Page 1

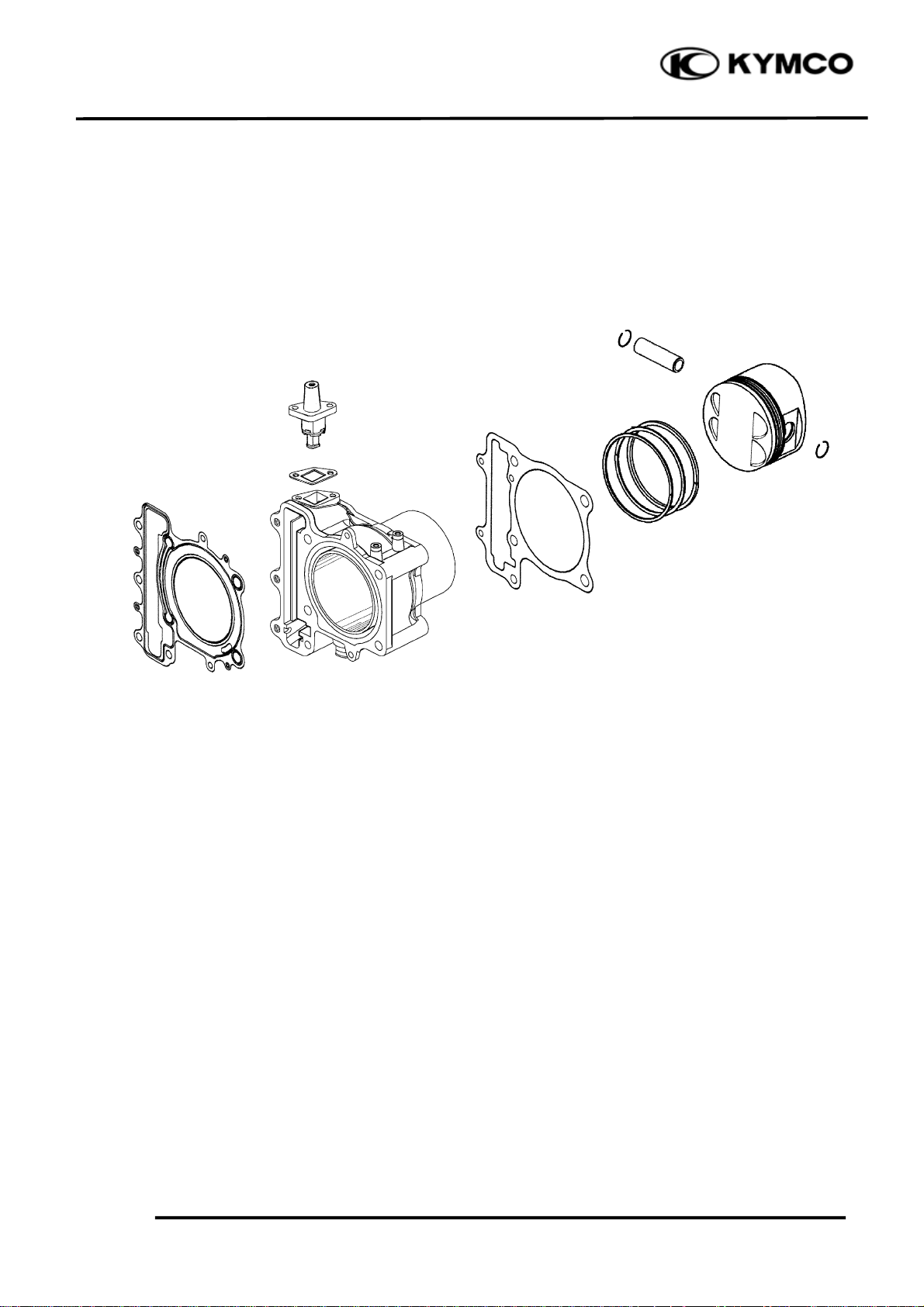

9. CYLINDER/PISTON

XCITING 500

9

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

CYLINDER/PISTON

__________________________________________________________________________________

SCHEMATIC DRAWING ------------------------------------------------- 9-1

SERVICE INFORMATION------------------------------------------------ 9-2

TROUBLESHOOTING----------------------------------------------------- 9-2

CYLINDER/PISTON REMOVAL---------------------------------------- 9-3

CYLINDER/PISTON INSTALLATION--------------------------------- 9-7

9

9-0

Page 2

9. CYLINDER/PISTON

SCHEMATIC DRAWING

XCITING 500

9-1

Page 3

9. CYLINDER/PISTON

m

d

r

XCITING 500

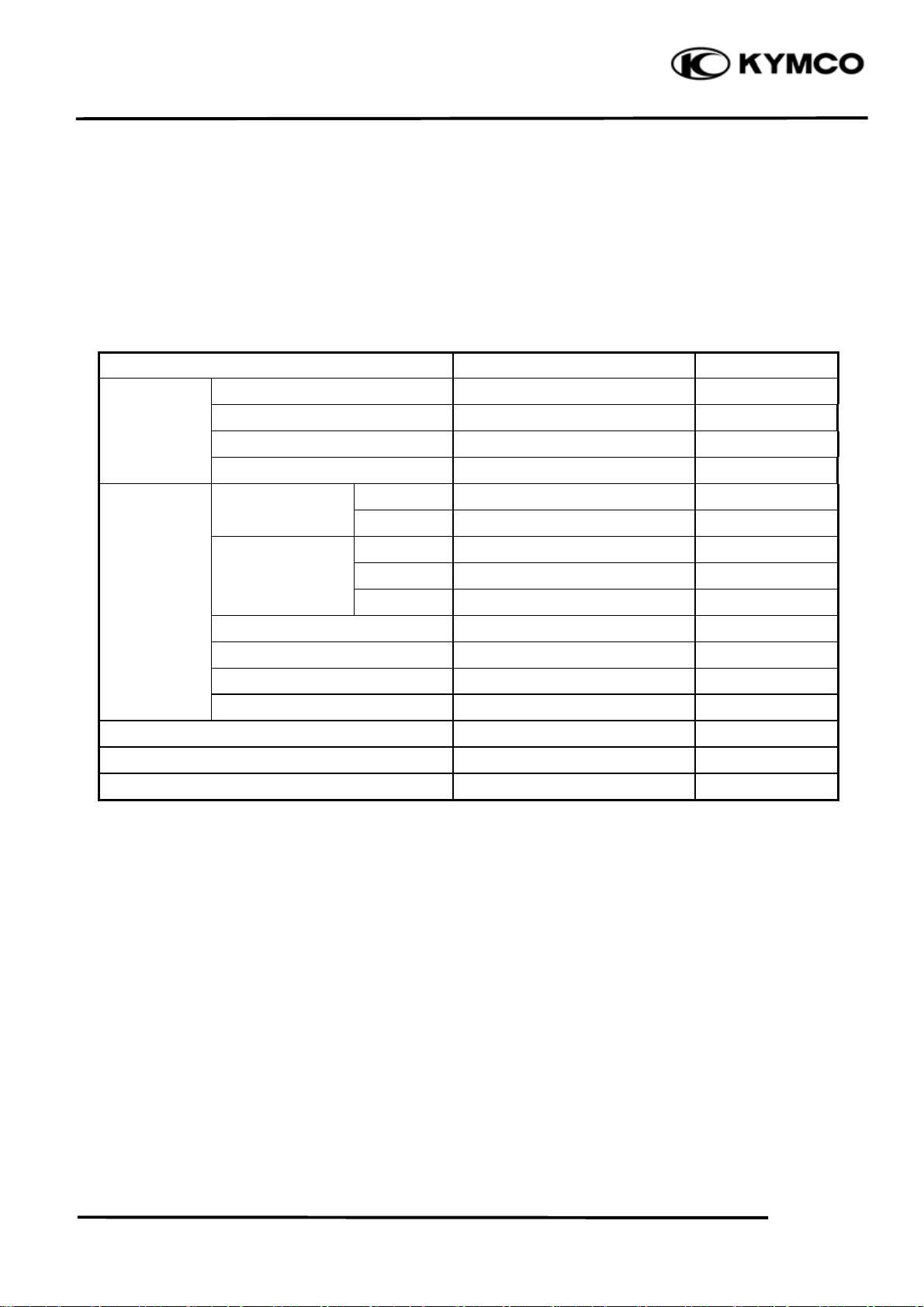

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The cylinder and piston can be serviced with the engine installed in the frame.

• When installing the cylinder, use a new cylinder gasket and make sure that the dowel pins are

correctly installed.

• After disassembly, clean the removed parts and dry them with compressed air before inspection.

SPECIFICATIONS Unit: mm (in)

Ite

I.D. 92.005 (3.6802)~92.015 (3.6806) 92.1 (3.684)

Cylinde

Piston, Ring end gap Second

piston ring Oil side rail

. Piston-to-cylinder clearance

Piston pin O.D

Piston-to-piston pin clearance

Connecting rod small end I.D. bore

Warpage

Cylindricity

True roundness

Ring-to-groove top

clearance

Piston O.D.

Piston O.D. measuring position

Piston pin hole I.D.

Second

top

Standar

0.01 (0.0004)

0.01 (0.0004)

0.01 (0.0004)

0.03 (0.0012)~0.065 (0.0026) 0.08 (0.003)

0.015 (0.0006)~0.05 (0.002) 0.065 (0.0026)

0.15 (0.006)~0.3 (0.012) 0.5 (0.02)

0.03 (0.012)~0.45 (0.018) 0.65 (0.026)

0.2 (0.008)~0.7 (0.028)

91.96 (3.6784)~91.98 (3.6793) 91.9 (3.676)

10 mm from bottom of skirt -

0.01 (0.0004)~0.045 (0.0018) 0.1 (0.004)

22.002 (0.8801)~22.008 (0.8803) 22.04 (0.8826)

21.994 (0.8798)~22 ( 0 . 8 8 ) 21.96 (0.8784)

0.002 (0.0001)~0.014 (0.0006) 0.02 (0.001)

22.016 (0.8806)~22.034 (0.8814) 22.06 (0.8824)

Service Limit

0.05 (0.002)

0.1 (0.004)

0.1 (0.004)

1 (0.04)

TROUBLESHOOTING

• When hard starting or poor performance at low speed occurs, check the crankcase breather for

white smoke. If white smoke is found, it means that the piston rings are worn, stuck or broken.

Compression too low or uneven

compression Excessive smoke from exhaust muffler

• Worn or damaged cylinder and piston rings • Worn or damaged piston rings

• Worn, stuck or broken piston rings • Worn or damaged cylinder and piston

Compression too high Abnormal noisy piston

• Excessive carbon build-up in combustion • Worn cylinder, piston and piston rings

chamber or on piston head • Worn piston pin hole and piston pin

• Incorrectly installed piston

9-2

Page 4

9. CYLINDER/PISTON

XCITING 500

CYLINDER/PISTON

Remove the cylinder head (page 8-11).

Take the block pin out.

Remove the water hose from the cylinder.

Remove the two cylinder bolts.

Remove the cylinder and gasket.

Remove the dowel pins

REMOVAL

Bolts Cylinder/Gasket Block Pin

Water Hose

Dowel Pins

Remove the piston pin clip.

*

Place a clean shop towel in the crankcase

to keep the piston pin clip from falling

into the crankcase.

Press the piston pin out of the piston and

remove the piston.

9-3

Dowel Pins

Piston Pin Clip

Piston Piston Pin

Page 5

9. CYLINDER/PISTON

Spread each piston ring and remove it by

lifting up at a point opposite the gap

*

Do not damage the piston ring by

spreading the ends too far.

Clean carbon deposits from the piston ring

grooves.

INSPECTION

Piston ring

Inspect the piston rings for movement by

rotating the rings. The rings should be able to

move in their grooves without catching.

XCITING 500

Push the ring until the outer surface of the

piston ring is nearly flush with the piston and

measure the ring-to-groove clearance.

Service Limits: Top: 0.08 mm (0.003 in)

2nd: 0.065 mm (0.0026 in)

Insert each piston ring into the bottom of the

cylinder squarely.

*

Use the piston head to push each piston

ring into the cylinder.

Measure the piston ring end gap.

Service Limit:

Top: 0.5 mm (0.02 in)

2nd: 0.65 mm (0.026 in)

Oil ring: 1 mm (0.04 in)

9-4

Page 6

9. CYLINDER/PISTON

m

m

Piston/Piston pin

Measure the piston O.D. at the point 10 mm

from the bottom and 90° to the piston pin

hole.

Service Limit: 91.9 mm (3.676 in)

Calculate the cylinder-to-piston clearance

(cylinder I.D.: page 9-6)

Measure the piston pin hole. Take the

maximum reading to determine the I.D..

XCITING 500

10 m

10 m

Service Limit: 22.04 mm (0.8826 in)

Measure the piston pin O.D. at piston and

connecting rod sliding areas.

Service Limit: 21.96 mm (0.8784 in)

Measure the piston-to-piston pin clearance.

Service Limit: 0.002 mm (0.0001 in)

9-5

Page 7

9. CYLINDER/PISTON

Cylinder

Check the cylinder for warpage with a

straight edge and feeler gauge in the

directions shown.

Service Limit: 0.05 mm (0.002 in)

XCITING 500

Check the cylinder wall for wear or damage.

Measure and record the cylinder I.D. at three

levels in an X and Y axis. Take the maximum

reading to determine the cylinder wear.

Service Limit: 92.1 mm (3.684 in)

Calculate the piston-to-cylinder clearance.

Take a maximum reading to determine the

clearance. Refer to page 9-5 for measurement

of the piston O.D..

Service Limit: 0.1 mm (0.004 in)

Calculate the taper and out-of-round at three

levels in an X and Y axis. Take the maximum

reading to determine them.

Service Limit:

Taper: 0.1 mm (0.004 in)

Out-of-round: 0. 1 mm (0.004 in)

TOP

MIDDLE

BOTTOM

9-6

Page 8

9. CYLINDER/PISTON

d

Measure the connecting rod small end I.D..

Service Limit: 22.06 mm (0.8824 in)

Calculate the connecting rod-to-piston pin

clearance.

Service Limit: 0.06 mm (0.002 in)

XCITING 500

CYLINDER/PISTON

INSTALLATION

PISTON RING INSTALLATION

Carefully install the piston rings into the

piston ring grooves with the markings facing

up.

*

Be careful not to damage the piston an

rings.

Do not confuse the top and second rings.

To install the oil ring, install the oil ring,

then install the side rails.

Stagger the piston ring end gaps 120° degrees

apart from each other.

Stagger the side rail end gaps as shown.

9-7

Page 9

9. CYLINDER/PISTON

XCITING 500

CYLINDER/PISTON INSTALLATION

Clean any gasket material from the cylinder

mating surfaces of the crankcase and oil

passage.

Apply engine oil to the piston pin.

Apply engine oil to the connecting rod small

end and piston pin hole.

Install the piston with the “IN” mark face

intake side and piston pin.

Place a clean shop towel over the crankcase

prevent the clip from falling into the

crankcase.

Piston “IN” Mark

Piston Pin

Piston Pin Clip

Install the new pin clip.

*

Make sure that the piston pin clips are

seated securely.

Do not align the piston pin clip end gap

with the piston cut-out

Install the dowel pins.

Piston Piston Pin

Dowel Pins

Dowel Pins

9-8

Page 10

9. CYLINDER/PISTON

Install the gasket.

Apply engine oil to the cylinder wall, piston

and piston ring outer surfaces.

Pass the cam chain through the cylinder and

install the cylinder over the piston.

*

Be careful not to damage the piston rings

and cylinder walls.

Install and tighten the two cylinder bolts to

specified torque.

Torque: 10 N•m (1 kgf•m, 7 lbf•ft)

Install the block pin.

Connect the water hose.

XCITING 500

Bolts Cylinder/Gasket Block Pin

Water Hose

9-9

Loading...

Loading...