Page 1

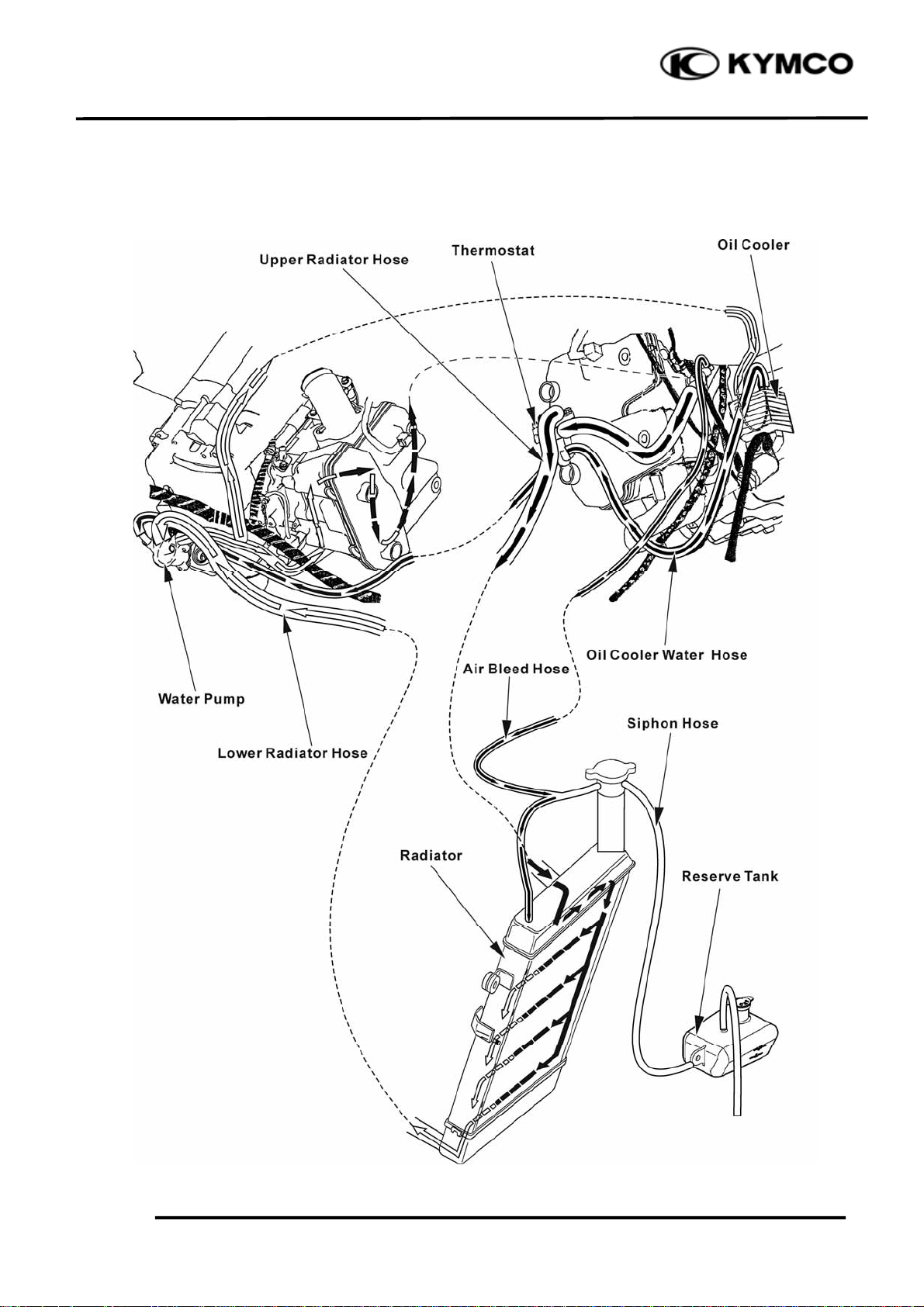

6. COOLING SYSTEM

XCITING 500

6

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

COOLING SYSTEM

__________________________________________________________________________________

SYSTEM FLOW PATTERN----------------------------------------------- 6- 1

SERVICE INFORMATION------------------------------------------------ 6- 2

TROUBLESHOOTING----------------------------------------------------- 6- 4

COOLING SYSTEM TESTING------------------------------------------- 6- 5

COOLANT REPLACEMENT --------------------------------------------- 6- 5

THERMOSTAT-------------------------------------------------------------- 6- 8

WATER PUMP -------------------------------------------------------------- 6-10

RADIATOR ------------------------------------------------------------------ 6-13

FAN MOTOR SWITCH ---------------------------------------------------- 6-16

WATER TEMPERATURE SENSOR ------------------------------------ 6-17

RAIDATOR RESERVE TANK ------------------------------------------- 6-18

6

6-0

Page 2

6. COOLING SYSTEM

SCHEMATIC DRAWING

XCITING 500

6-1

Page 3

6. COOLING SYSTEM

XCITING 500

SERVICE INFORMATION

GENERAL INSTRUCTIONS

WARING:

Removing the radiator cap while the engine is hot can allow the coolant to spray out,

seriously scalding you. Always let the engine and radiator cool down before removing the

radiator cap.

CAUTION:

Radiator coolant is toxic. Keep it away from eyes, mouth, skin and clothes.

• If any coolant gets in your eyes, rinse them with water and consult a physician immediately.

• If any coolant in swallowed, induce vomiting, gargle and consult a physician immediately.

• If any coolant gets on your skin or clothes, rinse thoroughly with plenty of water.

NOTE:

Use coolant with silicate inhibitors may cause premature wear of water pump seals or blockage of

radiator passages. Using tap water may cause engine damage.

• This section covers service of the cooling system.

• These services can be done with the engine installed in the frame.

• Add coolant at the reserve tank. Do not remove the radiator cap except to refill or drain the

system.

• All cooling system services can be done with the engine in the frame.

• Avoid spilling coolant on painted surfaces.

• After servicing the system, check for leaks with a cooling system tester.

6-2

Page 4

6. COOLING SYSTEM

p

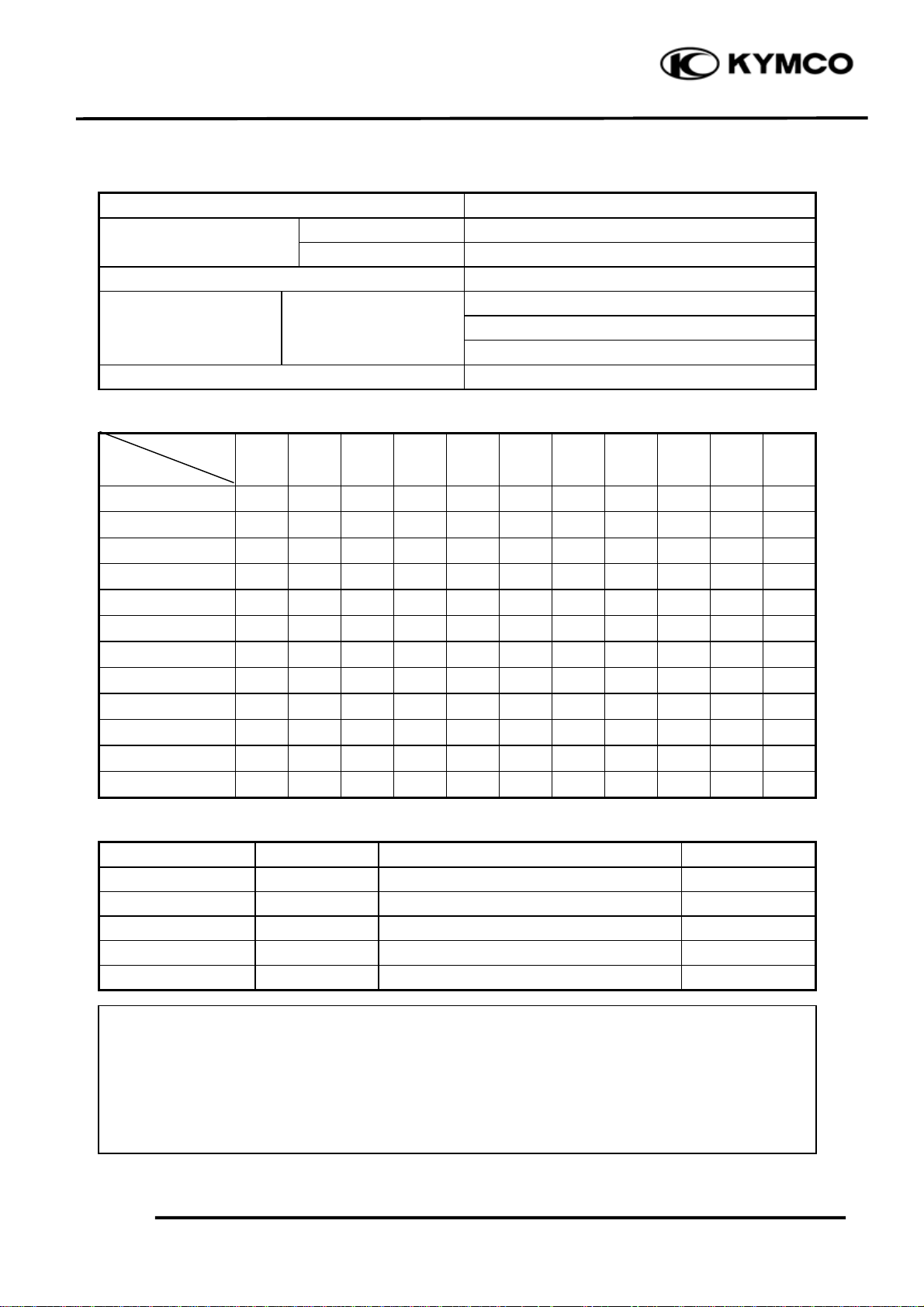

SPECIFICATIONS

ITEM SPECIFICATIONS

Radiator and engine 2 liter (2.1 US qt, 1.76 lmp qt)Coolant capacity

Reserve tank 0.37 liter (0.4 US qt, 0.33 lmp qt)

Radiator cap relief pressure 108 kPa (1.1 kgf/cm2, 16 psi)

Thermostat

Standard coolant concentration 1:1 mixture with soft water

COOLANT GRAVITY CHART

Tem

. ℃

Coolant

concentration

5% 1.009 1.009 1.008 1.008 1.007 1.006 1.005 1.003 1.001 0.009 0.997

10% 1.018 1.107 1.017 1.016 1.015 1.014 0.013 1.011 1.009 1.007 1.005

15% 1.028 1.027 1.026 1.025 1.024 1.022 1.020 1.018 1.016 1.014 1.012

20% 1.036 1.035 1.034 1.033 1.031 1.029 1.027 1.025 1.023 1.021 1.019

25% 1.045 1.044 1.043 1.042 1.040 1.038 1.036 1.034 1.031 1.028 1.025

30% 1.053 1.051 1.051 1.049 1.047 1.045 1.043 1.041 1.038 1.035 1.032

35% 1.063 1.062 1.060 1.058 1.056 1.054 1.052 1.049 1.046 1.043 1.040

40% 1.072 1.070 1.068 1.066 1.064 1.062 1.059 1.056 1.053 1.050 1.047

45% 1.080 1.078 1.076 1.074 1.072 1.069 1.056 1.063 1.062 1.057 1.054

50% 1.086 1.084 1.082 1.080 1.077 1.074 1.071 1.068 1.065 1.062 1.059

55% 1.095 1.093 1.091 1.088 1.085 1.082 1.079 1.076 1.073 1.070 1.067

60% 1.100 1.098 1.095 1.092 1.089 1.086 1.083 1.080 1.077 1.074 1.071

Begin to open 80 - 84°C (176 - 183°F)

Fully open 95°C (203°F)

Valve lift 8 mm (0.3 in) minimum

0 5 10 15 20 25 30 35 40 45 50

XCITING 500

COOLANT MIXTURE (WITH ANTI-RUST AND ANTI-FREEZING EFFECTS)

Freezing Point Mixing Rate KYMCO SIGMA Coolant Concentrate Distilled Water

-9℃ 20%

-15℃ 30% 425cc 975cc

-25℃ 40%

-37℃ 50%

-44.5℃ 55%

Cautions for Using Coolant:

• Use coolant of specified mixing rate. (The mixing rate of 425cc KYMCO SIGMA coolant

concentrate + 975cc distilled water is 30%.)

• Do not mix coolant concentrate of different brands.

• Do not drink the coolant which is poisonous.

• The freezing point of coolant mixture shall be 5℃lower than the freezing point of the riding

area.

6-3

Page 5

6. COOLING SYSTEM

TORQUE VALUES

Water pump cover bolt 13 N•m (1.3 kgf•m, 9 lbf•ft)

Fan motor bolt 5 N•m (0.53 kgf•m, 3.8 lbf•ft)

Radiator shroud mounting nut 9 N•m (0.9 kgf•m, 6.5 lbf•ft)

TROUBLESHOOTING

Engine temperature too high

• Faulty radiator cap

• Faulty temperature gauge or thermosensor

• Air in system

• Thermostat stuck closed

• Insufficient coolant

• Passages blocked in radiator, hoses or water jacket

• Faulty cooling fan motor

• Faulty fan motor switch

• Faulty water pump

XCITING 500

Engine temperature too low

• Faulty temperature gauge or thermosensor

• Thermostat stuck open

• Faulty fan motor switch

Coolant leak

• Faulty water pump mechanical seal

• Deteriorated O-rings

• Faulty radiator cap

• Damaged or deteriorated cylinder head gasket

• Loose hose connection or clamp

• Damaged or deteriorated hoses

6-4

Page 6

6. COOLING SYSTEM

r

r

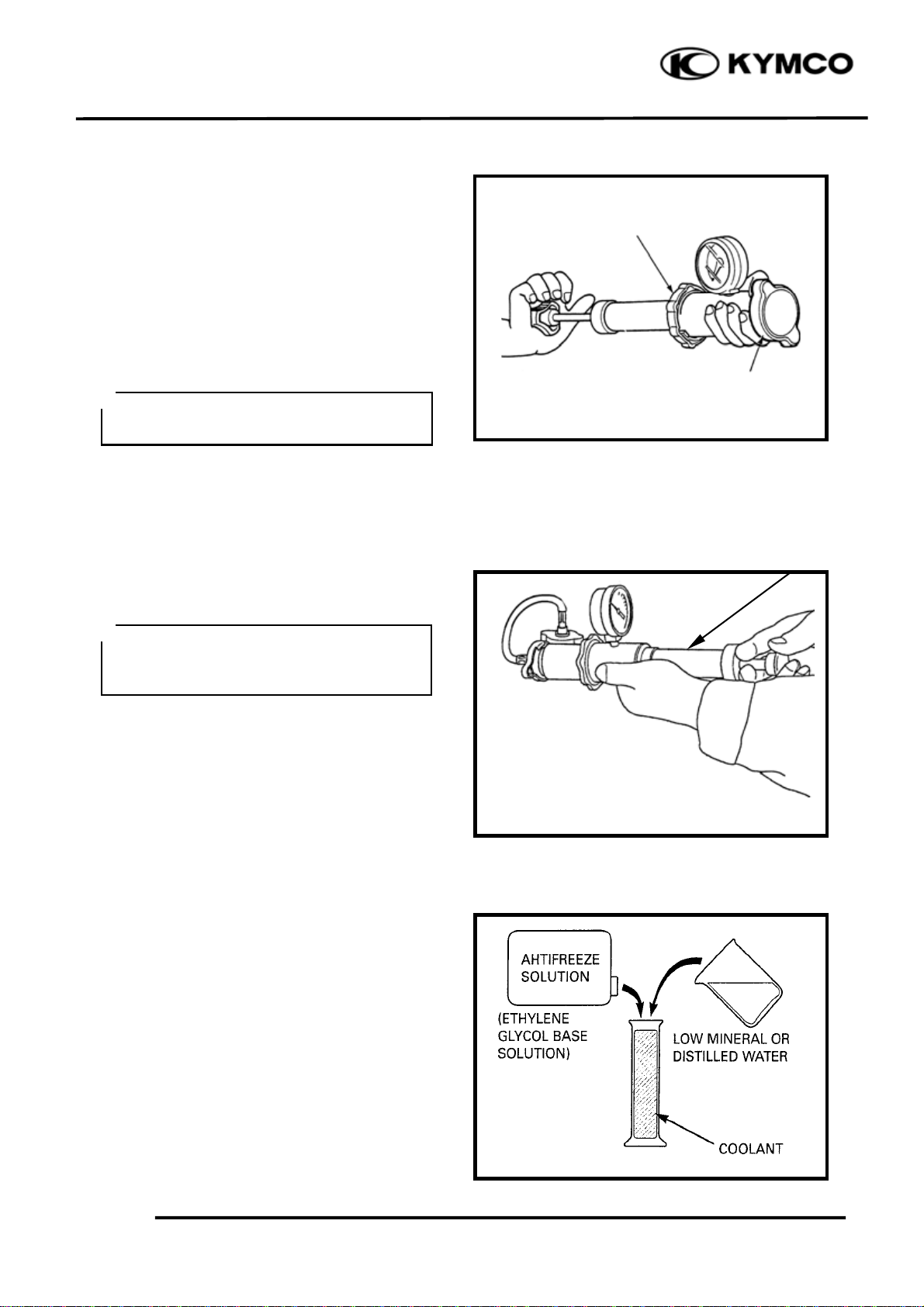

COOLING SYSTEM TESTING

XCITING 500

RADIATOR CAP INSPECTION

Remove the radiator cap (page 6-6).

Pressure test the radiator cap.

Replace the radiator cap if it does not hold

pressure, or if relief pressure is too high or

too low.

It must hold the specified pressure for at

least six seconds.

*

Before installing the cap in the tester,

wet the sealing surfface.

Radiator Cap Relief Pressure:

108 kPa (1.1 kg/cm², 16 psi)

Pressurize the radiator, engine and hoses,

and check for leaks.

*

Excessive pressure can damage the

cooling system components. Do not

exceed 137 kPa (1.4 kg/cm², 20 psi).

Cap Teste

Radiator Cap

Cap Teste

Repair or replace components if the system

will not hold the specified pressure for at

least six seconds.

COOLANT REPLACEMENT

PREPARATION

● The effectiveness of coolant decreases

with the accumulation of rest or if there is

a change in the mixing proportion during

usage. Therefore, for best performance

change the coolant regularly as specified

in he maintenance schedule.

● Mix only distilled, low mineral water

with the antifreeze.

Recommended mixture:

1:1 (Distilled water and antifreeze)

6-5

Page 7

6. COOLING SYSTEM

t

XCITING 500

REPLACEMENT/AIR BLEEDING

Remove the front cover (page 2-11).

Remove the front lower cover (page 2-15).

*

When filling the system or reserve tank

with coolant (checking the coolant

level), place the scooter in a vertical

position on a flat, level surface.

Remove the radiator cap.

Disconnect the water lower hose and drain

the coolant from the system.

Radiator Cap

Remove the floor mat.

Remove the screw and reserve tank lid.

Water Lower Hose

Reserve Tank Lid Screw

Floor Ma

6-6

Page 8

6. COOLING SYSTEM

Remove the reserve tank cap and drain the

coolant from the reserve tank.

Reconnect the water lower hose securely.

Place the scooter on its center stand on a

flat, level surface.

Fill the reserve tank to the upper level line.

XCITING 500

Reserve Tank Cap

Fill the system with the recommended

coolant through the filler opening up to the

filler neck.

6-7

Upper Level Line

Filler Neck

Page 9

6. COOLING SYSTEM

t

r

Bleed air from the system as follow:

1. Start the engine and let it idle for 2−3

minutes.

2. Snap the throttle three to four times to

bleed air from the system.

3. Stop the engine and add coolant to the

proper level if necessary. Reinstall the

radiator cap.

4. Check the level of coolant in the reserve

tank and fill to the upper level if it is

low.

THERMOSTAT

REMOVAL

Remove the floorboard (page 2-6).

Remove the ignition coil (page 18-5).

XCITING 500

Nu

Remove the nut and thermostat housing

stay from the frame.

Remove the bolts, housing stay and

thermostat housing cover.

Housing stay

Housing Stay Housing Cove

Bolts

6-8

Page 10

6. COOLING SYSTEM

r

t

t

Remove the O-ring from the housing cover.

Remove the thermostat.

INSPECTION

Visually inspect the thermostat for damage.

XCITING 500

Thermosta

O-ring

Thermosta

Heat the water with an electric heating

element to operating temperature for five

minutes.

Suspend the thermostat in heated water to

check its operation.

*

● Keep flammable materials away from

the electric heating element.

● Do not let the thermostat or

thermometer touch the pan, or you will

get false readings.

Replace the thermostat if the valve stays

open at room temperature, or if it respond at

temperatures other than those specified.

Thermostat begin to open:

80−84°C (176−183°F)

Valve lift:

8 mm (0.3 in) minimum at 95°C (203°F)

Thermostat

Thermomete

6-9

Page 11

6. COOLING SYSTEM

INSTALLATION

Install the thermostat into the housing with

its air bleed hole facing up and aligning

bleed hole with the tab in the housing.

Install a new O-ring into the housing cover

groove.

XCITING 500

Air Bleed Hole

Tab Align

Install the housing cover and housing stay

to the housing.

Tighten the bolts securely.

Install the housing stay to the frame.

Tighten the nut securely.

Fill the system with recommended coolant

and bleed the air (page 6-6).

WATER PUMP

MECHANICAL SEAL INSPECTION

Inspect the telltale hole for sign of coolant

leakage.

If there is leakage, the mechanical seal is

defective, and water pump should be

replaced

O-ring

Telltale Hole

6-10

Page 12

6. COOLING SYSTEM

r

XCITING 500

REMOVAL

Remove the exhaust muffler (page 2-15)

Drain the coolant (page 6-6).

Loosen the hose bands and disconnect the

water hoses and bypass hose from the water

pump.

Remove he bolts and water pump cover.

Water Hoses

Bypass Hose Bolts

Water Pump Cove

Remove the O-ring from the water pump

cover.

6-11

Bolts

Water Hoses

Page 13

6. COOLING SYSTEM

XCITING 500

Remove the water pump body from the

crankcase.

INSTALLATION

Apply engine oil to a new O-ring and install

it onto the stepped portion of the water

pump.

Water Pump Body

Align

Install the water pump into the crankcase

while aligning the water pump shaft groove

with oil pump shaft end.

Align the mounting bolt holes in the water

pump and crankcase and make sure the

water pump is securely installed.

Install a new O-ring into the groove in the

water pump cover.

Install the water pump cover and tighten the

bolts to the specified toque.

Torque: 13 N•m (1.3 kgf•m, 9 lbf•ft)

O-ring

Connect the water hoses and bypass hose,

then tighten the hose bands.

Fill the system with recommended coolant

and bleed the air (page 6-6).

6-12

Page 14

6. COOLING SYSTEM

r

RADIATOR

REMOVAL

Drain the coolant (page 6-6).

Remove the inner cover (page 2-14).

Remove the front lower cover (page 2-15)

Disconnect the fan motor connector.

Loosen the hose band and disconnect the

radiator lower hose from the radiator.

XCITING 500

Fan Moto

Loosen the hose band and disconnect the

coolant filler hose from the radiator.

6-13

Lower Hose

Filler Hose

Page 15

6. COOLING SYSTEM

r

XCITING 500

Disconnect the fan motor switch

connectors.

Disconnect the air bleed hose.

Remove the four nuts and radiator from the

frame.

*

Be careful not to damage the radiato

core.

Fan Motor Switch Connectors

Air Bleed Hose

Loosen the hose band and disconnect the

radiator upper hose from the radiator.

Nuts

Upper Hose

6-14

Page 16

6. COOLING SYSTEM

XCITING 500

DISSASSEMBLY

Remove the four bolts and fan

motor/shroud assembly.

Check the fan motor to operate using an

available battery.

Bolts

ASSEMBLY

Install the fan motor/shroud assembly to the

radiator with the fan motor wire facing up.

Install and tighten the bolts securely.

6-15

Fan Motor Wire

Page 17

6. COOLING SYSTEM

FAN MOTOR SWITCH

REMOVAL

Disconnect the fan motor switch connector

(page 6-14).

Remove the fan motor switch.

INSPECTION

Place the fan motor switch in oil contained

in a pan as shown and raise the oil

temperature gradually to check for the

temperature at which the switch starts to

operate.

If the switch operating temperature is not

within the specified range, replace the

switch with a new one.

OFF→ON Over 88−92°C

ON→OFF Lower 88−92°C

XCITING 500

Fan Motor Wire

*

● Handle the cooling fan motor switch

carefully as it is vulnerable to impact.

● Do not allow the cooling fan motor

switch Îand the thermometer Ïto

come in contact with the bottom of the

pan.

INSTALLATION

Fit the O-ring.

Tighten the cooling fan motor switch to

specified torque.

Torque: 17 N•m (1.8 kgf•m, 13 lbf•ft)

*

● Replace the O-ring a new one.

● Do not coat grease to the O-ring.

O-ring

6-16

Page 18

6. COOLING SYSTEM

r

r

r

WATER TEMPERATURE

SENSOR

REMOVAL

Remove the side body cover (page 2-8)

Disconnect the water temperature sensor

connector.

Remove the water temperature sensor.

XCITING 500

Water Temperature Senso

INSPECTION

Connect the water temperature sensor to the

ohmmeter and dip it in oil contained in a

pan which is placed on an electric heater.

Gradually raise oil temperature while

reading the thermometer in the pan and the

ohmmeter connected. If the resistance

measured is out of specification, replace the

temperature gauge with a new one.

Temperature Standard resistance

50℃ 140–310Ω

115℃ 24.1–28.2Ω

*

● Handle the water temperature sensor

carefully as it is vulnerable to impact.

● Do not allow the water temperature

sensor and the thermometer to come in

contact with the bottom of the pan.

After the water temperature sensor has been

installed, fill coolant and perform air

bleeding (page 6-6).

Water Temperature Senso

Thermomete

INSTALLATION

With thread lock applied to the threaded

part, tighten the water temperature sensor.

Torque: 8 N•m (0.8 kgf•m, 5.8 lbf•ft)

6-17

Page 19

6. COOLING SYSTEM

RADIATOR RESERVE TANK

REMOVAL

Remove the floorboard (page 2-6).

Remove the two nuts and radiator reserve

tank from the frame.

Open the reserve tank cap and drain the

coolant from the reserve tank.

XCITING 500

Nuts

Disconnect the siphon hose.

INSTALLATION

Installation is in the reverse order of

removal.

Pour the recommended coolant to the upper

level line with the center stand applied

Siphon Hose

6-18

Loading...

Loading...