Page 1

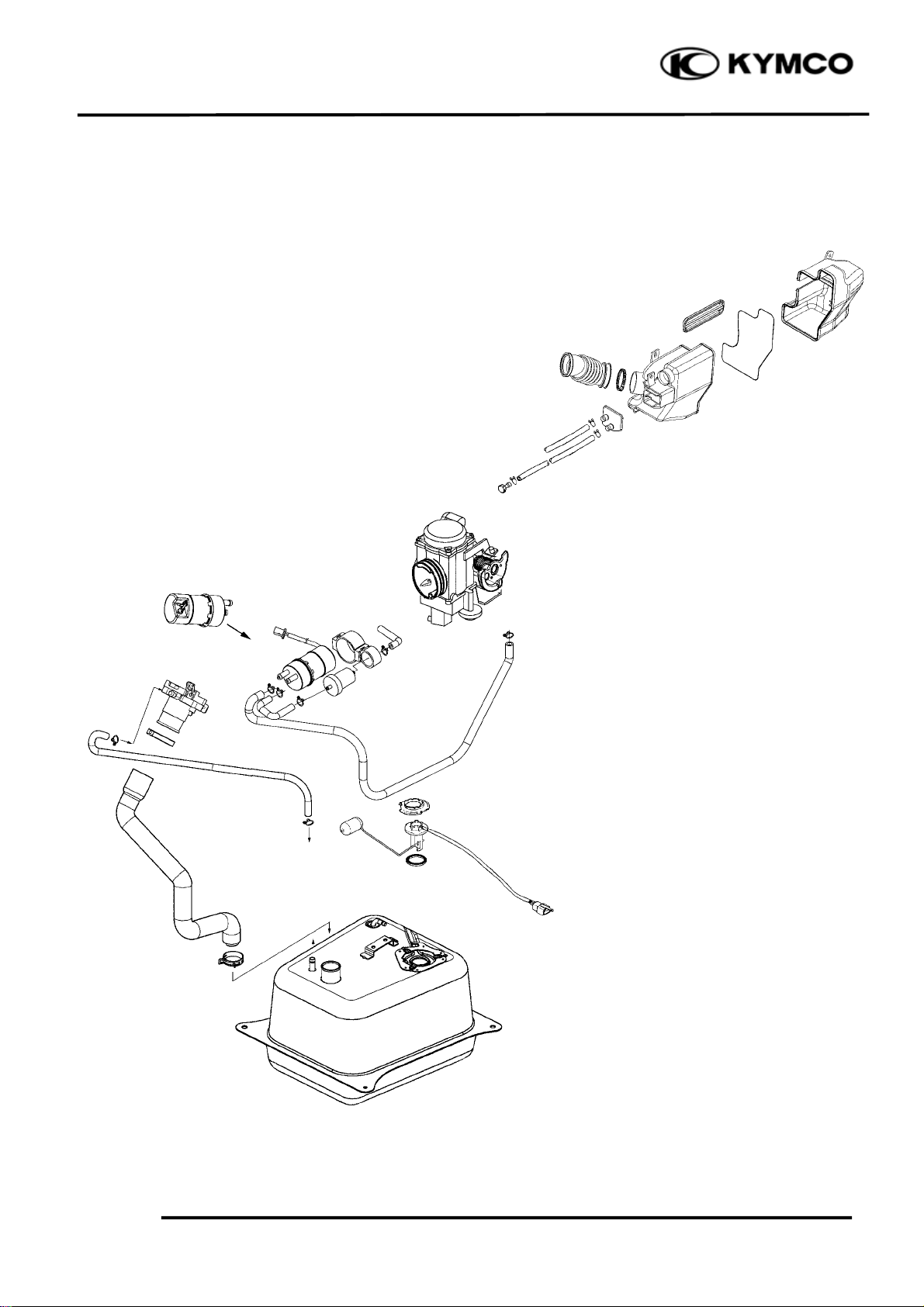

5. FUEL SYSTEM/FUEL PUMP

/FUEL TANK/CARBURETOR

XCITING 500

5

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

FUEL SYSTEM/FUEL PUMP/

FUEL TANK/CARBURETOR

__________________________________________________________________________________

SCHEMATIC DRAWING-------------------------------------------------- 5- 1

FUEL SYSTEM -------------------------------------------------------------- 5- 2

FUEL PUMP CONSTRUCTION ------------------------------------------ 5- 2

SERVICE INFORMATION ------------------------------------------------ 5- 3

TROUBLESHOOTING ----------------------------------------------------- 5- 4

CARBURETOR -------------------------------------------------------------- 5- 5

FUEL FILTER/FUEL PUMP-----------------------------------------------5-16

FUEL TANK------------------------------------------------------------------5-18

5

5-0

Page 2

5. FUEL SYSTEM /FUEL PUMP

/FUEL TANK/CARBURETOR

SCHEMATIC DRAWING

XCITING 500

5-1

Page 3

5. FUEL SYSTEM/FUEL PUMP

/FUEL TANK/CARBURETOR

XCITING 500

FUEL SYSTEM

The fuel pump is operated by an electromagnetic force and its electrical energy is supplied from the

battery. The fuel sent under pressure by the fuel pump flows into the float chamber when the float of

the carburetor has dropped and the needle valve is open. When the needle valve closes, the pressure of

the fuel in the hose connecting the carburetor and the fuel pump increases, and when the set pressure

is reached, the operation of the fuel pump is stopped by the fuel pressure to prevent excessive supply.

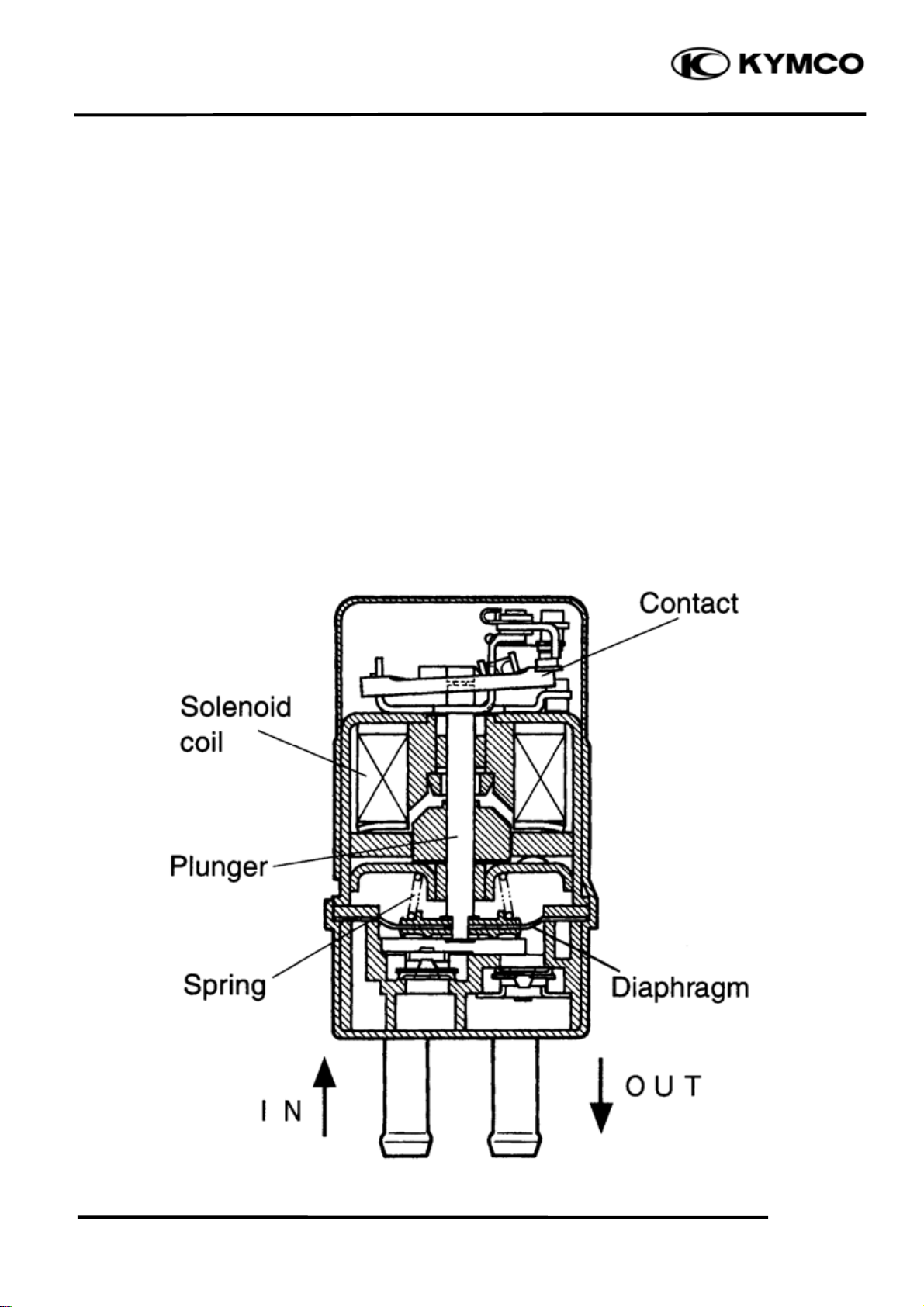

FUEL PUMP CONSTRUCTION

When voltage is applied between the fuel pump terminals, current flows into the solenoid coil which

then pulls up the plunger together with the diaphragm allowing fuel to be drawn into the pump. At this

time, the contact which is linked with the plunger opens and interrupts current causing the coil to be

de-energized. This allows the diaphragm to go down by the spring force, thereby pressurizing and

delivering fuel to the outlet. When the fuel pressure builds up and overcomes the spring force, the

plunger stops at pulled up position with the contact in open position.

5-2

Page 4

5. FUEL SYSTEM /FUEL PUMP

/FUEL TANK/CARBURETOR

XCITING 500

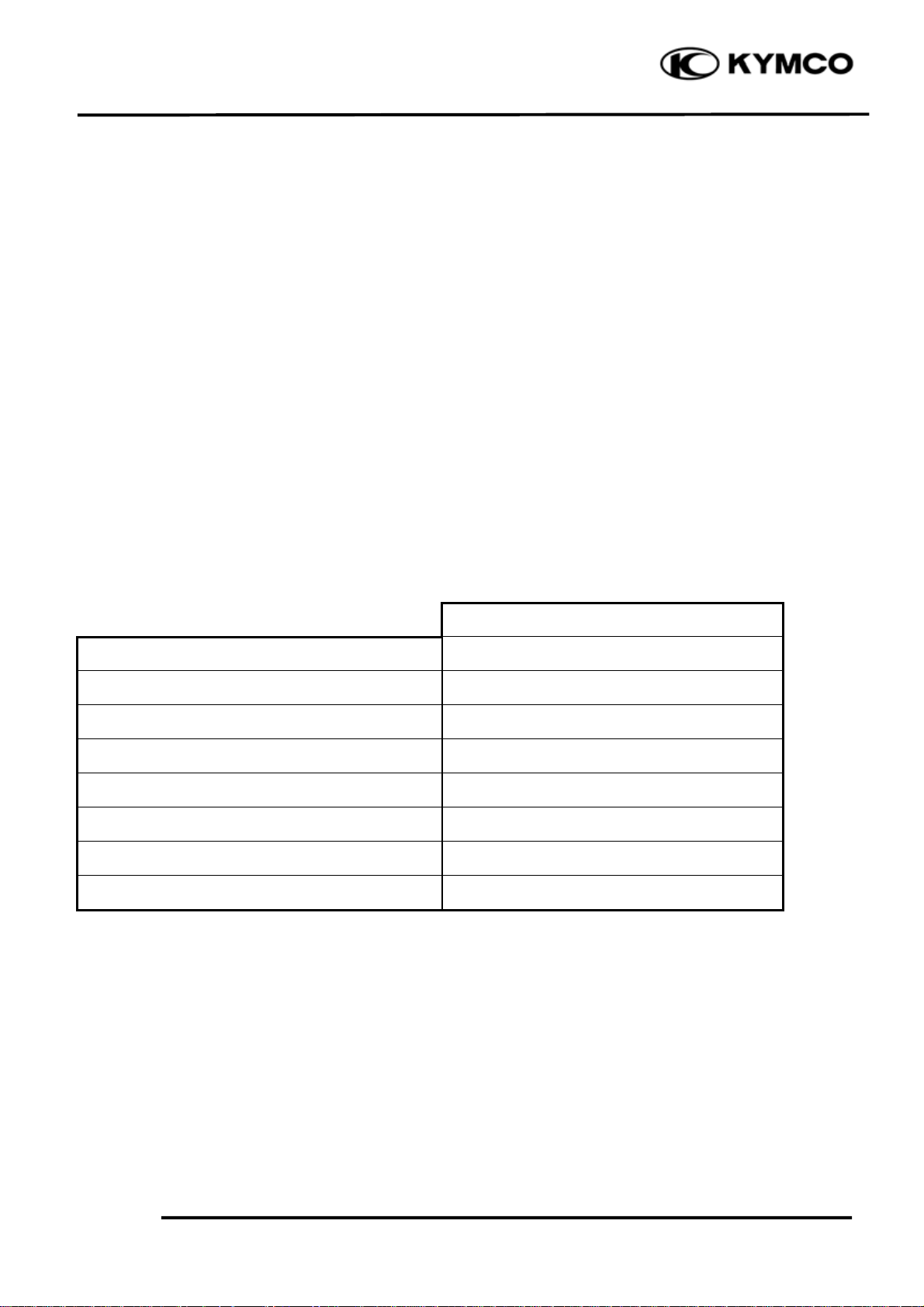

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• When working with gasoline, keep away from sparks and flames.

• Note the locations of O-rings when disassembling and replace them with new ones during

assembly.

• Before float chamber disassembly, drain the residual gasoline from the float chamber.

• Do not try to disassemble the automatic choke.

• When assembling the vacuum chamber and air cut-off valve, be careful not to damage the

diaphragms.

• All cables, fuel lines and wires must be routed and secured at correct locations.

• When removing the fuel tank, keep sparks and flames away from the working area.

• When removing the fuel tank, the remaining fuel in the tank must be lower than 1/2 of the fuel

tank capacity to avoid gasoline overflowing.

• Fuel tank capacity: 12.8 liters

SPECIFICATIONS

XCITING 500

Type CVK

Carburetor identification number 15F8 SD8

Size of bore (mm) Ø36

Main jet #108

Slow jet #38

Idle speed 1400±100

Pilot screw opening 3½ ± ½ turns out

Fuel pump flow (at 12V) 370 ml (12.6 US oz, 13 lmp oz)/min

5-3

Page 5

5. FUEL SYSTEM/FUEL PUMP

/FUEL TANK/CARBURETOR

XCITING 500

TROUBLESHOOTING

Engine does not start Engine idles roughly, stalls or runs poorly

• No fuel in tank • Incorrect idle speed

• Restricted fuel line • Rich mixture

• Too much fuel getting to cylinder • Lean mixture

• Clogged air cleaner • Clogged air cleaner

• Contaminated fuel • Intake air leak

• Faulty fuel pump • Contaminated fuel

• Faulty air-cut off valve

• Damaged vacuum tube and connectors

• Damaged carburetor insulator

Throttle does not open fully, so engine stalls Rich mixture

• Damaged vacuum piston diaphragm • Automatic valve opens excessively

• Clogged diaphragm hole • Faulty float valve

• Float level too high

Lean mixture • Clogged air jets

• Clogged fuel jets • Automatic choke valve set plate installed in

• Clogged fuel tank cap breather hole

• Clogged fuel filter •Clogged air cleaner

• Bent, kinked or restricted fuel line

• Faulty float valve

• Float level too low

• Faulty fuel pump or insufficient output

the wrong groove

Engine is hard to start

• No fuel in tank

• Restricted fuel line

• Clogged fuel strainer

• Faulty fuel pump

• Broken or clogged vacuum tube

• Faulty or clogged charcoal canister

Lean mixture

• Clogged charcoal canister

• Bent, kinked or restricted fuel line

• Clogged fuel strainer

• Float level too low

5-4

Page 6

5. FUEL SYSTEM /FUEL PUMP

r

r

/FUEL TANK/CARBURETOR

CARBURETOR

REMOVAL

Remove the luggage box (page 2-3)

Loosen the air cleaner clamp screw.

Loosen the carburetor clamp screw.

Disconnect the vacuum hose from the

carburetor.

Pull the carburetor out from the air cleaner

and intake manifold.

.

Disconnect the fuel hose from the

carburetor.

Disconnect the carburetor heater connector.

XCITING 500

Carburetor Clamp Screw

Air Cleaner Clamp Screw Vacuum Hose

Fuel Hose

Disconnect the throttle cables.

Disconnect the automatic choke connector.

Disconnect the T.P.S connector.

Remove the carburetor.

5-5

Carburetor Heater Connecto

T.P.S Connector Throttle Cables

Automatic Choke Connecto

Page 7

5. FUEL SYSTEM/FUEL PUMP

r

/FUEL TANK/CARBURETOR

DISASSEMBLY

With the automatic choke cover removed,

remove the screw and automatic choke

assembly.

*

The automatic choke assembly is a nondisassemblable type

Remove the carburetor heater.

XCITING 500

Automatic Choke Assembly

Automatic Choke Cover Screw

Carburetor Heate

Remove the four screws and top cap.

Top Cap

Screws

5-6

Page 8

5. FUEL SYSTEM /FUEL PUMP

r

g

r

/FUEL TANK/CARBURETOR

Remove the spring , spring retainer, jet needle

and throttle valve.

Remove the two screws and casting

enrichment valve cover and then take out the

spring.

XCITING 500

Throttle Valve Spring Retaine

Jet Needle Sprin

Casting Enrichment Valve Cove

Remove the casting enrichment valve and Oring.

5-7

Screws

O-ring

Casting Enrichment Valve

Page 9

5. FUEL SYSTEM/FUEL PUMP

r

r

m

/FUEL TANK/CARBURETOR

Remove the three screws and accelerating

pump cover.

Remove the accelerating pump diaphragm

and O-ring.

XCITING 500

Screws

Accelerating Pump Cove

O-ring

Remove the four screws and float chamber.

Accelerating Pump Diaphrag

Float Chambe

Screws

5-8

Page 10

5. FUEL SYSTEM /FUEL PUMP

r

t

/FUEL TANK/CARBURETOR

Pull float pin outs, then remove the float and

float valve.

Remove the slow jet.

Remove the main jet.

XCITING 500

Float Float Valve

Float Pin

Main Jet Slow Je

Remove the needle jet holder.

5-9

Needle Jet Holde

Page 11

5. FUEL SYSTEM/FUEL PUMP

t

t

/FUEL TANK/CARBURETOR

Remove the needle jet.

XCITING 500

Needle Je

Pilot Screw

Remove the pilot screw, spring, washer and

O-ring.

*

Before pilot screw removal, slowly turn

the pilot screw clockwise and count the

number of turns until the screw is lightly

seated. Make a note of how many turns

were made so the screw can be reset

correctly.

FLOAT/FLOAT VALVE INSPECTION

Inspect the float for deformation or damage.

Floa

5-10

Page 12

5. FUEL SYSTEM /FUEL PUMP

t

t

/FUEL TANK/CARBURETOR

Check the float valve and valve seat for

foreign substance, clogging or damage.

Check the tip of the float valve, where it

contacts the valve seat, for stepped wear or

contamination.

Check the operation of the float valve.

CARBURETOR BODY/JETS

INSPECTION AND CLEANING

Check carburetor body and each jet for wear

or damage.

Clean all jets with a spray-type carburetor

cleaner and dry them using compressed air.

Clean all circuits of the carburetor

thoroughly-not just the perceived problem

area. Clean the circuits in the carburetor

body with a spray-type cleaner and allow

each circuit to soak, if necessary, to loosen

dirt and varnish. Blow the body dry using

compressed air.

XCITING 500

Main Jet/Needle Jet Holder/Needle Je

*

● Some carburetor cleaning chemicals ,

especially dip type soaking solutions,

are very corrosive and must be handled

carefully. Always follow the chemical

manufacturer’s instructions on proper

use, handling and storage.

● Do not use a wire to clean the jets or

passageways. A wire can damage the

jets and passageways. If the

components cannot be cleaned with a

spray cleaner it may be necessary to

use a dip-type cleaning solution and

allow them to soak. Always follow the

chemical manufacturer’s instructions

for proper use and cleaning of the

carburetor components.

After cleaning, reassemble the carburetor

with new seals.

5-11

Slow Je

Page 13

5. FUEL SYSTEM/FUEL PUMP

e

e

m

/FUEL TANK/CARBURETOR

PILOT SCREW INSPECTION

Remove the O-ring from the pilot screw.

Check the pilot screw for wear or damage.

*

The pilot screw is factory pre-set and

should not be removed unless the

carburetor is overhauled.

Damage to the pilot screw is tightened

against the seat.

THROTTLE VALVE/JET NEEDLE

INSPECTION

Check the throttle valve and jet needle for

scratches, wear or damage.

XCITING 500

Pilot Screw O-ring

Wash Spring

Throttle Valv

CASTING ENRICHMENT

VALVE/ACCELERATING PUMP

DIAPHRAGM INSPECTION

Check the casting enrichment

valve/accelerating pump diaphragm for

damage and clogging.

If any abnormal condition is found, wash the

part clean. If damage or clogging is found,

replace the part with a new one.

Jet Needl

Accelerating Pump Diaphrag

Casting Enrichment Valve

5-12

Page 14

5. FUEL SYSTEM /FUEL PUMP

e

r

/FUEL TANK/CARBURETOR

FLOAT LEVEL INSPECTION

Check the float level after checking the float

valve, valve seat and float.

Set the carburetor so that the float valve end

just contacts the float arm lip. Make sure the

float valve tip is securely in contact with the

valve seat.

Measure the float level with the float level

gauge.

Float level (A): 18.5mm (0.74 in)

The float level cannot be adjusted.

Replace the float assembly if the float level

is out of specification.

AUTO-BYSTARTER INSPECTION

Disconnect the connector.

Remove the automatic choke cover.

XCITING 500

(A)

Automatic Chok

Connect the positive (+) terminal of a 12 V

battery to Yellow lead and the negative (-)

terminal to the other Yellow lead.

Check that the automatic choke section is

heated in 5 minutes after the battery has

been connected.

To inspect the function, check for change of

temperature from the cold condition.

*

Do not attempt to disassemble the

automatic choke for the purpose of

checking temperature.

CARBURETOR HEATER INSPECTION

Disconnect the carburetor heater terminal

leads.

Carburetor Heate

5-13

Carburetor Heater Terminal Leads

Page 15

5. FUEL SYSTEM/FUEL PUMP

r

/FUEL TANK/CARBURETOR

Connect the positive (+) terminal of a 12 V

battery to the terminal of the carburetor

heater and the battery negative (-) terminal

to the terminal.

Check that the heater section is heated in 5

minutes after the battery has been connected.

REASSEMBLY

Carburetor reassembly can be performed in

the reverse order of disassembly. When

reassembling, carefully observe the

following instructions.

XCITING 500

Carburetor Heate

*

● Assemble the parts taking

consideration of their function.

● Replace O-rings and seals with new

ones.

Fit a new O-ring in to the float chamber

groove securely.

O-ring

5-14

Page 16

5. FUEL SYSTEM /FUEL PUMP

m

/FUEL TANK/CARBURETOR

Assemble the accelerating pump diaphragm

and new O-ring.

*

Install the accelerating pump diaphragm

with the small convex facing up.

Assemble the coasting enrichment valve and

new O-ring.

XCITING 500

O-ring Small Convex

Accelerating Pump Diaphrag

O-ring

Assemble the jet needle, spring retainer,

spring and throttle valve

Apply thermo-grease to the threads and

tighten the carburetor heater securely.

After cleaning, reinstall the pilot screw to

the original setting by turn the screw in until

it lightly seats, and then backing it out the

same number of turns counted during

disassembly.

*

Replace the O-ring with a new one.

Casting Enrichment Valve

After the assembly and installation on the

engine have been completed, perform the

following adjustment.

Throttle cable adjustment (page 3-5)

Idle speed adjustment (page 3-14)

INSTALLATION

Installation is in the reverse order of

removal.

5-15

Page 17

5. FUEL SYSTEM/FUEL PUMP

r

/FUEL TANK/CARBURETOR

FUEL FILTER/FUEL PUMP

FUEL FILTER INSPECTION

Visually check the fuel filter. If

accumulation of sediment or clogging is

found, replace the fuel filter with a new one.

Install the fuel filter with the arrow mark

facing forward.

FUEL PUMP INSPECTION

XCITING 500

Fuel Filter Arrow Mark

Fuel Pump Couple

Measure resistance between the terminals of

fuel pump lead wire coupler.

If the measurement is out of specification

replace the fuel pump.

Fuel pump resistance: 1-2.5Ω

As shown in the right illustration, connect

the battery to the fuel pump and measure the

pump discharge amount per minute using

kerosene.

Battery (+) to Black/Red

Battery (-) to Green

Discharge amount per minute:

370 ml (12.6 US oz, 13 lmp oz)

Fuel Pump

If the measurement is less than the standard

value, replace the fuel pump with a new one.

*

Do not use gasoline in this test as its is

highly combustible.

5-16

Page 18

5. FUEL SYSTEM /FUEL PUMP

r

t

t

/FUEL TANK/CARBURETOR

REMOVAL

Remove the floorboard (page 2-6)

Disconnect the fuel hoses.

Disconnect the fuel pump connector.

Remove the fuel pump and filter.

INSTALLATION

Installation is in the reverse order of

removal.

XCITING 500

Fuel Pump Connector Fuel Hoses

“Arrow” Mark Inlet Duc

*

● Install the fuel pump with the arrow

mark facing up.

● Connect the fuel inlet hose between the

inlet duct of the fuel pump and fuel

filter.

● Connect the fuel outlet hose between

the outlet duct of the fuel pump and

carburetor.

FUEL TANK

REMOVAL

Remove the floorboard (page

Remove the inner cover (page 2-14).

Remove the front lower cover (page 2-15).

Remove the fuel pump and fuel filter (page

5-17).

2-6

).

Outlet Duc

Remove the front heat insulation cover.

5-17

Heat Insulation Cove

Page 19

5. FUEL SYSTEM/FUEL PUMP

r

r

/FUEL TANK/CARBURETOR

Disconnect the fuel unit connector.

Remove the four nuts from the fuel tank.

Disconnect the ground wire connector.

Disconnect the fuel filler cap open cable.

XCITING 500

Fuel Unit Connecto

Nuts

Ground Wire Connecto

Remove the two nuts and left floorboard set

holder from the frame.

Remove the AICV control solenoid valve

from the left floorboard set holder.

Fuel Filler Cap Open Cable

ACIV Control Solenoid Valve

Nuts

5-18

Page 20

5. FUEL SYSTEM /FUEL PUMP

/FUEL TANK/CARBURETOR

Remove the fuel tank from the frame left

side.

XCITING 500

Fuel Tank

INSTALLATION

Installation is in the reverse order of

removal.

5-19

Fuel Tank

Fuel Tank

Loading...

Loading...