Page 1

2. GENERAL INFORMATION

2-0

YUP 5 0

1

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

GENERAL INFORMATION

__________________________________________________________________________________

ENGINE SERIAL NUMBER/IDENTIFICATION ........................ 2- 1

SERVICE PRECAUTIONS ........................................................ 2- 2

SERVICE INFORMATION........................................................ 2- 6

TORQUE VALUES................................................................... 2- 8

SPECIAL TOOLS ..................................................................... 2- 9

LUBRICATION POINTS........................................................... 2-11

WIRING DIAGRAM.................................................................. 2-12

CABLE & HARNESS ROUTING ............................................... 2-13

TROUBLESHOOTING.............................................................. 2-17

2

Page 2

2. GENERAL INFORMATION

2-1

YUP 5 0

ENGINE SERIAL NUMBER/IDENTIFICATION

Location of Engine Serial Number

Page 3

2. GENERAL INFORMATION

2-2

YUP 5 0

SERVICE PRECAUTIONS

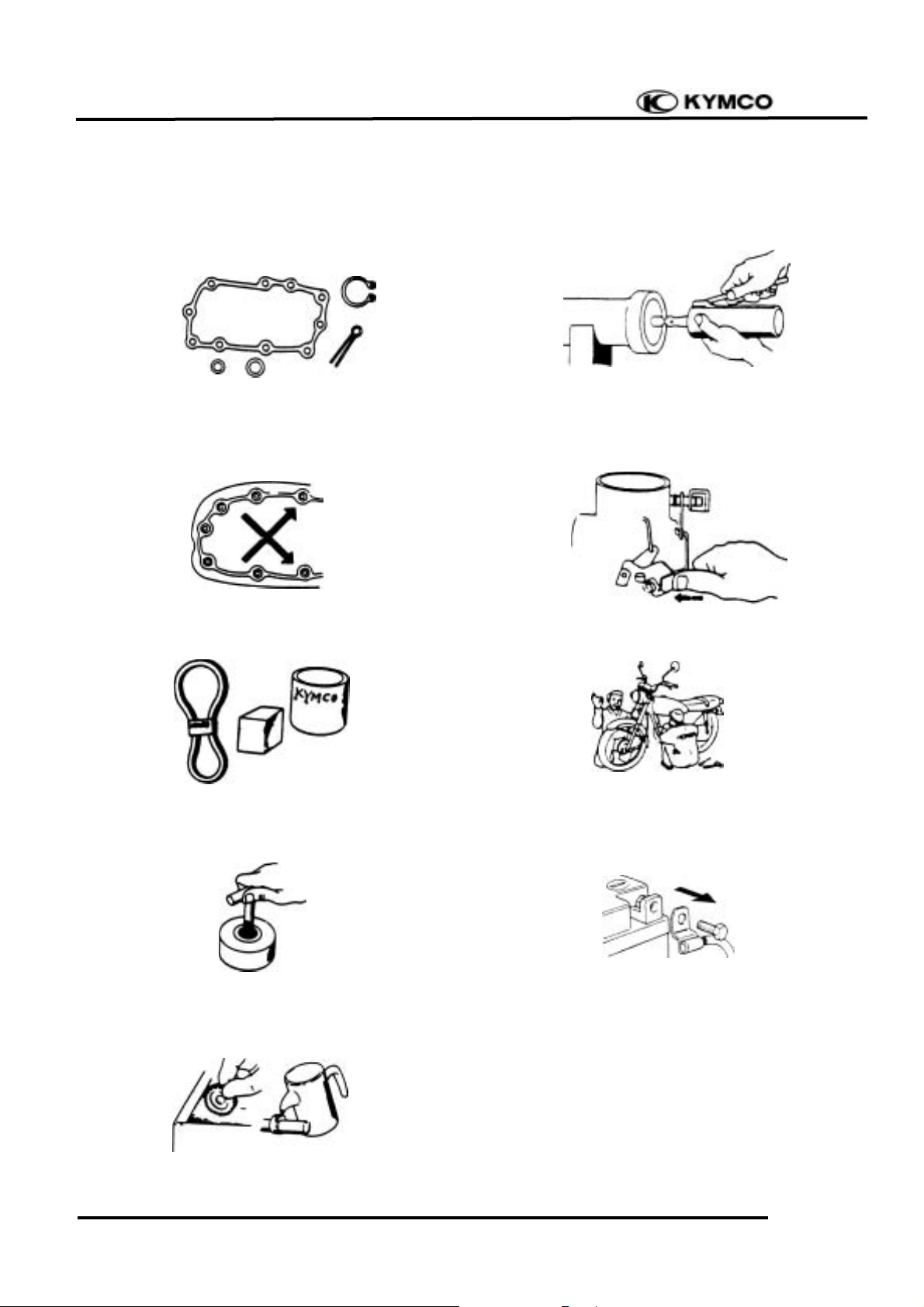

n Make sure to install new gaskets, O-rings,

circlips, cotter pins, etc. when reassembling.

n When tightening bolts or nuts, begin with

larger-diameter to smaller ones at several

times, and tighten to the specified torque

diagonally.

n Use genuine parts and lubricants.

n When servicing the motorcycle, be sure to

use special tools for removal and

installation.

n After disassembly, clean removed parts.

Lubricate sliding surfaces with engine oil

before reassembly.

n Apply or add designated greases and

lubricants to the specified lubrication

points.

n After reassembly, check all parts for

proper tightening and operation.

n When two persons work together, pay

attention to the mutual working safety.

n Disconnect the battery negative (-) terminal

before operation.

n When using a spanner or other tools, make

sure not to damage the motorcycle surface.

n After operation, check all connecting

points, fasteners, and lines for proper

connection and installation.

n When connecting the battery, the positive

(+) terminal must be connected first.

n After connection, apply grease to the

battery terminals.

n Terminal caps shall be installed securely.

Page 4

2. GENERAL INFORMATION

2-3

YUP 5 0

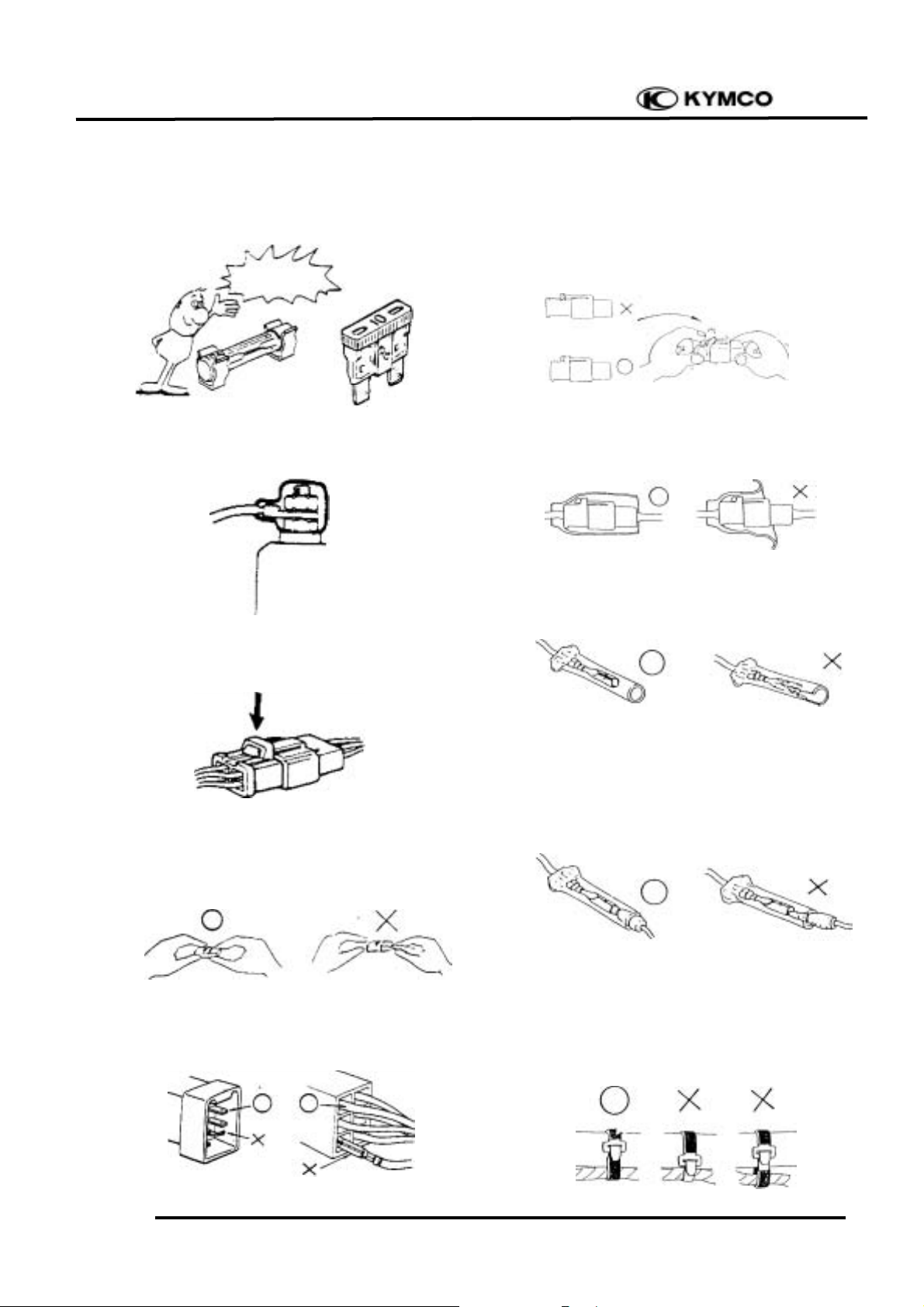

n If the fuse is burned out, find the cause and

repair it. Replace it with a new one

according to the specified capacity.

n After operation, terminal caps shall be

installed securely.

n When taking out the connector, the lock on

the connector shall be released before

operation.

n Hold the connector body when connecting

or disconnecting it.

n Do not pull the connector wire.

n Check if any connector terminal is bending,

protruding or loose.

n The connector shall be inserted

completely.

n If the double connector has a lock, lock

it at the correct position.

n Check if there is any loose wire.

n Before connecting a terminal, check for

damaged terminal cover or loose negative

terminal.

n Check the double connector cover for

proper coverage and installation.

n Insert the terminal completely.

n Check the terminal cover for proper

coverage.

n Do not make the terminal cover opening

face up.

n Secure wire harnesses to the frame with

their respective wire bands at the

designated locations.

Tighten the bands so that only the

insulated surfaces contact the wire

harnesses.

Easy confirm

Page 5

2. GENERAL INFORMATION

2-4

YUP 5 0

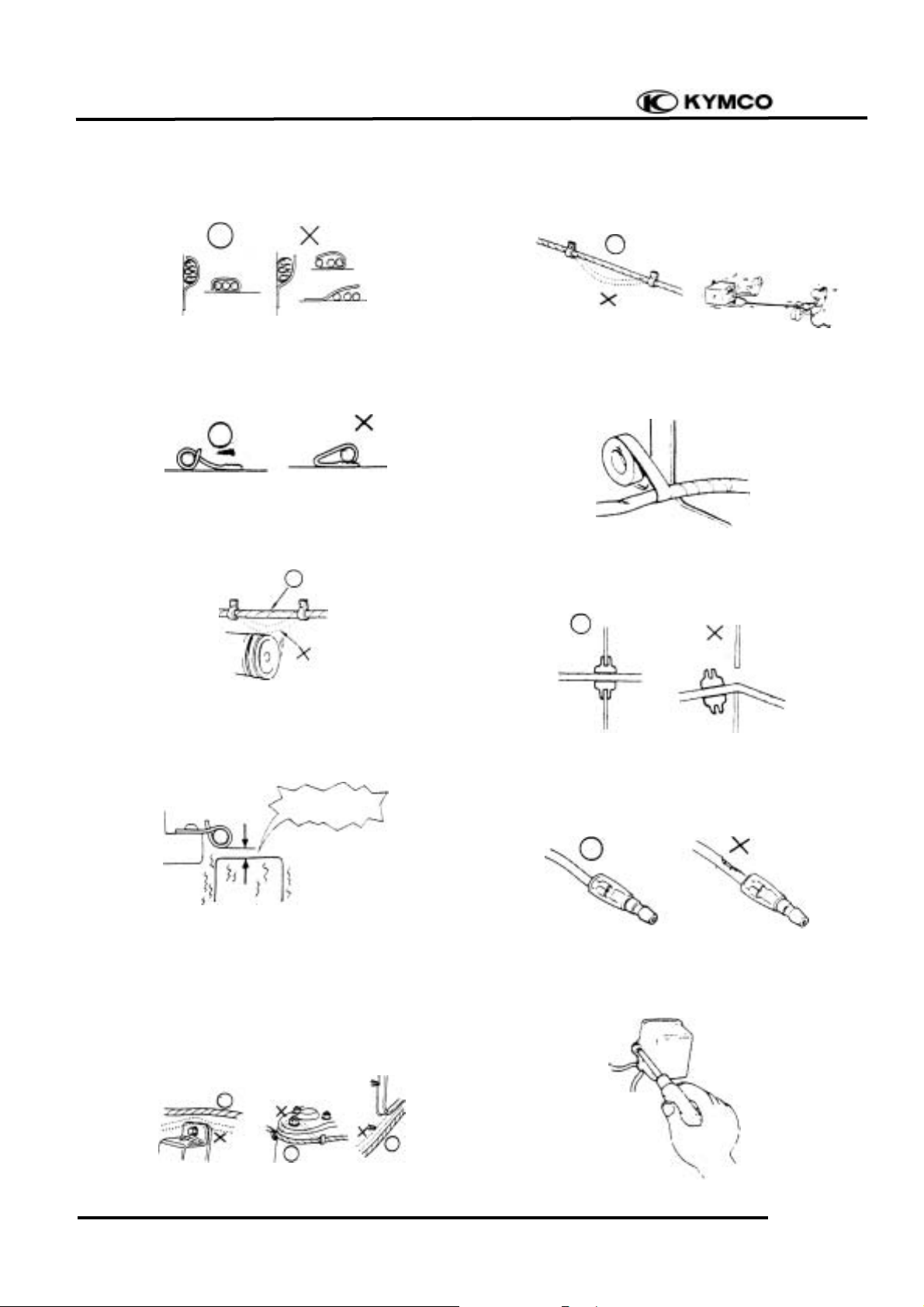

n After clamping, check each wire to make

sure it is secure.

n Do not squeeze wires against the weld or

its clamp.

n After clamping, check each harness to make

sure that it is not interfering with any

moving or sliding parts.

n When fixing the wire harnesses, do not

make it contact the parts which will

generate high heat.

n Route wire harnesses to avoid sharp edges

or corners. Avoid the projected ends of

bolts and screws.

n Route wire harnesses passing through the

side of bolts and screws. Avoid the

projected ends of bolts and screws.

n Route harnesses so they are neither

pulled tight nor have excessive slack.

n Protect wires and harnesses with electrical

tape or tube if they contact a sharp edge or

corner.

n When rubber protecting cover is used to

protect the wire harnesses, it shall be

installed securely.

n Do not break the sheath of wire.

n If a wire or harness is with a broken sheath,

repair by wrapping it with protective tape

or replace it.

n When installing other parts, do not press or

squeeze the wires.

Don’t touch

Page 6

2. GENERAL INFORMATION

2-5

YUP 5 0

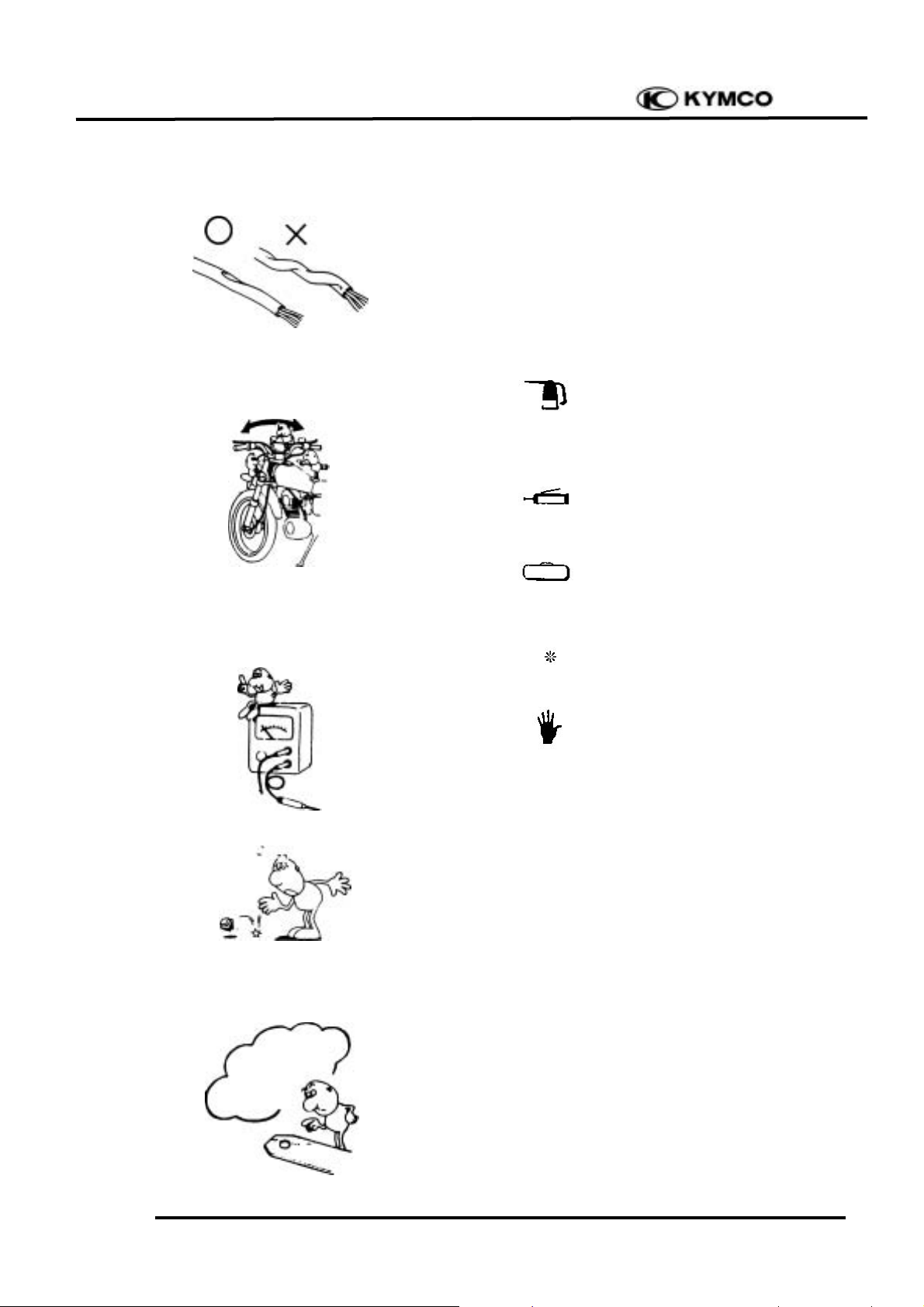

n After routing, check that the wire harnesses

are not twisted or kinked.

n Wire harnesses routed along with handlebar

should not be pulled tight, have excessive

slack or interfere with adjacent or

surrounding parts in all steering positions.

n When a testing device is used, make sure to

understand the operating methods

thoroughly and operate according to the

operating instructions.

n Be careful not to drop any parts.

n When rust is found on a terminal, remove

the rust with sand paper or equivalent

before connecting.

n Symbols:

The following symbols represent the

servicing methods and cautions included in

this service manual.

: Apply engine oil to the

specified points. (Use

designated engine oil for

lubrication.)

: Apply grease for lubrication.

: Use special tool.

: Caution

: Warning

(!12-3) : Refer to page 12-3.

Engine Oil

Grease

Special

*

Remove the rest

Page 7

2. GENERAL INFORMATION

2-6

YUP 5 0

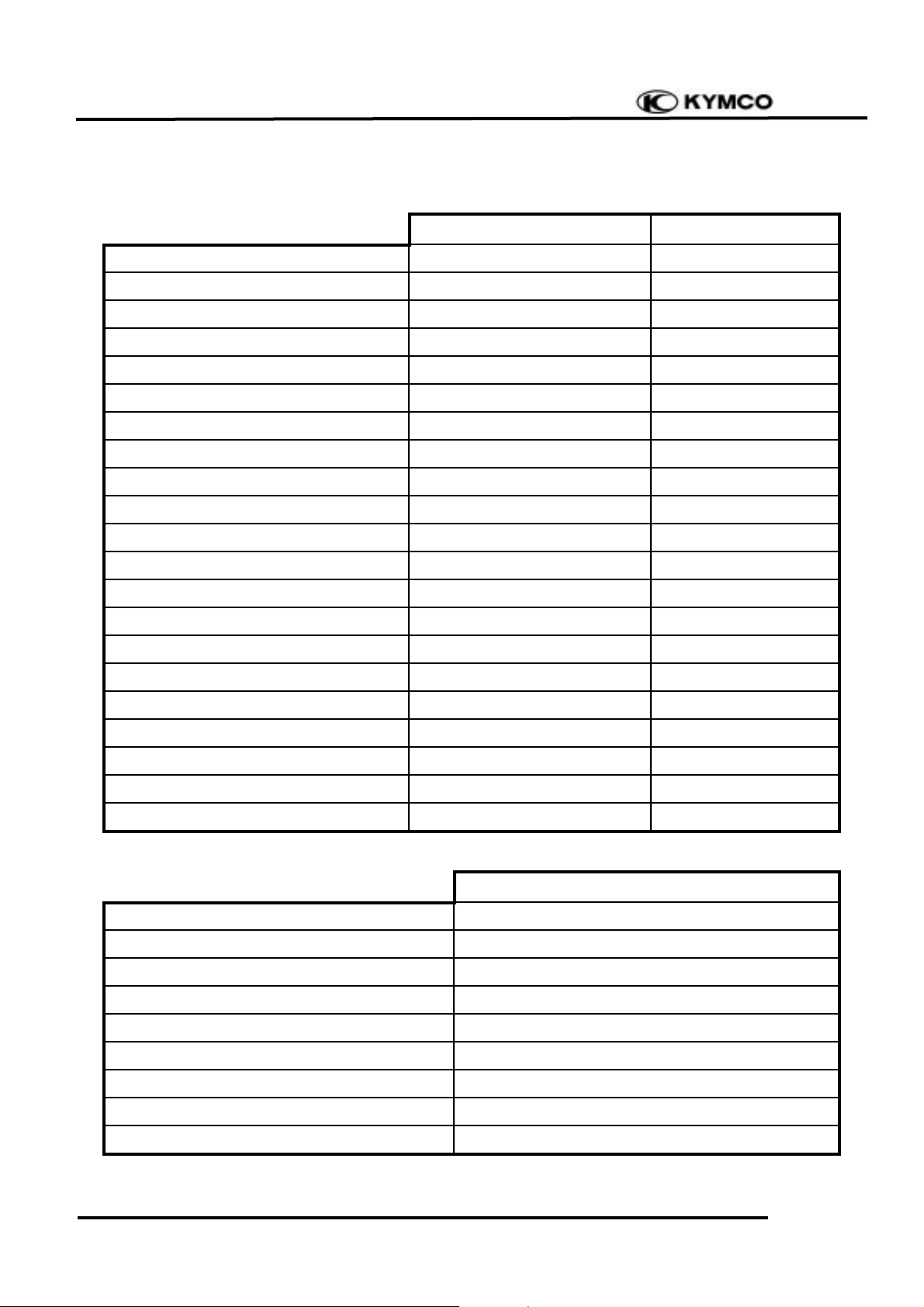

SERVICE INFORMATION

ENGINE

Standard (mm)

Service Limit (mm)

Item

YUP 50

YUP 50

Cylinder head warpage

æ

0.10

Piston O.D.(5mm from bottom of piston

38.955_ 38.970

38.90

Cylinder-to- piston clearance

0.10

Piston pin hole I.D.

12.002_ 12.008

12.03

Piston pin O.D.

11.994_ 12.0

11.98

Piston-to-piston pin clearance

¨

¨

Piston ring end gap (top/second)

0.10_ 0.25

0.40

Connecting rod small end I.D.

17.005_ 17.017

17.03

Cylinder bore

39.0_ 39.025

39.05

Drive belt width

18

17

Drive pulley collar O.D.

20.01_ 20.025

¨

Movable drive face ID.

20.035_ 20.085

19.97

Weight roller O.D.

8.5

8.2

Clutch outer I.D.

107_ 107.2

107.5

Driven face spring free length

87.9

82.6

Driven face O.D.

¨

¨

Movable driven face I.D.

¨

¨

Connecting rod big end side clearance

¨

¨

Connecting rod big end radial clearance

¨

¨

Crankshaft runout A/B

æ

¨

CARBURETOR

YUP 50

Venturi dia.

14mm

Identification number

014A

Float level

5.0mm

Main jet

#75

Slow jet

#35

Air screw opening

1 ±_

Idle speed

2100±100rpm

Throttle grip free play

2_ 6mm

Jet needle clip notch

1st notch

Page 8

2. GENERAL INFORMATION

2-7

YUP 5 0

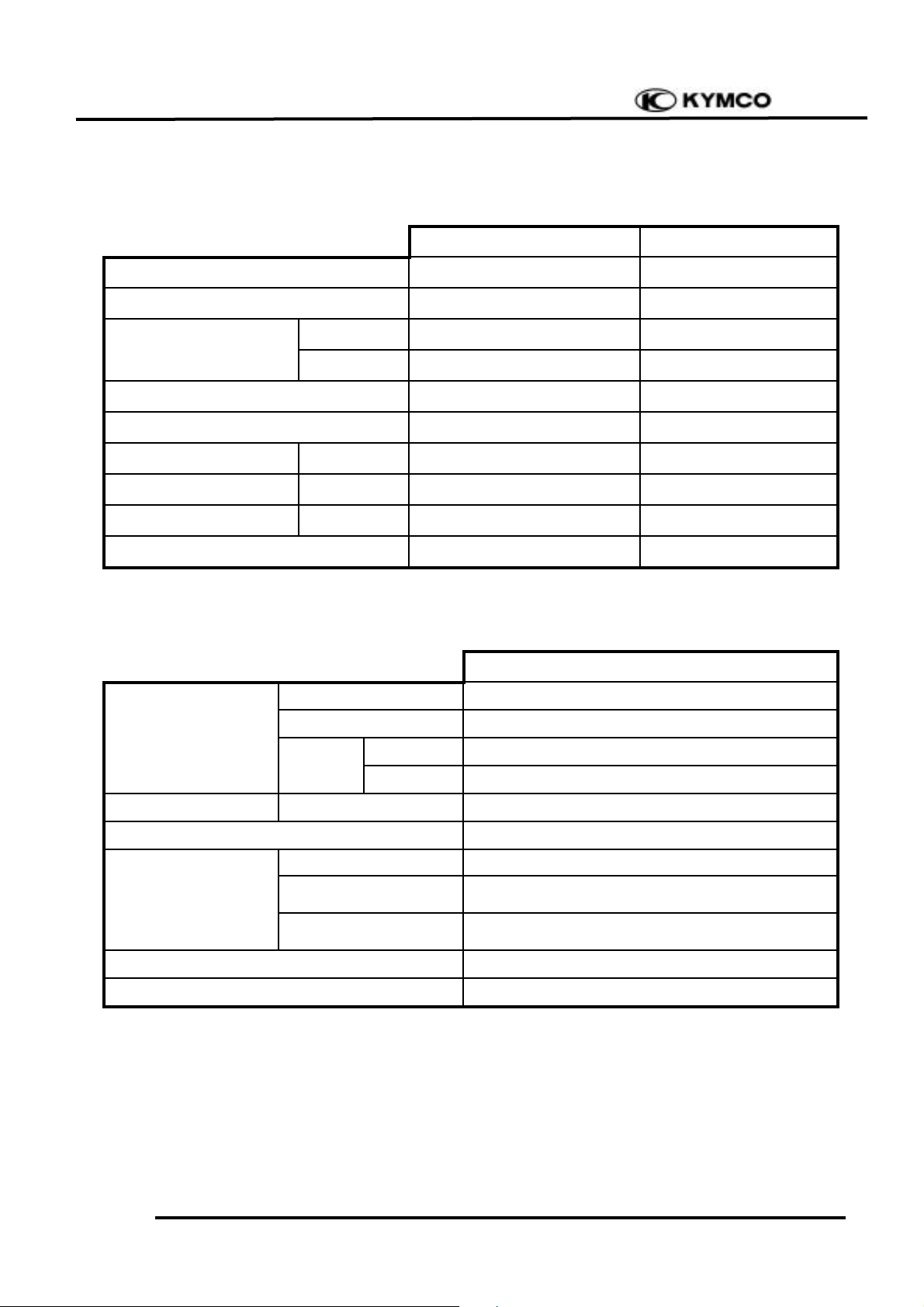

FRAME

Standard (mm)

Service Limit (mm)

Item

YUP50

YUP50

Axle shaft runout

æ

0.2

Radial

Front wheel rim runout

Axial

Front shock absorber spring free length

200.0

182.8

Rear wheel rim runout

2.0

Brake drum I.D.

Front/rear

110

111

Brake lining thickness

Front/rear

4.0/4.0

2.0/2.0

Brake disk runout

Front/rearæ0.30

Rear shock absorber spring free length

235.7

218.7

ELECTRICAL EQUIPMENT

YUP50

Capacity

12V3AH

Voltage

13.0_ 13.2V

Charging

Standard

0.4A/5H

Battery

current

Quick

4A/0.5H

Spark plug

(NGK)

BR8HSA

Spark plug gap

0.6_ 0.7mm

Primary coil

0.153_ 0.187W

Secondary coil

(with plug cap)

6.99_ 10.21KW

Ignition coil resistance

Secondary coil

(without plug cap)

3.24_ 3.96KW

Pulser coil resistance (20℃ )

80_ 160W

Ignition timing

13.5°±2°BTDC/2000rpm

Page 9

2. GENERAL INFORMATION

2-8

YUP 5 0

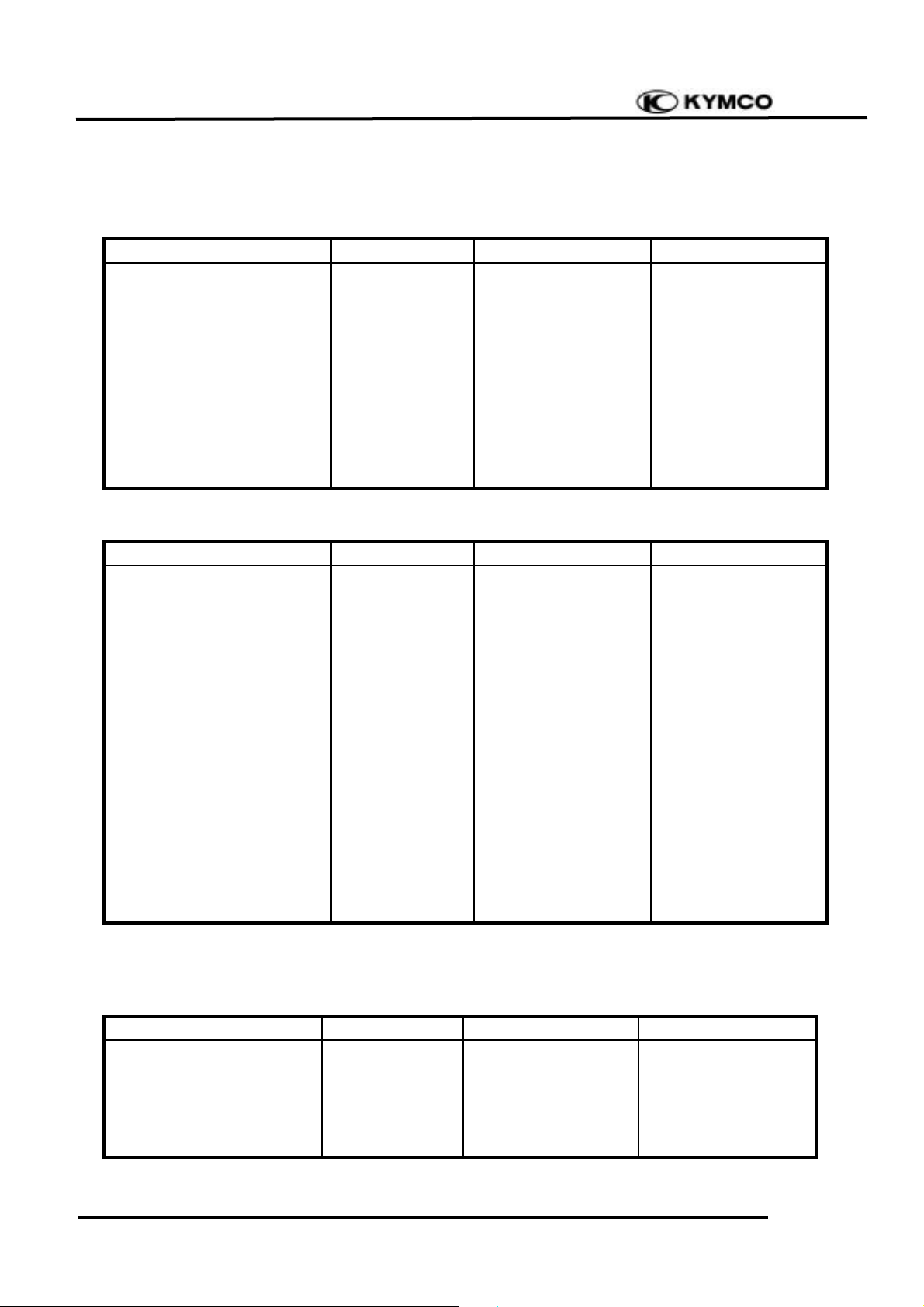

TORQUE VALUES

ENGINE

Item

Thread dia. (mm)

Torque (kg-m)

Remarks

Cylinder head bolt

Clutch drive plate nut

Clutch outer nut

Drive face nut

Oil check bolt

Engine mounting bolt

Engine hanger bracket bolt

Exhaust muffler joint lock nut

Exhaust muffler lock bolt

Spark plug

BF7x115

10

NH10

NH12

10

BF10x95

BF10x50

NC6mm

BF8x35

1.5_ 1.7

3.5_ 4.0

3.5_ 4.5

5.0_ 6.0

1.0_ 1.5

4.5_ 5.5

3.5_ 4.5

1.0_ 1.4

3.0_ 3.6

1.1_ 1.7

(cold)

(cold)

FRAME

Item

Thread dia. (mm)

Torque (kg-m)

Remarks

Handlebar lock nut

Steering stem lock nut

Steering top cone race

Front axle nut

Rear axle nut

Rear brake arm bolt

Front shock absorber:

upper mount bolt

lower mount bolt

hex bolt

Front damper nut

Front pivot arm bolt

Rear shock absorber:

upper mount bolt

lower mount bolt

lower joint nut

10

25.4

25.4

12

16

8

8

10

8

8

4.5_ 5.0

6.0_ 8.0

0.5_ 1.3

5.0_ 7.0

11.0_ 13.0

3.3

3.3

1.5_ 3.0

1.5_ 3.0

3.5_ 4.5

2.4_ 3.0

1.5_ 2.5

Flange bolt/U-nut

Flange U-nut

Flange U-nut

Flange nut

Flange bolt/U-nut

Cross head

Apply locking agent

Flange screw/U-nut

Flange nut

Torque specifications listed above are for important fasteners. Others should be tightened to

standard torque values below.

STANDARD TORQUE VALUES SH bolt: 8mm Flange 6mm bolt

Item

Torque (kg-m)

Item

Torque (kg-m)

5mm bolt, nut

6mm bolt, nut

8mm bolt, nut

10mm bolt, nut

12mm bolt, nut

0.45_ 0.6

0.8_ 1.2

1.8_ 2.5

3.0_ 4.0

5.0_ 6.0

5mm screw

6mm screw, SH bolt

6mm flange bolt, nut

8mm flange bolt, nut

10mm flange bolt, nut

0.35_ 0.5

0.7_ 1.1

1.0_ 1.4

2.4_ 3.0

3.5_ 4.5

Page 10

2. GENERAL INFORMATION

2-9

YUP 5 0

SPECIAL TOOLS

Tool Name

Tool No.

Remarks

Universal bearing puller

E030

Crankshaft bearing removal

Lock nut socket wrench

F001

Top cone race holding

Lock nut wrench,

F002

Stem lock nut tightening

Crankcase puller

E026

Crankcase disassembly

Bearing remover set, 12mm

(Spindle assy, 12mm)

(Remover weight)

E020

Drive shaft bearing removal/installation

Bearing remover set, 15mm

(Spindle assy, 15mm)

(Remover head, 15mm)

(Remover shaft, 15mm)

E018

Drive shaft bearing removal/installation

Bearing outer driver, 28x30mm

E014

Bearing installation

Clutch spring compressor

E027

Driven pulley disassembly/assembly

Crankcase assembly collar

E023

Driven shaft, crankshaft & crankcase

assembly

Crankcase assembly tool

E024

Crankshaft & crankcase assembly

Ball race remover

F005

Steering stem bearing races

Rear shock absorber compressor

F004

Rear shock absorber disassembly/assembly

Universal holder

E017

Flywheel holding

Flywheel puller

E001

Flywheel removal

Bearing outer driver, 32x35mm

E014

Drive shaft bearing installation

Final shaft bearing installation

Bearing outer driver, 37x40mm

E014

Drive shaft bearing installation Final shaft

bearing installation Crankshaft bearing

installation

Universal bearing puller

E030

Crankshaft bearing removal

Page 11

2. GENERAL INFORMATION

2-10

YUP 5 0

LUBRICATION POINTS

ENGINE

NO.

Lubrication Points

Lubricant

Remarks

1

Crankcase sliding & movable parts

JASO-FC or API-TC

2

Cylinder movable parts

JASO-FC or API-TC

3

Transmission gear (final gear)

SAE-90#

4

Kick starter spindle bushing

Grease

5

Drive pulley movable parts

Grease

6

Starter pinion movable parts

Grease

FRAME

Apply clean engine oil or grease to cables and movable parts not specified. This will avoid

abnormal noise and rise the durability of the motorcycle.

Front/Rear Brake Lever

Seat Lock

Rear Wheel Bearing

Throttle Cable

Main Stand Pivot

Engine Oil

Grease

Speedometer Gear/

Brake Cam/Front

Shock Absorber

Lower Mount

Bushings/Pivot

Grease

Grease

Grease

Grease

Rear Brake Cable

Page 12

2. GENERAL INFORMATION

2-11

YUP 5 0

WIRING DIAGRAM

Page 13

2. GENERAL INFORMATION

2-12

YUP 5 0

CABLE & HARNESS ROUTING

Front Brake Reservoir

Rear Brake Cable

Throttle Cable

Ignition Switch

Regulator/Rectifier

Front Brake Fluid Tube

Resistor

Front Stop Switch Wire

Rear Stop Switch Wire

Speedometer Cable

Horn

Page 14

2. GENERAL INFORMATION

2-13

YUP 5 0

Wire Harness

Rear Brake Cable

Throttle Cable

Speedometer Cable

Ignition Switch

Page 15

2. GENERAL INFORMATION

2-14

YUP 5 0

Front Brake Fluid Tube

Rear Brake Cable

Throttle Cable

Throttle Cable

Ignition Coil

Wire Harness

Page 16

2. GENERAL INFORMATION

2-15

YUP 5 0

Ignition Coil

Fuel Unit

Fuel Filter

Oil Tank Cap

Starter Relay

CDI Unit

Throttle Cable

Wire Harness

Ignition Coil

Oil Tube

Spark Plug

Auto Bystarter Cable

A C G Cable

Page 17

2. GENERAL INFORMATION

2-16

YUP 5 0

Vacuum Tee

Oil Meter

Ignition Coil

Fuel Tube

Fuel Tank Cap

Spark Plug Cap

A C G Cable

Pulser Cable

Oil Tube

Throttle Cable

Page 18

2. GENERAL INFORMATION

2-17

YUP 5 0

TROUBLESHOOTING

ENGINE WILL NOT START OR IS HARD TO START

Å Empty fuel tank

Ç Clogged float valve

É Clogged fuel filter

Ñ Faulty auto fuel valve

Å Faulty spark plug

Ç Fouled spark plug

É Faulty CDI unit

Ñ Faulty A.C. generator

Ö Broken or short ed

ignit ion coil

Ü Broken or short ed

exciter coil

áFaulty ignition switch

Å Burned or worn

cylinder piston

Ç Faulty reed valve

É Blown cylinder head

gasket

Ñ Leaking crankcase

Ö Faulty crankcase oil

seal

Å Incorrectly adjusted idle

speed

Ç Air leaking through

intake pipe

É Incorrect ignition

timing

Å Flooded carburetor

Ç Throttle valve

excessively open

Å Faulty auto bystarter

Check if fuel reaches

carburetor by

loosening drain screw.

Remove spark plug

and install it into

spark plug cap to test

spark by connecting it

to engine ground.

Inspection/Adjustment

Symptom

Probable Cause

Fuel reaches

carburetor

Spark jumps

Dry spark plug

Not clogged

Normal

compression

Engine does not

fire

Fuel does not

reach carburetor

Weak or no spark

Wet spark plug

Clogged

Low or no

compression

Engine fires but

does not start

Test cylinder

compression.

Remove spark plug and

inspect again.

Wait for 30 minutes

and then remove the

carbu-retor auto choke

circuit hose and blow

the hose with mouth.

Start engine by following normal starting

procedure.

Page 19

2. GENERAL INFORMATION

2-18

YUP 5 0

ENGINE STOPS IMMEDIATELY AFTER IT STARTS

Å Empty fuel tank

Ç Clogged float valve

É Clogged fuel filter

Ñ Faulty auto fuel valve

Å Fouled spark plug

Ç Incorrect heat range

plug

Å Fouled spark plug

Ç Faulty CDI unit

É Faulty A.C. generator

Ñ Faulty ignition coil

Ö Broken or shorted high

tension wire

Ü Faulty ignition switch

Å Worn cylinder and

piston rings

Ç Blown cylinder head

gasket

É Flaws in cylinder head

Ñ Faulty reed valve

Ö Seized piston

Å Clogged carburetor jets

Å Faulty CDI unit or A.C.

generator

Ç A.C.G. flywheel not

aligned

Å Mixture too rich (turn

screw out)

Ç Mixture too lean (turn

screw in)

Check if fuel reaches

carburetor by

loosening drain screw.

Inspection/Adjustment

Symptom

Probable Cause

Fuel reaches

carburetor

Good spark

Remove spark plug

and install it into

spark plug cap to test

spark by connecting it

to engine ground.

Correct timing

Correctly adjusted

Plug not fouled or

discolored

Normal

compression

Not Clogged

Fuel does not

reach carburetor

Weak or inter mittent spark

Incorrect timing

Incorrectly adjusted

Plug fouled or

discolored

Abnormal

compression

Clogged

Test cylinder

compression (using a

compression gauge).

Check carburetor for

clogging.

Check ignition timing.

Check carburetor air

screw adjustment.

Remove spark plug

and install it into

spark plug cap to test

spark by connecting it

to engine ground.

Page 20

2. GENERAL INFORMATION

2-19

YUP 5 0

Å Carburetor not securely

tightened

Ç Faulty intake manifold

gasket

É Deformed or broken

carburetor O-ring

Å Broken cable

Ç Dirty auto bystarter

É Faulty auto bystarter

Å Faulty auto bystarter

Inspection/Adjustment

Symptom

Probable Cause

No air leak

Not clogged

Clogged

Air leaks

Clogged

Not Clogged

Check carburetor

gasket for air leaks.

Connect auto bystarter

wire to battery. Wait

for 5 minutes, then

connect a hose to fuel

enriching circuit and

then blow the hose

with mouth.

Remove auto bystarter

connecting wire and

check if bypass fuel

line is clogged.

Page 21

2. GENERAL INFORMATION

2-20

YUP 5 0

ENGINE LACKS POWER

Å Clogged air cleaner

Ç Clogged fuel filter

É Clogged exhaust

muffler

Ñ Faulty auto bystarter

Å Faulty CDI unit

Ç Faulty A.C. generator

Å Worn cylinder and

piston rings

Ç Blown cylinder head

gasket

É Faulty reed valve

Å Clogged carburetor jets

Å Fouled spark plug

Ç Incorrect heat range

plug

Å Mixture too lean

Ç Poor quality fuel

É Excessive carbon build-

up in combustion chamber

Ñ Ignition timing too

early

Å Excessive carbon build-

up in combustion chamber

Ç Poor quality fuel

É Clutch slipping

Ñ Mixture too lean

Inspection/Adjustment

Symptom

Probable Cause

Engine speed

increases

Engine overheats

Correct timing

Engine does not

knock

Plug not fouled or

discolored

Normal

compression

Not Clogged

Engine speed does

not increase

sufficiently

Engine does not

overheats

Incorrect timing

Engine knocks

Plug fouled or

discolored

Abnormal

compression

Clogged

Start engine and

accelerate lightly for

observation.

Check ignition timing

(using a timing light).

Rapidly accelerate or

run at high speed

Test cylinder

compression (using a

compression gauge)

Check carburetor for

clogging

Remove spark plug

and

inspect

Check if engine

overheats

Page 22

2. GENERAL INFORMATION

2-21

YUP 5 0

POOR PERFORMANCE (ESPECIALLY AT IDLE AND LOW SPEEDS)

Å Faulty CDI unit

Ç Faulty A.C. generator

Å Mixture too rich (turn

screw out)

Ç Mixture too lean (turn

screw in)

Å Carburetor not securely

tightened

Ç Faulty intake manifold

gasket

É Deformed carburetor

O-ring

Å Faulty or fouled spark

plug

Ç Faulty CDI unit

É Faulty A.C. generator

Ñ Faulty ignition coil

Ö Broken or shorted high

tension wire

Ü Faulty ignition switch

Å Broken auto bystarter

wire

Ç Faulty auto bystarter

Inspection/Adjustment

Symptom

Probable Cause

Clogged

Not clogged

Remove spark plug

and install it into

spark plug cap to test

spark by connecting it

to engine ground.

Check ignition timing.

Connect auto bystarter

wire to battery. Wait

for 5 minutes, then

connect a hose to fuel

enriching circuit and

then blow the hose

with mouth.

Remove auto bystarter

connecting wire and

check if bypass fuel

line is clogged.

Check carburetor

gasket for air leaks.

Check carburetor air

screw adjustment.

Correct timing

Incorrect timing

Correctly adjusted

Incorrectly adjusted

No air leak

Air leaks

Good spark

Weak or inter mittent spark

Not clogged

Clogged

Page 23

2. GENERAL INFORMATION

2-22

YUP 5 0

POOR PERFORMANCE (AT HIGH SPEED)

Å Faulty CDI unit

Ç Loose A.C.G. stator

É Faulty A.C. generator

Å Empty fuel tank

Ç Clogged fuel tube or

filter

É Clogged charcoal

canister

Å Clean and unclog

Å Broken auto bystarter

wire

Ç Faulty auto bystarter

Å Faulty auto bystarter

Inspection/Adjustment

Symptom

Probable Cause

Clogged

Not clogged

Check ignition timing.

Connect auto bystarter

wire to battery. Wait

for 5 minutes, then

connect a hose to fuel

enriching circuit and

then blow the hose

with mouth.

Remove auto bystarter

connecting wire and

check if bypass fuel

line is clogged.

Check carburetor jets

for clogging.

Check auto fuel valve

for fuel supply.

Correct timing

Incorrect timing

Fuel flows freely

Fuel flow

restricted

Not clogged

Clogged

Not clogged

Clogged

Page 24

2. GENERAL INFORMATION

2-23

YUP 5 0

CLUTCH, DRIVE AND DRIVEN PULLEYS

Å Worn or slipping drive belt

Ç Broken ramp plate

É Broken driven face spring

Ñ Separated clutch lining

Ö Damaged driven pulley shaft

splines

Ü Damaged final gear

á Seized final gear

Å Broken shoe spring

Ç Clutch outer and clutch weight

stuck

ÉSeized pivot

Å Worn or slipping drive belt

Ç Worn weight rollers

É Seized drive pulley bearings

Ñ Weak driven face spring

Ö Worn or seized driven pulley

bearings

Å Worn or slipping drive belt

Ç Worn weight rollers

É Worn or seized driven pulley

bearings

Å Oil or grease fouled drive belt

Ç Worn drive belt

É Weak driven face spring

Ñ Worn or seized driven pulley

bearings

STEERING HANDLEBAR DOES NOT TRACK STRAIGHT

(Front and rear tire pressures are normal)

Å Steering stem nut too tight

Ç Broken steering steel balls

Å Excessive wheel bearing play

Ç Bent rim

É Loose axle nut

Å Misaligned front and rear wheels

Ç Bent front fork

Engine starts but

motor-cycle does not

move

Engine lacks power at

start of a grade (poor

slope performance)

Steering is heavy

Front or rear wheel is

wobbling

Symptom

Symptom

Probable Cause

Probable Cause

Engine lacks power at

high speed

There is abnormal

noise

or smell while running

Motorcycle creeps or

engine starts but soon

stops or seems to rush

out (Rear wheel

rotates when engine

idles)

Steering handlebar pulls

to one side

Page 25

2. GENERAL INFORMATION

2-24

YUP 5 0

POOR SUSPENSION PERFORMANCE

(Front and rear tire pressures are normal)

Å Weak shock spring

Ç Excessive load

É Shock damper oil leaking

Å Bent fork tube or shock rod

Ç Fork slider and tube binding

Å Fork tube and spring binding

Ç Fork slider and tube binding

POOR BRAKE PERFORMANCE

(Adjust brake according to standards)

Å Worn brake linings

Ç Worn brake cam contacting area

on

brake shoes

É Worn brake cam

Ñ Worn brake drum

Å Worn brake linings

Ç Foreign matter on brake linings

É Rough brake drum contacting area

Å Sluggish or elongated brake cables

Ç Brake shoes improperly contact

brake drum

É Water and mud in brake system

Ñ Oil or grease on brake linings

Å Faulty brake master cylinder

Ç Faulty brake caliper

É Oil or grease on brake disk

Ñ Deformed brake disk

Ö Leaking brake fluid tube

Suspension is too soft

Brake squeaks

Symptom

Symptom

Probable Cause

Probable Cause

Suspension is too hard

Suspension is noisy

Brake performance is

poor

Index mark on brake

panel aligns with wear

indicator arrow

Expanding

Brake

Hydraulic

Brake

Page 26

2. GENERAL INFORMATION

2-25

YUP 5 0

Faulty

OIL METER

1. Motor oil indicator light does not come on when there is no motor oil (Ignition switch ON)

Å Burned out fuse

Ç Weak or dead battery

É Faulty ignition switch

Ñ Loose or disconnected

connector

Ö Broken wire harness

ÅBurned out bulb

Å Loose wire connector

Ç Broken wire harness

É Incorrectly connected

wire

Å Faulty float

Ç Broken or shorted wire

in

meter

2. Motor oil is sufficient but the indicator light remains on (Ignition switch ON)

Å Loose or disconnected

connector

Ç Broken wire harness

É Incorrectly connected

wire

Å Faulty float

Ç Broken or shorted wire

in meter

Å Damaged oil tank

Ç Foreign matters in oil

tank

Inspection/Adjustment

Symptom

Inspection/Adjustment

Probable Cause

Symptom

Probable Cause

Signals operate

properly

Signals dim, remain

on or don‘t

operate

Bulb lights

Bulb does not light

Good

Faulty

Remove oil meter and

check operation of

indicator light by

moving float

Check connectors for

proper connection.

Good

Good

Faulty

Remove oil meter and

check operation of

indicator light by

moving float

Check connectors for

proper operation.

Connect indicator

light bulb to battery

for bulb inspection.

Check battery circuit

by operating turn

signals.

Good

Faulty

Float up = Light off

Float down = Light on

Float up = Light off

Float down = Light on

Page 27

2. GENERAL INFORMATION

2-26

YUP 5 0

FUEL GAUGE

1. Pointer does not register correctly (Ignition switch ON)

Å Burned out fuse

Ç Weak or dead battery

É Faulty ignition switch

Ñ Loose or disconnected

connector

Ö Broken wire harness

Å Faulty float

Å Broken or shorted fuel

unit wire

Å Loose or disconnected

connector

Ç Incorrectly connected

connector

Å Broken or shorted wire

in fuel gauge

2. Pointer fluctuates or swings (Ignition switch ON)

Å Burned out fuse

Ç Weak or dead battery

É Faulty ignition switch

Ñ Loose or disconnected

connector

Ö Broken wire harness

Å Poor contact in fuel

unit

Å Insufficient damping oil

in fuel gauge

Å Loose or disconnected

connector

Å Broken or shorted wire

in fuel gauge

Inspection/Adjustment

Inspection/Adjustment

Symptom

Symptom

Signals operate

properly

Signals operate

properly

Signals dim, remain

on or don‘t

operate

Signals dim, remain

on or don‘t

Pointer does not

move

Pointer does not

move

Good

Good

Pointer moves

Pointer moves

Pointer moves

Pointer does not

move in accordance with float

Faulty

Faulty

Pointer does not

move

Pointer moves in

accordance with

float

Probable Cause

Probable Cause

Remove fuel unit and

check operation of

pointer by moving

float up and down.

Check battery circuit

by operating turn

signals.

Check operation of

pointer by opening

and shorting fuel unit

terminal on wire

harness side.

Check connectors for

proper connection.

Remove fuel unit and

check operation of

pointer by moving

float up and down.

Check battery circuit

by operating turn

signals and horn.

Move float up and

down rapidly (1 round

/sec.) to check the

operation of pointer.

Check connectors for

proper connection.

Page 28

2. GENERAL INFORMATION

2-27

YUP 5 0

STARTER MOTOR

1. Starter motor won‘t turn

Å Burned out fuse

Ç Weak or dead battery

É Faulty stop switch

Ñ Loose or disconnected

connector

Ö Broken or shorted

ignition switch wire

Å Faulty or weak battery

Å Poor starter button

connection

Ç Faulty starter relay

É Loose or disconnected

connector

Å Faulty starter motor

Å Faulty wire harness

2. Starter motor turns slowly or idles

Å Weak or dead battery

Å Loose or disconnected

connector

Ç Faulty starter relay

Å Seized cylinder

Å Broken or shorted

starter motor cable

Ç Faulty starter pinion

3. Starter motor does not stop turning

Å Faulty starter pinion

Å Starter relay shorted or

stuck

closed

Inspection/Adjustmen

Inspection/Adjustment

Inspection/Adjustment

Symptom

Symptom

Symptom

Signals operate

properly

Signals operate

properly

Signals dim, remain

on or don‘t

Signals dim, remain

on or don‘t

operate

Stoplight does not

come on

Starter motor

Turns easily

Not stopped

Stoplight comes

St arter does not

turn

Hard to turn

Stopped

Relay operates

properly

Starter motor

turns slowly

Probable Cause

Probable Cause

Probable Cause

Relay does not

operate

Starter motor

turns normally

Check operation of

stop switch by

applying brake.

Check battery

circuit by operating

turn signals.

Check battery

circuit by operating

turn signals.

Turn ignition switch

OFF.

Check operation of

starter relay by

depressing starter

button.

Connect starter

motor directly to

battery.

Connect starter

motor directly to

battery.

Rotate crankshaft.

Loading...

Loading...