OSITIE

20W-40 , 20W-50

20W-40, 20W-50

15W-40 , 15W-50

15W-40, 15W-50

10W-40

10W-40

10W-30

10W-30

20W-40 , 20W-50

5W-50

-10 0 10 20 30 40 C

0 20 40 60 80 100 F

0

0

ENGINE OIL

DOWNTOWN 125i

Engine oil recommendation

Use a premium quality 4-stroke motor oil to

ensure longer service life of your scooter. Use

only oils which are rated, SJ under the API

service classification. The recommended

viscosity is SAE 15W-40. If a SAE 15W-40

motor oil is not available, select an alternative

according to the chart.

Engine oil capacity:

At disassembly:

1.2 L (0.968 lmp qt, 1.166 US qt)

At change:

1.0 L

Engine oil level check

2. Stop the engine and put the scooter on its

center stand on level ground.

3. After a few minutes, remove the oil filler

cap/dipstick, wipe it clean, and reinsert the

oil filler cap/dipstick without screwing it

in. Remove the oil filler cap/dipstick. The

oil level should be between the upper and

lower marks on the oil filler cap/dipstick.

4. If required, add the specified oil up to the

upper level mark. Do not overfill.

5. Reinstall the oil filler cap/dipstick. Check

for oil leaks.

*

Let the engine and exhaust system cool

before working in those areas.

Check the engine oil level each day before

riding the scooter.

The level must be maintained between the

upper and lower level marks on the oil filler

cap/dipstick.

1. Start the engine and let it idle for a few

minutes.

3-5

Page 39

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

Engine oil replacement

Engine oil quality is the chief factor affecting

engine service life. Change the engine oil as

specified in the maintenance schedule.

When running in very dusty conditions, oil

changes should be performed more frequently

than specified in the maintenance schedule.

Please dispose of used engine oil in a manner

that is compatible with the environment. We

suggest you take it in a sealed container to

your local recycling center or service station

for reclamation. Do not throw it in the trash

or pour it on the ground or down a drain.

Used engine oil may cause skin cancer if

repeatedly left in contact with the skin for

prolonged periods. Although this is unlikely

unless you handle used oil on a daily basis, it

is still advisable to thoroughly wash your

hands with soap and water as soon as possible

after handling used oil.

DOWNTOWN 125i

Change the engine oil with the engine at

normal operating temperature and the scooter

on its center stand to assure complete and

rapid draining.

3-6

Page 40

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

1. Remove the oil filler cap/dipstick(1)

from the right crankcase cover.

2. Place a container under the left crankcase.

3. Remove the oil drain plug (2) to drain the

oil.

4. Reinstall the drain plug and tighten the

drain plug to specification.

Oil drain plug torque:

25 N-m (2.5 kgf-m,)

5. Fill the crankcase with the recommended

grade oil and install the oil filler cap.

Oil capacity (after draining):

1.0 L(0.95 US qt, 0.8 lmp qt)

6. Start the engine and let it idle for 2-3

minutes.

7. Stop the engine and check that the oil level

is at the upper level mark on the oil filler

cap/dipstick with the scooter upright on

firm, level ground. Make sure there are no

oil leaks.

DOWNTOWN 125i

(1)

*

Let the engine and exhaust system cool

before working in those areas.

(2)

3-7

Page 41

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

Oil strainer screen clean

Change the engine oil with the engine at

normal operating temperature and the scooter

on its center stand to assure complete and

rapid draining.

*

Let the engine and exhaust system cool

before working in those areas.

1. Remove the oil filler cap/dipstick (1) from

the right crankcase cover.

2. Place a drain pan under the crankcase and

remove the oil strainer screen cap (2).

The spring (3) and oil strainer screen (4)

will come out when the drain plug is

removed.

Let the engine oil drain out.

3. Clean the oil strainer screen.

4. Check that the oil strainer screen, sealing

rubber and drain plug O-ring are in good

condition.

5. Install the oil strainer screen, spring and oil

strainer screen cap.

DOWNTOWN 125i

(1)

Oil strainer screen cap torque:

15N-m (1.5 kgf-m)

6. Fill the crankcase with the recommended

grade oil and install the oil strainer screen

cap.

Oil capacity (after draining):

1.0 L

7. Start the engine and let it idle for 2-3

minutes.

8. Stop the engine and check that the oil level

is at the upper level mark on the oil filler

cap/dipstick with the scooter upright on

firm, level ground. Make sure there are no

oil leaks.

3-8

Page 42

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

Oil filter replacement

Change the engine oil with the engine at

normal operating temperature and the scooter

on its center stand to assure complete and

rapid draining.

*

Let the engine and exhaust system cool

before working in those areas.

1. Remove the oil filler cap/dipstick (1) from

the right crankcase cover.

2. Place a drain pan under the crankcase.

Remove three bolts and then remove the

oil filter cap (2) and O-ring (3).

The spring (4) will come out when the

filter cap is removed.

Let the engine oil drain out.

DOWNTOWN 125i

(1)

3. Remove and discard the oil filter (5).

*

Do not remain the rubber seal on the oil

filter in the oil filter housing.

4. Check that the O-ring is in good condition.

(2)

3-9

Page 43

3

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

5. Install the new oil filter.

*

Make sure the rubber seal on the oil filte

facing the left crankcase.

6. Install the spring, O-ring and cap.

Torque:

12 N-m (1.2 kgf-m)

DOWNTOWN 125i

Rubber Seal

7. Fill the crankcase with the recommended

grade oil and install the oil filler cap.

Oil capacity (after draining):

1.0 L

8. Start the engine and let it idle for 2-3

minutes.

9. Stop the engine and check that the oil level

is at the upper level mark on the oil filler

cap/dipstick with the scooter upright on

firm, level ground. Make sure there are no

oil leaks.

3-10

Page 44

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

TRANSMISSION OIL

Oil change

1. Place the scooter in its center stand.

2. Place a drain pan under the drain bolt (1).

3. Remove the transmission oil drain bolt.

4. Remove the transmission oil filler bolt (2),

slowly turn the rear wheel and drain the

oil.

After draining the oil completely, install

the oil drain bolt with a new sealing

washer and tighten it.

Torque: 13 N-m (1.3 kgf-m)

DOWNTOWN 125i

(1)

5. Fill the transmission case with

recommended oil.

Recommended transmission oil: SAE 90

Oil capacity (at draining):

0.12 L

6. Install the transmission oil filler bolt with a

new sealing washer and tighten it.

Torque: 13 N-m (1.3 kgf-m)

(2)

3-11

Page 45

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

AIR CLEANER

The air cleaner should be serviced at regular

intervals. Service more frequently when

riding in unusually wet or dusty areas.

Air cleaner element replacement

1. Remove the screws from the air cleaner

cover , then remove air cleaner cover.

2. Remove screws from the air cleaner

element , then remove and discard this air

cleaner element.

4. The new air cleaner element installation is

in the reverse order of removal.

DOWNTOWN 125i

Use the KYMCO genuine air cleaner element

or an equivalent air cleaner element specified

for your model. Using the wrong KYMCO air

cleaner element or a non-KYMCO air cleaner

element which is not of equivalent quality

may cause premature engine wear or

performance problems.

1. Remove the band (1).

3-12

Page 46

3

k

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

SPARK PLUG

Remove the spark plug cap and spark plug

Check the spark plug for wear and fouling

deposits.

Clean any fouling deposits with a spark plug

cleaner or a wire brush.

Specified Spark Plug:

NGK CR7E

Measure the spark plug gap.

Spark Plug Gap: 0.6~0.7 mm

DOWNTOWN 125i

Cracks

Damage

Deformation

*

When installing, first screw in the spar

plug by hand and then tighten it with a

spark plug wrench.

Torque: 0.9 kgf-m (9 N-m)

Gap

Wear

Fouling

Deposits

}

0.6~0.7mm

3-13

Page 47

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

VALVE CLEARANCE

*

• Inspect and adjust valve clearance

while the engine is cold (below 35℃).

Remove the four bolts , then remove cylinder

head cover.

Remove the timing hole cap and O-ring

Remove the crankshaft hole cap and O-ring .

DOWNTOWN 125i

Timing hole cap

Turn the A.C. generator flywheel to the top

dead center (TDC) on the compression stroke

so that the “T” mark on the flywheel aligns

with the index mark on the left crankcase

cover.

The punch mark on the camshaft should face

upward as shown.

If the punch mark on the camshaft are facing

downward, turn the crankshaft one full turn

(180°) and the punch mark are facing upward.

Crankshaft hole cap

Punch Mark

3-14

Page 48

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

Adjust by loosening the valve adjusting screw

lock-nut and turning the adjusting screw

until there is a slight drag on the thickness

gauge .

Valve Clearance: IN: 0.1 mm

EX:0.1 mm

Apply oil to the valve adjusting screw locknut threads and seating surface.

Hold the adjusting screw and tighten the lock

nut to the specified torque.

Torque: 0.9 kgf-m (9 N-m)

Special tool:

Valve adjuster A120E00036

DOWNTOWN 125i

After tightening the lock-nut, recheck the

valve clearance.

Install the removed parts in the reverse order

of removal.

IDLE SPEED

*

● It is not necessary to adjust idle speed

for DOWNTOWN125i. The throttle

body is factory preset originally, do not

loosen or tighten the painted bolts and

screws of throttle body. Loosening or

tightening them can cause throttle a idle

and valve with failure.

Warm up the engine before this operation.

Start the engine and connect a tachometer.

Turn the throttle stop screw (1) to obtain the

specified idle speed.

Idle Speed:

DINK 125: 1700 rpm

DOWNTOWN125i: 1850 rpm

When the engine misses or run erratic, adjust

the pilot screw (2).

3-15

Page 49

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

CYLINDER COMPRESSION

Warm up the engine before compression test.

Remove the center cover and spark plug cap.

Remove the spark plug .

Insert a compression gauge.

Open the throttle valve fully and push the

starter button to test the compression.

Compression:

Downtown125i:15 kg/cm²

If the compression is low, check for the

following:

‧Leaky valves

‧Valve clearance too small

‧Leaking cylinder head gasket

‧Worn pistons

‧Worn piston/cylinder

If the compression is high, it indicates that

carbon deposits have accumulated on the

combustion chamber and the piston head.

DOWNTOWN 125i

DRIVE BELT

Remove the left crankcase cover.

Inspect the drive belt

for cracks or excessive wear.

Replace the drive belt with a new

one if necessary and in accordance

with the Maintenance Schedule.

3-16

Page 50

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

CLUTCH SHOE WEAR

Start the engine and check the clutch

operation by increasing the engine speed

gradually.

If the scooter tends to creep, or the engine

stalls, check the clutch shoes for wear and

replace if necessary (refer to the “DRIVE

PULLEY, DRIVE BELT AND DRIVEN

PULLEY” section in the chapter 8).

DOWNTOWN 125i

HEADLIGHT AIM

Remove the front cover

Place the scooter on a level surface

Adjust the headlight beam adjuster.

A clockwise rotation moves the beam up

and counterclockwise rotation moves the

beam down.

Adjust the headlight beam horizontally by

turning the horizontal beam adjuster.

A clockwise rotation moves the beam toward

the right side of the rider.

Horizontally Adjusting Screw

Vertically Adjusting Screw

3-17

Page 51

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

COOLANT

Inspection

The reserve tank is under left foot board.

Check the coolant level through the

inspection window (1) at the front lower

cover while the engine is at the normal

operating temperature with the scooter in an

upright position. If the coolant level is below

the LOWER level mark (3), remove screw (4)

and reserve tank lid (5) and reserve tank cap

(6) and add coolant mixture until it reaches

the upper level mark (2).

Always add coolant to the reserve tank. Do

not attempt to add coolant by removing the

radiator cap.

If the reserve tank is empty, or if coolant loss

is excessive, check for leaks and see your

KYMCO dealer for repair.

DOWNTOWN 125i

3-18

Page 52

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

BRAKE FLUID

Brake fluid level

With the scooter in an upright position, check

the front and rear fluid level. It should be

above the lower level mark. If the level is at

or below the lower level mark "L", check the

brake pads for wear.

Worn pads should be replaced. If the pads are

not worn, have your brake system inspected

for leaks.

The recommended brake fluid is DOT 4

brake fluid from a sealed container, or an

equivalent.

Other checks

Make sure there are no fluid leaks. Check for

deterioration or cracks in the hoses and

fittings.

DOWNTOWN 125i

Front brake

BRAKE PAD WEAR

Brake pad wear depends upon the severity of

usage, the type of riding, and road conditions.

(Generally, the pads will wear faster on wet

and dirty roads.) Inspect the pads at each

regular maintenance interval.

Front brake /Rear brake

Check the cutout in each pad.

If either pad is worn to the cutout, replace

both pads as a set. See your KYMCO dealer

for this service.

Rear brake

3-19

Page 53

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

NUTS/BOLTS/FASTENERS

Check all important chassis nuts and bolts for

looseness.

Tighten them to their specified torque values

if any looseness is found.

WHEELS/TIRES

Tire pressure

Insufficient air pressure in the tires not only

hastens tire wear but also seriously affects the

stability of the scooter. Under inflated tires

make smooth cornering difficult and

overinflated tires decrease the amount of tire

in contact with the ground which can lead to

skids and loss of control. Be sure that the tire

pressure is within the specified limits at all

times. Tire pressure should only be adjusted

when the tires are cold.

DOWNTOWN 125i

Cold inflation tire pressure

1 Rider (75 kg) 2 Riders (150 kg)

2.0kg/cm² 2.25 kg/cm²

Front

2.0kg/cm² 2.25 kg/cm²

Rear

3-20

Page 54

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

SUSPENSION

Check the action of the front/rear shock

absorbers by compressing them several times.

Check the entire shock absorber assembly for

oil leaks, looseness or damage.

Jack the rear wheel off the ground and move

the rear wheel sideways with force to see if

the engine hanger bushings are worn.

Replace the engine hanger bushings if there is

any looseness.

DOWNTOWN 125i

Rear suspension adjustment

3-21

Page 55

3

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. INSPECTION/ADJUSTMENT

SIDE STAND

Perform the following maintenance in

accordance with the maintenance schedule.

Functional check

Check the spring for damage or loss of

tension and the side stand assembly for

freedom of movement.

Check the side stand ignition cut-off system:

DOWNTOWN 125i

1. Place the scooter on its center stand.

2. Put the side stand up and start the engine.

3. Lower the side stand. The engine should

stop as you put the side stand down.

If the side stand system does not operate as

described, see your KYMCO dealer for

service.

Side stand up

Side stand down

3-22

Page 56

4

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. LUBRICATION SYSTEM

DOWNTOWN 125i

4

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

4

LUBRICATION SYSTEM

__________________________________________________________________________________

LUBRICATION SYSTEM DIAGRAM---------------------------------- 4-1

SERVICE INFORMATION------------------------------------------------ 4-2

TROUBLESHOOTING----------------------------------------------------- 4-2

OIL PUMP ------------------------------------------------------------------- 4-3

4-0

Page 57

4

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. LUBRICATION SYSTEM

LUBRICATION SYSTEM DIAGRAM

Rocker Arm Shaft

DOWNTOWN 125i

4-1

Crankshaft

Oil Straine

Screen

Oil Pump

Oil Filter Screen

Page 58

4

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. LUBRICATION SYSTEM

DOWNTOWN 125i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The maintenance of lubrication system can be performed with the engine installed in the frame.

• Drain the coolant before starting any operations.

• Be careful when removing and installing the oil pump not to allow dust and foreign matters to

enter the engine and oil line.

• Do not attempt to disassemble the oil pump. The oil pump must be replaced as a set when it

reaches its service limit.

• After the oil pump is installed, check each part for oil leaks.

SPECIFICATIONS Unit: mm

Standard

Inner rotor-to-outer rotor clearance 0.15

Outer rotor-to-pump body clearance 0.15~0.2

Rotor end-to-pump body clearance 0.04~0.09

ENGINE OIL

Engine Oil Capacity

Recommended Oil SAE15W40 API: SJ

At disassembly: 1.2 liter

At change: 1.0 liter

TROUBLESHOOTING

Oil level too low Poor lubrication pressure

• Natural oil consumption • Oil level too low

• Oil leaks • Clogged oil filter or oil passage

• Worn piston rings • Faulty oil pump

• Worn valve guide

• Worn valve guide seal

Oil contamination

• Oil not changed often enough

• Faulty cylinder head gasket

• Loose cylinder head bolts

4-2

Page 59

4

r

t

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. LUBRICATION SYSTEM

OIL PUMP

DOWNTOWN 125i

REMOVAL

Remove the flywheel and driven gear (refer

to the “STARTER CLUTCH” section in the

chapter 10).

Remove the bolt and then oil separator cover.

*

When removing and installing the oil

pump, be careful not to allow dust or dirt

to enter the engine.

Pry the snap ring off and remove the oil pump

driven gear, then remove the oil pump drive

chain.

Bolts

Oil Separator Cove

Remove the two oil separator bolts to remove

the oil pump.

4-3

Snap Ring

Oil Separator Bol

Oil Pump Driven Gea

Oil Pump

Page 60

4

p

r

r

t

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. LUBRICATION SYSTEM

DOWNTOWN 125i

INSTALLATION

Install the oil pump and oil separator and

tighten the two bolts.

The arrow mark must be keep upward.

*

Make sure the pump shaft rotates freely

and arrow on the oil pump is upside.

Install the pump drive chain and driven gear,

then set the snap ring securely on the pump

shaft.

Arrow Mark

Oil Separato

Pump Drive Chain Snap Ring

Bolts

Snap Ring

Install the oil separator cover properly.

*

Fit the tab of the separator cover into the

slit in the separator.

Pump Driven Gea

Oil Se

arator Cove

Bol

4-4

Page 61

4

r

r

r

t

r

r

t

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. LUBRICATION SYSTEM

DISASSEMBLY

Remove the screw and disassemble the oil

pump as shown.

Pump Cove

DOWNTOWN 125i

Outer Roto

Screw

ASSEMBLY

Inner Roto

Pump Body

Dowel Pin

Pump Shaf

Install the outer rotor, inner rotor and pump

shaft into the pump body.

*

Insert the pump shaft by aligning the flat

on the shaft with the flat in the inner

rotor. Install the dowel pin.

There is one punch mark on the surface of the

inner rotor and outer rotor.

The mark is upside.

4-5

Dowel Pin

Outer Roto

Inner Roto

Pump Body

Pump Shaf

Page 62

5

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. ENGINE REMOVAL/INSTALLATION

DOWNTOWN 125i

5

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

5

ENGINE REMOVAL/INSTALLATION

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 5-1

ENGINE REMOVAL/INSTALLATION--------------------------------- 5-2

ENGINE HANGER --------------------------------------------------------- 5-8

5-0

Page 63

5. ENGINE REMOVAL/INSTALLATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

DOWNTOWN 125i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• A floor jack or other adjustable support is required to support and maneuver the engine. Be

careful not to damage the scooter body, cables and wires during engine removal.

• Use shop towels to protect the scooter body during engine removal.

• Drain the coolant before removing the engine.

• After the engine is installed, fill the cooling system with coolant and be sure to bleed air from the

water jacket. Start the engine to check for coolant leaks.

• Before removing the engine, the rear brake caliper must be removed first. Be careful not to bend

or twist the brake fluid tube.

SPECIFICATIONS

Engine oil capacity: at disassembly: 1.2 L ( 1.27 US qt)

: at change: 1.0 L ( 1.06 US qt)

Coolant capacity:

Radiator capacity : 0.87 liter

Reserve tank capacity : 0.49 liter

TORQUE VALUES

Engine hanger (Engine side) 5 kgf-m (50 N-m)

Engine hanger (Frame side) 6.5 kgf-m (65 N-m)

5-1

Page 64

5

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. ENGINE REMOVAL/INSTALLATION

ENGINE

REMOVAL/INSTALLATION

REMOVAL

Remove the air cleaner

Disconnect the ECU connector (A)

Disconnect the O2 heater/O2 sensor

connector

Disconnect the throttle cable(B)

DOWNTOWN 125i

(A)

*

Remove a bolt from fuel hose guide (C).

Disconnect the fuel hose (D) from fuel

injector.

Disconnect the WTS connector (E) from

WTS.

Disconnect the coolant temperature

sensor connector (F) from coolant

temperature sensor.

Disconnect the fuel injector connector(G)

Disconnect the output water hose(H)

Disconnect the air bleed hose(I)

(B)

(G)

(C) (D) (E) (F)

(I)

(H)

5-2

Page 65

5. ENGINE REMOVAL/INSTALLATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

Loosen the rear axle nut.

Support the scooter securely on its main

stand.

Remove three bolts (1) attaching to rear brake

hose clamps.

Remove the two bolts (2), then remove the

rear brake caliper.

DOWNTOWN 125i

(1)(2)

Disconnect the alternator connector (3).

Disconnect the ignition pulse generator

connector (4).

Release the rubber cap and remove the

terminal screw (5) to disconnect the start

motor cable from the start motor.

(4) (3)

(5)

5-3

Page 66

5

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. ENGINE REMOVAL/INSTALLATION

Remove the bolts and engine

ground cable.

DOWNTOWN 125i

Remove the two nuts (7), then remove the

intake manifold from cylinder head.

Remove the bolt (8), then remove the

thermostat from cylinder head.

Remove the spark plug cap .

5-4

Page 67

5. ENGINE REMOVAL/INSTALLATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

Disconnect the lower radiator hose from

lower radiator pipe.

DOWNTOWN 125i

Remove the right and left rear shock absorber

lower mount bolts .

5-5

Page 68

5

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. ENGINE REMOVAL/INSTALLATION

Remove the engine mount nut

Pull out the engine mount bolt.

Remove the engine from the frame.

DOWNTOWN 125i

*

At removing the engine, be careful not to

catch your hand or finger between the

engine hanger and crankcase.

5-6

Page 69

5. ENGINE REMOVAL/INSTALLATION

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

INSTALLATION

Installation is in the reverse order of removal.

Tighten the engine mounting bolt/nut to the

specified torque.

Torque: 5 kgf-m (50 N-m)

Tighten the right and left rear shock absorber

lower mount bolts to the specified torque.

Torque: 4.0kgf-m (40N-m)

Install the rear brake caliper and tighten the

mount bolts to the specified torque.

Torque: 3.2 kgf-m (32 N-m, 23 lbf-ft)

DOWNTOWN 125i

After installation, inspect and adjust the

following:

• Throttle grip free play

• Fill the cooling system with coolant and

start the engine to bleed air from the system.

API/ABV Reset(Refer to chapter14 page 17)

5-7

Page 70

5

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. ENGINE REMOVAL/INSTALLATION

ENGINE HANGER

REMOVAL

Remove the engine mount nut .

Pull the engine mount bolt out.

*

Be careful to put the engine down.

Remove the left engine hanger mount bolt .

Remove the right engine hanger mount bolt

and collar .

Remove the engine from frame.

INSTALLATION

Installation is in the reverse order of removal.

DOWNTOWN 125i

Tighten the engine hanger mount bolts to the

specified torque.(engine side)

Torque: 5 kgf-m (50 N-m)

Tighten the engine mount bolt/nut to the

specified torque. (frame side)

Torque: 5 kgf-m (50 N-m, 36 lbf-ft)

5-8

Page 71

6

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

DOWNTOWN 125i

6 .

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

CYLINDER HEAD/VALVES

__________________________________________________________________________________

SCHEMATIC DRAWING ------------------------------------------------- 6- 1

SERVICE INFORMATION------------------------------------------------ 6- 2

TROUBLESHOOTING----------------------------------------------------- 6- 3

CYLINDER HEAD COVER----------------------------------------------- 6- 4

CAMSHAFT HOLDER----------------------------------------------------- 6- 5

CAMSHAFT ----------------------------------------------------------------- 6- 8

CYLINDER HEAD---------------------------------------------------------- 6- 13

6

6-0

Page 72

6

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

SCHEMATIC DRAWING

DOWNTOWN 125i

6-1

Page 73

6

m

d

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

DOWNTOWN 125i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The cylinder head can be serviced with the engine installed in the frame. Coolant in the radiator

and water jacket must be drained first.

• When assembling, apply molybdenum disulfide grease or engine oil to the valve guide movable

parts and valve arm sliding surfaces for initial lubrication.

• The valve rocker arms are lubricated by engine oil through the cylinder head engine oil passages.

Clean and unclog the oil passages before assembling the cylinder head.

• After disassembly, clean the removed parts and dry them with compressed air before inspection.

• After removal, mark and arrange the removed parts in order. When assembling, install them in

the reverse order of removal.

SPECIFICATIONS

Ite

Valve clearance (cold)

Cylinder head compression pressure

Cylinder head warpage ⎯

Camshaft cam height EX 25.810

Valve rocker arm I.D.

Valve rocker arm shaft IN 9.972~9.987

O.D. EX 9.972~9.987

Valve stem O.D.

Valve guide I.D.

Valve stem-to-guide IN 0.010~0.037

clearance EX 0.030~0.057

IN 0.1

EX 0.1

15kg/cm²

IN 25.965

IN 10.0~10.015

EX 10.0~10.015

IN 4.975~4.970

EX 4.975~4.970

IN 5.0~5.012

EX 5.0~5.012

Standar

Unit: mm

TORQUE VALUES

Cylinder head cover bolt 0.8~0.9 kgf-m

Tensioner mounting bolt 0.9 kgf-m

Tensioner sealing bolt 0.9 kgf-m

Cylinder head cap nut 2 kgf-m

Cylinder head bolt 0.7~1.1 kgf-m

Apply engine oil to threads

6-2

Page 74

6

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

SPECIAL TOOLS

Valve spring compressor A120E00040

DOWNTOWN 125i

TROUBLESHOOTING

• The poor cylinder head operation can be diagnosed by a compression test or by tracing engine

Poor performance at idle speed White smoke from exhaust muffler

• Compression too low • Worn valve stem or valve guide

• Damaged valve stem oil seal

Compression too low

• Incorrect valve clearance adjustment Abnormal noise

• Burned or bend valves • Incorrect valve clearance adjustment

• Incorrect valve timing • Sticking valve or broken valve spring

• Broken valve spring • Damaged or worn camshaft

• Poor valve and seat contact • Worn cam chain tensioner

• Leaking cylinder head gasket • Worn camshaft and rocker arm

• Warped or cracked cylinder head

• Poorly installed spark plug

Compression too high

• Excessive carbon build-up in combustion

chamber

6-3

Page 75

6

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

CYLINDER HEAD COVER

REMOVAL

Remove four bolts then remove the cylinder

head cover.

DOWNTOWN 125i

INSTALLATION

Install a new cylinder head cover O-ring and

install the cylinder head cover.

*

Be sure to install the O-ring into the

groove properly.

Install and tighten the cylinder head cover

bolts to the specified torque in a crisscross

pattern.

Torque: 0.8~0.9kgf-m

6-4

Page 76

6

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

CAMSHAFT HOLDER

REMOVAL

Turn the A.C. generator flywheel so that the

T mark on the flywheel aligns with the index

mark on the crankcase.

Hold the round hole on the camshaft gear

facing up and location is the top dead center

on the compression stroke.

Remove two bolts attaching cam chain

tensioner.

Remove four nuts of camshaft holder and

remove the sprocket fixed nut then remove

the sprocket.

DOWNTOWN 125i

Remove the camshaft gear bolt.

INSTALLATION

Install the camshaft gear bolt and holder

washers and nuts.

Tighten four cylinder head nuts to the

specified torque.

Torque:

0.7~1.1 kgf-m (Holder nuts)

1.0~1.4 kgf-m (Cam shaft set plate)

1.8~2.2 kgf-m (Cylinder head M8X1.25)

*

• Install the camshaft holder with the

“EX” mark face exhaust valve side.

• Apply engine oil to the threads of the

cylinder head cap nuts.

• Diagonally tighten the cylinder head

nuts in 2~3 times.

6-5

Page 77

6

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

DISASSEMBLY

Take out the valve rocker arm shafts

Remove the valve rocker arms.

INSPECTION

DOWNTOWN 125i

Rocker Arm Shafts

Camshaft Holde

Inspect the camshaft holder, valve rocker

arms and rocker arm shafts for wear or

damage.

*

If the valve rocker arm contact surface is

worn, check each cam lobe for wear or

damage.

Inspect the rocker arm bore, cam lobe contact

surface and adjuster surface for

wear/pitting/scratches/blue discoloration.

Rocker Arm Shafts

Rocker Arm Bore

If any defects are found, replace the rocker

arm shaft with a new one, then inspect

lubrication system.

Contact SurfaceAdjuster Surface

6-6

Page 78

6

m

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

ASSEMBLY

Apply engine oil to the rocker arms and

rocker arm shafts.

Install the rocker arms and shafts into the

camshaft holder.

• Install the exhaust valve rocker ar

shaft on the “EX” side of the camshaft

holder

• Clean the intake valve rocker arm shaft

off any grease before installation.

DOWNTOWN 125i

Rocker Arm Shafts

6-7

Page 79

6

t

t

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

CAMSHAFT

REMOVAL

Turn the A.C. generator flywheel so that the

“T” mark on the flywheel aligns with the

index mark on the crankcase.

Hold the round hole on the camshaft gear

facing up and the location is the top dead

center on the compression stroke.

Remove the tensioner sealing bolt and spring.

Remove the two bolts from cam chain

tensioner and then remove the tensioner and

gasket.

DOWNTOWN 125i

Tensioner Sealing Bol

Round Hole

Remove the camshaft gear and bolt.

Remove the camshaft from the cylinder head

Camshaf

6-8

Page 80

6

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

INSPECTION

Camshaft

Inspect camshaft lobes for

pitting/scratches/blue discoloration.

If any defects are found, replace the camshaft

with a new one, then inspect lubrication

system.

DOWNTOWN 125i

Camshaft Bearings

Check each camshaft bearing for play or

damage. Replace the camshaft assembly with

a new one if the bearings are noisy or have

excessive play.

6-9

Page 81

6

t

t

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

DOWNTOWN 125i

INSTALLATION

Turn the A.C. generator flywheel so that the

“T” mark on the flywheel aligns with the

index mark on the crankcase.

Keep the round hole on the camshaft gear

facing up and align the punch marks on the

camshaft gear with the cylinder head surface

(Position the intake and exhaust cam lobes

down.) and install the cam chain onto the

camshaft gear.

Install the rocker arms shafts fixed bolt .

Punch Marks

Round Hole

Cam shaf

Install the camshaft gear

Bol

Camshaft Gea

6-10

Page 82

6

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

DOWNTOWN 125i

DISASSEMBLY

Remove the valve spring cotters, retainers,

springs, spring seats, oil seals and valves

using a valve spring compressor.

*

• Be sure to compress the valve springs

with a valve spring compressor.

• Mark all disassembled parts to ensure

correct reassembly.

Special tool:

Valve Spring Compressor A120E00040

Valve Spring Compresso

Valves

6-11

Page 83

6

t

r

r

Cortesia de/ Courtesy of: www.batmotos.com

Cortesia de/ Courtesy of: www.batmotos.com

. CYLINDER HEAD/VALVES

INSPECTION

DOWNTOWN 125i

Remove carbon deposits from the exhaust

port and combustion chamber.

*

Be careful not to damage the cylinde

head mating surface.

Valve /Valve guide

Inspect each valve for bending, burning,

scratches or abnormal stem wear.

If any defects are found, replace the valve

with a new one.