Page 1

12. A.C. GENERATOR/STARTER CLUTCH

XCITING 500

12

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

12

A.C. GENERATOR/STARTER CLUTCH

__________________________________________________________________________________

SCHEMATIC DRAWING ------------------------------------------------- 12-1

SERVICE INFORMATION------------------------------------------------ 12-2

TROUBLESHOOTING----------------------------------------------------- 12-2

ALTERANTOR STATOR-------------------------------------------------- 12-3

FLYWHEEL/STARTER CLUTCH--------------------------------------- 12-4

12-0

Page 2

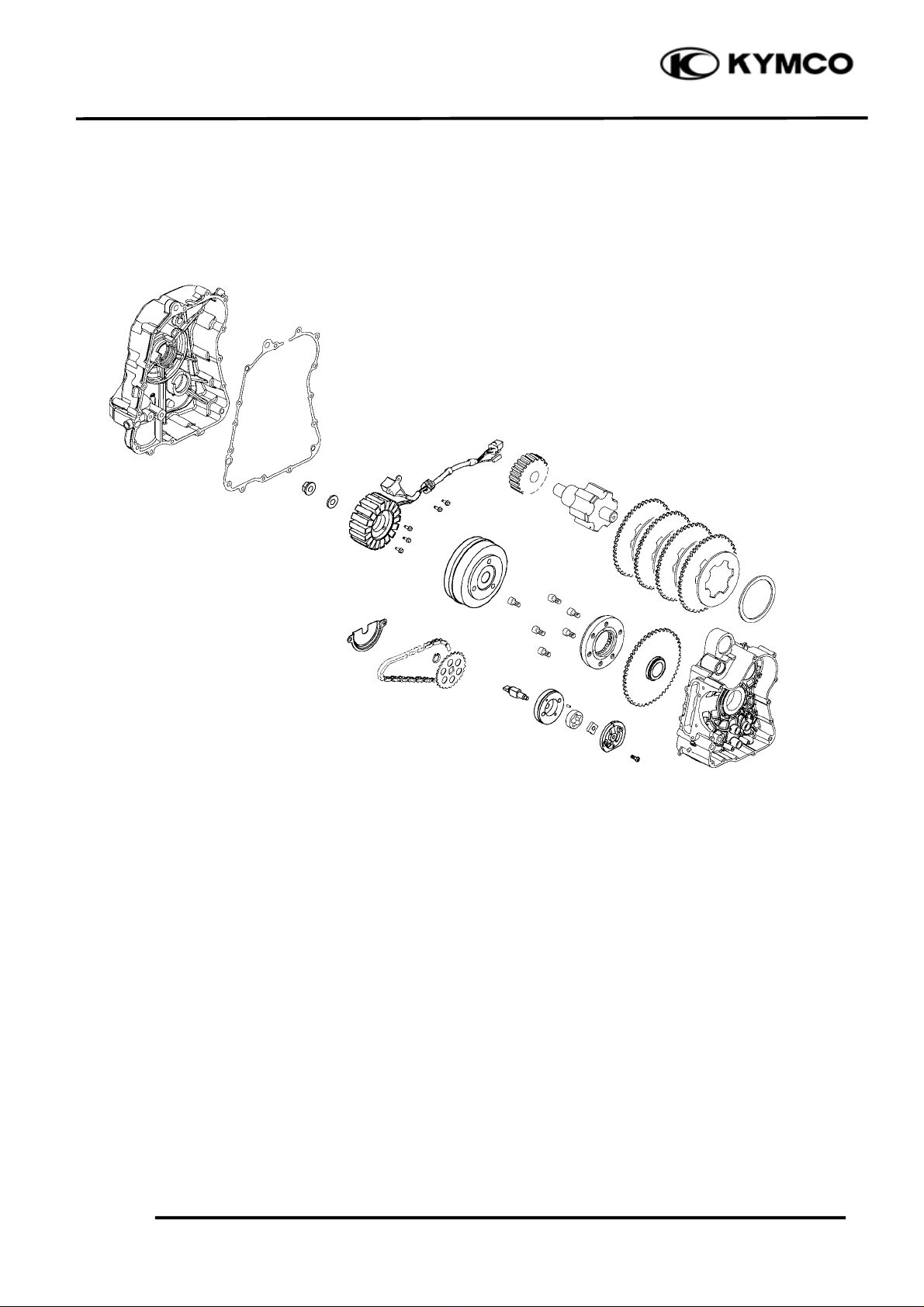

12. A.C. GENERATOR/STARTER CLUTCH

SCHEMATIC DRAWING

XCITING 500

12-1

Page 3

12. A.C. GENERATOR/STARTER CLUTCH

XCITING 500

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• All servicing operations and inspections in this section can be made with the engine installed.

• Drain the coolant before removing the right crankcase cover.

• Be careful not to drain the coolant when the engine temperature is high. (Perform this operation

when the engine is cold.)

• Drain the coolant into a clean container.

• Drain the engine oil into a clean container before removing the right crankcase cover.

• When the right crankcase cover is installed, fill with the recommended engine oil and coolant.

Then, bleed air from the water jacket.

• Refer to section 17 for alternator inspection, and to section 18 for ignition pulse generator

inspection.

SPECIFICATIONS Unit: mm (in)

Item Standard Service Limit

Starter driven gear I.D. 27.026 (1.081)~27.045 (1.0818) 27.1 (1.084)

Starter driven gear O.D. 45.66 (1.8264)~45.673 (1.8292) 45.6 (1.824)

SPECIAL TOOLS

Flywheel puller E054

Flywheel holder E021

TORQUE VALUES

Flywheel nut: 55 N•m (5.5 kgf•m, 40 lbf•ft)

TROUBLESHOOTING

Starter motor turns, but engine does not turn

• Faulty starter clutch

• Damaged starter reduction gear

12-2

Page 4

12. A.C. GENERATOR/STARTER CLUTCH

r

t

t

Right Crankcase Cove

ALTERNATOR STATOR

REMOVAL

Remove the right center body cover (page 2-

5).

Remove the exhaust muffler (page 2-15).

Remove water pump (page 6-10).

Remove the fifteen bolts and right crankcase

cover, dowel pins and gasket.

XCITING 500

Remove the two pulse coil mount bolts.

Remove the three stator mount bolts,

grommet and the stator from the right

crankcase cover.

INSTALLATION

Install the stator and tighten the stator mount

bolts to the specified torque.

Torque: 12 N•m (1.2 kgf•m, 9 lbf•ft)

Apply sealant to the grommet seating surface

and install it to the cover groove properly.

Install the pulse coil and tighten mount bolts

to the specified torque.

Torque: 12 N•m (1.2 kgf•m, 9 lbf•ft)

Clean the mating surfaces of the right

crankcase and cover.

Stator Bolts Gromme

Bolts Pulse Coil

Dowel Pins Gaske

Install the dowel pins and gasket.

Install the right crankcase cover and tighten

the bolts in a crisscross pattern in 2 or 3 steps.

12-3

Page 5

12. A.C. GENERATOR/STARTER CLUTCH

r

r

Flywheel Holder Nut/Washe

FLYWHEEL/STARTER CLUTCH

REMOVAL

Remove the right crankcase cover (page 12-

3).

Hold the flywheel with the special tool and

loosen the flywheel nut.

Special tool:

Flywheel holder E021

Remove the flywheel nut and washer.

Flywheel Pulle

Remove the flywheel/starter driven gear

assembly using the special tool.

XCITING 500

Special tool:

Flywheel puller E054

Remove the woodruff key.

Woodruff Key

12-4

Page 6

12. A.C. GENERATOR/STARTER CLUTCH

r

r

Reduction Gea

Remove the reduction gear.

Driven gea

XCITING 500

INSPECTION

Check the operation of the sprag clutch by

turning the driven gear.

You should be able to turn the driven gear

clockwise smoothly, but the gear should not

turn counterclockwise.

Remove the starter driven gear by turning the

driven gear.

Check the starter driven gear teeth for wear or

damage.

Measure the starter driven gear boss O.D..

Flywheel

Service limit: 45.6 mm (1.824 in)

Measure the starter driven gear bushing I.D..

Service limit: 27.1 mm (1.084 in)

12-5

Page 7

12. A.C. GENERATOR/STARTER CLUTCH

r

r

r

XCITING 500

Check the starter reduction gear teeth and

shaft for wear or damage.

Apply oil to the starter reduction gear.

Install the starter reduction gear to the right

crankcase.

Reduction Gea

Reduction Gea

Apply molybdenum oil solution to the

starter driven gear bushing.

Install the starter driven gear by turning the

driven gear clockwise.

Driven gea

Flywheel

12-6

Page 8

12. A.C. GENERATOR/STARTER CLUTCH

r

Clean any oil from tapered portion of the

crankshaft.

Install the woodruff key in the crankshaft

key groove.

Woodruff Key

XCITING 500

Clean any oil from the tappered portion of

the flywheel I.D..

Install the flywheel/driven gear onto the

crankshaft, aligning the key way with

woodruff key.

Apply oil to the washer and flywheel nut

threads and seating surface.

Install the washer and flywheel nut to the

crankshaft.

Hold the flywheel with the special tool and

tighten the flywheel nut to the specified

torque.

Special tool:

Flywheel holder E021

Torque: 55 N•m (5.5 kgf•m, 40 lbf•ft)

Flywheel Holder Nut/Washe

12-7

Loading...

Loading...